Enhancing the Efficiency of Integrated Energy Systems by the Redistribution of Heat Based on Monitoring Data

Abstract

1. Introduction

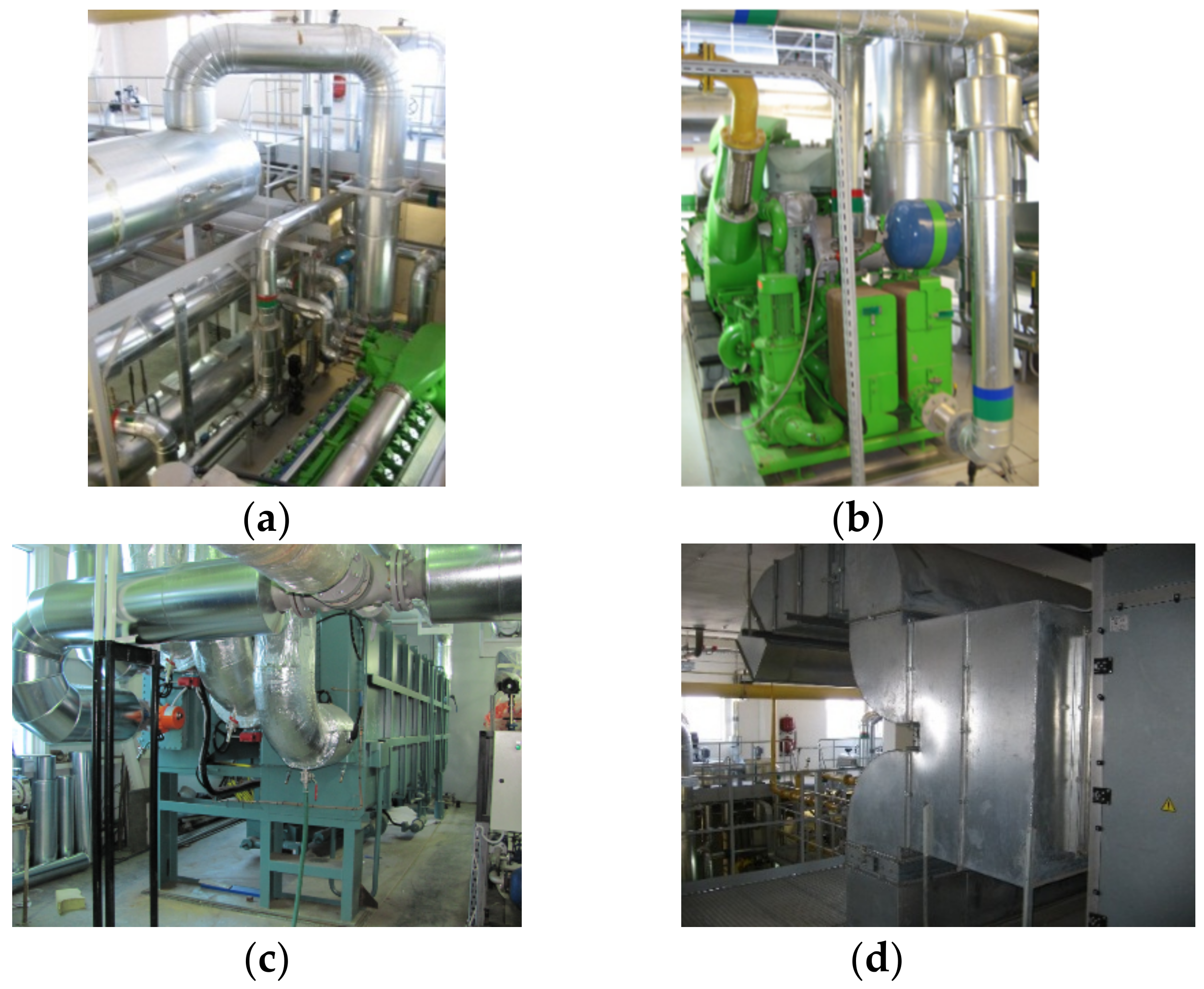

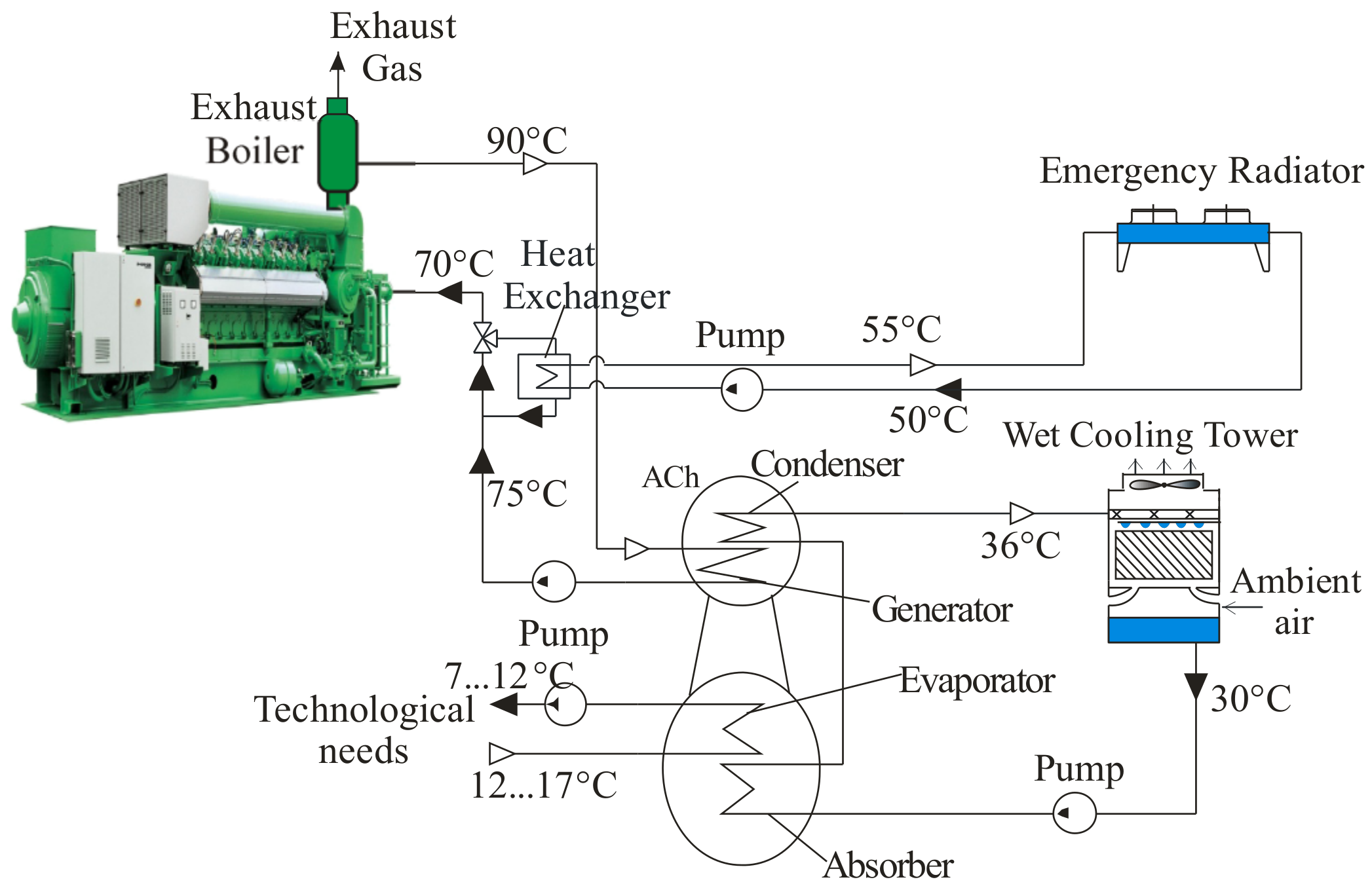

2. Materials and Methods

2.1. General Assumptions and Hypothesis

2.2. Calculation Procedure

3. Results and Discussion of Investigation

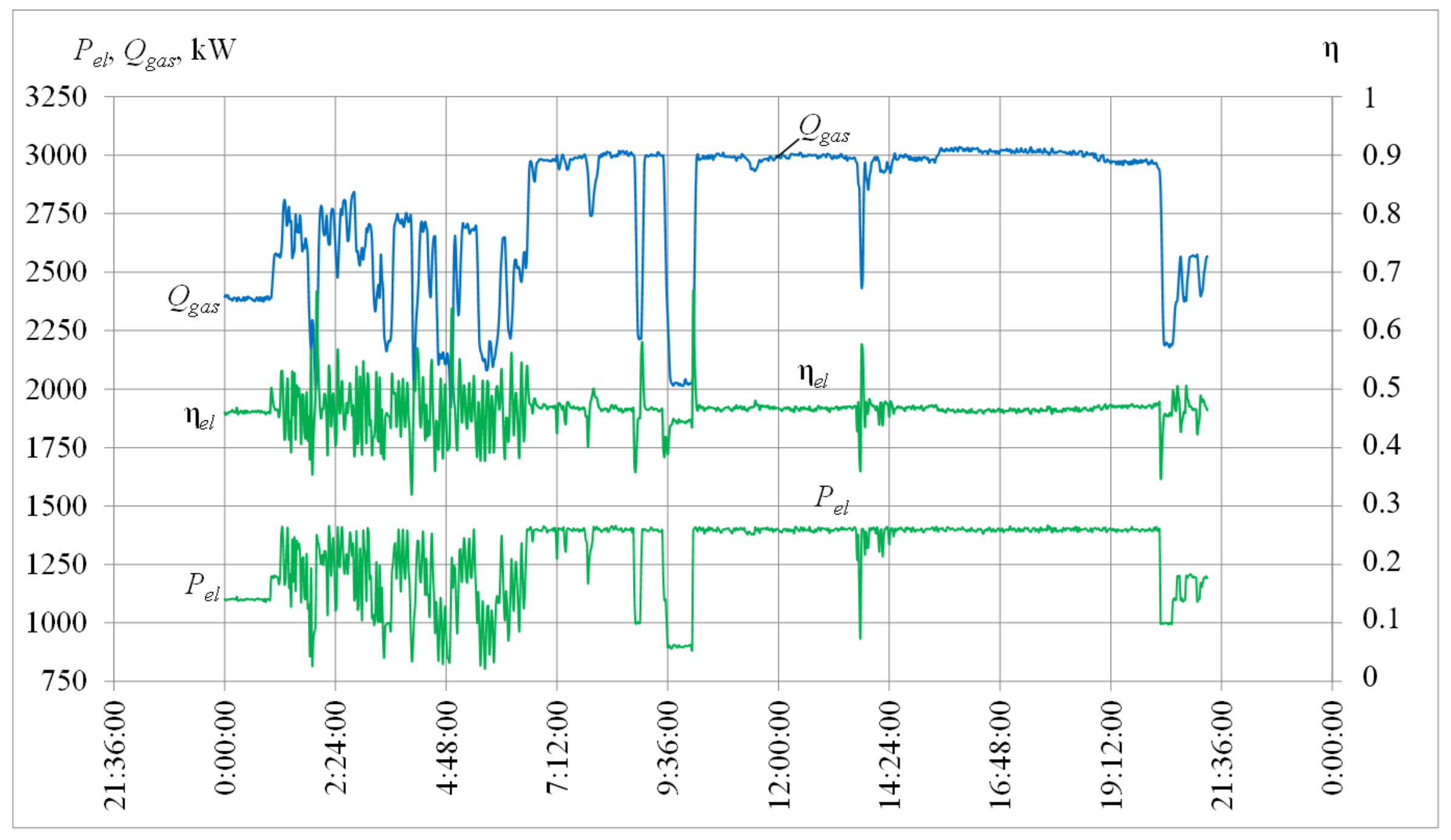

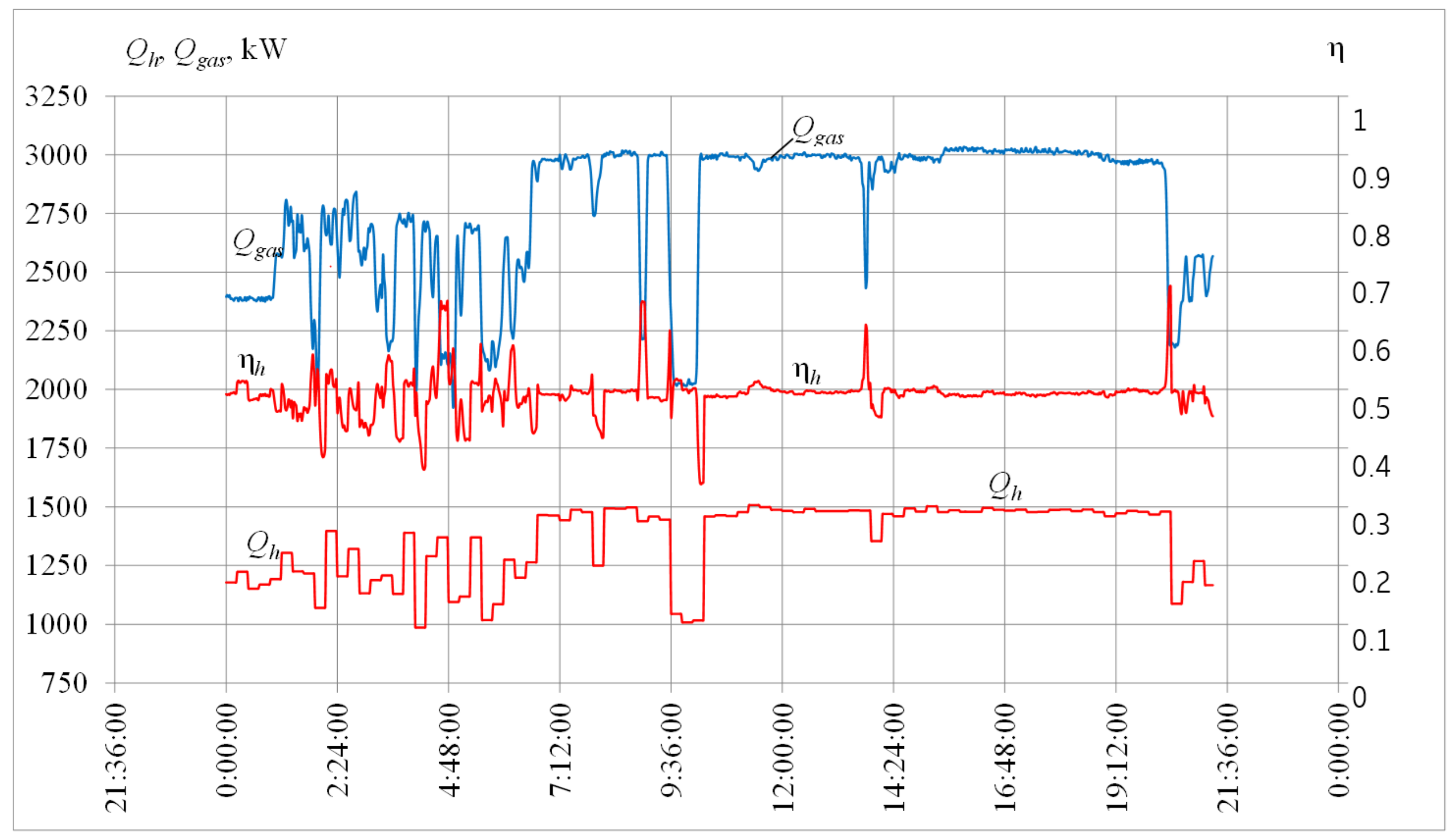

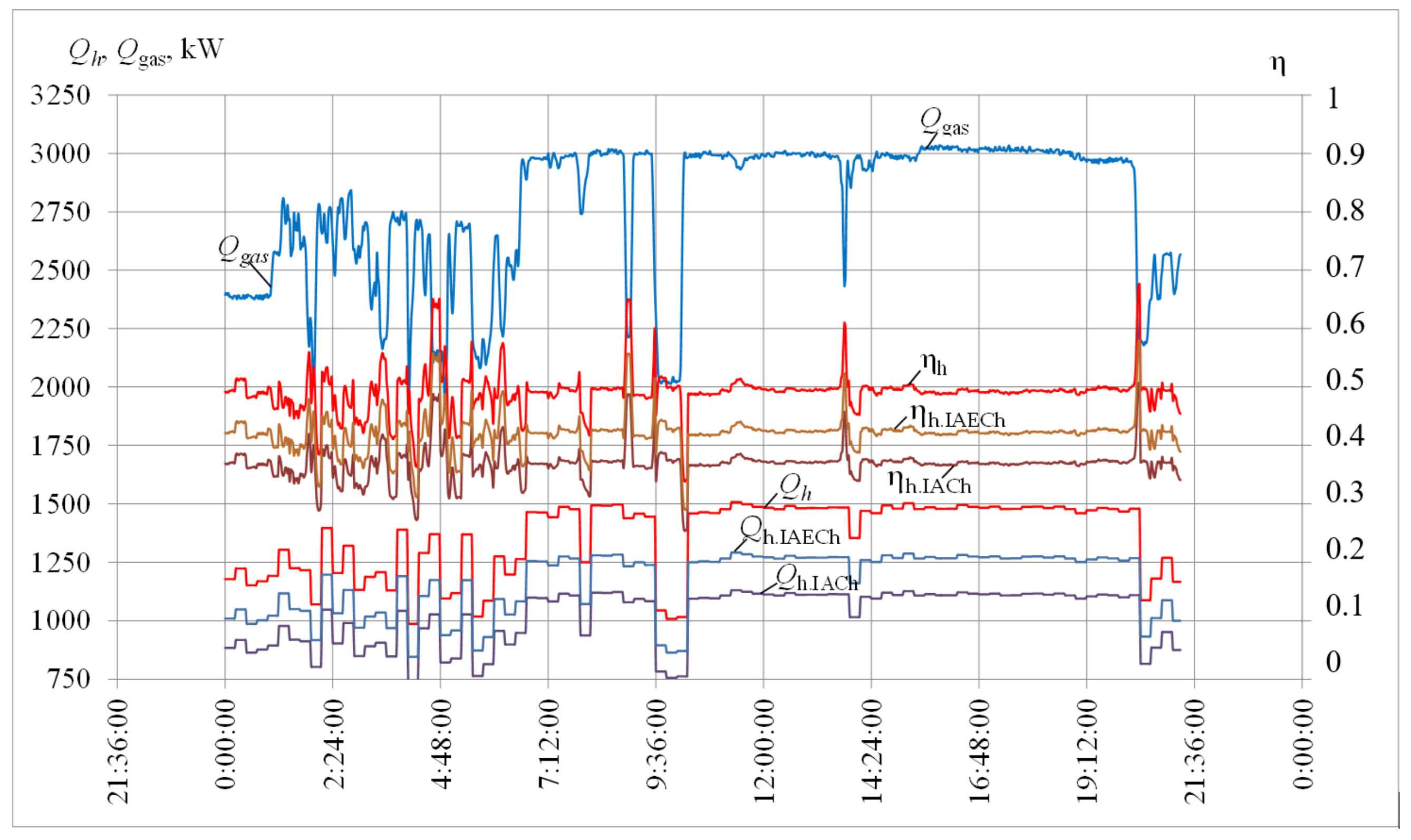

3.1. Estimation of Heat Lost in Typical IES with an ACh

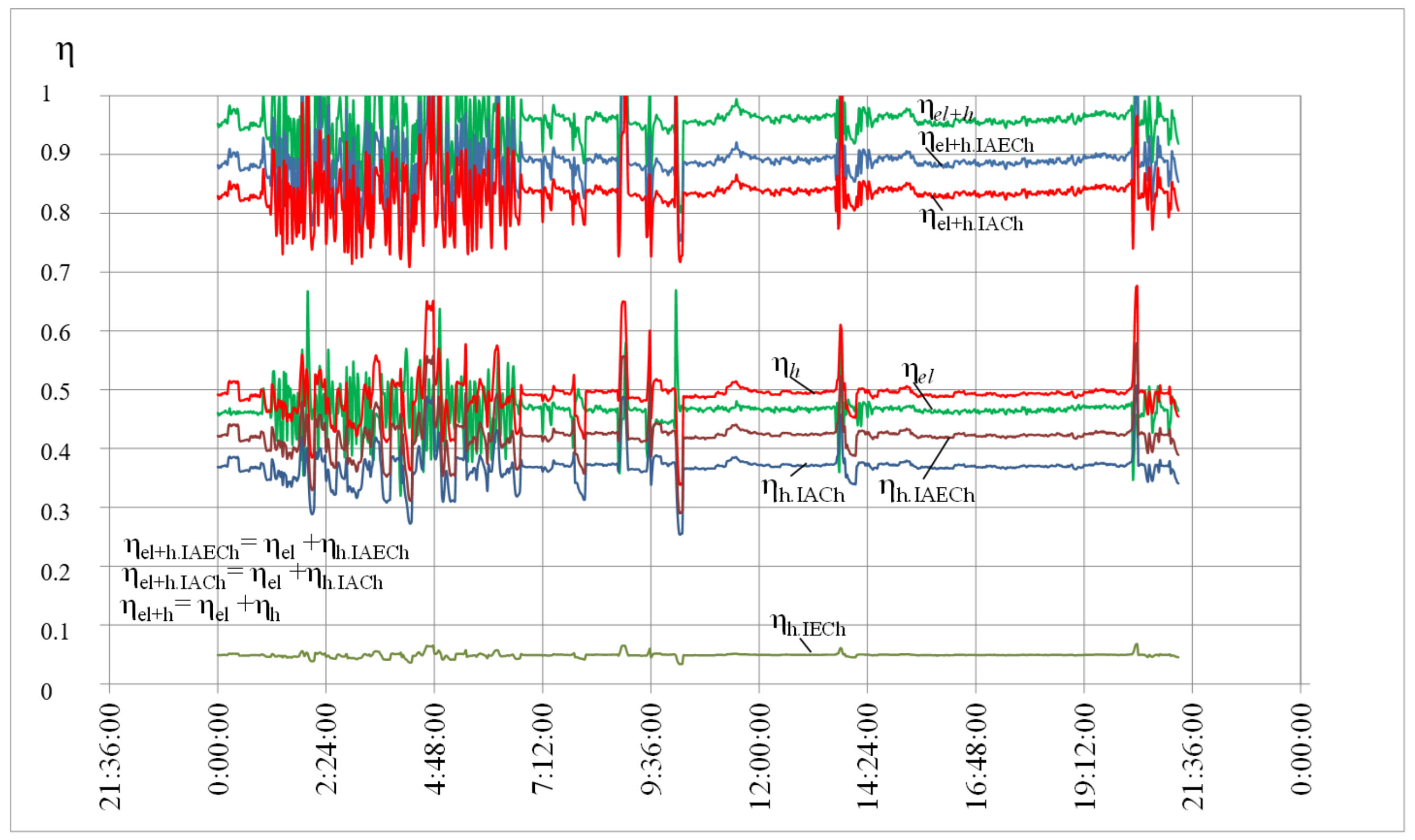

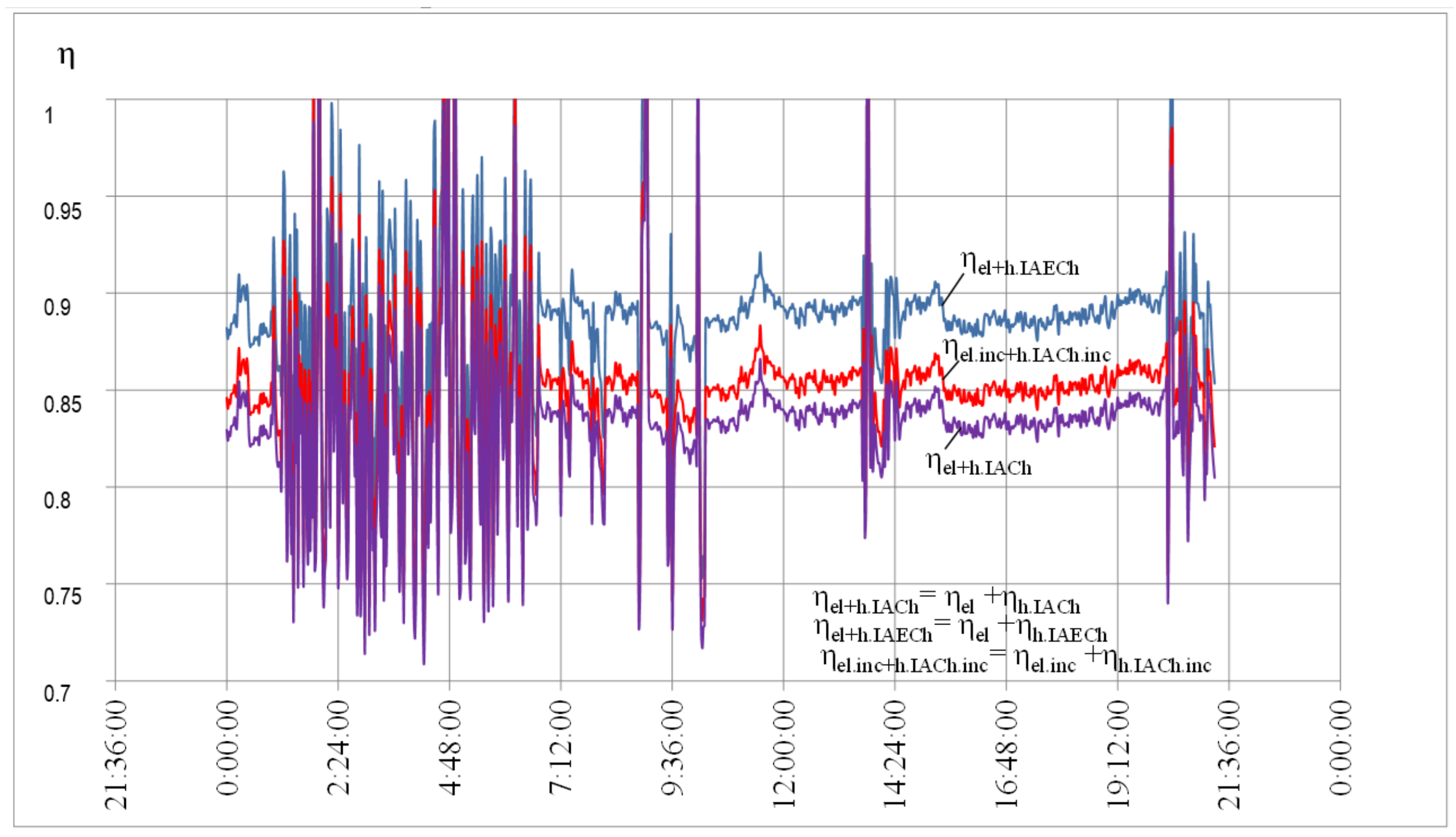

3.2. Estimation of Thermodynamic Efficiency of a Typical IES by Traditional Method

3.3. Estimation of Thermodynamic Efficiency of a Typical IES by Improved Method

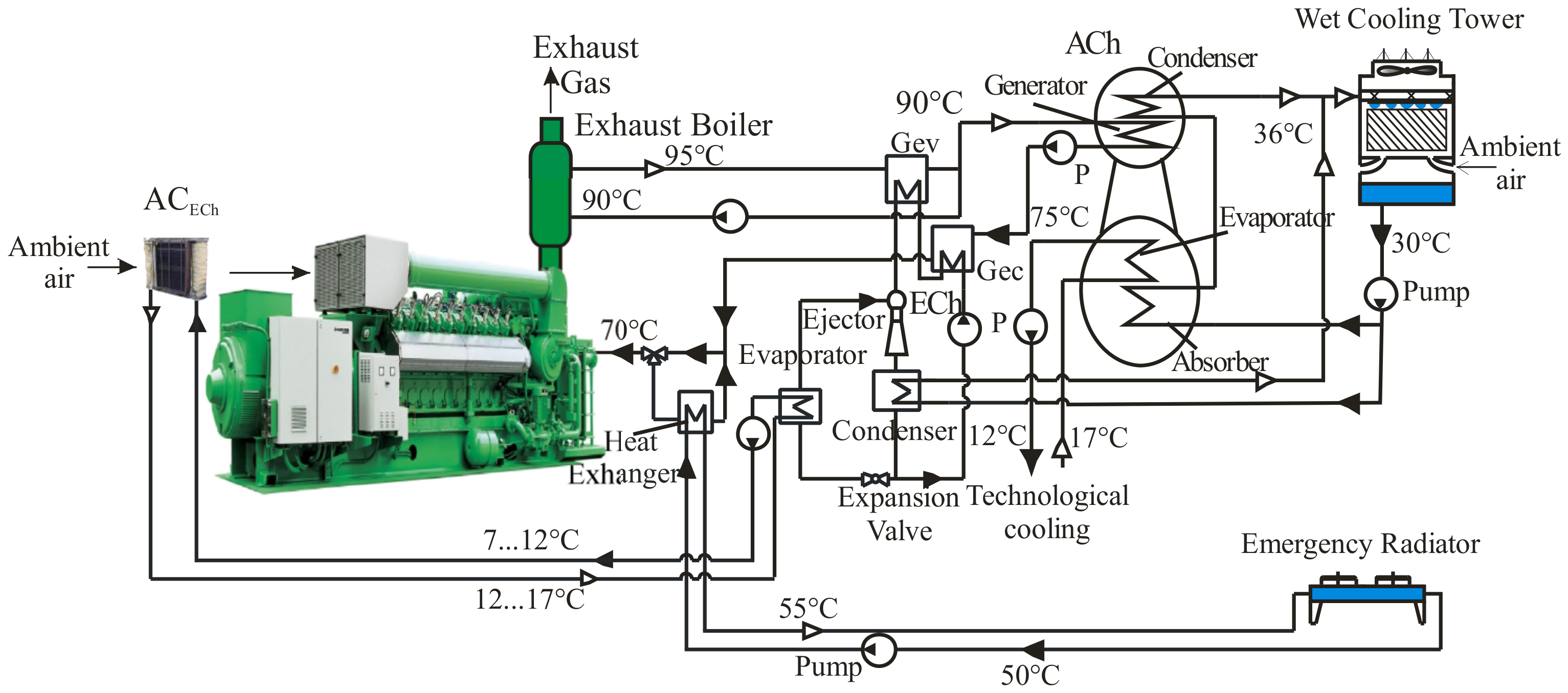

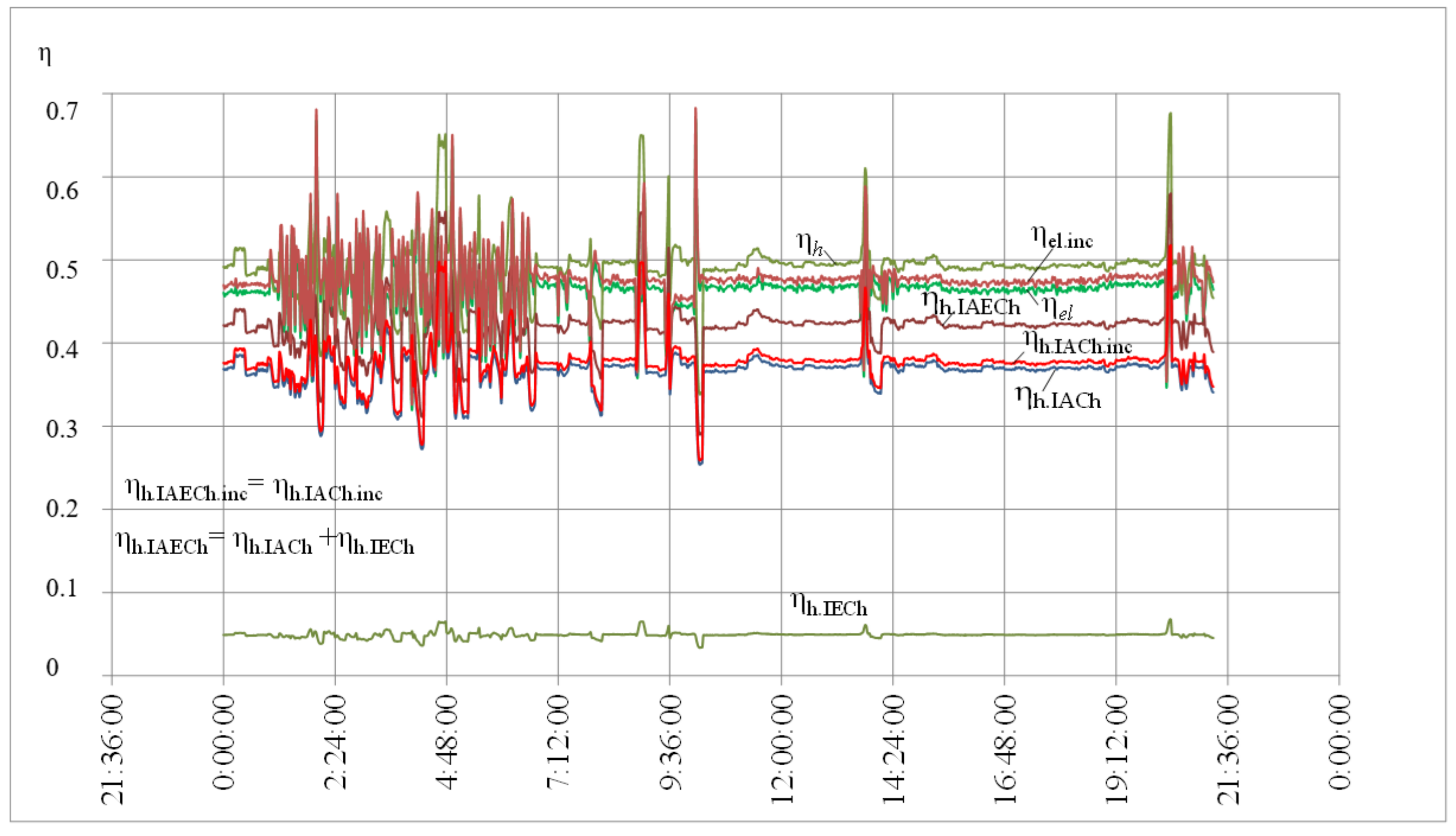

3.4. Estimation of Thermodynamic Efficiency of Innovative Waste Heat Recovery System by Improved Method

3.5. Estimation of Thermodynamic Efficiency of Innovative IES with Cooling Engine Sucked Air

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| AC | air cooler | |

| ACh | absorption lithium-bromide chiller | |

| AECh | absorption-ejector chiller | |

| COP | coefficient of performance | |

| ECh | ejector chiller | |

| LHV | Low Heat Value | kJ/kg |

| Symbols and unIES | ||

| damb | ambient air absolute humidity | g/kg |

| Ga | air mass flow rate | kg/s |

| Pe | power output | kW |

| Q0 | overall cooling capacity | kW |

| q0 | specific cooling capacity—per unit air mass flow rate | kW/(kg/s) or kJ/kg |

| t | temperature | °C |

| tamb | ambient air temperature | °C |

| ta2 | outlet air temperature | °C |

| t0 | refrigerant boiling temperature | °C |

| ξ | specific heat ratio of the overall heat (latent and sensible) related to sensible heat | |

| τ | time interval | h |

| φamb | ambient air relative humidity | % |

| Δt | air temperature decrease | K, °C |

| Subscripts | ||

| a | air | |

| amb | ambient | |

| max | maximum | |

| opt | optimal | |

| rat | rational | |

References

- DFIC—Dr. Fromme International Consulting. Cogeneration & Trigeneration—How to Produce Energy Efficiently: A Practical Guide for Experts in Emerging and Developing Economies; Zellner, S., Burgtorf, J., Kraft-Schäfer, D., Eds.; Deutsche Gesellschaft für Internationale Zusammenarbeit (GIZ) GmbH: Eschborn, Germany, 2016; p. 144. [Google Scholar]

- Gluesenkamp, K.; Hwang, Y.; Radermacher, R. High efficiency micro trigeneration systems. Appl. Therm. Eng. 2013, 50, 6. [Google Scholar] [CrossRef]

- Fahad, A. Al-Sulaiman; Ibrahim Dincer; Feridun Hamdullahpur Thermoeconomic optimization of three trigeneration systems using organic Rankine cycles: Part I—Formulations. Energy Convers. Manag. 2013, 69, 199–208. [Google Scholar]

- Maraver, D.; Sin, A.; Royo, J.; Sebastián, F. Assessment of CCHP systems based on biomass combustion for small-scale applications through a review of the technology and analysis of energy efficiency parameters. Appl. Energy 2013, 102, 1303–1313. [Google Scholar] [CrossRef]

- Popli, S.; Rodgers, P.; Eveloy, V. Trigeneration scheme for energy efficiency enhancement in a natural gas processing plant through turbine exhaust gas waste heat utilization. Appl. Energy 2012, 93, 623–636. [Google Scholar] [CrossRef]

- Rocha, M.; Andreos, R.; Simões-Moreira, J.R. Performance tests of two small trigeneration pilot plants. Appl. Therm. Eng. 2012, 41, 84–91. [Google Scholar] [CrossRef]

- Khaliq, A.; Dincer, I.; Sharma, P.B. Development and analysis of industrial waste heat based trigeneration for combined generation of power heat and cold. J. Energy Inst. 2010, 83, 79–85. [Google Scholar] [CrossRef]

- Abusaa, G.; Issa, K. Performance Improvements of Power Generation Using Waste Heat Hybrid Cooling Plant. Kingdom Trigeneration Summit 29 September 2013; p. 24. Available online: http://www.adcenergysystems.com/images/Downloads/Tri-Gen%202013%Performance%20Improvements%20of%20Power%20Generation%20–%20K.Issa,%20ADC.pdf (accessed on 20 February 2020).

- Oktay, Z.; Coskun, C.; Dincer, I. A new approach for predicting cooling degree-hours and energy requirements in buildings. Energy 2011, 36, 4855–4863. [Google Scholar] [CrossRef]

- Ullah, I.; Hussain, I.; Rehman, K.; Wróblewski, P.; Lewicki, W.; Kavin, B.P. Exploiting the Moth–Flame Optimization Algorithm for Optimal Load Management of the University Campus: A Viable Approach in the Academia Sector. Energies 2022, 15, 3741. [Google Scholar] [CrossRef]

- Shukla, A.K.; Sharma, A.; Sharma, M.; Mishra, S. Performance Improvement of Simple Gas Turbine Cycle with Vapor Compression Inlet Air Cooling. Mater. Today Proc. 2018, 5, 19172–19180. [Google Scholar] [CrossRef]

- Barreto, D.; Fajardo, J.; Caballero, G.C.; Escorcia, Y.C. Innovative exergy and exergoeconomic analysis of a gas power system with steam injection and air cooling with a compression refrigeration machine. Energy Technol. 2021, 9, 2000993. [Google Scholar] [CrossRef]

- Radchenko, R.; Pyrysunko, M.; Kornienko, V.; Scurtu, I.-C.; Patyk, R. Improving the Ecological and Energy Efficiency of Internal Combustion Engines by Ejector Chiller Using Recirculation Gas Heat. In Lecture Notes in Networks and Systems; Nechyporuk, M., Pavlikov, V., Kritskiy, D., Eds.; Integrated Computer Technologies in Mechanical Engineering—2020; ICTM 2020; Springer: Cham, Switzerland, 2021; Volume 188, pp. 531–544. [Google Scholar]

- Radchenko, M.; Mikielewicz, D.; Andreev, A.; Vanyeyev, S.; Savenkov, O. Efficient Ship Engine Cyclic Air Cooling by Turboexpander Chiller for Tropical Climatic Conditions. In Integrated Computer Technologies in Mechanical Engineering—2020; Nechyporuk, M., Pavlikov, V., Kritskiy, D., Eds.; ICTM 2020; Lecture Notes in Networks and Systems; Springer: Cham, Switzerland, 2021; Volume 188, pp. 498–507. [Google Scholar]

- Farouk, N.; Sheng, L.; Hayat, Q. Effect of Ambient Temperature on the Performance of Gas Turbines Power Plant. Int. J. Comput. Sci. 2013, 10, 439–442. [Google Scholar]

- Patel, V.R.; Chaudhari, K.V.; Pathak, B.C.; Shekh, A.A. Evaluation of output and heat rate of the simple cycle gas turbine during the base load condition. Int. J. Adv. Res. Eng. Sci. Technol. 2015, 2, 2394–2444. [Google Scholar]

- CIMAC Position Paper Gas Engine Aftertreatment Systems by CIMAC WG 17, Gas Engines, May 2017. Available online: https://www.cimac.com/cms/upload/Publication_Press/WG_Publications/CIMAC_WG17_2017_Aug_Position_Paper_Gas_Engine_Aftertreatment_Systems.pdf (accessed on 5 March 2019).

- Jenbacher. Available online: http://www.intma.ru/energetica/power_stations/thermal_ps_trigeneration_ru.html (accessed on 5 March 2019).

- Radchenko, N.; Trushliakov, E.; Radchenko, A.; Tsoy, A.; Shchesiuk, O. Methods to determine a design cooling capacity of ambient air conditioning systems in climatic conditions of Ukraine and Kazakhstan. AIP Conf. Proc. 2020, 2285, 030074. [Google Scholar] [CrossRef]

- Pavlenko, A.M.; Koshlak, H. Application of Thermal and Cavitation Effects for Heat and Mass Transfer Process Intensification in Multicomponent Liquid Media. Energies 2021, 14, 7996. [Google Scholar] [CrossRef]

- Al-Ibrahim, A.M.; Varnham, A. A review of inlet air-cooling technologies for enhancing the performance of combustion turbines in Saudi Arabia. Appl. Therm. Eng. 2010, 30, 1879–1888. [Google Scholar] [CrossRef]

- Radchenko, A.; Radchenko, N.; Tsoy, A.; Portnoi, B.; Kantor, S. Increasing the efficiency of gas turbine inlet air cooling in actual climatic conditions of Kazakhstan and Ukraine. AIP Conf. Proc. 2020, 2285, 030071. [Google Scholar] [CrossRef]

- Liang, X.; He, G.; Zhou, S.; Hao, Z.; Cai, D. Absorption characteristics of NH3/NaSCN working pair in an adiabatic absorber with structured packing. Appl. Therm. Eng. 2021, 185, 116325. [Google Scholar] [CrossRef]

- Al-Tahaineh, H.A. Cooling of compressor air inlet of a gas turbine power plant using ammonia-water vapor absorption system. Int. J. Energy Eng. 2013, 3, 267–271. [Google Scholar]

- Umberto, L. Adsorber efficiency in adsorbtion refrigeration. Renew. Sustain. Energy Rev. 2013, 20, 570–575. [Google Scholar]

- Sur, A.; Das, R.K.; Sah, R. Influence of initial bed temperature on bed performance of an adsorption refrigeration system. Therm. Sci. 2018, 22, 2583–2595. [Google Scholar] [CrossRef]

- Forduy, S.; Radchenko, A.; Kuczynski, W.; Zubarev, A.; Konovalov, D. Enhancing the fuel efficiency of gas engines in integrated energy system by chilling cyclic air. In Grabchenko’s International Conference on Innovative Manufacturing Process; InterPartner-2019. Lecture Notes in Mechanical Engineering; Tonkonogyi, V., Ed.; Springer: Cham, Switzerland, 2020; pp. 500–509. [Google Scholar] [CrossRef]

- Blecich, P. Experimental investigation of the effects of airflow nonuniformity on performance of a fin-and-tube heat exchanger. Int. J. Refrig. 2015, 59, 65–74. [Google Scholar] [CrossRef]

- Dizaji, H.S.; Hu, E.J.; Chen, L.; Pourhedayat, S. Using novel integrated Maisotsenko cooler and absorption chiller for cooling of gas turbine inlet air. Energy Convers. Manag. 2019, 195, 1067–1078. [Google Scholar] [CrossRef]

- Radchenko, R.; Radchenko, N.; Tsoy, A.; Forduy, S.; Zybarev, A.; Kalinichenko, I. Utilizing the heat of gas module by an absorption lithium-bromide chiller with an ejector booster stage. AIP Conf. Proc. 2020, 2285, 030084. [Google Scholar] [CrossRef]

- Radchenko, M.; Radchenko, A.; Radchenko, R.; Kantor, S.; Konovalov, D.; Kornienko, V. Rational loads of turbine inlet air absorption-ejector cooling systems. Proc. Inst. Mech. Eng. Part A J. Power Energy 2021, 236, 450–462. [Google Scholar] [CrossRef]

- Konovalov, D.; Kobalava, H.; Maksymov, V.; Radchenko, R.; Avdeev, M. Experimental Research of the Excessive Water Injection Effect on Resistances in the Flow Part of a Low-Flow Aerothermopressor. In Advances in Design, Simulation and Manufacturing III (DSMIE 2020); Lecture Notes in Mechanical Engineering; Ivanov, V., Ed.; Springer: Cham, Switzerland, 2020; pp. 292–301. [Google Scholar]

- Butrymowicz, D.; Gagan, J.; Śmierciew, K.; Łukaszuk, M.; Dudar, A.; Pawluczuk, A.; Łapiński, A.; Kuryłowic, A. Investigations of prototype ejection refrigeration system driven by low grade heat. HTRSE-2018 E3S Web Conf. 2018, 70, 7. [Google Scholar] [CrossRef]

- Smierciew, K.; Gagan, J.; Butrymowicz, D.; Karwacki, J. Experimental investigations of solar driven ejector air-conditioning system. Energy Build. 2014, 80, 260–267. [Google Scholar] [CrossRef]

- Konovalov, D.; Radchenko, M.; Kobalava, H.; Kornienko, V.; Maksymov, V.; Radchenko, A.; Radchenko, R. Research of characteristics of the flow part of an aerothermopressor for gas turbine intercooling air. Proc. Inst. Mech. Eng. Part A J. Power Energy 2022, 236, 634–646. [Google Scholar] [CrossRef]

- Yang, Z.; Konovalov, D.; Radchenko, M.; Radchenko, R.; Kobalava, H.; Radchenko, A.; Kornienko, V. Analyzing the efficiency of thermopressor application for combustion engine cyclic air cooling. Energies 2022, 15, 2250. [Google Scholar] [CrossRef]

- Korze’n, A.; Taler, D. Modeling of transient response of a plate fin and tube heat exchanger. Int. J. Therm. Sci. 2015, 92, 188–198. [Google Scholar] [CrossRef]

- Taler, D. Mathematical modeling and control of plate fin and tube heat exchangers. Energy Convers. Manag. 2015, 96, 452–462. [Google Scholar] [CrossRef]

- Pavlenko, A. Energy conversion in heat and mass transfer processes in boiling emulsions. Therm. Sci. Eng. Prog. 2020, 15, 100439. [Google Scholar] [CrossRef]

- Pavlenko, A. Change of emulsion structure during heating and boiling. Int. J. Energy A Clean Environ. 2019, 20, 291–302. [Google Scholar] [CrossRef]

- Konovalov, D.; Kobalava, H.; Radchenko, M.; Scurtu, I.-C.; Sviridov, V. Determination of the evaporation chamber optimal length of a low-flow aerothermopressor for gas turbines. In Proceedings of the Lecture Notes in Mechanical Engineering, Innovative Manufacturing Processes II, Selected Papers from the 2nd Grabchenko’s International Conference on Innovative Manufacturing Processes (InterPartner-2020), Odessa, Ukraine, 8–11 September 2020; Tonkonogyi, V., Ed.; Springer: Cham, Switzerland, 2021; pp. 654–663. [Google Scholar]

- Kruzel, M.; Bohdal, T.; Dutkowski, K.; Radchenko, M. The Effect of Microencapsulated PCM Slurry Coolant on the Efficiency of a Shell and Tube Heat Exchanger. Energies 2022, 15, 5142. [Google Scholar] [CrossRef]

- Kruzel, M.; Bohdal, T.; Dutkowski, K.; Kuczyński, W.; Chliszcz, K. Current Research Trends in the Process of Condensation of Cooling Zeotropic Mixtures in Compact Condensers. Energies 2022, 15, 2241. [Google Scholar] [CrossRef]

- Yang, Z.; Korobko, V.; Radchenko, M.; Radchenko, A.; Radchenko, R. Improving thermoacoustic low temperature heat recovery systems. Sustainability 2022, 14, 12306. [Google Scholar] [CrossRef]

- Radchenko, A.; Trushliakov, E.; Tkachenko, V.; Portnoi, B.; Prjadko, O. Improvement of the Refrigeration Capacity Utilizing for the Ambient Air Conditioning System. In Innovative Manufacturing Processes II. InterPartner 2020; Lecture Notes in Mechanical Engineering; Tonkonogyi, V., Ed.; Springer: Cham, Switzerland, 2021; pp. 714–723. [Google Scholar]

- Radchenko, N.; Radchenko, A.; Tsoy, A.; Mikielewicz, D.; Kantor, S.; Tkachenko, V. Improving the efficiency of railway conditioners in actual climatic conditions of operation. AIP Conf. Proc. 2020, 2285, 030072. [Google Scholar] [CrossRef]

- Yang, Z.; Kornienko, V.; Radchenko, M.; Radchenko, A.; Radchenko, R.; Pavlenko, A. Capture of pollutants from exhaust gases by low-temperature heating surfaces. Energies 2022, 15, 120. [Google Scholar] [CrossRef]

- Fan, C.; Pei, D.; Wei, H. A novel cascade energy utilization to improve efficiency of double reheat cycle. Energy Convers. Manag. 2018, 171, 1388–1396. [Google Scholar] [CrossRef]

- Kornienko, V.; Radchenko, R.; Stachel, A.; Andreev, A.; Pyrysunko, M. Correlations for pollution on condensing surfaces of exhaust gas boilers with water-fuel emulsion combustion. In Grabchenko’s International Conference on Innovative Manufacturing Process. InterPartner-2019; Lecture Notes in Mechanical Engineering; Tonkonogyi, V., Ed.; Springer: Cham, Switzerland, 2020; pp. 530–539. [Google Scholar] [CrossRef]

- Kornienko, V.; Radchenko, R.; Bohdal, Ł.; Kukiełka, L.; Legutko, S. Investigation of condensing heating surfaces with reduced corrosion of boilers with water-fuel emulsion combustion. In Integrated Computer Technologies in Mechanical Engineering—2020. ICTM 2020. Lecture Notes in Networks and Systems; Nechyporuk, M., Pavlikov, V., KrIESkiy, D., Eds.; Springer: Cham, Switzerland, 2021; Volume 188, pp. 300–309. [Google Scholar]

- Kornienko, V.; Radchenko, R.; Radchenko, M.; Radchenko, A.; Pavlenko, A.; Konovalov, D. Cooling cyclic air of marine engine with water-fuel emulsion combustion by exhaust heat recovery chiller. Energies 2022, 15, 248. [Google Scholar] [CrossRef]

- Yang, Z.; Kornienko, V.; Radchenko, M.; Radchenko, A.; Radchenko, R. Research of Exhaust Gas Boiler Heat Exchange Surfaces with Reduced Corrosion when Water-fuel Emulsion Combustion. Sustainability 2022, 14, 11927. [Google Scholar] [CrossRef]

- Radchenko, R.; Kornienko, V.; Pyrysunko, M.; Bogdanov, M.; Andreev, A. Enhancing the Efficiency of Marine Diesel Engine by Deep Waste Heat Recovery on the Base of IES Simulation Along the Route Line. In Integrated Computer Technologies in Mechanical Engineering (ICTM 2019); Advances in Intelligent Systems and Computing; Nechyporuk, M., Pavlikov, V., Krieskiy, D., Eds.; Springer: Cham, Switzerland, 2020; Volume 1113, pp. 337–350. [Google Scholar] [CrossRef]

- Mikielewicz, D.; Klugmann, M.; Wajs, J. Flow boiling intensification in minichannels by means of mechanical flow turbulising inserts. Int. J. Therm. Sci. 2013, 65, 79–91. [Google Scholar] [CrossRef]

- Dąbrowski, P.; Klugmann, M.; Mikielewicz, D. Channel Blockage and Flow Maldistribution during Unsteady Flow in a Model Microchannel Plate heat Exchanger. J. Appl. Fluid Mech. 2019, 12, 1023–1035. [Google Scholar] [CrossRef]

- Dąbrowski, P.; Klugmann, M.; Mikielewicz, D. Selected studies of flow maldistribution in a minichannel plate heat exchanger. Arch. Thermodyn. 2017, 38, 135–148. [Google Scholar] [CrossRef][Green Version]

- Kumar, R.; Singh, G.; Mikielewicz, D. A New Approach for the Mitigating of Flow Maldistribution in Parallel Microchannel Heat Sink. J. Heat Transf. 2018, 140, 72401–72410. [Google Scholar] [CrossRef]

- Kumar, R.; Singh, G.; Mikielewicz, D. Numerical Study on Mitigation of Flow Maldistribution in Parallel Microchannel Heat Sink: Channels Variable Width Versus Variable Height Approach. J. Electron. Packag. 2019, 141, 21009–21011. [Google Scholar] [CrossRef]

- Khan, M.G.; Fartaj, A. A review on microchannel heat exchangers and potential applications. Int. J. Energy Res. 2011, 35, 553–582. [Google Scholar] [CrossRef]

- Bohdal, T.; Sikora, M.; Widomska, K.; Radchenko, A.M. Investigation of flow structures during HFE-7100 refrigerant condensation. Arch. Thermodyn. 2015, 36, 25–34. [Google Scholar] [CrossRef]

- Wajs, J.; Mikielewicz, D.; Jakubowska, B. Performance of the domestic micro ORC equipped with the shell-and-tube condenser with minichannels. Energy 2018, 157, 853–861. [Google Scholar] [CrossRef]

- Kuczyński, W.; Kruzel, M.; Chliszcz, K. A Regressive Model for Periodic Dynamic Instabilities during Condensation of R1234yf and R1234ze Refrigerants. Energies 2022, 15, 2117. [Google Scholar] [CrossRef]

- Kuczyński, W.; Kruzel, M.; Chliszcz, K. Regression Model of Dynamic Pulse Instabilities during Condensation of Zeotropic and Azeotropic Refrigerant Mixtures R404A, R448A and R507A in Minichannels. Energies 2022, 15, 1789. [Google Scholar] [CrossRef]

- Yang, Z.; Radchenko, M.; Radchenko, A.; Mikielewicz, D.; Radchenko, R. Gas turbine intake air hybrid cooling systems and a new approach to their rational designing. Energies 2022, 15, 1474. [Google Scholar] [CrossRef]

- Radchenko, A.; Scurtu, I.-C.; Radchenko, M.; Forduy, S.; Zubarev, A. Monitoring the efficiency of cooling air at the inlet of gas engine in integrated energy system. Therm. Sci. 2022, 26, 185–194. [Google Scholar] [CrossRef]

- Marques, R.P.; Hacon, D.; Tessarollo, A.; Parise, J.A.R. Thermodynamic analysis of trigeneration systems taking into account refrigeration, heating and electricity load demands. Energy Build. 2010, 42, 2323–2330. [Google Scholar] [CrossRef]

- Chacartegui, R.; Jiménez-Espadafor, F.; Sánchez, D.; Sánchez, T. Analysis of combustion turbine inlet air cooling systems applied to an operating cogeneration power plant. Energy Convers. Manag. 2008, 49, 2130–2141. [Google Scholar] [CrossRef]

- Lozano, M.; Ramos, J.C.; Serra, L.M. Cost Optimization of the Design of CHCP (Combined Heat, Cooling and Power) Systems under Legal Constraints. Energy 2010, 35, 794–805. [Google Scholar] [CrossRef]

- Mohapatra, A.K. Comparative analysis of inlet air cooling techniques integrated to cooled gas turbine plant. J. Energy Inst. 2015, 88, 344–358. [Google Scholar] [CrossRef]

- Sandhaas, A.; Kim, H.; Hartmann, N. Methodology for Generating Synthetic Load Profiles for Different Industry Types. Energies 2022, 15, 3683. [Google Scholar] [CrossRef]

- Radchenko, A.; Trushliakov, E.; Kosowski, K.; Mikielewicz, D.; Radchenko, M. Innovative turbine intake air cooling systems and their rational designing. Energies 2020, 13, 6201. [Google Scholar] [CrossRef]

- Jamaluddin, K.; Wan Alwi, S.R.; Abdul Manan, Z.; Hamzah, K.; Klemeš, J.J. Development of numerical trigeneration system cascade analysis with transmission and storage energy losses consideration. IOP Conf. Ser. Mater. Sci. Eng. 2020, 884, 012019. [Google Scholar] [CrossRef]

- Fumo, N.; Mago, P.J.; Smith, A.D. Analysis of combined cooling, heating, and power systems operating following the electric load and following the thermal load strategies with no electricity export. Proc. Inst. Mech. Eng. Part A J. Power Energy 2011, 225, 1016–1025. [Google Scholar] [CrossRef]

- Radchenko, M.; Radchenko, A.; Mikielewicz, D.; Radchenko, R.; Andreev, A. A novel degree-hour method for rational design loading. Proc. Inst. Mech. Eng. Part A J. Power Energy 2022, 35, 2455–2460. [Google Scholar] [CrossRef]

- Pavlenko, A.M. Force interaction of boiling dispersed emulsion particles. In Proceedings of the 4th Thermal and Fluids Engineering Conference, Las Vegas, NV, USA, 14–17 April 2019; pp. 1051–1059. [Google Scholar] [CrossRef]

- Yang, Z.; Radchenko, R.; Radchenko, M.; Radchenko, A.; Kornienko, V. Cooling potential of ship engine intake air cooling and IES realization on the route line. Sustainability 2022, 14, 15058. [Google Scholar] [CrossRef]

- Suamir, I.N.; Tassou, S.A. Performance evaluation of integrated trigeneration and CO2 refrigeration systems. Appl. Therm. Eng. 2013, 50, 1487–1495. [Google Scholar] [CrossRef]

- Ortiga, J.; Bruno, J.C.; Coronas, A. Operational optimization of a complex trigeneration system connected to a district heating and cooling network. Appl. Therm. Eng. 2013, 50, 1536–1542. [Google Scholar] [CrossRef]

- Pedro, A.R.; Rodriguez-Hidalgo, M.d.; José, I. Nogueira, Antonio Lecuona, María del Carmen Veneg. Dist. Heat. Cool. Bus. Build. Madr. Appl. Therm. Eng. 2013, 50, 1496–1503. [Google Scholar]

- Freschi, F.; Giaccone, L.; Lazzeroni, P.; Repetto, M. Economic and environmental analysis of a trigeneration system for food-industry: A case study. Appl. Energy 2013, 107, 157–172. [Google Scholar] [CrossRef]

- Canova, A.; Cavallero, C.; Freschi, F.; Giaccone, L.; Repetto, M.; Tartaglia, M. Optimal energy management. IEEE Ind. Appl. Mag. 2009, 15, 62–65. [Google Scholar] [CrossRef]

- Cardona, E.; Piacentino, A. A methodology for sizing a trigeneration plant in mediterranean areas. Appl. Therm. Eng. 2003, 23, 15. [Google Scholar] [CrossRef]

- Giaccone, L.; Canova, A. Economical comparison of CHP systems for industrial user with large steam demand. Appl. Energy 2009, 86, 904–914. [Google Scholar] [CrossRef]

- Carvalho, M.; Lozano, M.A.; Serra, L.M. Multicriteria synthesis of trigeneration systems considering economic and environmental aspects. Appl. Energy 2012, 91, 245–254. [Google Scholar] [CrossRef]

- Geldermann, J.; Rentz, O. Multi-criteria analysis for the assessment of environmentally relevant installations. J. Ind. Ecol. 2020, 9, 127–142. [Google Scholar] [CrossRef]

- Kavvadias, K.C.; Tosios, A.P.; Maroulis, Z.B. Design of a combined heating, cooling and power system: Sizing, operation strategy selection and parametric analysis. Energy Convers Manag. 2010, 51, 833–845. [Google Scholar] [CrossRef]

- Pavlenko, A.; Koshlak, H. Heat and Mass Transfer During Phase Transitions in Liquid Mixtures. Rocz. Ochr. Srodowiska 2019, 21, 234–249. [Google Scholar]

- Kalhori, S.B.; Rabiei, H.; Mansoori, Z. Mashad trigeneration potential–An opportunity for CO2 abatement in Iran. Energy Conv. Manag. 2012, 60, 106–114. [Google Scholar] [CrossRef]

- Forsyth, J.L. Gas turbine inlet air chilling for LNG. IGT Int. Liq. Nat. Gas Conf. Proc. 2013, 3, 1763–1778. [Google Scholar]

- Komuro, T.; Ito, E.; Sonoda, T.; Tomita, Y.; Hidaka, K.; Shibutani, S. Power output augmentation of gas turbine combined cycle by inlet-air cooling system of chiller type under high ambient air temperature. MIESubishi Heavy Ind. Tech. Rev. 2010, 47, 33–39. [Google Scholar]

- Radchenko, A.; Radchenko, M.; Mikielewicz, D.; Pavlenko, A.; Radchenko, R.; Forduy, S. Energy saving in trigeneration plant for food industries. Energies 2022, 15, 1163. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Radchenko, A.; Radchenko, M.; Koshlak, H.; Radchenko, R.; Forduy, S. Enhancing the Efficiency of Integrated Energy Systems by the Redistribution of Heat Based on Monitoring Data. Energies 2022, 15, 8774. https://doi.org/10.3390/en15228774

Radchenko A, Radchenko M, Koshlak H, Radchenko R, Forduy S. Enhancing the Efficiency of Integrated Energy Systems by the Redistribution of Heat Based on Monitoring Data. Energies. 2022; 15(22):8774. https://doi.org/10.3390/en15228774

Chicago/Turabian StyleRadchenko, Andrii, Mykola Radchenko, Hanna Koshlak, Roman Radchenko, and Serhiy Forduy. 2022. "Enhancing the Efficiency of Integrated Energy Systems by the Redistribution of Heat Based on Monitoring Data" Energies 15, no. 22: 8774. https://doi.org/10.3390/en15228774

APA StyleRadchenko, A., Radchenko, M., Koshlak, H., Radchenko, R., & Forduy, S. (2022). Enhancing the Efficiency of Integrated Energy Systems by the Redistribution of Heat Based on Monitoring Data. Energies, 15(22), 8774. https://doi.org/10.3390/en15228774