Aging of Polymeric Insulators under Various Conditions and Environments: Another Look

Abstract

:1. Introduction

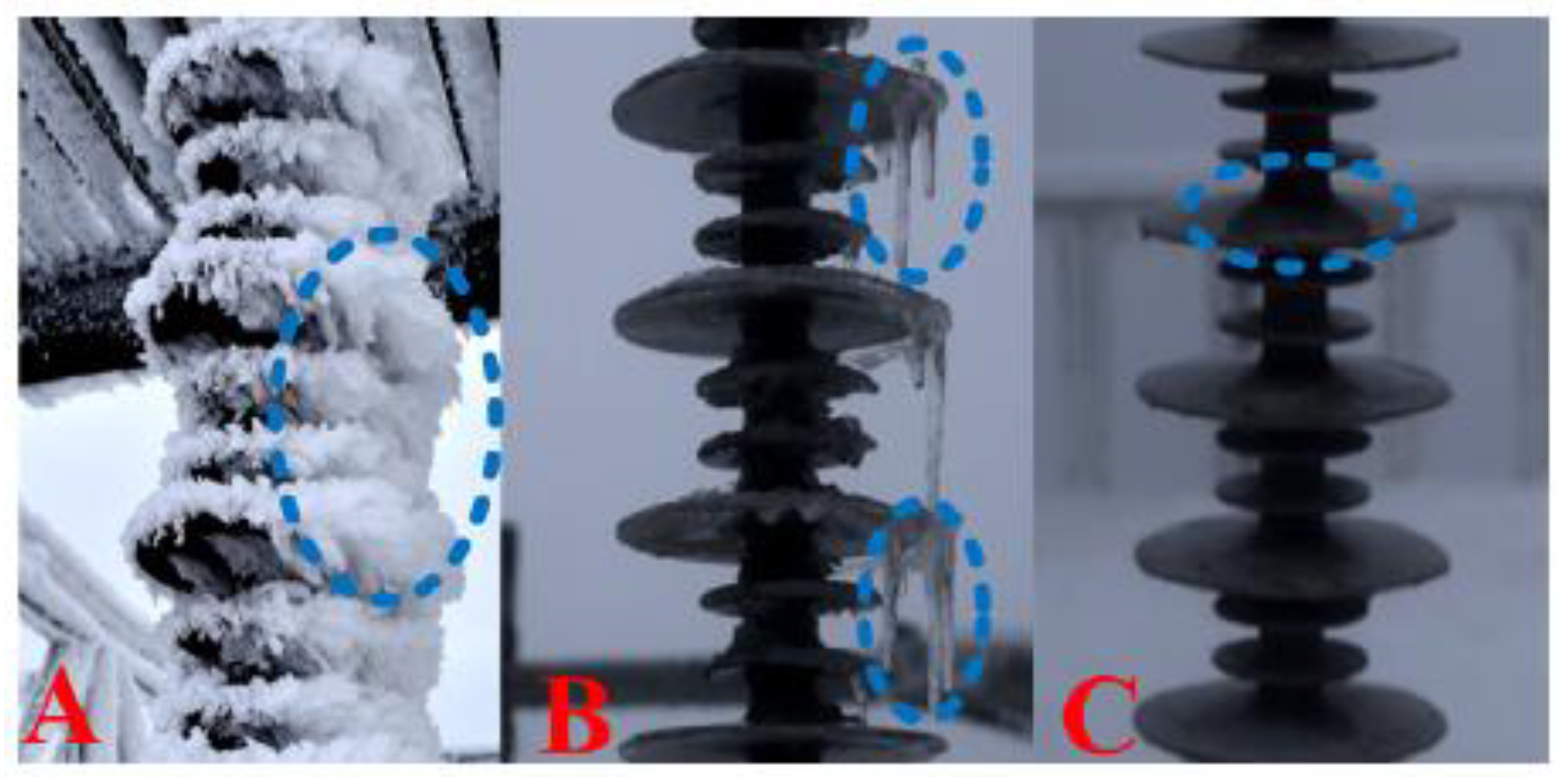

2. Characterization Techniques of Electrical Performance and Aging Characteristics of Polymeric Insulators

2.1. Electrical Performance

2.2. Physical Appearance

2.3. Chemical Performance

3. Aging Mechanisms and the Performance of Polymeric Insulators under Various Operating Conditions and Environments

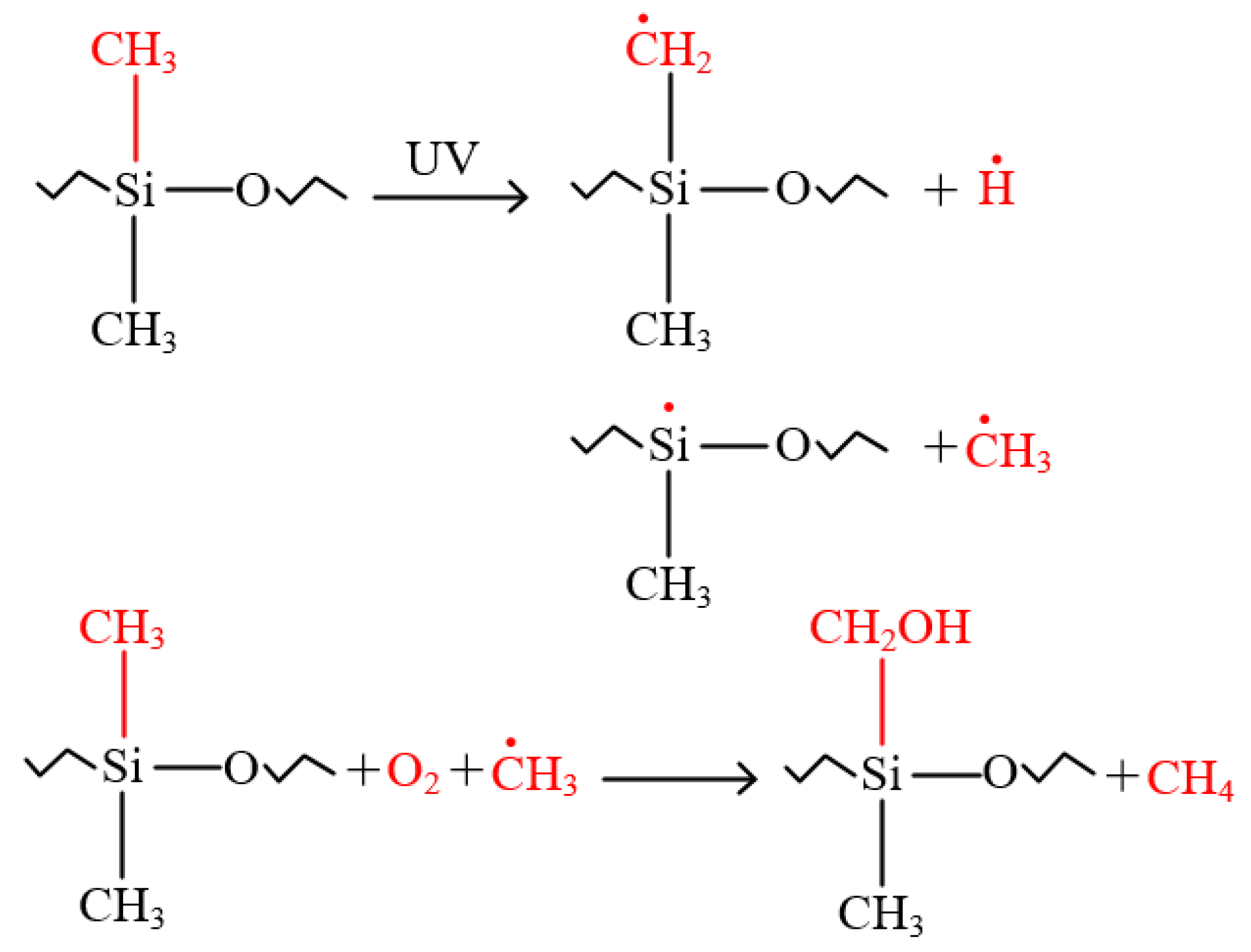

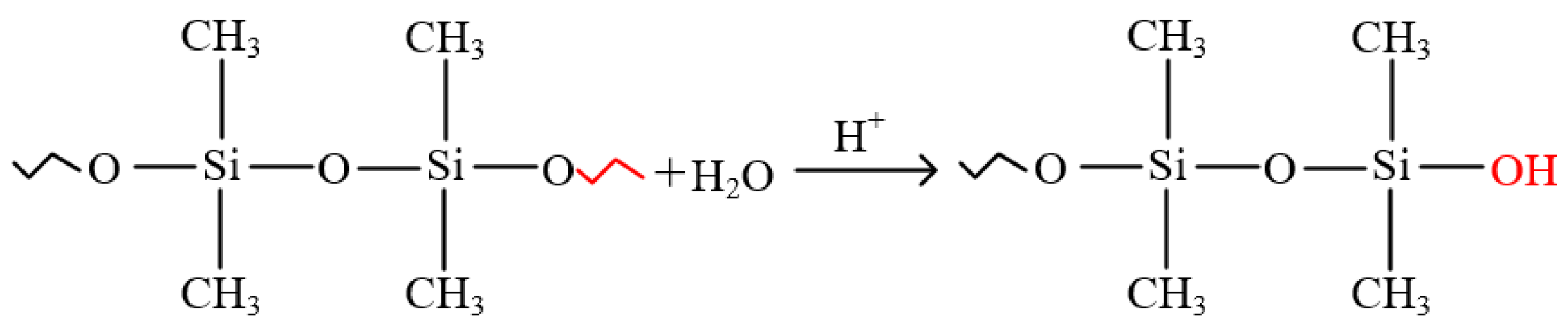

3.1. Aging under UV, Acidic and High Field Environments

3.2. Aging under Various Environments

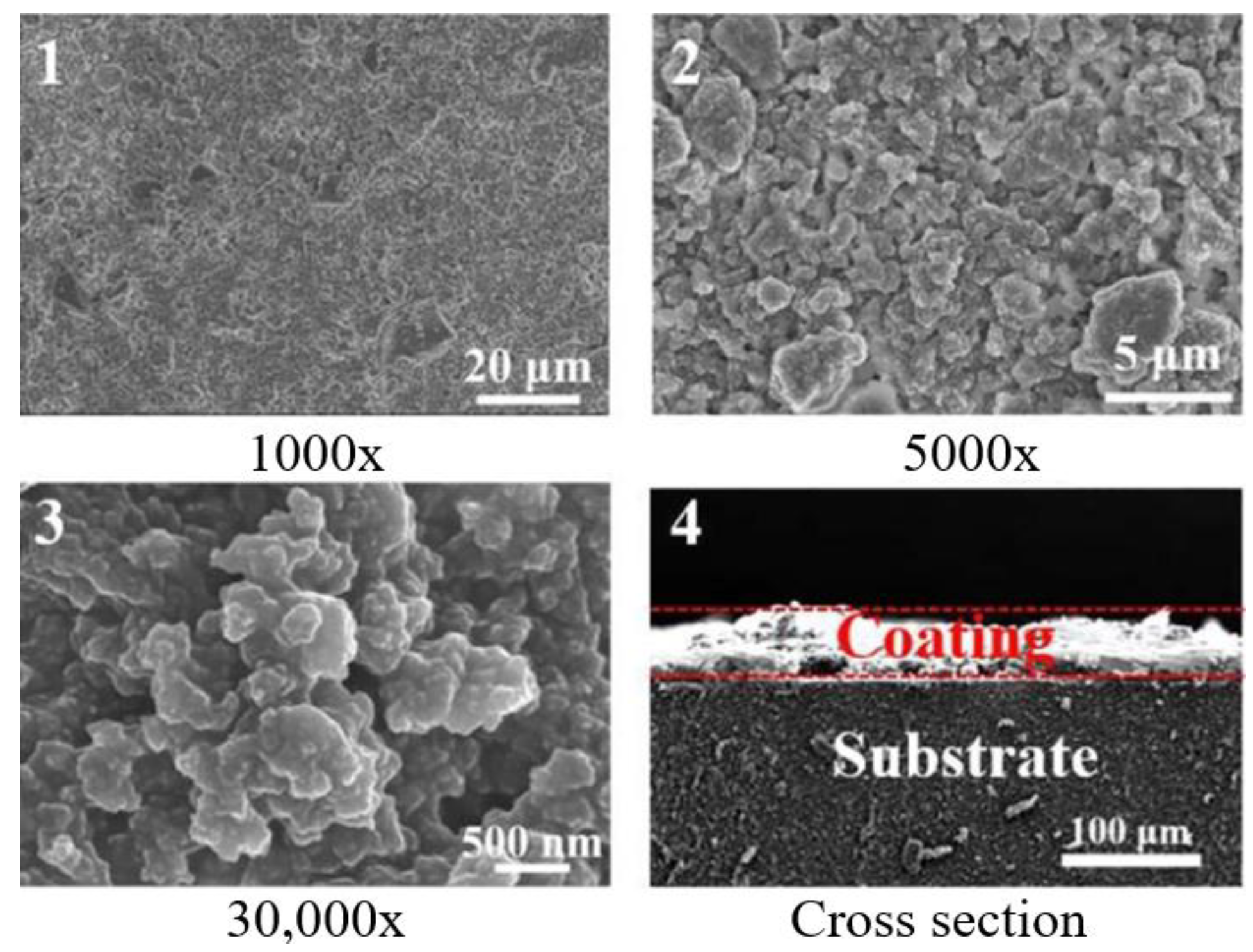

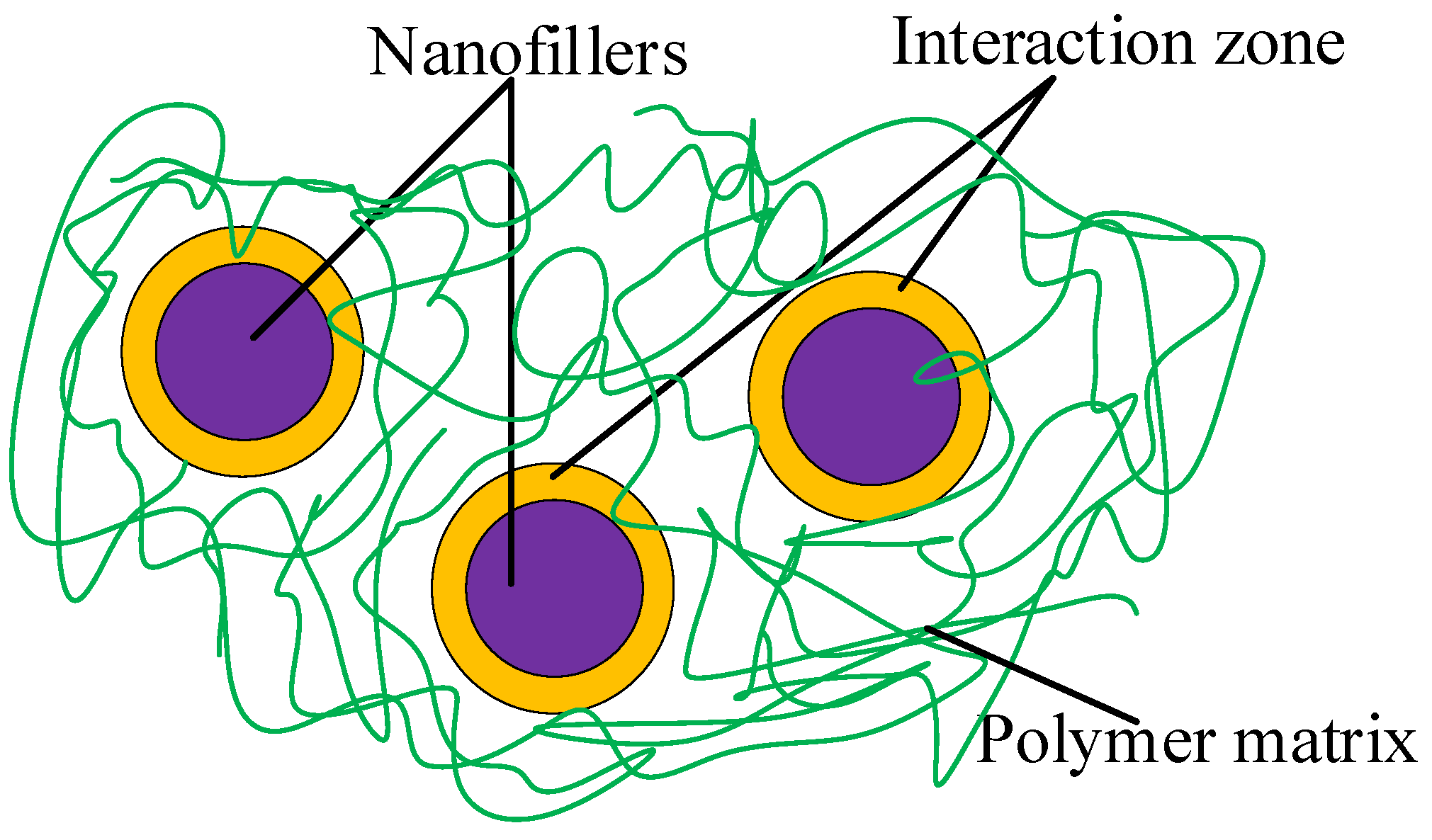

4. Enhanced Performance of Polymeric Insulators

4.1. Enhancement Methods

4.2. Future Research Directions

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nan, J.; Li, H.; Wan, X.; Huo, F.; Lin, F. Pollution Flashover Characteristics of Composite Crossarm Insulator with a Large Diameter. Energies 2021, 14, 20. [Google Scholar] [CrossRef]

- Qiao, X.; Zhang, Z.; Sundararajan, R.; Jiang, X.; Hu, J.; Fang, Z. AC Breakdown Characteristics of Polluted 10-kV Post Insulator With Concentric Externally Gapped Line Arrester. IEEE Trans. Power Deliv. 2022, 37, 59–66. [Google Scholar] [CrossRef]

- Zhao, X.; Yang, X.; Hu, J.; Wang, H.; Yang, H.; Li, Q.; He, J.; Xu, Z.; Li, X. Grading of electric field distribution of AC polymeric outdoor insulators using field grading material. IEEE Trans. Dielectr. Electr. Insul. 2019, 26, 1253–1260. [Google Scholar] [CrossRef]

- Ming, L.; Yangyang, L.; Jianlin, H. Influence of Sheds Damage on the AC Pollution Flashover Performance of Different Voltage Class Composite Insulators. IEEE Access 2020, 8, 84713–84719. [Google Scholar] [CrossRef]

- Qiao, X.; Zhang, Z.; Sundararajan, R.; Jiang, X.; Hu, J.; Fang, Z. The failure arc paths of the novel device combining an arrester and an insulator under different pollution levels. Int. J. Electr. Power Energy Syst. 2021, 125, 106549. [Google Scholar] [CrossRef]

- Qiao, X.; Zhang, Z.; Jiang, X.; Sundararajan, R.; Ma, X.; Li, X. AC failure voltage of iced and contaminated composite insulators in different natural environments. Int. J. Electr. Power Energy Syst. 2020, 120, 105993. [Google Scholar] [CrossRef]

- Georgiev, G.; Ivanova, M.; Dimitrova, R.; Rangelov, Y. In Polymeric Composite Insulators for Overhead Power Lines. A Review of In-Service Damages and Diagnostic Approaches. In Proceedings of the 2021 17th Conference on Electrical Machines, Drives and Power Systems (ELMA), Sofia, Bulgaria, 1–4 July 2021; pp. 1–6. [Google Scholar]

- Kokkinaki, O.; Klini, A.; Polychronaki, M.; Mavrikakis, N.C.; Siderakis, K.G.; Koudoumas, E.; Pylarinos, D.; Thalassinakis, E.; Kalpouzos, K.; Anglos, D. Assessing the type and quality of high voltage composite outdoor insulators by remote laser-induced breakdown spectroscopy analysis: A feasibility study. Spectrochim. Acta Part B 2020, 165, 105768. [Google Scholar] [CrossRef]

- Jiang, H.; Li, B.; Zhao, B.; Wang, Y. Aging characterization of 500-kV field-serviced silicone rubber composite insulators with self-normalized photothermal radiometry. Infrared Phys. Technol. 2021, 116, 103763. [Google Scholar] [CrossRef]

- Chen, L.; Guo, F.; Yang, T.; Hu, T.; Bennett, P.; Yang, Q.; Liu, D. Aging characteristics and self-healing properties of laser-textured superhydrophobic silicone rubber for composite insulators. Polym. Degrad. Stab. 2021, 192, 109693. [Google Scholar] [CrossRef]

- Learning from Service Experience with Composite Line Insulators; INMR: 2020. Available online: http://www.inmr.com/learning-from-service-experience-with-composite-line-insulators-2/ (accessed on 10 November 2022).

- Jiao, J.; Li, L.; Wu, B.; He, C. Novel capacitive proximity sensors for assessing the aging of composite insulators. Sens. Actuators A 2017, 253, 75–84. [Google Scholar] [CrossRef]

- Homma, T.; Kumada, A.; Fujii, T.; Homma, H.; Oishi, Y. Depth profiling of surface degradation of silicone rubber composite insulators by remote laser-induced breakdown spectroscopy. Spectrochim. Acta Part B 2021, 180, 106206. [Google Scholar] [CrossRef]

- Francis, U.U.; Philip, A.N. Degradation of epoxy reinforced Banana fibers and eggshell particles hybrid composite high-voltage insulators via accelerated UV aging processes. Chem. Data Collect. 2022, 38, 100842. [Google Scholar] [CrossRef]

- Ullah, I.; Akbar, M. Anti-aging characteristics of RTV-SiR aided HV insulator coatings: Impact of DC polarity and fillers. Mater. Chem. Phys. 2022, 278, 125634. [Google Scholar] [CrossRef]

- Taghvaei, M.; Sedighizadeh, M.; NayebPashaee, N.; Fini, A.S. Reliability assessment of RTV and nano-RTV-coated insulators concerning contamination severity. Electr. Power Syst. Res. 2021, 191, 106892. [Google Scholar] [CrossRef]

- Shen, L.; Zou, L.; Ding, M.; Zhao, T.; Zhang, L.; Li, Q. Investigation of physical properties of epoxy-functionalized graphene nanoplatelets composite coatings on DC-GIL insulators by molecular dynamics simulation. Appl. Surf. Sci. 2020, 505, 144197. [Google Scholar] [CrossRef]

- Liang, M.; Wong, K.L. Improving the Long-term Performance of Composite Insulators Use Nanocomposite: A Review. Energy Procedia 2017, 110, 168–173. [Google Scholar] [CrossRef]

- Gutman, I.; Hartings, R.; Matsuoka, R.; Kondo, K. Experience with IEC 1109 1000 h salt fog ageing test for composite insulators. IEEE Electr. Insul. Mag. 1997, 13, 36–39. [Google Scholar] [CrossRef]

- Sun, Y.; Tu, Y.; Wang, C.; Wang, S.; Cheng, Y.; Peng, Q.; Chen, X. In Contamination and AC pollution flashover characteristics of insulators under fog-haze environment. In Proceedings of the 2015 IEEE 11th International Conference on the Properties and Applications of Dielectric Materials (ICPADM), Sydney, Australia, 19–22 July 2015; pp. 596–599. [Google Scholar]

- Saadati, H.; Werle, P.; Gockenbach, E.; Borsi, H.; Seifert, J.M. In Flashover performance of polluted composite insulators under AC and hybrid AC/DC field stress. In Proceedings of the 2016 IEEE Electrical Insulation Conference (EIC), Montreal, QC, Canada, 19–22 June 2016; pp. 170–173. [Google Scholar]

- Wang, W.; Lu, H.; Li, C.; Deng, Y.; Lan, L.; Wen, X.; Luo, B.; Xiao, W. Study on the relationship between the characteristics of water droplets on the shed of composite insulators and the pollution flashover voltage. Energy Rep. 2022, 8, 1071–1077. [Google Scholar] [CrossRef]

- Qiao, X.; Zhang, Z.; Jiang, X.; Sundararajan, R.; You, J. DC pollution flashover performance of HVDC composite insulator under different non-uniform pollution conditions. Electr. Power Syst. Res. 2020, 185, 106351. [Google Scholar] [CrossRef]

- Mohammadi Savadkoohi, E.; Mirzaie, M.; Seyyedbarzegar, S.; Mohammadi, M.; Khodsuz, M.; Ghorbani Pashakolae, M.; Biazar Ghadikolaei, M. Experimental investigation on composite insulators AC flashover performance with fan-shaped non-uniform pollution under electro-thermal stress. Int. J. Electr. Power Energy Syst. 2020, 121, 106142. [Google Scholar] [CrossRef]

- Dadashizadeh Samakosh, J.; Mirzaie, M. Investigation and analysis of AC flashover voltage of SiR insulators under longitudinal and fan-shaped non-uniform pollutions. Int. J. Electr. Power Energy Syst. 2019, 108, 382–391. [Google Scholar] [CrossRef]

- Rahman, M.S.A.; Kadir, M.Z.A.A.; Ab-Rahman, M.S.; Osman, M.; Nor, S.F.M. In Lightning Impulse Strength of 275 kV and 132 kV Tower with Composite Crossarm. In Proceedings of the 2019 11th Asia-Pacific International Conference on Lightning (APL), Hong Kong, China, 12–14 June 2019; pp. 1–6. [Google Scholar]

- Ilhan, S.; Ozdemir, A. In Flashover performance of 380 kV V-strings with composite insulators under lightning and switching impulses. In Proceedings of the 2009 IEEE Bucharest PowerTech, Bucharest, Romania, 28 June–2 July 2009; pp. 1–6. [Google Scholar]

- Zhang, H.; Tu, Y.; Lu, Y.; Chen, J.; Chen, C.; Xie, L. In Influence of the electric field on TSC characteristics of 110kV silicone rubber insulator sheds in service. In Proceedings of the 2012 IEEE International Symposium on Electrical Insulation, San Juan, Puerto R, USA, 10–13 June 2012; pp. 469–472. [Google Scholar]

- Zhang, G.; Zhao, L.; Zhou, R.; Shen, W.; Liang, X. Review on aging characterization and evaluation of silicon rubber composite insulator. High Volt. Appar. 2016, 52, 1–15. [Google Scholar]

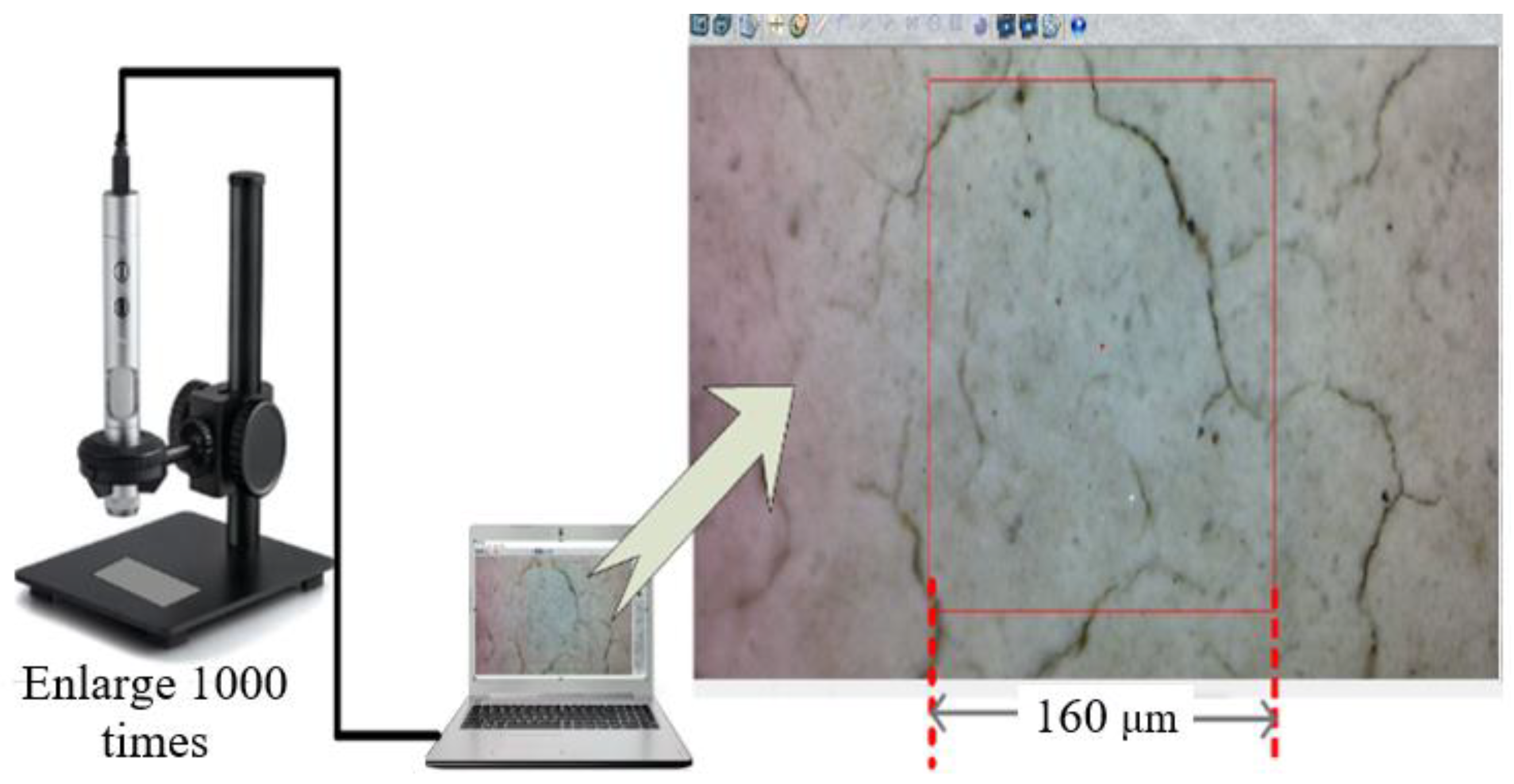

- Qiao, X.; Zhang, Z.; Jiang, X.; Li, X.; He, Y. A New Evaluation Method of Aging Properties for Silicon Rubber Material Based on Microscopic Images. IEEE Access 2019, 7, 15162–15169. [Google Scholar] [CrossRef]

- Li, S.; Liang, X.; Gao, Y.; Liu, Y.; Yin, Y.; Li, Z. A modified 5000 h test procedure for silicone rubber insulator based on contamination and hydrophobicity change simulation. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 1818–1828. [Google Scholar] [CrossRef]

- Du, B.X.; Li, Y.P.; Liu, Y. Hydrophobicity evaluation of silicone rubber insulator using DC discharge induced acoustic wave. IEEE Trans. Dielectr. Electr. Insul. 2013, 20, 1836–1844. [Google Scholar] [CrossRef]

- Cao, H.; Yan, D.; Han, J.; Ren, H.; Lu, M.; Lv, Z.; Guo, H. Investigation and corroboration of a novel method to estimate the hydrophobicity of composite insulators. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 2029–2036. [Google Scholar]

- Sundararajan, R.; Mohammed, A.; Chaipanit, N.; Karcher, T.; Liu, Z. In-service aging and degradation of 345 kV EPDM transmission line insulators in a coastal environment. IEEE Trans. Dielectr. Electr. Insul. 2004, 11, 348–361. [Google Scholar] [CrossRef]

- Xu, Z. An inclined plane based dynamic contact angle algorithm and its validity in application of hydrophobicity measurement for insulating materials. IEEE Trans. Dielectr. Electr. Insul. 2013, 20, 1832–1835. [Google Scholar] [CrossRef]

- Miyoshi, M.; Homma, H.; Goshima, H. In Effect of Local Arc Discharge on Hydrophobicity Decrease of Silicone Rubber Surface: -Investigation on Hydrophobicity Change by Measuring Water Drop Velocity and Surface Analysis. In Proceedings of the 2020 International Symposium on Electrical Insulating Materials (ISEIM), Virtual, 13–17 September 2020; pp. 206–209. [Google Scholar]

- Du, B.X.; Ma, Z.L.; Cheng, X.X.; Liu, Y. Hydrophobicity evaluation of silicone rubber insulator using PD-induced electromagnetic wave. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 1060–1067. [Google Scholar] [CrossRef]

- Valle, P.M.d.; Álvarez, R.E.; Catalano, L.J.; Calo, E.; Mayora, H. In Overhead line transmission composite insulators. Evaluation of their technical condition in the laboratory after their removal from service. In Proceedings of the 2021 IEEE Electrical Insulation Conference (EIC), Virtual, 7–28 June 2021; pp. 238–241. [Google Scholar]

- Wang, X.; Hong, X.; Chen, P.; Zhao, C.; Jia, Z.; Wang, L.; Zou, L. Surface Hardness Analysis of Aged Composite Insulators via Laser-Induced Plasma Spectra Characterization. IEEE Trans. Plasma Sci. 2019, 47, 387–394. [Google Scholar] [CrossRef]

- Jing, P.; Zhiqiang, L.; Peng, W.; Qian, J.; Chunjie, W.; Yuxin, L. In Research on Ultraviolet Aging Properties of Modified Silicone Rubber for Composite Insulator. In Proceedings of the 2020 International Symposium on Electrical Insulating Materials (ISEIM), Virtual, 13–17 September 2020; pp. 202–205. [Google Scholar]

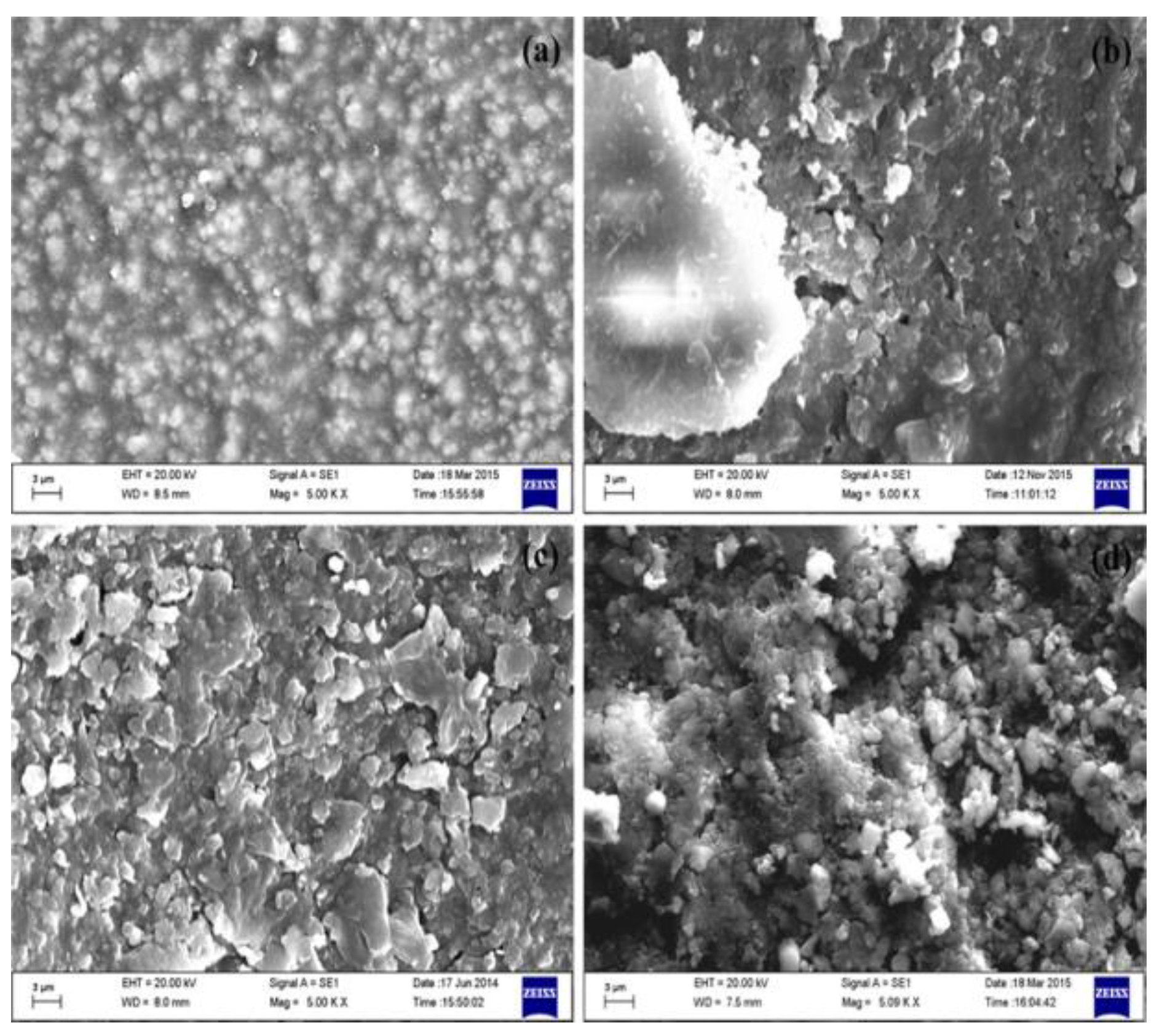

- Shen, H.; Deng, Y.; Zhou, J.; Wang, J.; Lei, L.; Xu, J.; Wang, X. In The Application of SEM in the Decay-Like Aging of Silicon Rubber Composite Insulator. In Proceedings of the 2020 IEEE International Conference on High Voltage Engineering and Application (ICHVE), Beijing, China, 6–10 September 2020; pp. 1–4. [Google Scholar]

- Subba Reddy, B.; Ramamurthy, P.C. Analysis of in-service composite insulators used in overhead railway traction. Eng. Fail. Anal. 2020, 108, 104227. [Google Scholar] [CrossRef]

- Ghosh, D.; Khastgir, D. Degradation and stability of polymeric high-voltage insulators and prediction of their service life through environmental and accelerated aging processes. ACS Omega 2018, 3, 11317–11330. [Google Scholar] [CrossRef]

- Rowland, S.M.; Robertson, J.; Xiong, Y.; Day, R.J. Electrical and material characterization of field-aged 400 kV silicone rubber composite insulators. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 375–383. [Google Scholar] [CrossRef]

- Mavrikakis, N.C.; Mikropoulos, P.N.; Siderakis, K. Evaluation of field-ageing effects on insulating materials of composite suspension insulators. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 490–498. [Google Scholar] [CrossRef]

- Gao, Y.; Liang, X.; Bao, W.; Li, S.; Wu, C. Failure analysis of a field brittle fracture composite insulator: Characterization by FTIR analysis and fractography. IEEE Trans. Dielectr. Electr. Insul. 2018, 25, 919–927. [Google Scholar] [CrossRef]

- Xiong, Y.; Rowland, S.M.; Robertson, J.; Hoffmann, S. In Characterization of field-aged 400 kV silicone rubber composite insulators. In Proceedings of the 2006 IEEE Conference on Electrical Insulation and Dielectric Phenomena, Kansas City, MI, USA, 15–18 October 2006; pp. 417–420. [Google Scholar]

- Ehsani, M.; Borsi, H.; Gockenbach, E.; Morshedian, J.; Bakhshandeh, G.R.; Shayegani, A.A. In Effect of aging on dielectric behavior of outdoor polymeric insulators. In Proceedings of the 2004 IEEE International Conference on Solid Dielectrics, ICSD 2004, Virtual, 22–26 March 2004; Volume 1, pp. 312–315. [Google Scholar]

- Li, Y.; Chen, C.; Jia, Z.; Ye, W. In Thermal stability and organic component analysis of HTV silicone rubber composite insulator. In Proceedings of the 2015 IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Arbor, MI, USA, 18–20 October 2015; pp. 721–724. [Google Scholar]

- Khan, Y.; Al-Arainy, A.A.; Malik, N.H.; Qureshi, M.I.; Al-Ammar, A.E. In Loss and Recovery of Hydrophobicity of EPDM Insulators in Simulated Arid Desert Environment. In Proceedings of the 2010 Asia-Pacific Power and Energy Engineering Conference, Chengdu, China, 28–31 March 2010; pp. 1–4. [Google Scholar]

- Hernández, R.; Vallejo, G.; Montoya, G.; Ramirez, I. In Performance of hydrophobicity of different polymeric insulators in an accelerated ageing test. In Proceedings of the 2012 Annual Report Conference on Electrical Insulation and Dielectric Phenomena, Montreal, QC, Canada, 14–17 October; 2012; pp. 753–756. [Google Scholar]

- Peng, X.; Lin, H.; Wang, R.; Wang, Z.; Fang, P. Review on Aging Mechanism and Service Life Prediction of Silicone Rubber Composite Insulator. High Volt. Appar. 2018, 54, 1–8. [Google Scholar]

- Verma, A.R.; Reddy, B.S. Tracking and erosion resistance of LSR and HTV silicon rubber samples under acid rain conditions. IEEE Trans. Dielectr. Electr. Insul. 2018, 25, 46–52. [Google Scholar] [CrossRef]

- Verma, A.R.; Reddy, B.S. In Tracking and erosion resistance of Liquid Silicone Rubber under normal and acidic environment. In Proceedings of the 2017 4th IEEE Uttar Pradesh Section International Conference on Electrical, Computer and Electronics (UPCON), Mathura, India, 26–28 October 2017; pp. 223–227. [Google Scholar]

- Sun, H.; Delun, M.; Boveri-Yibo, Z.; Wu, F.; Chen, J.; Hillborg, H. In Performance of liquid silicone rubber exposed to acid fog under DC stress. In Proceedings of the 2015 IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Sydney, Australia, 22 July 2015; pp. 229–232. [Google Scholar]

- Ma, X.; Zhang, Z.; Ma, X.; Huang, H.; Jiang, X. In Study on Corrosion Failure Characteristics of Silicone Rubber in Acidic Environment. In Proceedings of the 2021 International Conference on Electrical Materials and Power Equipment (ICEMPE), Chongqing, China, 11–15 April 2021; pp. 1–4. [Google Scholar]

- Lehretz, F.; Kreßler, J.; Nase, M.; Rennert, M.; Schulte-Fischedick, J.; Seifert, J.M. Enhancement of Acid Stability of Silicone Elastomers by Using Inert Fillers. IEEE Trans. Dielectr. Electr. Insul. 2020, 27, 2188–2194. [Google Scholar] [CrossRef]

- Sarathi, R.; Mishra, P.; Gautam, R.; Vinu, R. Understanding the influence of water droplet initiated discharges on damage caused to corona-aged silicone rubber. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 2421–2431. [Google Scholar] [CrossRef]

- Rajini, V.; Udayakumar, K. Degradation of Silicone Rubber under AC or DC Voltages in Radiation Environment. IEEE Trans. Dielectr. Electr. Insul. 2009, 16, 834–841. [Google Scholar] [CrossRef]

- Gustavsson, T.G.; Gubanski, S.M.; Hillborg, H.; Karlsson, S.; Gedde, U.W. Aging of silicone rubber under ac or dc voltages in a coastal environment. IEEE Trans. Dielectr. Electr. Insul. 2001, 8, 1029–1039. [Google Scholar] [CrossRef]

- Fernando, M.A.R.M.; Gubanski, S.M. Ageing of silicone rubber insulators in coastal and inland tropical environment. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 326–333. [Google Scholar] [CrossRef]

- Gubanski, S.M.; Karlsson, S.; Fernando, M.A.R.M. In Performance of Biologically Contaminated High Voltage Insulators. In Proceedings of the First International Conference on Industrial and Information Systems, Tirtayasa, Indonesia, 8–11 August 2006; pp. 30–35. [Google Scholar]

- Ouyang, X.; Jia, Z.; Yang, S.; Shang, X.; Wang, X.; Chen, H.; Zhou, D.; Liu, R. Influence of algae growth on the external insulation performance of HVDC insulators. IEEE Trans. Dielectr. Electr. Insul. 2018, 25, 263–271. [Google Scholar] [CrossRef]

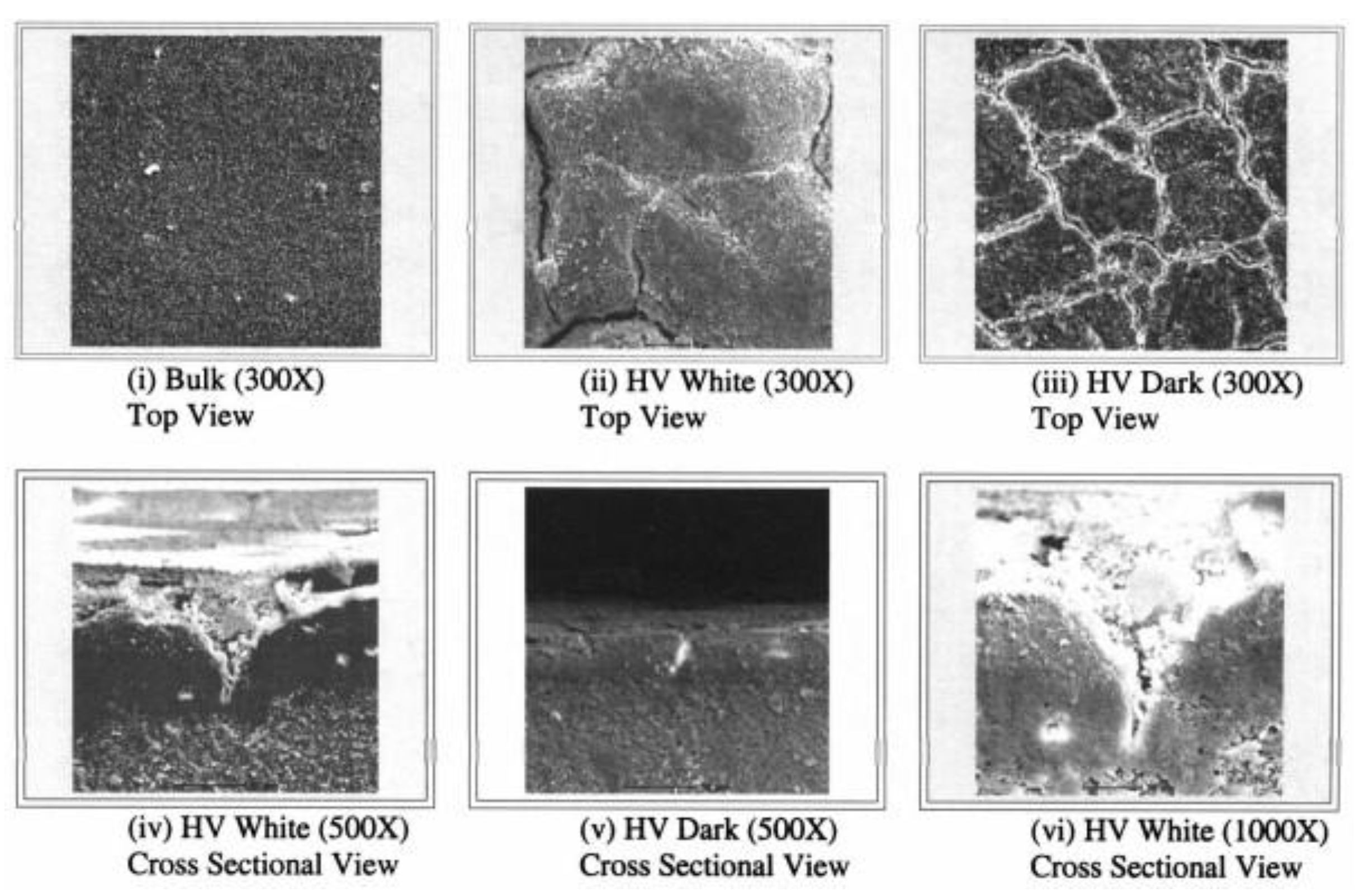

- Zhang, Z.; Liang, T.; Li, C.; Jiang, X.; Wu, J.; Wu, B. Electrical Strength and Physicochemical Performances of HTV Silicone Rubber under Salt-Fog Environment with DC Energized. Polymers 2020, 12, 324. [Google Scholar] [CrossRef] [PubMed]

- Zhijin, Z.; Tian, L.; Xingliang, J.; Chen, L.; Shenghuan, Y.; Yi, Z. Characterization of Silicone Rubber Degradation Under Salt-Fog Environment With AC Test Voltage. IEEE Access 2019, 7, 66714–66724. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhang, X.; Fang, J. In Influence of environmental factor on hydrophobicity transfer of silicone rubber used for outdoor insulation. In Proceedings of the 2017 International Symposium on Electrical Insulating Materials (ISEIM), Toyohashi, Japan, 11–15 September 2017; pp. 32–35. [Google Scholar]

- Du, B.X.; Xu, H.; Liu, Y. Effects of wind condition on hydrophobicity behavior of silicone rubber in corona discharge environment. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 385–393. [Google Scholar] [CrossRef]

- Ullah, I.; Akbar, M.; Khan, H.A. Degradation analysis of RTV-SiR based composites under both polarities DC voltage for insulators coating. Mater. Today Commun. 2021, 29, 102890. [Google Scholar] [CrossRef]

- Sundararajan, R.; Nowlin, R.W. In Effect of altitude on the flashover voltage of contaminated insulators. In Proceedings of the Conference on Electrical Insulation and Dielectric Phenomena-CEIDP ‘96, Denver, CO, USA, 23 October 1996; Volume 2, pp. 433–436. [Google Scholar]

- Guo, Y.; Jiang, X.; Sree, V.G.; Sundararajan, R. In AC flashover performance of porcelain, glass and polymeric insulators at high altitudes. In Proceedings of the 2015 IEEE 11th International Conference on the Properties and Applications of Dielectric Materials (ICPADM), Sydney, Australia, 19–22 July 2015; pp. 484–487. [Google Scholar]

- Liu, S.; Liu, S.; Wang, Q.; Zuo, Z.; Wei, L.; Chen, Z.; Liang, X. Improving surface performance of silicone rubber for composite insulators by multifunctional Nano-coating. Chem. Eng. J. 2023, 451, 138679. [Google Scholar] [CrossRef]

- Faiza; Khattak, A.; Rehman, A.U.; Ali, A.; Mahmood, A.; Imran, K.; Ulasyar, A.; Sheh Zad, H.; Ullah, N.; Khan, A. Multi-Stressed Nano and Micro-Silica/Silicone Rubber Composites with Improved Dielectric and High-Voltage Insulation Properties. Polymers 2021, 13, 1400. [Google Scholar] [CrossRef]

- Lau, K.Y.; Piah, M. Polymer nanocomposites in high voltage electrical insulation perspective: A review. Malays. Polym. J. 2011, 6, 58–69. [Google Scholar]

- Li, S.; Li, J.; Zhang, R. In Hydrophobicity Improvement of Polluted Silicone Rubber by Plasma Jet in High Humidity Environment. In Proceedings of the 2021 International Conference on Electrical Materials and Power Equipment (ICEMPE), Chongqing, China, 11–15 April 2021; pp. 1–4. [Google Scholar]

- Ning, K.; Lu, J.; Xie, P.; Hu, J.; Huang, J.; Sheng, K. Study on surface modification of silicone rubber for composite insulator by electron beam irradiation. Nucl. Instrum. Methods Phys. Res. Sect. B 2021, 499, 7–16. [Google Scholar] [CrossRef]

- Wang, B.; Zhu, D.; Li, C.; Chen, J. Performance of Full Compositional W/Cu Functionally Gradient Materials Under Quasi-Steady-State Heat Loads. IEEE Trans. Plasma Sci. 2018, 46, 1551–1555. [Google Scholar] [CrossRef]

- Jie, X.; Xinhua, Z.; Zhongyan, M. Effect of the interdiffusion reaction on the compatibility in PZT/PNN functionally gradient piezoelectric materials. IEEE Trans. Compon. Packag. Technol. 1999, 22, 11–16. [Google Scholar] [CrossRef]

- Cao, X.; Shi, J.; Jin, F. Effect of gradient dielectric coefficient in a functionally graded material (FGM) substrate on the propagation behavior of love waves in an FGM-piezoelectric layered structure. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2012, 59, 1253–1257. [Google Scholar] [CrossRef]

| Failure Type | % of Failure Recorded (221) |

|---|---|

| Brittle fracture | 51.1% |

| Flashunder | 24.9% |

| Mechanical failure: rod failure | 10.4% |

| Rod destruction by discharge activity | 8.1% |

| End fitting pullout | 0.5% |

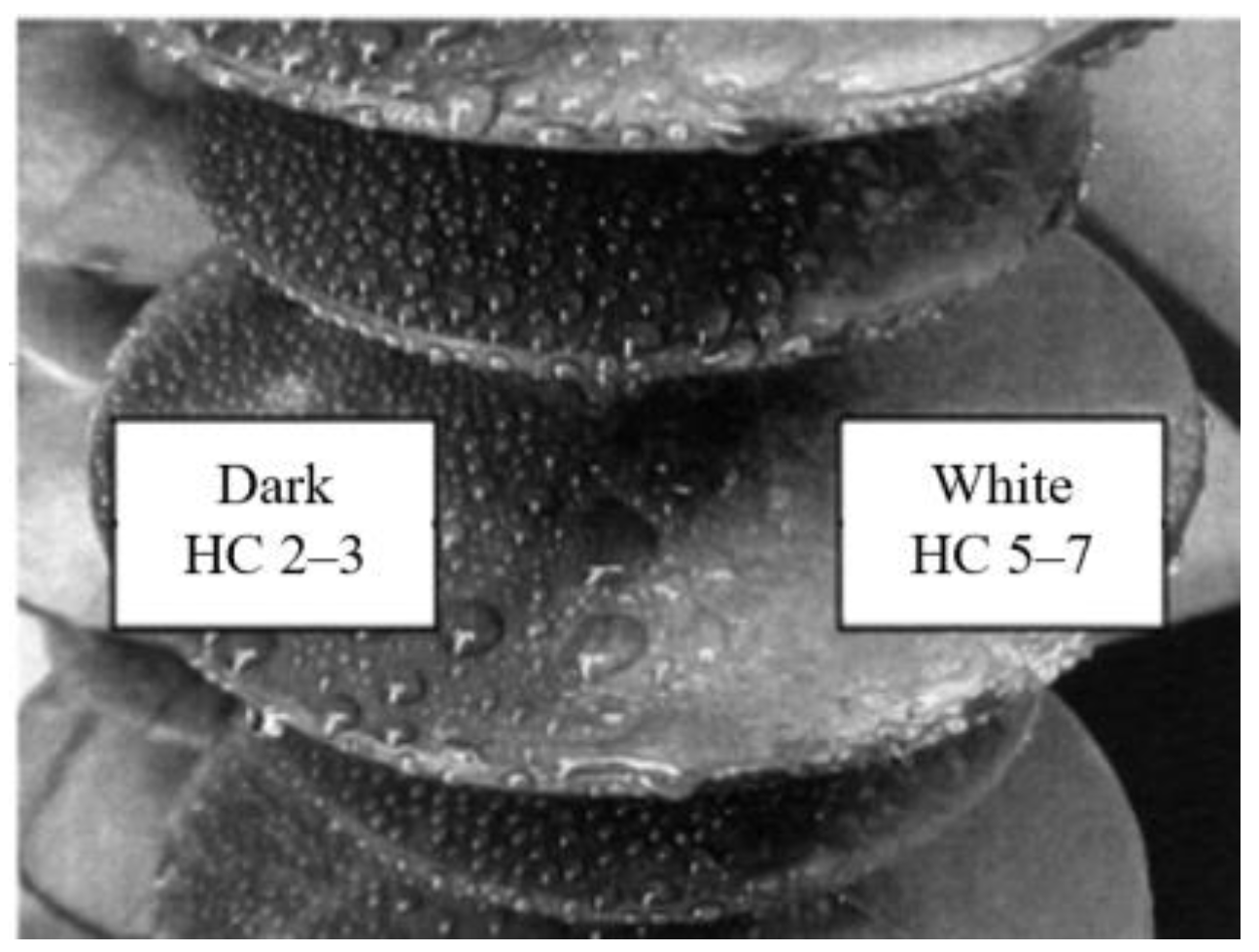

| Weathershed | Surface | HC |

|---|---|---|

| High voltage end | White (aged/discolored) Dark | HC5 HC2–3 |

| Middle | White (aged/discolored) Dark | HC4 HC2 |

| Low voltage end | White (aged/discolored) Dark | HC5 HC3 |

| Characteristic Group | Wave Number/cm−1 |

|---|---|

| O–H | 3700–3200 |

| CH3(C–H) | 2960 |

| C–H | 1440–1410 |

| Si–CH3(C–H) | 1270–1255 |

| Si–O–Si(Si–O) | 1100–1000 |

| O–Si(CH3)2–O(Si–O) | 840–790 |

| Si(CH3)3 | 800–700 |

| Silicone Rubber Compounds | ATH Parts Per Hundred Rubber/Weight% | Inert Parts Per Hundred Rubber/Weight% |

|---|---|---|

| 52 wt% untreated ATH | 110/52 | - |

| 52 wt% precoated ATH | 110/52 | - |

| 52 wt% insitu coated ATH vinyl silane | 110/52 | - |

| ATH + 25 wt% SiO2 | 55/25 | 55/25 |

| ATH + 9 wt% BaSO4 | 100/9 | 20/9 |

| ATH + 13.5 wt% BaSO4 | 90/13.5 | 30/13.5 |

| ATH + 18 wt% BaSO4 | 80/18 | 40/18 |

| ATH + 36 wt% BaSO4 | 40/36 | 80/36 |

| 54 wt% BaSO4 | 0/0 | 120/54 |

| Treatment | Contact Angle, o | Self-Cleaning | Surface Charge Optimization | Flashover Improvement |

|---|---|---|---|---|

| PDMS + ZnO coating | 162 | Yes | Yes | 16.7% increase in dry flashover |

| Liquid silicone rubber + SiO2 coating | 161.8 | Not mentioned | Not mentioned | 10.5% increase in wet flashover |

| DBD plasma treatments | ~100 | Yes | Yes | Not mentioned |

| Raisin-based primer + SiO2 topcoat | 161 | Not mentioned | Not mentioned | 29% increase in pollution flashover |

| PDMS + ZnO + MWCNT coating | 152 | Yes | Yes | 28.8% increase in dry flashover |

| Pico second laser-ablated template + PDMS/SiO2 coating | 150.3 | Yes | Yes | Not mentioned |

| Al2O3 + CNT + Polyamide mesh | 160 | Yes | Yes | 30% increase in dry flashover |

| EP + PDMS + grafted SiO2 | 162 | Yes | Yes | 60% increase in wet flashover |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qiao, X.; Ming, Y.; Xu, K.; Yi, N.; Sundararajan, R. Aging of Polymeric Insulators under Various Conditions and Environments: Another Look. Energies 2022, 15, 8809. https://doi.org/10.3390/en15238809

Qiao X, Ming Y, Xu K, Yi N, Sundararajan R. Aging of Polymeric Insulators under Various Conditions and Environments: Another Look. Energies. 2022; 15(23):8809. https://doi.org/10.3390/en15238809

Chicago/Turabian StyleQiao, Xinhan, Yue Ming, Ke Xu, Ning Yi, and Raji Sundararajan. 2022. "Aging of Polymeric Insulators under Various Conditions and Environments: Another Look" Energies 15, no. 23: 8809. https://doi.org/10.3390/en15238809

APA StyleQiao, X., Ming, Y., Xu, K., Yi, N., & Sundararajan, R. (2022). Aging of Polymeric Insulators under Various Conditions and Environments: Another Look. Energies, 15(23), 8809. https://doi.org/10.3390/en15238809