Optimal Dispatch of Agricultural Integrated Energy System with Hybrid Energy Storage

Abstract

:1. Introduction

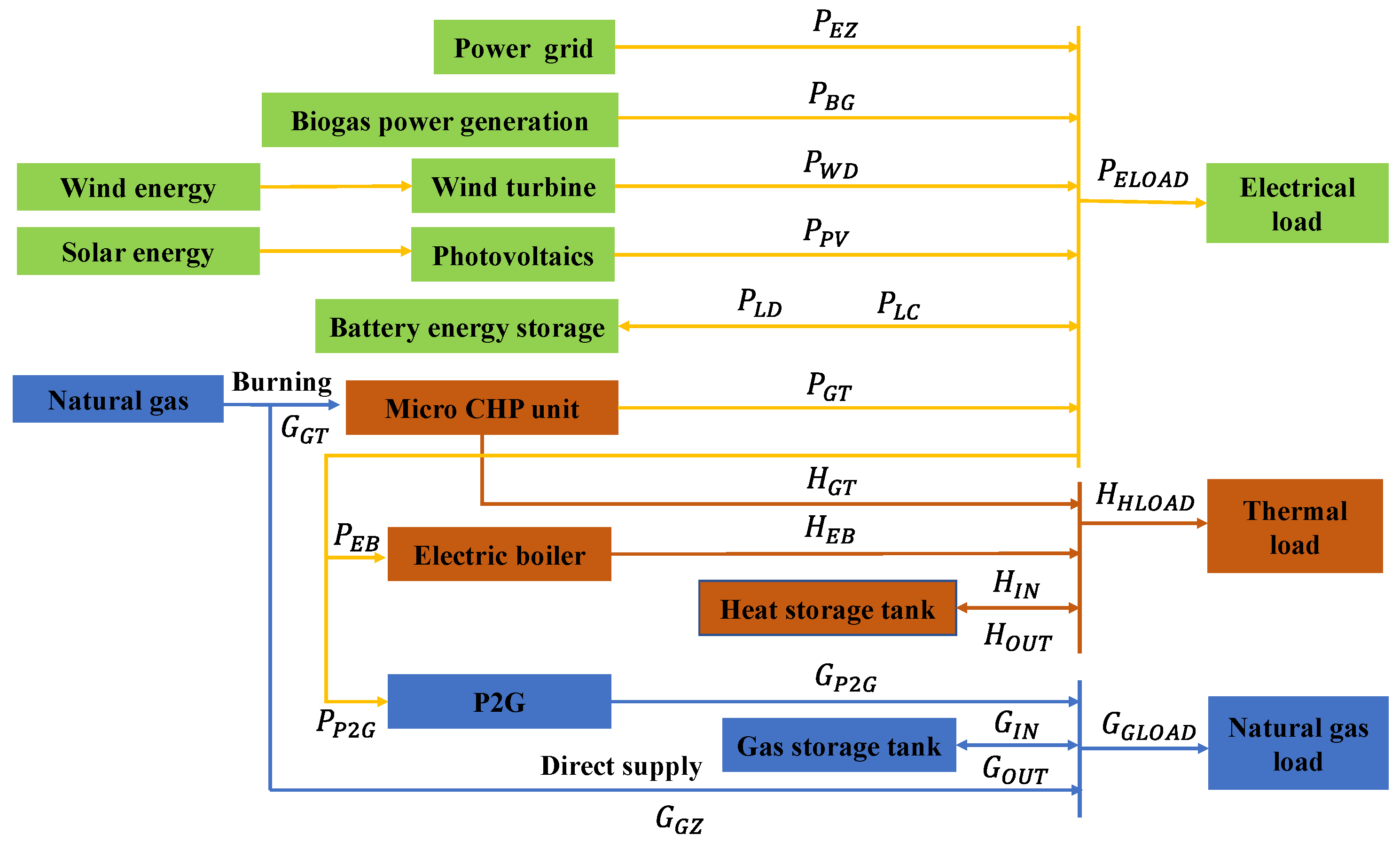

2. AIES Structure with HES and Its Equipment Model

2.1. The AIES Structure

2.2. Equipment Model of AIES

- MG-CHP unit

- 2.

- Electric boiler

- 3.

- P2G

- 4.

- Biogas power generation unit

- 5.

- Battery energy storage

- 6.

- Heat storage tank

- 7.

- Gas storage tank

3. Optimal Dispatching Model of AIES

3.1. Objective Function

3.2. Constraints

- Electrical power balance constraint.

- Thermal power balance constraint

- Natural gas power balance constraint

- Equipment output constraint

- Equipment climbing constraint.

4. Results and Analysis

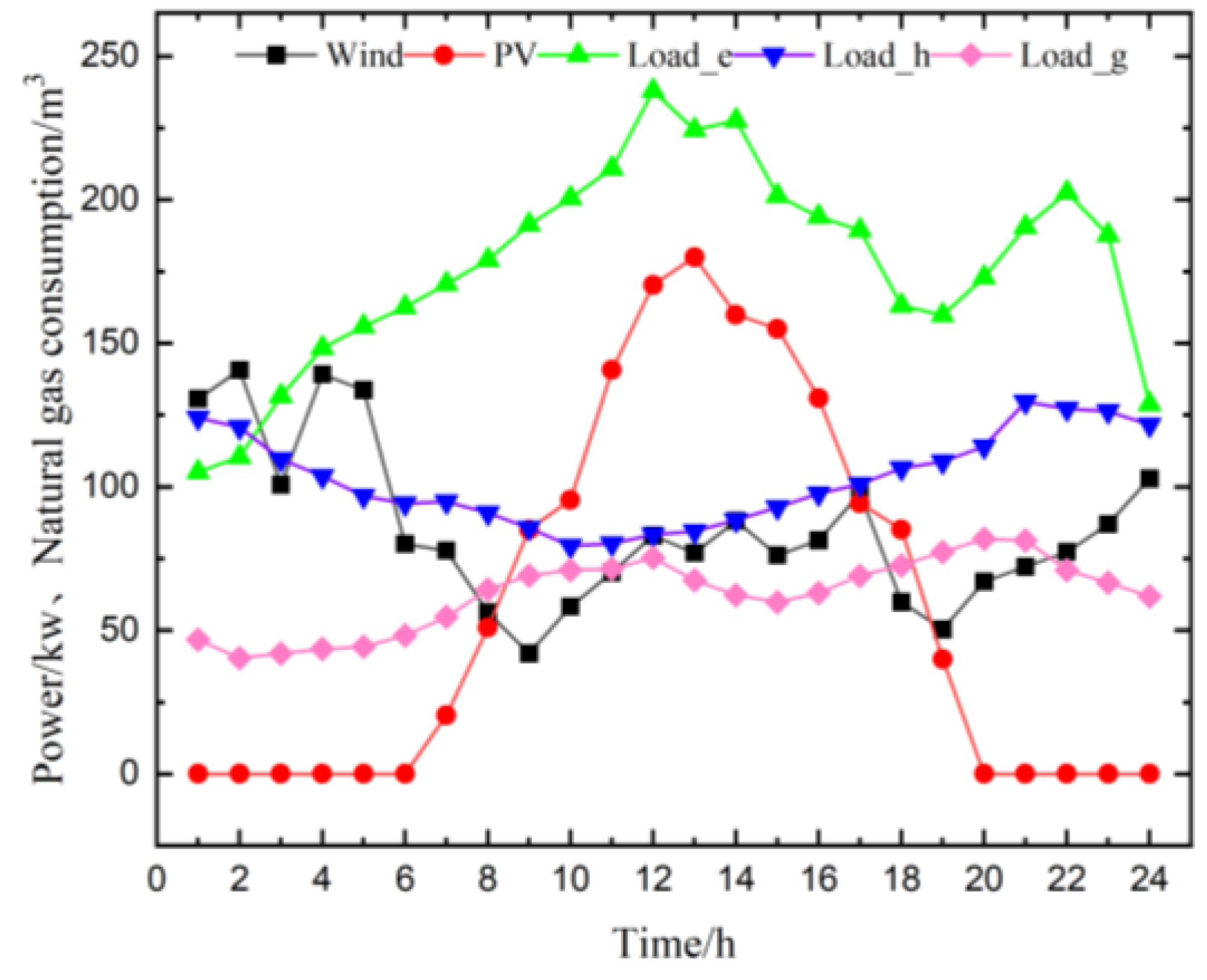

4.1. Typical Day Selection

4.2. Simulation Parameters

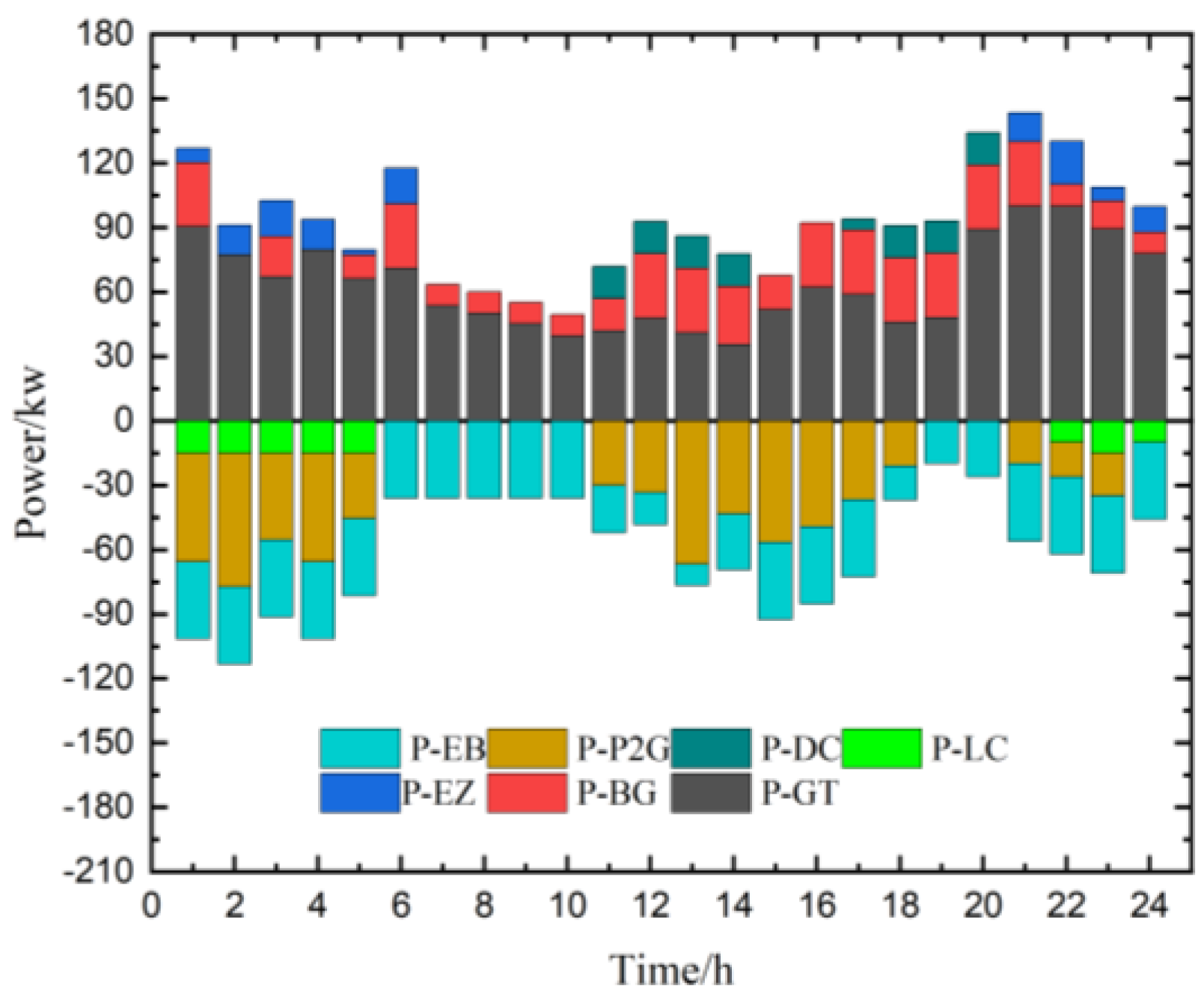

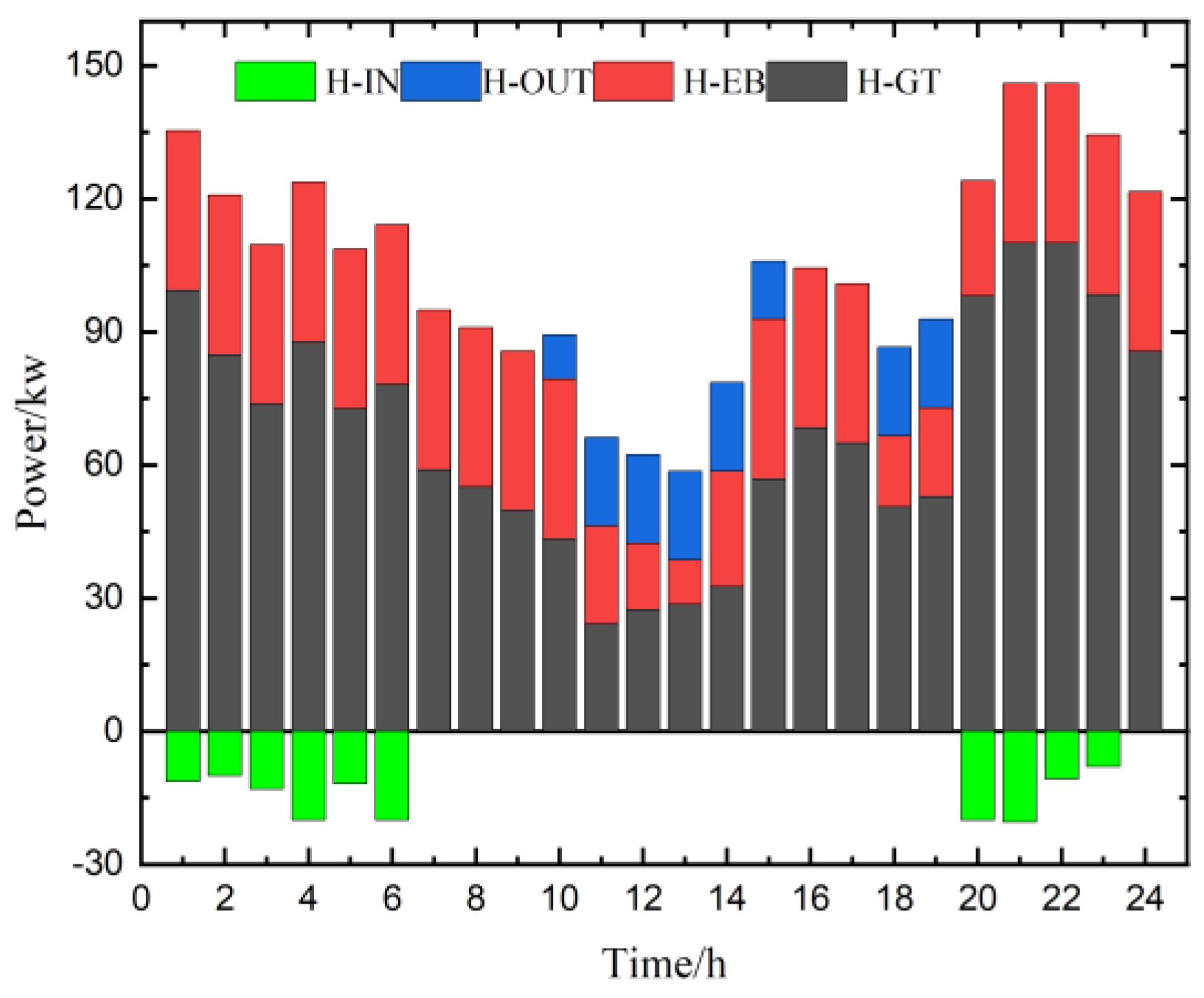

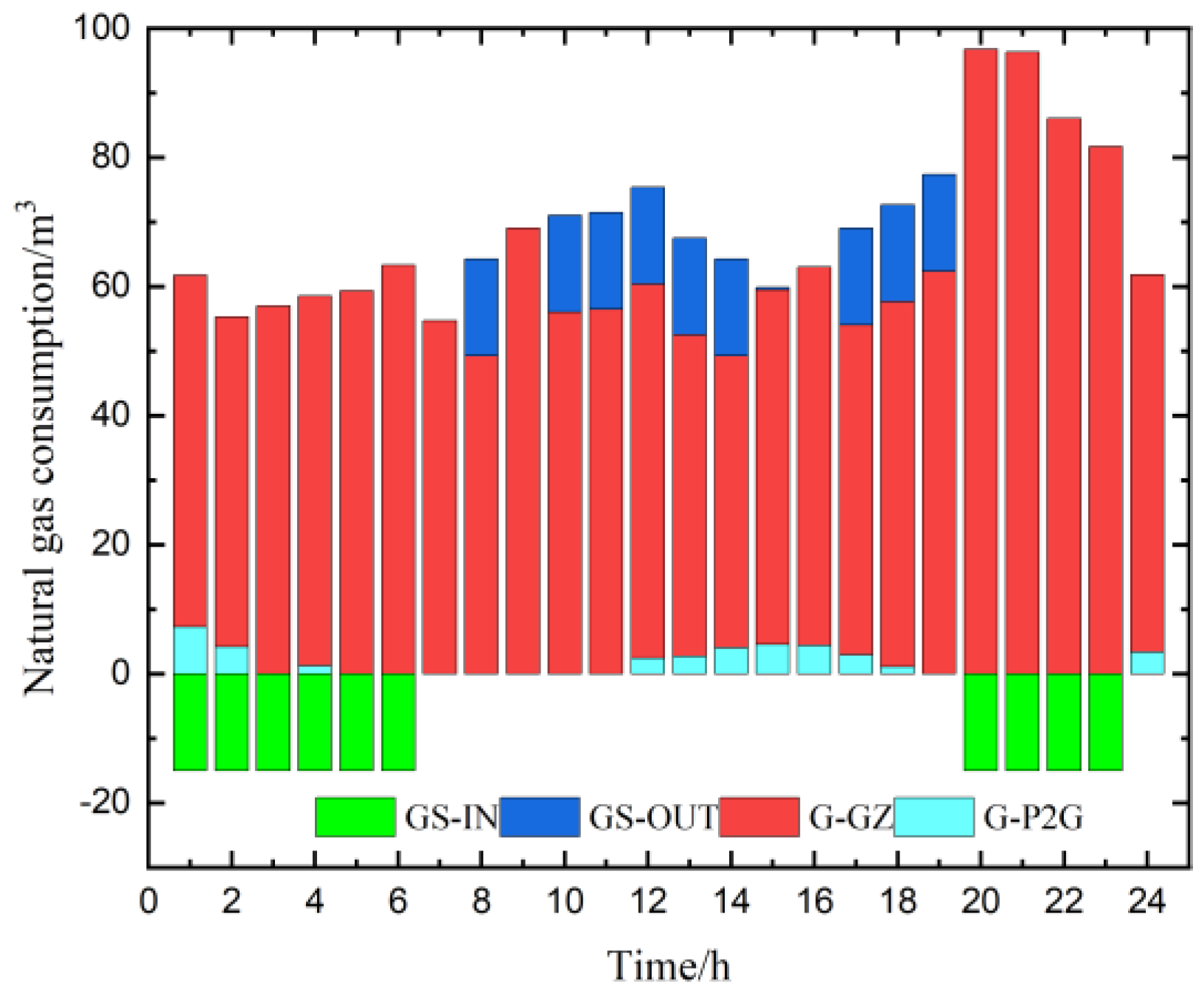

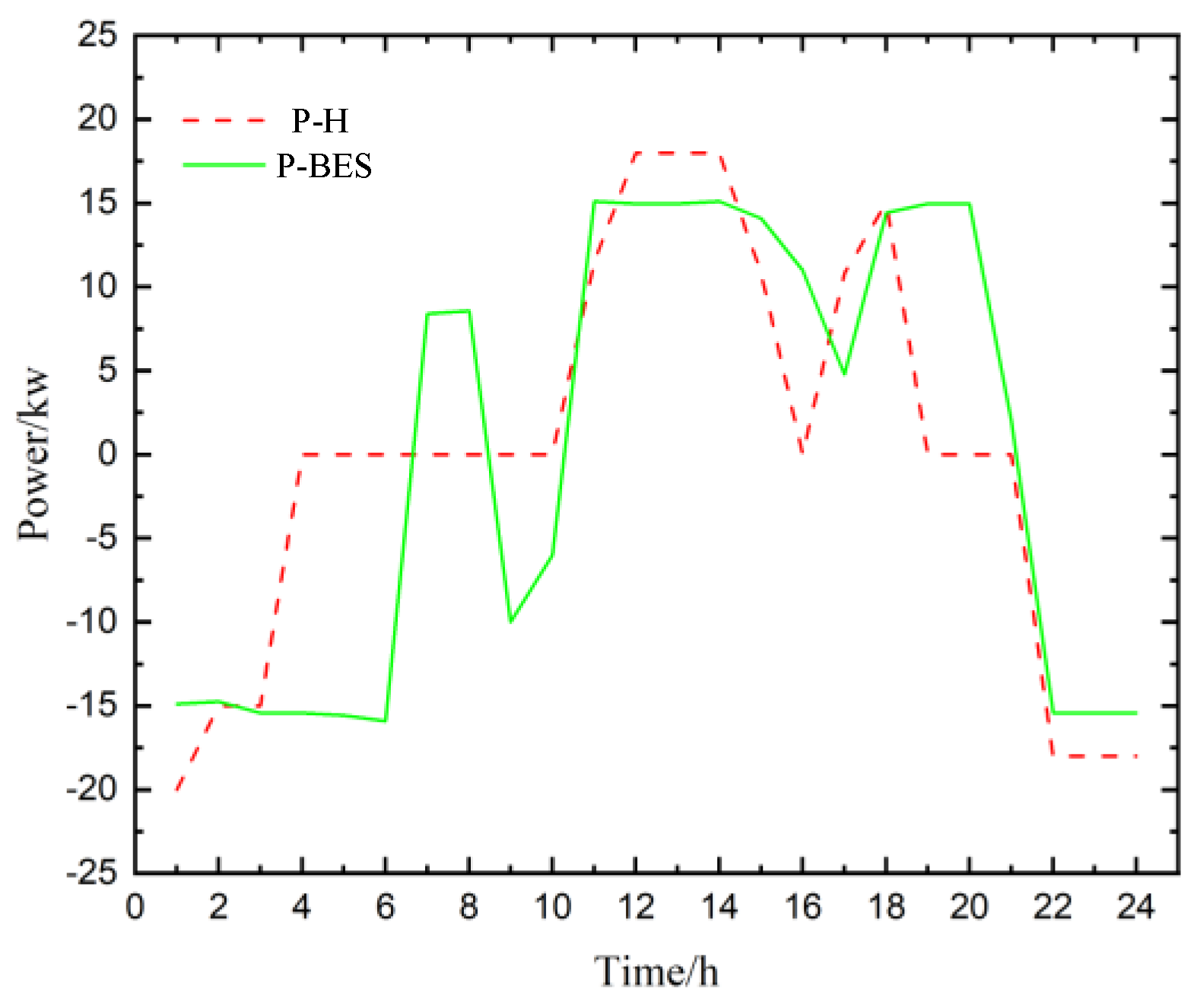

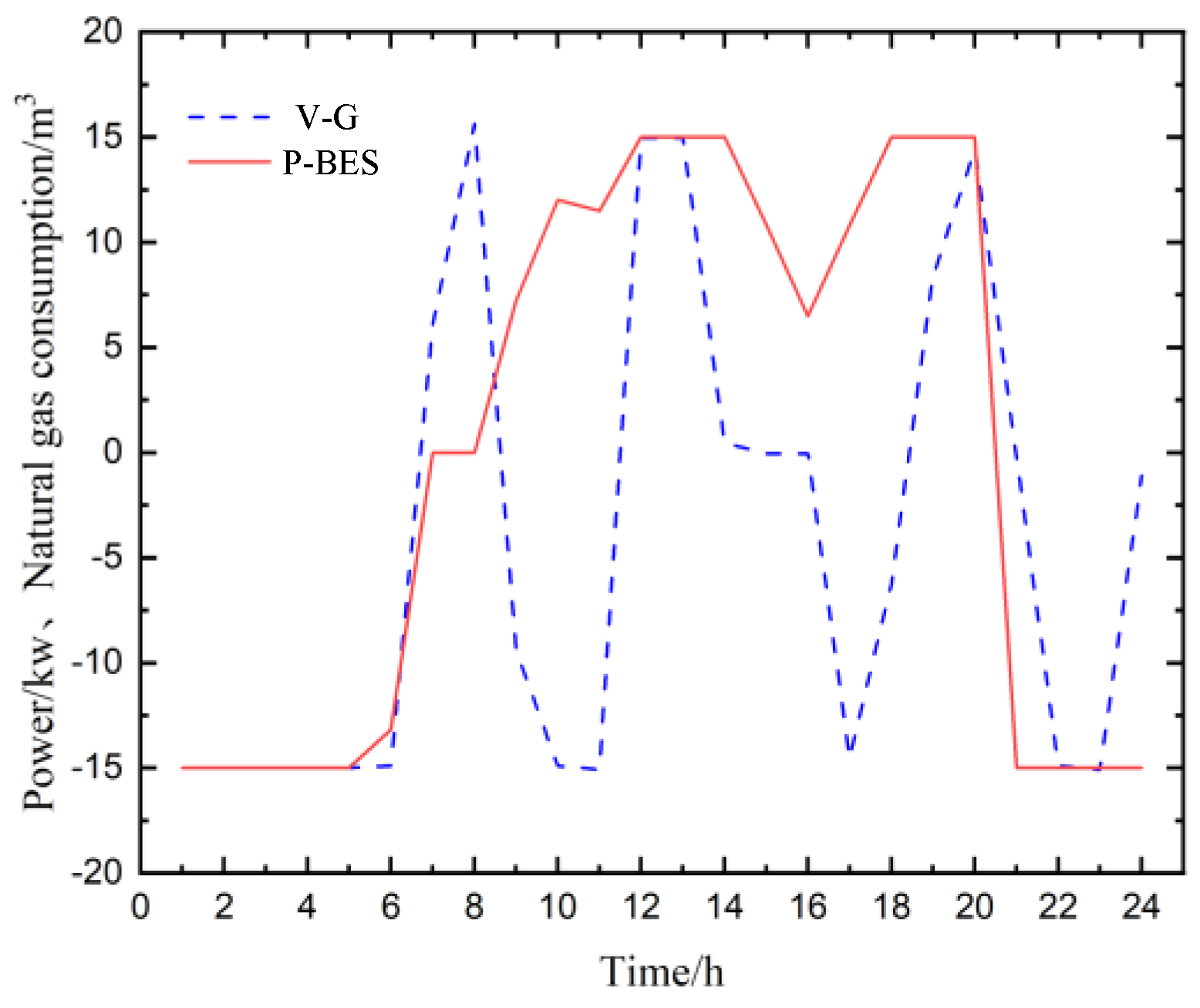

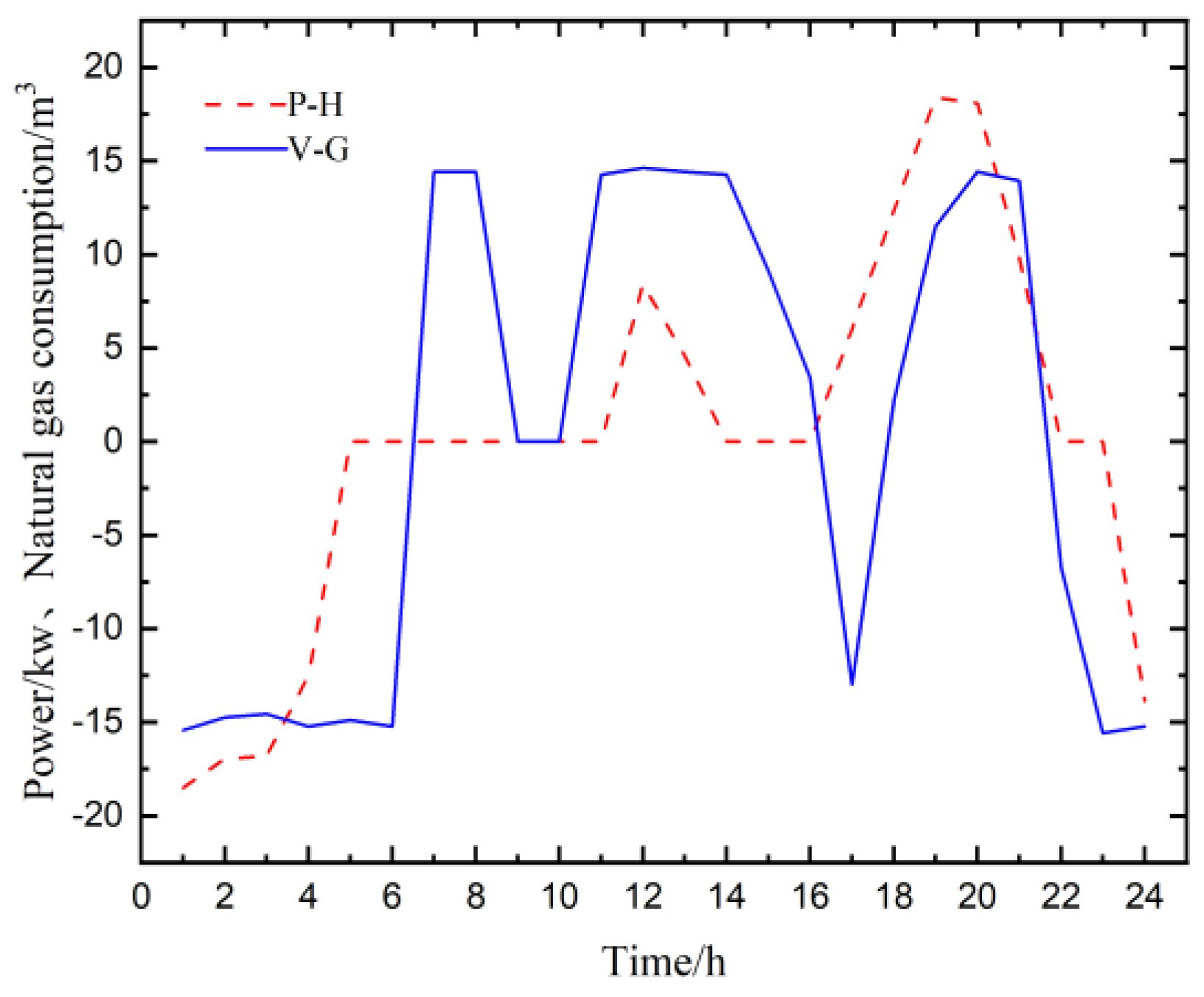

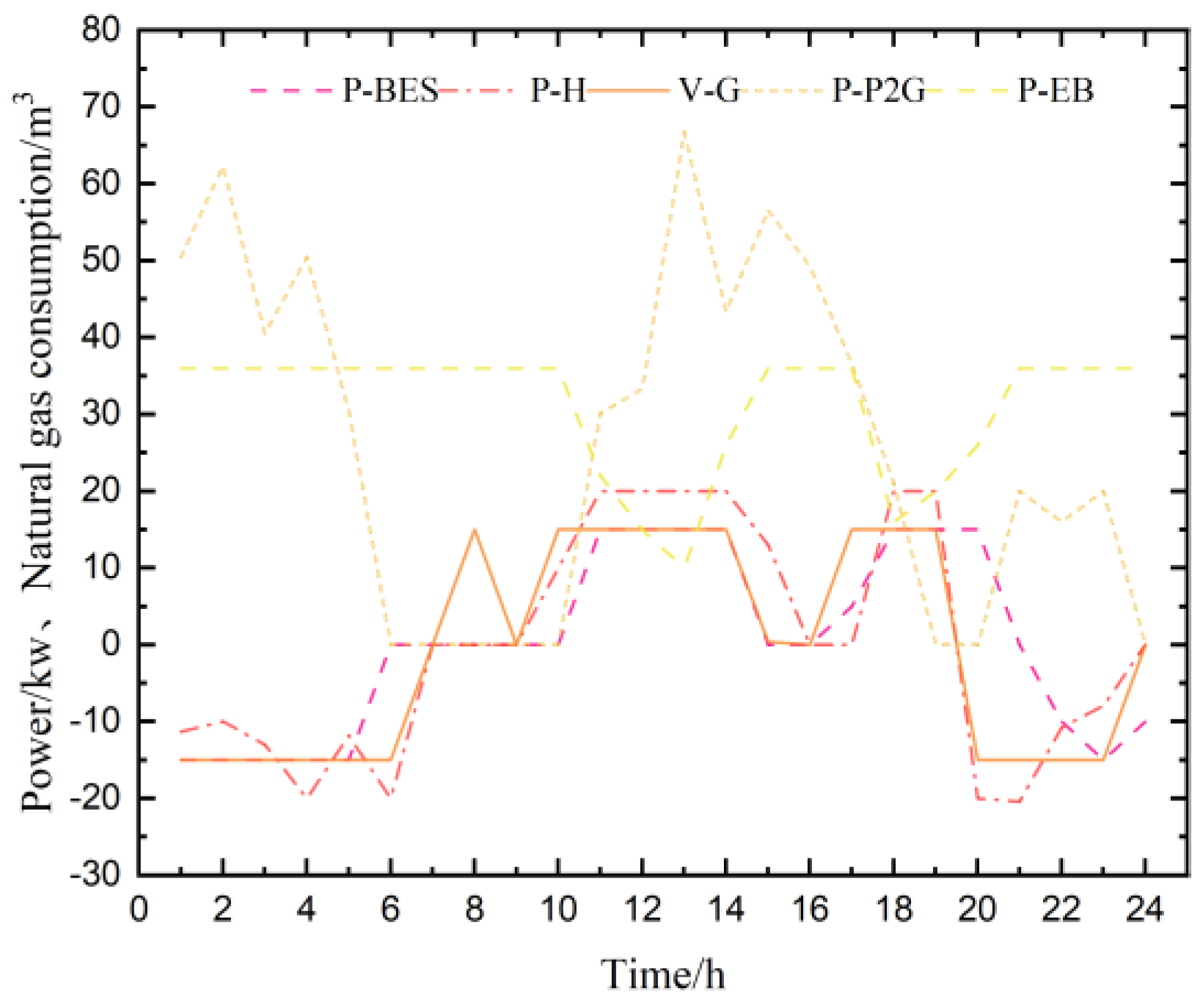

4.3. Analysis of Dispatching Results

5. Conclusions

- Compared with the original system, the optimized system reduces the comprehensive cost by 20%, reduces the environmental protection cost by around 23.2%, and improves the energy efficiency by around 51%. The system can balance economy and energy utilization efficiency after introducing HES, P2G, and EB equipment.

- Under the HES mode, the output power of energy storage equipment is mainly based on the change in demand of the corresponding load, with fewer transformation times between different energies and less energy transformation loss.

- Multi-energy coupled AIES can realize low-cost renewable energy accommodation and can enhance the flexibility of system operation. At the same time, the efficiencies offered by AIES can lead to energy independence, economic competitiveness, job creation, and the more intelligent use of resources.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ali, F.; Ahmar, M.; Jiang, Y.; AlAhmad, M. A techno-economic assessment of hybrid energy systems in rural Pakistan. Energy 2021, 215, 119103. [Google Scholar] [CrossRef]

- Liu, Y.; Zang, Y.; Yang, Y. China’s rural revitalization and development: Theory, technology and management. J. Geogr. Sci. 2020, 30, 1923–1942. [Google Scholar] [CrossRef]

- MacDonald, S.; Winner, B.; Smith, L.; Juillerat, J.; Belknap, S. Bridging the rural efficiency gap: Expanding access to energy efficiency upgrades in remote and high energy cost communities. Energy Effic. 2020, 13, 503–521. [Google Scholar] [CrossRef] [Green Version]

- Tan, C.; Yu, M.; Wang, J.; Geng, S.; Niu, D.; Tan, Z. Feasibility study on the construction of multi-energy complementary systems in rural areas—Eastern, central, and western parts of China are taken as examples. Energy 2022, 249, 123571. [Google Scholar] [CrossRef]

- Sen, S.; Ganguly, S. Opportunities, barriers and issues with renewable energy development–A discussion. Renew. Sustain. Energy Rev. 2017, 69, 1170–1181. [Google Scholar] [CrossRef]

- Li, J.; Wang, Z.; Cheng, X.; Shuai, J.; Shuai, C.; Liu, J. Has solar PV achieved the national poverty alleviation goals? Empirical evidence from the performances of 52 villages in rural China. Energy 2020, 201, 117631. [Google Scholar] [CrossRef]

- Yanine, F.F.; Sauma, E.E. Review of grid-tie micro-generation systems without energy storage: Towards a new approach to sustainable hybrid energy systems linked to energy efficiency. Renew. Sustain. Energy Rev. 2013, 26, 60–95. [Google Scholar] [CrossRef]

- Wang, Y.; Guo, L.; Ma, Y.; Han, X.; Xing, J.; Miao, W.; Wang, H. Study on operation optimization of decentralized integrated energy system in northern rural areas based on multi-objective. Energy Rep. 2022, 8, 3063–3084. [Google Scholar] [CrossRef]

- Huang, Y.Q.; He, W.; Zhao, Z.W.; Li, J.; Rao, Z. Hierarchical Management for Rural Integrated Energy Systems Considering Dynamic Response Characteristics. Proc. CSU-EPSA 2022, 34. [Google Scholar] [CrossRef]

- Mitali, J.; Dhinakaran, S.; Mohamad, A. Energy storage systems: A review. Energy Storage Sav. 2022, 1, 166–216. [Google Scholar] [CrossRef]

- Kamal, M.M.; Ashraf, I.; Fernandez, E. Efficient two-layer rural electrification planning and techno-economic assessment integrating renewable sources. Energy Storage 2022, 4, e314. [Google Scholar] [CrossRef]

- Kabeyi, M.J.B.; Olanrewaju, O.A. Biogas production and applications in the sustainable energy transition. J. Energy 2022, 2022, 8750221. [Google Scholar] [CrossRef]

- Sodri, A.; Septriana, F.E. Biogas Power Generation from Palm Oil Mill Effluent (POME): Techno-Economic and Environmental Impact Evaluation. Energies 2022, 15, 7265. [Google Scholar] [CrossRef]

- Ding, W.; Niu, H.; Chen, J.; Du, J.; Wu, Y. Influence of household biogas digester useon household energy consumption in a semi-arid rural region of northwest China. Appl. Energy 2012, 97, 16–23. [Google Scholar] [CrossRef]

- Ahmed, J.; Harijan, K.; Shaikh, P.H.; Lashari, A.A. Techno-economic Feasibility Analysis of an Off-grid Hybrid Renewable Energy System for Rural Electrification. J. Electr. Electron. Eng. 2021, 9, 7. [Google Scholar] [CrossRef]

- Bamisile, O.; Huang, Q.; Li, J.; Dagbasi, M.; Kemena, A.D.; Abid, M.; Hu, W. Modelling and performance analysis of an innovative CPVT, wind and biogas integrated comprehensive energy system: An energy and exergy approach. Energy Convers. Manag. 2020, 209, 112611. [Google Scholar] [CrossRef]

- Teng, Y.; Wang, Z.; Li, Y.; Ma, Q.; Hui, Q.; Li, S. Multi-energy storage system model based on electricity heat and hydrogen coordinated optimization for power grid flexibility. CSEE J. Power Energy Syst. 2019, 5, 266–274. [Google Scholar] [CrossRef]

- Yang, D.; Wang, M. Optimal operation of an integrated energy system by considering the multi energy coupling, AC-DC topology and demand responses. Int. J. Electr. Power Energy Syst. 2021, 129, 106826. [Google Scholar] [CrossRef]

- Liu, J.; Sun, W.; Yan, J. Effect of P2G on Flexibility in Integrated Power-Natural Gas-Heating Energy Systems with Gas Storage. Energies 2021, 14, 196. [Google Scholar] [CrossRef]

- Luo, F.; Shao, J.; Jiao, Z.; Zhang, T. Research on optimal allocation strategy of multiple energy storage in regional integrated energy system based on operation benefit increment. Int. J. Electr. Power Energy Syst. 2021, 125, 106376. [Google Scholar] [CrossRef]

- Men, X.Y.; Cao, J.; Wang, Z.S.; Du, W.J. The constructing of multi-energy complementary system of energy internet microgrid and energy storage model analysis. Proc. CSEE 2018, 38, 5727–5737. [Google Scholar]

- Zhe, Z. Multi-objective optimal dispatch of mining area integrated energy system with P2G and hybrid electric energy storage. Electr. Power Autom. Equip. 2021, 41, 8–15. [Google Scholar]

- Rahman, A.; Farrok, O.; Haque, M. Environmental impact of renewable energy source based electrical power plants: Solar, wind, hydroelectric, biomass, geothermal, tidal, ocean, and osmotic. Renew. Sustain. Energy Rev. 2022, 161, 112279. [Google Scholar] [CrossRef]

- Jiang, Z.; Li, S.; Ma, X.; Li, X.; Kang, Y.; Li, H.; Dong, H. State Estimation of Regional Power Systems with Source-Load Two-Terminal Uncertainties. CMES-Comput. Modeling Eng. Sci. 2022, 132, 295–317. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, Y.; Huang, Q.; Lee, W.-J. Market-oriented optimal dispatching strategy for a wind farm with a multiple stage hybrid energy storage system. CSEE J. Power Energy Syst. 2018, 4, 417–424. [Google Scholar] [CrossRef]

- Li, G.; Zhang, R.; Jiang, T.; Chen, H.; Bai, L.; Cui, H.; Li, X. Optimal dispatch strategy for integrated energy systems with CCHP and wind power. Appl. Energy 2017, 192, 408–419. [Google Scholar] [CrossRef]

- Alshammari, M.E.; Ramli MA, M.; Mehedi, I.M. Hybrid Chaotic Maps-Based Artificial Bee Colony for Solving Wind Energy-Integrated Power Dispatch Problem. Energies 2022, 15, 4578. [Google Scholar] [CrossRef]

- Dong, Z.; Wong, K.P.; Meng, K.; Luo, F.; Yao, F.; Zhao, J. Wind power impact on system operations and planning. In Proceedings of the IEEE PES General Meeting, Minneapolis, MN, USA, 25–29 July 2010; pp. 1–5. [Google Scholar] [CrossRef]

- Zakari, A.; Khan, I.; Tan, D.; Alvarado, R.; Dagar, V. Energy efficiency and sustainable development goals (SDGs). Energy 2022, 239, 122365. [Google Scholar] [CrossRef]

- Hua, H.S.; Liu, Y.Q.; Xiong, W.; Xu, H.; Shi, Y.; Dong, S. Multi-objective optimized operation of energy system considering comprehensive energy efficiency. South. Power Syst. Technol. 2018, 12, 81–84. [Google Scholar]

- Li, S.; Li, X.; Kang, Y.; Gao, Q. Load capability assessment and enhancement for transformers with integration of large-scale renewable energy: A brief review. Front. Energy Res. 2022, 10, 1002973. [Google Scholar] [CrossRef]

| Equipment | Capacity | Parameter | Value |

|---|---|---|---|

| MG-CHP/kw | 110 | 0.4 | |

| 0.05 | |||

| 0.8 | |||

| 0.02 | |||

| PV/kw | 180 | 0.15 | |

| WP/kw | 160 | 0.03 | |

| BG/kw | 30 | 600 | |

| 0.02 | |||

| EB/kw | 40 | 0.9 | |

| P2G/kw | 120 | 0.5 | |

| 0.08 | |||

| BES/kw·h | 200 | 0.95 | |

| 0.096 | |||

| HST/kw·h | 200 | 0.025 | |

| 0.98 | |||

| GST/m3 | 200 | - | - |

| Comparison Items | AIES without HES | AIES with HES | Rate of Change |

|---|---|---|---|

| Comprehensive cost/¥ | 1.48 × 105 | 1.23 × 105 | −20% |

| Energy purchase cost/¥ | 2.96 × 104 | 3.08 × 104 | 4.1% |

| Environmental protection costs/¥ | 2.43 × 104 | 1.87 × 104 | 23.2% |

| Energy efficiency factor/(kW·h)·kg–1 | 6.791 | 10.236 | 51% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, W.; Xia, Y.; Yu, X.; Zhang, H.; Lin, X.; Ma, H.; Du, Y.; Dong, H. Optimal Dispatch of Agricultural Integrated Energy System with Hybrid Energy Storage. Energies 2022, 15, 9131. https://doi.org/10.3390/en15239131

Yang W, Xia Y, Yu X, Zhang H, Lin X, Ma H, Du Y, Dong H. Optimal Dispatch of Agricultural Integrated Energy System with Hybrid Energy Storage. Energies. 2022; 15(23):9131. https://doi.org/10.3390/en15239131

Chicago/Turabian StyleYang, Wu, Yi Xia, Xijuan Yu, Huifeng Zhang, Xuming Lin, Hongxia Ma, Yuze Du, and Haiying Dong. 2022. "Optimal Dispatch of Agricultural Integrated Energy System with Hybrid Energy Storage" Energies 15, no. 23: 9131. https://doi.org/10.3390/en15239131