Review on Model Based Design of Advanced Control Algorithms for Cogging Torque Reduction in Power Drive Systems

Abstract

:1. Introduction

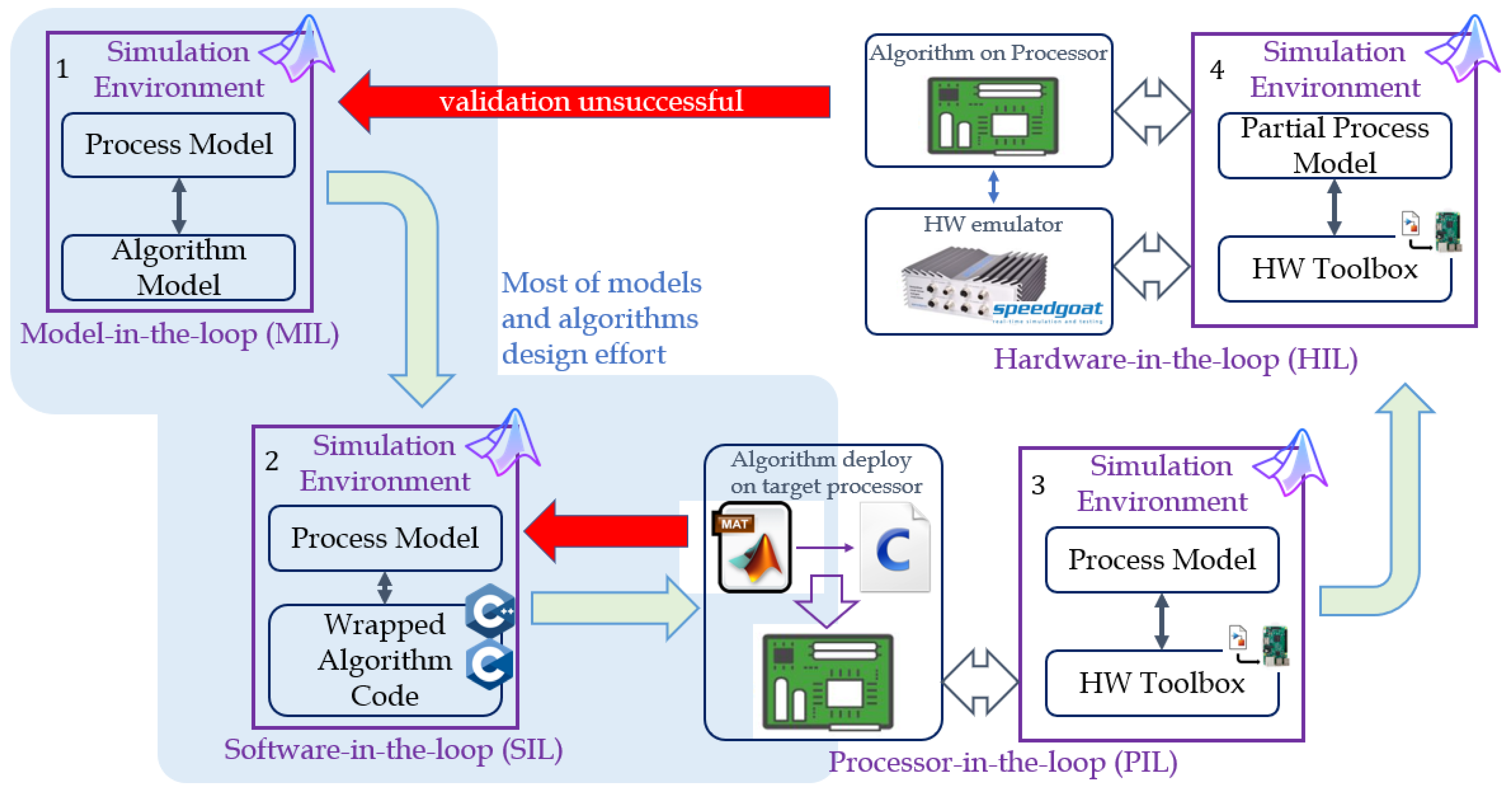

1.1. Brief Introduction to MBD for Mechatronics

1.2. Contributions

- Focus on the problem of cogging torque reduction by advanced control technique validated through MBD approach;

- Collect the most recent state-of-the-art work on this topic;

- Critical analysis of the control techniques proposed by various authors, with the aim of providing suggestions for implementation and improvement of the reported results.

1.3. Paper Organization

2. Cogging Torque’s Details and Modeling

2.1. Reasons for Control Design in Cogging Torque Reduction

2.2. Cogging Torque Modeling Approaches

3. Synchronous Motor and Advanced Electric Power Drives Modeling

3.1. Fundamental Components of Electric Power Drives in Mechatronics

- Static power converters: these are used to convert the electrical power regime to that which is useful for driving the electrical machine through the inverter. Configurations typically found in mechatronic systems of industrial interest are AC/DC converters to handle direct power from the mains or DC/DC converters to handle the DC bus level provided by a constant source, such as a Li-ion battery.

- Modulation system: conceptually separate from the system that integrates the control algorithm, but often implemented on the same embedded platform, it is the union of algorithm and HW interface for direct management of the inverter mosfets. The control algorithm typically provides a duty-cycle equivalent signal, which is converted into switching logic by the switching system, to manage the state of the inverter and power the electrical machine accordingly.

- Inverter: the electronic circuit that physically manages the (bidirectional) power transfer from the power source (DC side) to the electrical machine (AC side). The state of the inverter is decided by the modulation system. Conceptually, the inverter is a combinatorial logic network with combinations (in the three-phase case).

- Control system: the embedded platform on which the logic related to the feedback control algorithm is integrated. In modern embedded systems it coexists with the modulation system and cooperates via SW drivers. In the sensorless configuration, such a system also integrates the angular position/velocity estimation algorithm by exploiting direct measurement of electric current (from inverter or motor phase).

- Transduction system: the set of devices for measuring the physical quantities of primary interest for managing the electric drive. Typically it consists of:

- -

- Temperature sensors, placed at “critical” points, such as the electrical machine and static converters, which are subject to high currents and therefore need to be monitored for losses due to the Joule effect.

- -

- Position and angular velocity sensors: placed on the rotor axis if we are talking about encoders/resolvers or placed inside the structure if we are talking about hall effect sensors.

- -

- Voltage/current sensors: typically placed on the inverter, since motor phases and inverter branches are necessarily traversed by the same current.

3.2. Synchronous Motor Modeling including Cogging Torque

- The term denotes the power absorbed by the machine and is formally defined as the scalar product between voltage vector and current vector .

- The term denotes the heating losses of the windings, which, as is known from physics, depend on the resistance of the circuit and the square of the modulus of the current, formally .

- The term represents the magnetic power stored in the equivalent circuit and due exclusively to self and mutual induction phenomena; formally .

- The term represents the mechanical power delivered by the machine, against electromechanical conversion (Lentz’s law). For Synchronous motors, it depends on the angular position, via the counter-electro motion force (more precisely its gradient), the electric current, and of course the angular speed.

3.3. Modulation System in Advanced Power Drives

3.4. Complete Dynamics Modeling including Cogging Torque

4. Most Used Algorithms for Cogging Torque Reduction

4.1. Model Predictive Control

- Calculate, over a finite horizon, a future control sequence that optimizes a given performance index and satisfies constraints on the control action;

- Use the first control in the sequence as the plant’s input.

4.2. Feedback Linearization Control

4.3. Resonant Control

4.4. Others Control Techniques

- Direct Adaptive Control: in this case, the mathematical model of the physical system is taken as known and the control action is adapted by going to change its online parameters;

- Indirect Adaptive Control: in this case, a simplified model, such as a linearized version, is used as a basis, going to modify its parameters based on the error between the actual measurements and the model’s prediction, also modifying a posterior the controller parameters that must be adapted accordingly.

4.5. Final Considerations

4.5.1. Model Predictive Control

- Easy way of dealing with constraints on controls and states;

- High performance controllers and accurate;

- No need to generate solutions for the whole time-horizon;

- Flexibility: managing any model, any optimal objective function;

- Includes cogging torque information directly in the control law.

- High computational complexity (poorly suited to typical embedded systems);

- Problems of robustness with respect to uncertainties in the reference mathematical model;

- Strict dependence on the dynamic model.

4.5.2. Feedback Linearization Control

- Management of highly non-linear models;

- Joint use of other highly effective techniques on stationary linear systems;

- Fully algebraic control law (no on-line recursion required);

- Includes information on cogging torque through the most accurate model possible (optimizing compensation);

- Relative simplicity of implementation;

- Robust respect to the model parameters uncertainty.

- Strict dependence on the mathematical modeling;

- Does not inherently manage operational constraints on dynamic variables.

4.5.3. Resonant Controller

- Good ability to handle sinusoidal disturbances (as the cogging torque);

- Relative easy to tune;

- Simple to implement in embedded system.

- Strongly dependent on the operating condition under which the control coefficients are chosen;

- Does not exploit completely the cogging torque modeling.

4.5.4. Adaptive and Sliding Mode Controllers

- Inherent problems of convergence and numerical stability;

- Partial or ineffective use of the cogging torque model.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Akundi, A.; Lopez, V. A Review on Application of Model Based Systems Engineering to Manufacturing and Production Engineering Systems. Procedia Comput. Sci. 2021, 185, 101–108. [Google Scholar] [CrossRef]

- Barbieri, G.; Fantuzzi, C.; Borsari, R. A model-based design methodology for the development of mechatronic systems. Mechatronics 2014, 24, 833–843. [Google Scholar] [CrossRef]

- Alcázar-García, D.; Martínez, J.L.R. Model-based design validation and optimization of drive systems in electric, hybrid, plug-in hybrid and fuel cell vehicles. Energy 2022, 254, 123719. [Google Scholar] [CrossRef]

- Dini, P.; Saponara, S. Processor-in-the-Loop Validation of a Gradient Descent-Based Model Predictive Control for Assisted Driving and Obstacles Avoidance Applications. IEEE Access 2022, 10, 67958–67975. [Google Scholar] [CrossRef]

- Cosimi, F.; Dini, P.; Giannetti, S.; Petrelli, M.; Saponara, S. Analysis and design of a non-linear MPC algorithm for vehicle trajectory tracking and obstacle avoidance. In International Conference on Applications in Electronics Pervading Industry, Environment and Society; Springer: Cham, Switzerland, 2021; pp. 229–234. [Google Scholar]

- Bernardeschi, C.; Dini, P.; Domenici, A.; Mouhagir, A.; Palmieri, M.; Saponara, S.; Sassolas, T.; Zaourar, L. Co-simulation of a Model Predictive Control System for Automotive Applications. In International Conference on Software Engineering and Formal Methods; Springer: Cham, Switzerland, 2022. [Google Scholar]

- Karnopp, D.C.; Margolis, D.L.; Rosenberg, R.C. System Dynamics: Modeling, Simulation, and Control of Mechatronic Systems; John Wiley & Sons: Hoboken, NJ, USA, 2012. [Google Scholar]

- Chen, X.; Salem, M.; Das, T.; Chen, X. Real time software-in-the-loop simulation for control performance validation. Simulation 2008, 84, 457–471. [Google Scholar] [CrossRef]

- NXP. NXP Model-Based Design Toolbox (MBDT). 2022. Available online: https://www.nxp.com/design/development-boards/motor-control-development-solutions/model-based-design-toolbox-mbdt:MBDT (accessed on 10 November 2022).

- Zheng, C.; Qin, X.; Eynard, B.; Li, J.; Bai, J.; Zhang, Y.; Gomes, S. Interface model-based configuration design of mechatronic systems for industrial manufacturing applications. Robot. Comput.-Integr. Manuf. 2019, 59, 373–384. [Google Scholar] [CrossRef]

- Millitzer, J.; Mayer, D.; Henke, C.; Jersch, T.; Tamm, C.; Michael, J.; Ranisch, C. Recent developments in hardware-in-the-loop testing. Model Valid. Uncertain. Quantif. 2019, 3, 65–73. [Google Scholar]

- SpeedGoat. Real-Time Simulation and Testing. Emulation of Plant Components. 2022. Available online: https://www.speedgoat.com/ (accessed on 10 November 2022).

- Zhou, M.; Zhang, X.; Zhao, W.; Ji, J.; Hu, J. Influence of magnet shape on the cogging torque of a surface-mounted permanent magnet motor. Chin. J. Electr. Eng. 2019, 5, 40–50. [Google Scholar] [CrossRef]

- Anuja, T.; Doss, M.A.N. Reduction of cogging torque in surface mounted permanent magnet brushless DC motor by adapting rotor magnetic displacement. Energies 2021, 14, 2861. [Google Scholar] [CrossRef]

- An, Y.; Ma, C.; Zhang, N.; Guo, Y.; Degano, M.; Gerada, C.; Bu, F.; Yin, X.; Li, Q.; Zhou, S. Calculation model of armature reaction magnetic field of interior permanent magnet synchronous motor with segmented skewed poles. IEEE Trans. Energy Convers. 2021, 37, 1115–1123. [Google Scholar] [CrossRef]

- Tong, W.; Li, S.; Pan, X.; Wu, S.; Tang, R. Analytical model for cogging torque calculation in surface-mounted permanent magnet motors with rotor eccentricity and magnet defects. IEEE Trans. Energy Convers. 2020, 35, 2191–2200. [Google Scholar] [CrossRef]

- Ortega, A.J.P.; Paul, S.; Islam, R.; Xu, L. Analytical model for predicting effects of manufacturing variations on cogging torque in surface-mounted permanent magnet motors. IEEE Trans. Ind. Appl. 2016, 52, 3050–3061. [Google Scholar] [CrossRef]

- Hemeida, A.; Hannon, B.; Vansompel, H.; Sergeant, P. Comparison of three analytical methods for the precise calculation of cogging torque and torque ripple in axial flux PM machines. Math. Probl. Eng. 2016, 2016, 2171547. [Google Scholar] [CrossRef] [Green Version]

- Shin, K.H.; Park, H.I.; Cho, H.W.; Choi, J.Y. Analytical calculation and experimental verification of cogging torque and optimal point in permanent magnet synchronous motors. IEEE Trans. Magn. 2017, 53, 1–4. [Google Scholar] [CrossRef]

- Ebadi, F.; Mardaneh, M.; Rahideh, A.; Bianchi, N. Analytical energy-based approaches for cogging torque calculation in surface-mounted PM motors. IEEE Trans. Magn. 2019, 55, 1–10. [Google Scholar] [CrossRef]

- Yang, Y.; Bianchi, N.; Zhang, C.; Zhu, X.; Liu, H.; Zhang, S. A method for evaluating the worst-case cogging torque under manufacturing uncertainties. IEEE Trans. Energy Convers. 2020, 35, 1837–1848. [Google Scholar] [CrossRef]

- Kim, S.; Lee, S.G.; Kim, J.M.; Lee, T.H.; Lim, M.S. Uncertainty identification method using kriging surrogate model and Akaike information criterion for industrial electromagnetic device. IET Sci. Meas. Technol. 2020, 14, 250–258. [Google Scholar] [CrossRef]

- Lee, C.S.; Kim, H.J. Harmonic Order Analysis of Cogging Torque for Interior Permanent Magnet Synchronous Motor Considering Manufacturing Disturbances. Energies 2022, 15, 2428. [Google Scholar] [CrossRef]

- Verma, M.; Singh, M.; Sreejeth, M. Integrated Taguchi method-assisted polynomial Metamodelling & Genetic Algorithm based optimisation of a surface inset permanent synchronous motor for performance improvement. IET Electr. Syst. Transp. 2022, 12, 26–35. [Google Scholar]

- Reales, A.; Jara, W.; Hermosilla, G.; Madariaga, C.; Tapia, J.; Bramerdorfer, G. A Machine Learning Based Method to Efficiently Analyze the Cogging Torque Under Manufacturing Tolerances. In Proceedings of the 2021 IEEE Energy Conversion Congress and Exposition (ECCE), Virtual, 10–14 October 2021; pp. 1353–1357. [Google Scholar]

- Brescia, E.; Costantino, D.; Massenio, P.R.; Monopoli, V.G.; Cupertino, F.; Cascella, G.L. A Design Method for the Cogging Torque Minimization of Permanent Magnet Machines with a Segmented Stator Core Based on ANN Surrogate Models. Energies 2021, 14, 1880. [Google Scholar] [CrossRef]

- Vukosavic, S.N. Mathematical model of synchronous machine. In Electrical Machines; Springer: Berlin/Heidelberg, Germany, 2013; pp. 545–569. [Google Scholar]

- Das, S. Modeling and Simulation of Mechatronic Systems Using Simscape. Synth. Lect. Mech. Eng. 2020, 5, 1–171. [Google Scholar]

- Gasparetto, A.; Seriani, S.; Scalera, L. Modelling and control of mechatronic and robotic systems. Appl. Sci. 2021, 11, 3242. [Google Scholar] [CrossRef]

- Wu, Y.; He, N.; Chen, M.; Xu, D. Generalized space-vector-modulation method for soft-switching three-phase inverters. IEEE Trans. Power Electron. 2020, 36, 6030–6045. [Google Scholar] [CrossRef]

- Pila, A.W. Introduction To Lagrangian Dynamics; Springer: Berlin/Heidelberg, Germany, 2019. [Google Scholar]

- Mora, A.; Orellana, A.; Juliet, J.; Cardenas, R. Model predictive torque control for torque ripple compensation in variable-speed PMSMs. IEEE Trans. Ind. Electron. 2016, 63, 4584–4592. [Google Scholar] [CrossRef]

- Fei, Q.; Deng, Y.; Li, H.; Liu, J.; Shao, M. Speed ripple minimization of permanent magnet synchronous motor based on model predictive and iterative learning controls. IEEE Access 2019, 7, 31791–31800. [Google Scholar] [CrossRef]

- Suchỳ, O.; Janouš, Š.; Talla, J.; Peroutka, Z. Torque Ripple Reduction of IPMSM Drive with Non-sinusoidal Back-EMF by Predictive Control. In Proceedings of the 2022 IEEE 31st International Symposium on Industrial Electronics (ISIE), Anchorage, AL, USA, 1–3 June 2022; pp. 1064–1069. [Google Scholar]

- Huang, W.; Hua, W. A finite-control-set-based model-predictive-flux-control strategy with iterative learning control for torque ripple minimization of flux-switching permanent magnet machines. In Proceedings of the 2016 IEEE Vehicle Power and Propulsion Conference (VPPC), Hangzhou, China, 17–20 October 2016; pp. 1–6. [Google Scholar]

- Isidori, A. Lectures in Feedback Design for Multivariable Systems; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar]

- Dini, P.; Saponara, S. Cogging torque reduction in brushless motors by a nonlinear control technique. Energies 2019, 12, 2224. [Google Scholar] [CrossRef] [Green Version]

- Dini, P.; Saponara, S. Design of an observer-based architecture and non-linear control algorithm for cogging torque reduction in synchronous motors. Energies 2020, 13, 2077. [Google Scholar] [CrossRef]

- Bernardeschi, C.; Dini, P.; Domenici, A.; Saponara, S. Co-simulation and Verification of a Non-linear Control System for Cogging Torque Reduction in Brushless Motors. In International Conference on Software Engineering and Formal Methods; Springer: Berlin/Heidelberg, Germany, 2019; pp. 3–19. [Google Scholar]

- Dini, P.; Saponara, S. Model-Based Design of an Improved Electric Drive Controller for High-Precision Applications Based on Feedback Linearization Technique. Electronics 2021, 10, 2954. [Google Scholar] [CrossRef]

- Pierpaolo, D.; Saponara, S. Control System Design for Cogging Torque Reduction Based on Sensor-Less Architecture. In International Conference on Applications in Electronics Pervading Industry, Environment and Society; Springer: Berlin/Heidelberg, Germany, 2019; pp. 309–321. [Google Scholar]

- Bernardeschi, C.; Dini, P.; Domenici, A.; Palmieri, M.; Saponara, S. Formal verification and co-simulation in the design of a synchronous motor control algorithm. Energies 2020, 13, 4057. [Google Scholar] [CrossRef]

- Arias, A.; Caum, J.; Ibarra, E.; Grino, R. Reducing the cogging torque effects in hybrid stepper machines by means of resonant controllers. IEEE Trans. Ind. Electron. 2018, 66, 2603–2612. [Google Scholar] [CrossRef] [Green Version]

- Ignatev, E.A.; Nos, O.V. Torque Ripple Reduction of Permanent Magnet Synchronous Motor Using Proportional-Integral-Resonant Controller with Delay of Control Response Compensation. In Proceedings of the 2021 IEEE 22nd International Conference of Young Professionals in Electron Devices and Materials (EDM), Souzga, Russia, 30 June–4 July 2021; pp. 431–435. [Google Scholar]

- Gao, J.; Wu, X.; Huang, S.; Zhang, W.; Xiao, L. Torque ripple minimisation of permanent magnet synchronous motor using a new proportional resonant controller. IET Power Electron. 2017, 10, 208–214. [Google Scholar] [CrossRef]

- Chuan, H.; Fazeli, S.M.; Wu, Z.; Burke, R. Mitigating the torque ripple in electric traction using proportional integral resonant controller. IEEE Trans. Veh. Technol. 2020, 69, 10820–10831. [Google Scholar] [CrossRef]

- Rafaq, M.S.; Midgley, W.; Steffen, T. Proportional-integral-resonant control for the periodic disturbance minimization of the PMSM. In Proceedings of the 11th International Conference on Power Electronics, Machines and Drives (PEMD 2022), Newcastle, UK, 21–23 June 2022; pp. 240–244. [Google Scholar]

- Minghe, T.; Bo, W.; Yong, Y.; Xing, M.; Qinghua, D.; Dianguo, X. Proportional resonant-based active disturbance rejection control for speed fluctuation suppression of PMSM drives. In Proceedings of the 2019 22nd International Conference on Electrical Machines and Systems (ICEMS), Harbin, China, 11–14 August 2019; pp. 1–6. [Google Scholar]

- Dini, P.; Saponara, S. Electro-Thermal Model-Based Design of Bidirectional On-Board Chargers in Hybrid and Full Electric Vehicles. Electronics 2021, 11, 112. [Google Scholar] [CrossRef]

- Benedetti, D.; Agnelli, J.; Gagliardi, A.; Dini, P.; Saponara, S. Design of an Off-Grid Photovoltaic Carport for a Full Electric Vehicle Recharging. In Proceedings of the 2020 IEEE International Conference on Environment and Electrical Engineering and 2020 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I&CPS Europe), Madrid, Spain, 9–12 June 2020; pp. 1–6. [Google Scholar]

- Benedetti, D.; Agnelli, J.; Gagliardi, A.; Dini, P.; Saponara, S. Design of a digital dashboard on low-cost embedded platform in a fully electric vehicle. In Proceedings of the 2020 IEEE International Conference on Environment and Electrical Engineering and 2020 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I&CPS Europe), Madrid, Spain, 9–12 June 2020; pp. 1–5. [Google Scholar]

- Hu, Y.; Gu, W.; Zhang, H.; Chen, H. Adaptive robust triple-step control for compensating cogging torque and model uncertainty in a DC motor. IEEE Trans. Syst. Man, Cybern. Syst. 2018, 49, 2396–2405. [Google Scholar] [CrossRef]

- Huang, W.; Hua, W.; Zhu, X.; Fan, Y.; Cheng, M. Comparison of Cogging Torque Compensation Methods for a Flux-Switching Permanent Magnet Motor by Harmonic Current Injection and Iterative Learning Control. In Proceedings of the 2020 International Conference on Electrical Machines (ICEM), Gothenburg, Sweden, 23–26 August 2020; Volume 1, pp. 1971–1977. [Google Scholar]

- Dou, B.; He, R.; Wang, Z.; Li, Q.; Chen, C.; Dong, J.; Peng, Q.; Yu, T.; Huang, Y. The Repetitive Controller Design for Inhibiting the Torque Ripple of PMSM. In Proceedings of the 2020 7th International Conference on Information Science and Control Engineering (ICISCE), Changsha, China, 18–20 December 2020; pp. 2245–2249. [Google Scholar]

- Dini, P.; Saponara, S. Design of adaptive controller exploiting learning concepts applied to a BLDC-based drive system. Energies 2020, 13, 2512. [Google Scholar] [CrossRef]

- Liu, J.; Li, H.; Deng, Y. Torque ripple minimization of PMSM based on robust ILC via adaptive sliding mode control. IEEE Trans. Power Electron. 2017, 33, 3655–3671. [Google Scholar] [CrossRef]

- Du, R.; Li, C.; Bu, F.; Liu, J. Low-Speed Disturbance Suppression Strategy of Direct Drive Servo Motor Based on Combination of Sliding Mode Control and Disturbance Compensation. In Proceedings of the 2021 24th International Conference on Electrical Machines and Systems (ICEMS), Gyeongju, Korea, 31 October–3 November 2021; pp. 1933–1937. [Google Scholar]

| Space Vector | State Leg A | State Leg B | State Leg C | |||

|---|---|---|---|---|---|---|

| 0 | 0 | 0 | 0 | 0 | 0 | |

| 1 | 0 | 0 | ||||

| 1 | 1 | 0 | ||||

| 0 | 1 | 0 | ||||

| 0 | 1 | 1 | ||||

| 0 | 0 | 1 | ||||

| 1 | 0 | 1 | ||||

| 1 | 1 | 1 | 0 | 0 | 0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dini, P.; Saponara, S. Review on Model Based Design of Advanced Control Algorithms for Cogging Torque Reduction in Power Drive Systems. Energies 2022, 15, 8990. https://doi.org/10.3390/en15238990

Dini P, Saponara S. Review on Model Based Design of Advanced Control Algorithms for Cogging Torque Reduction in Power Drive Systems. Energies. 2022; 15(23):8990. https://doi.org/10.3390/en15238990

Chicago/Turabian StyleDini, Pierpaolo, and Sergio Saponara. 2022. "Review on Model Based Design of Advanced Control Algorithms for Cogging Torque Reduction in Power Drive Systems" Energies 15, no. 23: 8990. https://doi.org/10.3390/en15238990