Dynamic Process Modeling of Topside Systems for Evaluating Power Consumption and Possibilities of Using Wind Power

Abstract

:1. Introduction

2. Materials and Methods

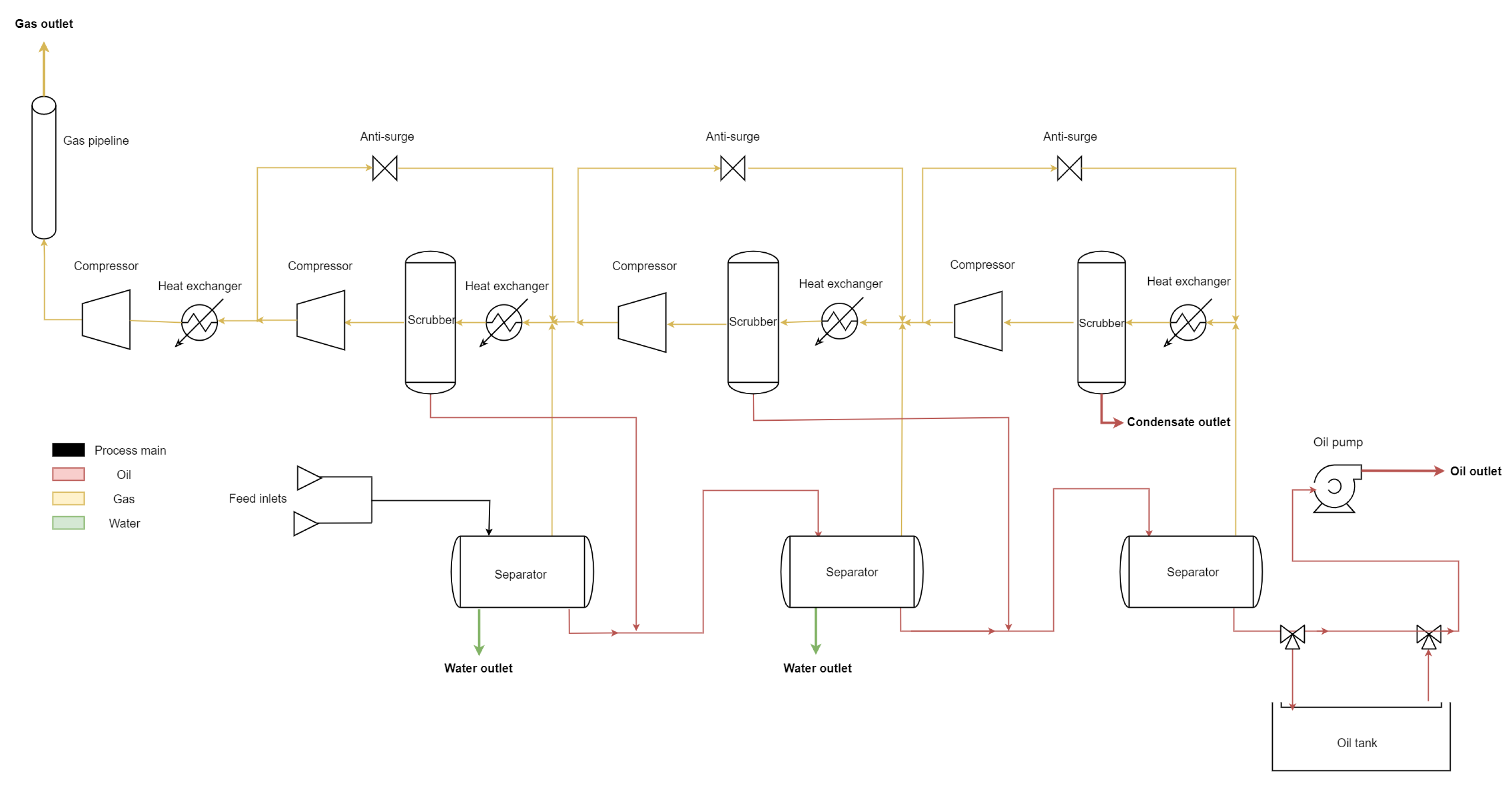

2.1. Case Study

2.2. Dynamic Model of the Topside Processing System

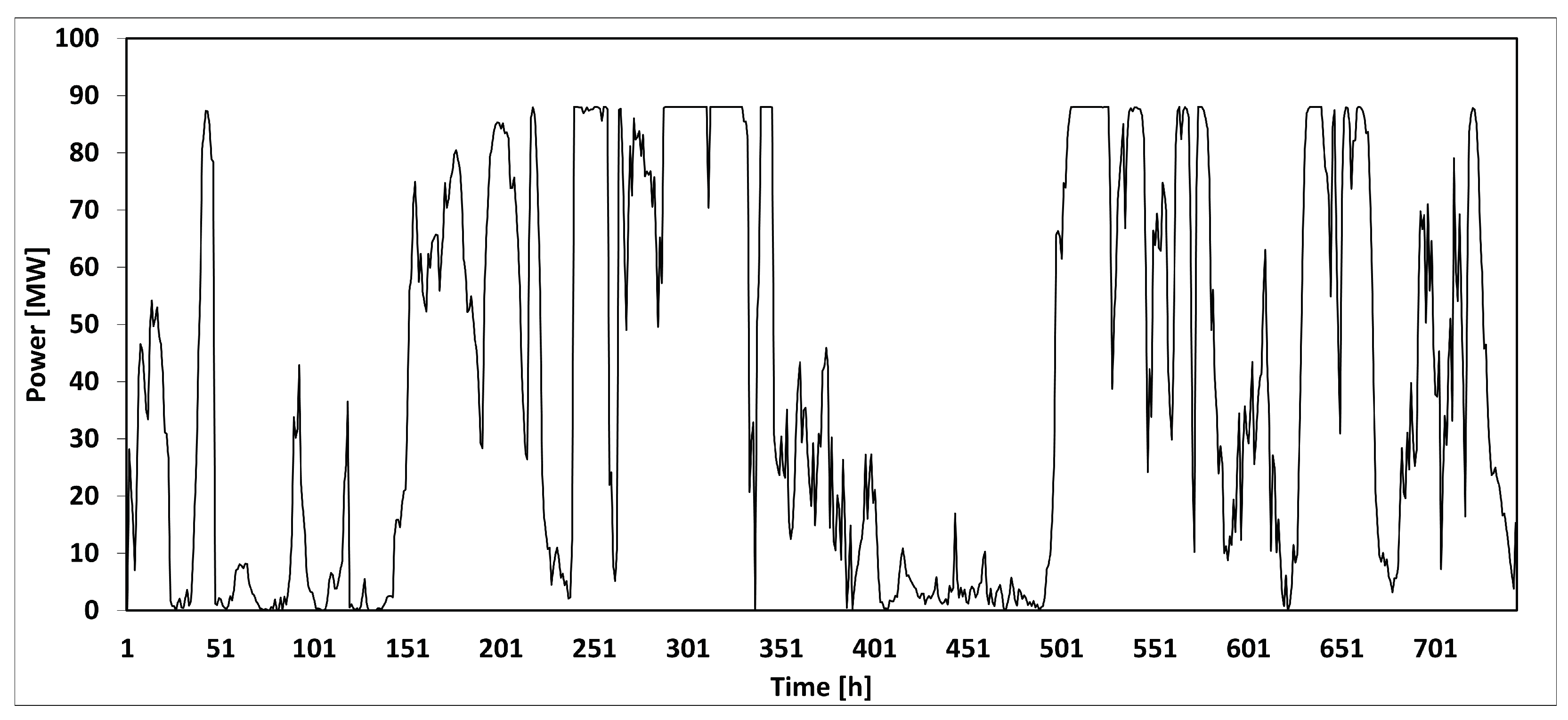

2.3. Power Supply from Wind Power

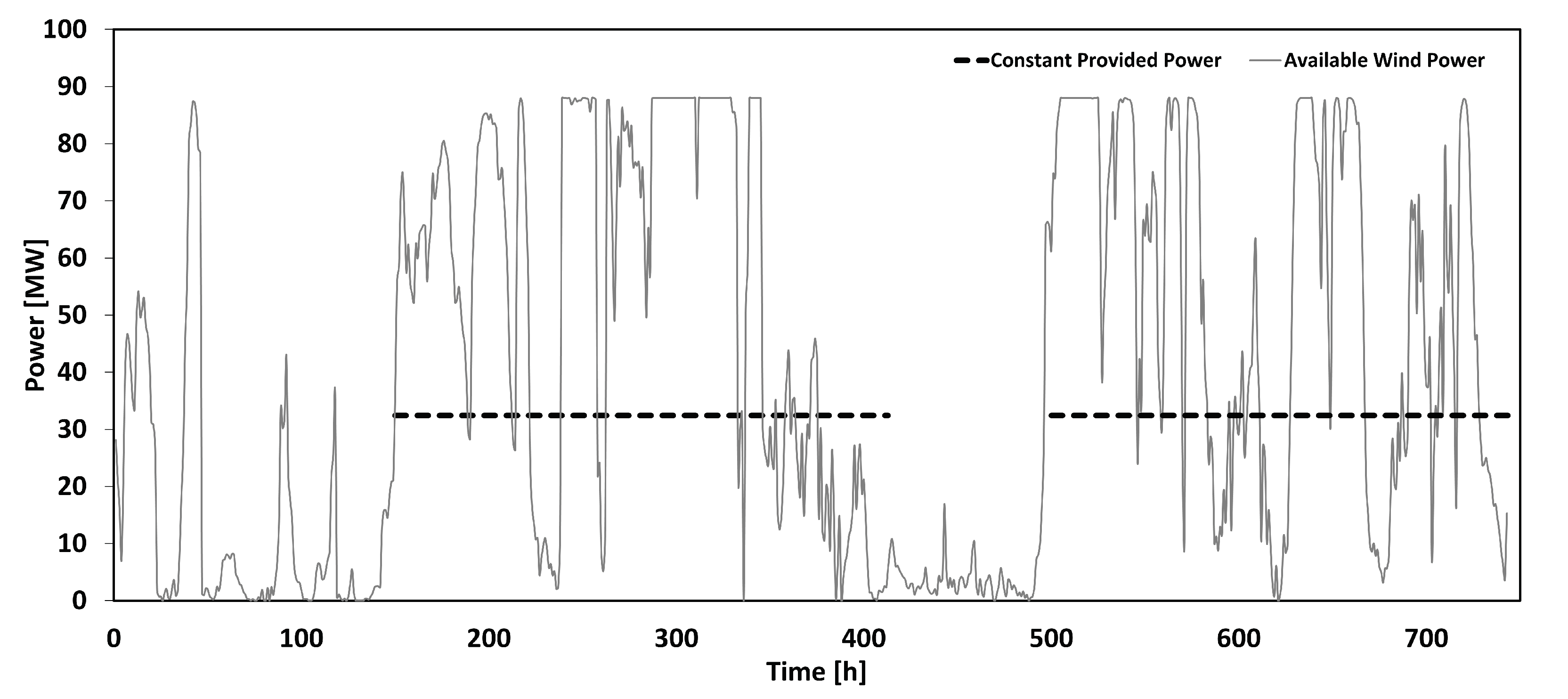

2.3.1. Method 1: Variable Wind Energy and Small Backups of Gas Turbines

- 1.

- When the power produced by the wind farm was greater than the maximal required power of the processing facility (33.06 MW), the power consumption was set to this maximal value, leaving the extra available power unused.

- 2.

- When the available wind power was within the required power range of the processing facility (between 33.06 and 6.37 MW), the power consumption of the processing facility was set to the value of the available wind power.

- 3.

- When the available wind power was below the minimum power threshold of the processing facility (6.37 MW), the power consumption was set to this value. Thus, the available wind power could not meet the requirements of the system, and a production stop was also not considered as an option. An alternative power supply was assumed to maintain the minimum required power.

2.3.2. Power Supply Derived from the Integration of Wind Energy, Energy Storage, and Gas Turbines

Method 2: Wind Energy and Energy Storage

Method 3: Wind Energy, Energy Storage, and Gas Turbines

2.4. Energy Storage Alternatives: Hydrogen and Ammonia

3. Results and Discussion

3.1. Method 1: Variable Wind Energy and Small Backups of Gas Turbines

CO2 Emissions of Method 1

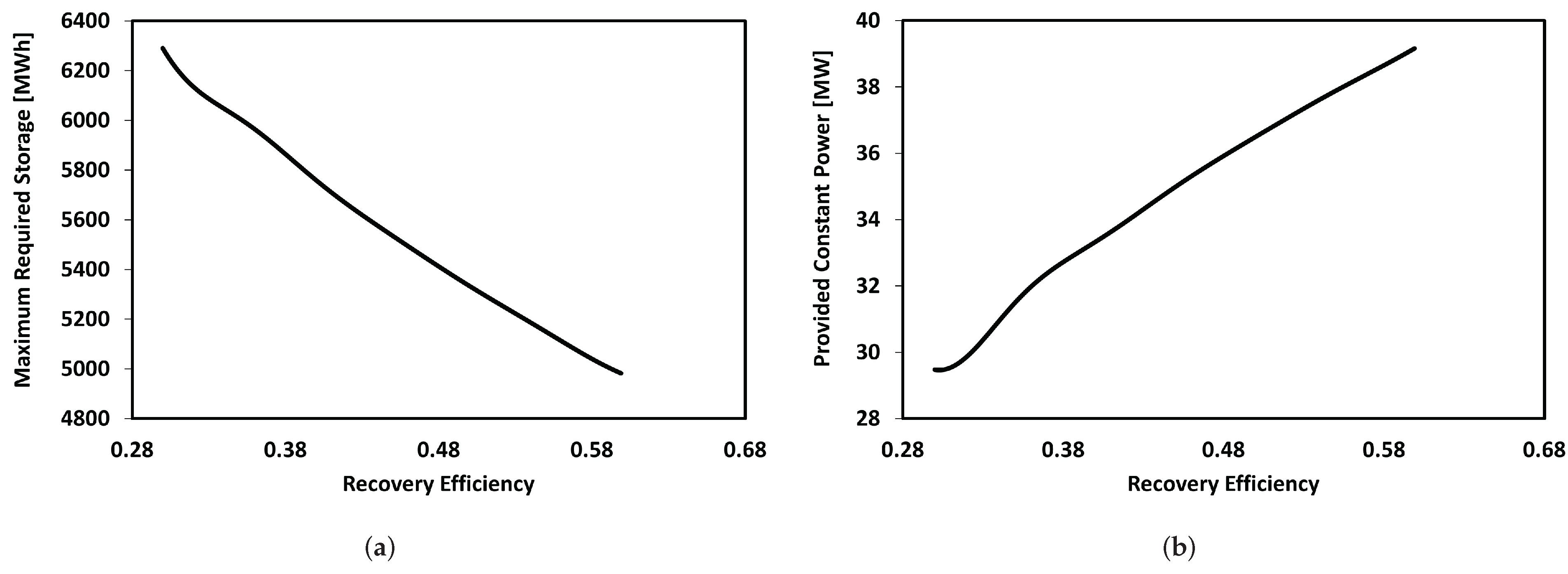

3.2. Method 2: Wind Energy and Energy Storage

3.2.1. CO2 Emissions of Method 2

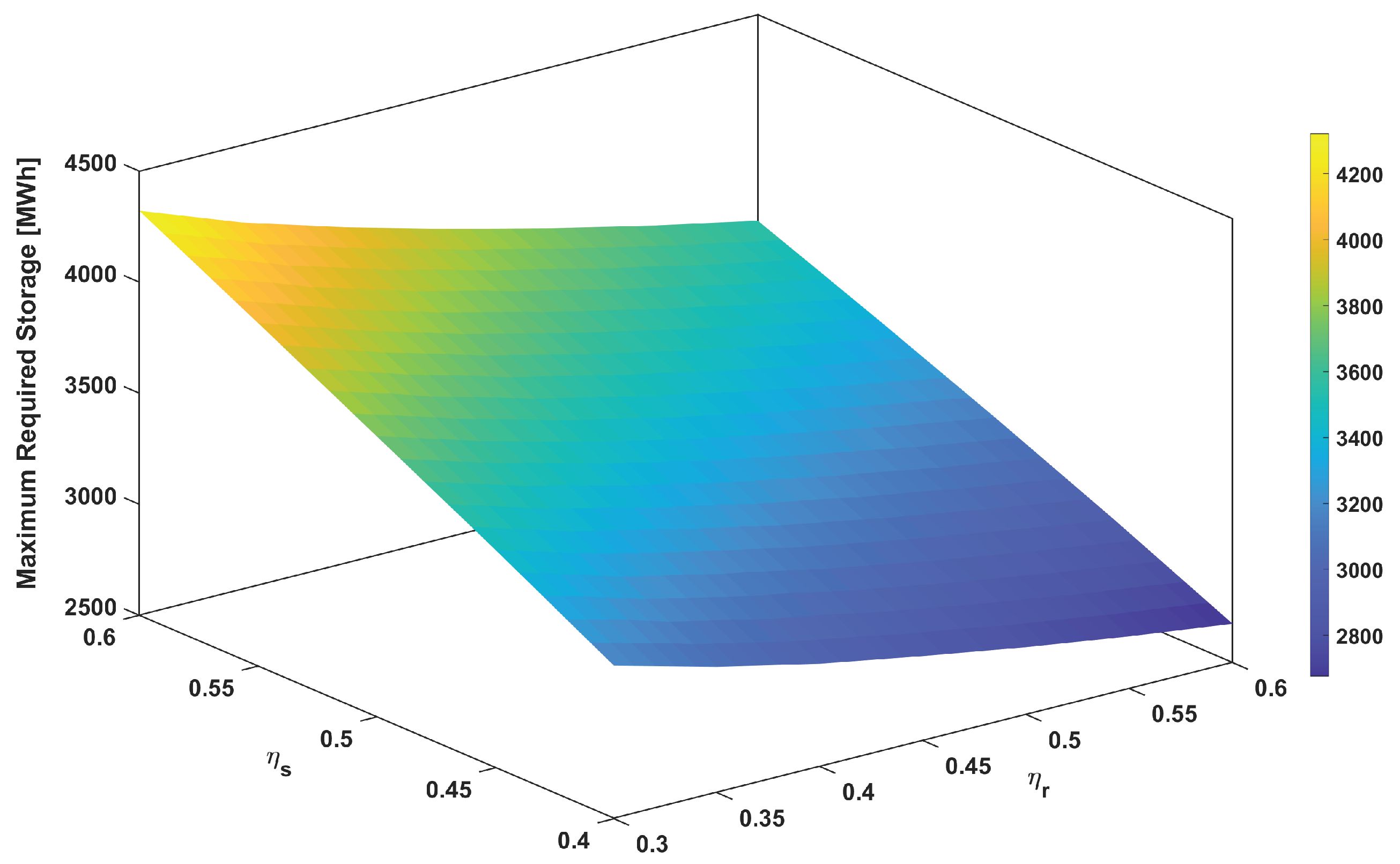

3.2.2. Sensitivity Analysis

3.2.3. Discussion about Energy Storage for Method 2

3.3. Method 3: Wind Energy, Energy Storage and Gas Turbines

3.3.1. CO2 Emissions of Method 3

3.3.2. Discussion about Energy Storage for Method 3

3.4. Results Summary

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Recovery energy efficiency | |

| Storing energy efficiency | |

| Carbon dioxide | |

| Enhanced oil recovery | |

| Gas/oil ratio | |

| Gigawatt | |

| Megajoules | |

| Megawatt | |

| Norwegian Continental Shelf | |

| Constant power, [MW] | |

| Available wind power, [MW] | |

| Recovering energy rare, [MWh] | |

| s | Required size of energy storage, [MWh] |

| Storing energy rate, [MWh] | |

| Variable renewable electricity | |

| Water cut |

References

- Svendsen, H.G. Optimised operation of low-emission offshore oil and gas platform integrated energy systems. arXiv 2022, arXiv:2202.05072. [Google Scholar]

- He, W.; Jacobsen, G.; Anderson, T.; Olsen, F.; Hanson, T.D.; Korpås, M.; Toftevaag, T.; Eek, J.; Uhlen, K.; Johansson, E. The potential of integrating wind power with offshore oil and gas platforms. Wind Eng. 2010, 34, 125–137. [Google Scholar] [CrossRef]

- Eyni, L.; Stanko, M.; Schümann, H. Methods for early-phase planning of offshore fields considering environmental performance. Energy 2022, 256, 124495. [Google Scholar] [CrossRef]

- Santibanez-Borda, E.; Korre, A.; Nie, Z.; Durucan, S. A multi-objective optimisation model to reduce greenhouse gas emissions and costs in offshore natural gas upstream chains. J. Clean. Prod. 2021, 297, 126625. [Google Scholar] [CrossRef]

- Shojaeddini, E.; Naimoli, S.; Ladislaw, S.; Bazilian, M. Oil and gas company strategies regarding the energy transition. Prog. Energy 2019, 1, 012001. [Google Scholar] [CrossRef]

- The European Parliament; The Council of the European Union. Directive (EU) 2018/2001 of the European Parliament and of the Council of 11 December 2018 on the promotion of the use of energy from renewable sources. Off. J. Eur. Union 2018, 5. [Google Scholar]

- Yang, X.; Liu, N.; Zhang, P.; Guo, Z.; Ma, C.; Hu, P.; Zhang, X. The current state of marine renewable energy policy in China. Mar. Policy 2019, 100, 334–341. [Google Scholar] [CrossRef]

- International Energy Agency. Offshore Wind Outlook. World Energy Outlook Special Report. 2019. Available online: https://www.iea.org/ (accessed on 1 December 2022).

- Mäkitie, T.; Normann, H.E.; Thune, T.M.; Gonzalez, J.S. The green flings: Norwegian oil and gas industry’s engagement in offshore wind power. Energy Policy 2019, 127, 269–279. [Google Scholar] [CrossRef]

- McLaurin, D.; Paulin, M.; Peng, C.; Yadlapati, R. The Use of Offshore Wind to Reduce Greenhouse Gas Emissions in Offshore Hydrocarbon Production-A Case Study. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 16–19 August 2021. [Google Scholar]

- McKenna, R.; D’Andrea, M.; González, M.G. Analysing long-term opportunities for offshore energy system integration in the Danish North Sea. Adv. Appl. Energy 2021, 4, 100067. [Google Scholar] [CrossRef]

- Regional Investment Plan 2020 Northern Seas. Available online: https://www.entsoe.eu/ (accessed on 1 December 2022).

- Hu, D.; Zhao, X.; Cai, X.; Wang, J. Impact of wind power on stability of offshore platform power systems. In Proceedings of the 2008 Third International Conference on Electric Utility Deregulation and Restructuring and Power Technologies, Nanjing, China, 6–9 April 2008; pp. 1688–1692. [Google Scholar]

- Korpås, M.; Warland, L.; He, W.; Tande, J.O.G. A case-study on offshore wind power supply to oil and gas rigs. Energy Procedia 2012, 24, 18–26. [Google Scholar] [CrossRef] [Green Version]

- McDonagh, S.; Ahmed, S.; Desmond, C.; Murphy, J.D. Hydrogen from offshore wind: Investor perspective on the profitability of a hybrid system including for curtailment. Appl. Energy 2020, 265, 114732. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhang, H.; Yan, Y.; Yan, J.; He, J.; Li, Z.; Shang, W.; Liang, Y. Sustainable and clean oilfield development: How access to wind power can make offshore platforms more sustainable with production stability. J. Clean. Prod. 2021, 294, 126225. [Google Scholar] [CrossRef]

- Zou, X.; Qiu, R.; Yuan, M.; Liao, Q.; Yan, Y.; Liang, Y.; Zhang, H. Sustainable offshore oil and gas fields development: Techno-economic feasibility analysis of wind–hydrogen–natural gas nexus. Energy Rep. 2021, 7, 4470–4482. [Google Scholar] [CrossRef]

- Wang, B.; Zhou, M.; Xin, B.; Zhao, X.; Watada, J. Analysis of operation cost and wind curtailment using multi-objective unit commitment with battery energy storage. Energy 2019, 178, 101–114. [Google Scholar] [CrossRef]

- Hywind Tampen: The World’s First Renewable Power for Offshore Oil and Gas. Available online: https://www.equinor.com/energy/hywind-tampen/ (accessed on 1 December 2022).

- Younas, M.; Shafique, S.; Hafeez, A.; Javed, F.; Rehman, F. An overview of hydrogen production: Current status, potential, and challenges. Fuel 2022, 316, 123317. [Google Scholar] [CrossRef]

- Service, R.F. Ammonia—A Renewable Fuel Made from Sun, Air, And Water—Could Power the Globe without Carbon. Available online: https://www.science.org/content/article/ammonia-renewable-fuel-made-sun-air-and-water-could-power-globe-without-carbon (accessed on 12 July 2018).

- El kadi, J.; Collin Smith, L.T.M. H2 and NH3—The Perfect Marriage in a Carbon-Free Society. Available online: https://www.thechemicalengineer.com/features/h2-and-nh3-the-perfect-marriage-in-a-carbon-free-society/ (accessed on 28 May 2020).

- Valera-Medina, A.; Xiao, H.; Owen-Jones, M.; David, W.I.; Bowen, P. Ammonia for power. Prog. Energy Combust. Sci. 2018, 69, 63–102. [Google Scholar] [CrossRef]

- MacFarlane, D.R.; Cherepanov, P.V.; Choi, J.; Suryanto, B.H.; Hodgetts, R.Y.; Bakker, J.M.; Vallana, F.F.M.; Simonov, A.N. A Roadmap to the Ammonia Economy. Joule 2020, 13, 1186–1205. [Google Scholar] [CrossRef]

- Smith, C.; Hill, A.K.; Torrente-Murciano, L. Current and future role of Haber–Bosch ammonia in a carbon-free energy landscape. Energy Environ. Sci. 2020, 13, 331–344. [Google Scholar] [CrossRef]

- Lysyy, M.; Fernø, M.; Ersland, G. Seasonal hydrogen storage in a depleted oil and gas field. Int. J. Hydrogen Energy 2021, 46, 25160–25174. [Google Scholar] [CrossRef]

- Craig, A.; Newman, S.; Stephenson, P.; Evans, C.; Yancazos, S.; Barber, S. Hydrogen Storage Potential of Depleted Oil and Gas Fields in Western Australia. APPEA J. 2022, 62, 185–195. [Google Scholar] [CrossRef]

- LowEmission 2019–2026. Available online: https://www.sintef.no/projectweb/lowemission/ (accessed on 1 December 2022).

| Inlet temperature (C) | 40 |

| Inlet pressure (bara) | 55 |

| Outlet oil pressure (bara) | 50 |

| Outlet Gas Pressure (bara) | 200 |

| First-stage separator pressure (bara) | 25 |

| First-stage separator temperature (C) | 40 |

| Second-stage separator pressure (bara) | 6 |

| Second-stage separator temperature (C) | 30 |

| Third-stage separator pressure (bara) | 1.59 |

| Third-stage separator temperature (C) | 15 |

| Total mass flow rate (kg/h) | 534,500 |

| Total Production Rate (10 kg/h) | Power Consumption (MW) |

|---|---|

| 210 | 6.37 |

| 245 | 6.37 |

| 267.3 | 6.37 |

| 320.7 | 8.71 |

| 374.2 | 10.54 |

| 427.6 | 12.44 |

| 481.1 | 14.93 |

| 534.5 | 18.80 |

| 588.0 | 24.91 |

| 641.4 | 33.06 |

| Method 1 | Method 2 | Method 3 | |

|---|---|---|---|

| Energy storage requirement | NO | YES | YES |

| Gas turbines requirement | YES | NO | YES |

| Initial storage requirement | NO | YES | NO |

| Wind penetration [%] | 74 | 100 | 68 |

| Provided power [MW] | [6.37:33.06] | 19 | 32.4 |

| Maximal required energy storage [MWh] | 0 | 3500 | 1850 |

| Required hydrogen storage [MWh] | 0 | 5540 | 2950 |

| Required ammonia storage [MWh] | 0 | 4630 | 2450 |

| Emissions of CO2 | YES | NO | YES |

| Emission intensity reduction [] | 0.058 | 0.067 | 0.045 |

| Accumulated production [t] | 3.76 × | 3.99 × | 4.75 × |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Eyni, L.; Stanko, M.; Schümann, H.; Qureshi, A.H. Dynamic Process Modeling of Topside Systems for Evaluating Power Consumption and Possibilities of Using Wind Power. Energies 2022, 15, 9482. https://doi.org/10.3390/en15249482

Eyni L, Stanko M, Schümann H, Qureshi AH. Dynamic Process Modeling of Topside Systems for Evaluating Power Consumption and Possibilities of Using Wind Power. Energies. 2022; 15(24):9482. https://doi.org/10.3390/en15249482

Chicago/Turabian StyleEyni, Leila, Milan Stanko, Heiner Schümann, and Ali Hassan Qureshi. 2022. "Dynamic Process Modeling of Topside Systems for Evaluating Power Consumption and Possibilities of Using Wind Power" Energies 15, no. 24: 9482. https://doi.org/10.3390/en15249482

APA StyleEyni, L., Stanko, M., Schümann, H., & Qureshi, A. H. (2022). Dynamic Process Modeling of Topside Systems for Evaluating Power Consumption and Possibilities of Using Wind Power. Energies, 15(24), 9482. https://doi.org/10.3390/en15249482