Study of Bulk Properties Relation to SARA Composition Data of Various Vacuum Residues Employing Intercriteria Analysis

Abstract

:1. Introduction

2. Materials and Methods

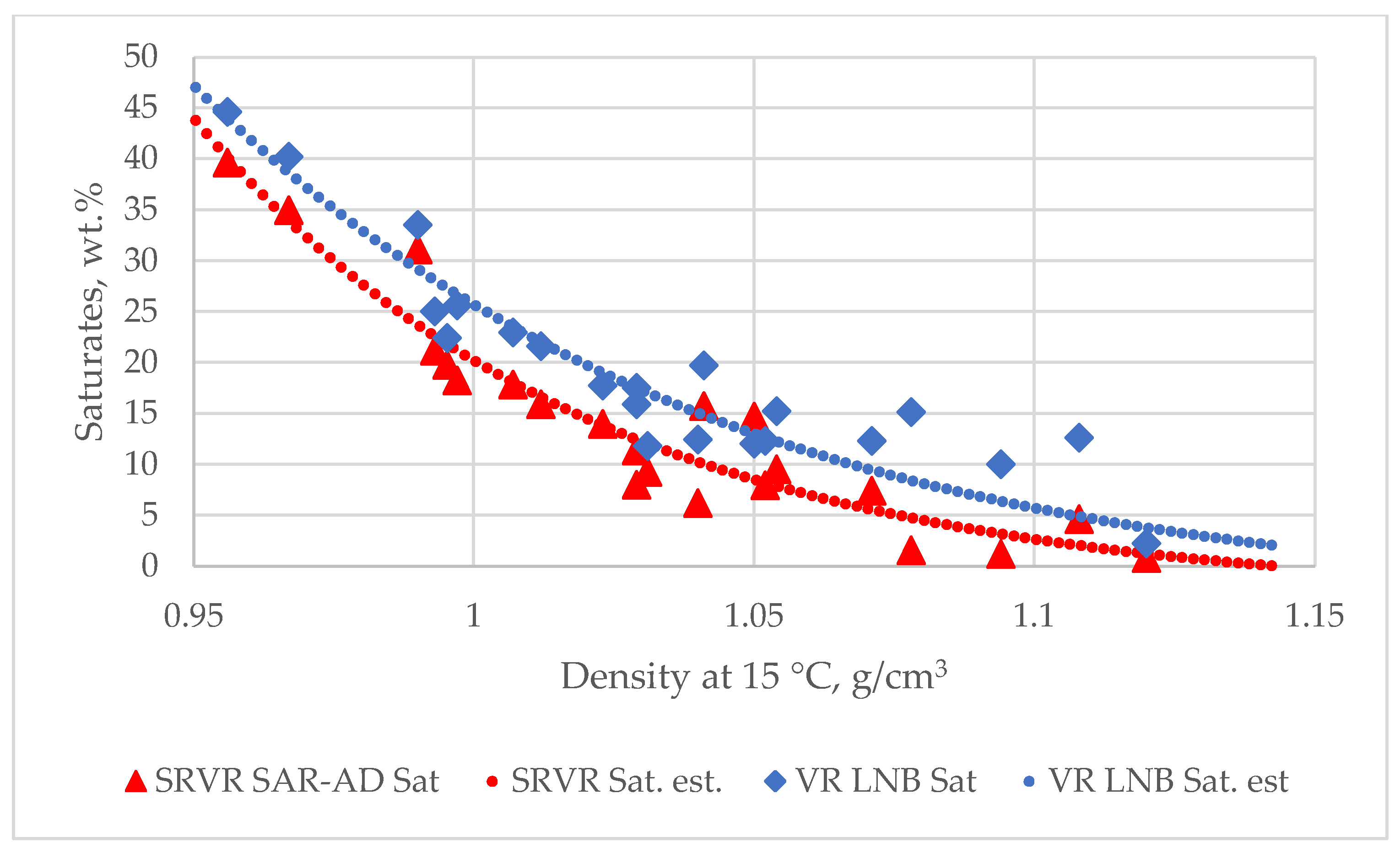

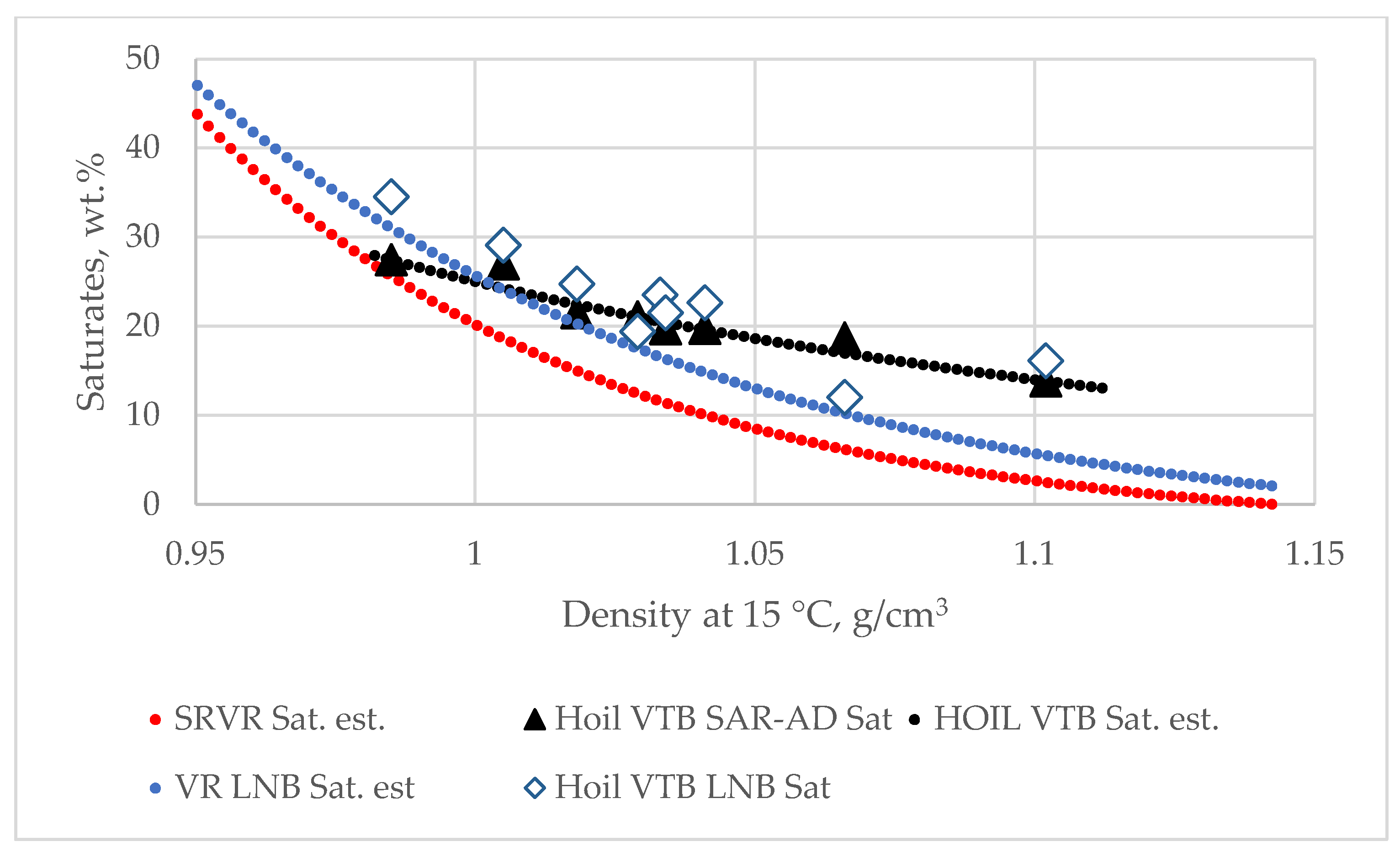

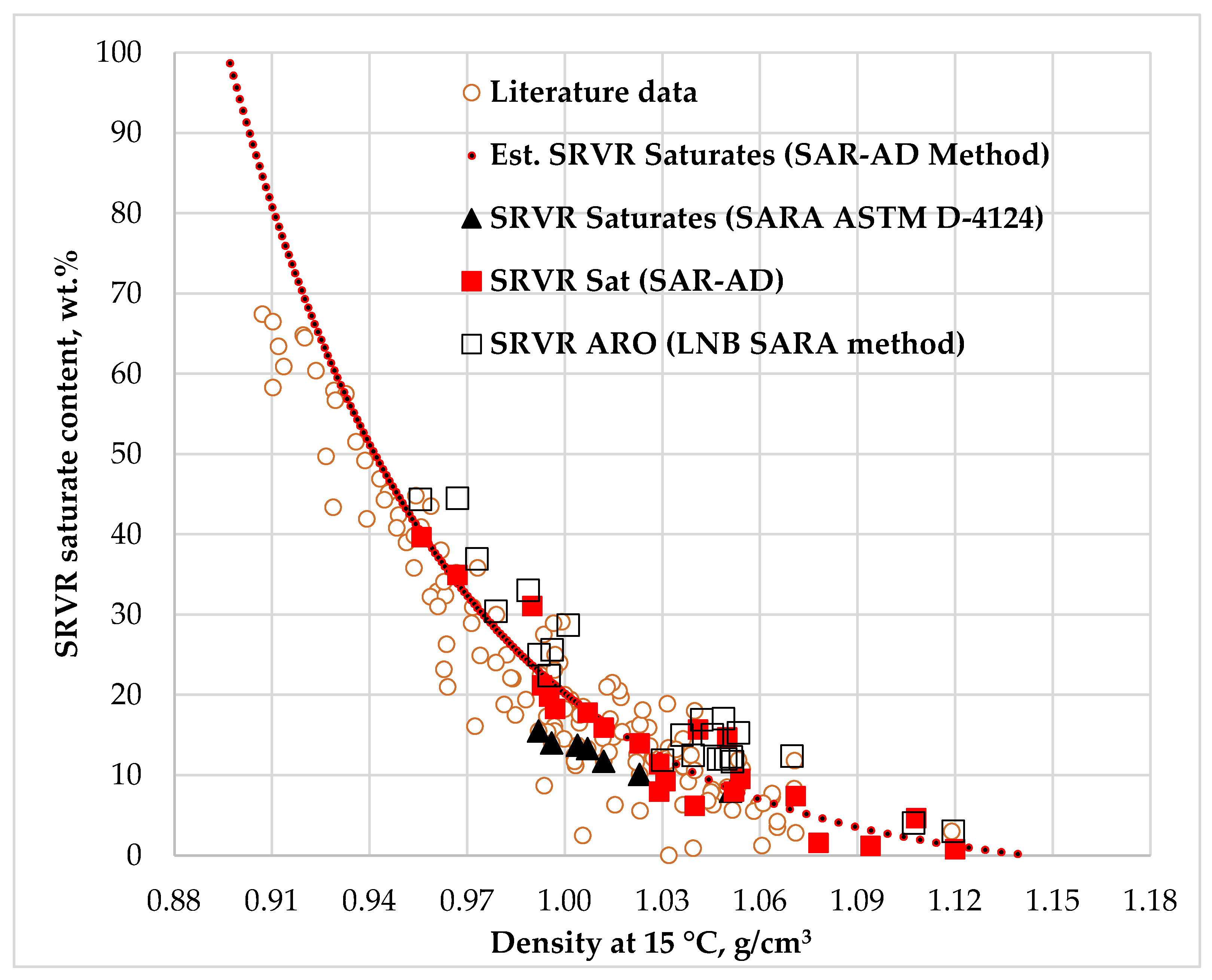

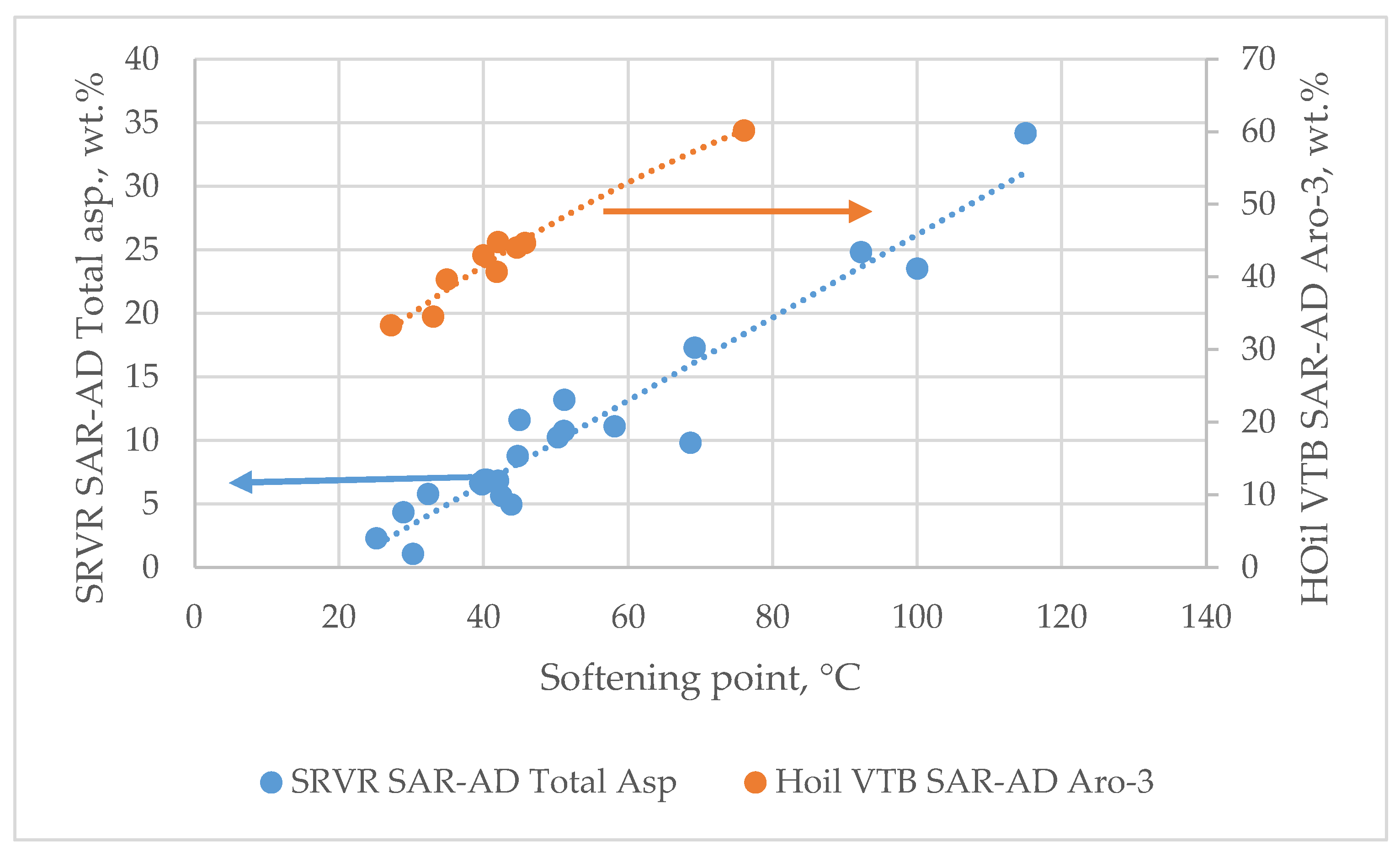

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Aro | Aromatic fraction content: wt.% |

| Asp | Asphaltenes content, wt.% |

| ATB | Atmospheric tower bottom product |

| av. dev. | Average deviation |

| CCR | Conradson carbon residue, wt.% |

| CH2Cl2 | Dichloromethane |

| Conv. | Conversion, wt.% |

| CyC6 | Cyclohexane |

| D15 | Density at 15 °C, g/cm3 |

| FBP | Final boiling point, °C |

| FCC | Fluid catalytic cracking |

| FID | Flame ionization detector |

| HCO | Heavy cycle oil |

| HPLC | High performance liquid chromatography |

| HTSD | High temperature simulated distillation |

| IBP | Initial boiling point, °C |

| ICrA | Intercriteria analysis |

| LNB | LUKOIL Neftohim Burgas |

| max.dev. | Maximum deviation |

| S | Sulphur content, wt.% |

| Sat | Saturates content, wt.% |

| SARA | Saturates, aromatics, resins, asphaltenes |

| SG | Specific gravity |

| SLO | Slurry oil from fluid catalytic cracking |

| SP | Softening point, °C |

| SRVR | Straight run vacuum residue |

| T50 | Temperature of 50% evaporate, °C |

| TBP | True boiling point |

| TLC | Thin layer chromatography |

| TRX | Reactor temperature, °C |

| TSE | Total sediment existent, wt.% |

| VTB | Vacuum tower bottom product |

| KV | Kinematic viscosity, cSt |

| VR | Vacuum residue |

| WABT | Weight average bed temperature, °C |

| WRI | Western Research Institute |

| X540+ | Weight percent of fraction boiling above 540 °C, % |

| µ | Positive consonance |

| υ | Negative consonance |

References

- Boduszynski, M.M. Composition of heavy petroleums. 2. Molecular characterization. Energy Fuels 1988, 2, 597–613. [Google Scholar] [CrossRef]

- Altgelt, K.; Boduszynski, M. Composition and Analysis of Heavy Petroleum Fractions, 1st ed.; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar] [CrossRef]

- Redelius, P.; Soenen, H. Relation between bitumen chemistry and performance. Fuel 2015, 140, 34–43. [Google Scholar] [CrossRef]

- Corbett, L.W. Composition of asphalt based on generic fractionation, using solvent deasphaltening, elution-adsorption chromatography, and densimetric characterization. Anal. Chem. 1969, 41, 576–579. [Google Scholar] [CrossRef]

- Stratiev, D.; Shishkova, I.; Kolev, I.; Yordanov, D.; Toteva, V. Petroleum crude slate effect on H-Oil performance. Int. J. Oil Gas Coal Technol. 2021, 28, 3. [Google Scholar] [CrossRef]

- Hao, J.; Che, Y.; Tian, Y.; Li, D.; Zhang, J.; Qiao, Y. Thermal cracking characteristics and kinetics of oil sand bitumen and its SARA fractions by TG−FTIR. Energy Fuels 2017, 31, 1295–1309. [Google Scholar] [CrossRef]

- Félix, G.; Ancheyta, J. Comparison of hydrocracking kinetic models based on SARA fractions obtained in slurry-phase reactor. Fuel 2019, 241, 495–505. [Google Scholar] [CrossRef]

- Hauser, A.; Alhumaidan, F.; Al-Rabiah, H.; Absi Halabi, M. Study on thermal cracking of Kuwaiti heavy oil (vacuum residue) and its SARA fractions by NMR spectroscopy. Energy Fuels 2014, 28, 4321–4332. [Google Scholar] [CrossRef]

- Xu, C.; Gao, J.; Zhao, S.; Lin, S. Correlation between feedstock SARA components and FCC product yields. Fuel 2005, 84, 669–674. [Google Scholar] [CrossRef]

- Sinnathambi, C.M.; Mohamad-Nor, N. Relationship between SARA fractions and crude oil fouling. J. Appl. Sci. 2012, 12, 2479–2483. [Google Scholar] [CrossRef]

- Fals, J.; Rafael-García, J.; Falco, M.; Sedran, U. Coke from SARA fractions in VGO. Impact on Y zeolite acidity and physical properties. Fuel 2018, 225, 26–34. [Google Scholar] [CrossRef]

- Yarranton, H.W. Estimation of SARA fraction properties with the SRK EOS. J. Can. Pet. Technol. 2004, 43, 9. [Google Scholar] [CrossRef]

- Farmani, Z.; Schrader, W. A Detailed look at the saturate fractions of different crude oils using direct analysis by ultrahigh resolution mass spectrometry (UHRMS). Energies 2019, 12, 3455. [Google Scholar] [CrossRef] [Green Version]

- Guilhem, C.; Lienemann, C.P.; Merdrignac, I.; Bouyssiere, B.; Lobinski, R. Element speciation analysis of petroleum and related materials. J. Anal. At. Spectrom. 2009, 24, 263–276. [Google Scholar] [CrossRef]

- Karevan, A.; Zirrahi, M.; Hassanzadeh, H. Standardized High-performance liquid chromatography to replace conventional methods for determination of saturate, aromatic, resin, and asphaltene (SARA) fractions. ACS Omega 2022, 7, 18897–18903. [Google Scholar] [CrossRef] [PubMed]

- Keshmirizadeh, E.; Shobeirian, S.; Memariani, M. Determination of saturates, aromatics, resins and asphaltenes (SARA) fractions in Iran crude oil sample with chromatography methods: Study of the geochemical parameters. J. Appl. Chem. Res. 2013, 7, 15–24. [Google Scholar]

- Jiang, C.; Larter, S.R.; Noke, K.J.; Snowdon, L.R. TLC—FID (Iatroscan) analysis of heavy oil and tar sand samples. Org. Geochem. 2008, 39, 1210–1214. [Google Scholar] [CrossRef]

- Bissada, K.K.A.; Tan, J.; Szymczyk, E.; Darnell, M.; Mei, M. Group-type characterization of crude oil and bitumen. Part I: Enhanced separation and quantification of saturates, aromatics, resins and asphaltenes (SARA). Org. Geochem. 2016, 95, 21–28. [Google Scholar] [CrossRef]

- ASTM D4124-09; Standard Test Methods for Separation of Asphalt into Four Fractions. American Society for Testing and Materials: West Conshohocken, PA, USA, 2012; Volume 403.

- Rezaee, S.; Tavakkoli, M.; Doherty, R.; Vargas, F.M. A new experimental method for a fast and reliable quantification of saturates, aromatics, resins, and asphaltenes in crude oils. Pet. Sci. Technol. 2020, 38, 955–961. [Google Scholar] [CrossRef]

- Karevan, A.; Yamchi, H.S.; Aghajamali, M.; Zirrahi, M.; Hassanzadeh, H. Automated high-performance liquid chromatography for SARA analysis (SARA-HPLC). Energy Fuels 2021, 35, 17642–17650. [Google Scholar] [CrossRef]

- ASTM D2007; Standard Test Method for Characteristic Groups in Rubber Extender and Processing Oils and Other Petroleum–Derived Oils by the Clay–Gel Absorption Chromatographic Method. American Society for Testing and Materials: West Conshohocken, PA, USA, 2007.

- Wu, W.; Saidian, M.; Gaur, S.; Prasad, M. Errors and repeatability in VSARA analysis of heavy oils. In Proceedings of the SPE Heavy Oil Conference Canada, Calgary, AB, Canada, 12–14 June 2012. [Google Scholar] [CrossRef]

- Stratiev, D.; Shishkova, I.; Nikolova, R.; Tsaneva, T.; Mitkova, M.; Yordanov, D. Investigation on precision of determination of SARA analysis of vacuum residual oils from different origin. Pet. Coal 2016, 58, 109–119. [Google Scholar]

- Adams, J.J.; Schabron, J.F.; Boysen, R. Quantitative vacuum distillation of crude oils to give residues amenable to the asphaltene determinator coupled with saturates, aromatics, and resins separation characterization. Energy Fuels 2015, 29, 2774–2784. [Google Scholar] [CrossRef]

- Todorova-Yankova, L.; Yordanov, D.; Stratiev, D.; Shishkova, I. Investigation of the group hydrocarbon composition of vacuum residues from different types of crude oil, crude oil sands and bitumens. Ind. Technol. 2021, 8, 51–64. (In Bulgarian) [Google Scholar]

- Zhang, J.; Tian, Y.; Qiao, Y.; Yang, C.; Shan, H. Structure and reactivity of Iranian vacuum residue and its eight group-fractions. Energy Fuels 2017, 31, 8072–8086. [Google Scholar] [CrossRef]

- Rudyk, S. Relationships between SARA fractions of conventional oil, heavy oil, natural bitumen and residues. Fuel 2018, 216, 330–340. [Google Scholar] [CrossRef]

- Fan, T.; Wang, J.; Buckley, J.S. Evaluating Crude oils by SARA analysis. In Proceedings of the SPE/DOE Improved Oil Recovery Symposium, Tulsa, OK, USA, 13–17 April 2002. SPE-75228-MS. [Google Scholar] [CrossRef]

- León, A.Y.; Parra, M.; Grosso, J.L. Estimation of critical properties of typically Colombian vacuum residue SARA fractions. CTF-Cienc. Tecnol. Futuro 2008, 3, 129–142. [Google Scholar] [CrossRef]

- Che, Y.; Yang, Z.; Qiao, Y.; Zhang, J.; Tian, Y. Study on pyrolysis characteristics and kinetics of vacuum residue and its eight group-fractions by TG-FTIR. Thermochim. Acta 2018, 669, 149–155. [Google Scholar] [CrossRef]

- Zhang, J.; Niwamanya, N.; Gao, C.; Sekyere, D.T.; Barigye, A.; Tian, Y. Structure and millisecond pyrolysis behavior of heavy oil and its eight group-fractions on solid base catalyst. Fuel 2022, 318, 123483. [Google Scholar] [CrossRef]

- Meléndez, L.V.; Lache, A.; Orrego-Ruiz, J.A.; Pachón, Z.; Mejía-Ospino, E. Prediction of the SARA analysis of Colombian crude oils using ATR–FTIR spectroscopy and chemometric methods. J. Pet. Sci. Eng. 2012, 90–91, 56–60. [Google Scholar] [CrossRef]

- Reyes-Gonzalez, D.; Ramirez-Jaramillo, E.; Manero, O.; Lira-Galeana, C.; del Rio, J.M. Estimation of the SARA Composition of Crude Oils from Bubblepoint Pressure Data. Energy Fuels 2016, 30, 6913–6922. [Google Scholar] [CrossRef]

- Yarranton, H. Prediction of Crude Oil Saturate Content from a SimDist Assay. Energy Fuels 2022, 36, 8809–8817. [Google Scholar] [CrossRef]

- Sanchez-Minero, F.; Ancheyta, J.; Silva-Oliver, G.; Flores-Valle, S. Predicting SARA composition of crude oil by means of NMR. Fuel 2013, 110, 318–321. [Google Scholar] [CrossRef]

- Stratiev, D.; Shishkova, I.; Tsaneva, T.; Mitkova, M.; Yordanov, D. Investigation of relations between properties of vacuum residual oils from different origin, and of their deasphalted and asphaltene fractions. Fuel 2016, 170, 115–129. [Google Scholar] [CrossRef]

- Stratiev, D.; Nenov, S.; Shishkova, I.; Georgiev, B.; Argirov, G.; Dinkov, R.; Yordanov, D.; Atanassova, V.; Vassilev, P.; Atanassov, K. Commercial investigation of the ebullated-bed vacuum residue hydrocracking in the conversion range of 55–93%. ACS Omega 2020, 51, 33290–33304. [Google Scholar] [CrossRef] [PubMed]

- Stratiev, D.; Shishkova, I.; Nikolaychuk, E.; Atanassova, V.; Atanassov, K. Investigation of relations of properties of straight run and H-Oil unconverted vacuum residual oils. Pet. Coal 2019, 61, 763–776. [Google Scholar]

- Stratiev, D.; Shishkova, I.; Dinkov, R.; Kolev, I.; Argirov, G.; Ivanov, V.; Ribagin, S.; Atanassova, V.; Atanassov, K.; Stratiev, D.D.; et al. Intercriteria analysis to diagnose the reasons for increased fouling in a commercial ebullated bed vacuum residue hydrocracker. ACS Omega 2022, 7, 30462–30476. [Google Scholar] [CrossRef] [PubMed]

- ASTM D4052-22; Standard Test Method for Density, Relative Density, and API Gravity of Liquids by Digital Density Meter. American Society for Testing and Materials: West Conshohocken, PA, USA, 1996.

- ASTM D4294-21; Standard Test Method for Sulfur in Petroleum and Petroleum Products by Energy Dispersive X-ray Fluorescence Spectrometry. American Society for Testing and Materials: West Conshohocken, PA, USA, 2010.

- ASTM D2892-20; Standard Test Method for Distillation of Crude Petroleum (15-Theoretical Plate Column). American Society for Testing and Materials: West Conshohocken, PA, USA, 2010.

- IFP 9305; Petroleum Products Separation of Saturates, Aromatics, Resins and Asphaltenes fractions Liquid Adsorption Chromatography. IFP (French Insitute of Petroleum): Rueil-Malmaison, France.

- Boysen, R.B.; Schabron, J.F. The automated asphaltene determinator coupled with saturates, aromatics, and resins separation for petroleum residua characterization. Energy Fuels 2013, 27, 4654–4661. [Google Scholar] [CrossRef]

- Adams, J.; Elwardany, M.; Planche, J.; Boysen, R.; Rovani, J. Diagnostic techniques for various asphalt refining and modification methods. Energy Fuels 2019, 33, 2680–2698. [Google Scholar] [CrossRef]

- Adams, J.J.; Rovani, J.F.; Planche, J.-P.; Stratiev, D.; Shishkova, I.; Kolev, I.; Atanassov, K.; Nenov, S.; Ribagin, S.; Stratiev, D.; et al. SAR-AD Method to Characterize Vacuum Residues from Different Origins as a Tool to Investigate the Performance of a Commercial Ebullated Bed Vacuum Residue Hydrocracker. Available online: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=4252478 (accessed on 24 November 2022).

- Diarov, I.N.; Batueva, I.U.; Sadikov, A.N.; Colodova, N.L. Chemistry of Crude Oil; Chimia Publishers: St. Peterburg, Russia, 1990. (In Russian) [Google Scholar]

| Nr | Crude Oils | Crude D15 | Crude S | ˃540 | Crude T50 | VR D15 | VR CCR | VR S | VR Sat | VR Aro | VR Res. | VR C7asp | VR C5asp | VR KV | VR SP | Sat | Aro 1 | Aro 2 | Aro 3 | Resins | CyC6 | Toluene | CH2Cl2 | Total Asp |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Urals 1 | 0.877 | 1.53 | 25.2 | 378 | 0.997 | 17.5 | 3 | 25.6 | 52.5 | 7.8 | 14.1 | 17.6 | 220.9 | 40.1 | 18.2 | 7.0 | 20.7 | 33.0 | 14.0 | 2.4 | 4.4 | 0.1 | 6.9 |

| 2 | Urals 2 | 0.875 | 1.39 | 24.94 | 377 | 0.995 | 17.2 | 2.9 | 22.4 | 66.5 | 4.9 | 6.3 | 13.9 | 195 | 42.4 | 19.8 | 7.6 | 22.7 | 32.6 | 11.7 | 2.0 | 3.6 | 0.1 | 5.7 |

| 3 | Arab Med. | 0.872 | 2.48 | 25.2 | 376 | 1.031 | 20.7 | 5.4 | 11.8 | 68.3 | 5.3 | 14.6 | 25.5 | 338.3 | 44.7 | 9.2 | 8.0 | 25.4 | 37.5 | 11.0 | 2.4 | 6.1 | 0.3 | 8.8 |

| 4 | Arab Heavy | 0.889 | 2.91 | 32 | 429 | 1.04 | 23.6 | 5.8 | 12.4 | 61.9 | 4.4 | 21.3 | 32.9 | 374.6 | 51.2 | 6.2 | 6.8 | 23.5 | 36.7 | 13.6 | 3.3 | 9.5 | 0.3 | 13.2 |

| 5 | Basrah L | 0.878 | 2.85 | 28.3 | 392 | 1.052 | 23.8 | 5.9 | 12.3 | 64.8 | 4.9 | 18 | 27.7 | 368.9 | 50.3 | 7.9 | 6.4 | 22.7 | 38.3 | 14.4 | 2.8 | 7.2 | 0.3 | 10.3 |

| 6 | Basrah H | 0.905 | 3.86 | 33.8 | 418 | 1.071 | 28.9 | 7.1 | 12.3 | 54.1 | 5.8 | 27.7 | 37 | 731.9 | 68.6 | 7.4 | 6.5 | 23.9 | 38.9 | 13.4 | 3.0 | 6.6 | 0.3 | 9.9 |

| 7 | Kirkuk | 0.873 | 2.65 | 24.6 | 345 | 1.054 | 25.2 | 5.9 | 15.2 | 55.4 | 5 | 24.3 | 33.1 | 514.1 | 58.1 | 9.5 | 6.6 | 23.3 | 39.2 | 10.2 | 2.3 | 8.4 | 0.5 | 11.2 |

| 8 | El Bouri | 0.891 | 1.76 | 26.2 | 401 | 1.05 | 25.5 | 3.3 | 12 | 57.9 | 12.6 | 17.5 | 27.3 | 303 | 45 | 14.7 | 8.3 | 21.4 | 33.8 | 10.1 | 2.3 | 8.8 | 0.5 | 11.6 |

| 9 | CPC | 0.805 | 0.63 | 9.3 | 238 | 0.956 | 16 | 2.1 | 44.6 | 40.8 | 10.3 | 3.4 | 11 | 65 | 25.2 | 39.6 | 10.5 | 18.1 | 22.4 | 7.0 | 0.4 | 1.6 | 0.2 | 2.3 |

| 10 | LSCO | 0.854 | 0.57 | 18.7 | 352 | 0.993 | 14 | 1.6 | 25 | 61.1 | 6.1 | 7.8 | 15.5 | 149.1 | 28.9 | 21.2 | 9.4 | 19.4 | 32.2 | 13.4 | 1.3 | 2.9 | 0.1 | 4.4 |

| 11 | Prinos | 0.875 | 3.71 | 20.3 | 349 | 1.108 | 32.8 | 9.1 | 12.6 | 50.6 | 6.8 | 30 | 38.8 | 550 | 69.2 | 4.6 | 4.6 | 17.4 | 44.8 | 11.1 | 1.8 | 14.9 | 0.6 | 17.3 |

| 12 | Boscan | 1.002 | 5.5 | 63.1 | 571 | 1.078 | 27.8 | 6 | 15.1 | 44.5 | 5.3 | 35.2 | 41 | 1003 | 115 | 1.6 | 1.9 | 12.3 | 26.6 | 23.4 | 8.1 | 25.6 | 0.5 | 34.2 |

| 13 | Varandey | 0.85 | 0.63 | 14.9 | 362 | 0.99 | 15.1 | 1.7 | 33.5 | 47.6 | 11.3 | 7.6 | 13.5 | 103 | 43.8 | 31.1 | 7.1 | 15.8 | 27.9 | 13.1 | 1.6 | 3.2 | 0.2 | 5.0 |

| 14 | Albania | 1.001 | 5.64 | 48.2 | 531 | 1.094 | 31.4 | 8.7 | 10 | 52.9 | 6.3 | 37.7 | 49.7 | 680 | 92.2 | 1.2 | 2.0 | 17.5 | 41.5 | 12.9 | 5.5 | 18.7 | 0.6 | 24.8 |

| 15 | Tempa rossa | 0.94 | 5.35 | 37.6 | 428 | 1.12 | 34.3 | 9.3 | 2.2 | 48.4 | 12.6 | 36.8 | 46.8 | 759.5 | 100 | 0.8 | 2.1 | 18.3 | 44.2 | 10.9 | 4.5 | 18.4 | 0.7 | 23.5 |

| 16 | Rhemoura | 0.865 | 0.75 | 20.2 | 350 | 1.041 | 23.7 | 1.8 | 19.7 | 49.8 | 7.3 | 23.2 | 31.3 | 255 | 51.1 | 15.7 | 7.6 | 18.5 | 36.0 | 11.4 | 1.9 | 8.5 | 0.4 | 10.8 |

| 17 | Arab Light | 0.858 | 1.89 | 22.9 | 352 | 1.029 | 18.7 | 4.9 | 15.9 | 64.7 | 7.3 | 12.1 | 18.8 | 192 | 32.3 | 11.3 | 11.1 | 28.1 | 34.8 | 9.0 | 1.6 | 4.0 | 0.2 | 5.8 |

| 18 | Azeri Light | 0.848 | 0.2 | 14.8 | 321 | 0.967 | 9.5 | 0.5 | 40.2 | 50.1 | 8.4 | 1.4 | 5.4 | 77 | 30.2 | 34.9 | 6.9 | 15.7 | 30.7 | 10.7 | 0.2 | 0.7 | 0.1 | 1.1 |

| 19 | Imported AR | 0.878 | 1.5 | 25.5 | 380 | 1.029 | 19.2 | 3.28 | 17.5 | 60.7 | 8 | 13.7 | 21.8 | 215 | 40.5 | 8.0 | 7.3 | 26.4 | 39.3 | 12.1 | 2.1 | 4.7 | 0.2 | 6.9 |

| 20 | Ur.1(80%)/Basr L (20%) | 0.877 | 1.79 | 25.82 | 381 | 1.007 | 18.8 | 3.58 | 22.94 | 54.96 | 11.2 | 10.9 | 15.9 | 225 | 39.5 | 17.8 | 7.4 | 24.0 | 33.1 | 11.0 | 2.0 | 4.5 | 0.1 | 6.7 |

| 21 | Ur.1(70%)/Basr L (30%) | 0.878 | 1.93 | 26.13 | 382 | 1.012 | 19.4 | 3.87 | 21.61 | 56.19 | 9.7 | 12.5 | 20.5 | 230 | 39.8 | 15.9 | 7.6 | 24.6 | 34.4 | 10.9 | 2.1 | 4.3 | 0.1 | 6.6 |

| 22 | 14%Ur.36%LSCO/ 50%ME | 0.869 | 1.78 | 23.40 | 361 | 1.023 | 20.7 | 3.82 | 17.71 | 59.65 | 9.43 | 13.2 | 21.2 | 222 | 42 | 14.0 | 7.1 | 25.2 | 37.6 | 9.4 | 2.1 | 4.6 | 0.1 | 6.9 |

| Min | 0.805 | 0.20 | 9.30 | 238 | 0.956 | 9.5 | 0.50 | 2.20 | 40.80 | 4.40 | 1.4 | 5.4 | 65 | 25.2 | 0.8 | 1.9 | 12.3 | 22.4 | 7.0 | 0.2 | 0.7 | 0.1 | 1.1 | |

| Max | 1.002 | 5.64 | 63.10 | 571 | 1.12 | 34.3 | 9.30 | 44.60 | 68.30 | 12.60 | 37.7 | 49.7 | 1003 | 115 | 39.6 | 11.1 | 28.1 | 44.8 | 23.4 | 8.1 | 25.6 | 0.7 | 34.2 |

| ASTM D4124 | WRI SAR-AD | IFP 9305 | LNB | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Sat. wt.% | Arom. wt.% | Resins. wt.% | Asphaltenes, wt.% | Sat. wt.% | Arom. wt.% | Resins, wt.% | Asphaltenes, wt.% | Sat. wt.% | Arom. wt.% | Resins, wt.% | Asphaltenes, wt.% | Sat. wt.% | Arom. wt.% | Resins, wt.% | Asphaltenes, wt.% |

| 14.0 | 36.2 | 43 | 6.8 | 19.8 | 62.9 | 11.7 | 5.7 | 25.6 | 52.5 | 7.8 | 14.1 | ||||

| 17.1 | 38.6 | 35.9 | 7.2 | 18.2 | 60.8 | 14.0 | 6.9 | 17.5 | 39.5 | 35.7 | 5.8 | 22.4 | 66.5 | 4.9 | 6.3 |

| 13.3 | 39.9 | 40.3 | 6.5 | 17.8 | 64.5 | 11.0 | 6.7 | 22.9 | 55.0 | 11.2 | 10.9 | ||||

| 11.7 | 36.8 | 43.7 | 7.8 | 15.9 | 66.6 | 10.9 | 6.6 | 12.0 | 36.7 | 40.5 | 8.0 | 21.6 | 56.2 | 9.7 | 12.5 |

| 10.1 | 39.1 | 42.7 | 8.1 | 14.0 | 69.8 | 9.4 | 6.9 | 17.7 | 59.6 | 9.4 | 13.2 | ||||

| ASTM D4124 | WRI SAR-AD | IFP 9305 | LNB | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Sat. wt.% | Arom. wt.% | Resins. wt.% | Asphaltenes, wt.% | Sat. wt.% | Arom. wt.% | Resins, wt.% | Asphaltenes, wt.% | Sat. wt.% | Arom. wt.% | Resins, wt.% | Asphaltenes, wt.% | Sat. wt.% | Arom. wt.% | Resins, wt.% | Asphaltenes, wt.% |

| 17.8 | 40.6 | 35.6 | 6 | 27.44 | 61.5 | 6.03 | 5.68 | 27.2 | 36.0 | 28.0 | 5.0 | 34.5 | 41.0 | 8.8 | 15.7 |

| 17.1 | 38.6 | 35.9 | 8.4 | 26.98 | 60.2 | 5.93 | 6.95 | 24.9 | 33.9 | 30.1 | 8.9 | 29.1 | 53.9 | 5.0 | 12.0 |

| 15.9 | 37.6 | 35.1 | 11.4 | 21.01 | 66.8 | 5.97 | 6.24 | 19.4 | 54.6 | 4.7 | 21.3 | ||||

| 16.4 | 38.9 | 35.1 | 9.6 | 21.96 | 65.7 | 6.19 | 6.7 | 23.5 | 54.8 | 6.9 | 14.8 | ||||

| 15.7 | 36.6 | 37 | 10.7 | 19.76 | 68.2 | 6.01 | 6.58 | 18.4 | 33.4 | 35.5 | 9.7 | 22.6 | 48.9 | 10.0 | 18.5 |

| 15.2 | 40.8 | 34.4 | 9.6 | 19.72 | 71.1 | 4.37 | 6.85 | 21.5 | 52.6 | 8.6 | 17.3 | ||||

| Parameter | Case 1 | Case 2 | Case 3 | Case 4 | Case 5 | Case 6 | Case 7 | Case 8 | Case 9 |

|---|---|---|---|---|---|---|---|---|---|

| Crude blend, processed in LNB refinery | 100% Urals | 100% Urals | 85% Ur./ 15% ME | 80% Ur./ 20% ME | 70% Ur./ 30% ME | 14% Ur./ 36% LSCO/ 50% ME | 61.5% Ur/. 3% BL/2% AM/ 19.5% Kirkuk/ 7.5% LSCO/ 6.5% Prinos | 64% Ur./25% Kirkuk/ 11% BL | 88.6% Ur./5% LSCO/ 6.5% Kirkuk |

| FCC SLO in H-Oil feed, wt% | 0.0 | 0.0 | 7.6 | 6.1 | 8.2 | 7.5 | 11.8 | 0.0 | 0.0 |

| Recycle from H-Oil VTB, wt.% | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 29.4 | 12.89 | 0 |

| WABT, °C | 409 | 418 | 426 | 425 | 428 | 426 | 430.5 | 429.5 | 414.50 |

| LHSV, h−1 | 0.23 | 0.25 | 0.21 | 0.20 | 0.20 | 0.17 | 0.10 | 0.155 | 0.139 |

| ATB TSE, wt.% | 0.3 | 2.2 | 0.4 | 0.4 | 0.25 | 0.04 | 0.11 | 0.56 | 0.46 |

| Conversion, wt.% | 55 | 65 | 71.6 | 73 | 74.5 | 76.3 | 90.8 | 78.0 | 62.000 |

| VTB D15, g/cm3 | 0.985 | 1.005 | 1.029 | 1.033 | 1.041 | 1.034 | 1.102 | 1.066 | 1.0182 |

| VTB CCR, wt.% | 17.9 | 20.4 | 24.4 | 26 | 25.5 | 25.8 | 38 | 38.0 | 22.4 |

| VTB Sulphur, wt.% | 1.1 | 1.3 | 1.38 | 1.24 | 1.4 | 1.3 | 1.3 | 1.9 | 1.3 |

| VTB LNB Saturates, wt.% | 34.5 | 29.1 | 19.4 | 23.5 | 22.6 | 21.5 | 16.1 | 12.0 | 24.7 |

| VTB LNB Aromatics, wt.% | 41.0 | 53.9 | 54.6 | 54.8 | 48.9 | 52.6 | 39.8 | 57.5 | 49.0 |

| VTB LNB Resins, wt.% | 8.8 | 5.0 | 4.7 | 6.9 | 10.0 | 8.6 | 12.7 | 0.7 | 7.7 |

| VTB LNB C7 asphaltenes, wt.% | 15.7 | 12 | 21.3 | 14.8 | 18.5 | 17.3 | 31.4 | 29.8 | 18.6 |

| VTB LNB C5 asphaltenes, wt.% | 24.5 | 17 | 26.0 | 21.7 | 28.5 | 25.9 | 44.1 | 30.5 | 26.24 |

| VTB softening point, °C | 27.2 | 33 | 40 | 41.8 | 44.6 | 42 | 76 | 45.7 | 34.9 |

| VTB Fraas breaking point, °C | −15 | −14 | −12 | −10 | −11 | −9 | 25 | −10 | −14 |

| VTB specifc Engler viscosity, °E | 12.8 | 29.8 | 52.7 | 14.1 | 36.2 | 15.9 | 130.8 | 45.9 | 15.7 |

| VTB SARA-ADTM Saturates, wt.% | 27.44 | 26.98 | 21.01 | 21.96 | 19.76 | 19.72 | 13.85 | 18.66 | 21.48 |

| VTB SARA-ADTM Aro 1, wt.% | 9.34 | 8.22 | 6.85 | 7.15 | 6.77 | 7.48 | 3.04 | 5.92 | 8.41 |

| VTB SARA-ADTM Aro 2, wt.% | 18.76 | 17.43 | 16.89 | 17.82 | 17.35 | 18.80 | 14.75 | 18.07 | 20.30 |

| VTB SARA-ADTM Aro 3, wt.% | 33.41 | 34.59 | 43.04 | 40.77 | 44.09 | 44.86 | 60.20 | 44.74 | 39.67 |

| VTB SARA-ADTM Resins, wt.% | 6.03 | 5.93 | 5.97 | 6.19 | 6.01 | 4.37 | 2.46 | 4.42 | 4.17 |

| VTB SARA-ADTM CyC6 asp, wt.% | 0.38 | 0.34 | 0.23 | 0.25 | 0.23 | 0.17 | 0.07 | 0.22 | 0.14 |

| VTB SARA-ADTM Toluene asp. | 4.47 | 6.12 | 5.56 | 5.47 | 5.47 | 4.28 | 4.90 | 7.00 | 5.28 |

| VTB SARA-ADTM CH2Cl2 asp., wt.% | 0.18 | 0.39 | 0.46 | 0.39 | 0.33 | 0.32 | 0.71 | 0.95 | 0.53 |

| VTB SARA-ADTM Total asp, wt.% | 5.03 | 6.85 | 6.24 | 6.11 | 6.03 | 4.77 | 5.68 | 8.17 | 5.95 |

| SRVR Blends | Sat | Aro 1 | Aro 2 | Aro 3 | Resins | CyC6 | Toluene | CH2Cl2 | Total Asphaltenes |

|---|---|---|---|---|---|---|---|---|---|

| 100% Urals | 18.24 | 7.04 | 20.75 | 33.04 | 13.98 | 2.43 | 4.43 | 0.09 | 6.95 |

| 100% Basrah light | 7.92 | 6.44 | 22.66 | 38.30 | 14.41 | 2.81 | 7.18 | 0.28 | 10.27 |

| #33 H-Oil VTB from 80% Urals/20% Basrah light | 17.79 | 7.42 | 23.97 | 33.10 | 11.03 | 2.04 | 4.55 | 0.09 | 6.68 |

| Estimated assuming additivity (80% Ur./20% BL) | 16.17 | 6.92 | 21.13 | 34.10 | 14.07 | 2.51 | 4.98 | 0.12 | 7.61 |

| #27 70% Urals/30% Basrah Light | 15.90 | 7.60 | 24.58 | 34.39 | 10.95 | 2.14 | 4.33 | 0.11 | 6.58 |

| Estimated assuming additivity (70% Ur./30% BL) | 15.14 | 6.86 | 21.32 | 34.62 | 14.11 | 2.55 | 5.26 | 0.14 | 7.95 |

| #29 50% Urals/50% Basrah Light | 14.0 | 7.1 | 25.2 | 37.6 | 9.4 | 2.1 | 4.6 | 0.1 | 6.9 |

| Estimated assuming additivity (50% Ur./50% BL) | 13.08 | 6.74 | 21.70 | 35.67 | 14.19 | 2.62 | 5.81 | 0.18 | 8.61 |

| μ | Crude D15 | Crude S | ˃540 | VR D15 | VR CCR | VR S | VR Sat | VR Aro | VR Res. | VR C7asp | VR C5asp | VR VIS | VR SP | Sat | Aro 1 | Aro 2 | Aro 3 | Resins | CyC6 | Toluene | CH2Cl2 | Total Asp |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Crude D15 | 1.00 | 0.80 | 0.93 | 0.78 | 0.77 | 0.75 | 0.21 | 0.49 | 0.42 | 0.78 | 0.79 | 0.82 | 0.76 | 0.18 | 0.26 | 0.49 | 0.68 | 0.64 | 0.85 | 0.79 | 0.59 | 0.79 |

| Crude S | 0.80 | 1.00 | 0.82 | 0.85 | 0.85 | 0.94 | 0.18 | 0.49 | 0.37 | 0.84 | 0.86 | 0.89 | 0.79 | 0.11 | 0.24 | 0.53 | 0.75 | 0.57 | 0.82 | 0.83 | 0.67 | 0.83 |

| ˃540 | 0.93 | 0.82 | 1.00 | 0.77 | 0.76 | 0.77 | 0.23 | 0.54 | 0.43 | 0.77 | 0.78 | 0.83 | 0.75 | 0.19 | 0.29 | 0.53 | 0.67 | 0.63 | 0.88 | 0.78 | 0.56 | 0.77 |

| VR D15 | 0.78 | 0.85 | 0.77 | 1.00 | 0.94 | 0.88 | 0.13 | 0.48 | 0.39 | 0.92 | 0.94 | 0.90 | 0.86 | 0.08 | 0.26 | 0.49 | 0.82 | 0.55 | 0.77 | 0.88 | 0.77 | 0.87 |

| VR CCR | 0.77 | 0.85 | 0.76 | 0.94 | 1.00 | 0.89 | 0.16 | 0.44 | 0.44 | 0.90 | 0.91 | 0.89 | 0.85 | 0.13 | 0.27 | 0.46 | 0.79 | 0.53 | 0.77 | 0.89 | 0.75 | 0.88 |

| VR S | 0.75 | 0.94 | 0.77 | 0.88 | 0.89 | 1.00 | 0.17 | 0.49 | 0.41 | 0.83 | 0.85 | 0.86 | 0.78 | 0.11 | 0.26 | 0.54 | 0.80 | 0.52 | 0.77 | 0.81 | 0.68 | 0.80 |

| VR Sat | 0.21 | 0.18 | 0.23 | 0.13 | 0.16 | 0.17 | 1.00 | 0.40 | 0.61 | 0.19 | 0.17 | 0.18 | 0.23 | 0.87 | 0.64 | 0.42 | 0.21 | 0.46 | 0.20 | 0.19 | 0.15 | 0.19 |

| VR Aro | 0.49 | 0.49 | 0.54 | 0.48 | 0.44 | 0.49 | 0.40 | 1.00 | 0.32 | 0.43 | 0.45 | 0.45 | 0.42 | 0.47 | 0.63 | 0.78 | 0.58 | 0.48 | 0.51 | 0.45 | 0.33 | 0.44 |

| VR Res. | 0.42 | 0.37 | 0.43 | 0.39 | 0.44 | 0.41 | 0.61 | 0.32 | 1.00 | 0.39 | 0.39 | 0.38 | 0.39 | 0.62 | 0.57 | 0.45 | 0.43 | 0.30 | 0.37 | 0.40 | 0.36 | 0.38 |

| VR C7asp | 0.78 | 0.84 | 0.77 | 0.92 | 0.90 | 0.83 | 0.19 | 0.43 | 0.39 | 1.00 | 0.97 | 0.90 | 0.90 | 0.12 | 0.23 | 0.45 | 0.78 | 0.61 | 0.81 | 0.91 | 0.74 | 0.91 |

| VR C5asp | 0.79 | 0.86 | 0.78 | 0.94 | 0.91 | 0.85 | 0.17 | 0.45 | 0.39 | 0.97 | 1.00 | 0.91 | 0.90 | 0.10 | 0.24 | 0.48 | 0.81 | 0.59 | 0.80 | 0.92 | 0.74 | 0.91 |

| VR VIS | 0.82 | 0.89 | 0.83 | 0.90 | 0.89 | 0.86 | 0.18 | 0.45 | 0.38 | 0.90 | 0.91 | 1.00 | 0.88 | 0.12 | 0.24 | 0.47 | 0.77 | 0.61 | 0.83 | 0.89 | 0.68 | 0.88 |

| VR SP | 0.76 | 0.79 | 0.75 | 0.86 | 0.85 | 0.78 | 0.23 | 0.42 | 0.39 | 0.90 | 0.90 | 0.88 | 1.00 | 0.17 | 0.20 | 0.40 | 0.73 | 0.62 | 0.78 | 0.87 | 0.74 | 0.87 |

| Sat | 0.18 | 0.11 | 0.19 | 0.08 | 0.13 | 0.11 | 0.87 | 0.47 | 0.62 | 0.12 | 0.10 | 0.12 | 0.17 | 1.00 | 0.73 | 0.45 | 0.16 | 0.40 | 0.17 | 0.13 | 0.15 | 0.13 |

| Aro 1 | 0.26 | 0.24 | 0.29 | 0.26 | 0.27 | 0.26 | 0.64 | 0.63 | 0.57 | 0.23 | 0.24 | 0.24 | 0.20 | 0.73 | 1.00 | 0.64 | 0.32 | 0.30 | 0.23 | 0.25 | 0.24 | 0.23 |

| Aro 2 | 0.49 | 0.53 | 0.53 | 0.49 | 0.46 | 0.54 | 0.42 | 0.78 | 0.45 | 0.45 | 0.48 | 0.47 | 0.40 | 0.45 | 0.64 | 1.00 | 0.61 | 0.41 | 0.51 | 0.43 | 0.31 | 0.42 |

| Aro 3 | 0.68 | 0.75 | 0.67 | 0.82 | 0.79 | 0.80 | 0.21 | 0.58 | 0.43 | 0.78 | 0.81 | 0.77 | 0.73 | 0.16 | 0.32 | 0.61 | 1.00 | 0.48 | 0.66 | 0.75 | 0.61 | 0.74 |

| Resins | 0.64 | 0.57 | 0.63 | 0.55 | 0.53 | 0.52 | 0.46 | 0.48 | 0.30 | 0.61 | 0.59 | 0.61 | 0.62 | 0.40 | 0.30 | 0.41 | 0.48 | 1.00 | 0.63 | 0.59 | 0.44 | 0.59 |

| CyC6 | 0.85 | 0.82 | 0.88 | 0.77 | 0.77 | 0.77 | 0.20 | 0.51 | 0.37 | 0.81 | 0.80 | 0.83 | 0.78 | 0.17 | 0.23 | 0.51 | 0.66 | 0.63 | 1.00 | 0.81 | 0.61 | 0.82 |

| Toluene | 0.79 | 0.83 | 0.78 | 0.88 | 0.89 | 0.81 | 0.19 | 0.45 | 0.40 | 0.91 | 0.92 | 0.89 | 0.87 | 0.13 | 0.25 | 0.43 | 0.75 | 0.59 | 0.81 | 1.00 | 0.74 | 0.98 |

| CH2Cl2 | 0.59 | 0.67 | 0.56 | 0.77 | 0.75 | 0.68 | 0.15 | 0.33 | 0.36 | 0.74 | 0.74 | 0.68 | 0.74 | 0.15 | 0.24 | 0.31 | 0.61 | 0.44 | 0.61 | 0.74 | 1.00 | 0.74 |

| Total Asp | 0.79 | 0.83 | 0.77 | 0.87 | 0.88 | 0.80 | 0.19 | 0.44 | 0.38 | 0.91 | 0.91 | 0.88 | 0.87 | 0.13 | 0.23 | 0.42 | 0.74 | 0.59 | 0.82 | 0.98 | 0.74 | 1.00 |

| υ | Crude D15 | Crude S | ˃540 | VR D15 | VR CCR | VR S | VR Sat | VR Aro | VR Res. | VR C7asp | VR C5asp | VR VIS | VR SP | Sat | Aro 1 | Aro 2 | Aro 3 | Resins | CyC6 | Toluene | CH2Cl2 | Total Asp |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Crude D15 | 0.000 | 0.173 | 0.043 | 0.195 | 0.199 | 0.221 | 0.762 | 0.489 | 0.541 | 0.195 | 0.186 | 0.156 | 0.221 | 0.797 | 0.706 | 0.485 | 0.303 | 0.325 | 0.104 | 0.186 | 0.234 | 0.178 |

| Crude S | 0.173 | 0.000 | 0.173 | 0.143 | 0.143 | 0.052 | 0.810 | 0.507 | 0.606 | 0.152 | 0.134 | 0.104 | 0.204 | 0.887 | 0.740 | 0.463 | 0.242 | 0.411 | 0.143 | 0.165 | 0.178 | 0.156 |

| ˃540 | 0.043 | 0.173 | 0.000 | 0.225 | 0.234 | 0.221 | 0.766 | 0.455 | 0.550 | 0.221 | 0.212 | 0.165 | 0.247 | 0.810 | 0.684 | 0.459 | 0.329 | 0.351 | 0.091 | 0.217 | 0.273 | 0.212 |

| Crude T50 | 0.095 | 0.238 | 0.078 | 0.299 | 0.290 | 0.286 | 0.701 | 0.476 | 0.515 | 0.294 | 0.286 | 0.238 | 0.294 | 0.745 | 0.658 | 0.489 | 0.403 | 0.303 | 0.139 | 0.255 | 0.312 | 0.260 |

| VR D15 | 0.195 | 0.143 | 0.225 | 0.000 | 0.052 | 0.108 | 0.866 | 0.520 | 0.584 | 0.074 | 0.056 | 0.095 | 0.134 | 0.913 | 0.714 | 0.498 | 0.173 | 0.429 | 0.199 | 0.113 | 0.078 | 0.113 |

| VR CCR | 0.199 | 0.143 | 0.234 | 0.052 | 0.000 | 0.104 | 0.836 | 0.558 | 0.537 | 0.100 | 0.082 | 0.104 | 0.143 | 0.862 | 0.710 | 0.528 | 0.204 | 0.455 | 0.195 | 0.104 | 0.087 | 0.100 |

| VR S | 0.221 | 0.052 | 0.221 | 0.108 | 0.104 | 0.000 | 0.823 | 0.502 | 0.571 | 0.169 | 0.143 | 0.139 | 0.212 | 0.883 | 0.719 | 0.450 | 0.199 | 0.459 | 0.191 | 0.191 | 0.152 | 0.186 |

| VR Sat | 0.762 | 0.810 | 0.766 | 0.866 | 0.836 | 0.823 | 0.000 | 0.597 | 0.368 | 0.801 | 0.827 | 0.814 | 0.766 | 0.126 | 0.338 | 0.567 | 0.788 | 0.524 | 0.766 | 0.810 | 0.693 | 0.797 |

| VR Aro | 0.489 | 0.507 | 0.455 | 0.520 | 0.558 | 0.502 | 0.597 | 0.000 | 0.667 | 0.571 | 0.546 | 0.550 | 0.580 | 0.533 | 0.355 | 0.217 | 0.420 | 0.502 | 0.463 | 0.550 | 0.507 | 0.550 |

| VR Res. | 0.541 | 0.606 | 0.550 | 0.584 | 0.537 | 0.571 | 0.368 | 0.667 | 0.000 | 0.597 | 0.597 | 0.602 | 0.589 | 0.364 | 0.394 | 0.537 | 0.554 | 0.667 | 0.584 | 0.584 | 0.459 | 0.589 |

| VR C7asp | 0.195 | 0.152 | 0.221 | 0.074 | 0.100 | 0.169 | 0.801 | 0.571 | 0.597 | 0.000 | 0.026 | 0.100 | 0.104 | 0.879 | 0.758 | 0.541 | 0.221 | 0.381 | 0.160 | 0.091 | 0.100 | 0.074 |

| VR C5asp | 0.186 | 0.134 | 0.212 | 0.056 | 0.082 | 0.143 | 0.827 | 0.546 | 0.597 | 0.026 | 0.000 | 0.091 | 0.104 | 0.905 | 0.740 | 0.515 | 0.195 | 0.398 | 0.169 | 0.082 | 0.100 | 0.074 |

| VR VIS | 0.156 | 0.104 | 0.165 | 0.095 | 0.104 | 0.139 | 0.814 | 0.550 | 0.602 | 0.100 | 0.091 | 0.000 | 0.117 | 0.883 | 0.745 | 0.528 | 0.225 | 0.377 | 0.143 | 0.113 | 0.156 | 0.104 |

| VR SP | 0.221 | 0.204 | 0.247 | 0.134 | 0.143 | 0.212 | 0.766 | 0.580 | 0.589 | 0.104 | 0.104 | 0.117 | 0.000 | 0.827 | 0.784 | 0.593 | 0.273 | 0.364 | 0.191 | 0.126 | 0.104 | 0.113 |

| Sat | 0.797 | 0.887 | 0.810 | 0.913 | 0.862 | 0.883 | 0.126 | 0.533 | 0.364 | 0.879 | 0.905 | 0.883 | 0.827 | 0.000 | 0.251 | 0.550 | 0.840 | 0.589 | 0.801 | 0.866 | 0.693 | 0.853 |

| Aro 1 | 0.706 | 0.740 | 0.684 | 0.714 | 0.710 | 0.719 | 0.338 | 0.355 | 0.394 | 0.758 | 0.740 | 0.745 | 0.784 | 0.251 | 0.000 | 0.342 | 0.658 | 0.667 | 0.719 | 0.736 | 0.589 | 0.745 |

| Aro 2 | 0.485 | 0.463 | 0.459 | 0.498 | 0.528 | 0.450 | 0.567 | 0.217 | 0.537 | 0.541 | 0.515 | 0.528 | 0.593 | 0.550 | 0.342 | 0.000 | 0.381 | 0.571 | 0.459 | 0.563 | 0.528 | 0.563 |

| Aro 3 | 0.303 | 0.242 | 0.329 | 0.173 | 0.204 | 0.199 | 0.788 | 0.420 | 0.554 | 0.221 | 0.195 | 0.225 | 0.273 | 0.840 | 0.658 | 0.381 | 0.000 | 0.507 | 0.312 | 0.251 | 0.229 | 0.251 |

| Resins | 0.325 | 0.411 | 0.351 | 0.429 | 0.455 | 0.459 | 0.524 | 0.502 | 0.667 | 0.381 | 0.398 | 0.377 | 0.364 | 0.589 | 0.667 | 0.571 | 0.507 | 0.000 | 0.325 | 0.394 | 0.390 | 0.385 |

| CyC6 | 0.104 | 0.143 | 0.091 | 0.199 | 0.195 | 0.191 | 0.766 | 0.463 | 0.584 | 0.160 | 0.169 | 0.143 | 0.191 | 0.801 | 0.719 | 0.459 | 0.312 | 0.325 | 0.000 | 0.160 | 0.234 | 0.143 |

| Toluene | 0.186 | 0.165 | 0.217 | 0.113 | 0.104 | 0.191 | 0.810 | 0.550 | 0.584 | 0.091 | 0.082 | 0.113 | 0.126 | 0.866 | 0.736 | 0.563 | 0.251 | 0.394 | 0.160 | 0.000 | 0.100 | 0.009 |

| CH2Cl2 | 0.234 | 0.178 | 0.273 | 0.078 | 0.087 | 0.152 | 0.693 | 0.507 | 0.459 | 0.100 | 0.100 | 0.156 | 0.104 | 0.693 | 0.589 | 0.528 | 0.229 | 0.390 | 0.234 | 0.100 | 0.000 | 0.095 |

| Total Asp | 0.178 | 0.156 | 0.212 | 0.113 | 0.100 | 0.186 | 0.797 | 0.550 | 0.589 | 0.074 | 0.074 | 0.104 | 0.113 | 0.853 | 0.745 | 0.563 | 0.251 | 0.385 | 0.143 | 0.009 | 0.095 | 0.000 |

| μ | TRX | LHSV | Conv. | D15 | CCR | Sul. | Sat. 1 | Aro 1 | Res. 1 | C7 Asp. 1 | C5 Asp. 1 | SP. | Fraas | VIS | Sat | Aro 1 | Aro 2 | Aro 3 | Resins | CyC6 | Toluene | CH2Cl2 | Total Asp. |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TRX | 1.00 | 0.25 | 0.92 | 0.92 | 0.81 | 0.67 | 0.11 | 0.53 | 0.50 | 0.78 | 0.81 | 0.92 | 0.81 | 0.83 | 0.08 | 0.03 | 0.28 | 0.89 | 0.36 | 0.22 | 0.56 | 0.64 | 0.56 |

| LHSV | 0.25 | 1.00 | 0.19 | 0.19 | 0.19 | 0.31 | 0.69 | 0.53 | 0.39 | 0.19 | 0.17 | 0.19 | 0.19 | 0.36 | 0.81 | 0.67 | 0.42 | 0.22 | 0.75 | 0.86 | 0.64 | 0.28 | 0.61 |

| Conv. | 0.92 | 0.19 | 1.00 | 0.94 | 0.89 | 0.61 | 0.14 | 0.58 | 0.53 | 0.72 | 0.75 | 0.94 | 0.89 | 0.78 | 0.08 | 0.11 | 0.36 | 0.92 | 0.36 | 0.22 | 0.50 | 0.58 | 0.50 |

| D15 | 0.92 | 0.19 | 0.94 | 1.00 | 0.89 | 0.64 | 0.14 | 0.53 | 0.58 | 0.78 | 0.81 | 1.00 | 0.86 | 0.78 | 0.08 | 0.11 | 0.36 | 0.92 | 0.36 | 0.22 | 0.50 | 0.64 | 0.50 |

| CCR | 0.81 | 0.19 | 0.89 | 0.89 | 1.00 | 0.56 | 0.14 | 0.61 | 0.47 | 0.67 | 0.69 | 0.89 | 0.86 | 0.67 | 0.11 | 0.14 | 0.39 | 0.86 | 0.39 | 0.25 | 0.50 | 0.67 | 0.53 |

| Sul. | 0.67 | 0.31 | 0.61 | 0.64 | 0.56 | 1.00 | 0.17 | 0.53 | 0.28 | 0.61 | 0.64 | 0.64 | 0.56 | 0.69 | 0.17 | 0.17 | 0.33 | 0.61 | 0.36 | 0.28 | 0.61 | 0.58 | 0.61 |

| Sat. 1 | 0.11 | 0.69 | 0.14 | 0.14 | 0.14 | 0.17 | 1.00 | 0.39 | 0.56 | 0.19 | 0.22 | 0.14 | 0.17 | 0.19 | 0.89 | 0.86 | 0.67 | 0.11 | 0.67 | 0.75 | 0.39 | 0.25 | 0.42 |

| Aro 1 | 0.53 | 0.53 | 0.58 | 0.53 | 0.61 | 0.53 | 0.39 | 1.00 | 0.11 | 0.47 | 0.39 | 0.53 | 0.53 | 0.53 | 0.50 | 0.42 | 0.56 | 0.50 | 0.61 | 0.56 | 0.72 | 0.61 | 0.75 |

| Res. 1 | 0.50 | 0.39 | 0.53 | 0.58 | 0.47 | 0.28 | 0.56 | 0.11 | 1.00 | 0.53 | 0.61 | 0.58 | 0.53 | 0.47 | 0.44 | 0.53 | 0.44 | 0.56 | 0.44 | 0.42 | 0.19 | 0.33 | 0.19 |

| C7 asp. 1 | 0.78 | 0.19 | 0.72 | 0.78 | 0.67 | 0.61 | 0.19 | 0.47 | 0.53 | 1.00 | 0.92 | 0.78 | 0.64 | 0.78 | 0.19 | 0.22 | 0.42 | 0.75 | 0.25 | 0.19 | 0.50 | 0.75 | 0.50 |

| C5 asp. 1 | 0.81 | 0.17 | 0.75 | 0.81 | 0.69 | 0.64 | 0.22 | 0.39 | 0.61 | 0.92 | 1.00 | 0.81 | 0.67 | 0.75 | 0.17 | 0.19 | 0.44 | 0.78 | 0.28 | 0.19 | 0.47 | 0.72 | 0.47 |

| SP. | 0.92 | 0.19 | 0.94 | 1.00 | 0.89 | 0.64 | 0.14 | 0.53 | 0.58 | 0.78 | 0.81 | 1.00 | 0.86 | 0.78 | 0.08 | 0.11 | 0.36 | 0.92 | 0.36 | 0.22 | 0.50 | 0.64 | 0.50 |

| Fraas | 0.81 | 0.19 | 0.89 | 0.86 | 0.86 | 0.56 | 0.17 | 0.53 | 0.53 | 0.64 | 0.67 | 0.86 | 1.00 | 0.67 | 0.11 | 0.17 | 0.39 | 0.89 | 0.33 | 0.19 | 0.42 | 0.56 | 0.44 |

| VIS | 0.83 | 0.36 | 0.78 | 0.78 | 0.67 | 0.69 | 0.19 | 0.53 | 0.47 | 0.78 | 0.75 | 0.78 | 0.67 | 1.00 | 0.19 | 0.17 | 0.19 | 0.75 | 0.36 | 0.31 | 0.61 | 0.72 | 0.61 |

| Sat | 0.08 | 0.81 | 0.08 | 0.08 | 0.11 | 0.17 | 0.89 | 0.50 | 0.44 | 0.19 | 0.17 | 0.08 | 0.11 | 0.19 | 1.00 | 0.86 | 0.61 | 0.06 | 0.72 | 0.83 | 0.50 | 0.31 | 0.53 |

| Aro 1 | 0.03 | 0.67 | 0.11 | 0.11 | 0.14 | 0.17 | 0.86 | 0.42 | 0.53 | 0.22 | 0.19 | 0.11 | 0.17 | 0.17 | 0.86 | 1.00 | 0.75 | 0.14 | 0.58 | 0.69 | 0.36 | 0.28 | 0.39 |

| Aro 2 | 0.28 | 0.42 | 0.36 | 0.36 | 0.39 | 0.33 | 0.67 | 0.56 | 0.44 | 0.42 | 0.44 | 0.36 | 0.39 | 0.19 | 0.61 | 0.75 | 1.00 | 0.39 | 0.44 | 0.47 | 0.39 | 0.39 | 0.42 |

| Aro 3 | 0.89 | 0.22 | 0.92 | 0.92 | 0.86 | 0.61 | 0.11 | 0.50 | 0.56 | 0.75 | 0.78 | 0.92 | 0.89 | 0.75 | 0.06 | 0.14 | 0.39 | 1.00 | 0.28 | 0.14 | 0.47 | 0.61 | 0.47 |

| Resins | 0.36 | 0.75 | 0.36 | 0.36 | 0.39 | 0.36 | 0.67 | 0.61 | 0.44 | 0.25 | 0.28 | 0.36 | 0.33 | 0.36 | 0.72 | 0.58 | 0.44 | 0.28 | 1.00 | 0.86 | 0.50 | 0.28 | 0.53 |

| CyC6 | 0.22 | 0.86 | 0.22 | 0.22 | 0.25 | 0.28 | 0.75 | 0.56 | 0.42 | 0.19 | 0.19 | 0.22 | 0.19 | 0.31 | 0.83 | 0.69 | 0.47 | 0.14 | 0.86 | 1.00 | 0.56 | 0.25 | 0.58 |

| Toluene | 0.56 | 0.64 | 0.50 | 0.50 | 0.50 | 0.61 | 0.39 | 0.72 | 0.19 | 0.50 | 0.47 | 0.50 | 0.42 | 0.61 | 0.50 | 0.36 | 0.39 | 0.47 | 0.50 | 0.56 | 1.00 | 0.64 | 0.97 |

| CH2Cl2 | 0.64 | 0.28 | 0.58 | 0.64 | 0.67 | 0.58 | 0.25 | 0.61 | 0.33 | 0.75 | 0.72 | 0.64 | 0.56 | 0.72 | 0.31 | 0.28 | 0.39 | 0.61 | 0.28 | 0.25 | 0.64 | 1.00 | 0.67 |

| Total asp. | 0.56 | 0.61 | 0.50 | 0.50 | 0.53 | 0.61 | 0.42 | 0.75 | 0.19 | 0.50 | 0.47 | 0.50 | 0.44 | 0.61 | 0.53 | 0.39 | 0.42 | 0.47 | 0.53 | 0.58 | 0.97 | 0.67 | 1.00 |

| υ | TRX | LHSV | Conv. | D15 | CCR | Sul. | Sat. 1 | Aro 1 | Res. 1 | C7 Asp. 1 | C5 Asp. 1 | SP. | Fraas | VIS | Sat | Aro 1 | Aro 2 | Aro 3 | Resins | CyC6 | Toluene | CH2Cl2 | Total Asp. |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TRX | 0.00 | 0.69 | 0.06 | 0.06 | 0.14 | 0.14 | 0.86 | 0.44 | 0.47 | 0.19 | 0.17 | 0.06 | 0.11 | 0.14 | 0.89 | 0.94 | 0.69 | 0.08 | 0.61 | 0.72 | 0.39 | 0.31 | 0.42 |

| LHSV | 0.69 | 0.00 | 0.78 | 0.78 | 0.75 | 0.50 | 0.28 | 0.44 | 0.58 | 0.78 | 0.81 | 0.78 | 0.72 | 0.61 | 0.17 | 0.31 | 0.56 | 0.75 | 0.22 | 0.08 | 0.36 | 0.67 | 0.36 |

| Conv. | 0.06 | 0.78 | 0.00 | 0.06 | 0.08 | 0.22 | 0.86 | 0.42 | 0.47 | 0.28 | 0.25 | 0.06 | 0.06 | 0.22 | 0.92 | 0.89 | 0.64 | 0.08 | 0.64 | 0.75 | 0.47 | 0.39 | 0.50 |

| D15 | 0.06 | 0.78 | 0.06 | 0.00 | 0.08 | 0.19 | 0.86 | 0.47 | 0.42 | 0.22 | 0.19 | 0.00 | 0.08 | 0.22 | 0.92 | 0.89 | 0.64 | 0.08 | 0.64 | 0.75 | 0.47 | 0.33 | 0.50 |

| CCR | 0.14 | 0.75 | 0.08 | 0.08 | 0.00 | 0.25 | 0.83 | 0.36 | 0.50 | 0.31 | 0.28 | 0.08 | 0.06 | 0.31 | 0.86 | 0.83 | 0.58 | 0.11 | 0.58 | 0.69 | 0.44 | 0.28 | 0.44 |

| Sul. | 0.14 | 0.50 | 0.22 | 0.19 | 0.25 | 0.00 | 0.67 | 0.31 | 0.56 | 0.22 | 0.19 | 0.19 | 0.28 | 0.14 | 0.67 | 0.67 | 0.50 | 0.22 | 0.47 | 0.53 | 0.19 | 0.22 | 0.22 |

| Sat. | 0.86 | 0.28 | 0.86 | 0.86 | 0.83 | 0.67 | 0.00 | 0.61 | 0.44 | 0.81 | 0.78 | 0.86 | 0.78 | 0.81 | 0.11 | 0.14 | 0.33 | 0.89 | 0.33 | 0.22 | 0.58 | 0.72 | 0.58 |

| Aro | 0.44 | 0.44 | 0.42 | 0.47 | 0.36 | 0.31 | 0.61 | 0.00 | 0.89 | 0.53 | 0.61 | 0.47 | 0.42 | 0.47 | 0.50 | 0.58 | 0.44 | 0.50 | 0.39 | 0.42 | 0.25 | 0.36 | 0.25 |

| Res. | 0.47 | 0.58 | 0.47 | 0.42 | 0.50 | 0.56 | 0.44 | 0.89 | 0.00 | 0.47 | 0.39 | 0.42 | 0.42 | 0.53 | 0.56 | 0.47 | 0.56 | 0.44 | 0.56 | 0.56 | 0.78 | 0.64 | 0.81 |

| C7 asp. | 0.19 | 0.78 | 0.28 | 0.22 | 0.31 | 0.22 | 0.81 | 0.53 | 0.47 | 0.00 | 0.08 | 0.22 | 0.31 | 0.22 | 0.81 | 0.78 | 0.58 | 0.25 | 0.75 | 0.78 | 0.47 | 0.22 | 0.50 |

| C5 asp. | 0.17 | 0.81 | 0.25 | 0.19 | 0.28 | 0.19 | 0.78 | 0.61 | 0.39 | 0.08 | 0.00 | 0.19 | 0.28 | 0.25 | 0.83 | 0.81 | 0.56 | 0.22 | 0.72 | 0.78 | 0.50 | 0.25 | 0.53 |

| SP. | 0.06 | 0.78 | 0.06 | 0.00 | 0.08 | 0.19 | 0.86 | 0.47 | 0.42 | 0.22 | 0.19 | 0.00 | 0.08 | 0.22 | 0.92 | 0.89 | 0.64 | 0.08 | 0.64 | 0.75 | 0.47 | 0.33 | 0.50 |

| Fraas | 0.11 | 0.72 | 0.06 | 0.08 | 0.06 | 0.28 | 0.78 | 0.42 | 0.42 | 0.31 | 0.28 | 0.08 | 0.00 | 0.28 | 0.83 | 0.78 | 0.56 | 0.06 | 0.61 | 0.72 | 0.50 | 0.36 | 0.50 |

| VIS | 0.14 | 0.61 | 0.22 | 0.22 | 0.31 | 0.14 | 0.81 | 0.47 | 0.53 | 0.22 | 0.25 | 0.22 | 0.28 | 0.00 | 0.81 | 0.83 | 0.81 | 0.25 | 0.64 | 0.67 | 0.36 | 0.25 | 0.39 |

| Sat | 0.89 | 0.17 | 0.92 | 0.92 | 0.86 | 0.67 | 0.11 | 0.50 | 0.56 | 0.81 | 0.83 | 0.92 | 0.83 | 0.81 | 0.00 | 0.14 | 0.39 | 0.94 | 0.28 | 0.14 | 0.47 | 0.67 | 0.47 |

| Aro 1 | 0.94 | 0.31 | 0.89 | 0.89 | 0.83 | 0.67 | 0.14 | 0.58 | 0.47 | 0.78 | 0.81 | 0.89 | 0.78 | 0.83 | 0.14 | 0.00 | 0.25 | 0.86 | 0.42 | 0.28 | 0.61 | 0.69 | 0.61 |

| Aro 2 | 0.69 | 0.56 | 0.64 | 0.64 | 0.58 | 0.50 | 0.33 | 0.44 | 0.56 | 0.58 | 0.56 | 0.64 | 0.56 | 0.81 | 0.39 | 0.25 | 0.00 | 0.61 | 0.56 | 0.50 | 0.58 | 0.58 | 0.58 |

| Aro 3 | 0.08 | 0.75 | 0.08 | 0.08 | 0.11 | 0.22 | 0.89 | 0.50 | 0.44 | 0.25 | 0.22 | 0.08 | 0.06 | 0.25 | 0.94 | 0.86 | 0.61 | 0.00 | 0.72 | 0.83 | 0.50 | 0.36 | 0.53 |

| Resins | 0.61 | 0.22 | 0.64 | 0.64 | 0.58 | 0.47 | 0.33 | 0.39 | 0.56 | 0.75 | 0.72 | 0.64 | 0.61 | 0.64 | 0.28 | 0.42 | 0.56 | 0.72 | 0.00 | 0.11 | 0.47 | 0.69 | 0.47 |

| CyC6 | 0.72 | 0.08 | 0.75 | 0.75 | 0.69 | 0.53 | 0.22 | 0.42 | 0.56 | 0.78 | 0.78 | 0.75 | 0.72 | 0.67 | 0.14 | 0.28 | 0.50 | 0.83 | 0.11 | 0.00 | 0.39 | 0.69 | 0.39 |

| Toluene | 0.39 | 0.36 | 0.47 | 0.47 | 0.44 | 0.19 | 0.58 | 0.25 | 0.78 | 0.47 | 0.50 | 0.47 | 0.50 | 0.36 | 0.47 | 0.61 | 0.58 | 0.50 | 0.47 | 0.39 | 0.00 | 0.31 | 0.00 |

| CH2Cl2 | 0.31 | 0.67 | 0.39 | 0.33 | 0.28 | 0.22 | 0.72 | 0.36 | 0.64 | 0.22 | 0.25 | 0.33 | 0.36 | 0.25 | 0.67 | 0.69 | 0.58 | 0.36 | 0.69 | 0.69 | 0.31 | 0.00 | 0.31 |

| Total asp. | 0.42 | 0.36 | 0.50 | 0.50 | 0.44 | 0.22 | 0.58 | 0.25 | 0.81 | 0.50 | 0.53 | 0.50 | 0.50 | 0.39 | 0.47 | 0.61 | 0.58 | 0.53 | 0.47 | 0.39 | 0.00 | 0.31 | 0.00 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stratiev, D.; Shishkova, I.; Palichev, G.N.; Atanassov, K.; Ribagin, S.; Nenov, S.; Nedanovski, D.; Ivanov, V. Study of Bulk Properties Relation to SARA Composition Data of Various Vacuum Residues Employing Intercriteria Analysis. Energies 2022, 15, 9042. https://doi.org/10.3390/en15239042

Stratiev D, Shishkova I, Palichev GN, Atanassov K, Ribagin S, Nenov S, Nedanovski D, Ivanov V. Study of Bulk Properties Relation to SARA Composition Data of Various Vacuum Residues Employing Intercriteria Analysis. Energies. 2022; 15(23):9042. https://doi.org/10.3390/en15239042

Chicago/Turabian StyleStratiev, Dicho, Ivelina Shishkova, Georgi Nikolov Palichev, Krassimir Atanassov, Simeon Ribagin, Svetoslav Nenov, Dimitar Nedanovski, and Vitaly Ivanov. 2022. "Study of Bulk Properties Relation to SARA Composition Data of Various Vacuum Residues Employing Intercriteria Analysis" Energies 15, no. 23: 9042. https://doi.org/10.3390/en15239042