1. Introduction

Coal is a significant energy source and the primary engine for the sustained growth of the world economy. Effective transportation is one of the keys for efficient coal production. The standards for efficient and safe transportation, however, are challenging for conventional mining transportation vehicles to achieve [

1,

2,

3]. To increase the effectiveness of the transportation of coal, it is necessary to create intelligent transportation technologies. The ‘Guidelines for the Intelligent Construction of Coal Mines’ were jointly published in June 2021 by the National Energy Administration and the National Mine Safety Supervision Bureau to help the entire industry carry out the intelligent construction of coal mines in a methodical and organized way [

4]. Presently, the nation’s major coal-producing provinces, regions, and large coal-producing companies have begun building intelligent demonstration coal mines, changing the intelligence of coal mines from passive to active construction, to implement the demands of the state, the government, and the National Energy Group for the intelligent construction of mines, to develop unmanned mining vehicles quickly, and to build intelligent mine transportation and efficient transportation in order to actively respond to the national slogan of carbon peaking and carbon neutrality [

5].

For effective transportation information, driverless technology mostly relies on on-board sensors including cameras, radar, Lidar, and GPS [

6,

7,

8,

9]. However, the mining transportation environment is more challenging, the workload is heavier, and there are stricter requirements for unmanned systems. For the complicated coal mine environment, the different sensors stated above are readily rendered useless. The routes are curvy, narrow, and have an uneven surface in the harsh, dusty environment of the coal mine. In addition, the lighting is weak, making it difficult to see and capture feature details. The aforementioned issues slow down the development of intelligent driving. It is essential to take into account a wide range of factors, including equipped mining truck hardware, unmanned driving systems, vehicle planning and scheduling, and challenging operating conditions. At present, many researchers are focusing their efforts on overcoming the technical issues associated with unmanned driving in mines. They conduct research from various perspectives on perception, positioning, path planning, decision control, and scheduling, and they are actively encouraging the advancement of unmanned driving technology in mine transportation [

10,

11,

12,

13,

14]. Several reviews of intelligent coal mine technology have been published in recent years. However, the majority of current reviews on self-driving technology are focused on single issues. Some reviews only cover a narrow range, such as object detection, location technology, path planning, and so forth [

15,

16,

17,

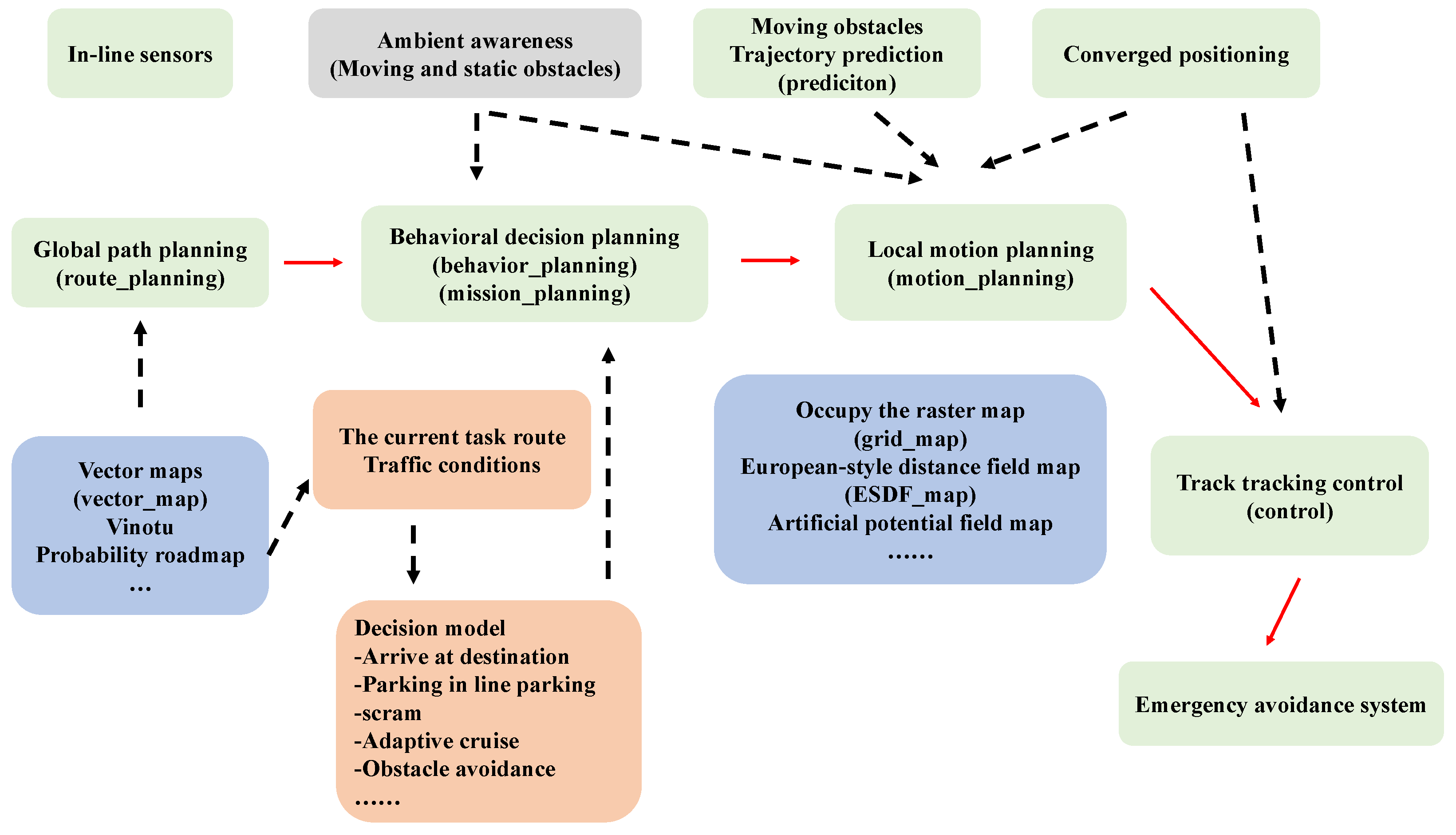

18]. There are some reviews which cover the entire intelligent system in their scope, as shown in

Figure 1; however, the comprehensive introductions to both the theory and the practice are incomplete and rare [

6,

15,

19].

This review aimed at exploring which research methods and approaches are being utilized by researchers studying the issues related to improving the accuracy and effectiveness of unmanned driving systems. We conducted a systematic review of the literature, studying several articles on the topic of research approaches to the intelligent technologies. This article identifies the current research gaps and can serve as a map of the work conducted so far about unmanned driving vehicles. The information from this article allows the methods used to be tested in terms of their effectiveness and frequency of use, while future researchers can find new research gaps that could become the subject of their research.

This paper intends to present a thorough understanding of recent self-driving cars in order to have a comprehensive grasp of the unmanned driving technology used in mine transportation. This assessment examines the current state of unmanned driving technology in mines both domestically and abroad, as well as the research status of both the general unmanned driving system technology in mines and the standard industrial mine transport vehicles. Finally, it concludes by summarizing the difficulties facing the current mine transportation system and providing a forecast for the development of autonomous mines in the future.

2. Overview of Unmanned Transportation Technology in Mines Both Domestically and Abroad

The development of intelligent mines includes unmanned coal mining technology, unmanned coal mine detection technology, and unmanned transportation technology. Unmanned transportation technology is particularly important among the abovementioned technologies. Unmanned driverless technology as one of the intelligent transportation technologies plays a significant role in enhancing effective and secure transportation in mines. Currently, many renowned businesses both domestically and abroad are making significant breakthroughs in the field of mining intelligent transportation technology to push the development of the intelligent coal mine.

2.1. Research Status of Unmanned Driving Technology in Foreign Mine Transportation

Currently, the demand for unmanned driving is rising as coal mine transportation tends to evolve in an intelligent manner. As artificial intelligence technology, big data systems, sensor hardware, and other technologies are constantly evolving and getting better, it has tremendously accelerated the development of unmanned mining vehicle technology and opened up new market potential for mining’s use of unmanned driving. Now, several well-known international businesses are pursuing research into unmanned driverless technology.

Since the 1970s, autonomous mining vehicles have been created that have attracted attention. Two mining vehicles manufactured by Caterpillar were put into action in the US in 1994, as shown in

Figure 2. Since November 2018, its driverless mining trucks have persisted in setting new technological records, and the amount of transportation has surpassed 1 billion tons, demonstrating a significant improvement in transportation efficiency. Currently, Caterpillar has 276 autonomous mining trucks in use. The Command-equipped vehicles have covered 67.6 million kilometers without a single fatality, further ensuring the safety of the fleet. Currently, the most complete mining operation and mobile equipment management system is integrated into Caterpillar unmanned mining vehicles. This system may be configured to meet the needs of the majority of mining operations, achieving high efficiency, and providing safe transportation. Many unmanned mining trucks have been utilized in mines since Komatsu’s first mining truck was used for unmanned mining experiments in a Japanese quarry in 1995. The 930E unmanned mining trucks were put to use in 2019 to help with the development of green mines, increase transportation effectiveness, and lessen potential safety risks. Over 2 billion tons of material had been transported using Komatsu’s unmanned transportation system (AHS) in April 2019 [

20]. In order to improve the development of mine unmanned transportation technology, Komatsu’s unmanned transportation system is currently being used in 10 mines across four different nations. Komatsu also continuously reforms, innovates, and improves the automatic transportation system, in order to push the rapid improvement of the intelligent coal mine.

2.2. Research Status of Unmanned Driving Technology in Domestic Mine Transportation

The development of unmanned vehicles has also been substantially helped by the domestic demand for intelligence. Major businesses are laying out unmanned mines strategically, working to advance the technology of unmanned mining systems, and making sure that unmanned mines are intelligent, effective, and cost-effective.

In November 2018, Tage Zhixing finished the Bayan Obo mining area’s unmanned mine management system development as well as the unmanned upgrade and transformation of two large mining trucks—the MT3600B and NTE150t—and one Tongli 90t wide-body truck. In the mixed marshalling test operation of various manufacturers and tonnage models, the fundamental technologies such as control, decision making, and smart mine operation management systems have made great development with an intelligent terminal-based, full-stack solution for autonomous transportation in open-pit mines. The technology is very adaptable and appropriate for heavy mining vehicles. It also encourages the development and adoption of fresh unmanned models, as well as the unmanned modernization and transformation of operational vehicles. In order to provide safe, effective, affordable, and environmentally friendly unmanned aerial vehicles for open-pit mines, Tage Zhixing supports the national development strategy of ‘new infrastructure’ and ‘smart mine’. Tage Zhixing consistently engages in technological innovation, taking the unique technological advantages as the guide and offering the engineering of landing ability as the guarantee.

Huituo has completed software, hardware, and product serialization to offer a whole solution for autonomous mines. To increase the stability and precision of the system, mining processes are simulated using a virtual simulation system. Huituo Intelligent offers autonomous mining solutions and has been used in more than 20 mining regions in China. Mining regions including Datang International Poly Mine, Maanshan Iron and Steel Mining, and Shenbao Group projects are examples of typical cases. The continuous operation of five vehicles in an extremely cold climate and all-weather environment has been completed by Qingdao Huituo Intelligence, Dayan Company (Baori Hiller Energy) in Qingdao City, Shandong Province, China and Aerospace Heavy Engineering Equipment Co., Ltd. In Xiaogan City, Hubei Province, China, at this time. The operation has played a key role in the relevant domestic regions and addressed a number of gaps in the field of autonomous mining equipment in current extremely cold locations.

An underground unmanned, trackless, rubber-tired vehicle with infrared top tracking and its control system was proposed by the Bao research team in 2018. The track set on top of the roadway is recognized by the infrared sensor mounted on top of the rubber-tired trackless vehicle. In order to design an unmanned driving system for battery-powered rubber-wheeled vehicles, line navigation, which depends on a range of sensors fitted on the body to perceive the environment and plan vehicle movements, is utilized. After that, it collaborated with the Taiyuan Research Institute of the China Coal Science and Industry Group to jointly develop and submit an innovation patent application for the first underground unmanned, trackless, rubber-wheel vehicle and its driving control technique in China. In November 2020, the Tashan Coal Mine of the Tongmei Group successfully completed the underground trial operation of the first unmanned, trackless, rubber-wheeled vehicle in China, as depicted in

Figure 3. The Shijiazhuang Coal Machinery Plant finished the autonomous trial operation of a monorail crane in October 2021. This monorail crane is capable of realizing intelligent functions including perception, positioning, and obstacle avoidance, as well as complete point-to-point intelligent driving. To guarantee safety when driving, emergency stop protection measures can be used when approaching objects within a safe distance. To increase vehicle safety and longevity, intelligent deceleration and parking can be implemented prior to parking.

3. Materials and Methods

The review included literature related to unmanned driving vehicles, classifying them as related to object detection, positioning, path planning, vehicle control, vehicle scheduling, or their application in industries. The review focused on studies written in English and influential (i.e., widely cited) scholarly texts. The literature was classified according to the sub-system of the intelligent technologies. Each sub-system is discussed in a separate section. Methodological choices, such as data processing methods, system boundaries, and system categories were analyzed. Moreover, methodological choices were analyzed for all sub-systems to find the tendencies, and the numeric results were systemized and analyzed for different technologies separately.

4. Experimental Methods

Our review paper is based on a comprehensive literature review and qualitative analysis rooted in creative coding. We decided to focus on the analysis of influential scholarly texts such as academic journal papers or theses. To identify texts, we employed the Scopus database, which is advertised as a daily updated ‘source-neutral abstract and citation database, curated by independent subject matter experts’. The search for relevant texts was carried out via two complementary paths; for both paths, ‘unmanned driving vehicle in coal mine’ remained the mandatory search term. One search employed keywords to search for relevant papers, which covered all publications using the keywords. It is worth noting that some papers appeared not to be relevant, and some of them had just the keywords provided by the authors of the published papers. Therefore, it was necessary to select some relevant papers for the topic again because there are too many unrelated papers after searching for the first time. The second method was more convenient; we searched for papers in the reference lists of downloaded papers, which was quicker for finding relevant papers. The number of published papers relevant to the various main themes were also counted, as shown in

Figure 4 The most common research themes were the coal mine underground, personnel positioning, object detection, and so on. The other themes were less common, such as path planning, SLAM technology, and vehicle scheduling. However, as can be seen from

Figure 5, more and more research is focused on the unmanned driving field.

Finally, we analyzed the papers and selected 71 papers to organize in this review as outlined, including the system of the unmanned driving vehicles and their application in industry. It is worth noting that the systems of the unmanned driving vehicles included object detection, positioning, path planning, vehicle control, and vehicles scheduling.

To proceed with the bibliometric analysis, papers published between 1973 and 2022 were collected which were correlated to the coal mine field greatly. The distribution of various types of publications over the studied period offers an overview of the progress made in this field. In this regard, the total number of published papers was analyzed and the results (

Figure 6) suggest that the number of papers did not show much significant growth before 2004. However, after 2005 the number of papers increased rapidly, and now this trend still rises.

5. Research on Unmanned Driving Systems in Mines

The core components of unmanned driving technology include perception, location, path planning, vehicle control, and scheduling. However, the driving conditions in a mine are different from those on typical road surfaces, and they have many drawbacks including heavy coal dust and inadequate lighting, which can easily result in poor perception accuracy. The smoothness of the driving road makes it difficult to precisely control the driving vehicles. The driving environment has the characteristics of being long and narrow, and signal transmission in the mining area is weak. Multi-vehicle transportation planning is inefficient, and information exchange is difficult. The following sections mainly discuss the different subsystems.

5.1. Mine Perception Technology for Mining Driverless Vehicles

As a particularly important part of unmanned driving, the perception system provides the basis of visual data for control decision making. The perception system mainly includes object detection, semantic segmentation, and so on. In the transportation process of unmanned driving cars, object detection systems are popular in intelligent systems. However, the environment of the underground mine is quite complicated, with insufficient light and too many devices and pieces of equipment. In addition, the space is full of coal dust, which easily attaches to the sensors, making it hard for them to detect. In the harsh environment of the mine, it is difficult to meet the application needs of accurate detection. Faced with the above difficulties, a number of approaches have been adopted to solve the problems.

Chai et al. established an underground dangerous areas object detection system architecture and a new object detecting algorithm for coal mine special areas. New algorithms based on scale-invariant feature transform (SIFT) used region matching and dimension reduction methods combined with a morphology pretreatment technique to advance system real-time ability. After cross-matching cursorily, the new algorithm combined random sample consensus (RANSAC) and Levenberg–Marquardt (L-M) nonlinear optimization algorithms to estimate optimization parameters, and it solved the current algorithms’ high computational complexity, long matching time, and low matching accuracy problems in this complex environment.

Qi et al. proposed a new ROIAlign model based on ROIPooling with Mask R-CNN for object detection in open-pit mine scenarios. The proposed method applied a bilinear interpolation algorithm to improve the pooling accuracy obviously, which could solve the distortion problem for the mismatch issues. Moreover, this method enhanced the ability to extract target features and improved the object detection accuracy.

5.1.1. The Single-Sensor Technologies for Object Detection Including Traditional and Current Deep Learning Technologies

Some researchers use traditional technology to realize the technology of object detection, with which it is difficult to satisfy the needs of detection. The traditional image recognition algorithm is generally implemented in two stages of detection. Firstly, the region of interest is extracted, and then the appropriate fixed operator is used to extract the image features, so as to realize the detection and recognition of the object and the determination of its position. The traditional fixed operator can quickly extract effective geometric features, but the robustness and generalization are poor, which makes it difficult to realize the application in practical scenarios. With the rapid development of convolutional neural networks, traditional fixed operators are replaced by convolutional neural networks, which can adaptively extract effective features according to the detection target, so as to achieve accurate image detection. However, because the current computing resources have difficulty meeting the needs of the overloaded data operations, the two-stage target detection detector is difficult to train perfectly, and the real-time performance is poor [

21]. End-to-end detection solves the above-mentioned problems well, and directly obtains the position and category information through the input image, which greatly improves the detection speed, improves the real-time detection, and relieves the excessive computing power requirements of the two stages. End-to-end target detection generally includes an acquisition-of-image preprocessing part, a Backbone part, a Neck part, and a Head part, for effective preprocessing according to the characteristics of the mine acquisition image, as well as feature extraction, feature construction, and detection [

22].

Insufficient lighting in coal mines, poor light stability, and the interference of coal dust and other factors mean that the detection features are prone to weak features. In response to the above problems, researchers have carried out effective processing from image preprocessing and detectors to achieve accurate detection of objects in mines. Xu et al. [

23] proposed an image preprocessing method for underground coal mines, aiming at the problem of image blur caused by low illumination and large dust interference in coal mines. The non-uniform distribution state of the level area is transformed into a uniform distribution state, which expands the dynamic range of the pixel gray value and effectively improves the visual effect of the image (

Figure 6). In addition, some works are focused on the improvement of network architecture. Yu et al. [

24] used the latest target detection YOLOv5 model in coal mines, as shown in

Figure 7. Based on the Neck layer, the FPN + PAN structure was used to accurately identify people, equipment, and gravel in the middle and on both sides of the track at different distances and positions. It accurately identified small target objects with low pixels in the well, achieving the purpose of early warning in the process of unmanned driving of electric locomotives, and improving driving safety.

Because the camera is highly sensitive to light and can only detect the two-dimensional plane information of an object, it is difficult to collect depth information for that object. Therefore, the application of radar is gradually being popularized, and the radar-based method has the advantages of being able to distinguish the details of obstacles, accurate ranging, and not being affected by light conditions. Chen et al. [

25] proposed a Lidar-based road-edge detection and mapping scheme in mining areas, as shown in

Figure 8. Through a variety of feature extraction algorithms, the road edge points are roughly obtained on the single-frame point cloud, and then using OctoMap to track the road edge, and finally they complete the construction of the road map of the mine area and achieve a better boundary between structured roads and unstructured areas. Although Lidar has more advantages in acquiring the pose and shape of the target, for the specificity of coal mining it is easy to lose point cloud, texture, and other information at close range.

5.1.2. The Multi-Sensor Fusion Technology for Object Detection

Sensors are optimally configured according to the different functional requirements of autonomous driving. Lidar has a long detection distance and can accurately locate, but it has poor environmental adaptability, and the price of Lidar currently on the market is higher than for other types of perception sensors. Although the cost of ultrasonic radar is low, the perception error is large, and it is only suitable for short-distance collision avoidance. Although the depth information detection capability of millimeter-wave radar is not as good as that of Lidar, because its seeker is millimeter-wave, it has a strong ability to penetrate fog, smoke, and dust. There are also infrared camera application features. According to the specific application scenarios of the mine, suitable sensors and multi-sensor fusion strategies can be selected according to the above sensors to achieve accurate object detection.

The key technology of unmanned perception in mines is limited by problems such as insufficient light in mines, poor light stability, and coal dust interference, and it is more difficult to focus on feature collection, feature extraction, and feature construction technology with just a single sensor. To improve the data quality, the multi-sensor fusion strategy is generally used for feature extraction to realize the expression of rich information, thereby improving the detection accuracy of downhole targets. The principle of step-by-step multi-characteristic fusion is shown in

Figure 9.

Due to insufficient light, poor stability, and coal dust interference in coal mines, information loss will occur in single-sensor detection. Many studies use multi-sensor perception information fusion to ensure rich image features. Perceptual fusion algorithms can be mainly divided into pre-fusion and post-fusion phases. Pre-fusion mainly realizes the fusion of collected data level and feature level, mainly the fusion of front-end data, and then realizes classification and positioning. Post-fusion mainly performs effective fusion based on extracted features to realize information fusion. Liu et al. used the post-fusion method to extract the features of the images collected by a visible light sensor, infrared sensor, and depth sensor through a distributed multi-feature fusion method to obtain rich image features, which improves the object detection accuracy [

26].

Qin et al. aimed at the lack of light in the underground environment, resulting in the lack of RGB image information, and the narrow roadway space resulted in more noise in the point cloud data collected by Lidar, and it was difficult to obtain a better detection effect from a single camera or Lidar sensor [

27]. A fusion image and radar point cloud detection model was proposed. The preprocessed image information was introduced into RPN to generate 2D-image candidate regions, and it was fused with point cloud data at the early feature level to generate 3D candidate regions. Based on the 3D candidate regions, it performed post-regional fusion and output 3D anchor boxes to achieve high-precision object detection.

For the complex coal mining environment, the data are collected in much dust and weak light, and a single sensor can not satisfy the requirements. To enhance the original data and the effective approach for data processing is very much necessary. In actual application, we should select the suitable model and strategies to fuse the data, which are from different sensors, pre-fusion and post-fusion according to the demand.

5.2. Research on Mine Intelligent Positioning Technology for Driverless Vehicles

The unmanned driving automobile makes heavy use of positioning technologies. Understanding this extremely valuable positioning technology is the key to maintaining safe driving. However, the complexity of underground coal mines makes signal transmission relatively weak, which leads to several technological issues. The radio signal transmission becomes weak in coal mines and is readily tampered with. Attenuation and distortion that happen throughout the transmission process cause the stability of the mine positioning system to fluctuate quickly. In order to realize the unmanned measurement and control system for making the appropriate judgments and exerting control, it is essential to ensure real-time monitoring of the location and the relative position of the mining vehicle in the environment while it is being driven underground.

Cui et al. established an 18-D model of an odometer-aided inertial navigation system (INS) and a positioning model of an extended Kalman filter-based ultra-wideband (UWB) based on the vehicle kinematics equation. A tight integrated state estimation model was proposed to restrain the long-time drift of the INS and enhance the instability of the UWB system. As a result, the proposed method could solve the positioning problems of most underground mobile devices operating in limited areas.

Due to the mine’s enclosed environment, the usage of positioning techniques like GPS and Beidou are all restricted due to their poor signal transmissibility. UWB ultra-wideband positioning, RFID wireless radio frequency positioning, Bluetooth positioning, and ZigBee positioning are now the most popular positioning technologies. ZigBee and UWB location technologies are employed more frequently because of the adaptability and stability of data transmission. By utilizing ZigBee technology and the CAN field bus transmission method, Chen et al. achieved the remote placement and monitoring of subsurface troops [

28]. The positioning of the underground personnel is made possible, the underground personnel’s safety is guaranteed, and the automation level of the mine is further increased by uploading the location data of subterranean mobile nodes to the upper computer in the dispatching room using the CAN bus. Zhang et al. investigated an underground worker wireless locating system based on ZigBee in order to comprehend the working environment of underground workers [

29]. The RSSI positioning algorithm was utilized to achieve real-time placement of subterranean workers and to comprehend the underground workers, with the CC2430/CC2431 chip as the core. It can boost subterranean staff positioning management’s efficiency and dependability. In order to design a coal mine underground locomotive monitoring system based on ZigBee wireless sensor network node localization, Chen et al. proposed an improved DV-Hop localization algorithm, combined it with a new node localization algorithm of the least square method, and improved the positioning accuracy [

30].

Despite being more expensive than ZigBee positioning technology, UWB positioning technology outperforms it in terms of positioning accuracy and signal transmission speed. In order to achieve high-precision positioning in the challenging mining environment, Chen et al. advocated the use of high-precision positioning technology based on UWB in coal mines [

31]. In order to achieve wireless transmission of positioning data, Shen et al. built a UWB-based system for wireless positioning transmission in coal mines [

32]. The system effectively combined UWB technology and the SDS-TWR ranging algorithm to gather positioning data, as illustrated in

Figure 10. It can operate steadily in the challenging coal mine environment and increase positioning precision. In order to achieve accurate underground positioning, provide accurate control for underground target management, and serve as a vital link in the mature positioning technology ecosystem, it is necessary to combine the benefits and drawbacks of various positioning technologies and environmental characteristics. The SDS-TWR algorithm compensates for time error with two communications between the position tag and the positioning base station error caused by clock offset. Moreover, it can avoid making clocks out of sync into an error, effectively improving the positioning accuracy. However, for the special mining environment, the original data error would exist. The proposed technology only solved the time out-of-sync problem, but the second communication strategy would enhance the error caused by the space between the station and the tag.

In a coal mine environment, the transmission of signals is too weak for the interference of the underground environment. In addition, the open-pit mines also have weak signals because the internet is not very effective. The reason is the existence of the device and the actual internet arrangement in a coal mine environment. Therefore, it is quite necessary to compensate for the loss and disturbance of the signal. To research methods and technologies to preserve normal transmission is thus necessary. The trend in positioning is to improve the algorithms and apply fusion strategy.

5.3. Research on Mine Unmanned Path-Planning Technology for Driverless Vehicles

In order to achieve accurate tracking of the vehicle, the autonomous vehicle primarily plans an appropriate real-time route based on environmental data gathered by the on-board sensors and its own dynamic model. Path planning can be divided into a global path based on past knowledge and a local path based on perceptual information from sensors while driving. This division is based on the various methods of gathering environmental information. The local path information is based on the data gathered by the sensors while the mining vehicles are being driven, while the global path planning is based on the knowledge about the known driving environment to carry out path planning. Planning the local ideal path is done after it is established that the local obstacle information makes it difficult to proceed on the global planned path. One of the key technologies used by unmanned vehicles to drive is path planning. The key technology is based on the created map, in accordance with the provided beginning point and target point to start the path planning, and discover an ideal way to accomplish efficient driving. The grid method, artificial potential field method, A*, D*, Dijkstra, LPA*, and D*lite algorithms are a few examples of path-planning methods [

33,

34,

35,

36,

37]. More recently, as artificial intelligence technology advances, a variety of optimized algorithms have been gradually used. The representative algorithms for path planning include genetic algorithms and neural network algorithms [

38,

39].

In the actual driving process of automatic vehicles, a decision-making system plays an important role in automatic driving when facing the complex external environment and changing traffic state. After perceiving a traffic light, vehicle, people, and so on, the current auxiliary driving system is considered to be an effective way to improve the driving efficiency and driving safety of vehicles. In the coal mining scenario, the scene is more fixed and the moving obstacles are relatively few. Therefore, it would be superior to driving in the coal mine environment. However, the road structure of coal mines is variable because of the special geological formations. The driving rules are not all-encompassing. The main road includes the following scenario shown in

Figure 11.

In the single-lane meeting scene (

Figure 11a), if two vehicles meet in the driving process, the vehicles should analyze the distance to the emergency chamber. Then, the vehicle that is closer to the emergency chamber would drive into the chamber. The other vehicle would drive straigh on and away. In the dual-lane meeting scene (

Figure 11b), the vehicle would drive directly with low speed. However, in the emergency state, if the two vehicles could not drive away, the vehicle that is closer to the emergency chamber would drive into the chamber for safety. In the intersection road environment 1 (

Figure 11c), the vehicle on the straight road would drive directly on and away and the vehicle on the skew road would stay until the meeting vehicle drove away. However, if the vehicle on the straight road would turn left, the vehicle on the skew road would drive into the emergency chamber until the meeting vehicle drove away. In the intersection road environment 2 (

Figure 11d), if the vehicle on the straight road drove directly on and away, the vehicle on the skew road would stay until the meeting vehicle drove away. However, if the vehicle on the straight road would turn right, the vehicle on the skew road would drive into the emergency chamber and wait until the meeting vehicle drove away.

From the algorithmic perspective, Wang et al. proposed a decision-making framework based on hierarchical state machine with a top-down structure of a three-layer, finite-state machine decision system. The upper layer classifies the driving scenario based on relative positions of the vehicle and its surrounding vehicles. The middle layer judges the optimal driving behavior according to the improved energy efficiency function targeted at multiple criteria including driving efficiency, safety, and the grid-based lane vacancy rate. The lower layer constructs the state transition matrix combined with the calculation results of the previous layer to predict the optimal pass way in the region. Liang et al. proposed a self-driving car decision model based on causal reasoning, that is, rational decision-making, not related reasoning. They established a decision model based on Bayesian network and reinforcement learning, combined with the characteristics of deep learning and rule-based expert systems, and deeply studied the decision model to improve the adaptability of complex scenarios when there are fewer samples or partial missing data. The generalization ability and transfer learning ability were improved.

Heiner et al. proposed generating the Pareto curve with pseudopolynomial running time, which could be turned into an algorithm for generating the smoothed Pareto set with small failure probability and polynomial running time. Sun et al. dealt with a decision-making framework for probabilistic fatigue inspection planning based on multi-objective optimization. The multiple objectives were converted into a single objective by using weights of the objectives, and as a result, a single optimum solution for inspection planning was obtained.

5.3.1. Research on Global Path-Planning Algorithms for Unmanned Driving in Mines

The landforms of underground coal mines are complicated, so a suitable algorithm is necessary for safe and fast driving. Currently, several search algorithms have already been proposed for application in mines. The heuristic A* search algorithm was first suggested by Hart et al. in the 1960s [

40], and it primarily defined the search direction by developing a node evaluation function. The number of nodes will be decreased and the search efficiency will be increased when the anticipated cost is close to the actual cost. The A* algorithm is capable of planning the shortest path, but there are drawbacks, including too many nodes in the planned path and a challenging real-time update mechanism in dynamic environments. The double A* algorithm was suggested in reference [

41], which employs the A* algorithm to plan the global and local paths, respectively, in order to efficiently realize the shortest path in a dynamic environment. In order to significantly increase the effectiveness of downhole path planning, Liu et al. devised an enhanced A* algorithm that employs cubic spline interpolation and exponential function weighting to enhance the classic A* algorithm’s search for numerous nodes and unequal paths. The A* algorithm’s primary goal is to plan the best course while assuming that nothing changes in the surrounding environment. In addition, Ivan suggested a D* search algorithm for determining the shortest path while taking placement uncertainty into account [

42]. Experiments in real-world scenarios demonstrate that this method is suitable for exploring a highly dynamic environment with moving impediments and dynamic changes in placement needs. Continuous optimization techniques are used to find the best route, and practical applications can successfully reach the goal point.

The real-time performance of conventional path-planning algorithms is subpar, and they are prone to issues like local optimum, sluggish convergence, and heavy computation. The artificial-intelligence-based intelligent optimization algorithm can tackle issues that arise in conventional algorithms and has better self-learning and adaptation capabilities. A better genetic algorithm was presented by Zhou et al. that keeps the genetic algorithm’s effective global search capability and the simulated annealing algorithm’s effective local search capability for enhancing speed [

43]. Li established an ideal path-planning model for open-pit mines with the aim of minimizing the total transportation and he proposed a suitable improvement for the open-pit mine path while taking into account the vehicle’s own load, the actual vehicle parameters, and according to the operating conditions [

44]. The ant colony algorithm incorporates crossover and mutation operators to increase population variety and enhance the algorithm’s global convergence performance. It also uses adaptive dynamic factors to modify the population pheromone updating process. Based on the self-adaptive and real-time features of the Q-learning algorithm, Xu et al. were able to address the problem of robot movement in an unknown coal mine condition and achieve a quick and accurate choice of the best course of action [

45].

5.3.2. Research on Local Path-Planning Algorithms for Unmanned Driving in Mines

Unmanned mining vehicles are vulnerable to unforeseen barriers while operating, such as dynamic information like moving traffic and pedestrians. To increase driving safety, local path planning is done as soon as movement information is noticed. Good efficiency and high stability must be guaranteed by an acceptable local path-planning method. Artificial potential field algorithms including the A* algorithm are currently employed extensively in the mining industry. The artificial potential field algorithm among them searches for the best driving path to avoid obstacles within the scope of the potential field, but it is easy to fall into the local minimum. It creates an external force environment by establishing virtual potential fields such as the gravitational potential field of the target point and the repulsive potential field of obstacles, point flaws that make it challenging for the vehicles to keep moving. In order to overcome the drawbacks of the local optimal solution of the conventional artificial potential field algorithm, Zhang et al. employed the A* algorithm to build nodes beforehand and then applied the artificial potential field method between the nodes [

46]. The concrete diagram is shown in

Figure 12. Gu et al. generated a repulsive force potential field function to resolve the conflict between the repulsion force and the gravitational force, calculating the relative distance between the vehicle and the target location by introducing adjustment parameters [

47]. Additionally, an APF-FC algorithm was suggested to address the issue that the algorithm has a tendency to quickly approach the local minimum point. This algorithm successfully addresses the shortcomings of the artificial potential field.

The driving road in the mine is relatively poor and it is challenging to design the best route for driving in both global and local planning because of the complicated unknown obstacles in the mine and the constrained driving space owing to the peculiarities of the mine structure. Therefore, creating an acceptable path-planning algorithm remains a difficult undertaking in light of the various technical issues discussed above.

For the special structure of the coal mine environment, the driving rule is different from normal roads. The moving targets are fewer than on normal roads because of the closed space, and the route is fairly fixed. The difficult points are the condition of vehicle intersection and how to choose the suitable strategy to realize effective driving. Therefore, the path planning should be combined with the route and condition of the coal mine environment. In this way, safety and efficiency can be guaranteed.

5.4. Research on Mine Intelligent Control Technology for Driverless Vehicles

To accomplish steady and safe driving, especially in the challenging road environment of the mine, it is required to accurately control the vehicle during driving based on front-end perception and path-planning information. The harsh bumps present during the vehicle’s quick drive make it challenging to maintain smooth control. Latitudinal and longitudinal control make up the majority of the control portion. The tracking control of the planned path is carried out to minimize the tracking error and guarantee the stability and comfort of the vehicle in accordance with the path, curvature, and other information output by the upper motion planning. Among them, the longitudinal control works in conjunction with the traverse control to ensure that the unmanned vehicle follows the predetermined planned path to the target location and is mostly utilized to regulate the vehicle’s brake and accelerator to achieve parking and speed regulation functions. The autonomous traverse control primarily aims to control the steering system while the vehicle is being driven. In order to achieve accurate tracking, it directs the vehicle to follow the planned path information, calculates the direction angle by adding the planned path information and the vehicle pose information, and then transmits the calculated data to the actuator.

Hou et al. designed a new trackless, rubber-tired vehicle control system design based on ARM. The system can be detected by the vehicle detector in coal mines underground without trackless, rubber-tired vehicle operation for real-time detection, and the obtained data is transmitted to the ARM chip of the trackless rubber-tired vehicle monitor, through the display monitor module for real-time display, and can be treated to upload data to the center of the monitoring system of the station, so as to realize the information for underground trackless, tired vehicle operating data acquisition and analysis in real-time.

5.4.1. Research on Longitudinal Control for Driverless Vehicles

The primary purposes of the longitudinal control of an intelligent vehicle are to regulate the vehicle’s acceleration and deceleration, prevent the vehicle from colliding with objects while driving, achieve the target speed or distance, and guarantee the precision and efficiency of the control. The driving road has features of a large slope and a lengthy slope, especially in the unique environment of the mine, and the road environment is significantly harsher in specific locations during rainy and snowy weather. It is challenging to develop a precise vehicle dynamics system model since the vehicle is a complicated system with strong nonlinearity and high coupling, and there are issues such as feedback signal lag and hysteresis. Therefore, it is important to guarantee the stability and high real-time performance of the intelligent vehicle system. The proportional integral derivative (PID) control approach is currently the most used. A state feedback PID control technique with strong robustness was proposed by Netto [

48] and is based on data from optimal path discovery. Fuzzy logic was introduced by Chen et al. on the foundation of PID control to realize parameter adaptive tuning to increase control precision [

49]. Chen et al. used the sliding mode control method to increase the resilience of the system against parameter uncertainty and external disturbances [

50]. The intended acceleration was first acquired using a sliding mode control to calculate the speed or position closed-loop, and then the desired acceleration was obtained using an inverse longitudinal dynamics model. Calculation is utilized to determine the driving and braking torque, and then the driving and braking actuators are employed, respectively, to track the desired torque via synovial control. To provide the best longitudinal control of autonomous cars, Huang et al. [

51] introduced the parametric batch processing reinforcement learning algorithm (PBACV). The method uses an actor–critic learning structure, and updating the parameters is done using the least squares method to increase learning effectiveness. Numerous trials demonstrated that the reinforcement learning algorithm outperforms the conventional longitudinal control method in terms of the performance of longitudinal control.

5.4.2. Research on Traverse Control for Driverless Vehicles

The primary purpose of traverse motion control is to acquire information on the position and posture of the vehicle using sensors, GPS/GIS systems, and other external constraints. The driving direction should be parallel to the longitudinal symmetry line of the vehicle body. Traverse control is challenging because of the uncertainty in the model, the mining environment, and the low measurement accuracy. Unlike other types of roads, mine roads are unique. Driving is a procedure in which the vehicle’s direction of travel is easily influenced by the road, particularly while traveling quickly, which makes traverse control even more challenging. In comparison to vertical control, traverse control is more crucial since it directly affects tracking performance and forms the cornerstone of unmanned vehicle safety and stability. In order to increase the overall performance of the controller, Li Fan [

52] used the traverse motion controller of the adaptive MPC method and converted the designed MPC controller, goal function, and system control constraints into a common quadratic programming problem. Lei Min [

53] used the curvature smoothing algorithm to smooth the abrupt shift in road curvature. The adaptive preview control approach may reduce traverse displacement deviation and heading angle deviation while the vehicle monitors the path, increase traverse stability, and dynamically modify the preview distance. While mine roads are mostly oriented toward paths with considerable curvature, the majority of studies are currently undertaken on paths with small curvature. A traverse extension preview switching control system for autonomous vehicles was created by Cai et al. using the concept of extensibility [

54]. The traverse system comprises upper-level control. The bottom controller is an extension domain and uses a feedforward–feedback control method, which resolves the traverse control issue on large curvature paths. The top controller is a classical domain and adopts the feedback control idea. The aforementioned techniques can be used to achieve unmanned driving that is accurate and efficient.

5.4.3. Research on Horizontal and Traverse Comprehensive Control

Because of the rough mine environment, it is challenging to drive steadily and safely on a standard road surface. The projected system performance will be compromised or even not achieved if the horizontal and vertical designs are combined. Vertical and horizontal control work best when used together. The best way to govern smart automobiles is to control everything at once. In order to precisely follow the required pace, longitudinal control primarily regulates vehicle speed and braking. It also works in tandem with traverse control to ensure safe driving. The longitudinal control system is a typical multi-input and multi-output complicated coupled dynamic system because it has the features of parameter uncertainty, temporal delay, and highly nonlinear dynamic characteristics. One challenging aspect of intelligent driving is how to build a control model that manages its parameter uncertainty and high nonlinearity. This is also a hot topic in the realm of intelligent vehicle research. Coordination of traverse and longitudinal control is required during the actual driving of unmanned vehicles in order to enhance the performance of the vehicle’s intelligent path-following driving. In order to solve the problems of system modeling uncertainty, external environmental interference, and time delay, Yu et al. proposed a feedforward–feedback fuzzy control algorithm based on model prediction [

55]. This algorithm allows the controller to better track the predetermined reference trajectory and has a good control effect.

5.5. Research on Mine Unmanned Multi-Vehicle Scheduling Technology

Mine vehicles are used to move the rich ore resources of the mine to a specified area for processing and usage after on-site mining. The number of intelligent mining trucks can be considerably expanded in order to maximize transportation efficiency, but only increasing the number of mining trucks would cause chaos in the production management system and waste resources. Unmanned mining truck scheduling and allocation are therefore crucial for enhancing transportation effectiveness. The road conditions of the mine should be thoroughly inspected and studied, as should the location, quantity, and type of ore to be transported. Using load statistics and other data, traffic flow planning and arrangement, and continuous optimization based on big data operations, a sensible scheduling scheme is provided to prevent congestion and consumption. These goals include enhancing transportation efficiency and reducing expenses. Increasing time and transportation efficiency will cut down on wasted time. The optimization of the traffic flow between the loading point and the unloading point is achieved by traffic flow planning, which serves as the foundation for the real-time dispatching of mine trucks. Linear programming, integer programming, and dynamic programming are the three most popular scheduling models for traffic planning [

56].

The dispatch system created by Liu et al. of the American Modular Company is the most popular [

57]. The system uses the linear programming approach to split the enterprise’s production target into two separate weakly connected models for two-stage optimization. The open-pit mine card optimization system, which was created by the Fushun Branch of the General Institute of Coal Science and the China Academy of Launch Vehicles in collaboration, was the first to be used in China [

58]. The investigation into the use of mobile vehicle-mounted terminals for GPS data collection for real-time settlement of coordinate positions by He, as well as the data collection from vehicle-mounted terminals, led to the logical design of a mining truck dispatching system that maximized efficiency and reduced resource consumption [

59]. Intelligent traffic control and management has gradually replaced traditional approaches to transportation problems as a result of the development and widespread use of intelligent transportation system technology. In order to build a coal mine underground auxiliary transportation system, Gao Feng [

60] combined the Artificial Neural Network (ANN) learning algorithm, network structure, and a neural network expert system (ANNES). Based on this, a complex nonlinear time-varying system was built, and an intelligent dispatching system based on time response was proposed, which resolved the current problem of clogging in coal mines. The dispatching logic algorithm still takes a long time with the current dispatching paradigm. The entire transportation time can be decreased by further enhancing the real-time optimal dispatching decision of mining trucks. To address the potential delay brought on by queuing, Bastos [

61] suggested a decision-making mechanism based on the Time Dependent Markov Decision Process (TiMDP). On the basis of satisfying the loading and unloading requirements of dump sites, D.M. Bajany [

62] suggested a model for the minimization of dump trucks and scrapers in open-pit mines and established an objective model to shorten queue times. In order to address the shortcomings of the existing traffic distribution and scheduling model, Bai developed a traffic distribution and scheduling model with the goal of minimizing output deviation and the waiting time and running time of mine carts [

63]. This improved the optimization of mining cart scheduling decisions. Sun created a mathematical traffic planning model that is consistent with four states, fixed mine car, unloading point, and optimized motor allocation. He merged the traditional production organization’s fixed car model with the locomotive allocation model for optimal scheduling [

64].

Zhang et al. presented a hybrid ant colony method to optimize expenses and reduce the cost of low-carbon dispatching of open-pit mine trucks in light of the ongoing and rapid development of machine learning and additional in-depth strategic study on intelligent dispatching [

65]. The minimal comprehensive cost is the optimization target as determined by the optimization results achieved using various process variables as the objective function, which lowers the production cost. For large and complicated nonlinear systems, certain clever algorithms now in use have weak robustness. The coding of decision variables is used as the operation object in a genetic algorithm, and the search information is directly taken from the fitness function value that corresponds to the value of the objective function. For the optimization calculations of complicated systems, the probabilistic search method is more appropriate. In order to improve the traffic distribution and scheduling model for large open-pit mines, Liu et al. used genetic algorithms. He also offered a fresh approach to the distribution and scheduling of truck traffic in open-pit mines [

66]. The first genetic algorithm was applied to the mining industry. By enhancing the hybrid operator of the genetic algorithm, Huang et al. improved the multi-objective traffic distribution and scheduling model of the minecart [

67]. The traffic distribution and scheduling model of the open-pit mining car was solved by Guo using the simulated annealing approach, and the modified genetic algorithm was able to obtain the best overall solution [

68].

In the multi-vehicle scheduling technology section, considering the complexity, we have mainly introduced some methods combined with intelligent technologies to keep it effective for multiple vehicles to drive. The multi-vehicle scheduling technology is a systematic strategy which should combine the status of the driving and the environmental conditions to allocate the task and communicate with the vehicles. To realize the optimal strategies, the RNN and other intelligent algorithms should be inducted into the system and enhance the comprehensive benefits.

6. Research Progress on Applications of Mine Unmanned Transport Vehicle Technology

The current mine intelligent transportation systems mainly operate in two modes: tracked and trackless. The tracked vehicle has high transportation efficiency due to its fixed track, but it lacks flexibility; the trackless vehicle has higher transportation mobility and is not restricted by the track. Underground electric locomotives, monorail cranes, and trackless, rubber-tired vehicles are typical intelligent transportation vehicles for coal mine transportation, and their unmanned level largely determines the unmanned process of the mine transportation system.

6.1. Research on the Application of Unmanned Electric Locomotive Systems

Electric locomotives for underground mining are crucial pieces of transportation machinery that are primarily utilized in tunnels, metal mines, and coal mines. Mine transport trucks have recently become more intelligent thanks to the recent rapid development of unmanned driving-related technology. The use of unmanned electric locomotives can significantly increase the automation of mine transportation, increase the effectiveness of transportation, and decrease the number of underground workers involved to lessen the need for subterranean workers’ intervention while ensuring the safety of construction workers. The technology of unmanned electric locomotives has only recently been studied elsewhere. As early as the early 1980s, the Swedish Kriuna mine began using unmanned electric locomotive technology. Canada developed the automatic guided operation technology in the Noranda Mining Company’s Norita underground mine in Toronto City, Canada in 1990. The “Unmanned Electric Vehicle Transportation Technology for Underground Mines”, which China Enfi Engineering Technology Co., Ltd in Beijing City, China. independently developed and put into commercial use in 2013, increased mine transportation automation and decreased accident rates. Additionally, the pre-programmed operation of the electric locomotive can continue. The locomotive may self-diagnose any problems that arise during operation and relay the results to the control room display for further processing. The automated driving system of the 1703 horizontal electric locomotive at the first mine owned by Jinchuan Group was successfully tested in September 2019. The system has features like remote automatic ore drawing, automatic switching of dual heads, unmanned operation of electric locomotives, constant speed cruise, etc. A significant milestone in the advancement of mine automation, information technology, and intelligence has been reached by efficiently reducing the interference of the external environment with the stability of the system’s operation. CRRC Zhuzhou electric Co., Ltd in Zhuzhou City, Hunan Province, China. developed an unmanned electric vehicle which adapts the technology of accurate positioning, object detection, and safe transport in 2021 (

Figure 13).

6.2. Research on the Application of Unmanned Monorail Crane Systems

The transfer of mining and production materials can be handled by an unmanned monorail crane technology, which is a vital component of mine production services. The production and operational efficiency of a huge number of transportation service positions, including drivers, escorts, dispatchers, etc., is poor, and their costs are high. As a result, the fully automatic unmanned monorail crane system has emerged as the current and future development trend for auxiliary transportation in coal mines.

There is not any pertinent international study on monorail crane unmanned driving at the moment. Even though there are not any fully developed autonomous monorail crane products in China, some universities have achieved advancements in the field. For instance, Shanjiao Electromechanical Taikuang Technology specifically built a high-power monorail crane powered by a hybrid of explosion-proof EFI diesel engine friction wheel and gear, as well as a monorail crane with a hybrid drive of an explosion-proof unique battery, with high safety performance, rapid acceleration, and powerful climbing capacity. The automated monorail crane system developed by Beijing Yilian Chuang’an Technology was put into use in the Fucun Coal Mine in 2020. The monorail crane unmanned system has two control modes: manual driving and intelligent driving, as depicted in

Figure 14. With the sophisticated driving system, starting remotely is conceivable. In order to realize the accurate placement and autonomous operation of locomotives, Xinsha Monorail Equipment Co., Ltd in Taian City, Shandong Province, China. independently created a whole set of PLC control programs, as illustrated in

Figure 15. The advantages of the unmanned monorail crane include a long service life, a huge capacity, and zero pollution. The battery life is 19 km. The unmanned trial operation of the monorail crane in the Shijiazhuang Coal Machinery Plant was completed by the China University of Mining and Technology in October 2021. This crane is capable of realizing functions like perception, positioning, and obstacle avoidance, as well as full point-to-point intelligent driving. Dual cameras are one of the features, and they are made for front and back obstructions using UWB and dual tag technologies for real-time detection. The driving on the test site can be precisely located thanks to technology. In order to ensure safety when driving, emergency stop protection mechanisms can be used when an obstruction is encountered within a safe range. To increase the vehicle’s driving safety and durability, intelligent deceleration and parking can be implemented prior to parking. There are currently very few domestic and international studies on unmanned monorail crane systems, and funding for these studies is thus urgently needed.

Monorail cranes’ autonomous technology enables high-speed travel, boosts productivity, and lowers labor costs, which is an unavoidable trend for the monorail cranes’ future development. In the coming years, research on unmanned monorail cranes will center on the system’s autonomous perception, planning of the transportation path, and functions for the best scheduling and transportation of vehicles.

6.3. Research on the Application of Unmanned, Trackless, Rubber-Wheeled Vehicle Systems

The trackless rubber-tired truck is a crucial transportation instrument for auxiliary transportation in the mine, primarily utilized for the transfer of subterranean goods, equipment, and employees. The mining environment is complicated and variable. The use of trackless transportation equipment in the mining industry started in foreign nations in the early 1950s, setting the stage for mining and transportation in non-ferrous metal mines using trackless rubber-tired vehicles. It took a while for domestic development to get up to speed, and it was not until the 1990s that these started to be used in mines. However, because of the unforgiving underground environment, transportation is inefficient and accidents happen frequently. Driverless technology has been gradually incorporated into underground, rubber-tired, trackless vehicles to support the development of intelligent transportation as mine intelligence continues to advance. The autonomous driving capability of the unmanned, trackless, rubber-tired vehicle enables unmanned and effective transportation while increasing productivity and lowering risks to people. An underground unmanned vehicle system for battery-powered, trackless, rubber-tired vehicles was created in 2018 by the Bao research team, as shown in

Figure 16 [

69]. A sensing system was created by carefully choosing sensors to control the vehicle control system on the basis of the WLR-9 mining battery trackless, rubber-tired vehicle. The results of the tests conducted in an underground tunnel after it was renovated demonstrated that it can successfully address the issues of subsurface tracking and obstacle avoidance. In order to ensure intelligent train dispatching, automation of locomotive control and state acquisition, and the integration of the transportation monitoring center and the dispatching center, Han Jianghong of Hefei University of Technology and others proposed an underground unmanned locomotive system architecture [

70]. This architecture is based on the seamless combination of an information network and a control network. Five-person driving modes like remote control and autonomous operation are compatible with it. In order to control the driving operation of the trackless rubber-tired vehicle’s unmanned driving system, Zhang et al. modified the trackless rubber-tired vehicle by utilizing Lidar and ultrasonic sensors to detect road information, and Hall sensors to measure the vehicle’s speed [

71].

7. The Existing Challenge and Future Research

Even though self-driving car technology has advanced quickly, there are still several unresolved problems that affect the situation today. The environment of a coal mine is so complex that the actual application of current technologies cannot be met. Intelligent technologies and integrated devices with several functionalities are now challenging to apply in real-world settings. To advance the development of intelligent technology, a lot of enhancements must be made to the far more advanced self-driving automobile technology.

The abundance of coal dust and the inadequate lighting in an underground coal mine prevent some sensors from being used to their full potential. Many methods and techniques are now being investigated to improve the object detection accuracy. However, the atmosphere in the coal mine is different from that of the general area. The coal dust in the underground mine is thick and sticks to the camera and Lidar lenses. Additionally, the point cloud map is easily impacted by coal dust noise. In particular, the Lidar data is primarily made up of point cloud data, which substantially harms the Lidar data. The sensors are additionally sensitive to light and coal dust, because both the camera and the Lidar process the digital data. Additionally, the camera is light-sensitive due to its unstable feature and its sensitivity to light change. Moreover, the target objects in the underground coal mine fall into multiple categories, and most object algorithms tend to focus on a single class or a small number of unique situations. For the entire scenery application, the unified module is limited. A comprehensive module that can be used throughout the entire scene must be built.

The road is so uneven that the driving car’s steadiness is really bad. It can be challenging to accurately control the vehicle. The complicated terrain affects both upward control and traverse control. It is challenging to achieve stable control. In order to adjust to the complex road situation, it is required to refine the control strategy.

Additionally, it is challenging to move through the restricted area when automobiles are used. Furthermore, there are no driving regulations, which results in low driving efficiency. The rules for driving must be developed. The hauling task is ongoing, and the surrounding scenery is intricate. Consequently, it is essential to create a uniform driving rule.

There are different types of obstacles. It is challenging to drive the cars smoothly. The area is cluttered with several devices and impromptu barriers. The car needs to revise its driving route as it is traveling and create a fast pass local route. However, in other circumstances, it is challenging for the vehicle to continue moving because the impediments are too big or the situations too complicated. Therefore, it is essential to design for the integrated multi-arm function in order to remove impediments. Additionally, a self-driving car with a single purpose has a poor efficiency level during job operations. Moreover, some tasks are just not possible to perform using the limited functions. The development of a comprehensive function is necessary for efficient driving. Based on the previous research, the main findings classification could be concluded as shown in

Table 1.

Based on the research findings shown in

Table 1, there are specific action plans as follows:

- (1)

Along with the rapid development of artificial intelligence technology and high-capacity computing devices, it would be more efficient and robust to combine the deep-learning algorithm with the driving system, including object detection, position, control, and so on.

- (2)

It is better to develop multi-sensor fusion technology for object detection in the complicated environment of a coal mine since traditional single-sensor technology cannot satisfy the needs, being constrained by the coal dust and the weak light. It would be superior to fuse the camera and Lidar to realize the object detection. Moreover, it is also necessary to design a lightweight network to realize real-time object detection.

- (3)

SLAM technology is superior for the coal mining environment since signals are too weak and the transmission process is constrained. Some technologies like GPS, WiFi, and so on are not suitable for the coal mining environment. It would be more suitable to use the SLAM technology in the coal mining environment.

- (4)

The construction goals for intelligent open-pit coal mines are as follows. Production should focus on improving the construction of mine networks, data centers, and perception systems, including the construction of remote-control systems, unmanned driving systems, and remote operation and maintenance systems. The goal is to realize the digitization of the mining environment, with intelligent mining equipment, remote control of the production process, an information transmission network, and informatization of operation and management.

8. Conclusions

Self-driving car technology in the field of coal mine transportation has been a research hotspot in recent years due to the rapid growth of intelligent technology. This paper offers a thorough analysis of self-driving automobile technology and its industrial applications in the coal mine domain. The review begins with a discussion of the development trends of unmanned driving technology. Then, perception, path planning, position technology, vehicle control technology, and multi-vehicle scheduling technology are the next five sections. Additionally, each part is explained in detail.

Unmanned driving technology has also greatly improved the efficiency of mining in mining areas. According to the arrangement of the previous five-mining-car marshalling operations in the mining area, the seamless transition of shifts can be realized with unmanned marshalling, and the driver is no longer needed, which can save about 20 persons’ manpower and indirectly reduce the number of supporting service personnel and management personnel. Similar to the operation of the unmanned five trucks in the chemical industry, it is expected to increase the transportation volume by 500,000 tons per year.

As a result of the undertaken research on the listed articles about intelligent systems of unmanned driving vehicles, we observed a trend among researchers to focus on some points. Firstly, more and more researchers are focused on the fusion of multi-sensors to make up for the drawbacks of the single sensor in each sub-system. Secondly, more and more images and point-cloud data processing approaches were researched to remove coal dust. Thirdly, artificial intelligence technologies were adapted for the traditional object detection, path planning, and vehicle control technologies. In addition, more and more effective and light-weight algorithms were researched to enhance the precision and speed of the intelligent system. Fourthly, various vehicles in industries have gradually adopted the intelligent technologies and have been improving the systems to adapt to the complicated environment.

In order to comprehend the industrial situation, certain actual application vehicles are then introduced based on intelligent systems. Finally, we review the current existing issues and suggest a number of exciting new paths for the development of intelligent technology in the coal mining industry to adapt to the complex environment in a coal mine. This study offers a theoretical and practical introduction that is important for the advancement of intelligent systems and the actual application of intelligent technologies. This assessment offers insightful recommendations for further development.

The review provided a more comprehensive description of the systems of unmanned driving vehicles and typical industrial application cases. We analyzed the environment of the coal mine and current existing intelligent technologies including the current and latest research. Based on the above results, we can know the progress of the development of unmanned driving vehicles in coal mines and the real-time intelligent algorithms. Additionally, the key technologies remaining to be solved were also analyzed.

Through a more in-depth study of the reviews—not only by using key words—our research allowed us to fill the theoretical gap in the intelligent coal mining field from the perspective of theoretical techniques and actual applications of unmanned driving vehicles. The publications, therefore, reflect the growing understanding of well-structured intelligent coal mining transportation, ensuring efficient management of the intelligent coal transportation. Moreover, this review provides a combination of intelligent systems and industrial applications, which can supply a reference for the researchers in this field.