Power Plant Cycles: Evolution towards More Sustainable and Environmentally Friendly Technologies

Abstract

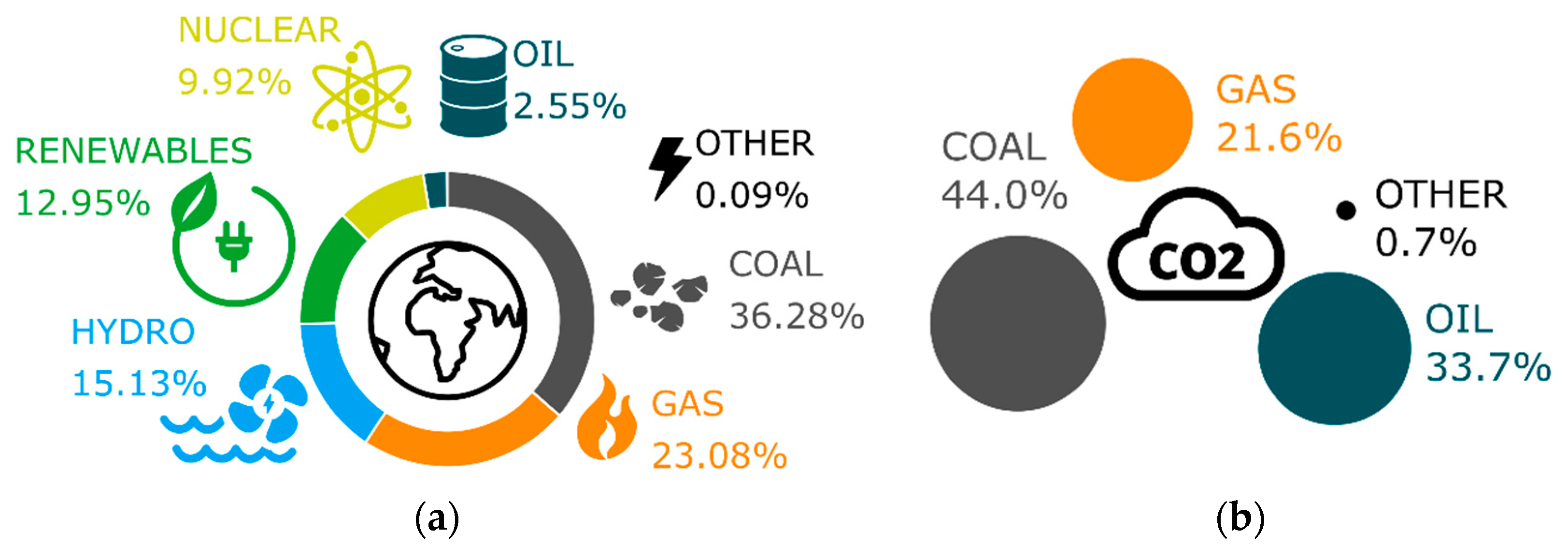

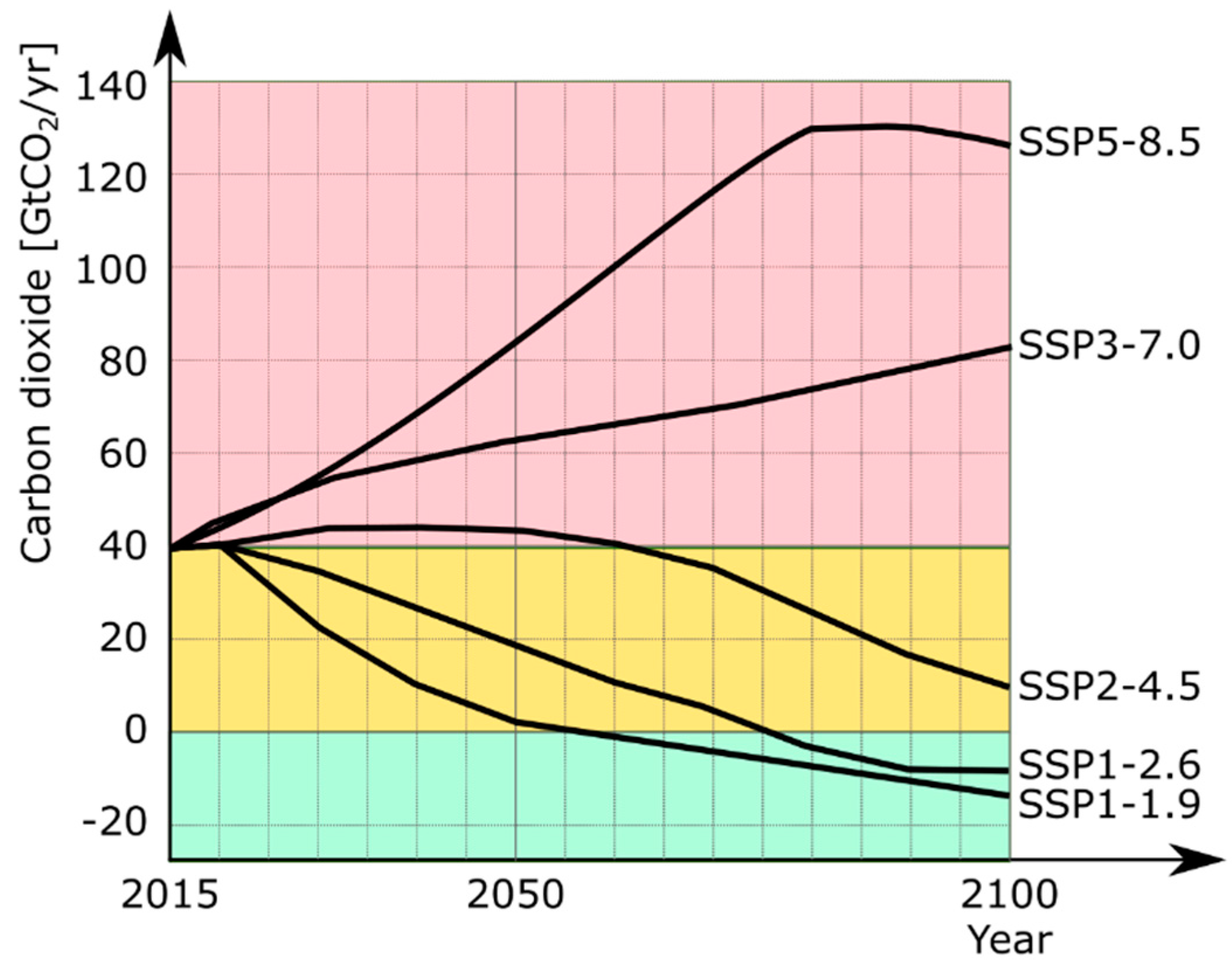

1. Introduction

2. Power Plant Thermodynamic Cycles

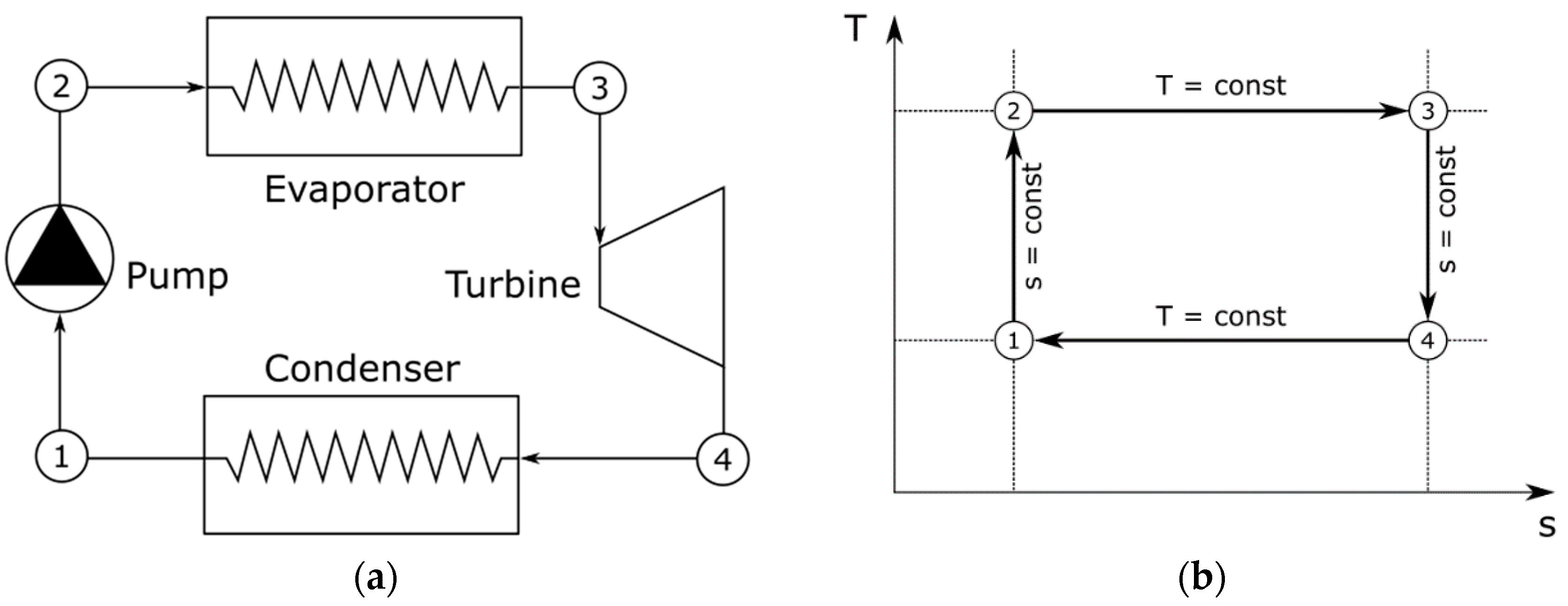

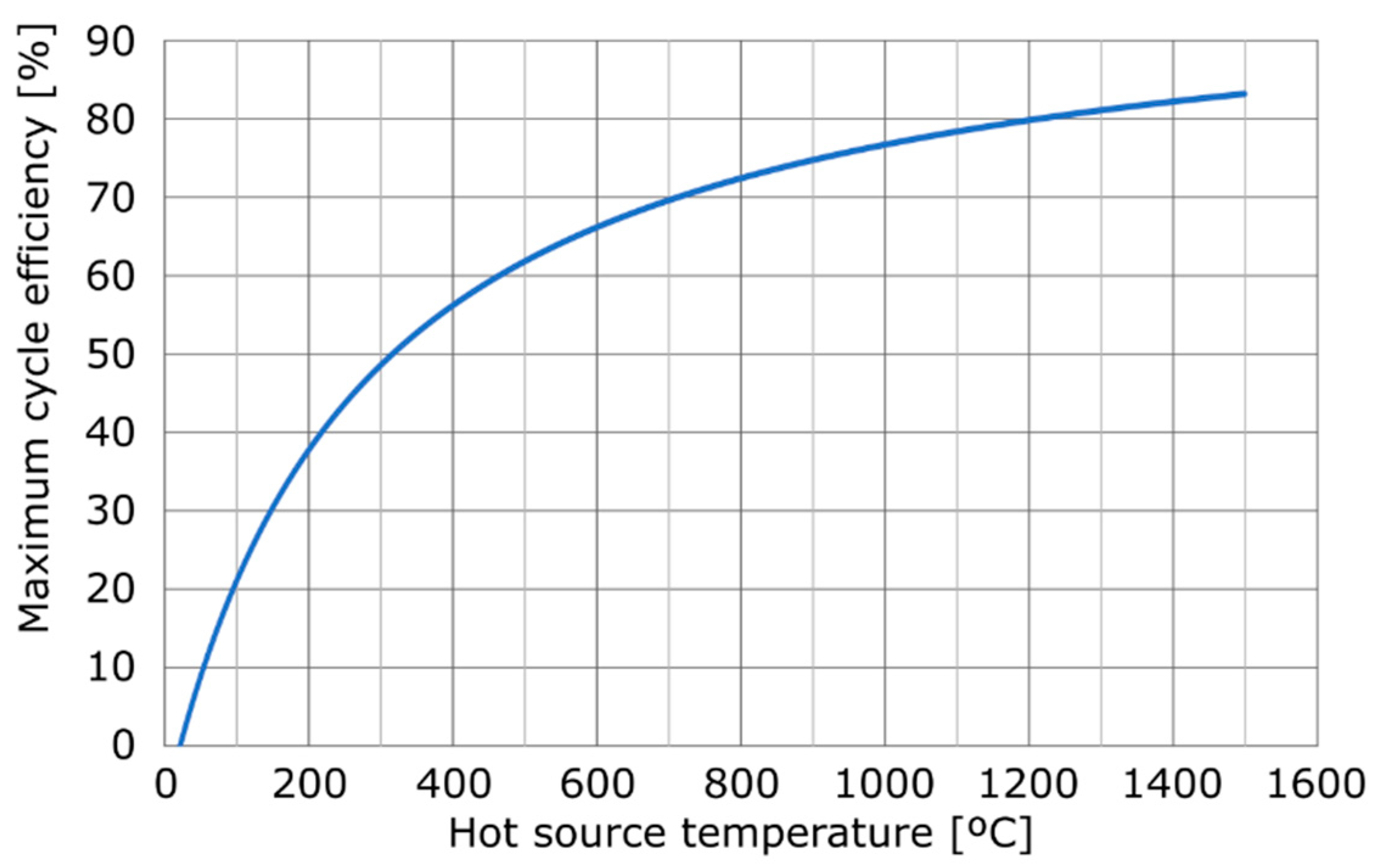

2.1. Carnot Cycle: Theoretical Reference

2.2. Stirling Cycle

2.3. Brayton Cycles

2.3.1. Simple Brayton Cycle

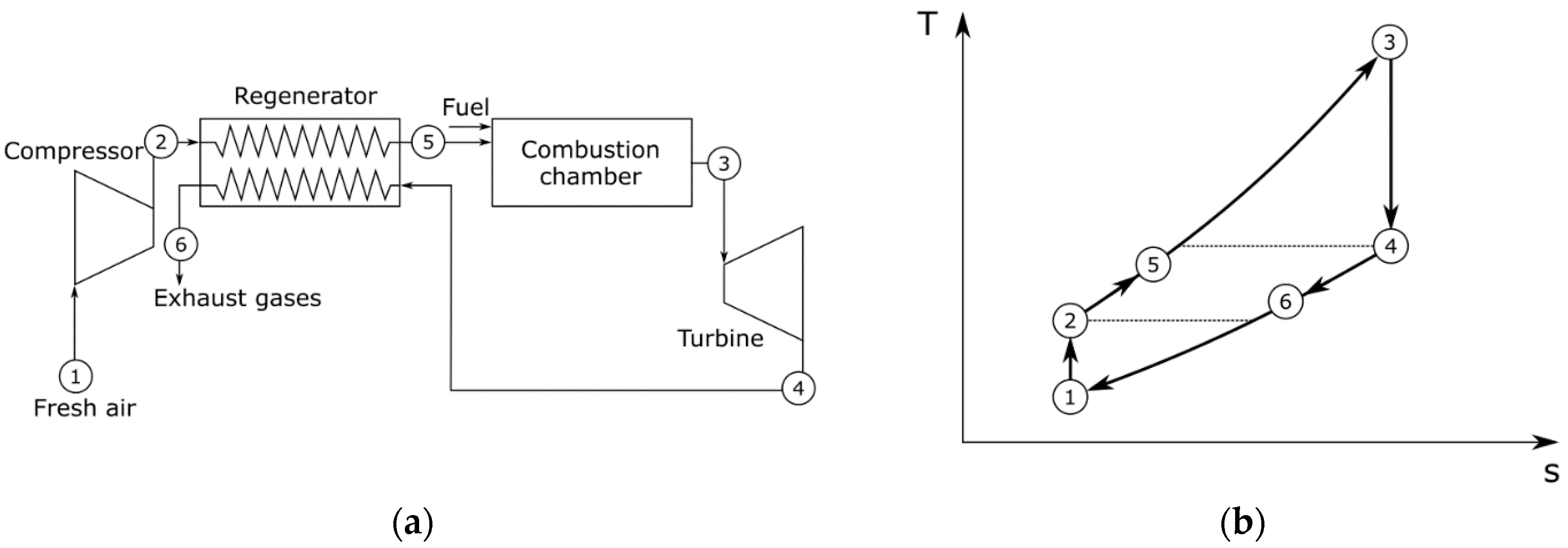

2.3.2. Regenerative Brayton Cycle

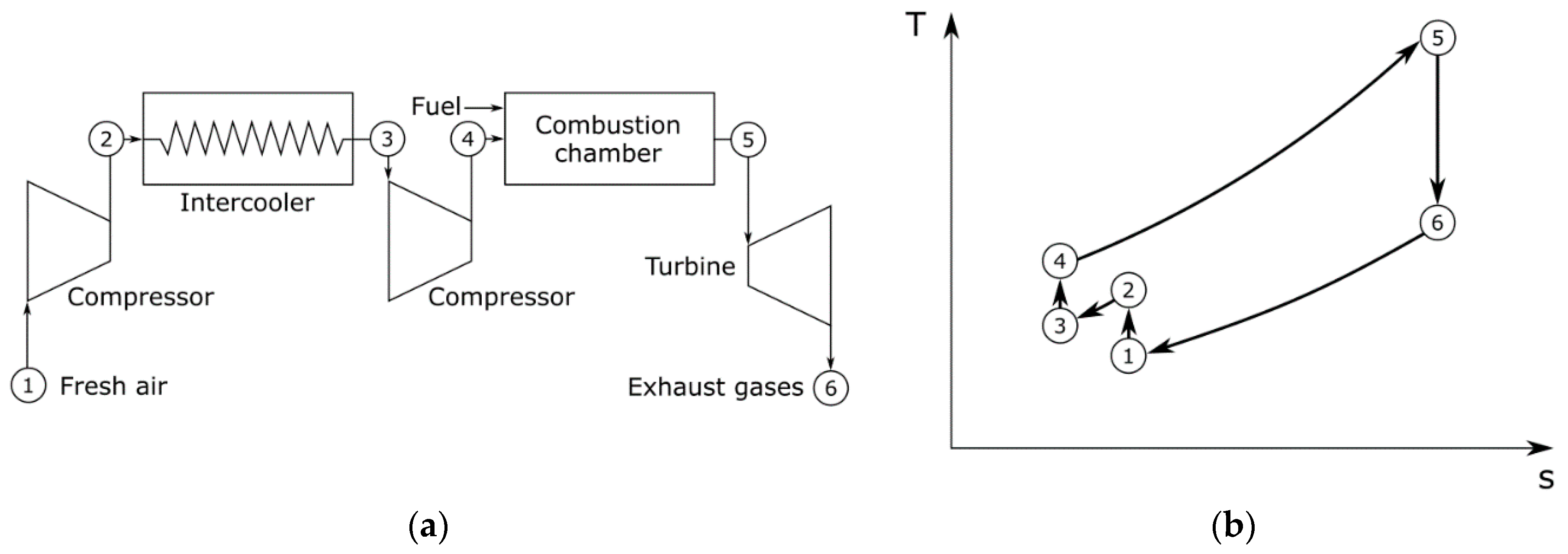

2.3.3. Brayton Cycle with Intercooling in the Compression

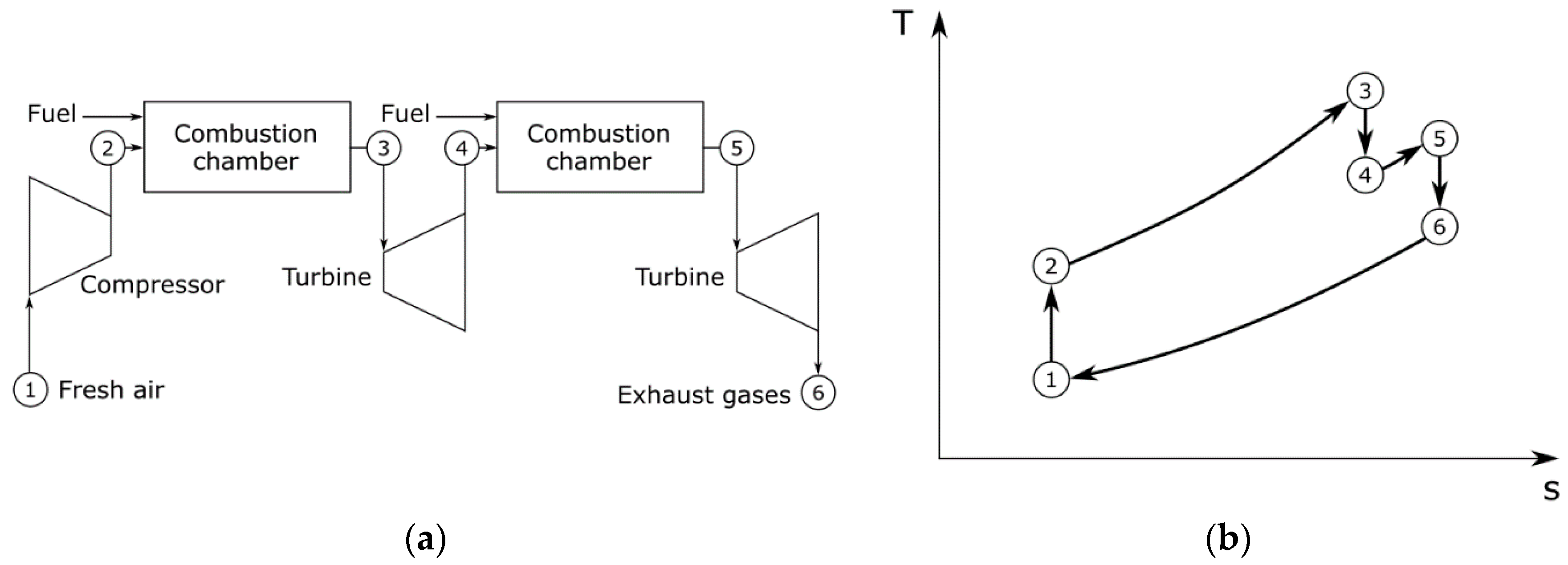

2.3.4. Brayton Cycle with Reheating

2.3.5. Recent Advances in Brayton Cycles

2.3.6. Supercritical CO2 Cycles

2.4. Rankine Cycles

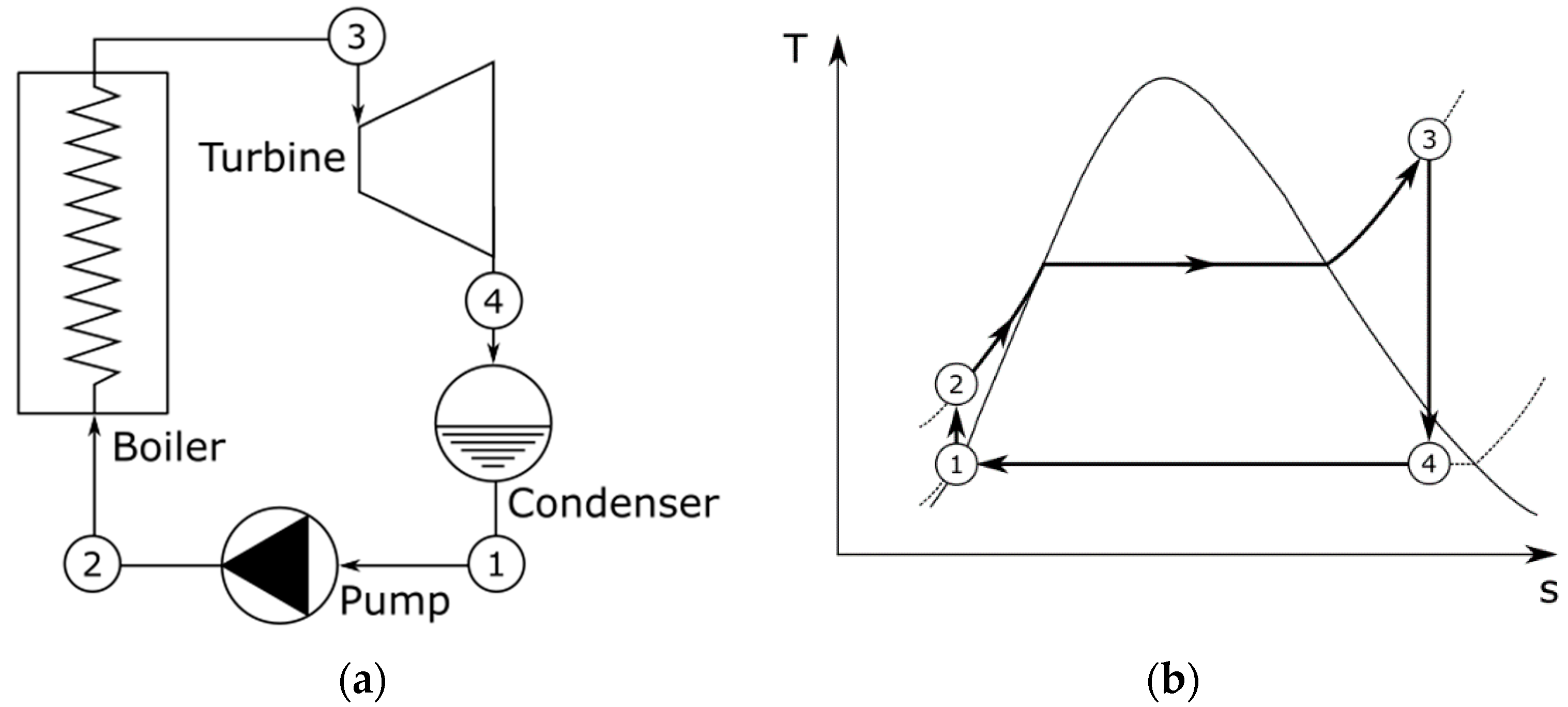

2.4.1. Original Rankine Cycle

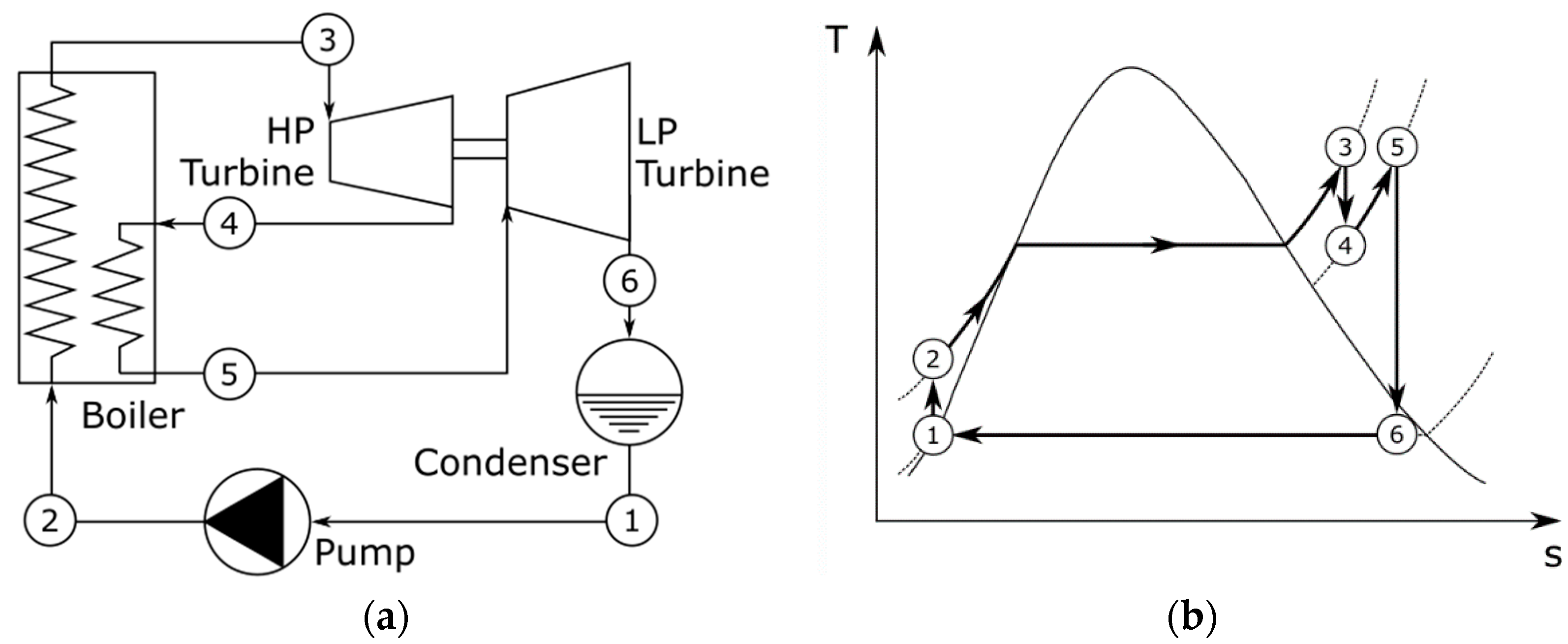

2.4.2. Rankine Cycle with Reheating

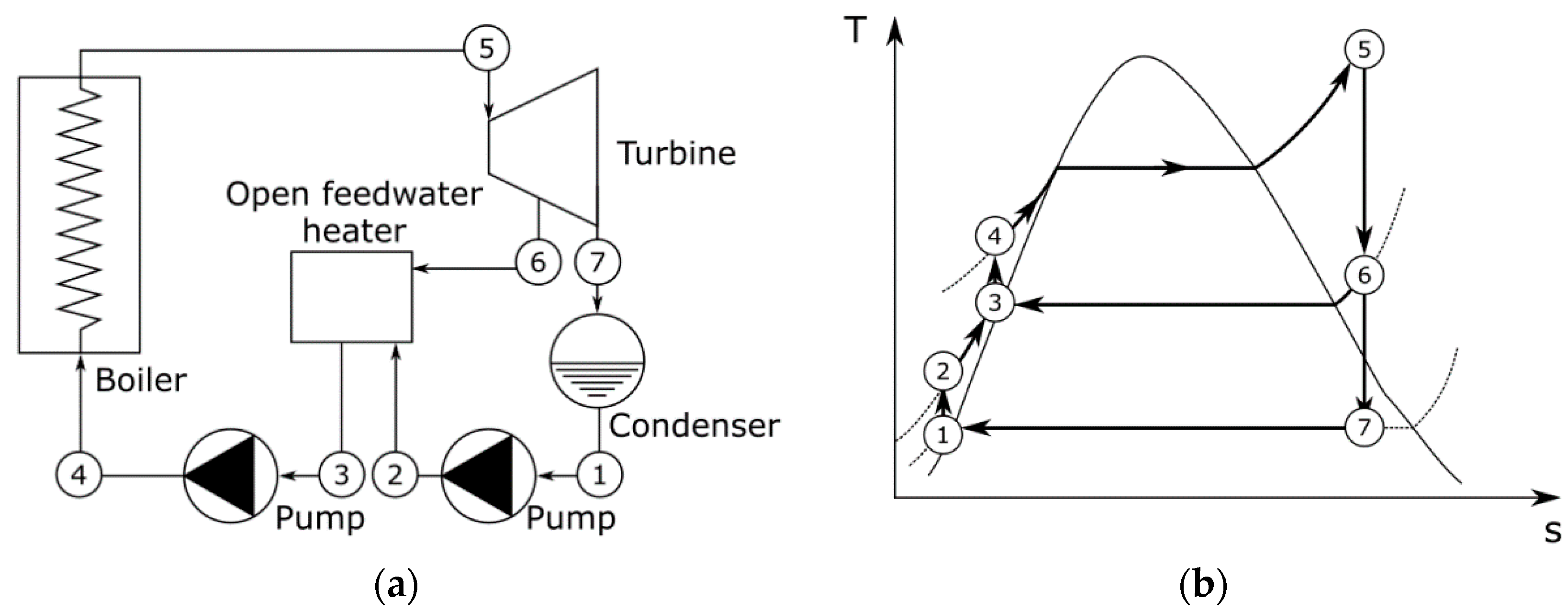

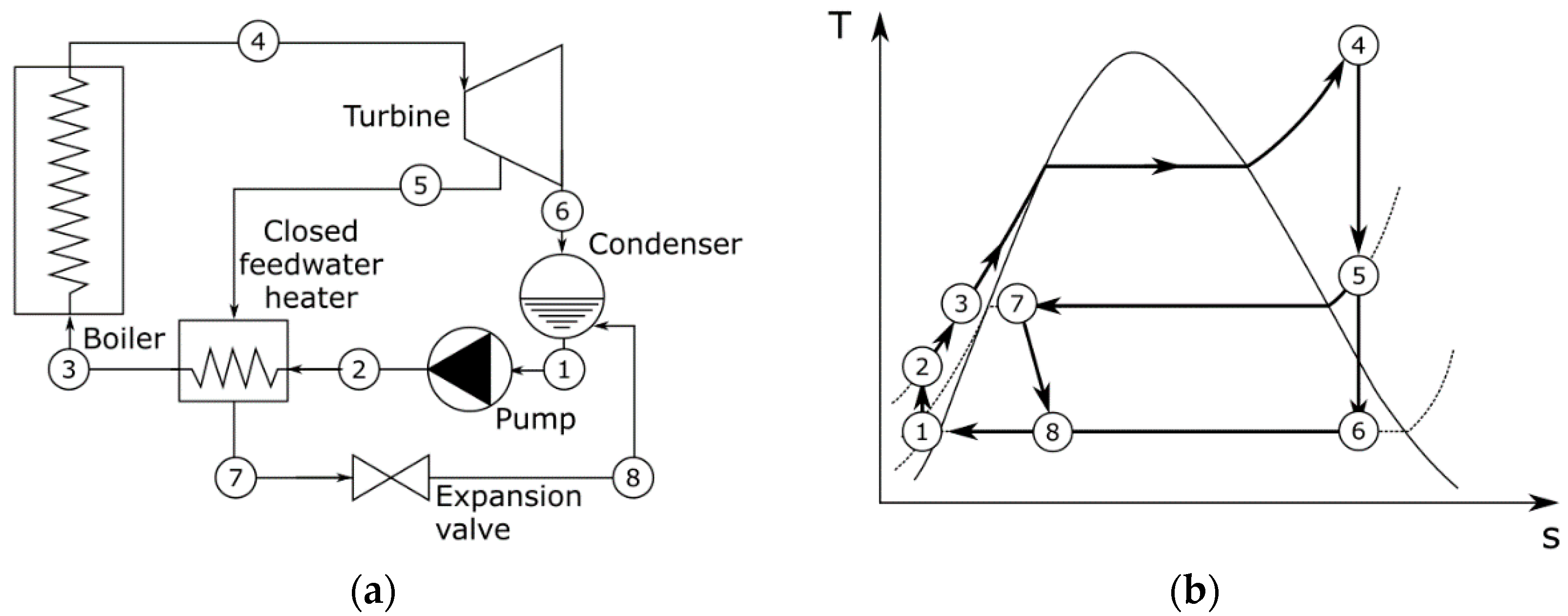

2.4.3. Regenerative Rankine Cycle

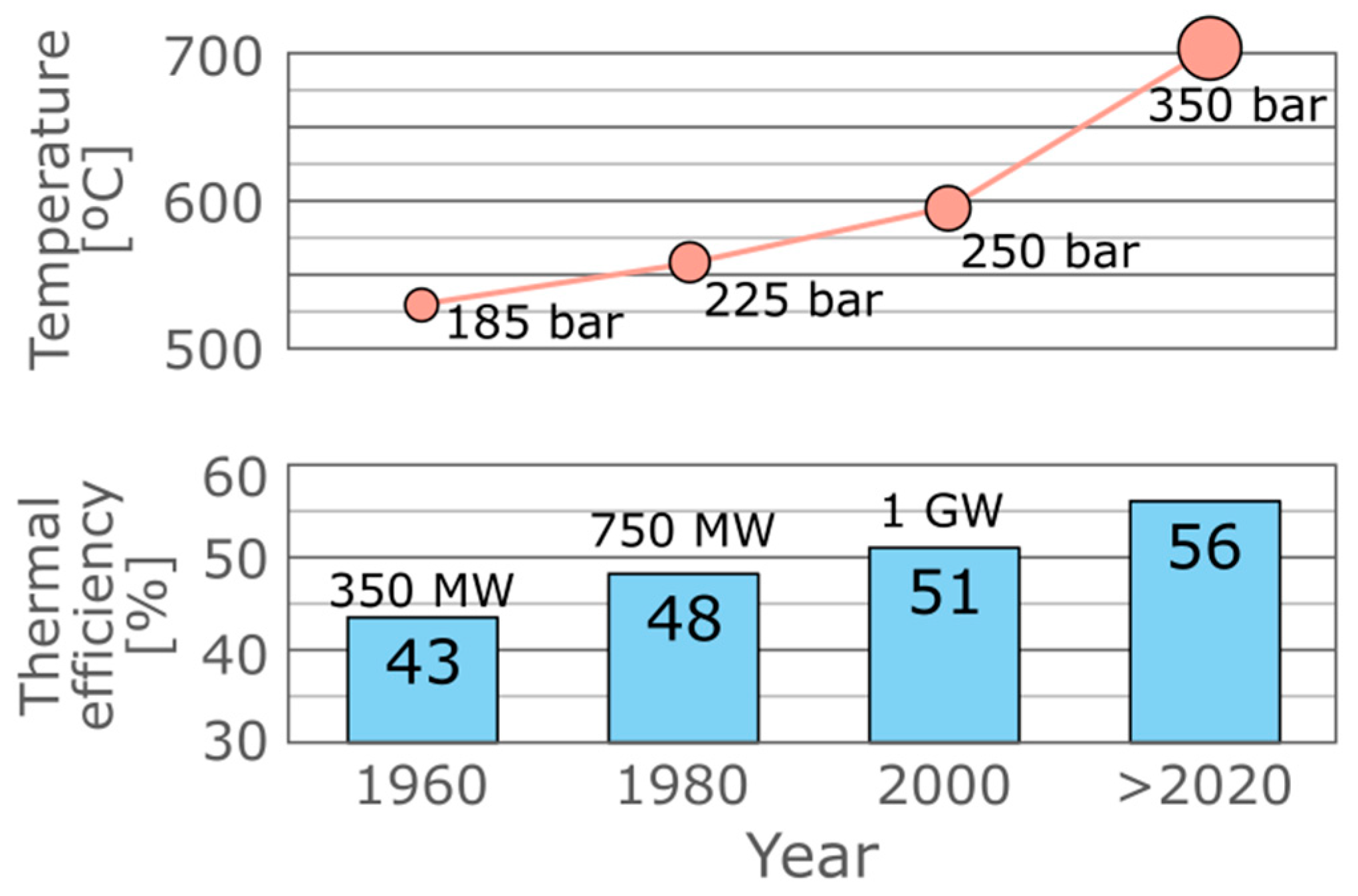

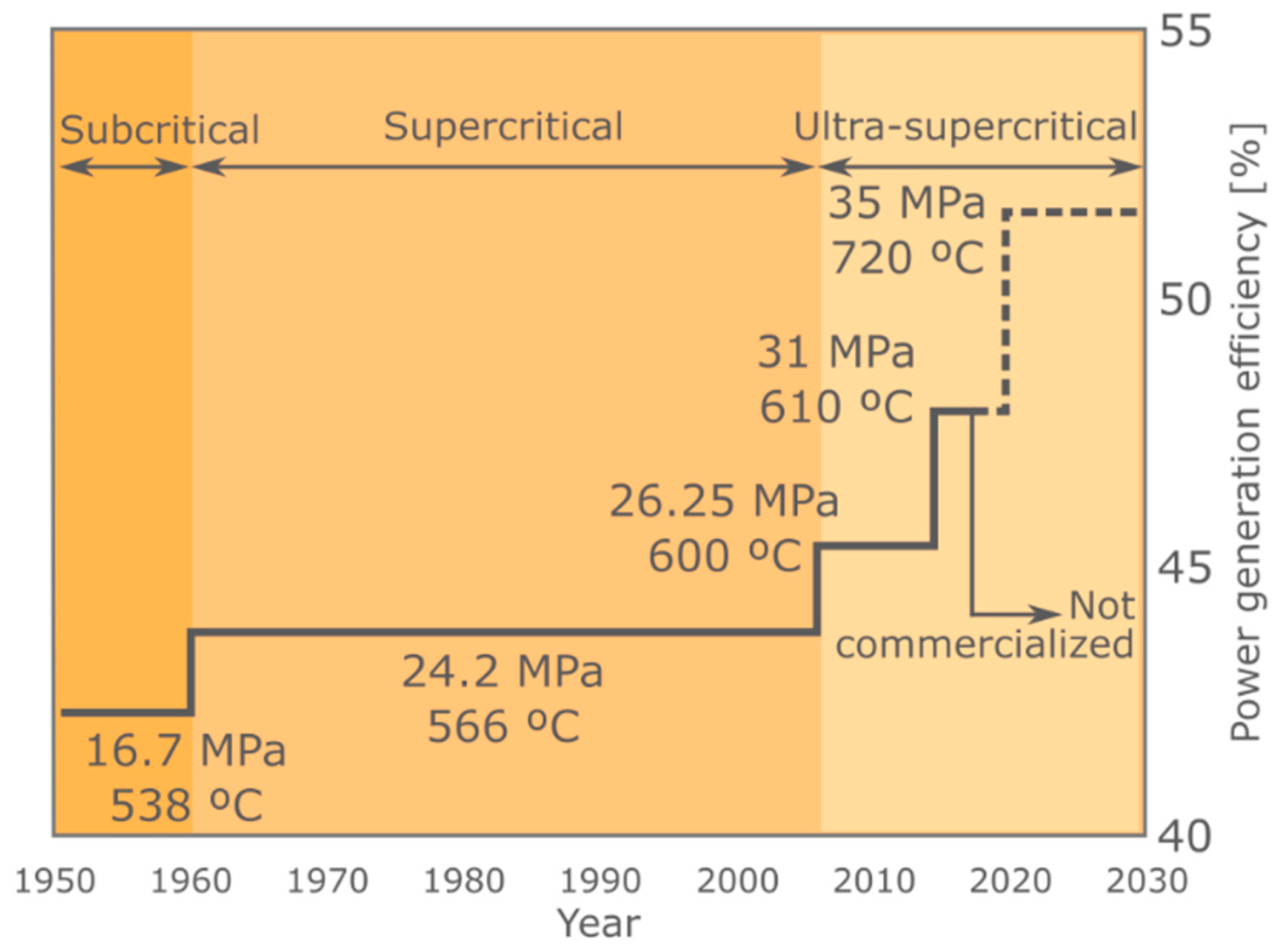

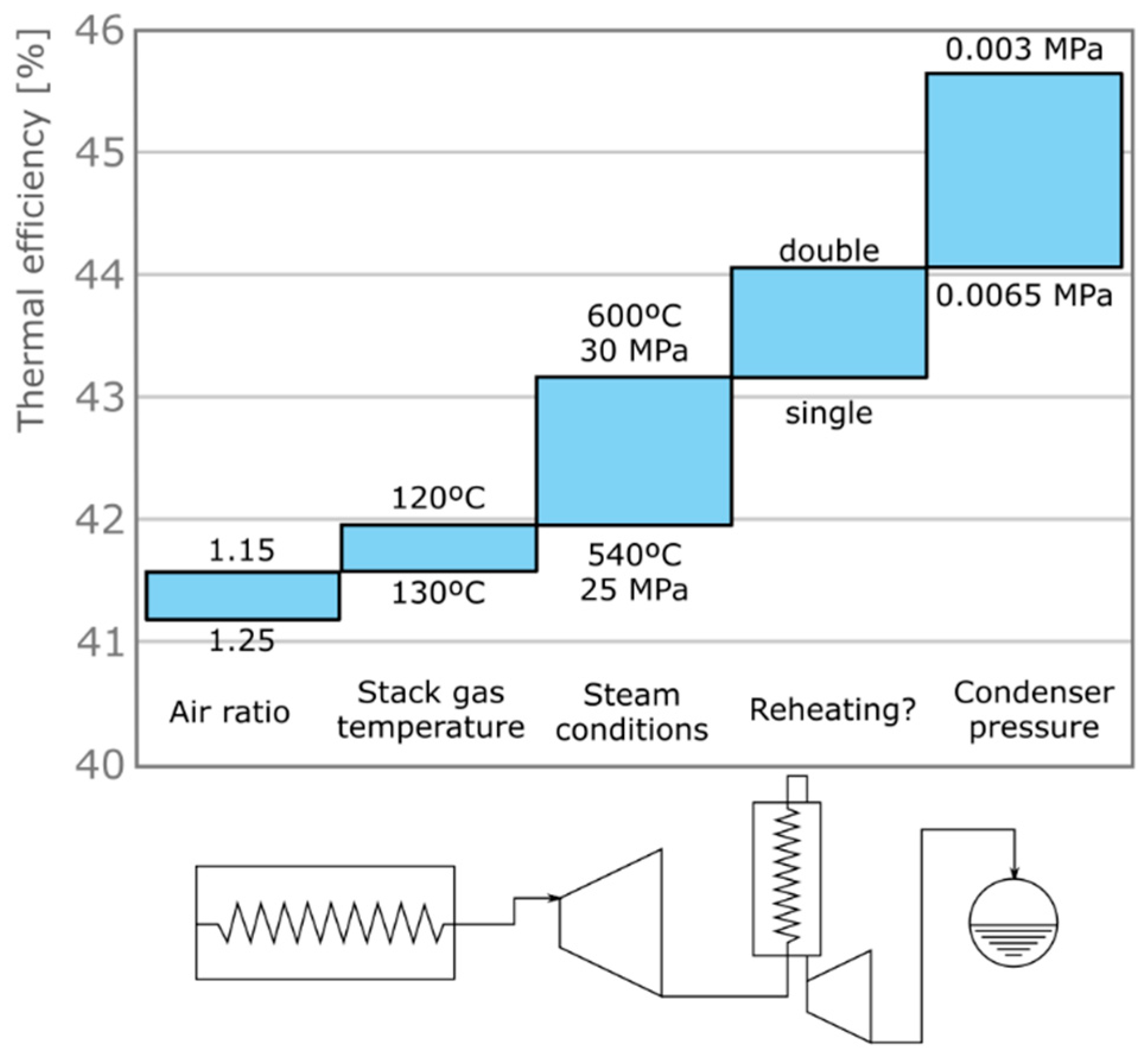

2.4.4. Increasing the Efficiency of Rankine Cycles

2.4.5. Critical and Supercritical Rankine Cycles

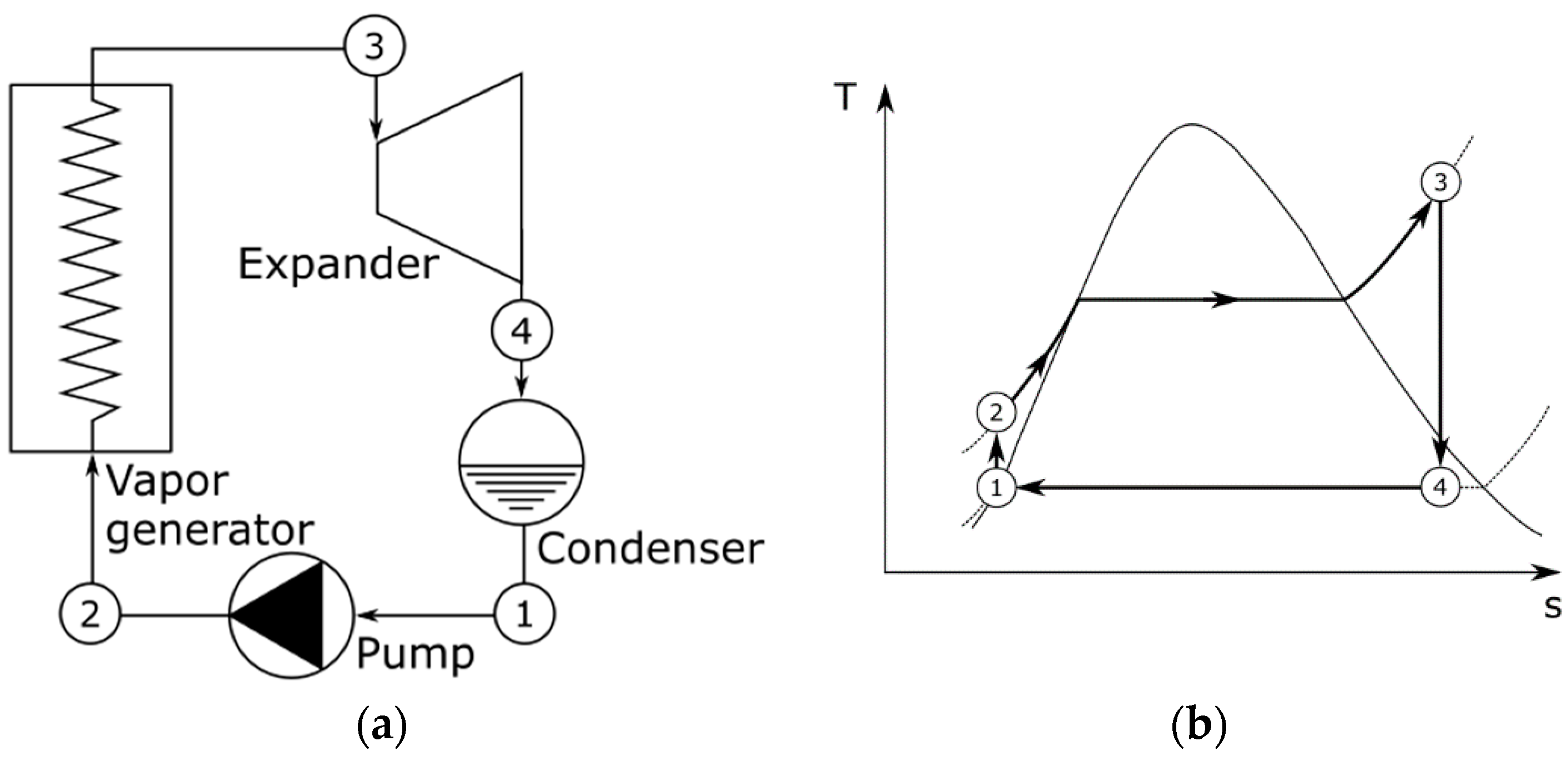

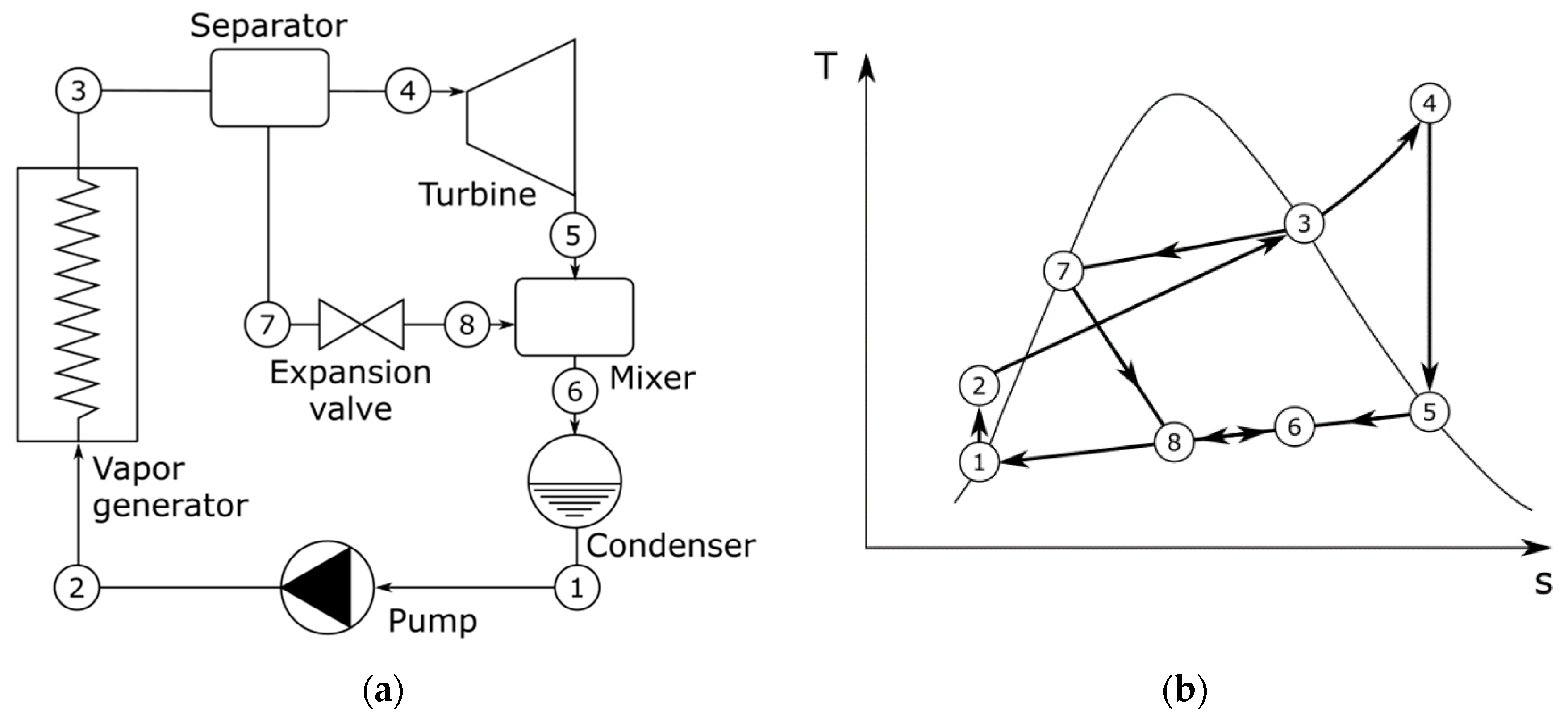

2.4.6. Organic Rankine Cycles (ORCs)

2.5. Absorption Power Cycles

2.5.1. Kalina Cycle

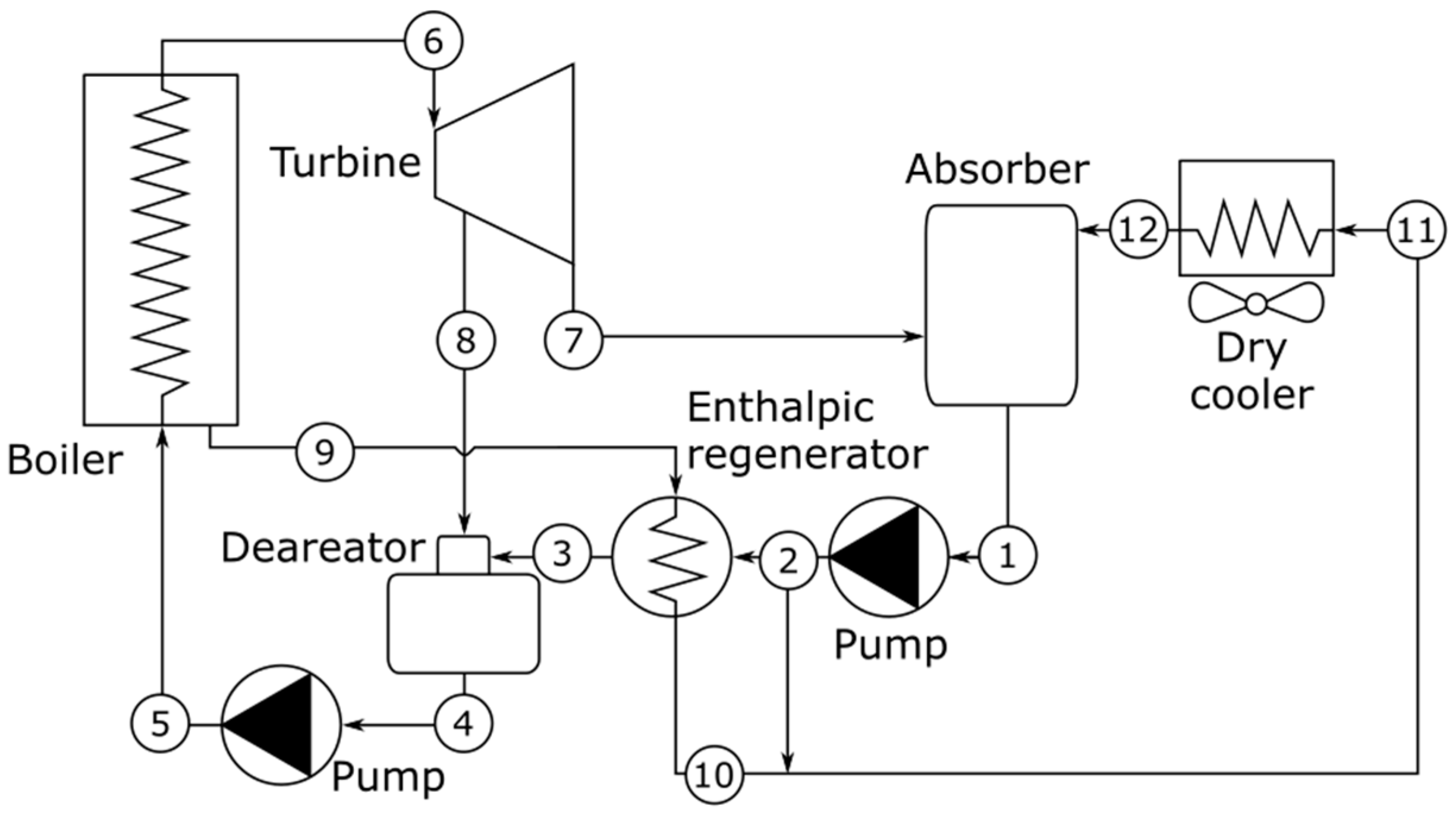

2.5.2. Hygroscopic Cycle

2.6. Combined Cycles

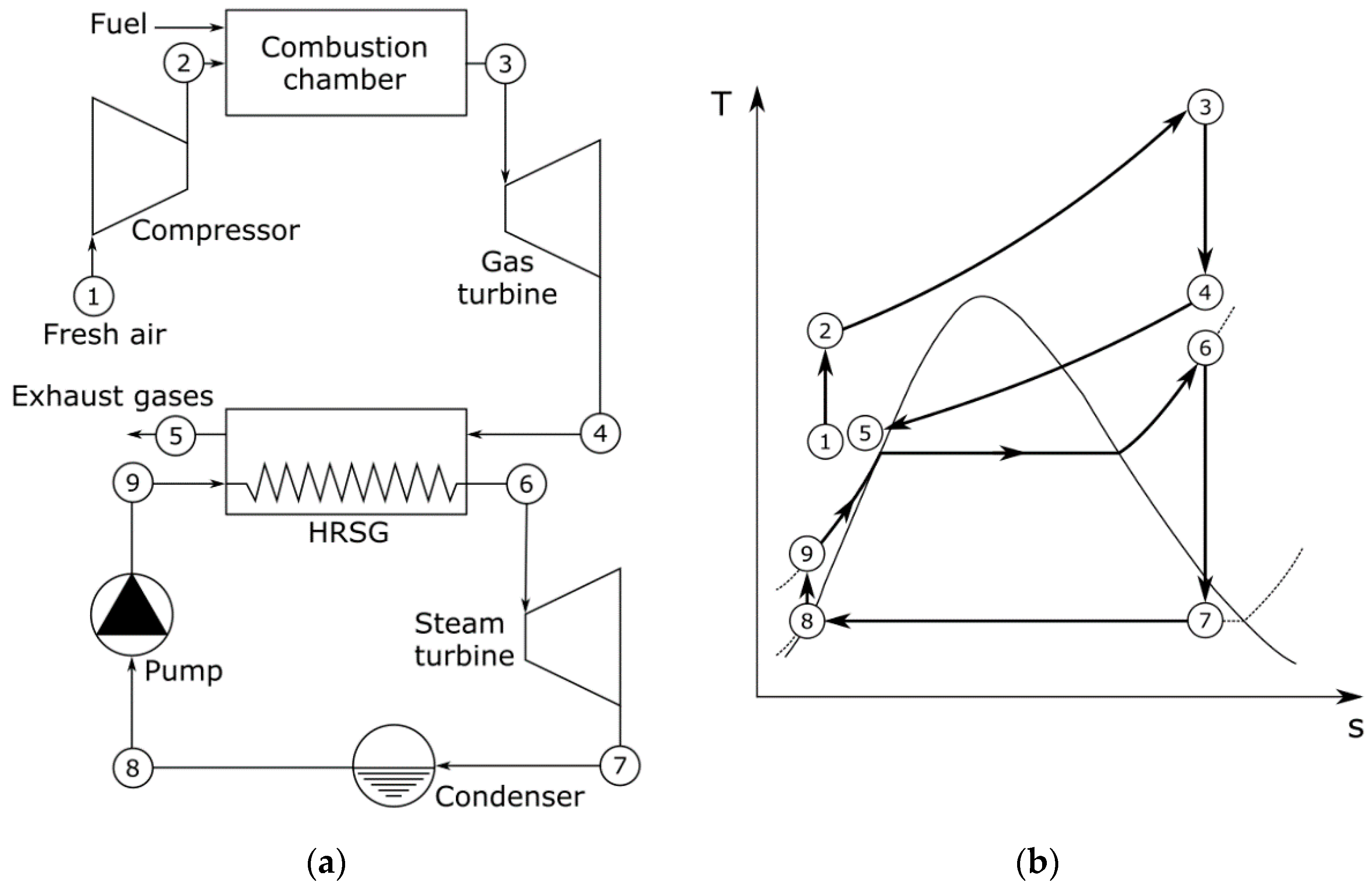

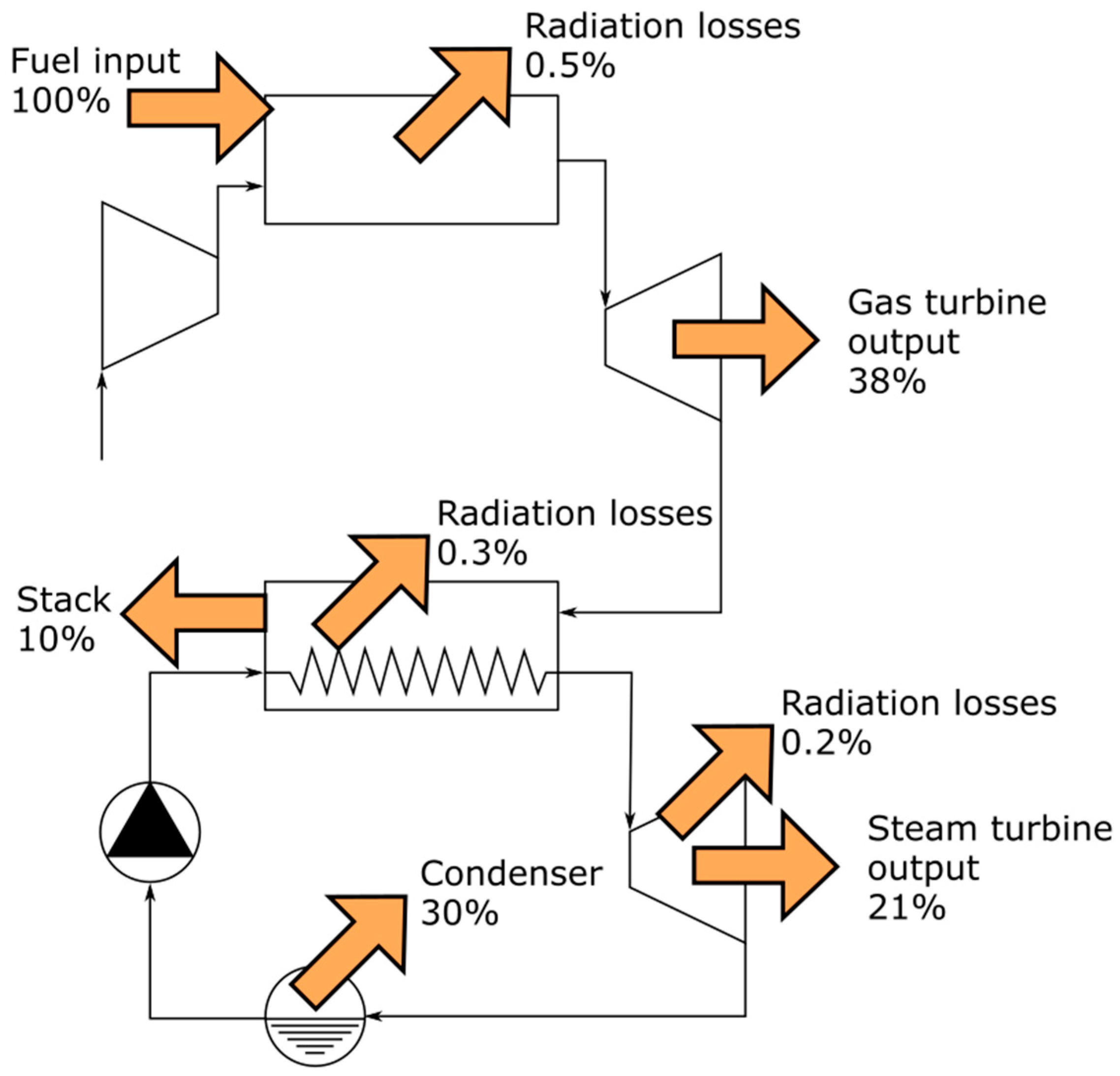

2.6.1. Typical Combined Cycle: Brayton & Rankine

2.6.2. Alternative Combined Cycles

2.6.3. Carbon Capture in Combined Cycles

2.6.4. Goswami Cycle

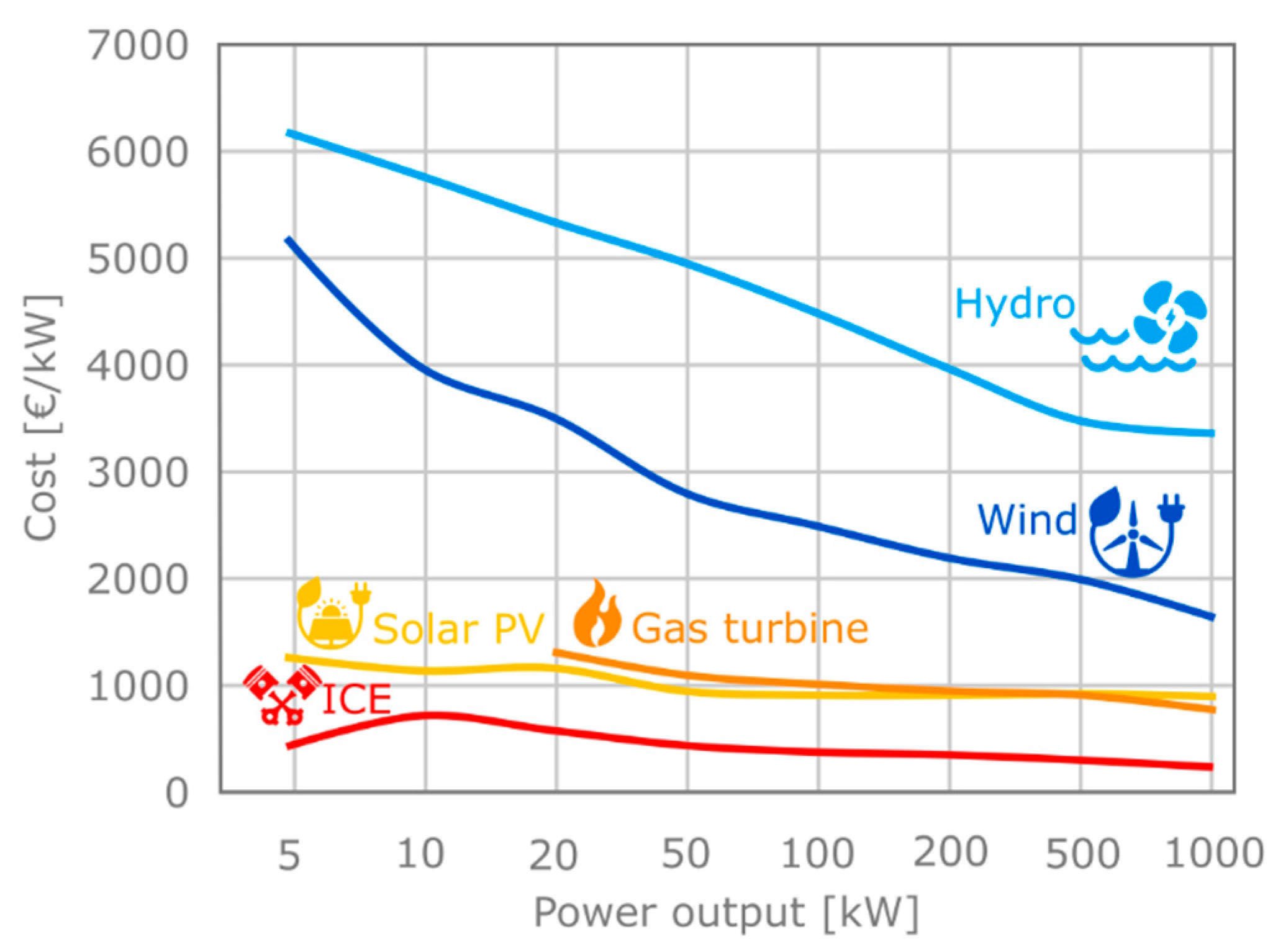

3. Power Cycle Applications: Comparison of Performance and Environmental Aspects

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- British Petroleum Statistical Review of World Energy. 2022. Available online: https://www.bp.com/content/dam/bp/business-sites/en/global/corporate/pdfs/energy-economics/statistical-review/bp-stats-review-2022-full-report.pdf (accessed on 27 October 2022).

- Energy Agency, I. Key World Energy Statistics. 2021. Available online: https://iea.blob.core.windows.net/assets/52f66a88-0b63-4ad2-94a5-29d36e864b82/KeyWorldEnergyStatistics2021.pdf (accessed on 27 October 2022).

- Masson-Delmotte, V.; Zhai, P.; Chen, Y.; Goldfarb, L.; Gomis, M.I.; Matthews, J.B.R.; Berger, S.; Huang, M.; Yelekçi, O.; Yu, R.; et al. Climate Change 2021 The Physical Science Basis. Available online: https://www.ipcc.ch/report/ar6/wg1/downloads/report/IPCC_AR6_WGI_SPM_final.pdf (accessed on 28 October 2022).

- Riahi, K.; van Vuuren, D.P.; Kriegler, E.; Edmonds, J.; O’Neill, B.C.; Fujimori, S.; Bauer, N.; Calvin, K.; Dellink, R.; Fricko, O.; et al. The Shared Socioeconomic Pathways and Their Energy, Land Use, and Greenhouse Gas Emissions Implications: An Overview. Glob. Environ. Chang. 2017, 42, 153–168. [Google Scholar] [CrossRef]

- UNESCO. Valuing Water. Available online: https://unesdoc.unesco.org/ark:/48223/pf0000375724 (accessed on 21 October 2022).

- Giovannelli, A. State of the Art on Small-Scale Concentrated Solar Power Plants. Energy Procedia 2015, 82, 607–614. [Google Scholar] [CrossRef]

- Allouhi, H.; Allouhi, A.; Buker, M.S.; Zafar, S.; Jamil, A. Recent Advances, Challenges, and Prospects in Solar Dish Collectors: Designs, Applications, and Optimization Frameworks. Sol. Energy Mater. Sol. Cells 2022, 241, 111743. [Google Scholar] [CrossRef]

- Sadrameli, S.M. Mathematical Models for the Simulation of Thermal Regenerators: A State-of-the-Art Review. Renew. Sustain. Energy Rev. 2016, 58, 462–476. [Google Scholar] [CrossRef]

- Turner, M.; Iyengar, A.; Woods, M. Cost and Performance Baseline for Fossil Energy Plants Supplement: Sensitivity to CO2 Capture Rate in Coal-Fired Power Plants; National Energy Technology Laboratory: Albany, OR, USA, 2020. [Google Scholar]

- Kumar, N.; Besuner, P.; Lefton, S.; Agan, D.; Hilleman, D. Power Plant Cycling Costs. Available online: http://www.osti.gov/bridge (accessed on 3 November 2022).

- Alsarayreh, M.; Mohamed, O.; Matar, M. Modeling a Practical Dual-Fuel Gas Turbine Power Generation System Using Dynamic Neural Network and Deep Learning. Sustainability 2022, 14, 870. [Google Scholar] [CrossRef]

- Asgari, H.; Chen, X.Q.; Morini, M.; Pinelli, M.; Sainudiin, R.; Spina, P.R.; Venturini, M. NARX Models for Simulation of the Start-up Operation of a Single-Shaft Gas Turbine. Appl. Therm. Eng. 2016, 93, 368–376. [Google Scholar] [CrossRef]

- Ben Rahmoune, M.; Hafaifa, A.; Kouzou, A.; Chen, X.Q.; Chaibet, A. Gas Turbine Monitoring Using Neural Network Dynamic Nonlinear Autoregressive with External Exogenous Input Modelling. Math Comput. Simul. 2021, 179, 23–47. [Google Scholar] [CrossRef]

- Yin, F.; Rao, A.G. A Review of Gas Turbine Engine with Inter-Stage Turbine Burner. Prog. Aerosp. Sci. 2020, 121, 100695. [Google Scholar] [CrossRef]

- Goldmer, J. Hydrogen as a Fuel for Gas Turbines. Available online: www.ge.com/gas-power/future-of-energy (accessed on 3 November 2022).

- Zhu, S.; Ma, Z.; Zhang, K.; Deng, K. Energy and Exergy Analysis of the Combined Cycle Power Plant Recovering Waste Heat from the Marine Two-Stroke Engine under Design and off-Design Conditions. Energy 2020, 210, 558. [Google Scholar] [CrossRef]

- Holy, F.; Textor, M.; Lechner, S. Gas Turbine Cogeneration Concepts for the Pressureless Discharge of High Temperature Thermal Energy Storage Units. J. Energy Storage 2021, 44, 103283. [Google Scholar] [CrossRef]

- Mohamed, O.; Khalil, A. Progress in Modeling and Control of Gas Turbine Power Generation Systems: A Survey. Energies 2020, 13, 2358. [Google Scholar] [CrossRef]

- Mohamed, O.; Wang, J.; Khalil, A.; Limhabrash, M. Predictive Control Strategy of a Gas Turbine for Improvement of Combined Cycle Power Plant Dynamic Performance and Efficiency. SpringerPlus 2016, 5, 980. [Google Scholar] [CrossRef] [PubMed]

- Ahn, Y.; Bae, S.J.; Kim, M.; Cho, S.K.; Baik, S.; Lee, J.I.; Cha, J.E. Review of Supercritical CO2 Power Cycle Technology and Current Status of Research and Development. Nucl. Eng. Technol. 2015, 47, 647–661. [Google Scholar] [CrossRef]

- Sathish, S.; Kumar, P. Equation of State Based Analytical Formulation for Optimization of SCO2 Brayton Cycle. J. Supercrit. Fluids 2021, 177, 105351. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, Y.; Huang, D. Supercritical CO2 Brayton Cycle: A State-of-the-Art Review. Energy 2019, 189, 115900. [Google Scholar] [CrossRef]

- Thanganadar, D.; Asfand, F.; Patchigolla, K.; Turner, P. Techno-Economic Analysis of Supercritical Carbon Dioxide Cycle Integrated with Coal-Fired Power Plant. Energy Convers Manag. 2021, 242, 114294. [Google Scholar] [CrossRef]

- Filippov, S.P.; Keiko, A.V. Coal Gasification: At the Crossroad. Technological Factors. Therm. Eng. 2021, 68, 209–220. [Google Scholar] [CrossRef]

- Wei, X.; Manovic, V.; Hanak, D.P. Techno-Economic Assessment of Coal- or Biomass-Fired Oxy-Combustion Power Plants with Supercritical Carbon Dioxide Cycle. Energy Convers. Manag. 2020, 221, 113143. [Google Scholar] [CrossRef]

- Du, Y.; Hu, C.; Yang, C.; Wang, H.; Dong, W. Size Optimization of Heat Exchanger and Thermoeconomic Assessment for Supercritical CO2 Recompression Brayton Cycle Applied in Marine. Energy 2022, 239, 306. [Google Scholar] [CrossRef]

- Rodríguez-de Arriba, P.; Crespi, F.; Sánchez, D.; Muñoz, A.; Sánchez, T. The Potential of Transcritical Cycles Based on CO2 Mixtures: An Exergy-Based Analysis. Renew. Energy 2022, 199, 1606–1628. [Google Scholar] [CrossRef]

- Crespi, F.; Sánchez, D.; Rodríguez, J.M.; Gavagnin, G. A Thermo-Economic Methodology to Select SCO2 Power Cycles for CSP Applications. Renew. Energy 2020, 147, 2905–2912. [Google Scholar] [CrossRef]

- Beér, J.M. High Efficiency Electric Power Generation: The Environmental Role. Prog. Energy Combust. Sci. 2007, 33, 107–134. [Google Scholar] [CrossRef]

- Achter, T.; Quinkertz, R.; Baca, M. Increased Efficiency and Flexibility of Large Coal-Fired Power Plants Applied to 350-MW-Class Units. In Proceedings of the Power-Gen Asia, Bangkok, Thailand, 20–22 September 2016; pp. 1–21. [Google Scholar]

- Fan, H.; Zhang, Z.; Dong, J.; Xu, W. China’s R&D of Advanced Ultra-Supercritical Coal-Fired Power Generation for Addressing Climate Change. Therm. Sci. Eng. Prog. 2018, 5, 364–371. [Google Scholar]

- Wu, D.; Sheng, L.; Zhou, D.; Chen, M. Dynamic Stationary Subspace Analysis for Monitoring Nonstationary Dynamic Processes. Ind. Eng. Chem. Res. 2020, 59, 20787–20797. [Google Scholar] [CrossRef]

- Si, Y.; Wang, Y.; Zhou, D. Key-Performance-Indicator-Related Process Monitoring Based on Improved Kernel Partial Least Squares. IEEE Trans. Ind. Electron. 2021, 68, 2626–2636. [Google Scholar] [CrossRef]

- Wu, D.; Zhou, D.; Chen, M.; Zhu, J.; Yan, F.; Zheng, S.; Guo, E. Output-Relevant Common Trend Analysis for KPI-Related Nonstationary Process Monitoring with Applications to Thermal Power Plants. IEEE Trans. Industr. Inform. 2021, 17, 6664–6675. [Google Scholar] [CrossRef]

- Çengel Yunus, A.; Boles Michael, A. Thermodynamics. An Engineering Approach, 8th ed.; McGraw-Hill: New York, NY, USA, 2015. [Google Scholar]

- Michael, J.M.; Howard, N.S.; Daisie, D.B.; Margaret, B.B. Fundamentals of Engineerings Thermodynamics, 8th ed.; Fowley, D., Ed.; Wiley: Hoboken, NJ, USA, 2014. [Google Scholar]

- Meana-Fernández, A.; Peris-Pérez, B.; Gutiérrez-Trashorras, A.J.; Rodríguez-Artime, S.; Ríos-Fernández, J.C.; González-Caballín, J.M. Optimization of the Propulsion Plant of a Liquefied Natural Gas Transport Ship. Energy Convers. Manag. 2020, 224, 113398. [Google Scholar] [CrossRef]

- Znad, O.A.; Mohamed, O.; Elhaija, W.A. Speeding-up Startup Process of a Clean Coal Supercritical Power Generation Station via Classical Model Predictive Control. Process Integr. Optim. Sustain. 2022, 6, 751–764. [Google Scholar] [CrossRef]

- Hussain, C.M.I.; Duffy, A.; Norton, B. Economic Appraisal of Hybrid Solar-Biomass Thermophotovoltaic Power Generation. Proc. Inst. Civ. Eng. Energy 2019, 172, 162–168. [Google Scholar] [CrossRef]

- Al-Maliki, W.A.K.; Hadi, A.S.; Al-Khafaji, H.M.H.; Alobaid, F.; Epple, B. Dynamic Modelling and Advanced Process Control of Power Block for a Parabolic Trough Solar Power Plant. Energies 2022, 15, 129. [Google Scholar] [CrossRef]

- Elsido, C.; Cremonesi, A.; Martelli, E. A Novel Sequential Synthesis Algorithm for the Integrated Optimization of Rankine Cycles and Heat Exchanger Networks. Appl. Therm. Eng. 2021, 192, 116594. [Google Scholar] [CrossRef]

- Nikam, K.C.; Kumar, R.; Jilte, R. Thermodynamic Modeling and Performance Evaluation of a Supercritical Coal-Fired Power Plant Situated in Western India. Energy Sources Part A Recovery Util. Environ. Eff. 2020, 1–19. [Google Scholar] [CrossRef]

- Kong, X.; Liu, X.; Lee, K.Y. An Effective Nonlinear Multivariable HMPC for USC Power Plant Incorporating NFN-Based Modeling. IEEE Trans. Industr. Inform. 2016, 12, 555–566. [Google Scholar] [CrossRef]

- Haddad, A.; Mohamed, O.; Zahlan, M.; Wang, J. Parameter Identification of a Highly Promising Cleaner Coal Power Station. J Clean Prod. 2021, 326, 129323. [Google Scholar] [CrossRef]

- Wu, D.; Zhou, D.; Chen, M. Performance-Driven Component Selection in the Framework of PCA for Process Monitoring: A Dynamic Selection Approach. IEEE Trans. Control. Syst. Technol. 2022, 30, 1171–1185. [Google Scholar] [CrossRef]

- Mohamed, O.; Khalil, A.; Wang, J. Modeling and Control of Supercritical and Ultra-Supercritical Power Plants: A Review. Energies 2020, 13, 2935. [Google Scholar] [CrossRef]

- Haddad, A.; Mohamed, O. Qualitative and Quantitative Comparison of Three Modeling Approaches for a Supercritical Once-through Generation Unit. Int. J. Energy Res. 2022, 46, 20780–20800. [Google Scholar] [CrossRef]

- Al-Momani, A.; Mohamed, O.; Abu Elhaija, W. Multiple Processes Modeling and Identification for a Cleaner Supercritical Power Plant via Grey Wolf Optimizer. Energy 2022, 252, 124090. [Google Scholar] [CrossRef]

- Draganescu, M.; Guo, S.; Wojcik, J.; Wang, J.; Liu, X.; Hou, G.; Xue, Y.; Gao, Q. Generalized Predictive Control for Superheated Steam Temperature Regulation in a Supercritical Coal-Fired Power Plant. CSEE J. Power Energy Syst. 2015, 1, 69–77. [Google Scholar] [CrossRef]

- Liu, X.J.; Kong, X.B.; Hou, G.L.; Wang, J.H. Modeling of a 1000 MW Power Plant Ultra Super-Critical Boiler System Using Fuzzy-Neural Network Methods. Energy Convers. Manag. 2013, 65, 518–527. [Google Scholar] [CrossRef]

- Deng, K.; Yang, C.; Chen, H.; Zhou, N.; Huang, S. Start-Up and Dynamic Processes Simulation of Supercritical Once-through Boiler. Appl. Therm. Eng. 2017, 115, 937–946. [Google Scholar] [CrossRef]

- Kumar, R.; Jilte, R.; Ahmadi, M.H.; Kaushal, R. A Simulation Model for Thermal Performance Prediction of a Coal-Fired Power Plant. Int. J. Low-Carbon Technol. 2019, 14, 122–134. [Google Scholar] [CrossRef]

- Wang, Y.; Cao, L.; Hu, P.; Li, B.; Li, Y. Model Establishment and Performance Evaluation of a Modified Regenerative System for a 660 MW Supercritical Unit Running at the IPT-Setting Mode. Energy 2019, 179, 890–915. [Google Scholar] [CrossRef]

- Yang, C.; Zhang, Z.; Wu, H.; Deng, K. Dynamic Characteristics Analysis of a 660 MW Ultra-Supercritical Circulating Fluidized Bed Boiler. Energies 2022, 15, 4049. [Google Scholar] [CrossRef]

- Han, Y.; Song, Y.H. Condition Monitoring Techniques for Electrical Equipment—A Literature Survey. IEEE Trans. Power Deliv. 2003, 18, 4–13. [Google Scholar] [CrossRef]

- Zhang, Y.; Dong, Z.Y.; Kong, W.; Meng, K. A Composite Anomaly Detection System for Data-Driven Power Plant Condition Monitoring. IEEE Trans. Industr. Inform. 2020, 16, 4390–4402. [Google Scholar] [CrossRef]

- Invernizzi, C.M. Closed Power Cycles: Thermodynamic Fundamentals and Applications; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Ofeldt, F.W. Engine. U.S. Patent No. 611,792, 4 October 1898. [Google Scholar]

- Casati, E.I.M. New Concepts FOR Organic Rankine Cycle Power Systems; Review Publishing & Printing Company: Philadelphia, PA, USA, 2014; ISBN 9789462593305. [Google Scholar]

- Pereira, J.S.; Ribeiro, J.B.; Mendes, R.; Vaz, G.C.; André, J.C. ORC Based Micro-Cogeneration Systems for Residential Application—A State of the Art Review and Current Challenges. Renew. Sustain. Energy Rev. 2018, 92, 728–743. [Google Scholar] [CrossRef]

- Liu, L.; Zhu, T.; Gao, N.; Gan, Z. A Review of Modeling Approaches and Tools for the Off-Design Simulation of Organic Rankine Cycle. J. Therm. Sci. 2018, 27, 305–320. [Google Scholar] [CrossRef]

- Iglesias Garcia, S.; Ferreiro Garcia, R.; Carbia Carril, J.; Iglesias Garcia, D. A Review of Thermodynamic Cycles Used in Low Temperature Recovery Systems over the Last Two Years. Renew. Sustain. Energy Rev. 2018, 81, 760–767. [Google Scholar] [CrossRef]

- Kumar, A.; Rakshit, D. A Critical Review on Waste Heat Recovery Utilization with Special Focus on Organic Rankine Cycle Applications. Clean Eng. Technol. 2021, 5, 100292. [Google Scholar] [CrossRef]

- Chen, H.; Goswami, D.Y.; Stefanakos, E.K. A Review of Thermodynamic Cycles and Working Fluids for the Conversion of Low-Grade Heat. Renew. Sustain. Energy Rev. 2010, 14, 3059–3067. [Google Scholar] [CrossRef]

- Yazawa, K.; Shakouri, A. Heat Flux Based Optimization of Combined Heat and Power Thermoelectric Heat Exchanger. Energies 2021, 14, 791. [Google Scholar] [CrossRef]

- Qyyum, M.A.; Khan, A.; Ali, S.; Khurram, M.S.; Mao, N.; Naquash, A.; Noon, A.A.; He, T.; Lee, M. Assessment of Working Fluids, Thermal Resources and Cooling Utilities for Organic Rankine Cycles: State-of-the-Art Comparison, Challenges, Commercial Status, and Future Prospects. Energy Convers Manag. 2022, 252, 115055. [Google Scholar] [CrossRef]

- Oyekale, J.; Heberle, F.; Petrollese, M.; Brüggemann, D.; Cau, G. Biomass Retrofit for Existing Solar Organic Rankine Cycle Power Plants: Conceptual Hybridization Strategy and Techno-Economic Assessment. Energy Convers. Manag. 2019, 196, 831–845. [Google Scholar] [CrossRef]

- Tocci, L.; Pal, T.; Pesmazoglou, I.; Franchetti, B. Small Scale Organic Rankine Cycle (ORC): A Techno-Economic Review. Energies 2017, 10, 413. [Google Scholar] [CrossRef]

- Nematollahi, O.; Kim, K.C. Real-Gas Effects: The State of the Art of Organic Rankine Cycles. J. Clean Prod. 2020, 277, 124102. [Google Scholar] [CrossRef]

- Eyerer, S.; Dawo, F.; Schifflechner, C.; Niederdränk, A.; Spliethoff, H.; Wieland, C. Experimental Evaluation of an ORC-CHP Architecture Based on Regenerative Preheating for Geothermal Applications. Appl. Energy 2022, 315, 119057. [Google Scholar] [CrossRef]

- Eliasson, L.; Valdimarsson, P.; Ing, S. Factors Influencing the Economics of the Kalina Power Cycle and Situations of Superior Performance. In Proceedings of the International Geothermal Conference, Reykjavík, Iceland, 24–17 September 2003. [Google Scholar]

- Modi, A.; Kærn, M.R.; Andreasen, J.G.; Haglind, F. Thermoeconomic Optimization of a Kalina Cycle for a Central Receiver Concentrating Solar Power Plant. Energy Convers. Manag. 2016, 115, 276–287. [Google Scholar] [CrossRef]

- Król, P.; Krajačić, G. Energy Analysis of Municipal Waste in Dubrovnik. Acta Innov. 2018, 40, 40–48. [Google Scholar] [CrossRef]

- Rubio-Serrano, F.J.; Gutiérrez-Trashorras, A.J.; Soto-Pérez, F.; Álvarez-Álvarez, E.; Blanco-Marigorta, E. Advantages of Incorporating Hygroscopic Cycle Technology to a 12.5-MW Biomass Power Plant. Appl. Therm. Eng. 2018, 131, 320–327. [Google Scholar] [CrossRef]

- Rubio-Serrano, F.J.; Soto-Pérez, F.; Gutiérrez-Trashorras, A.J. Influence of Cooling Temperature Increase in a Hygroscopic Cycle on the Performance of the Cooling Equipment. Energy Convers. Manag. 2019, 200, 112080. [Google Scholar] [CrossRef]

- Rubio-Serrano, F.J.; Soto-Pérez, F.; Gutiérrez-Trashorras, A.J. Experimental Study on the Influence of the Saline Concentration in the Electrical Performance of a Hygroscopic Cycle. Appl. Therm. Eng. 2020, 165, 114588. [Google Scholar] [CrossRef]

- Gülen, S.C. Steam Turbine—Quo Vadis? Front Energy Res. 2021, 8, 384. [Google Scholar] [CrossRef]

- Zhang, Z.; Duan, L.; Wang, Z.; Ren, Y. General Performance Evaluation Method of Integrated Solar Combined Cycle (ISCC) System. Energy 2022, 240, 122472. [Google Scholar] [CrossRef]

- Zaversky, F.; Les, I.; Sorbet, P.; Sánchez, M.; Valentin, B.; Brau, J.F.; Siros, F. The Challenge of Solar Powered Combined Cycles–Providing Dispatchability and Increasing Efficiency by Integrating the Open Volumetric Air Receiver Technology. Energy 2020, 194, 116796. [Google Scholar] [CrossRef]

- Martín, M. Challenges and Opportunities of Solar Thermal Energy towards a Sustainable Chemical Industry. Comput. Chem. Eng. 2022, 165, 107926. [Google Scholar] [CrossRef]

- Zaversky, F.; Cabello, F.; Bernardos, A.; Sánchez, M. A Novel High-Efficiency Solar Thermal Power Plant Featuring Electricity Storage–Ideal for the Future Power Grid with High Shares of Renewables. AIP Conf. Proc. 2022, 2445, 060008. [Google Scholar]

- Ortiz, C.; Tejada, C.; Chacartegui, R.; Bravo, R.; Carro, A.; Valverde, J.M.; Valverde, J. Solar Combined Cycle with High-Temperature Thermochemical Energy Storage. Energy Convers. Manag. 2021, 241, 114274. [Google Scholar] [CrossRef]

- Szima, S.; Arnaiz del Pozo, C.; Cloete, S.; Chiesa, P.; Jiménez Alvaro, Á.; Cormos, A.M.; Amini, S. Finding Synergy between Renewables and Coal: Flexible Power and Hydrogen Production from Advanced IGCC Plants with Integrated CO2 Capture. Energy Convers. Manag. 2021, 231, 113866. [Google Scholar] [CrossRef]

- Reyes-Belmonte, M.Á. A Bibliometric Study on Integrated Solar Combined Cycles (ISCC), Trends and Future Based on Data Analytics Tools. Sustainability 2020, 12, 8217. [Google Scholar] [CrossRef]

- Amirante, R.; Bruno, S.; Distaso, E.; la Scala, M.; Tamburrano, P. A Biomass Small-Scale Externally Fired Combined Cycle Plant for Heat and Power Generation in Rural Communities. Renew. Energy Focus 2019, 28, 36–46. [Google Scholar] [CrossRef]

- Bryant, C.; Coats, E.R. Integrating Dairy Manure for Enhanced Resource Recovery at a WRRF: Environmental Life Cycle and Pilot-Scale Analyses. Water Environ. Res. 2021, 93, 2034–2050. [Google Scholar] [CrossRef] [PubMed]

- Yaqoob, H.; Teoh, Y.H.; Ud Din, Z.; Sabah, N.U.; Jamil, M.A.; Mujtaba, M.A.; Abid, A. The Potential of Sustainable Biogas Production from Biomass Waste for Power Generation in Pakistan. J. Clean Prod. 2021, 307, 127250. [Google Scholar] [CrossRef]

- Ancona, M.A.; Bianchi, M.; Branchini, L.; de Pascale, A.; Melino, F.; Peretto, A.; Torricelli, N. Systematic Comparison of Orc and S-Co2 Combined Heat and Power Plants for Energy Harvesting in Industrial Gas Turbines. Energies 2021, 14, 3402. [Google Scholar] [CrossRef]

- Redko, A.; Redko, O.; DiPippo, R. Industrial Waste Heat Resources. In Low-Temperature Energy Systems with Applications of Renewable Energy; Elsevier: Amsterdam, The Netherlands, 2020; pp. 329–362. [Google Scholar]

- Wu, X.; Wang, M.; Shen, J.; Li, Y.; Lawal, A.; Lee, K.Y. Reinforced Coordinated Control of Coal-Fired Power Plant Retrofitted with Solvent Based CO2 Capture Using Model Predictive Controls. Appl. Energy 2019, 238, 495–515. [Google Scholar] [CrossRef]

- Van der Spek, M.; Manzolini, G.; Ramirez, A. New Approach to Techno-Economic Assessment of Power Plants with Carbon Capture and Storage: The Inclusion of Realistic Dispatch Profiles to Calculate Techno-Economics of Part Load Operations. Energy Fuels 2017, 31, 1047–1049. [Google Scholar] [CrossRef]

- Gatti, M.; Martelli, E.; di Bona, D.; Gabba, M.; Scaccabarozzi, R.; Spinelli, M.; Viganò, F.; Consonni, S. Preliminary Performance and Cost Evaluation of Four Alternative Technologies for Post-Combustion CO2 Capture in Natural Gas-Fired Power Plants. Energies 2020, 13, 543. [Google Scholar] [CrossRef]

- Ferguson, S.; Tarrant, A. Molten Carbonate Fuel Cells for 90% Post Combustion CO2 Capture From a New Build CCGT. Front. Energy Res. 2021, 9, 668431. [Google Scholar] [CrossRef]

- Khan, M.N.; Chiesa, P.; Cloete, S.; Amini, S. Integration of Chemical Looping Combustion for Cost-Effective CO2 Capture from State-of-the-Art Natural Gas Combined Cycles. Energy Convers. Manag. X 2020, 7, 100044. [Google Scholar] [CrossRef]

- Akinola, T.E.; Oko, E.; Wu, X.; Ma, K.; Wang, M. Nonlinear Model Predictive Control (NMPC) of the Solvent-Based Post-Combustion CO2 Capture Process. Energy 2020, 213, 8840. [Google Scholar] [CrossRef]

- Marx-Schubach, T.; Schmitz, G. Modeling and Simulation of the Start-up Process of Coal Fired Power Plants with Post-Combustion CO2 Capture. Int. J. Greenh. Gas Control 2019, 87, 44–57. [Google Scholar] [CrossRef]

- Wu, X.; Shen, J.; Li, Y.; Wang, M.; Lawal, A.; Lee, K.Y. Nonlinear Dynamic Analysis and Control Design of a Solvent-Based Post-Combustion CO2 Capture Process. Comput. Chem. Eng. 2018, 115, 397–406. [Google Scholar] [CrossRef]

- Paul Njock, J.; Thierry Sosso, O.; Stouffs, P.; Nzengwa, R. A Comparative Energy Analysis of Idealized Cycles Using an Ammonia-Water Mixture for Combined Power/Cooling. Energy 2022, 261, 5184. [Google Scholar] [CrossRef]

- Rivera, W.; Sánchez-Sánchez, K.; Hernández-Magallanes, J.A.; Jiménez-García, J.C.; Pacheco, A. Modeling of Novel Thermodynamic Cycles to Produce Power and Cooling Simultaneously. Processes 2020, 8, 320. [Google Scholar] [CrossRef]

- Sayyaadi, H.; Khosravanifard, Y.; Sohani, A. Solutions for Thermal Energy Exploitation from the Exhaust of an Industrial Gas Turbine Using Optimized Bottoming Cycles. Energy Convers. Manag. 2020, 207, 112523. [Google Scholar] [CrossRef]

- Ambriz-Díaz, V.M.; Rubio-Maya, C.; Chávez, O.; Ruiz-Casanova, E.; Pastor-Martínez, E. Thermodynamic Performance and Economic Feasibility of Kalina, Goswami and Organic Rankine Cycles Coupled to a Polygeneration Plant Using Geothermal Energy of Low-Grade Temperature. Energy Convers. Manag. 2021, 243, 114362. [Google Scholar] [CrossRef]

- Leveni, M.; Cozzolino, R. Energy, Exergy, and Cost Comparison of Goswami Cycle and Cascade Organic Rankine Cycle/Absorption Chiller System for Geothermal Application. Energy Convers. Manag. 2021, 227, 113598. [Google Scholar] [CrossRef]

- Colakoglu, M.; Durmayaz, A. Energy, Exergy, Economic and Emission Saving Analysis and Multiobjective Optimization of a New Multi-Generation System Based on a Solar Tower with Triple Combined Power Cycle. Sustain. Energy Technol. Assess. 2022, 52, 102289. [Google Scholar] [CrossRef]

- Shankar, R.; Srinivas, T. Options in Kalina Cycle Systems. Energy Procedia 2016, 90, 260–266. [Google Scholar] [CrossRef]

- Sabugal García, S.; Gómez Moñux, F. Centrales Térmicas de Ciclo Combinado; Ediciones Díaz de Santos: Madrid, Spain, 2006. [Google Scholar]

- Feretic, D.; Tomsic, Z. Probabilistic Analysis of Electrical Energy Costs Comparing: Production Costs for Gas, Coal and Nuclear Power Plants. Energy Policy 2005, 33, 5–13. [Google Scholar] [CrossRef]

- Siemens Energy Gas Turbines. Available online: https://www.siemens-energy.com/global/en/offerings/power-generation/gas-turbines.html (accessed on 31 October 2022).

- International Energy Agency. Available online: https://www.iea.org/ (accessed on 20 June 2021).

- Comisión Nacional de la Energía. Chile Informe de Costos de Tecnologías de Generación; Informe Annual; Comisión Nacional de la Energía: Madrid, Spain, 2022. [Google Scholar]

- Mac Kinnon, M.A.; Brouwer, J.; Samuelsen, S. The Role of Natural Gas and Its Infrastructure in Mitigating Greenhouse Gas Emissions, Improving Regional Air Quality, and Renewable Resource Integration. Prog. Energy Combust. Sci. 2018, 64, 62–92. [Google Scholar] [CrossRef]

- Plata, S.L.; Devenport, C.L.; Miara, A.; Sitterley, K.A.; Evans, A.; Talmadge, M.; van Allsburg, K.M.; Kurup, P.; Cox, J.; Kerber, S.; et al. Zero Liquid Discharge and Water Reuse in Recirculating Cooling Towers at Power Facilities: Review and Case Study Analysis. ACS EST Eng. 2022, 2, 508–525. [Google Scholar] [CrossRef]

- Grubert, E.; Sanders, K.T. Supplementary Information for Water Use in the US Energy System: A National Assessment and Unit Process Inventory of Water Consumption and Withdrawals. Environ. Sci. Technol. 2018, 52, 6695–6703. [Google Scholar] [CrossRef] [PubMed]

- Zappa, W.; Junginger, M.; van den Broek, M. Is a 100% Renewable European Power System Feasible by 2050? Appl. Energy 2019, 233–234, 1027–1050. [Google Scholar] [CrossRef]

| Plant | Power [MW] | Pressure [bar] | Temperature [°C] | Thermal Efficiency [%] | Installation Cost [€/kW] | |

|---|---|---|---|---|---|---|

| Steam (pulverized coal) | Subcritical | 350–1300 | <221 | <541 | 34–41 | 900–1000 |

| Supercritical | 540–790 | >240 | >550 | 36–44 | (not available) | |

| Ultra-supercritical | >500 | >300 | ≥593 | >39 | (not available) | |

| Advanced Ultra-supercritical | 352 | 680 | >43 | (not available) | ||

| Gas | Gas turbine | 2–593 | 140 | 1300 | 57 | 600–1400 |

| Configuration | 1P | 2P | 3P | 3P + R | 2P + R |

|---|---|---|---|---|---|

| Fuel heating value [MW] | 695 | 695 | 695 | 695 | 695 |

| Gas turbine power [MW] | 260.4 | 260.4 | 260.4 | 260.4 | 260.4 |

| Steam turbine power [MW] | 144.1 | 148.4 | 150.4 | 154.4 | 157.2 |

| Thermal efficiency [%] | 57.1 | 57.6 | 57.8 | 58.4 | 58.5 |

| Installed Power [MW] | Installation Cost [$/kW] | O&M Costs | ||

|---|---|---|---|---|

| Open Brayton cycle | 211 | 675 | Fixed | 4009 k$/year |

| Variable | 3.3 $/MWh | |||

| Combined cycle | 630 | 898 | Fixed | 11,970 k$/year |

| Variable | 2 $/MWh | |||

| Coal-fired steam cycle | 350 | 900–1000 | Fixed | 25,260 k$/year |

| Variable | 4.6 $/MWh | |||

| CO2 | NOx | SO2 | Ash | |

|---|---|---|---|---|

| Combined Cycle | ≤0.45 kg/kWh * | <50 mg/Nm3 | 0 | 0 |

| Coal Power Plant | ≤0.85 kg/kWh | 500 mg/Nm3 ** | 400 mg/Nm3 *** | <50 mg/Nm3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meana-Fernández, A.; González-Caballín, J.M.; Martínez-Pérez, R.; Rubio-Serrano, F.J.; Gutiérrez-Trashorras, A.J. Power Plant Cycles: Evolution towards More Sustainable and Environmentally Friendly Technologies. Energies 2022, 15, 8982. https://doi.org/10.3390/en15238982

Meana-Fernández A, González-Caballín JM, Martínez-Pérez R, Rubio-Serrano FJ, Gutiérrez-Trashorras AJ. Power Plant Cycles: Evolution towards More Sustainable and Environmentally Friendly Technologies. Energies. 2022; 15(23):8982. https://doi.org/10.3390/en15238982

Chicago/Turabian StyleMeana-Fernández, Andrés, Juan M. González-Caballín, Roberto Martínez-Pérez, Francisco J. Rubio-Serrano, and Antonio J. Gutiérrez-Trashorras. 2022. "Power Plant Cycles: Evolution towards More Sustainable and Environmentally Friendly Technologies" Energies 15, no. 23: 8982. https://doi.org/10.3390/en15238982

APA StyleMeana-Fernández, A., González-Caballín, J. M., Martínez-Pérez, R., Rubio-Serrano, F. J., & Gutiérrez-Trashorras, A. J. (2022). Power Plant Cycles: Evolution towards More Sustainable and Environmentally Friendly Technologies. Energies, 15(23), 8982. https://doi.org/10.3390/en15238982