A Microfluidic Experiment on CO2 Injection for Enhanced Oil Recovery in a Shale Oil Reservoir with High Temperature and Pressure

Abstract

1. Introduction

2. Materials and Methods

2.1. Material

2.2. Specific Experimental Parameters and Conditions

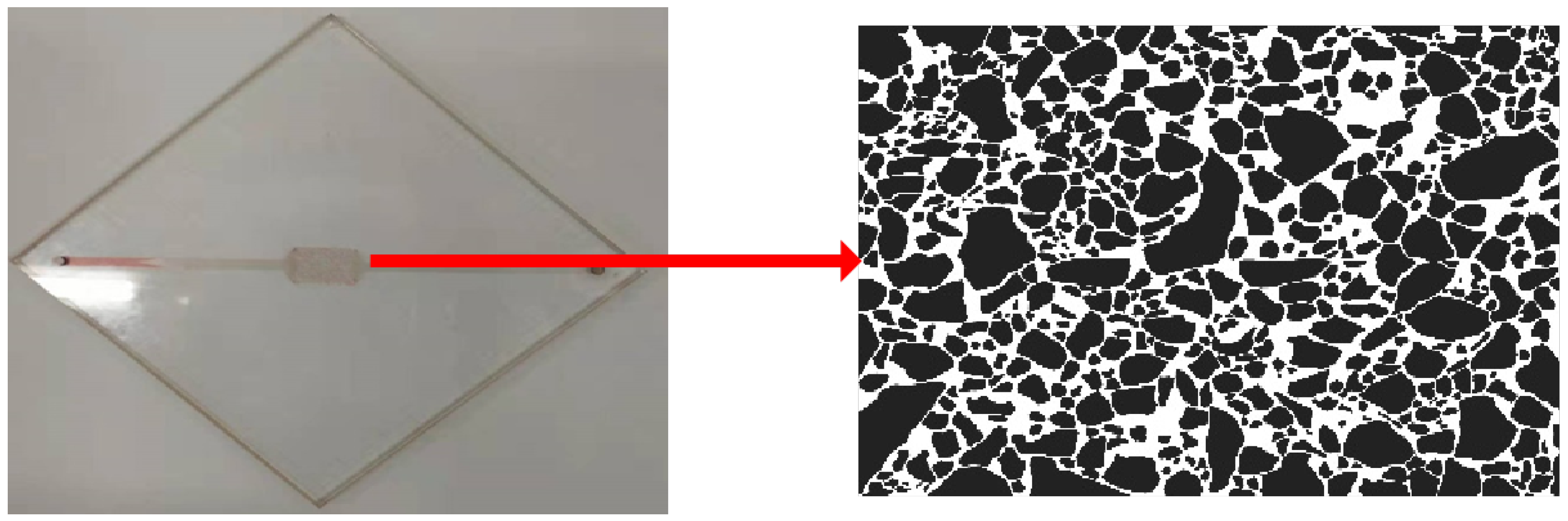

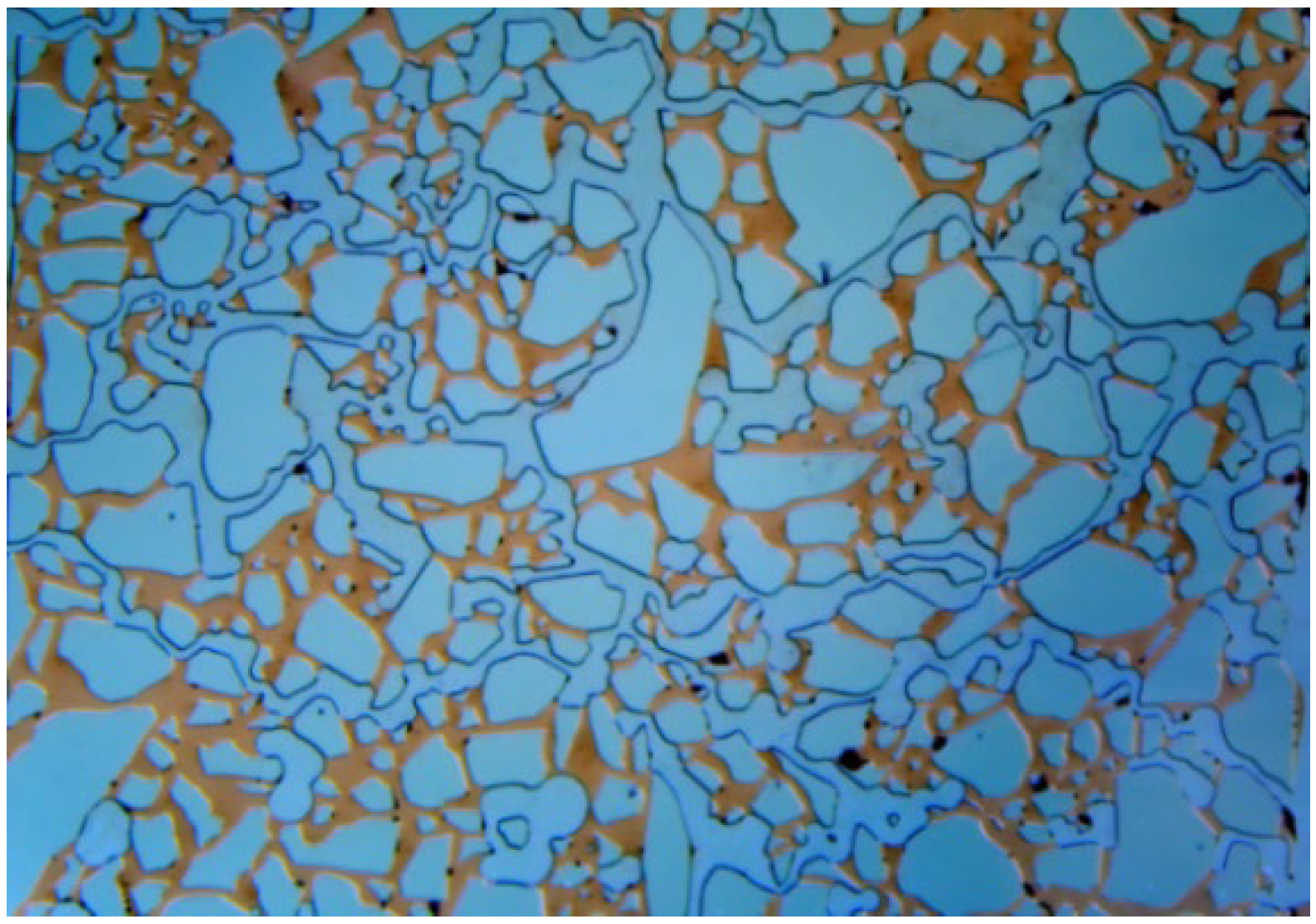

- Microscopic visualization model (shown in Figure 1): the material is glass with hydrophilic characteristics, high temperature and high-pressure resistance, changeable wettability (hydrophilic/oil film plating), strong bonding ability, good transmission imaging effect, etc.; Model size (L × wide × Thickness) is 75 mm × 75 mm × 3 mm, with a minimum diameter of 10 μm. The overall hole throat diameter of the chip is distributed in the range of 10–200 μm. Crude oil viscosity is 12.58 MPa·s and crude oil density is 0.86 g/cm3.

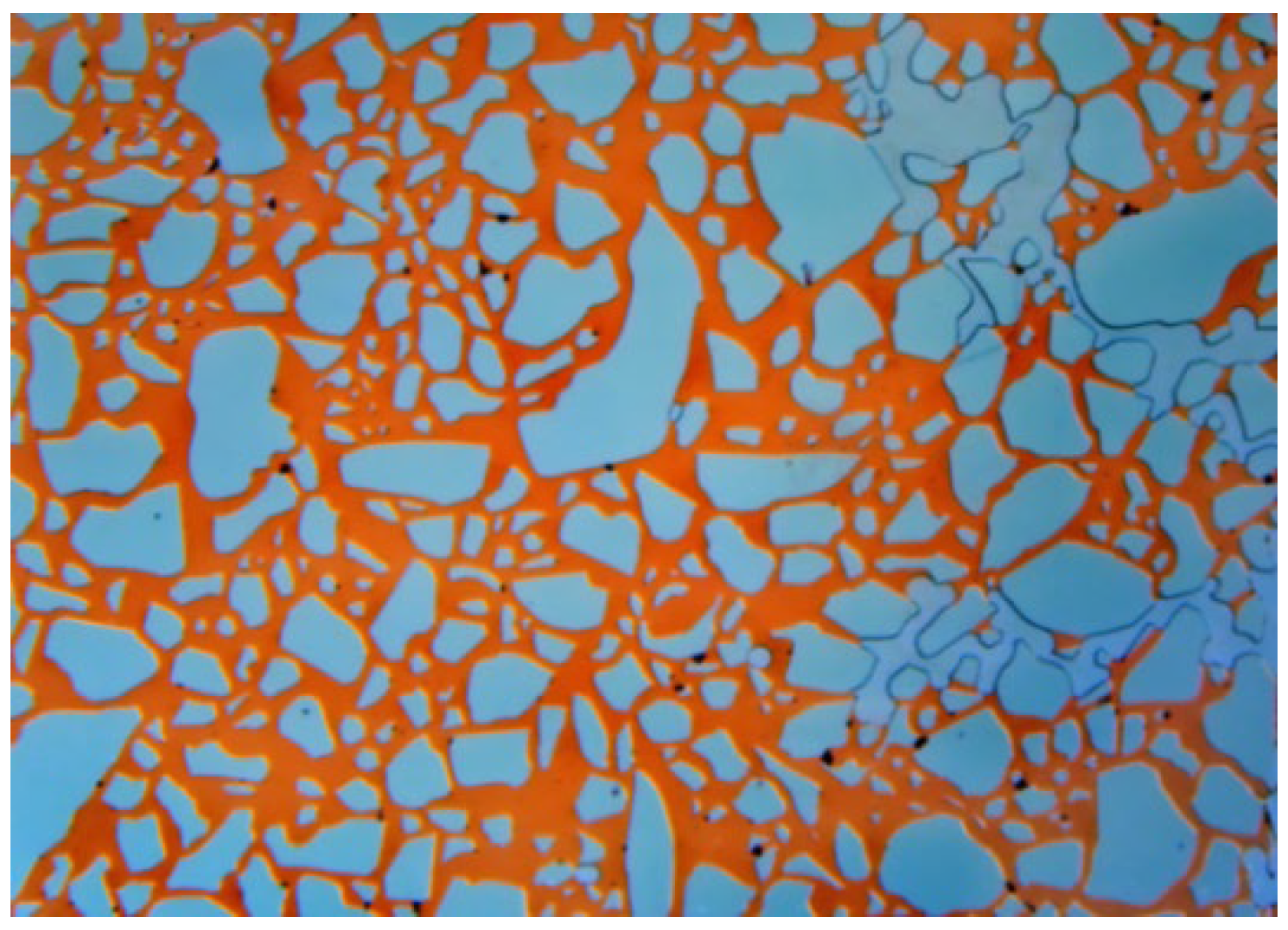

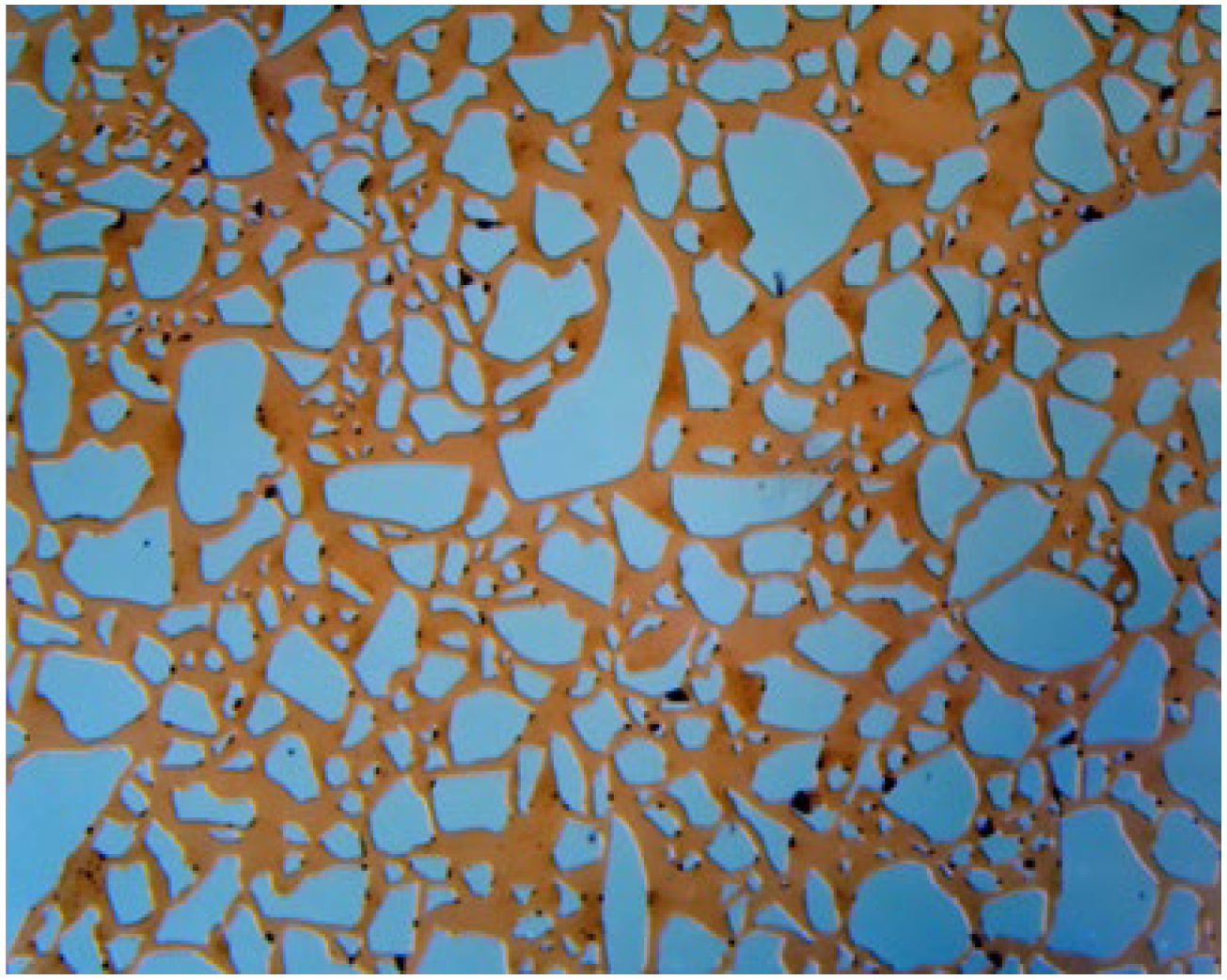

- The experimental crude oil was ground-degassed crude oil mixed with dye. According to the experimental results, Sudan III was selected to dye the transparent yellow crude oil red. The experimental temperature was 110 °C, and the well-plugging pressure and time at different points were set. This allows the identification of the status of oil and gas at different times. This technique allows a dynamic description of CO2 injection process at shale oil reservoir condition, in comparison to the static observation such as environmental scanning electron microscopy, laser focusing and micro fluorescence methods.

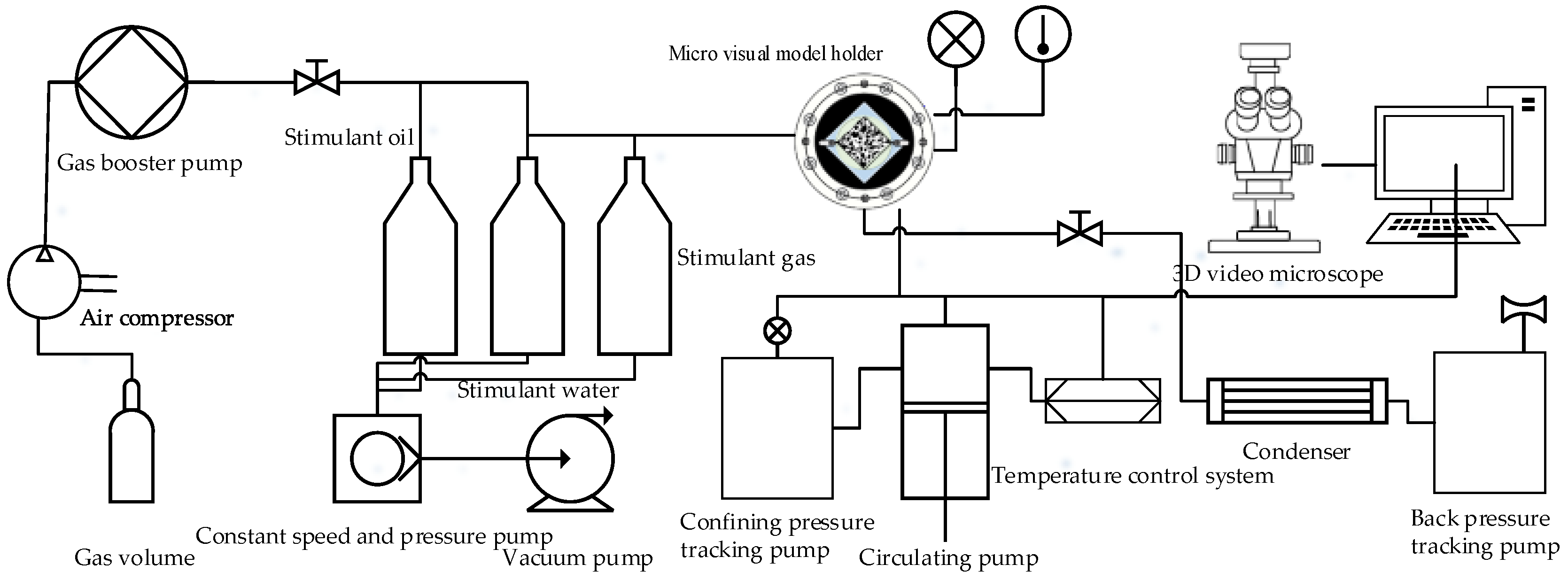

2.3. Instrument

2.4. Methods

- The model was vacuumed and saturated. The model level was put in the supporting system. The kerosene was saturated after vacuuming the model, and the model temperature and pressure were gradually raised to the original formation conditions. Then, the target reservoir crude oil to the model was saturated;

- Gas injection process. Gas was injected into the inlet of the model by the same injection method to capture and record the microscopic interaction time and the change process of gas and shale oil;

- Soaking process. After the gas enters, the inlet end and outlet end were closed. Well-soaking was conducted for 15–45 min. Meanwhile, microscopic changes in the gas and shale oil during the well plugging process were recorded;

- The above steps were repeated to carry out CO2 huff and puff experiments under different conditions of well-soaking pressure and time;

- The experiment ended. The displacement medium was replaced, either with petroleum ether or toluene. The visualization model was cleaned to the fluid in all pore structure was removed. The image and video of fluid flow in the channel were recorded with the matching software of the microscope, and the flow behavior of fluid in the model was observed in real time on the computer.

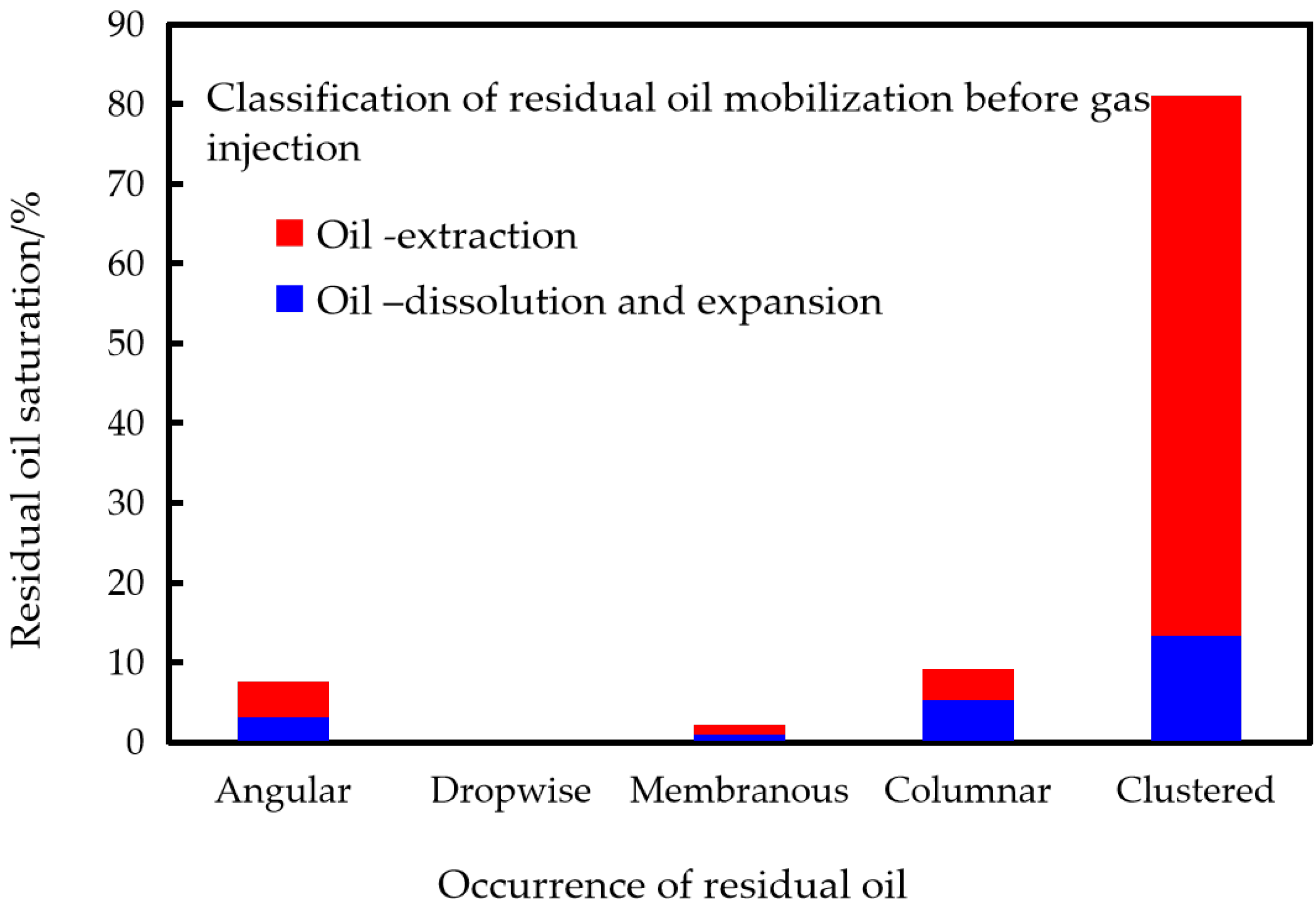

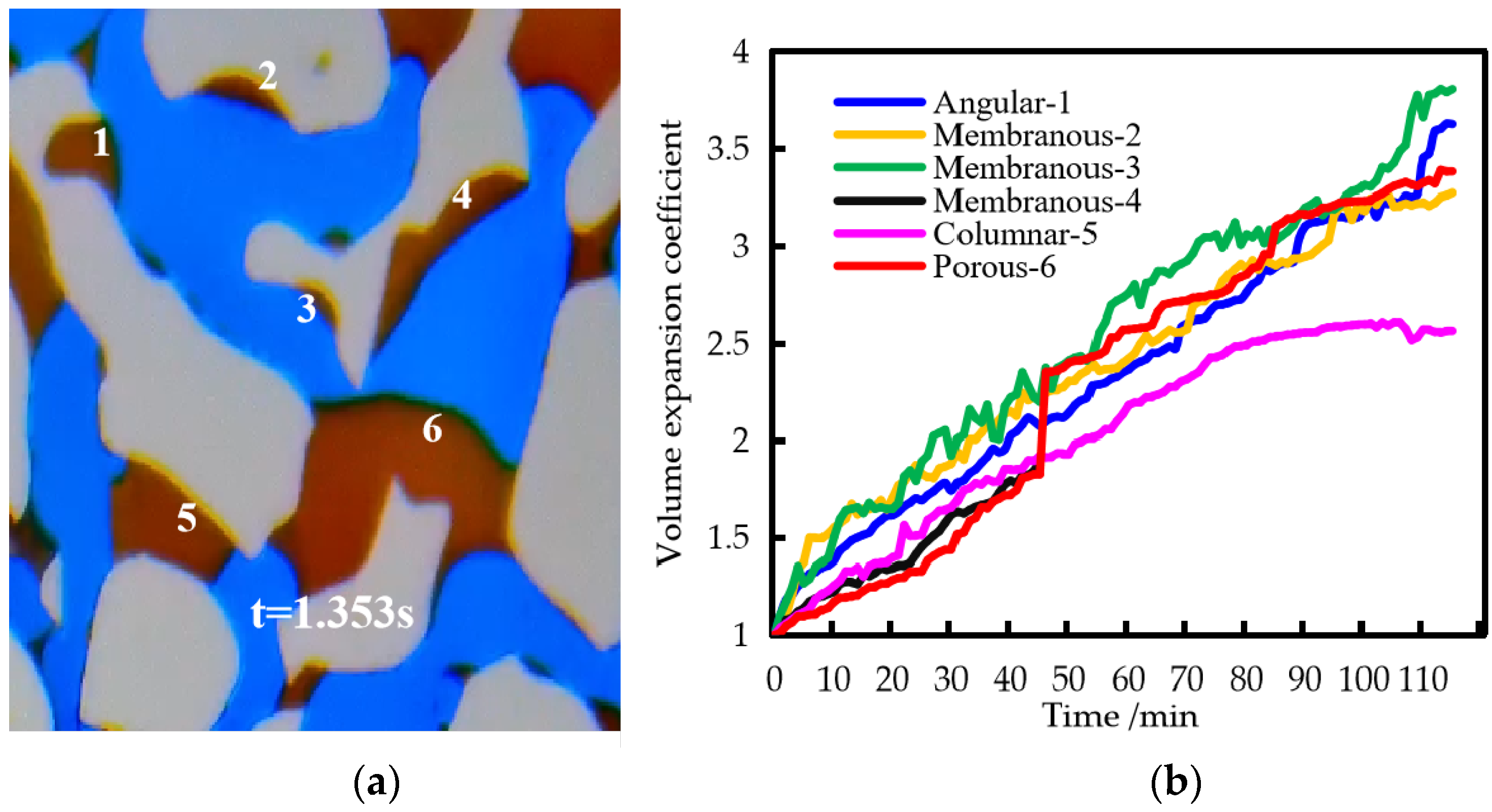

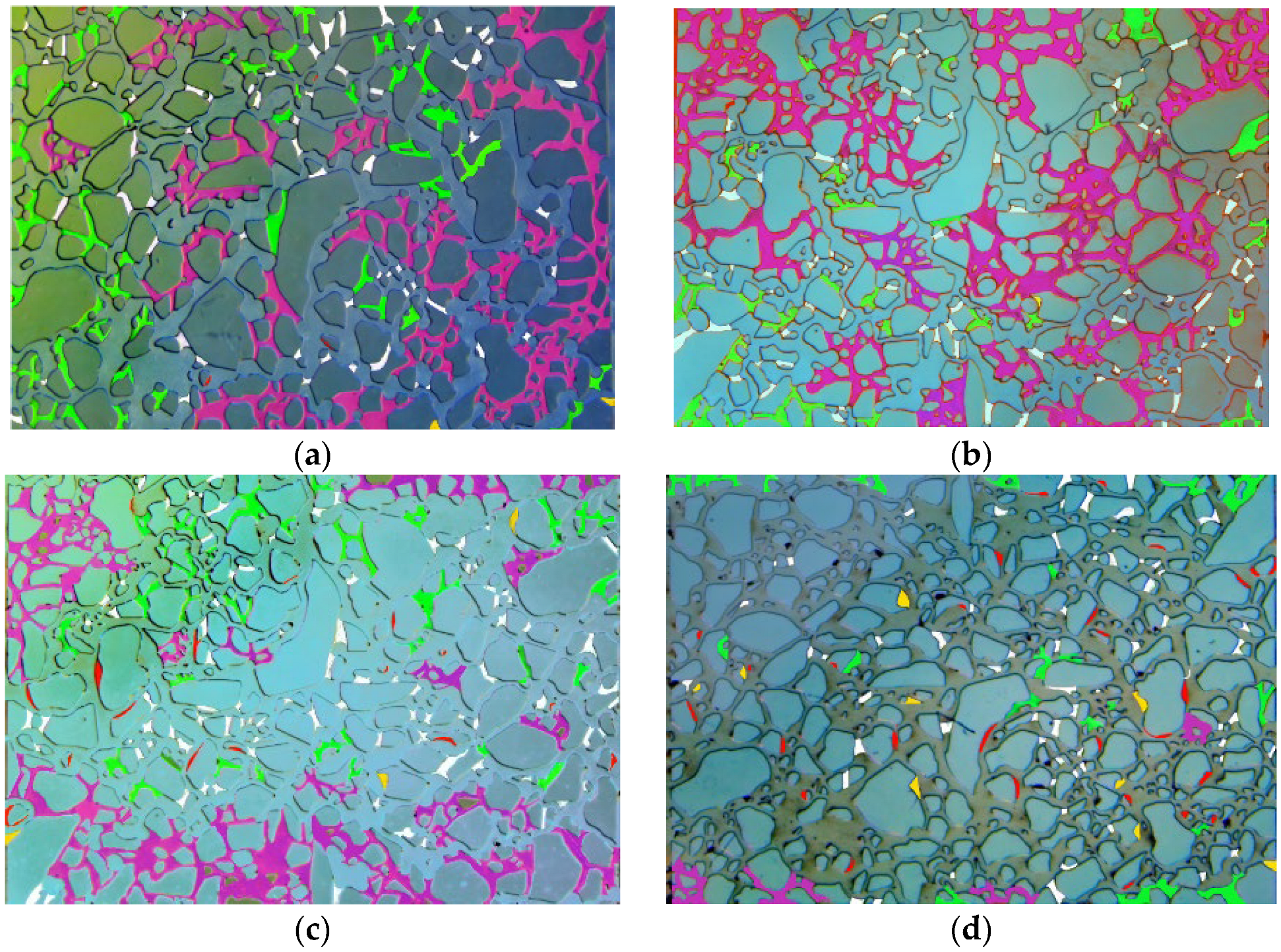

- The remaining oil was estimated by image processing and the crude oil was classified and concluded directly by shape including angular, dropwise, membranous, columnar and cluster.

- Through image processing, the chip after oil saturation was scanned, and the number of oil pixels in the saturated oil area was identified. After CO2 huff and puff, the number of remaining oil pixels was identified again. The number of eventually remaining oil pixels was divided by the number of original saturated oil pixels, and the remaining residual saturation was obtained.

3. Results and Discussion

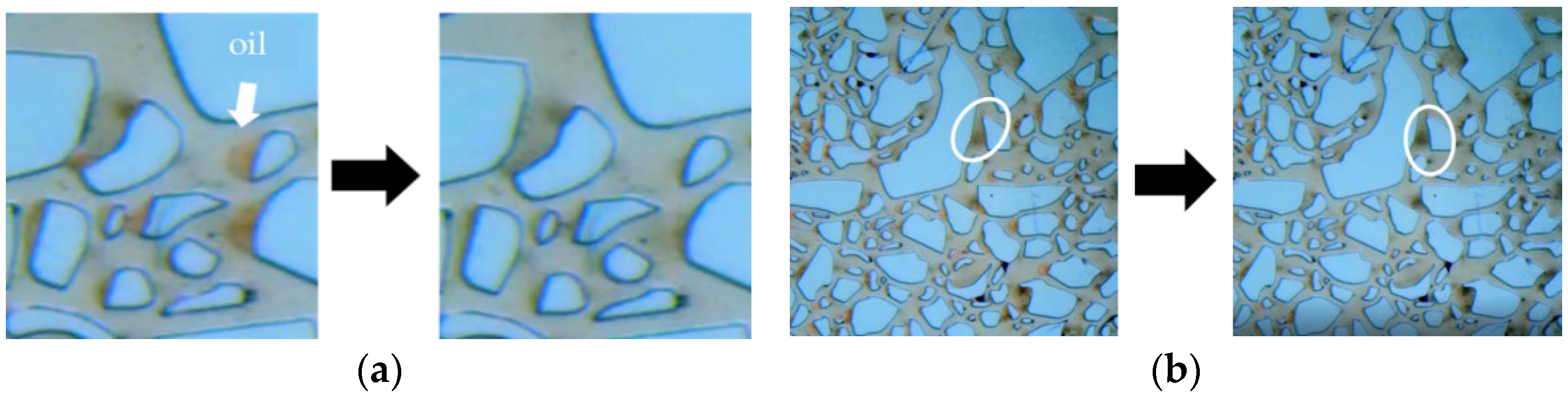

3.1. Microscopic Interaction Mechanism between CO2 and Crude Oil

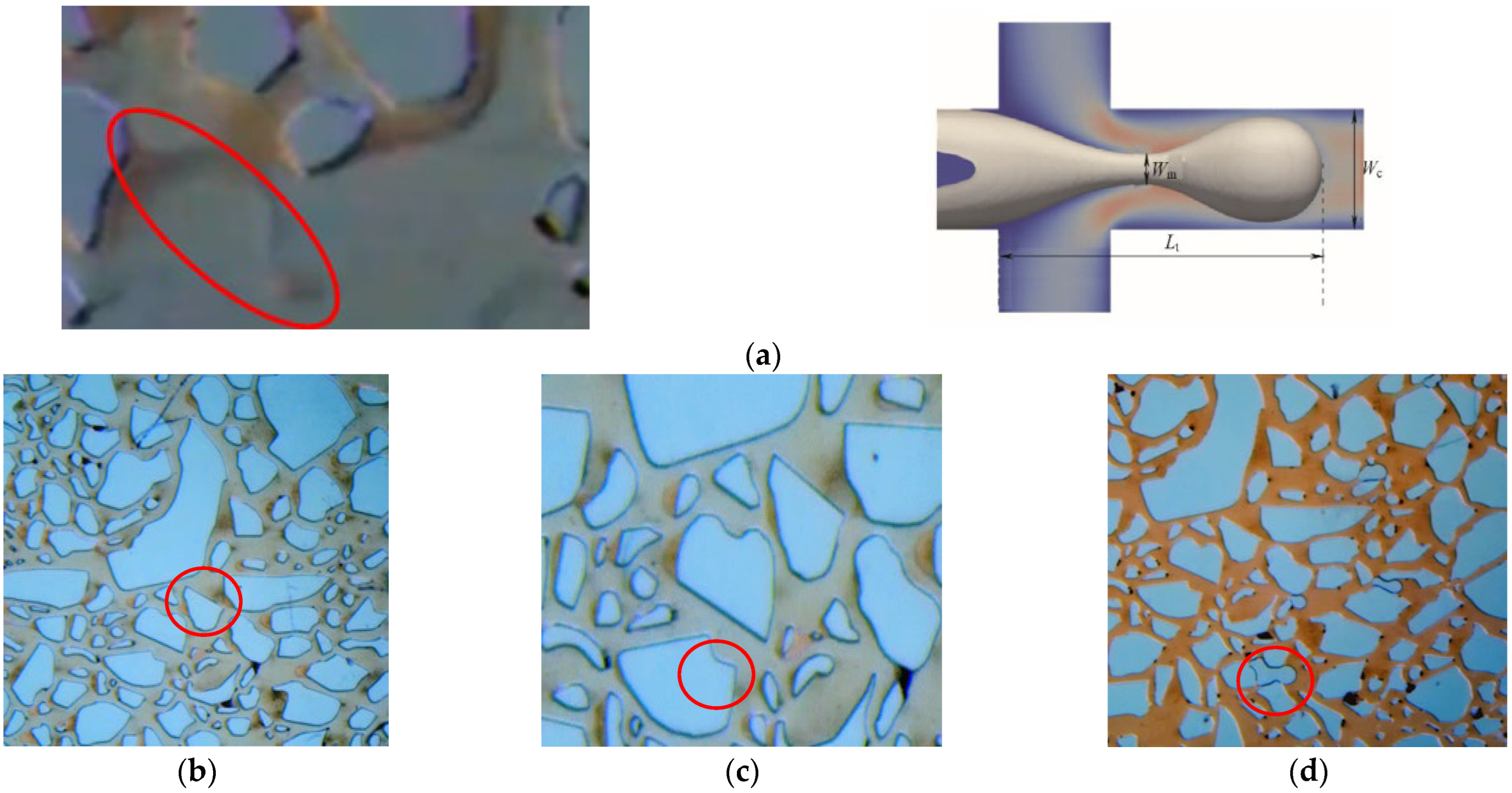

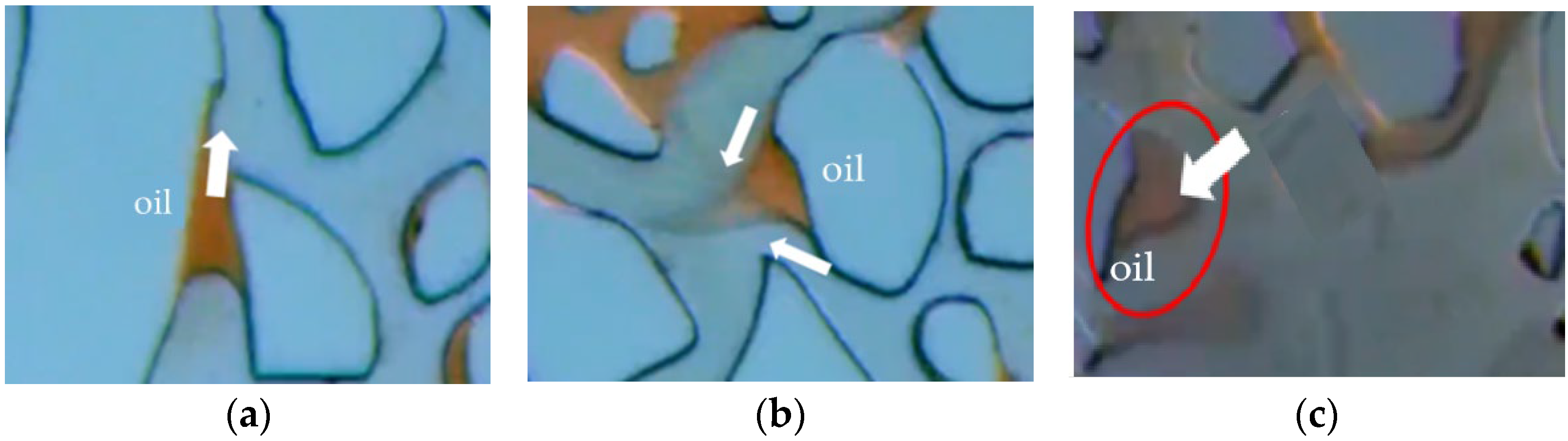

3.2. The Mechanism of Oil Mobilization

3.3. Occurrence State and Influencing Factors of Remaining Oil after Huff and Puff

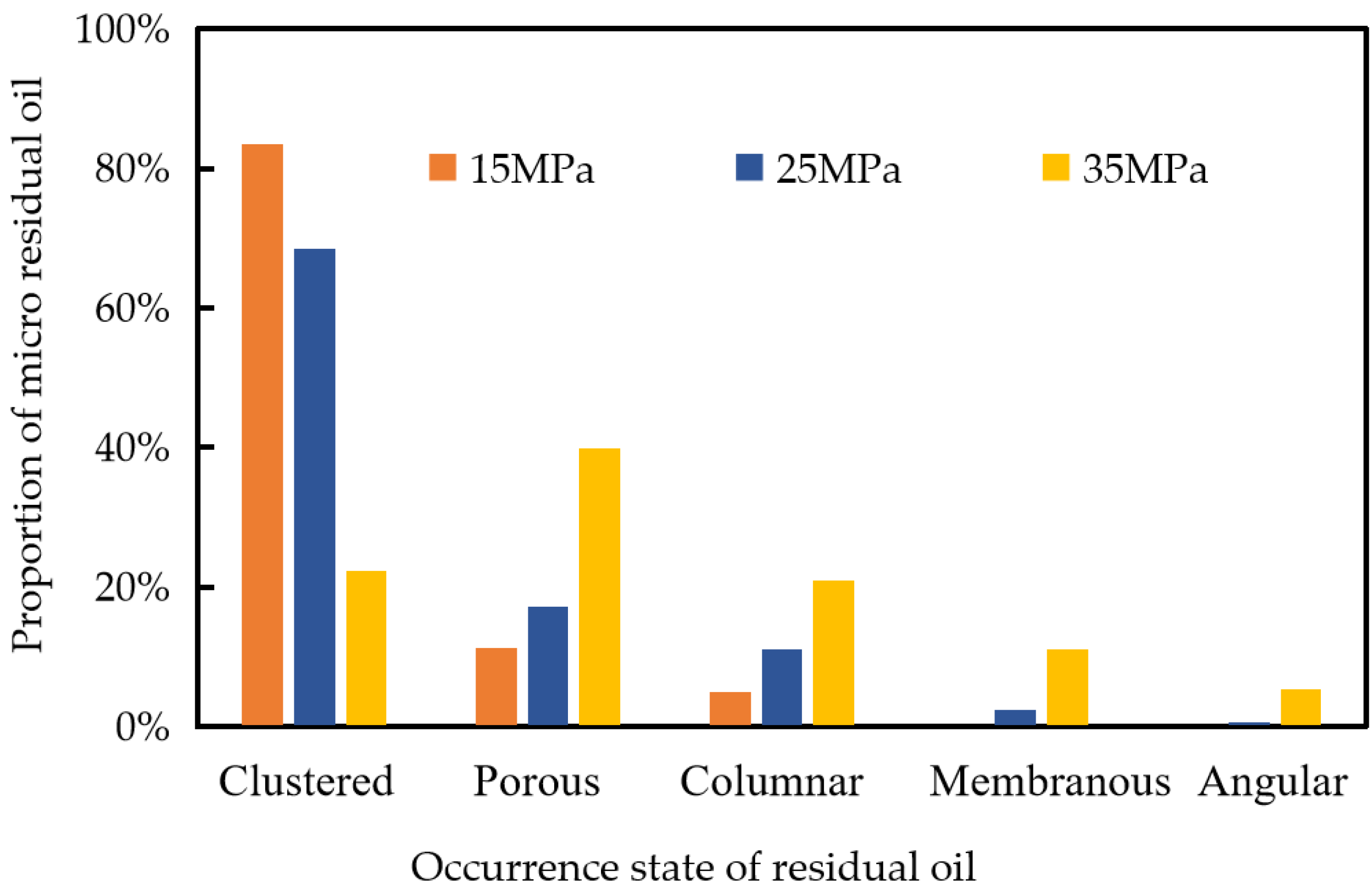

3.3.1. Soaking Pressure

3.3.2. Soaking Time

3.4. Further Research Plan

4. Conclusions

- The mechanisms of CO2 huff and puff include CO2 diffusion dissolution, miscibility with crude oil, dissolved gas flooding, extraction, etc. Gas–liquid miscibility can improve the recovery of crude oil. The extraction effect of CO2 on crude oil is more obvious than that of solution expansion;

- The mobilization mechanisms of crude oil mainly comprise four aspects, and different movability mechanisms correspond to different occurrence of states of crude oil. (1) The residual oil adhered to the matrix transforms from film to drop due to shear force formed by the flow of CO2 on both sides. The oil peels off the surface of the matrix under the continuous action of the shear force; (2) For the crude oil existing in the corner with poor fluidity, CO2 is mostly funnel-shaped to extract the light components of crude oil; (3) At pores with good flow capacity, CO2 and crude oil are miscible after multiple contacts, which decreases the interfacial tension between oil and gas and increases the flow capacity of oil; (4) When the gas content is high, CO2 contacts with the formation fluid and surrounds the crude oil, causing the crude oil to expand;

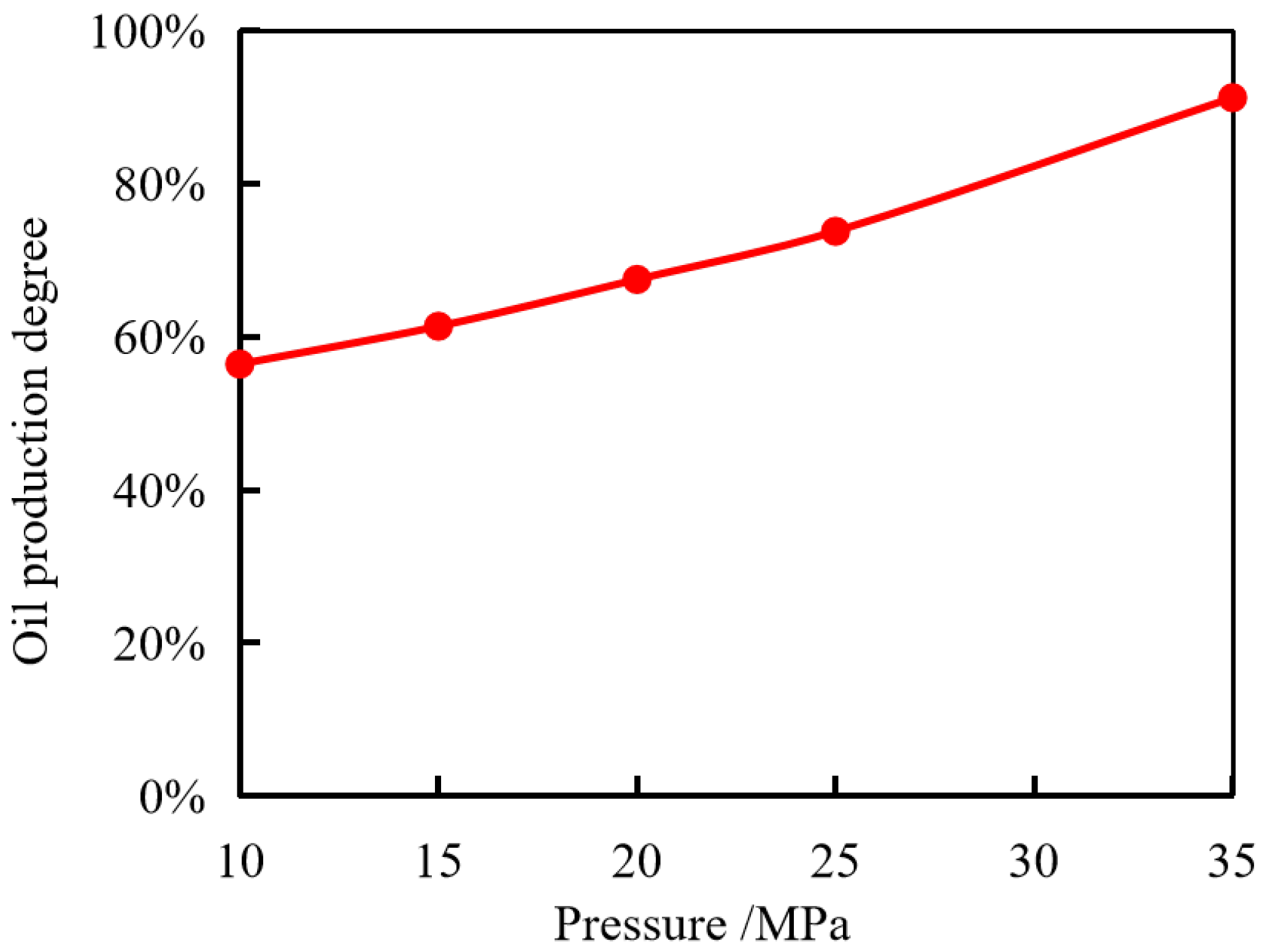

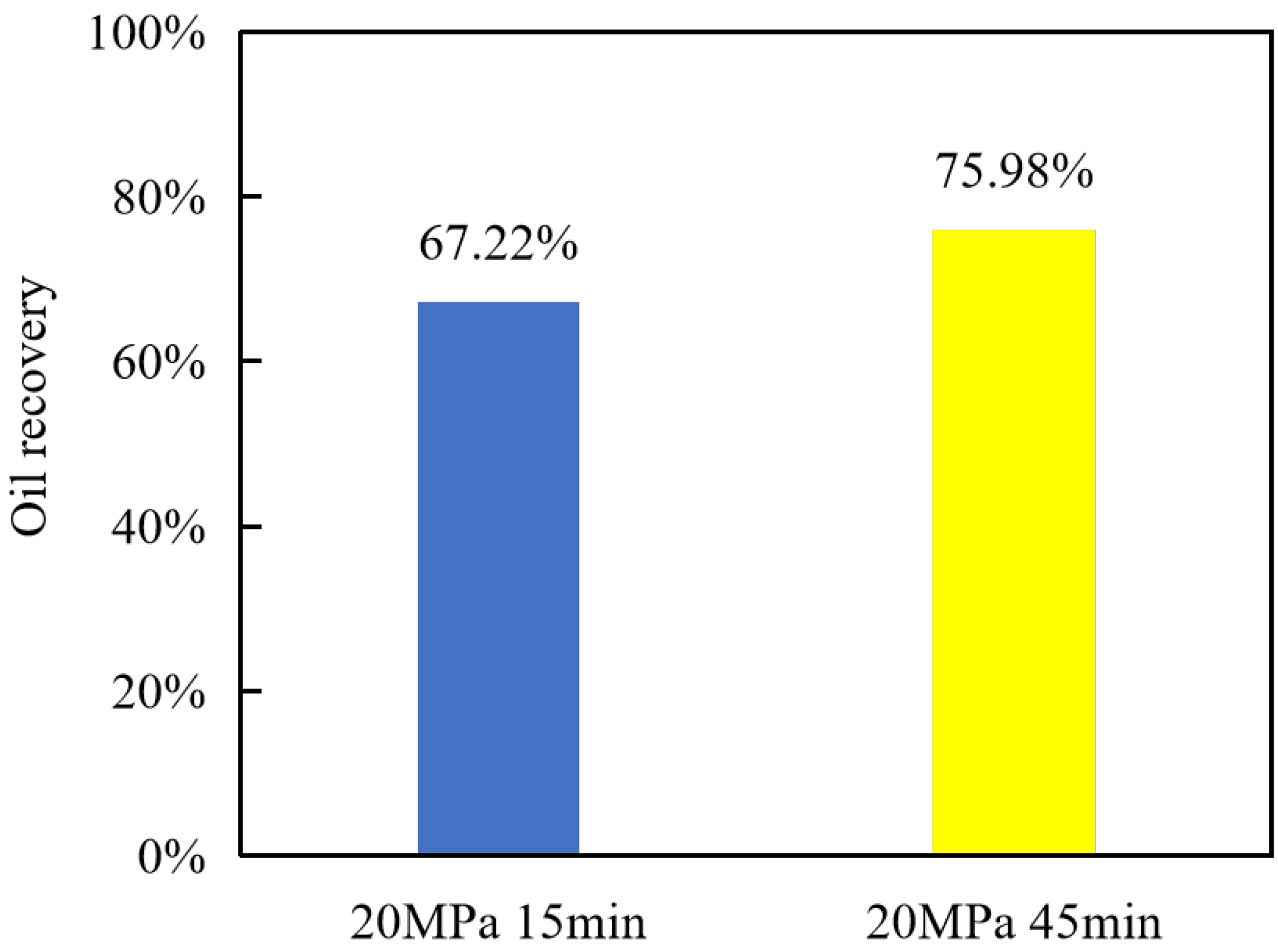

- With the increase of pressure, the recovery degree of crude oil gradually increases. When the gas injection pressure is higher than the miscible pressure, the recovery degree of crude oil at 35 MPa is significantly higher than that at 25 MPa by 23.74%, and the recovery degree of crude oil is as high as 91.22%; With the increase of the soaking time, the recovery degree of crude oil increases. Under 20 MPa, CO2 can fully diffuse into the crude oil with 45 min of soaking time. Compared with 15 min of soaking time at the same pressure, the crude oil recovery increased from 67.22% to 75.98%, an increase of 8.75%;

- With increase of pressure, the oil phase is divided and the remaining oil, in the form of cluster flow, transforms into a discontinuous phase, in the form of porous flow. The flow of crude oil becomes increasingly dispersed and the degree of discontinuity is intensified;

- In this experiment, the minimum pore throat is 10 μm. The results do not cover all type of shale reservoirs because there are shale reservoirs that have pore throats at the nanometer scale. In order to have comprehensive understanding about the mechanism of CO2, an experiment accurate to the nanometer scale is needed.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Alfarge, D.; Wei, M.; Bai, B. CO2 EOR mechanisms in huff and puff operations in shale oil reservoirs based on history matching results. Fuel 2018, 226, 112–120. [Google Scholar] [CrossRef]

- Huang, X.; Li, X.; Zhang, Y.; Li, T.; Zhang, R. Microscopic production characteristics of crude oil in nano-pores of shale oil reservoirs during CO2 huff and puff. Pet. Explor. Dev. 2022, 49, 557–564. [Google Scholar] [CrossRef]

- Yu, H.; Song, X.M.; Yang, S.Y.; Chen, D.F. Experimental and Numerical Simulation Study on Single Layer Injectivity for CO2 Flooding in Low Permeability Oil Reservoir. In Proceedings of the SPE Enhanced Oil Recovery Conference, Kuala Lumpur, Malaysia, 19–21 July 2011. [Google Scholar]

- Lei, L.; Sheng, J.J.; Xu, J. Gas Selection for huff and puff EOR in Shale Oil Reservoirs Based upon Experimental and Numerical Study. In Proceedings of the SPE Unconventional Resources Conference, Calgary, AB, Canada, 15–16 February 2017. [Google Scholar]

- Yuan, L.; Liu, S.; Zhang, J.; Zhang, Y.; Song, Y. Molecular Insight into the Extraction Behaviors of Confined Heavy Oil in the Nanopore by CO2/C3H8 in huff and puff Process. Energy Fuels 2022, 36, 3062–3075. [Google Scholar] [CrossRef]

- Li, L.; Su, Y.; Sheng, J.J.; Hao, Y.; Wang, W.; Lv, Y.; Zhao, Q.; Wang, H. Experimental and Numerical Study on CO2 Sweep Volume during CO2 huff and puff EOR Process in Shale Oil Reservoirs. Energy Fuels 2019, 33, 4017–4032. [Google Scholar] [CrossRef]

- Zhu, J.; Chen, J.; Wang, X.; Fan, L.; Nie, X. Experimental Investigation on the Characteristic Mobilization and Remaining Oil Distribution under CO2 Huff-n-Puff of Chang 7 Continental Shale Oil. Energies 2021, 14, 2782. [Google Scholar] [CrossRef]

- Tang, M.; Zhao, H.; Ma, H.; Lu, S.; Chen, Y. Study on CO2 huff and puff of horizontal wells in continental tight oil reservoirs. Fuel 2017, 188, 140–154. [Google Scholar] [CrossRef]

- Song, Z.; Song, Y.; Li, Y.; Bai, B.; Hou, J.; Song, K.; Jiang, A.; Su, S. A Critical Review of CO2 Enhanced Oil Recovery in Tight Oil Reservoirs of North America and China. In Proceedings of the SPE/IATMI Asia Pacific Oil & Gas Conference and Exhibition, Bali, Indonesia, 29–31 October 2019. [Google Scholar]

- Enab, K.; Emami-Meybodi, H. Effects of Diffusion, Adsorption, and Hysteresis on huff and puff Performance in Ultratight Reservoirs with Different Fluid Types and Injection Gases. Energies 2021, 14, 7379. [Google Scholar] [CrossRef]

- Alfarge, D.; Wei, M.; Bai, B. Factors Affecting CO2-EOR in Shale-Oil Reservoirs: Numerical Simulation Study and Pilot Tests. Energy Fuels 2017, 31, 8462–8480. [Google Scholar] [CrossRef]

- Wang, Q.; Jiang, H.; Han, J.; Wang, D.; Li, J. Adaptive Prediction of Enhanced Oil Recovery by N2 huff-n-puff in Fractured-Cavity Reservoir Using an FNN-FDS Hybrid Model. Appl. Sci. 2021, 11, 8871. [Google Scholar] [CrossRef]

- Su, X.; Yue, X.A.; Moghanloo, R.G. Interplay between Rock Permeability and the Performance of huff and puff CO2 Injection. ACS Omega 2020, 5, 16575–16583. [Google Scholar] [CrossRef]

- Ghasemi, M.; Astutik, W.; Alavian, S.A.; Whitson, C.H.; Sigalas, L.; Olsen, D.; Suicmez, V.S. Determining Diffusion Coefficients for Carbon Dioxide Injection in Oil-Saturated Chalk by Use of a Constant-Volume-Diffusion Method. SPE J. 2017, 22, 505–520. [Google Scholar] [CrossRef]

- Alfarge, D.; Wei, M.; Bai, B.; Almansour, A. Effect of Molecular-Diffusion Mechanism on CO2 huff and puff Process in Shale-Oil Reservoirs. In Proceedings of the SPE Kingdom of Saudi Arabia Technical Symposium & Exhibition, Dammam, Saudi Arabia, 24–27 April 2017. [Google Scholar]

- Sanaei, A.; Abouie, A.; Tagavifar, M.; Sepehrnoori, K. Comprehensive Study of Gas Cycling in the Bakken Shale. In Proceedings of the 2018 Unconventional Resources Technology Conference, Houston, TX, USA, 23–25 July 2018. [Google Scholar]

- Ding, M.; Wang, Y.; Wang, Y.; Gao, M.; Liu, D.; Chen, W. Experimental investigation of bypassed-oil recovery via CO2 soaking and huff and puff injection: Effects of miscibility and bypassed-oil size. Fuel 2019, 248, 152–160. [Google Scholar] [CrossRef]

- Cheng, C.; Ming, G. Investigation of cyclic CO2 huff-and-puff recovery in shale oil reservoirs using reservoir simulation and sensitivity analysis. Fuel 2017, 188, 102–111. [Google Scholar] [CrossRef]

- Meng, X.; Sheng, J.J. Experimental Study on Revaporization Mechanism of huff and puff Gas Injection to Enhance Condensate Recovery in Shale Gas Condensate Reservoirs. In Proceedings of the SPE Improved Oil Recovery Conference, Tulsa, OK, USA, 11–13 April 2016. [Google Scholar]

- Hemmati-Sarapardeh, A.; Ayatollahi, S.; Ghazanfari, M.H.; Masihi, M. Experimental Determination of Interfacial Tension and Miscibility of the CO2–Crude Oil System; Temperature, Pressure, and Composition Effects. J. Chem. Eng. Data 2014, 59, 946–955. [Google Scholar] [CrossRef]

- Qian, K.; Yang, S.; Dou, H.; Wang, Q.; Wang, L.; Huang, Y. Experimental Investigation on Microscopic Residual Oil Distribution During CO2 Huff-and-Puff Process in Tight Oil Reservoirs. Energies 2018, 11, 2843. [Google Scholar] [CrossRef]

- Orabi, F.; Firouz, A.Q.; Kavousi, A.; Asghari, K. Comparative evaluation of immiscible, near miscible and miscible CO2 huff and puff to enhance oil recovery from a single matrix-fracture system (experimental and simulation studies). Fuel 2012, 93, 443–453. [Google Scholar]

- Wang, H.; Tian, L.; Chai, X.; Wang, J.; Zhang, K. Effect of pore structure on recovery of CO2 miscible flooding efficiency in low permeability reservoirs. J. Pet. Sci. Eng. 2021, 208, 109305. [Google Scholar] [CrossRef]

- Abedini, A.; Mosavat, N.; Torabi, F. Determination of Minimum Miscibility Pressure of Crude Oil–CO2 System by Oil Swelling/Extraction Test. Energy Technol. 2014, 2, 431–439. [Google Scholar] [CrossRef]

- Zacharoudiou, I.; Boek, E.S. Capillary filling and Haines jump dynamics using free energy Lattice Boltzmann simulations. Adv. Water Resour. 2016, 92, 43–56. [Google Scholar] [CrossRef]

- Hou, G.; Ma, X.; Zhao, W.; Diwu, P.; Liu, T.; Hou, J. Synergistic Modes and Enhanced Oil Recovery Mechanism of CO2 Synergistic Huff and Puff. Energies 2021, 14, 3454. [Google Scholar] [CrossRef]

- Kong, X.; Wang, H.; Yu, W.; Wang, P.; Miao, J.; Fiallos-Torres, M. Compositional Simulation of Geological and Engineering Controls on Gas Huff-n-Puff in Duvernay Shale Volatile Oil Reservoirs, Canada. Energies 2021, 14, 2070. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lei, Z.; Liu, Y.; Wang, R.; Li, L.; Liu, Y.; Zhang, Y. A Microfluidic Experiment on CO2 Injection for Enhanced Oil Recovery in a Shale Oil Reservoir with High Temperature and Pressure. Energies 2022, 15, 9461. https://doi.org/10.3390/en15249461

Lei Z, Liu Y, Wang R, Li L, Liu Y, Zhang Y. A Microfluidic Experiment on CO2 Injection for Enhanced Oil Recovery in a Shale Oil Reservoir with High Temperature and Pressure. Energies. 2022; 15(24):9461. https://doi.org/10.3390/en15249461

Chicago/Turabian StyleLei, Zhengdong, Yishan Liu, Rui Wang, Lei Li, Yuqi Liu, and Yuanqing Zhang. 2022. "A Microfluidic Experiment on CO2 Injection for Enhanced Oil Recovery in a Shale Oil Reservoir with High Temperature and Pressure" Energies 15, no. 24: 9461. https://doi.org/10.3390/en15249461

APA StyleLei, Z., Liu, Y., Wang, R., Li, L., Liu, Y., & Zhang, Y. (2022). A Microfluidic Experiment on CO2 Injection for Enhanced Oil Recovery in a Shale Oil Reservoir with High Temperature and Pressure. Energies, 15(24), 9461. https://doi.org/10.3390/en15249461