A Novel Equivalent Numerical Simulation Method for Non-Darcy Seepage Flow in Low-Permeability Reservoirs

Abstract

1. Introduction

2. Mathematical Model

2.1. Apparent Permeability

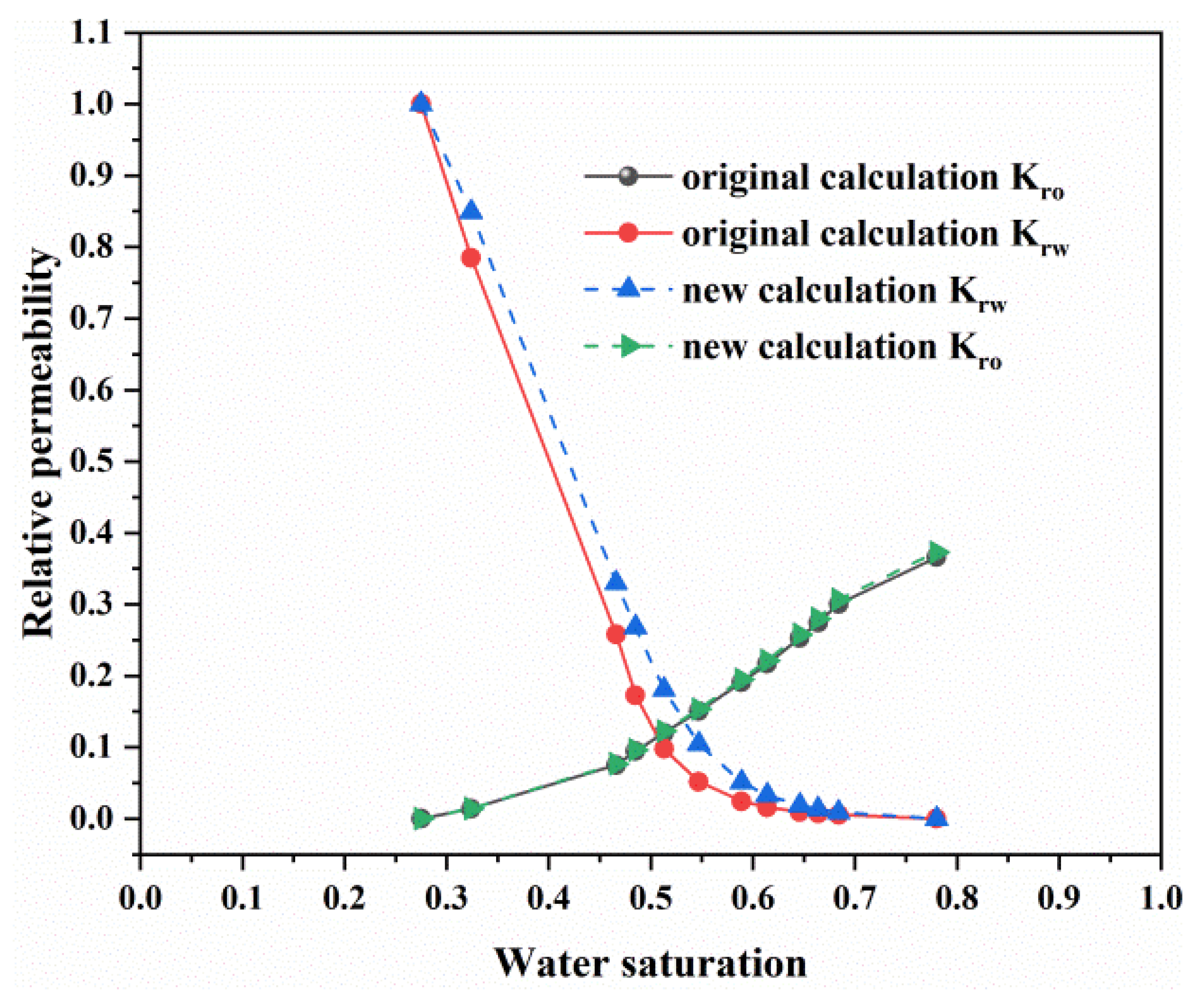

2.2. Relative Permeability Curve Processing

- (1)

- Correction of oil–water relative permeability curve

- (2)

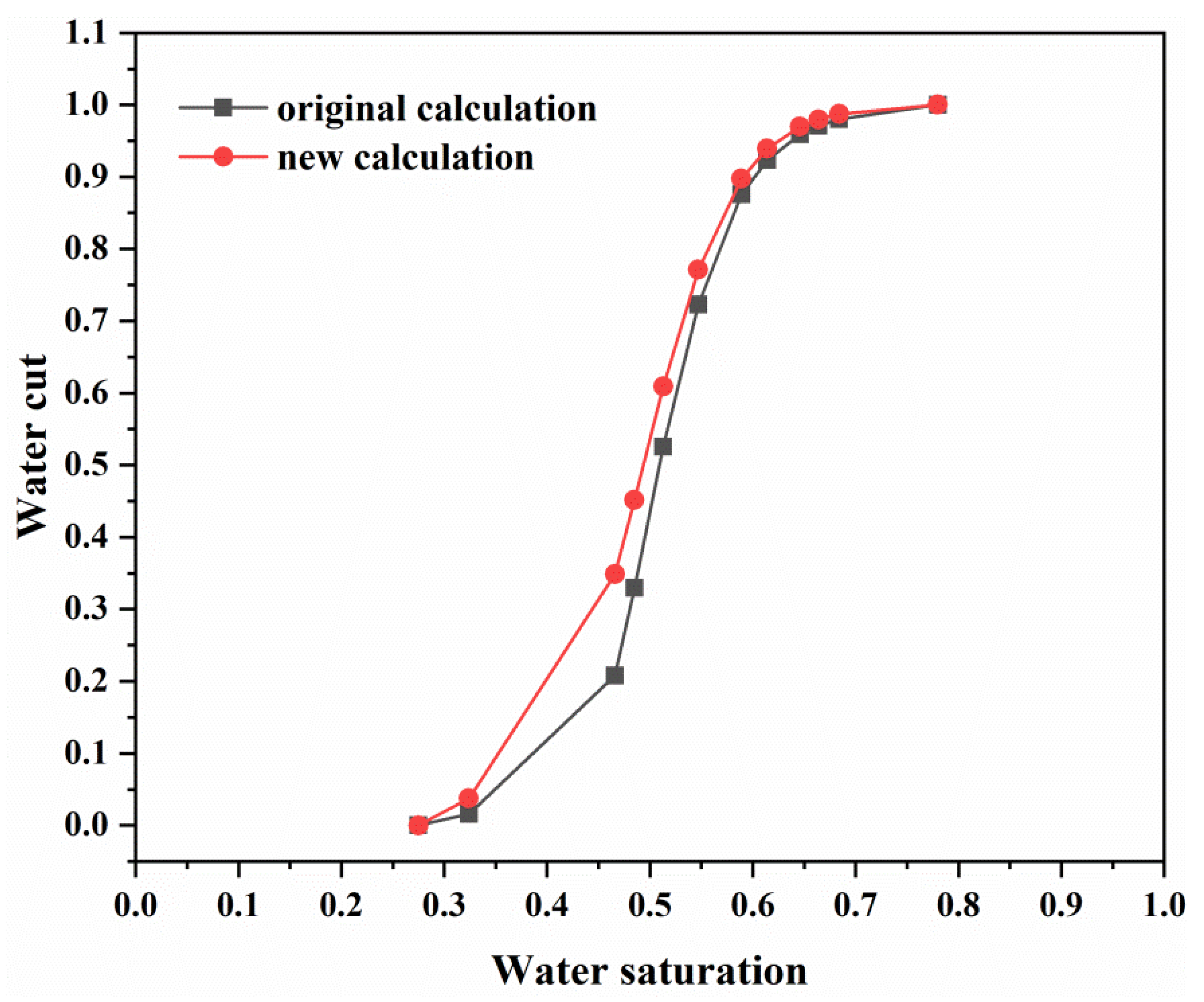

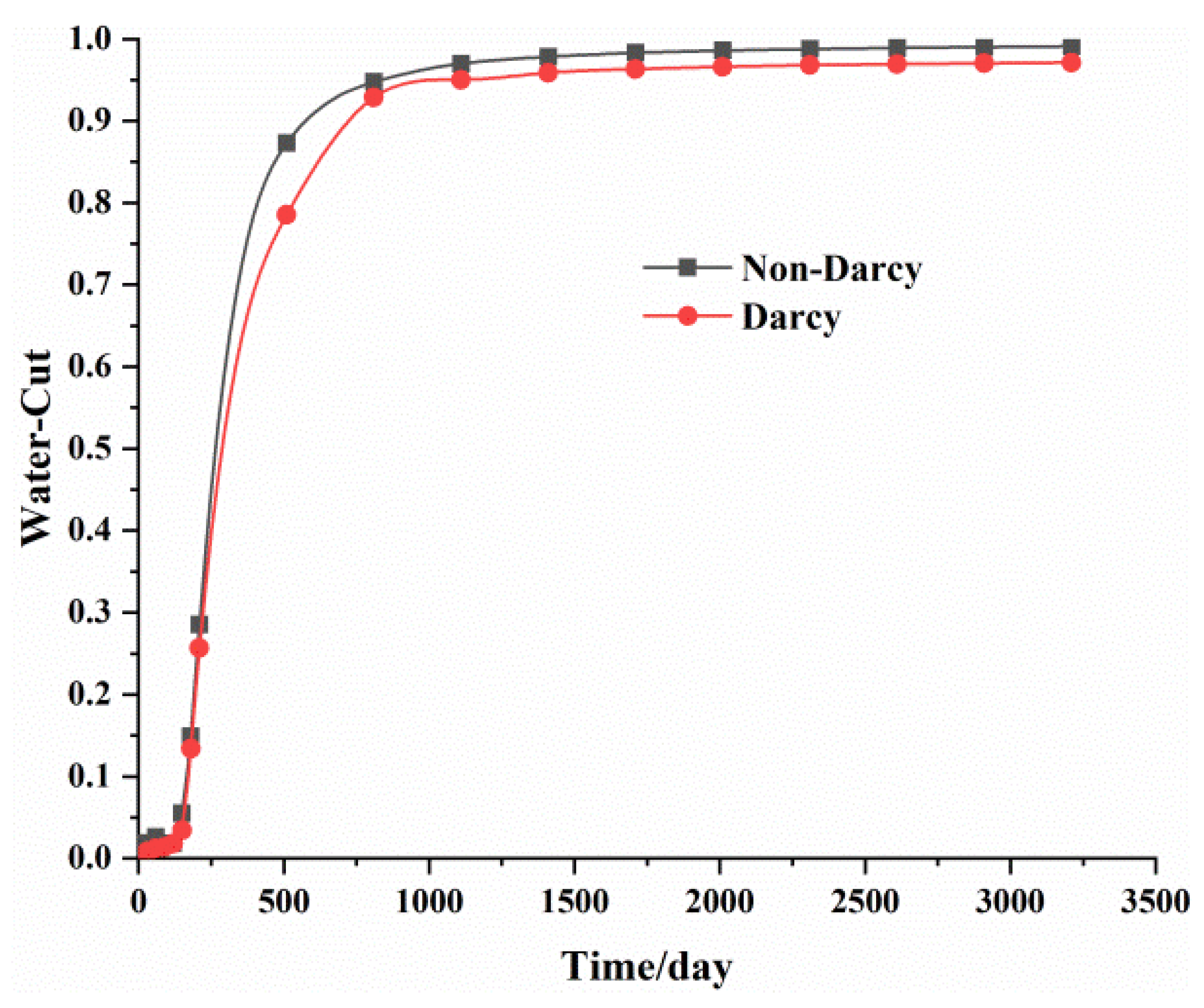

- Water cut model

3. Simulation Results

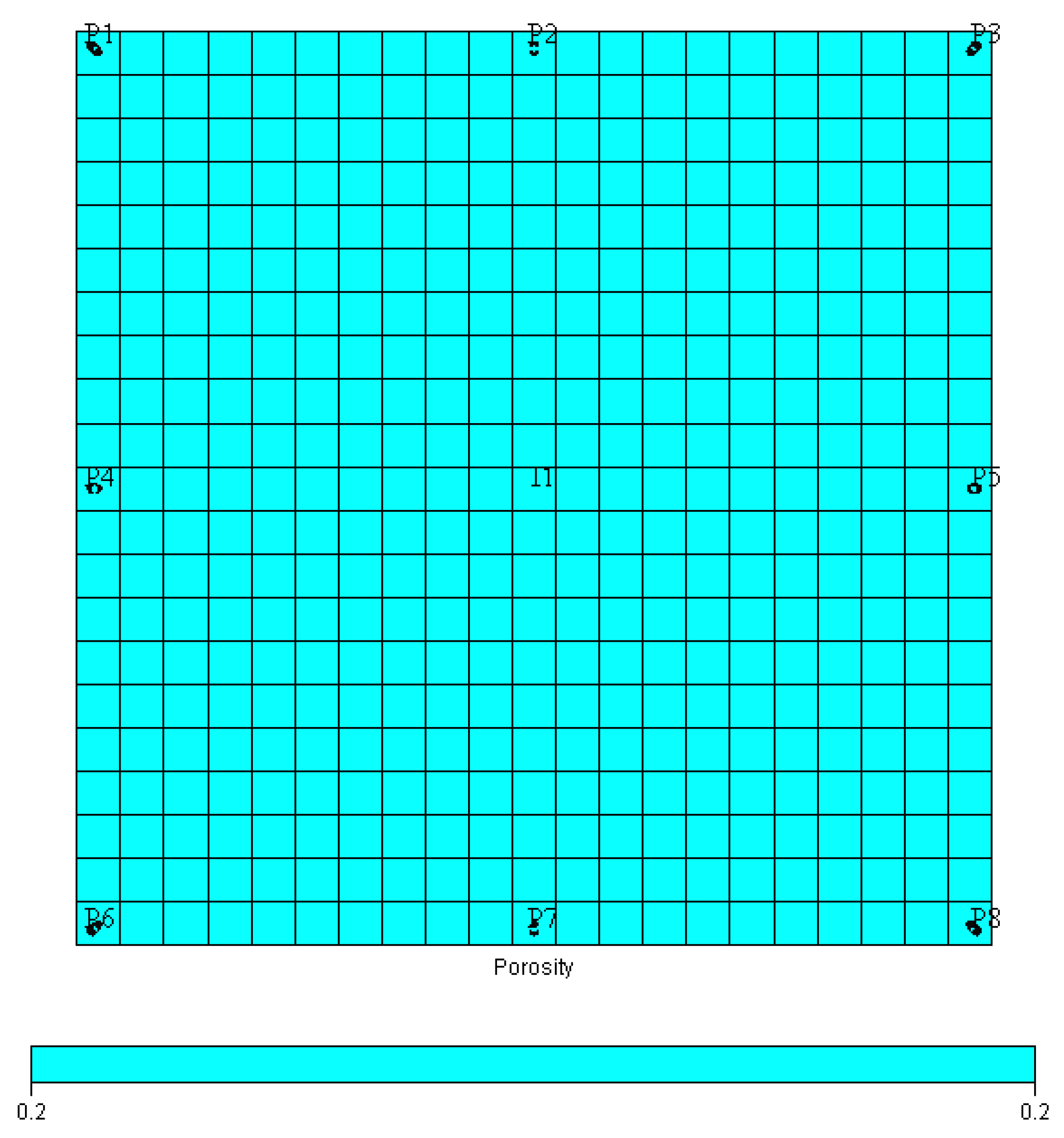

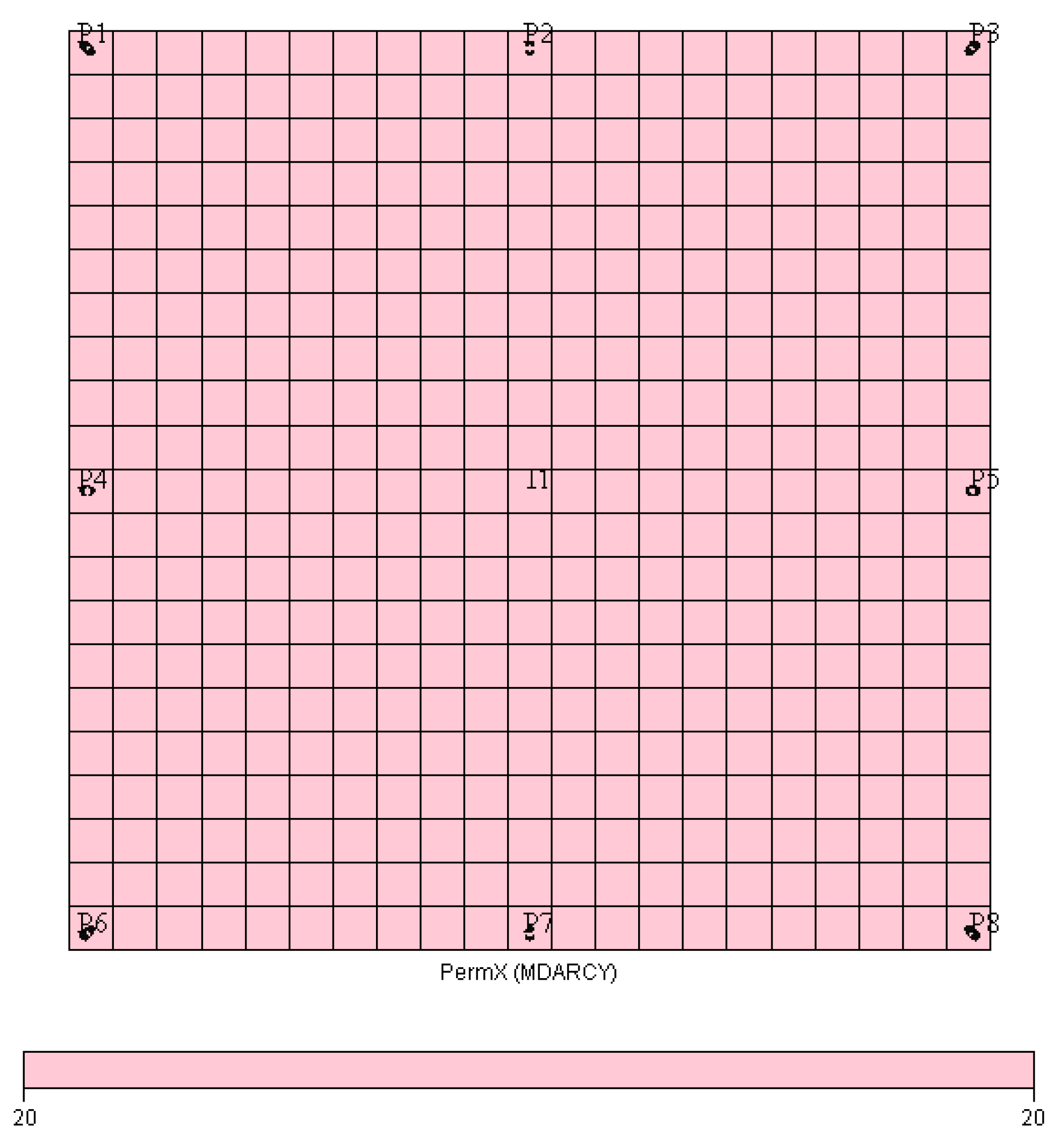

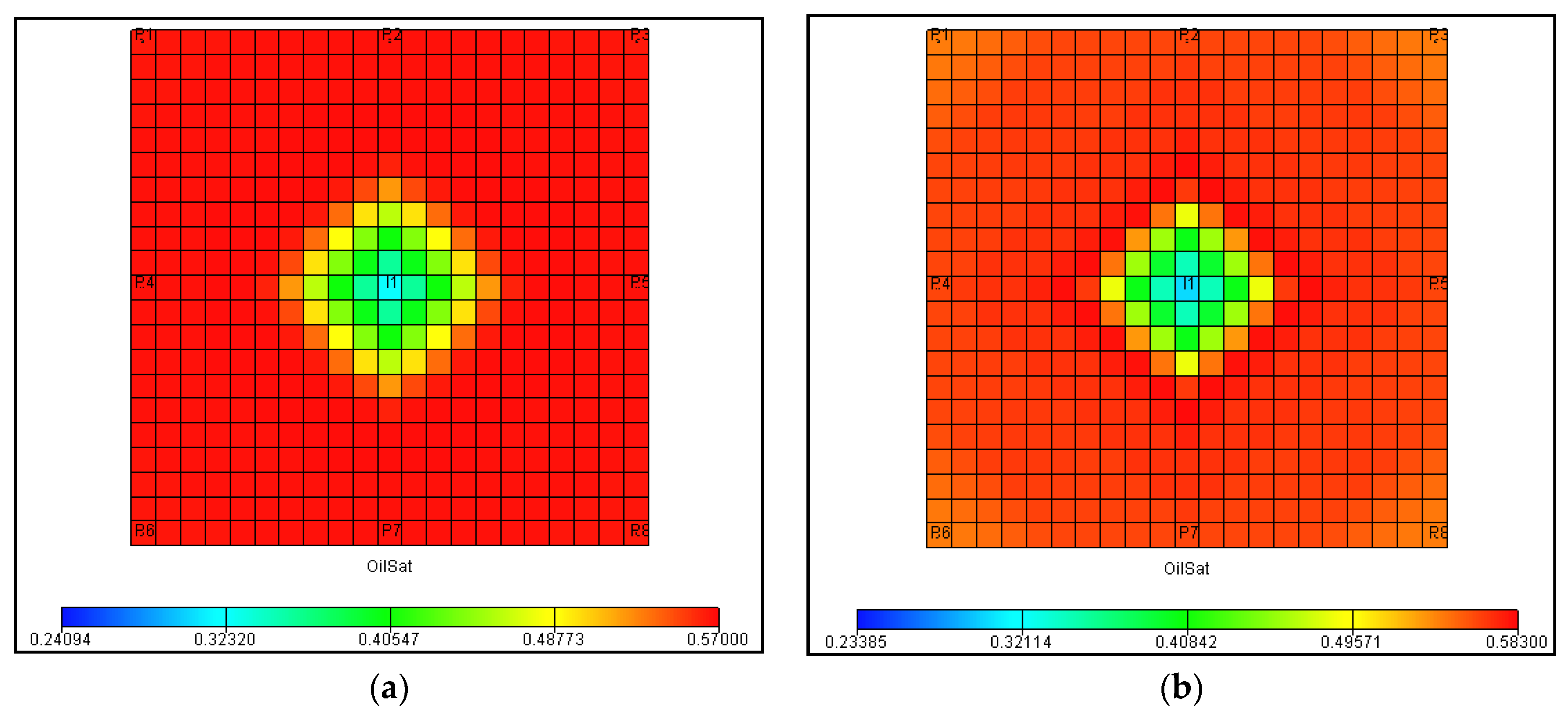

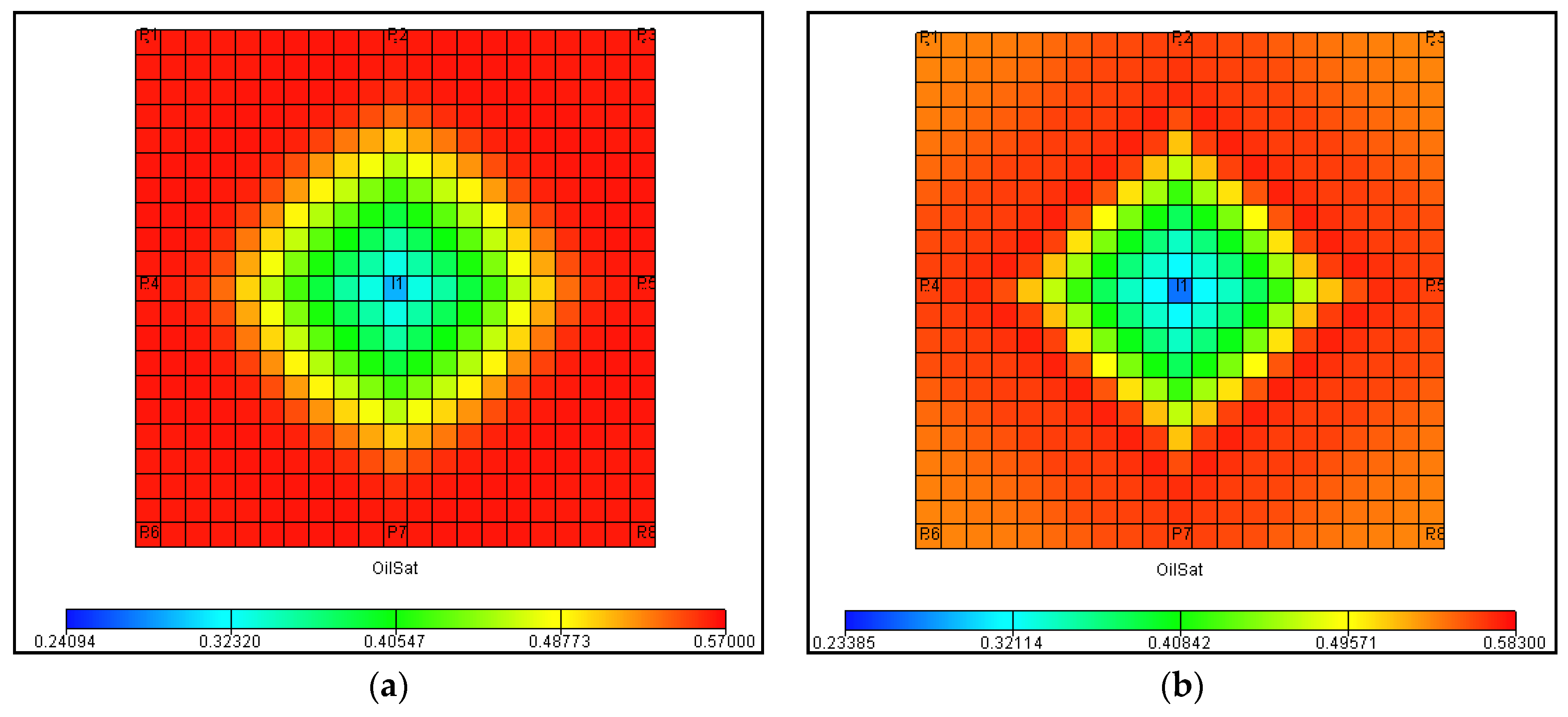

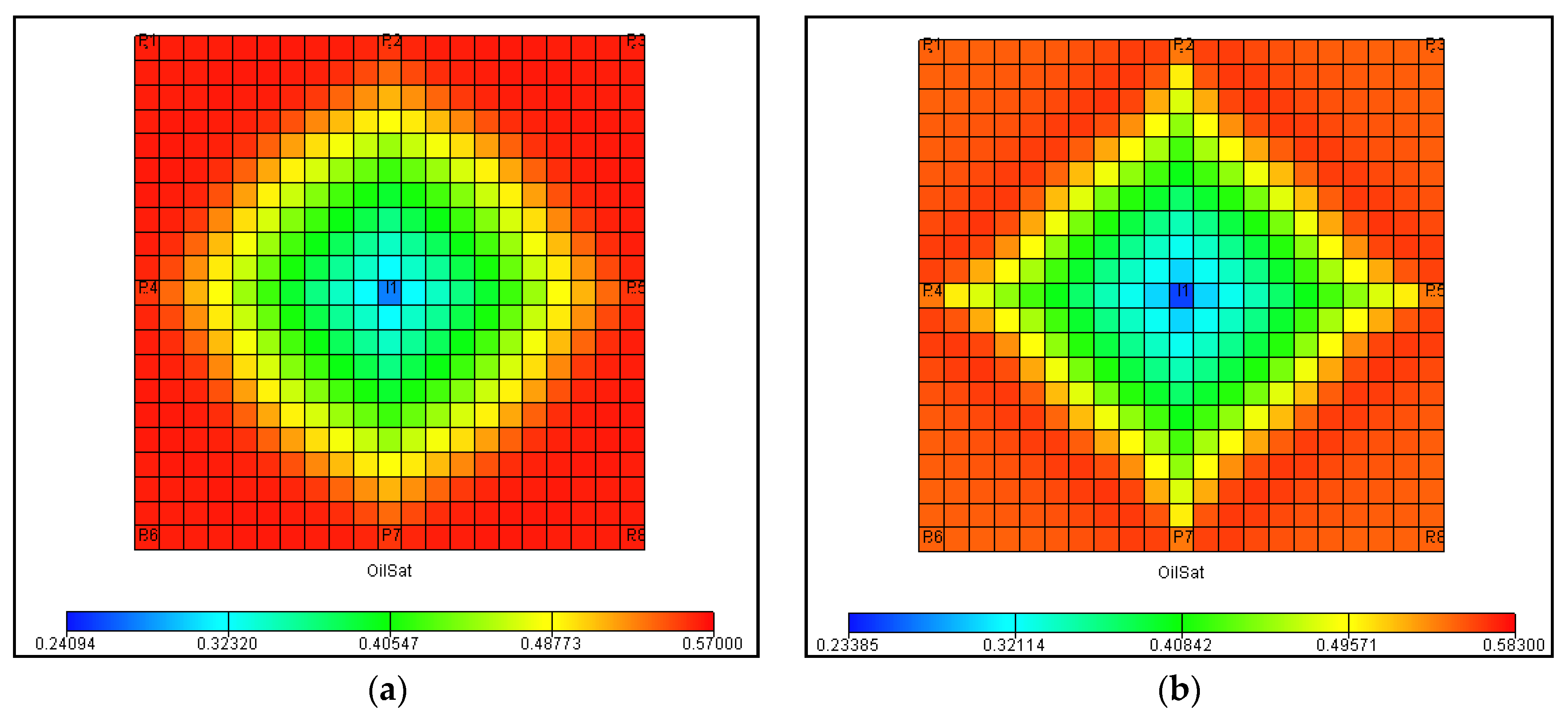

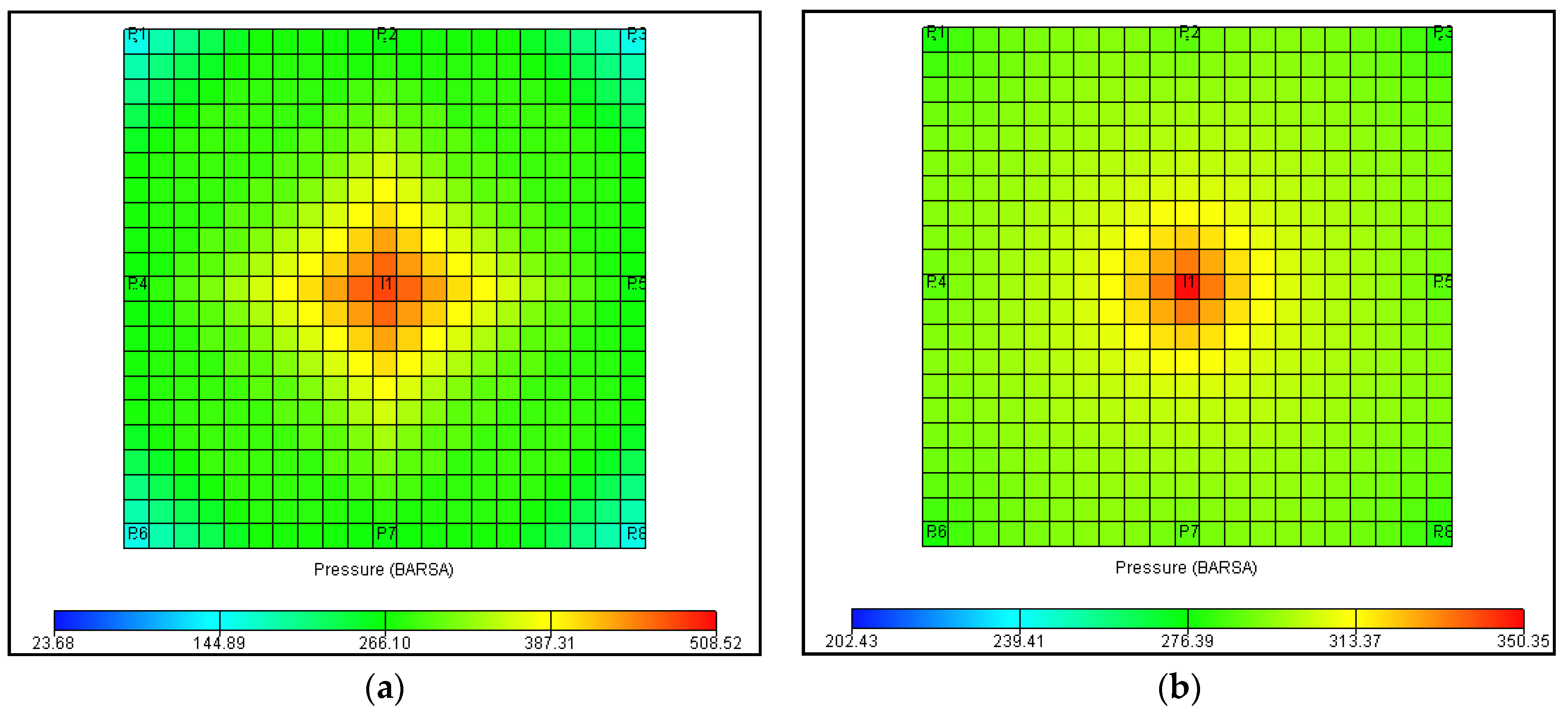

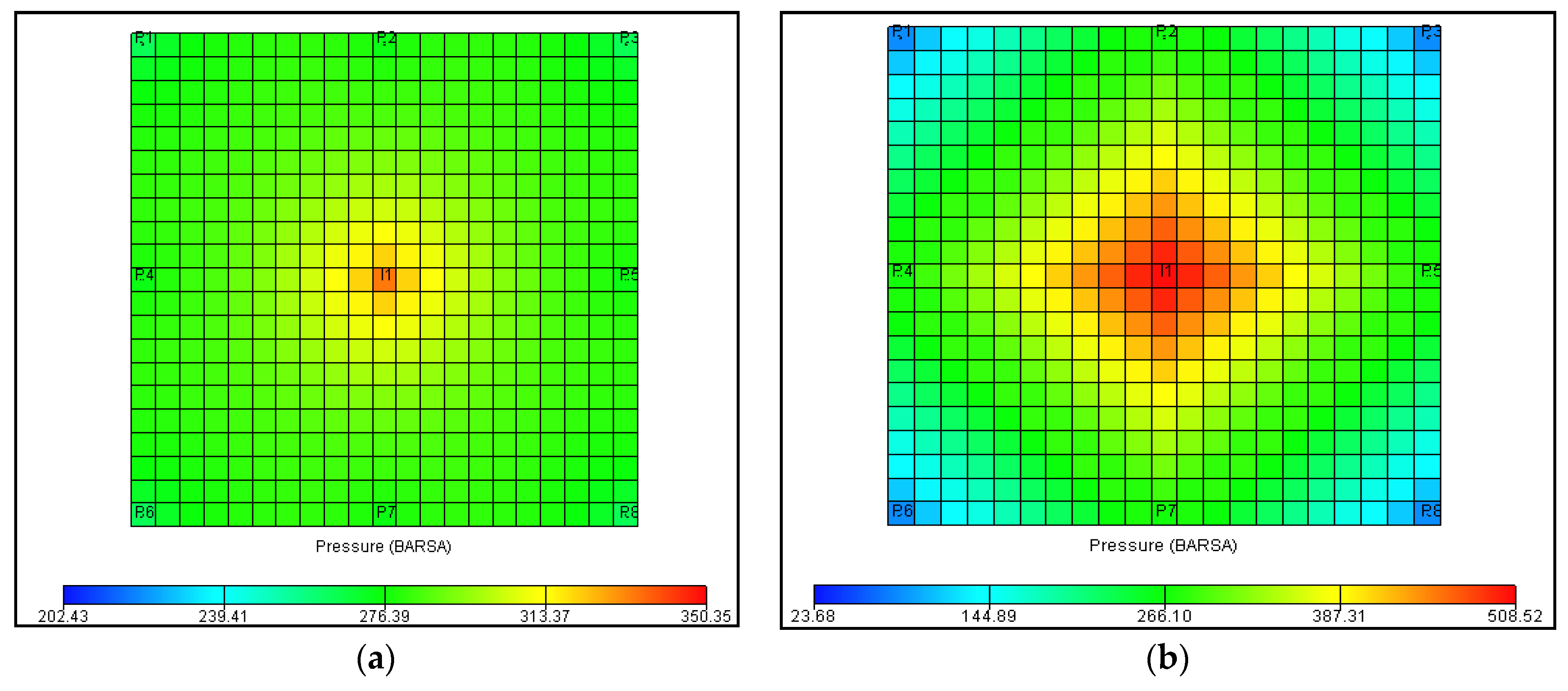

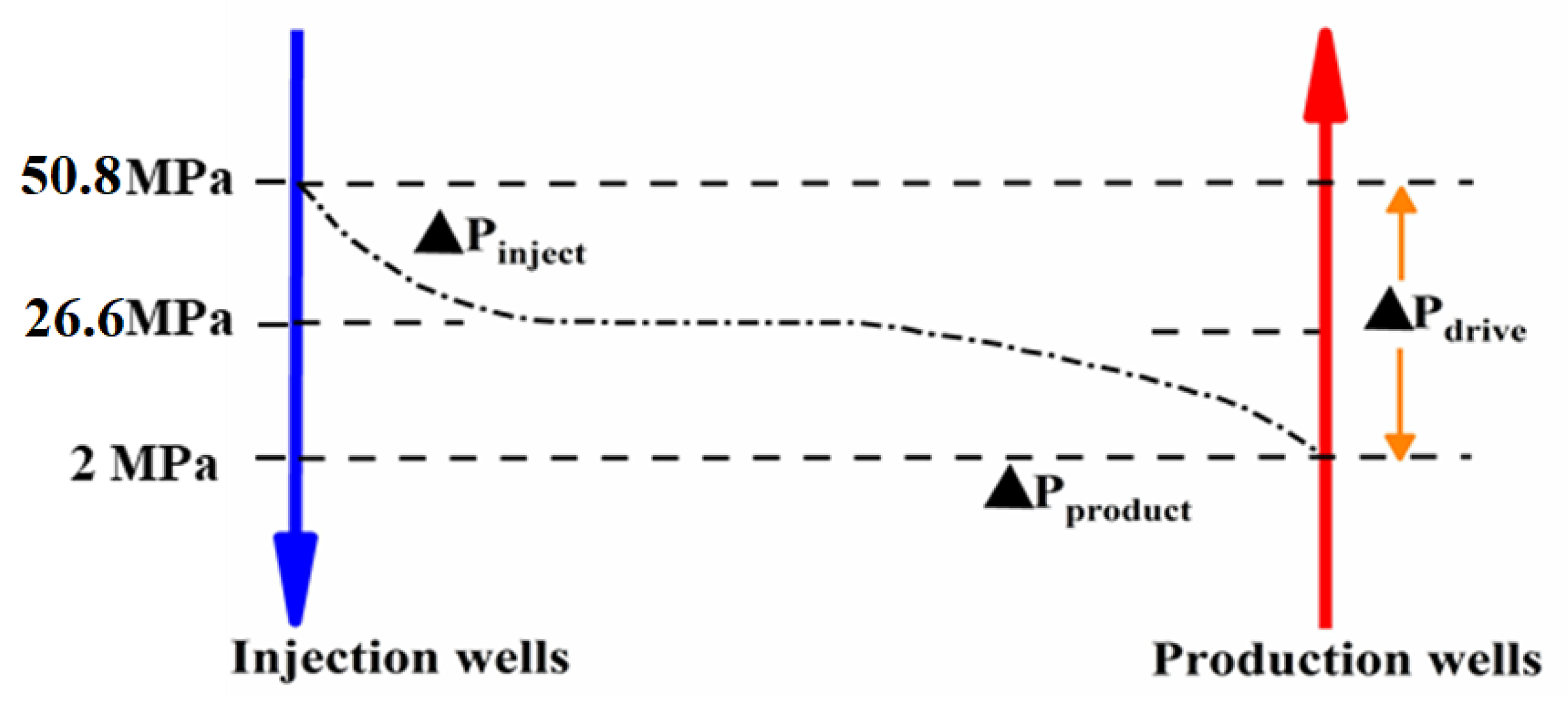

3.1. Conceptual Model

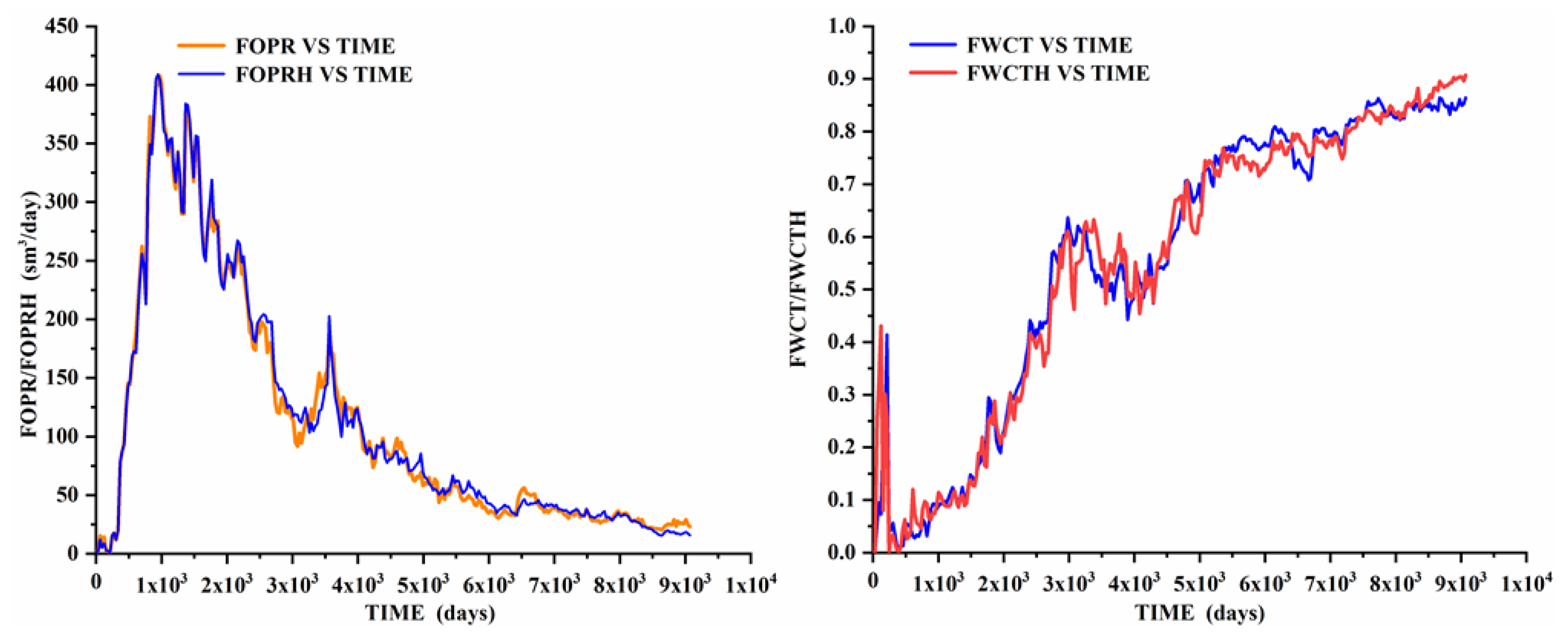

3.2. Fitting Results

4. Discussion

5. Conclusions

- (1)

- The boundary layer is the key parameter affecting the nonlinear characteristics of oil–water two-phase seepage in low-permeability reservoirs. Smaller pressure gradients and thicker boundary layers result in smaller effective seepage radii and smaller apparent permeability. Therefore, the equation between apparent permeability and pressure gradient constructed in this study can effectively characterize the nonlinear seepage characteristics of low-permeability reservoirs.

- (2)

- Based on the relationship between the apparent permeability and pressure gradient, the fractional flow equation was also modified in this study. The calculation results showed that the water cut calculated by the new fractional flow equation is higher than that calculated by Darcy seepage, and is consistent with the actual development of low-permeability reservoirs.

- (3)

- A numerical simulation of low-permeability reservoir was carried out, which proved that the calculated results were in good agreement with the test results. The key parameters of Equation (4) need to be obtained through laboratory experiments.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hao, P.; Xiang, J.; Wang, W.; Kang, Y. Study on the relationship between starting pressure gradient and permeability in low permeability reservoirs. J. Oil Gas Technol. 2008, 28, 1416–1423. [Google Scholar]

- Thauvin, F.; Mohanty, K.K. Network modeling of non-Darcy flow through porous media. Transp. Porous Media 1998, 31, 19–37. [Google Scholar] [CrossRef]

- Xiong, Y.; Yu, J.; Sun, H.; Yuan, J.; Huang, Z.; Wu, Y.S. A new Non-Darcy flow model for low-velocity multiphase flow in tight reservoirs. Transp. Porous Media 2017, 117, 367–383. [Google Scholar] [CrossRef]

- Xu, J.; Jiang, R.; Xie, L.; Wang, R.; Shan, L.; Li, L. Non-Darcy flow numerical simulation for low-permeability reservoirs. In Proceedings of the SPE Europec/EAGE Annual Conference, Copenhagen, Denmark, 4–7 June 2012. [Google Scholar]

- Ding, J.; Yang, S.; Nie, X.; Wang, Z. Dynamic threshold pressure gradient in tight gas reservoir. J. Nat. Gas Sci. Eng. 2014, 20, 155–160. [Google Scholar] [CrossRef]

- Hao, F.; Cheng, L.S.; Hassan, O.; Hou, J.; Liu, C.Z.; Feng, J.D. Threshold pressure gradient in ultra-low permeability reservoirs. Petrol. Sci. Technol. 2008, 26, 1024–1035. [Google Scholar] [CrossRef]

- Sedahmed, M.; Coelho, R.C.V.; Wardal, H.A. An improved multicomponent pseudopotential lattice Boltzmann method for immiscible fluid displacement in porous media. Phys. Fluids 2022, 34, 023102. [Google Scholar] [CrossRef]

- Zeng, J.; Wang, X.; Guo, J.; Zeng, F.; Zhang, Q. Composite linear flow model for multi-fractured horizontal wells in tight sand reservoirs with the threshold pressure gradient. J. Petrol. Sci. Eng. 2018, 165, 890–912. [Google Scholar] [CrossRef]

- Xu, P.; Qiu, S.; Yu, B.; Jiang, Z. Prediction of relative permeability in unsaturated porous media with a fractal approach. Int. J. Heat Mass Tran. 2013, 64, 829–837. [Google Scholar] [CrossRef]

- Sedahmed, M.; Coelho, R.C.V.; Araújo, N.A.M.; Wahba, E.M.; Wardal, H.A. Study of fluid displacement in three-dimensional porous media with an improved multicomponent pseudopotential lattice Boltzmann method. Phys. Fluids 2022, 34, 103303. [Google Scholar] [CrossRef]

- Zhao, L.; Jiang, H.; Wang, H.; Yang, H.; Sun, F.; Li, J. Representation of a new physics-based non-Darcy equation for low-velocity flow in tight reservoirs. J. Petrol. Sci. Eng. 2020, 184, 106518. [Google Scholar] [CrossRef]

- Lu, D.; Seadawy, A.R.; Khater, M.M.A. Structure of solitary wave solutions of the nonlinear complex fractional generalized Zakharov dynamical system. Adv. Differ. Equ. 2018, 2018, 266. [Google Scholar] [CrossRef]

- Liu, N.; Ju, B.; Yang, Y.; Brantson, E.T.; Wang, J.; Tian, Y. Experimental study of different factors on dynamic characteristics of dispersed bubbles rising motion behavior in liquid-saturated porous media. J. Petrol. Sci. Eng. 2019, 180, 396–405. [Google Scholar] [CrossRef]

- Zeng, Z.; Grigg, R. A criterion for non-Darcy flow in porous media. Transp. Porous Media 2006, 63, 57–69. [Google Scholar] [CrossRef]

- Cui, J.; Sang, Q.; Li, Y.; Yin, C.; Li, Y.; Dong, M. Liquid permeability of organic nanopores in shale: Calculation and analysis. Fuel 2017, 202, 426–434. [Google Scholar] [CrossRef]

- Guan, C.; Hu, W.; Li, Y.; Ma, R.; Ma, Z. Prediction of oil-water relative permeability with a fractal method in ultra-high water cut stage. Int. J. Heat Mass Tran. 2019, 130, 1045–1052. [Google Scholar] [CrossRef]

- Muljadi, B.P.; Blunt, M.J.; Raeini, A.Q.; Bijeljic, B. The impact of porous media heterogeneity on non-Darcy flow behaviour from pore-scale simulation. Adv. Water Resour. 2016, 95, 329–340. [Google Scholar] [CrossRef]

- Chai, Z.; Shi, B.; Lu, J.; Guo, Z. Non-Darcy flow in disordered porous media: A lattice Boltzmann study. Comput. Fluid 2010, 39, 2069–2077. [Google Scholar] [CrossRef]

- Feng, Q.; Xu, S.; Wang, S.; Li, Y.; Gao, F.; Xu, Y. Apparent permeability model for shale oil with multiple mechanisms. J. Petrol. Sci. Eng. 2019, 175, 814–827. [Google Scholar] [CrossRef]

- Liu, N.; Chen, X.; Ju, B.; He, Y.; Yang, Y.; Brantson, E.; Tian, Y. Microbubbles generation by an orifice spraying method in a water-gas dispersion flooding system for enhanced oil recovery. J. Petrol. Sci. Eng. 2021, 198, 108196. [Google Scholar] [CrossRef]

- Ren, X.J.; Zhang, G.H.; Liao, F.F. Criterion of starting pressure gradient existence of non-Darcy flowing in low permeability porous media. J. Liaoning Tech. Univ. 2009, 28, 273–276. [Google Scholar]

- Yao, Y.; Ge, J. Characteristics of non-Darcy flow in low-permeability reservoirs. Pet. Sci. 2011, 8, 55–62. [Google Scholar] [CrossRef]

- Wang, X.; Sheng, J.J. Effect of low-velocity non-Darcy flow on well production performance in shale and tight oil reservoirs. Fuel 2017, 190, 41–46. [Google Scholar] [CrossRef]

- Wang, C.; Liu, H.; Wang, X.C.; Zhang, L.H. High Blocking Capacity of Fuzzy-Ball Fluid to Further Enhance Oil Recovery after Polymer Flooding in Heterogeneous Sandstone Reservoirs. ACS Omega 2021, 6, 34035–34043. [Google Scholar] [CrossRef] [PubMed]

- Mohamed, K.; Seadawy, A. Finite volume scheme for numerical simulation of the sediment transport model. Int. J. Mod. Phys. B 2019, 33, 1950283. [Google Scholar] [CrossRef]

- Khan, K.A.; Seadawy, A.R.; Jhangeer, A. Numerical appraisal under the influence of the time dependent Maxwell fluid flow over a stretching sheet. Math. Methods Appl. Sci. 2021, 44, 5265–5279. [Google Scholar] [CrossRef]

| Time | Well | Formation Pressure MPa | Darcy Calculation MPa | Error % | Non-Darcy Calculation MPa | Error % |

|---|---|---|---|---|---|---|

| April 2020 | Y120 | 25.6 | 39.1 | 52.7 | 27.2 | 6.2 |

| April 2020 | Y4-2-14 | 30.5 | 40.2 | 31.8 | 32.3 | 5.9 |

| April 2020 | Y4-6-15 | 53.4 | 42.2 | −21.0 | 51.3 | −3.9 |

| April 2020 | Y4-4-17 | 50.7 | 41.1 | −18.9 | 49.9 | −1.6 |

| Layer | Monitoring Results | Darcy Calculation | Relative Error | Non-Darcy Calculation | Relative Error |

|---|---|---|---|---|---|

| 61 | 26.3 | 29.3 | 11.4 | 24.8 | −5.7 |

| 62 | 14.5 | 21.4 | 47.7 | 15.1 | 4.4 |

| 71 | 5.6 | 11.5 | 105.4 | 5.3 | −6.1 |

| 72 | 53.6 | 37.8 | −29.5 | 54.8 | 2.2 |

| Layer | Monitoring Results | Darcy Calculation | Relative Error | Non-Darcy Calculation | Relative Error |

|---|---|---|---|---|---|

| 61 | 23.6 | 27.3 | 15.8 | 22.4 | −5.0 |

| 62 | 11.7 | 18.7 | 59.7 | 12.1 | 3.4 |

| 71 | 22.4 | 19.4 | −13.2 | 20.9 | −6.5 |

| 72 | 42.4 | 34.6 | −18.3 | 44.6 | 5.3 |

| Layer | Thickness (m) | Testing Results | Darcy Calculation | Non-Darcy Calculation | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Liquid Production | Water Content | Liquid Production | Errors | Water Content | Errors | Liquid Production | Errors | Water Content | Errors | ||

| 61 | 15.5 | 35.4 | 87.6 | 31.1 | −12.1 | 85.3 | −2.6 | 34.4 | −2.8 | 88.7 | 1.3 |

| 62 | 8.8 | 38.1 | 92.4 | 17.6 | −53.8 | 91.7 | −0.8 | 38.6 | 1.3 | 91.7 | −0.8 |

| 71 | 7.7 | 6.7 | 10.4 | 12.5 | 86.7 | 54.7 | 426.0 | 5.9 | −11.9 | 11.5 | 10.6 |

| 721 | 13.8 | 14.5 | 72.1 | 26.2 | 80.6 | 84.4 | 17.1 | 15.5 | 6.9 | 71.1 | −1.4 |

| 722 | 6.9 | 5.3 | 9.6 | 12.6 | 137.6 | 60.4 | 529.2 | 5.6 | 5.7 | 11.1 | 15.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, H.; Liu, N.; Chen, Y.; Tian, Y.; Guo, Z.; Jiang, W.; He, Y. A Novel Equivalent Numerical Simulation Method for Non-Darcy Seepage Flow in Low-Permeability Reservoirs. Energies 2022, 15, 8505. https://doi.org/10.3390/en15228505

Xu H, Liu N, Chen Y, Tian Y, Guo Z, Jiang W, He Y. A Novel Equivalent Numerical Simulation Method for Non-Darcy Seepage Flow in Low-Permeability Reservoirs. Energies. 2022; 15(22):8505. https://doi.org/10.3390/en15228505

Chicago/Turabian StyleXu, Hui, Nannan Liu, Yan Chen, Yapeng Tian, Zhenghuai Guo, Wanjun Jiang, and Yanfeng He. 2022. "A Novel Equivalent Numerical Simulation Method for Non-Darcy Seepage Flow in Low-Permeability Reservoirs" Energies 15, no. 22: 8505. https://doi.org/10.3390/en15228505

APA StyleXu, H., Liu, N., Chen, Y., Tian, Y., Guo, Z., Jiang, W., & He, Y. (2022). A Novel Equivalent Numerical Simulation Method for Non-Darcy Seepage Flow in Low-Permeability Reservoirs. Energies, 15(22), 8505. https://doi.org/10.3390/en15228505