Economic Conditions to Circularize Clinical Plastics

Abstract

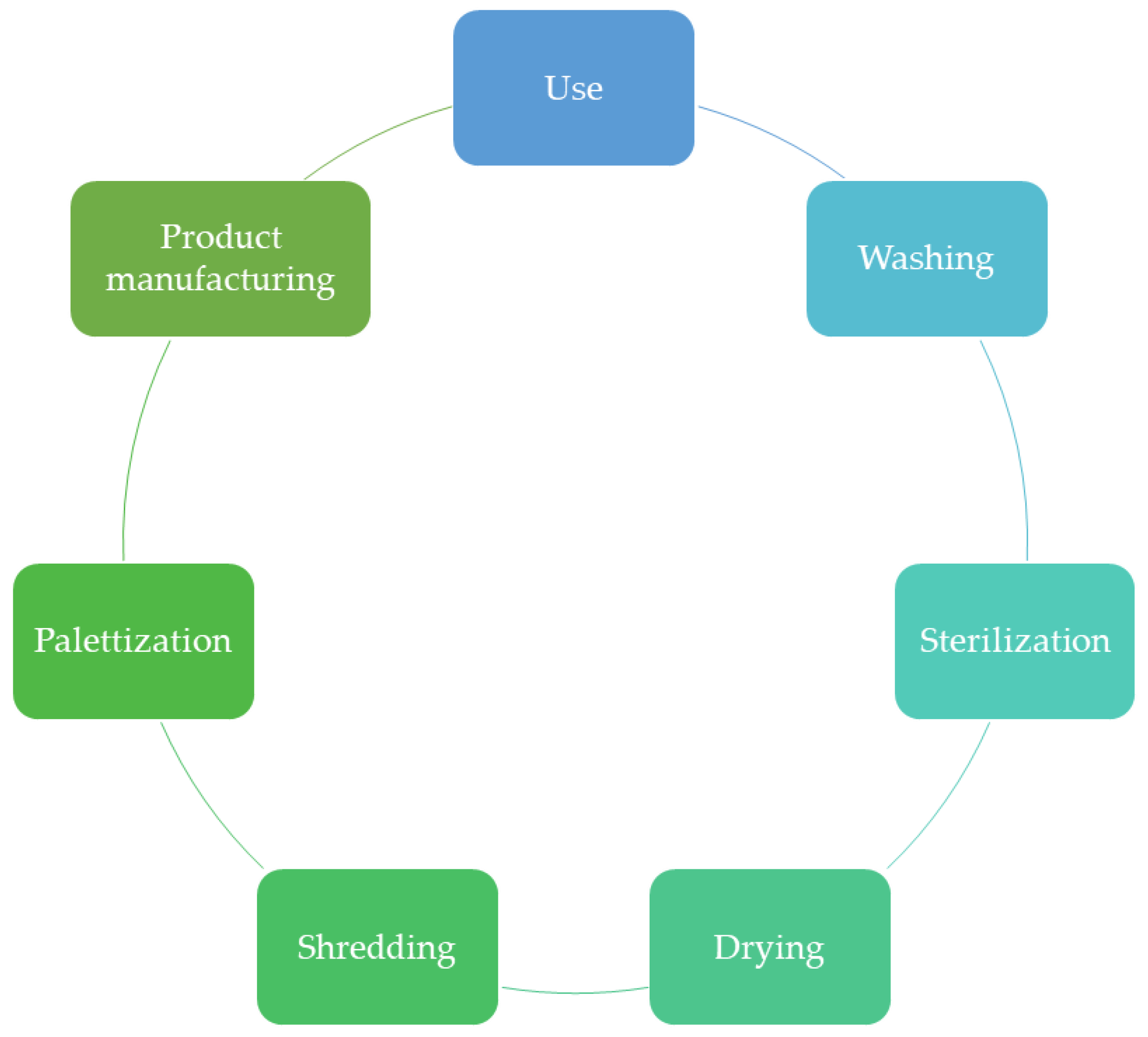

:1. Introduction

2. Literature Review

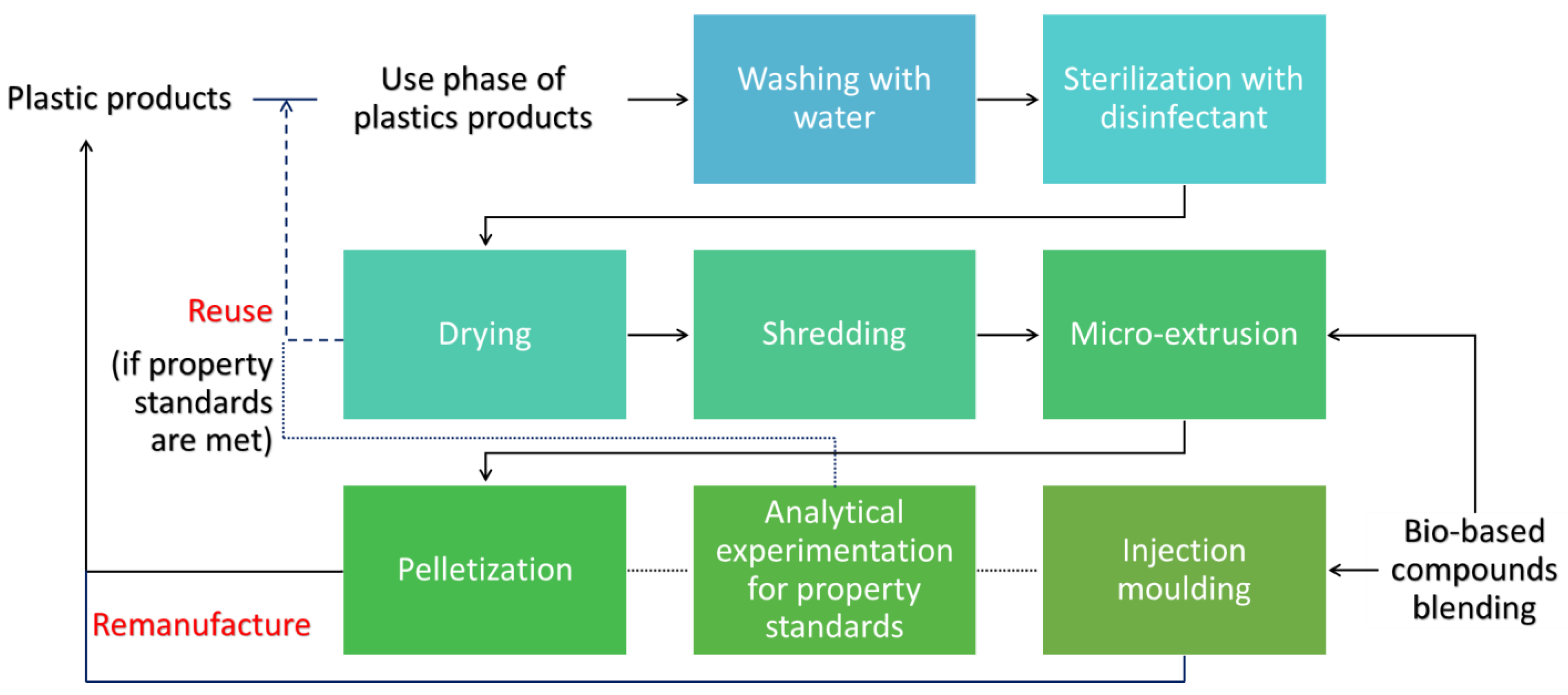

3. Materials and Methods

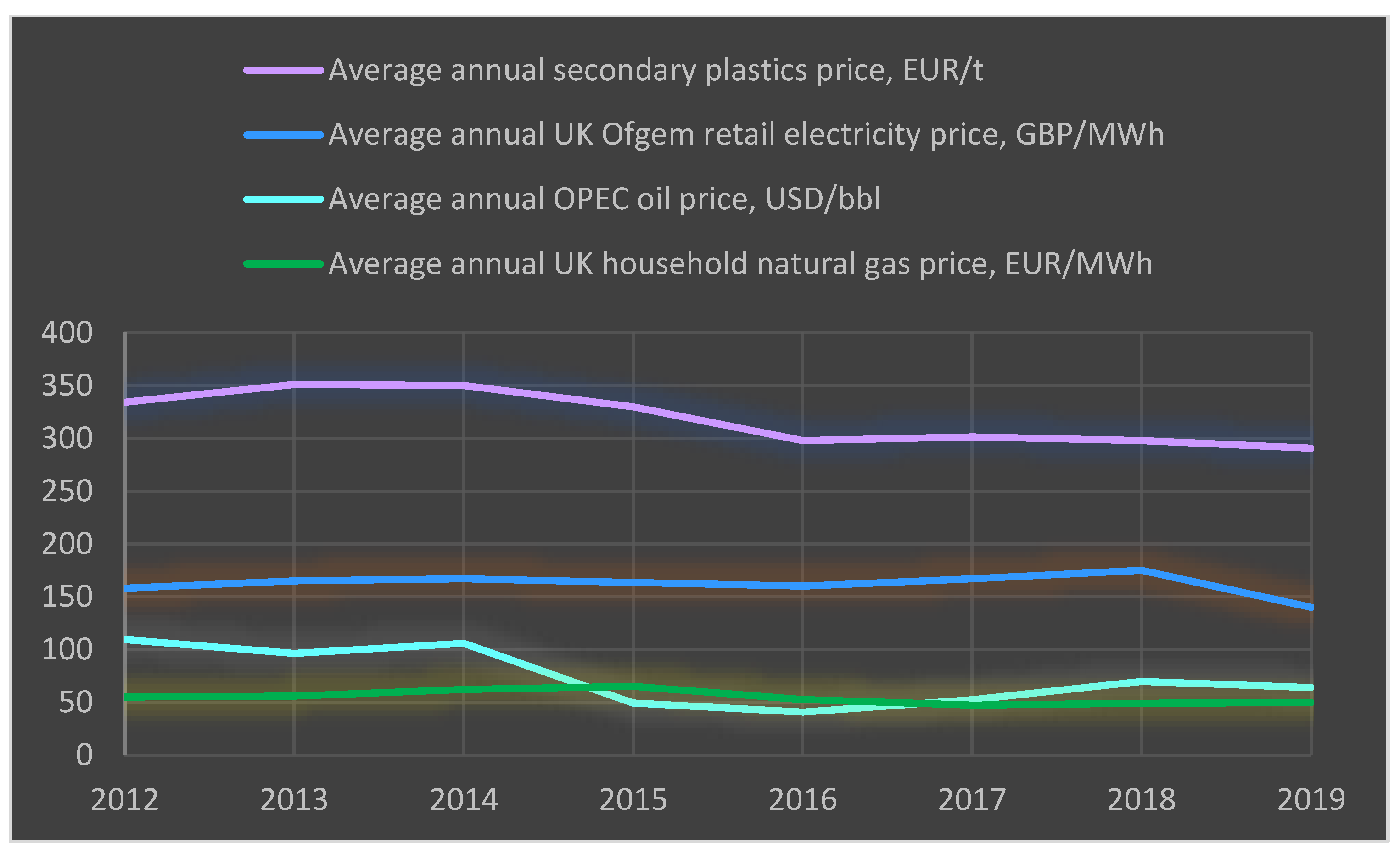

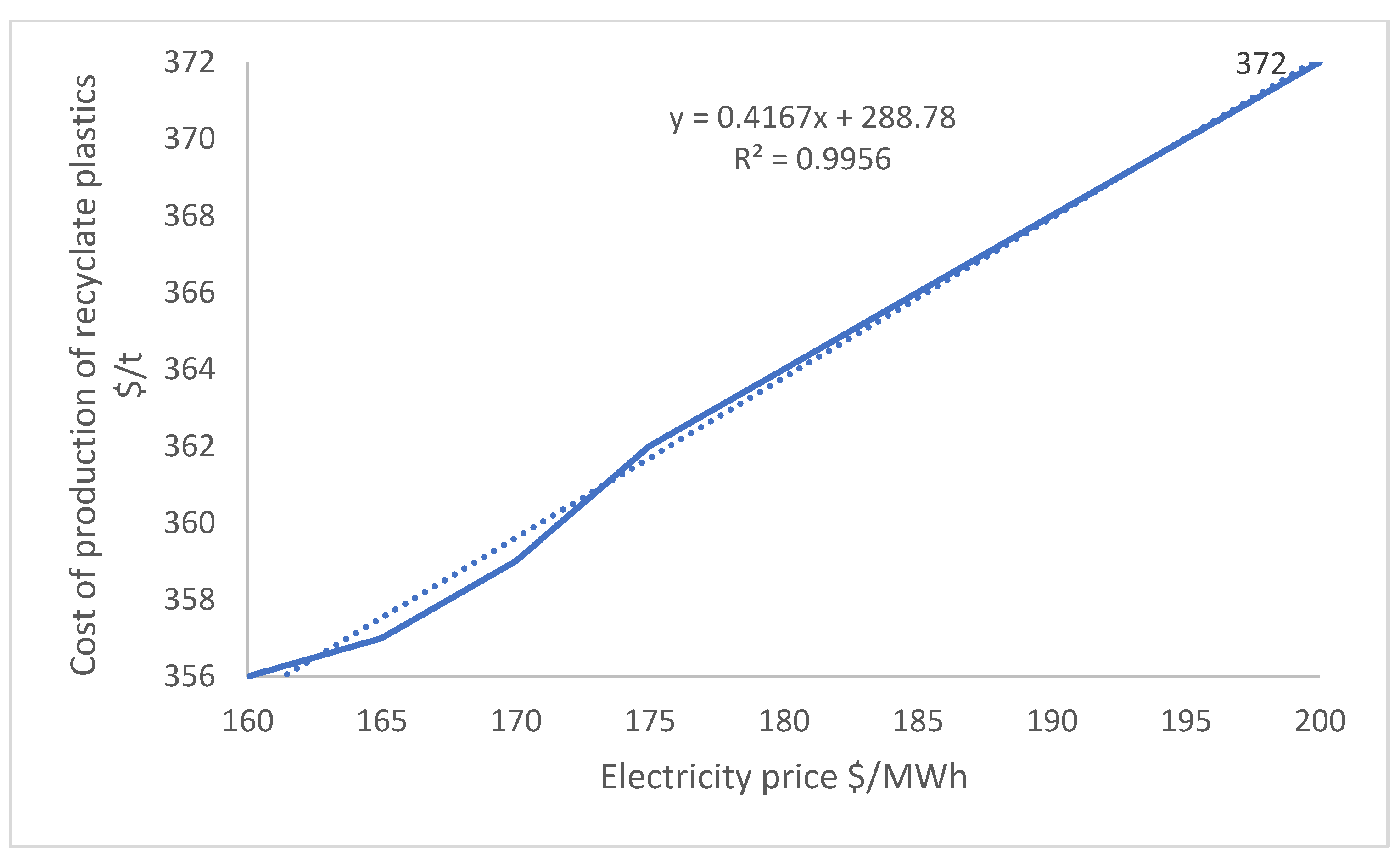

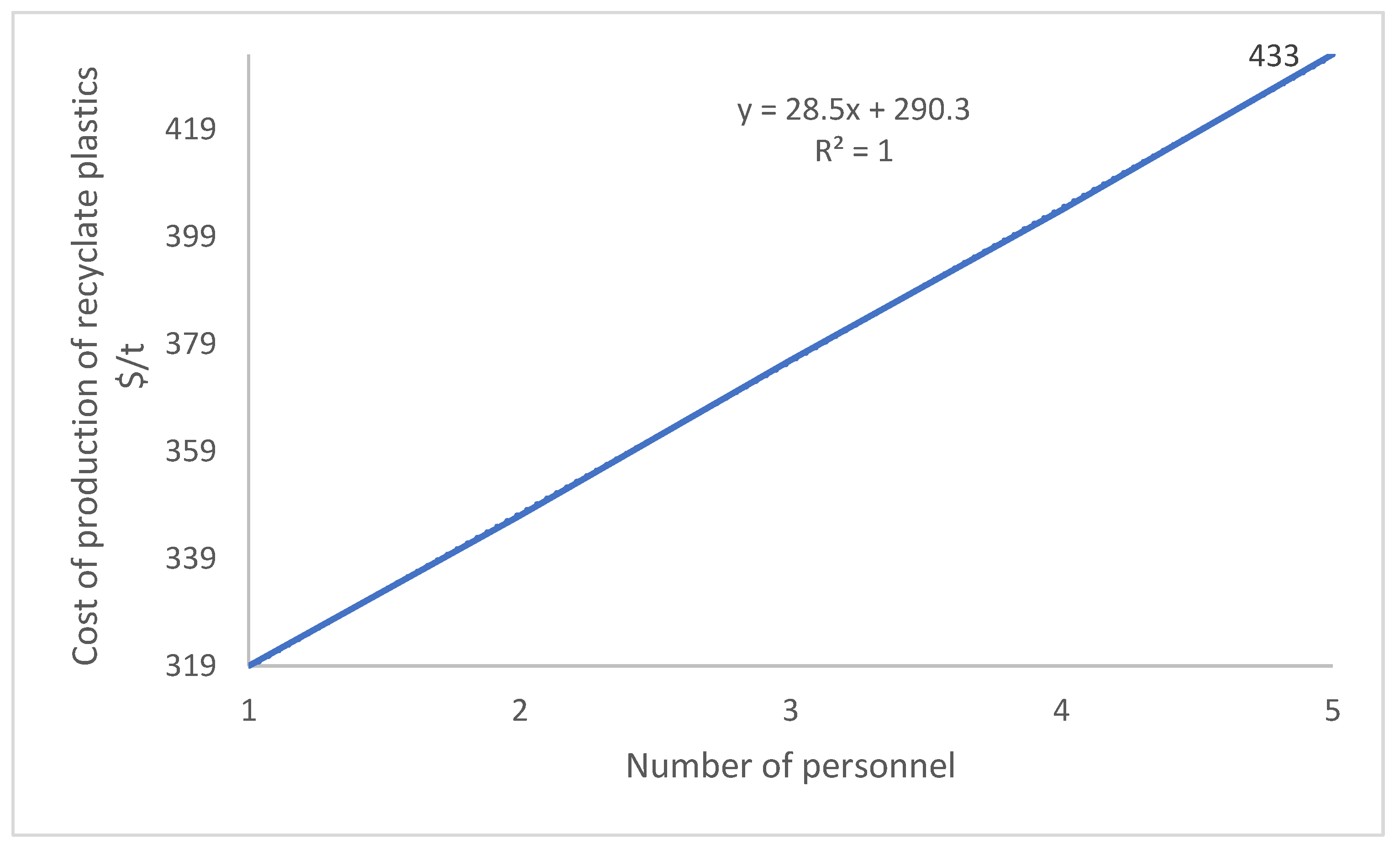

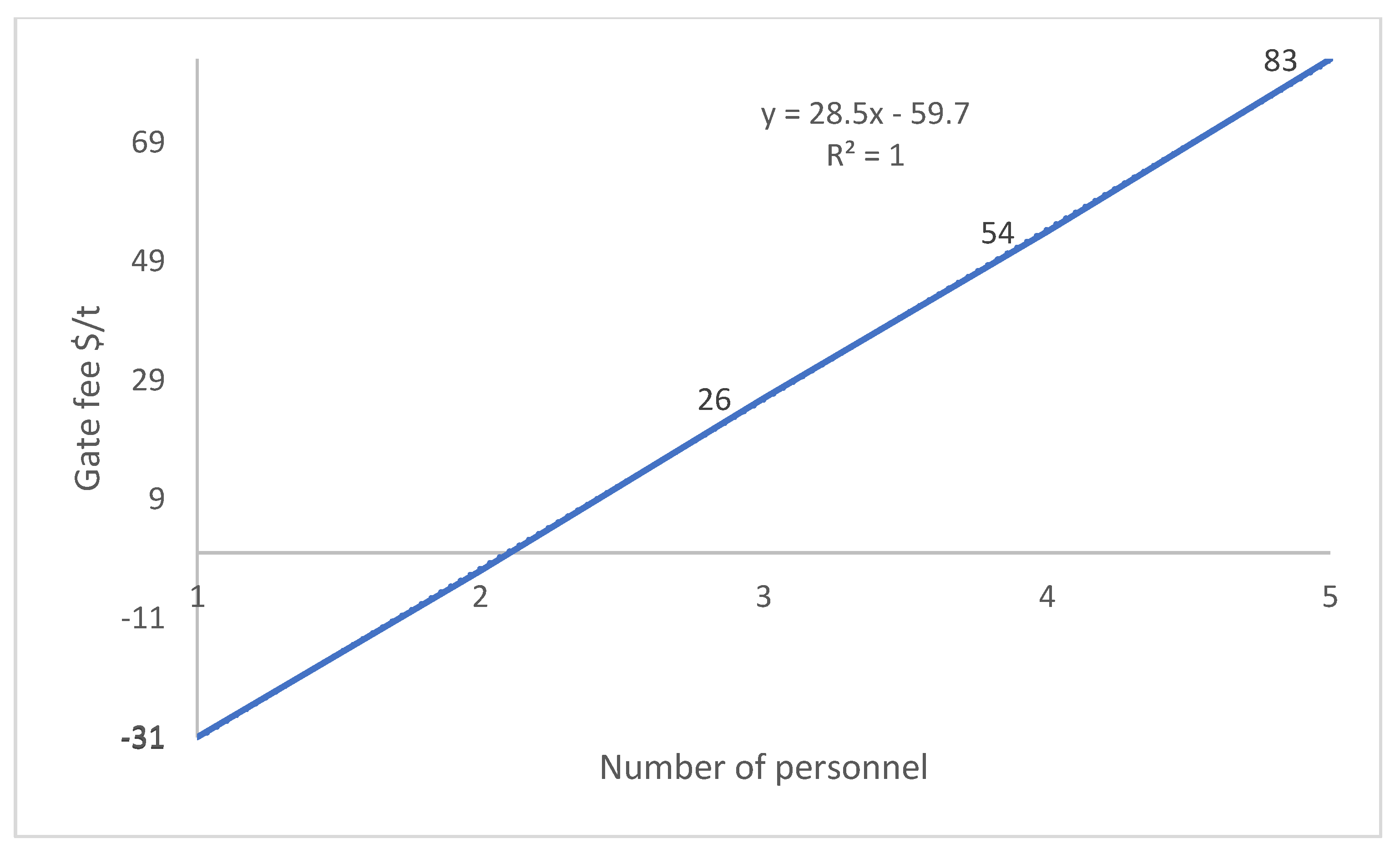

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Available online: https://www.eea.europa.eu/publications/the-plastic-waste-trade-in (accessed on 1 November 2022).

- Joseph, B.; James, J.; Kalarikkal, N.; Thomas, S. Recycling of medical plastics. Adv. Ind. Eng. Polym. Res. 2021, 4, 199–208. [Google Scholar] [CrossRef]

- Liu, M.; Wen, J.; Feng, Y.; Zhang, L.; Wu, J.; Wang, J.; Yang, X. A benefit evaluation for recycling medical plastic waste in China based on material flow analysis and life cycle assessment. J. Clean. Prod. 2022, 368, 133033. [Google Scholar] [CrossRef]

- Volk, R.; Stallkamp, C.; Steins, J.J.; Yogish, S.P.; Müller, R.C.; Stapf, D.; Schultmann, F. Techno-economic assessment and comparison of different plastic recycling pathways: A German case study. J. Ind. Ecol. 2021, 25, 1318–1337. [Google Scholar] [CrossRef]

- Gear, M.; Sadhukhan, J.; Thorpe, R.; Clift, R.; Seville, J.; Keast, M. A life cycle assessment data analysis toolkit for the design of novel processes–A case study for a thermal cracking process for mixed plastic waste. J. Clean. Prod. 2018, 180, 735–747. [Google Scholar] [CrossRef]

- Dharmaraj, S.; Ashokkumar, V.; Pandiyan, R.; Munawaroh, H.S.H.; Chew, K.W.; Chen, W.H.; Ngamcharussrivichai, C. Pyrolysis: An effective technique for degradation of COVID-19 medical wastes. Chemosphere 2021, 275, 130092. [Google Scholar] [CrossRef] [PubMed]

- Dogu, O.; Pelucchi, M.; Van de Vijver, R.; Van Steenberge, P.H.; D’hooge, D.R.; Cuoci, A.; Mehl, M.; Frassoldati, A.; Faravelli, T.; Van Geem, K.M. The chemistry of chemical recycling of solid plastic waste via pyrolysis and gasification: State-of-the-art, challenges, and future directions. Prog. Energy Combust. Sci. 2021, 84, 100901. [Google Scholar] [CrossRef]

- Nikiema, J.; Asiedu, Z. A review of the cost and effectiveness of solutions to address plastic pollution. Environ. Sci. Pollut. Res. 2022, 29, 24547–24573. [Google Scholar] [CrossRef]

- Luijsterburg, B.J. Mechanical Recycling of Plastic Packaging Waste; Universiteit Eindhoven: Eindhoven, The Netherlands, 2015. [Google Scholar] [CrossRef]

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, e1700782-10. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Singh, N.; Hui, D.; Singh, R.; Ahuja, I.P.S.; Feo, L.; Fraternali, F. Recycling of plastic solid waste: A state of art review and future applications. Compos. Part B 2017, 115, 409–422. [Google Scholar] [CrossRef]

- Devasahayam, S.; Raju, G.B.; Hussain, C.M. Utilization and recycling of end of life plastics for sustainable and clean industrial processes including the iron and steel industry. Mater. Sci. Energy Technol. 2019, 2, 634–646. [Google Scholar] [CrossRef]

- Civancik-Uslu, D.; Nhu, T.T.; Van Gorp, B.; Kresovic, U.; Larrain, M.; Billen, P.; Ragaert, K.; De Meester, S.; Dewulf, J.; Huysveld, S. Moving from linear to circular household plastic packaging in Belgium: Prospective life cycle assessment of mechanical and thermochemical recycling. Resour. Conserv. Recycl. 2021, 171, 105633. [Google Scholar] [CrossRef]

- Larrain, M.; Van Passel, S.; Thomassen, G.; Van Gorp, B.; Nhu, T.T.; Huysveld, S.; Van Geem, K.M.; De Meester, S.; Billen, P. Techno-economic assessment of mechanical recycling of challenging post-consumer plastic packaging waste. Resour. Conserv. Recycl. 2021, 170, 105607. [Google Scholar] [CrossRef]

- Bora, R.R.; Wang, R.; You, F. Waste polypropylene plastic recycling toward climate change mitigation and circular economy: Energy, environmental, and technoeconomic perspectives. ACS Sustain. Chem. Eng. 2020, 8, 16350–16363. [Google Scholar] [CrossRef]

- Sinnott, R.; Towler, G. Chemical Engineering Design; Butterworth-Heinemann: Oxford, UK, 2019. [Google Scholar]

- Sadhukhan, J.; Ng, K.S.; Martinez-Hernandez, E. Biorefineries and Chemical Processes: Design, Integration and Sustainability Analysis; Wiley: Chichester, UK, 2014; Available online: https://onlinelibrary.wiley.com/doi/book/10.1002/9781118698129 (accessed on 1 November 2022).

- Sekar, K. Recycling of Laboratory Plastics: A Material and Design Study. Master’s Thesis, University of Surrey, Guildford, UK, 2021. [Google Scholar]

- Sigma-Aldrich. Corning® Closed System Spinner Flask Disposable, Pre-Assembled, Capacity 1 L, Sterile. Available online: https://www.sigmaaldrich.com/GB/en/product/sigma/cls3546 (accessed on 1 November 2022).

- Sigma-Aldrich. Corning® Costar® Stripette® Serological Pipettes, Bulk Packed Capacity 1 mL. Available online: https://www.sigmaaldrich.com/GB/en/product/sigma/cls4010 (accessed on 1 November 2022).

- Sigma-Aldrich. Corning® 96 Well Clear Polystyrene Microplate Round Bottom Clear, Tissue Culture (TC)-Treated Surface, Bag of 20, Sterile, Lid. Available online: https://www.sigmaaldrich.com/GB/en/product/sigma/cls3358 (accessed on 1 November 2022).

- Sigma-Aldrich. CELLine Classic Bioreactor Flask CL 1000 (for 1L Volumes). Available online: https://www.sigmaaldrich.com/GB/en/product/sigma/z688029 (accessed on 1 November 2022).

- Sigma-Aldrich. Corning 96 Well PP 1.2 mL Cluster Tubes 96 Well Polypropylene Cluster Tubes, Individual Tube Format, Non-Treated, Non-Sterile, without Rack, Clear, 960/cs Cap Tubes. Available online: https://www.sigmaaldrich.com/GB/en/product/sigma/cls4401 (accessed on 1 November 2022).

- Sigma-Aldrich. DURAN® Membrane Screw Cap Polypropylene, GL 32 Cap, Pore Size 0.2 μm. Available online: https://www.sigmaaldrich.com/GB/en/product/aldrich/dwk291181907 (accessed on 1 November 2022).

- Sigma-Aldrich. Corning Erlenmeyer Baffled Cell Culture Flasks 500 mL Erlenmeyer Flask w/Vented Cap, Polycarbonate, Sterile, 25/cs Cell Culture Flasks. Available online: https://www.sigmaaldrich.com/GB/en/product/sigma/cls431401 (accessed on 1 November 2022).

- Sigma-Aldrich. TPP Cryotubes Polypropylene, Capacity 1.2 mL Cryo Tubes. Available online: https://www.sigmaaldrich.com/GB/en/product/sigma/z760943 (accessed on 1 November 2022).

- Sigma-Aldrich. Corning 15 mL Centrifuge Tubes Natural Polypropylene Conical Bottom, Sterile, Self Standing: No (Rack Packed), Cap (Plug Seal), Case of 500 15 ml Centrifuge Tubes. Available online: https://www.sigmaaldrich.com/GB/en/product/sigma/cls430052?gclid=Cj0KCQiA6NOPBhCPARIsAHAy2zDcvD7-KK8h0EMxtx8i7otOverEySsqLTjXN7W927hkkmNpl_qp3EaAs30EALw_wcB (accessed on 1 November 2022).

- Nalgene™ HDPE, Carboy with Spigot. Available online: https://www.thermofisher.com/order/catalog/product/2320-0050 (accessed on 1 November 2022).

- Nalgene™ HDPE Pans. Available online: https://www.thermofisher.com/order/catalog/product/7120-0020 (accessed on 1 November 2022).

- Nalgene™ Wide-Mouth Lab Quality HDPE Bottles. Available online: https://www.thermofisher.com/order/catalog/product/2104-0016 (accessed on 1 November 2022).

- Nalgene™ Pipet Cleaning Equipment Sets. Available online: https://www.thermofisher.com/order/catalog/product/5250-0050 (accessed on 1 November 2022).

- Nalgene™ Dropper Bottles with Control Dispensing Tip. Available online: https://www.thermofisher.com/order/catalog/product/2750-9125 (accessed on 1 November 2022).

- Nalgene™ Right-to-Understand Safety Wash Bottles featuring Globally Harmonized System (GHS) Labeling. Available online: https://www.thermofisher.com/order/catalog/product/2428-0504 (accessed on 1 November 2022).

- Nalgene™ LDPE, Round Carboy with Spigot. Available online: https://www.thermofisher.com/order/catalog/product/2318-0050 (accessed on 1 November 2022).

- Nalgene™ 980 Braided Clear PVC Tubing. Available online: https://www.thermofisher.com/order/catalog/product/8005-0100 (accessed on 1 November 2022).

- PVC Membrane Filter|PVC502500. Available online: https://www.merckmillipore.com/GB/en/product/PVC-Membrane-Filter,MM_NFPVC502500 (accessed on 1 November 2022).

- Nalgene™ Polycarbonate Baffled Culture Flasks. Available online: https://www.thermofisher.com/order/catalog/product/4110-0500 (accessed on 1 November 2022).

- Nalgene™ Square Polycarbonate Bottles with Closure. Available online: https://www.thermofisher.com/order/catalog/product/2015-0250 (accessed on 1 November 2022).

- Nalgene™ Straight-Sided Wide-Mouth Polycarbonate Jars with Closure. Available online: https://www.thermofisher.com/order/catalog/product/2116-0125V (accessed on 1 November 2022).

- Nalgene™ 870 Tubing. Available online: https://www.thermofisher.com/order/catalog/product/8051-0125 (accessed on 1 November 2022).

- Nalgene™ Fluorocarbon (PFA) Resin Plastic Graduated Cylinder. Available online: https://www.thermofisher.com/order/catalog/product/3666-0100 (accessed on 1 November 2022).

- Nalgene™ Griffin Low-Form PFA Plastic Beakers. Available online: https://www.thermofisher.com/order/catalog/product/1510-0250 (accessed on 1 November 2022).

- Nalgene™ Narrow-Mouth Bottles Made of Teflon™ PFA with Closure. Available online: https://www.thermofisher.com/order/catalog/product/1630-0032 (accessed on 1 November 2022).

- PTFE Tissue Grinders and Homogenisers. Available online: http://www.cowie.com/catalogue/homog.htm (accessed on 1 November 2022).

- PTFE Bottle Pourer. Available online: http://www.cowie.com/catalogue/pourer.htm (accessed on 1 November 2022).

- PTFE Labware. Available online: http://www.celscientific.com/PTFELabware.html (accessed on 1 November 2022).

- Lab Unlimited UK. LLG Labware LLG-Syringe Filter from PVDF, 0,22 μm 6285697. Available online: https://www.labunlimited.co.uk/s/pg_dl_28587/4AJ-6285697/LLG-Labware-LLGSyringe-filter-from-PVDF,-0,22-μm-6285697 (accessed on 1 November 2022).

- POLYCASA® SAN. Extruded Styrene-Acrylonitrile Copolymer Sheets. Available online: https://www.display.3acomposites.com/polycasa-san/ (accessed on 1 November 2022).

- Nalgene™ Right-to-Understand FEP Safety Wash Bottles with Globally Harmonized System (GHS) Labeling for Harsh Chemicals. Available online: https://www.thermofisher.com/order/catalog/product/2429-0503 (accessed on 1 November 2022).

- Nalgene™ Separatory Funnels made with Teflon™ Fluoropolymer with Closure Made with Tefzel™. Available online: https://www.thermofisher.com/order/catalog/product/4301-1000 (accessed on 1 November 2022).

- Nalgene™ Oak Ridge High-Speed Centrifuge Tubes made with Teflon™ Fluoropolymer and Closure made with Tefzel™. Available online: https://www.thermofisher.com/order/catalog/product/3114-0050 (accessed on 1 November 2022).

- Nalgene™ Narrow-Mouth Bottles Made of Teflon™ FEP with Closure. Available online: https://www.thermofisher.com/order/catalog/product/1600-0032 (accessed on 1 November 2022).

- Lab Unlimited. LLG Labware LLG-Adhesive PCR-Film, Polyester 6313398. Available online: https://www.labunlimited.com/s/pg_dl_18111/4AJ-6313398/LLG-Labware-LLGAdhesive-PCR-Film,-polyester-6313398 (accessed on 1 November 2022).

- Fisher Scientific. Merck Amicon™ Ultra-15 Centrifugal Filter Units: Centrifuges and Microcentrifuges Products. Available online: https://www.fishersci.co.uk/shop/products/amiconultra-15-centrifugal-filter-units/p-7232219 (accessed on 1 November 2022).

- Sealing Films, Foils & Tapes. Available online: https://www.sigmaaldrich.com/GB/en/products/labware/sealing-films-foils-andtapes#Tapes (accessed on 1 November 2022).

- Lee, B.K.; Ellenbecker, M.J.; Moure-Eraso, R. Analyses of the recycling potential of medical plastic wastes. Waste Manag. 2002, 22, 461–470. [Google Scholar] [CrossRef] [PubMed]

- Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Recycling_%E2%80%93_secondary_material_price_indicator (accessed on 1 November 2022).

- Available online: https://www.ofgem.gov.uk/sites/default/files/docs/2019/11/20191030_state_of_energy_market_revised.pdf (accessed on 1 November 2022).

- Available online: https://albayanmagazine.com/average-annual-opec-oil-price-from-2011-to-2021-in-usd-per-barrel/?lang=en (accessed on 1 November 2022).

- Available online: https://www.statista.com/statistics/418046/natural-gas-prices-for-households-in-the-uk/ (accessed on 1 November 2022).

- Available online: https://static.thermoscientific.com/images/D20826~.pdf (accessed on 1 November 2022).

- Sadhukhan, J. Net-Zero Action Recommendations for Scope 3 Emission Mitigation Using Life Cycle Assessment. Energies 2022, 15, 5522. [Google Scholar] [CrossRef]

- Ozimek, J.; Pielichowski, K. Recent advances in polyurethane/POSS hybrids for biomedical applications. Molecules 2021, 27, 40. [Google Scholar] [CrossRef] [PubMed]

- Rosenboom, J.G.; Langer, R.; Traverso, G. Bioplastics for a circular economy. Nat. Rev. Mater. 2022, 7, 117–137. [Google Scholar] [CrossRef] [PubMed]

- Sadhukhan, J.; Sen, S.; Randriamahefasoa, T.M.S.; Gadkari, S. Energy System Optimization for Net-Zero Electricity. Digit. Chem. Eng. 2022, 3, 100026. [Google Scholar] [CrossRef]

- Martinez-Hernandez, E.; Sadhukhan, J.; Aburto, J.; Amezcua-Allieri, M.A.; Morse, S.; Murphy, R. Modelling to analyse the process and sustainability performance of forestry-based bioenergy systems. Clean Technol. Environ. Policy 2022, 24, 1709–1725. [Google Scholar] [CrossRef]

- Sadhukhan, J.; Sen, S.; Gadkari, S. The mathematics of life cycle sustainability assessment. J. Clean. Prod. 2021, 309, 127457. [Google Scholar] [CrossRef]

- Wan, Y.K.; Sadhukhan, J.; Ng, K.S.; Ng, D.K. Techno-economic evaluations for feasibility of sago-based biorefinery, Part 1: Alternative energy systems. Chem. Eng. Res. Des. 2016, 107, 263–279. [Google Scholar] [CrossRef]

- Ng, K.S.; Zhang, N.; Sadhukhan, J. Techno-economic analysis of polygeneration systems with carbon capture and storage and CO2 reuse. Chem. Eng. J. 2013, 219, 96–108. [Google Scholar] [CrossRef] [Green Version]

- Available online: https://www.echemi.com/produce/pr2208311290-hydrogen-peroxide-99-white-liquid-7722-84-1-tingxuan.html (accessed on 1 November 2022).

- Available online: https://www.payscale.com/research/UK/Job=Process_Engineer/Sala (accessed on 1 November 2022).

- Available online: https://www.ofgem.gov.uk/information-consumers/energy-advice-households/check-if-energy-price-cap-affects-you (accessed on 1 November 2022).

- Available online: https://blog.recycleduklimited.com/current-plastic-recycling-price (accessed on 1 November 2022).

- Sadhukhan, J.; Martinez-Hernandez, E. Material flow and sustainability analyses of biorefining of municipal solid waste. Bioresour. Technol. 2017, 243, 135–146. [Google Scholar] [CrossRef] [Green Version]

- Sadhukhan, J.; Ng, K.S.; Martinez-Hernandez, E. Novel integrated mechanical biological chemical treatment (MBCT) systems for the production of levulinic acid from fraction of municipal solid waste: A comprehensive techno-economic analysis. Bioresour. Technol. 2016, 215, 131–143. [Google Scholar] [CrossRef] [PubMed]

- Available online: https://wrap.org.uk/sites/default/files/2022-07/WRAP%202021-22%20Gate%20Fees%20Report%20FINAL%20-%20%2823.05.22%29%20%28clean%29_0.pdf (accessed on 1 November 2022).

- Sadhukhan, J. Net zero electricity systems in global economies by life cycle assessment (LCA) considering ecosystem, health, monetization, and soil CO2 sequestration impacts. Renew. Energy 2022, 184, 960–974. [Google Scholar] [CrossRef]

- Honorato-Salazar, J.A.; Sadhukhan, J. Annual biomass variation of agriculture crops and forestry residues, and seasonality of crop residues for energy production in Mexico. Food Bioprod. Process. 2020, 119, 1–19. [Google Scholar] [CrossRef]

- Martinez-Hernandez, E.; Amezcua-Allieri, M.A.; Sadhukhan, J.; Anell, J.A. Sugarcane bagasse valorization strategies for bioethanol and energy production. In Sugarcane-Technology and Research; IntechOpen: London, UK, 2018. [Google Scholar] [CrossRef] [Green Version]

- Ng, K.S.; Lopez, Y.; Campbell, G.M.; Sadhukhan, J. Heat integration and analysis of decarbonised IGCC sites. Chem. Eng. Res. Des. 2010, 88, 170–188. [Google Scholar] [CrossRef] [Green Version]

- Sadhukhan, J.; Ng, K.S.; Shah, N.; Simons, H.J. Heat integration strategy for economic production of combined heat and power from biomass waste. Energy Fuels 2009, 23, 5106–5120. [Google Scholar] [CrossRef]

- Sadhukhan, J.; Pollet, B.G.; Seaman, M. Hydrogen Production and Storage: Analysing Integration of Photoelectrolysis, Electron Harvesting Lignocellulose, and Atmospheric Carbon Dioxide-Fixing Biosynthesis. Energies 2022, 15, 5486. [Google Scholar] [CrossRef]

- Sadhukhan, J.; Gadkari, S.; Martinez-Hernandez, E.; Ng, K.S.; Shemfe, M.; Torres-Garcia, E.; Lynch, J. Novel macroalgae (seaweed) biorefinery systems for integrated chemical, protein, salt, nutrient and mineral extractions and environmental protection by green synthesis and life cycle sustainability assessments. Green Chem. 2019, 21, 2635–2655. [Google Scholar] [CrossRef]

- Sadhukhan, J.; Lloyd, J.R.; Scott, K.; Premier, G.C.; Eileen, H.Y.; Curtis, T.; Head, I.M. A critical review of integration analysis of microbial electrosynthesis (MES) systems with waste biorefineries for the production of biofuel and chemical from reuse of CO2. Renew. Sustain. Energy Rev. 2016, 56, 116–132. [Google Scholar] [CrossRef]

- Sadhukhan, J.; Mustafa, M.A.; Misailidis, N.; Mateos-Salvador, F.; Du, C.; Campbell, G.M. Value analysis tool for feasibility studies of biorefineries integrated with value added production. Chem. Eng. Sci. 2008, 63, 503–519. [Google Scholar] [CrossRef] [Green Version]

- Sadhukhan, J.; Smith, R. Synthesis of industrial systems based on value analysis. Comp. Chem. Eng. 2007, 31, 535–551. [Google Scholar] [CrossRef]

- Sadhukhan, J.; Zhang, N.; Zhu, X.X. Analytical optimisation of industrial systems and applications to refineries, petrochemicals. Chem. Eng. Sci. 2004, 59, 4169–4192. [Google Scholar] [CrossRef]

- Sadhukhan, J.; Zhang, N.; Zhu, X.X. Value analysis of complex systems and industrial application to refineries. Ind. Eng. Chem. Res. 2003, 42, 5165–5181. [Google Scholar] [CrossRef]

- Martinez-Hernandez, E.; Campbell, G.M.; Sadhukhan, J. Economic and environmental impact marginal analysis of biorefinery products for policy targets. J. Clean. Prod. 2014, 74, 74–85. [Google Scholar] [CrossRef]

- Martinez-Hernandez, E.; Campbell, G.; Sadhukhan, J. Economic value and environmental impact (EVEI) analysis of biorefinery systems. Chem. Eng. Res. Des. 2013, 91, 1418–1426. [Google Scholar] [CrossRef] [Green Version]

- Martinez-Hernandez, E.; Campbell, G.; Sadhukhan, J. Economic Value and Environmental Impact analysis tool for sustainable biorefinery design. Comp. Aided Chem. Eng. 2012, 30, 11–15. [Google Scholar] [CrossRef]

| Base Polymer | Laboratory Clinical Plastics (Labware Plastics) | References |

|---|---|---|

| Polystyrene | microplates, bioreactor flask, serological pipettes, closed system spinner flask | [19,20,21,22] |

| Polypropylene | cluster tubes, screw caps, cell culture flasks, cryotubes, falcon tubes | [23,24,25,26,27] |

| High-density polyethylene | carboys, bottles, pans, pipet cleaning sets | [28,29,30,31] |

| Low-density polyethylene | carboys, bottles, wash bottles, dropper bottles with control dispensing tip | [32,33,34] |

| Polyvinyl chloride | membrane filters, high-pressure tubes | [35,36] |

| Polycarbonate | straight-sided wide-mouth jars with closure, square bottles, baffled culture flasks | [37,38,39] |

| Perfluoroalkoxy alkane | bottles, beakers, cylinders, tubing | [40,41,42,43] |

| Polytetrafluoroethylene | evaporating dish, the crucible, tweezers, shaft stirrer, bottle pourer, tissue grinder | [44,45,46] |

| Polyvinylidene fluoride | syringe filters | [47] |

| Styrene-acrylonitrile | protective sheets | [48] |

| Fluorine-ethylene-propylene | bottles, centrifuge tubes, funnels, wash bottles | [49,50,51,52] |

| Polyester | adhesive films | [53] |

| Base Polymer | Healthcare Clinical Plastics |

|---|---|

| Polystyrene | gloves, labware, medical packaging and other plastics, e.g., blood collection tubes |

| Polypropylene | IV bag, sharps, gloves, labware, nursery items |

| High-density polyethylene | IV bag, tubing |

| Polyethylene | sharps, medical packaging, nursery items |

| Polyvinyl chloride | IV bag, blood bag, tubing, gloves, labware, medical packaging, patient kits, and other plastics, e.g., blood collection tubes |

| Acrylonitrile-butadiene-styrene terpolymer | IV bag |

| Items | Calculation Method |

|---|---|

| Direct capital cost: delivered cost of equipment, installation, instrumentation and control, piping, electrical systems, building (including services), yard improvements, and service facilities | 3.02 times the delivered cost of equipment from vendors |

| Indirect capital cost: engineering and supervision, construction expenses, legal expenses, contractor fees, and contingency | 1.26 times the delivered cost of equipment from vendors |

| Working capital | 0.75 times the delivered cost of equipment from vendors |

| Total capital investment | Direct, indirect, and working capital = 5.03 times the delivered cost of equipment |

| Variable operating cost | Feedstock, reagent, and utility costs |

| Fixed operating costs dependent on annual indirect operating cost: maintenance, capital charges, insurance, local taxes, and royalties | 0.25 times the annual indirect capital cost |

| Fixed operating costs dependent on labor cost: personnel, laboratory, supervision, and plant overhead costs | 1.9 times the labor cost |

| Miscellaneous operating costs: sales expenses, general overheads, and research and development | 0.2 times the total of variable and fixed operating costs |

| Total operating cost (Opex on an annual basis) | Variable, fixed, and miscellaneous operating costs |

| Items | Cost | Unit |

|---|---|---|

| Direct capital cost: delivered cost of equipment, installation, instrumentation and control, piping, electrical systems, building (including services), yard improvements and service facilities | 403,774 | USD |

| Indirect capital cost: engineering and supervision, construction expenses, legal expenses, contractor fees and contingency | 168,462 | USD |

| Working capital | 100,275 | USD |

| Total capital investment | 672,511 | USD |

| Variable operating cost | 889,600 | USD/y |

| Fixed operating costs dependent on annual indirect operating cost: maintenance, capital charges, insurance, local taxes and royalties | 5475 | USD/y |

| Fixed operating costs dependent on labor cost: personnel, laboratory, supervision, and plant overhead costs | 475,000 | USD/y |

| Miscellaneous operating costs: sales expenses, general overheads and research and development | 274,015 | USD/y |

| Total operating cost (Opex on an annual basis) | 1,644,090 | USD/y |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sadhukhan, J.; Sekar, K. Economic Conditions to Circularize Clinical Plastics. Energies 2022, 15, 8974. https://doi.org/10.3390/en15238974

Sadhukhan J, Sekar K. Economic Conditions to Circularize Clinical Plastics. Energies. 2022; 15(23):8974. https://doi.org/10.3390/en15238974

Chicago/Turabian StyleSadhukhan, Jhuma, and Kartik Sekar. 2022. "Economic Conditions to Circularize Clinical Plastics" Energies 15, no. 23: 8974. https://doi.org/10.3390/en15238974

APA StyleSadhukhan, J., & Sekar, K. (2022). Economic Conditions to Circularize Clinical Plastics. Energies, 15(23), 8974. https://doi.org/10.3390/en15238974