An Experimental Study and Statistical Analysis on the Electrical Properties of Synthetic Ester-Based Nanofluids

Abstract

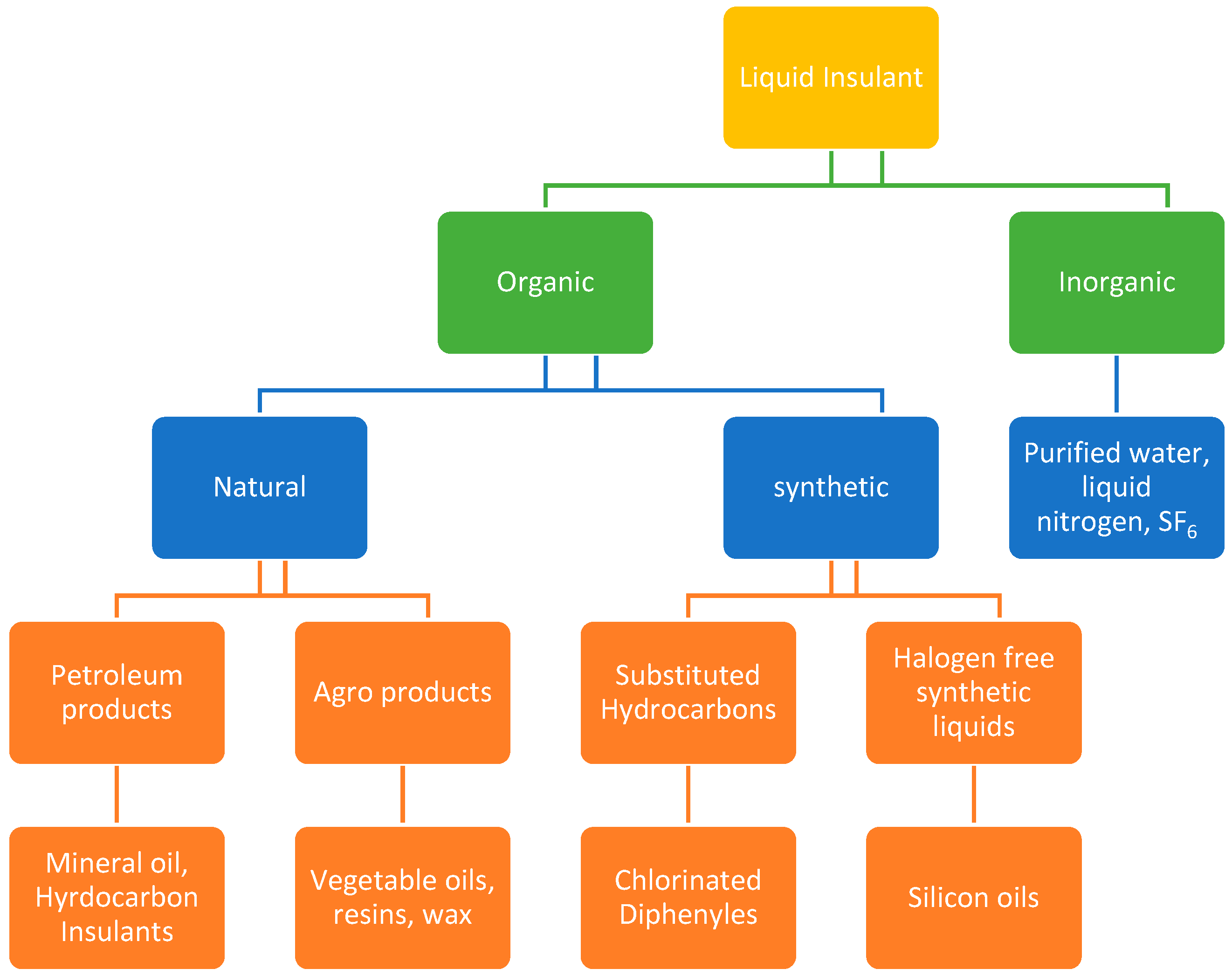

:1. Introduction

2. Experimental Work Arrangements, Steps, and Setup Description

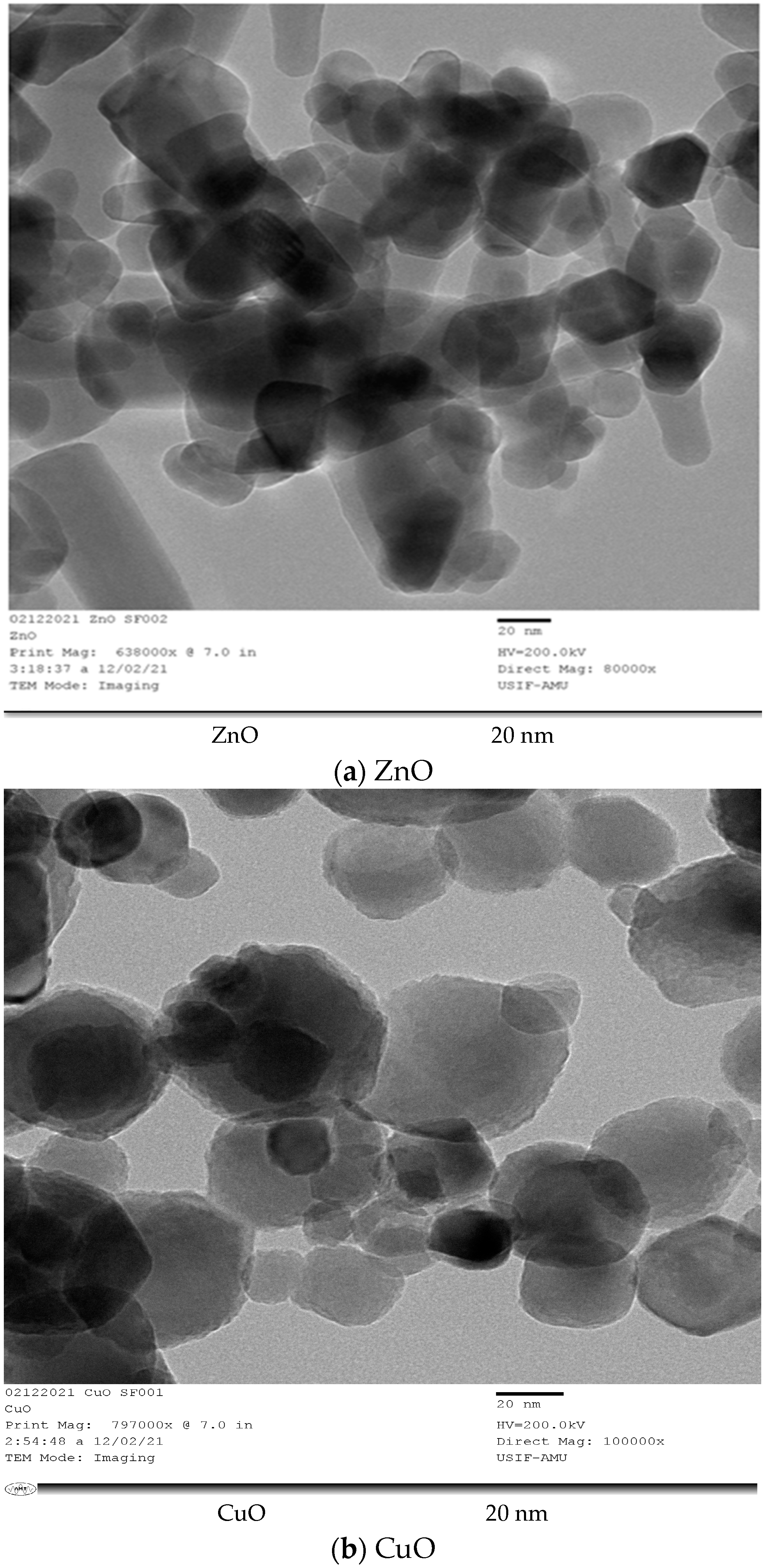

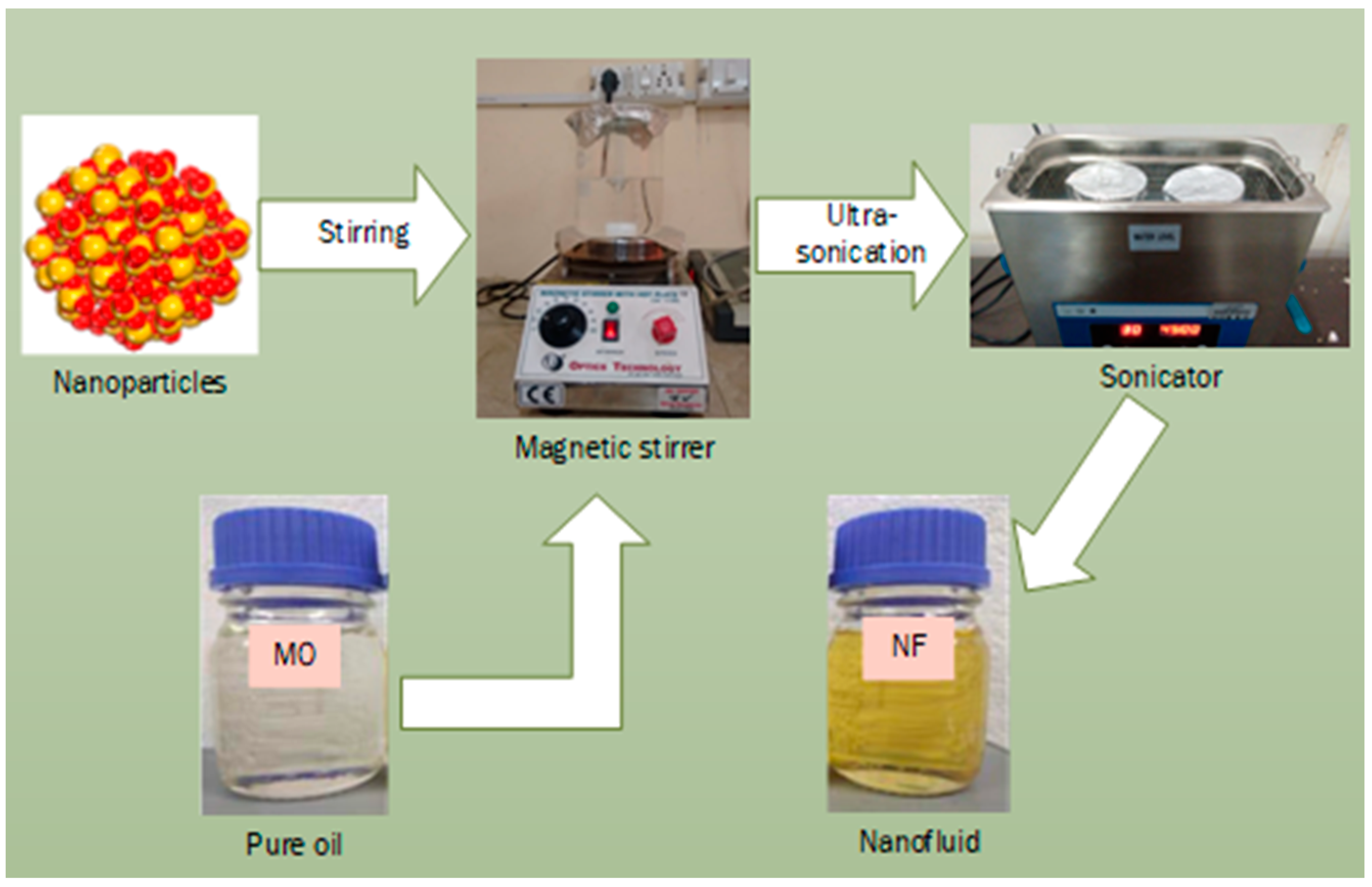

2.1. Materials Used and Preparation of Nanofluids

2.2. Stability of Nanofluids

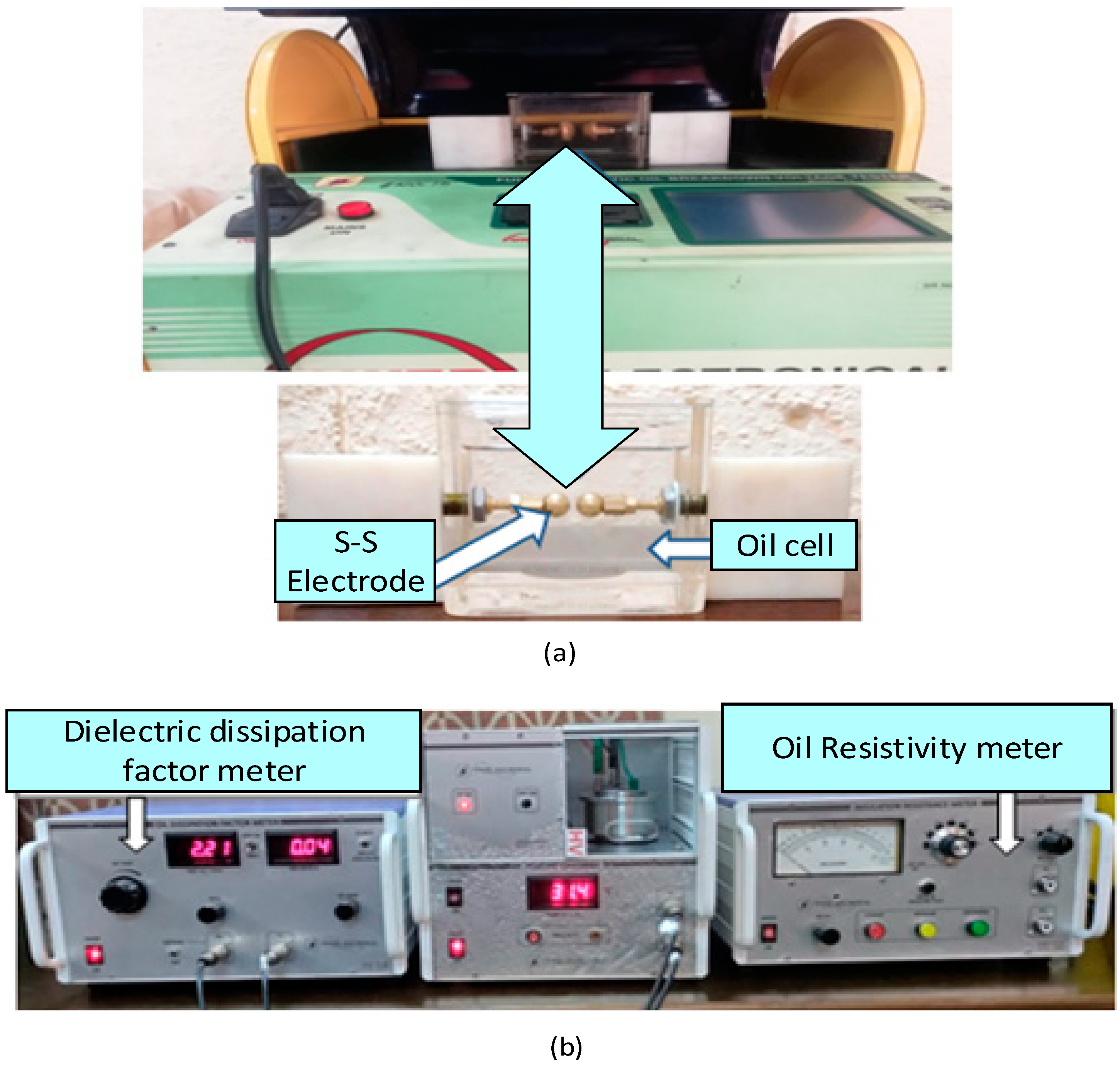

2.3. Measurement of Electrical Properties

2.4. Dielectric Modification Mechanism

3. Experimental Results and Discussion

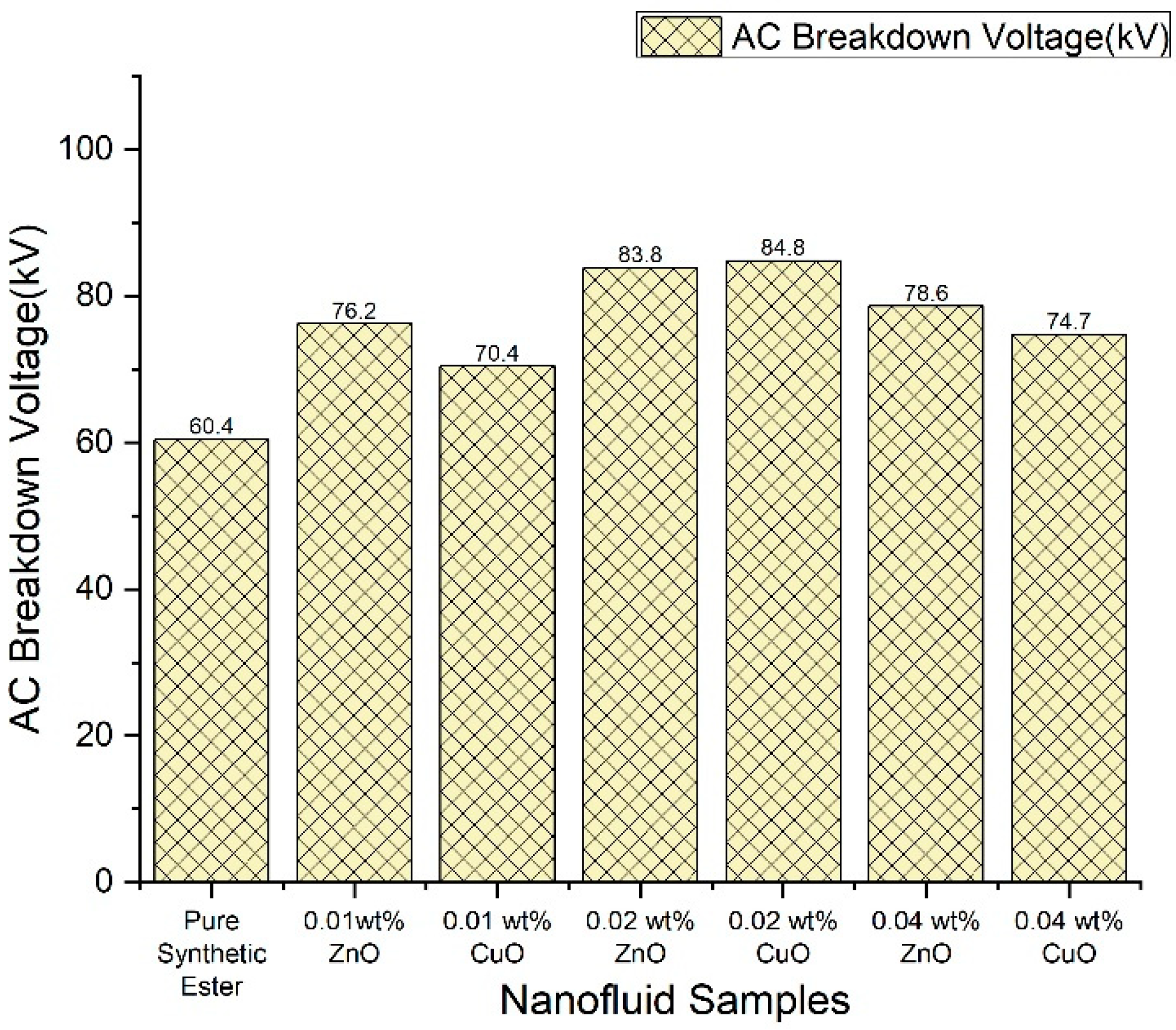

3.1. AC Breakdown Voltage

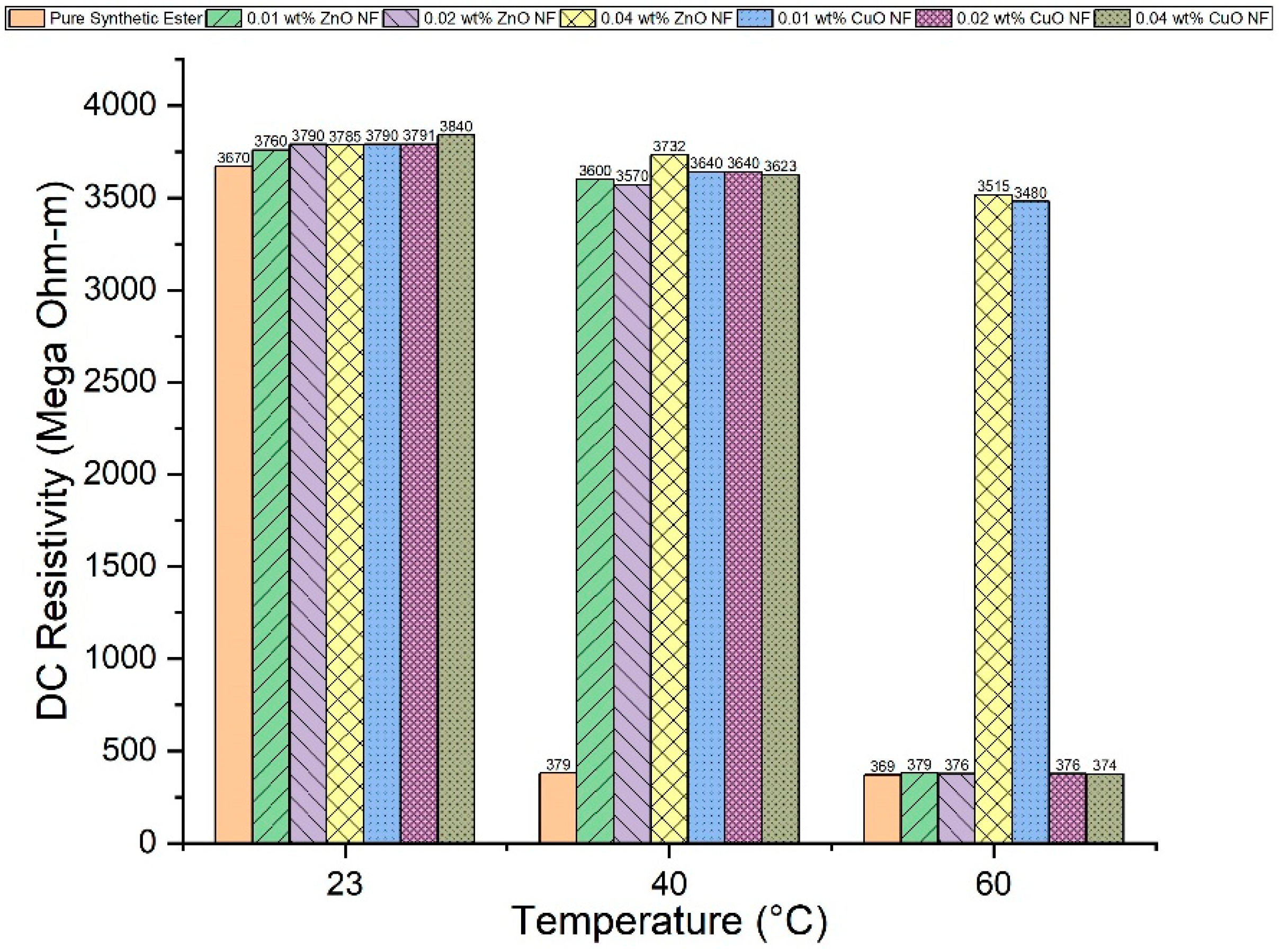

3.2. DC Resistivity

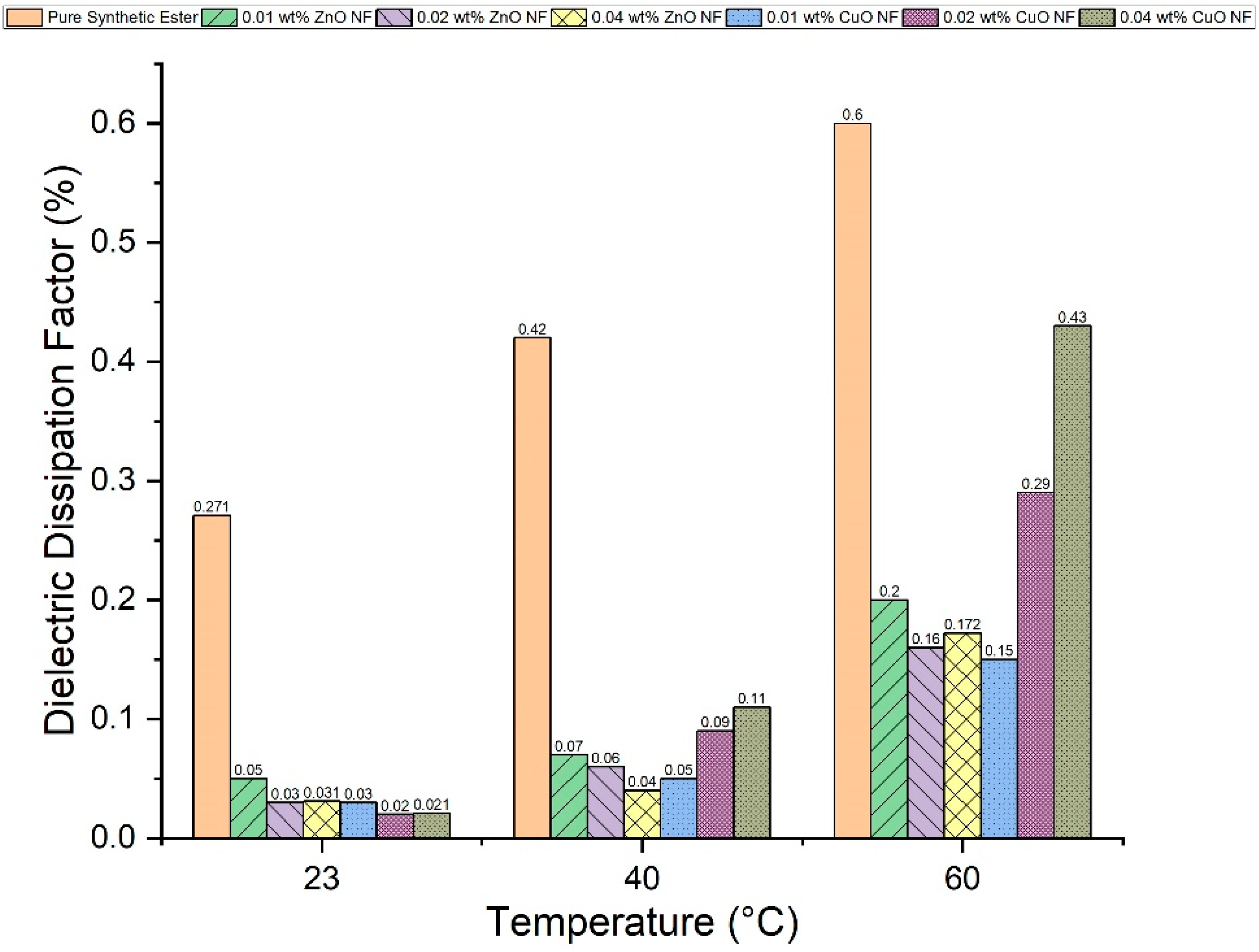

3.3. Dielectric Dissipation Factor (tanδ)

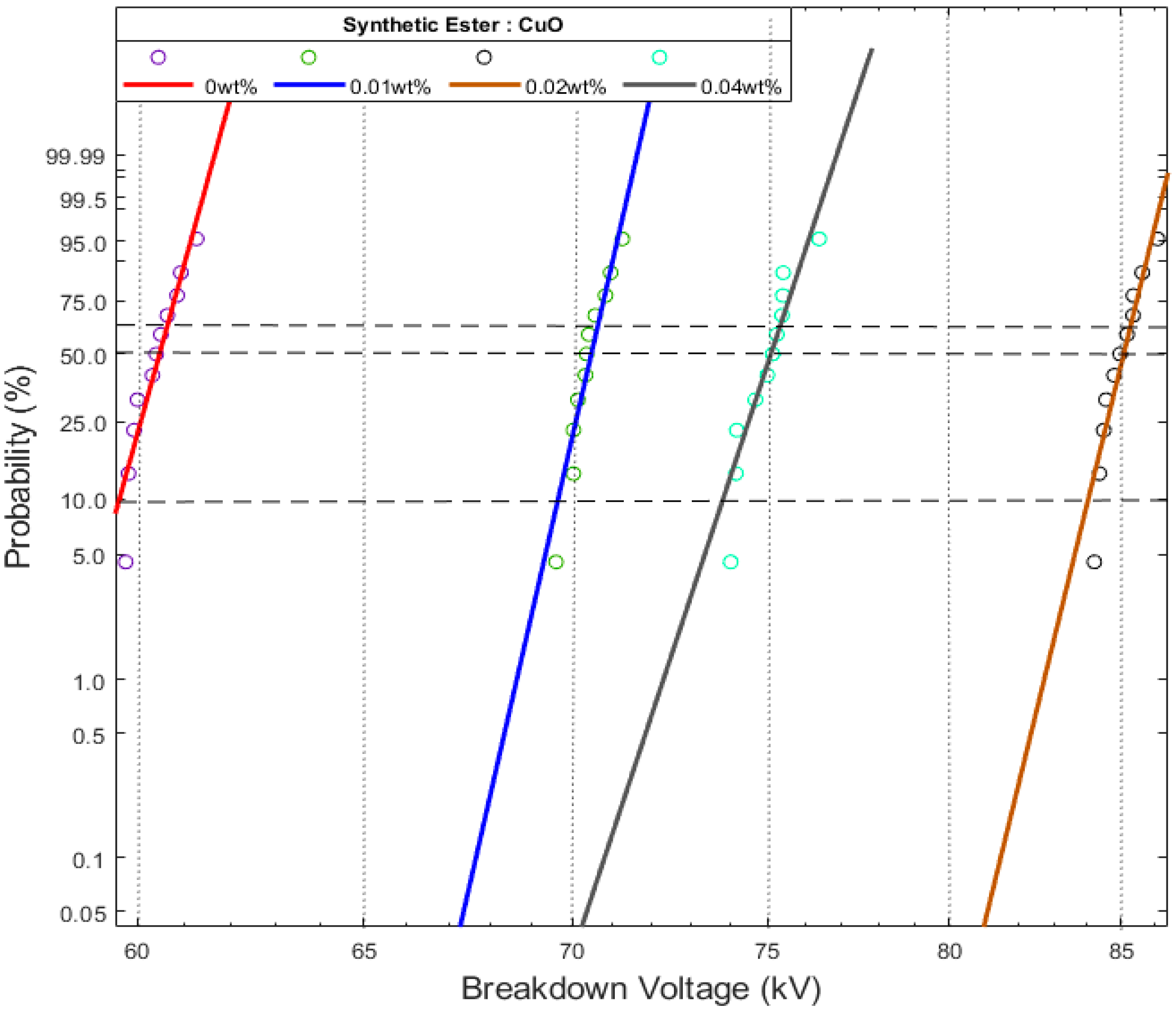

4. Statistical Analysis

5. Conclusions

- When ZnO and CuO were added to the pure fluid, the inclusion of nanoparticles increased the AC BDV for both materials. Up to a certain optimal concentration, the improvement is associated to the electron scavenge process and shallow trap theory, as stated before, but beyond that point, the BDV saturates because of the aggregation of nanoparticles at greater concentrations.

- Because ZnO nanofluid has better dielectric capabilities than CuO nanofluid and has a smaller relaxation time constant, it performed better than the latter.

- The inclusion of ZnO and CuO nanoparticles improved the nanofluids’ resistivity. The nanoparticles suppress streamer propagation, capture flow of electrons, and reduce conductivity while increasing resistance.

- When the temperature was under 40 °C, both nanofluids responded in nearly the same manner. Beyond 40 °C, 0.04 weight percent ZnO NF outperforms other concentrations in comparison to 0.01 weight percent CuO NF.

- By preventing leakage current from flowing, the inclusion of nanoparticles lowers the dissipation factor of NFs at all concentrations as compared to an unmodified SE. The dissipation factor is least for temperatures under 60 °C when ZnO nanofluids are incorporated with 0.02 weight percent, and 0.02 weight percent ZnO nanofluid performed better at 60 °C.

- The statistical technique applied gives enhanced breakdown voltage uniformly for synthetic esters due to ZnO and CuO nanoparticles at all probabilities, specifically more pronounced at lower concentrations and higher probability.

- For CuO nanofluids, 0.01 weight percent concentration yields the minimum values of the dissipation factor compared to those other concentrations for nearly the whole temperature range.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Prasath, R.T.A.R.; Roy, N.K.; Mahato, S.N.; Thomas, P. Mineral oil based high permittivity CaCu3Ti4O12 (CCTO) nanofluids for power transformer application. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 2344–2353. [Google Scholar] [CrossRef]

- Lv, Y.; Rafiq, M.; Li, C.; Shan, B. Study of Dielectric Breakdown Performance of Transformer Oil Based Magnetic Nanofluids. Energies 2017, 10, 1025. [Google Scholar] [CrossRef] [Green Version]

- Rafiq, M.; Shafique, M.; Azam, A.; Ateeq, M. The impacts of nanotechnology on the improvement of liquid insulation of transformers: Emerging trends and challenges. J. Mol. Liq. 2020, 302, 112482. [Google Scholar] [CrossRef]

- Amin, D.; Walvekar, R.; Khalid, M.; Vaka, M.; Mubarak, N.M.; Gupta, T.C.S.M. Recent Progress and Challenges in Transformer Oil Nanofluid Development: A Review on Thermal and Electrical Properties. IEEE Access 2019, 7, 151422–151438. [Google Scholar] [CrossRef]

- Du, B.X.; Li, X.L. Dielectric and thermal characteristics of vegetable oil filled with BN nanoparticles. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 956–963. [Google Scholar] [CrossRef]

- Perrier, C.; Beroual, A. Experimental investigations on insulating liquids for power transformers: Mineral, ester, and silicone oils. IEEE Electr. Insul. Mag. 2009, 25, 6–13. [Google Scholar] [CrossRef]

- Abd-Elhady, A.M.; Ibrahim, M.E.; Taha, T.; Izzularab, M.A. Effect of temperature on AC breakdown voltage of nanofilled transformer oil. IET Sci. Meas. Technol. 2018, 12, 138–144. [Google Scholar] [CrossRef]

- Yang, L.; Liao, R.; Sun, C.; Sun, H. Study on the influence of natural ester on thermal ageing characteristics of oil-paper in power transformer. In Proceedings of the 2008 International Conference on High Voltage Engineering and Application, Chongqing, China, 9–12 November 2008. [Google Scholar]

- Rozga, P.; Beroual, A.; Przybylek, P.; Jaroszewski, M.; Strzelecki, K. A Review on Synthetic Ester Liquids for Transformer Applications. Energies 2020, 13, 6429. [Google Scholar] [CrossRef]

- Du, Y.; Lv, Y.; Li, C.; Chen, M.; Zhong, Y.; Zhou, J.; Li, X.; Zhou, Y. Effect of semiconductive nanoparticles on insulating performances of transformer oil. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 770–776. [Google Scholar]

- Hwang, J.G.; O’Sullivan, F.; Zahn, M.; Hjortstam, O.; Pettersson, L.A.; Liu, R. Modelling of Streamer Propagation in Transformer Oil-Based Nanofluids. In Proceedings of the 2008 Annual Report, Conference on Electrical Insulation Dielectric Phenomena, Quebec, QC, Canada, 26–29 October 2008; pp. 361–366. [Google Scholar]

- O’Sullivan, F.; Hwang, J.G.; Zahn, M.; Hjortstam, O.; Pettersson, L.; Liu, R.; Biller, P. A model for the initiation and propagation of positivestreamers in transformer oil. In Proceedings of the IEEE International Symposium on Electrical Insulation ISEI08, Vancouver, BC, Canada, 9–12 June 2008; pp. 210–214. [Google Scholar]

- Segal, V.; Hjortsberg, A.; Rabinovich, A.; Nattrass, D.; Raj, K. AC (60 Hz) and impulse breakdown strength of a colloidal fluid based on transformer oil and magnetite nanoparticles. In Proceedings of the Conference Record of the 1998 IEEE International Symposium on Electrical Insulation (Cat. No.98CH36239), Arlington, VA, USA, 7–10 June 1998; pp. 619–622. [Google Scholar]

- Khan, Q.; Singh, V.; Ahmad, F.; Khan, A.A. Dielectric performance of magnetic nanoparticles-based ester oil. IET Nanodielectr. 2021, 4, 45–52. [Google Scholar] [CrossRef]

- Khan, S.A.; Tariq, M.; Khan, A.A.; Alamri, B. Effect of Iron/Titania-Based Nanomaterials on the Dielectric Properties of Mineral Oil, Natural and Synthetic Esters as Transformers Insulating Fluid. IEEE Access 2021, 9, 168971–168980. [Google Scholar] [CrossRef]

- Hwang, J.G.; Zahn, M.; O’Sullivan, F.M.; Pettersson, L.A.; Hjortstam, O.; Liu, R. Electron scavenging by conductive nanoparticles in oil insulated power transformers. In Proceedings of the Electronics Joint Conference, Boston, MA, USA, 2009; Available online: https://www.nanoqed.org/resources/2009Zahn.pdf (accessed on 24 October 2022).

- Hwang, J.G.; Zahn, M.; O’Sullivan, F.M.; Pettersson, L.A.; Hjortstam, O.; Liu, R. Effects of nanoparticle charging on streamer development in transformer oil-based nanofluids. J. Appl. Phys. 2010, 107, 014310. [Google Scholar] [CrossRef] [Green Version]

- Zhou, Y.; Sui, S.; Li, J.; Ouyang, Z.; Lv, Y.; Li, C.; Lu, W. The effects of shallow traps on the positive streamer electrodynamics in transformer oil based nanofluids. J. Phys. D Appl. Phys. 2018, 51, 105304. [Google Scholar] [CrossRef]

- Du, Y.; Lv, Y.; Li, C.; Chen, M.; Zhou, J.; Li, X.; Zhou, Y.; Tu, Y. Effect of electron shallow trap on breakdown performance of transformer oil-based nanofluids. J. Appl. Phys. 2011, 110, 104104. [Google Scholar] [CrossRef]

- YZhou, Y.; Zhong, Y.X.; Chen, M.T.; Zhang, S.N.; Du, Y.F.; Lv, Y.Z.; Li, C.; Liu, T. Effect of nanoparticles on electrical characteristics of transformer oil-based nanofluids impregnated pressboard. In Proceedings of the Conference Record of IEEE International Symposium on Electrical Insulation, San Juan, PR, USA, 10–13 June 2012; pp. 650–653. [Google Scholar]

- Khan, S.A.; Khan, A.A.; Tariq, M. Experimental Analysis for the Effect of Fe/Ti Oxides and Fe-Cu Nanoparticles on the Dielectric Strength of Transformer Oil. In Proceedings of the 2019 International Conference on High Voltage Engineering and Technology (ICHVET), Hyderabad, India, 7–8 February 2019; pp. 1–6. [Google Scholar]

- Khan, S.A.; Khan, A.A.; Tariq, M. Measurement of Tan-delta and DC Resistivity of Synthetic Ester Based Oil Filled with Fe2O3, TiO2 and Al2O3 Nanoparticles. Smart Sci. 2021, 9, 216–225. [Google Scholar] [CrossRef]

- Khan, S.A.; Tariq, M.; Khan, A.A.; Wali, S.; Taufiq, Z. Dielectric Performance of ZnO and CuO-based Synthetic Ester Fluid under Temperature Variation. In Proceedings of the 2022 2nd International Conference on Emerging Frontiers in Electrical and Electronic Technologies (ICEFEET), Patna, India, 24–25 June 2022; pp. 1–5. [Google Scholar] [CrossRef]

- Du, Y.-F.; Lv, T.-Z.; Zhou, J.-Q.; Li, X.-X.; Li, C.-R. Breakdown properties of transformer oil-based TiO2 nanofluid. In Proceedings of the 2010 Annual Report Conference on Electrical Insulation and Dielectic Phenomena, West Lafayette, IN, USA, 17–20 October 2010; pp. 1–4. [Google Scholar] [CrossRef]

- Peppas, G.D.; Charalampakos, V.P.; Pyrgioti, E.C.; Danikas, M.G.; Bakandritsos, A.; Gonos, I.F. Statistical investigation of AC breakdown voltage of nanofluids compared with mineral and natural ester oil. IET Sci. Meas. Technol. 2016, 10, 644–652. [Google Scholar] [CrossRef]

- Khaled, U.; Beroual, A.; Khan, Y. Statistical investigation of AC breakdown voltage of natural ester with electronic scavenger additives. IEEE Trans. Dielectr. Electr. Insul. 2019, 26, 2012–2018. [Google Scholar] [CrossRef]

| Parameters | ZnO | CuO |

|---|---|---|

| Particle size | 20–25 nm (TEM) | 20 nm (TEM) |

| Density (gm/cc) | 5.6 gm/cc | 6.3 gm/cc |

| Appearance | Fine powder | Fine Powder |

| Properties | Typical Values (MIDEL 7131) |

|---|---|

| Density at 20 °C (Kg/dm3) | 0.97 |

| Flash point (°C) | 260 |

| Appearance | Clear free from water |

| Fire point (°C) | 316 |

| Breakdown voltage (kV) | Greater than 75 |

| DC resistivity at 90 °C (GΩ·m) | Greater than 20 |

| Moisture content (ppm) | 50 |

| Biodegradability | Readily Biodegradable |

| Symbols and Abbreviations | Actual Meaning |

|---|---|

| NFs MO | Nanofluids Mineral oil |

| SE | Synthetic Ester |

| NE | Natural Ester |

| δ | Loss angle |

| bdv | Breakdown voltage |

| TEM | Transmission electron microscopy |

| nm | Nanometer |

| MΩ-m | Mega ohm-meter |

| wt% | Weight percent |

| Pure Synthetic Ester Oil BDV (kV) | Concentration | ZnO | CuO | ||

|---|---|---|---|---|---|

| BDV (kV) | % Enhancement | BDV (kV) | % Enhancement | ||

| 60.40 | 0.01 wt% | 76.20 | 26.20 | 70.40 | 16.50 |

| 60.40 | 0.02 wt% | 83.80 | 38.70 | 84.80 | 40.40 |

| 60.40 | 0.04 wt% | 78.60 | 30.13 | 74.70 | 23.67 |

| Temperature (°C) | DC Resistivity (Mega Ohm-m) | ||||||

|---|---|---|---|---|---|---|---|

| Pure Synthetic Ester | 0.01 wt% ZnO | 0.02 wt% ZnO | 0.04 wt% ZnO | 0.01 wt% CuO | 0.02 wt% CuO | 0.04 wt% CuO | |

| 23.0 | 3670.0 | 3760.0 | 3790.0 | 3785.0 | 3790.0 | 3791.0 | 3840.0 |

| 40.0 | 379.0 | 3600.0 | 3570.0 | 3732.0 | 3640.0 | 3640.0 | 3623.0 |

| 60.0 | 369.0 | 379.0 | 376.0 | 3515.0 | 3480.0 | 376.0 | 374.0 |

| Temperature (°C) | Dielectric Dissipation Factor (%) | ||||||

|---|---|---|---|---|---|---|---|

| Pure Synthetic Ester | 0.01 wt% ZnO | 0.02 wt% ZnO | 0.04 wt% ZnO | 0.01 wt% CuO | 0.02 wt% CuO | 0.04 wt% CuO | |

| 23.0 | 0.2710 | 0.050 | 0.030 | 0.031 | 0.030 | 0.020 | 0.021 |

| 40.0 | 0.420 | 0.070 | 0.060 | 0.040 | 0.050 | 0.090 | 0.11 |

| 60.0 | 0.60 | 0.20 | 0.160 | 0.172 | 0.150 | 0.290 | 0.43 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khan, S.A.; Tariq, M.; Khan, A.A.; Urooj, S.; Mihet-Popa, L. An Experimental Study and Statistical Analysis on the Electrical Properties of Synthetic Ester-Based Nanofluids. Energies 2022, 15, 9127. https://doi.org/10.3390/en15239127

Khan SA, Tariq M, Khan AA, Urooj S, Mihet-Popa L. An Experimental Study and Statistical Analysis on the Electrical Properties of Synthetic Ester-Based Nanofluids. Energies. 2022; 15(23):9127. https://doi.org/10.3390/en15239127

Chicago/Turabian StyleKhan, Suhaib Ahmad, Mohd Tariq, Asfar Ali Khan, Shabana Urooj, and Lucian Mihet-Popa. 2022. "An Experimental Study and Statistical Analysis on the Electrical Properties of Synthetic Ester-Based Nanofluids" Energies 15, no. 23: 9127. https://doi.org/10.3390/en15239127