Influence of Injection Pressure and Aluminium Oxide Nano Particle-Added Fish Oil Methyl Ester on the Performance and Emission of Compression Ignition Engine

Abstract

:1. Introduction

2. Methods and Materials

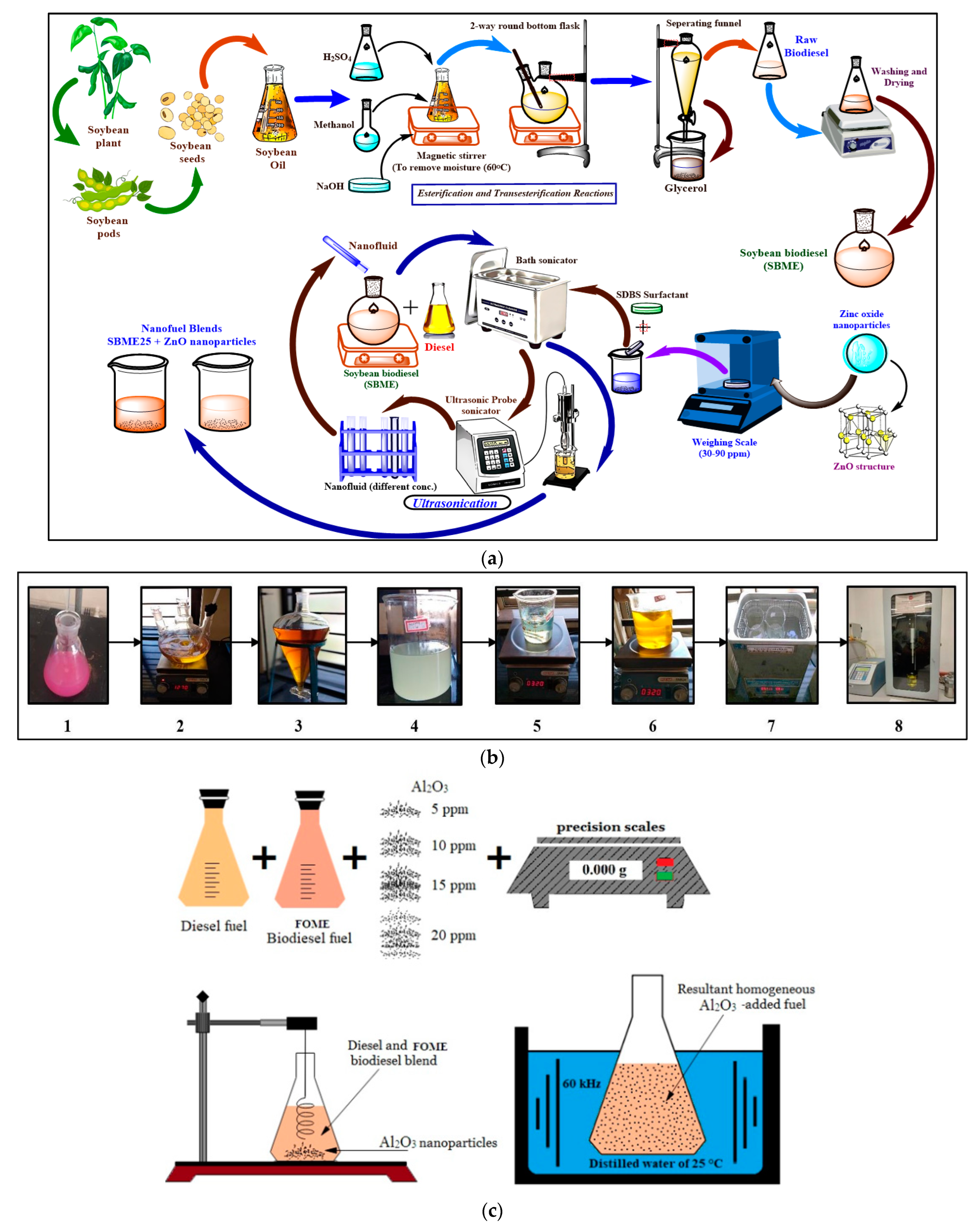

2.1. Preparation of Fish Oil Methyl Ester

2.2. Alumina (Al2O3) Nanopowder

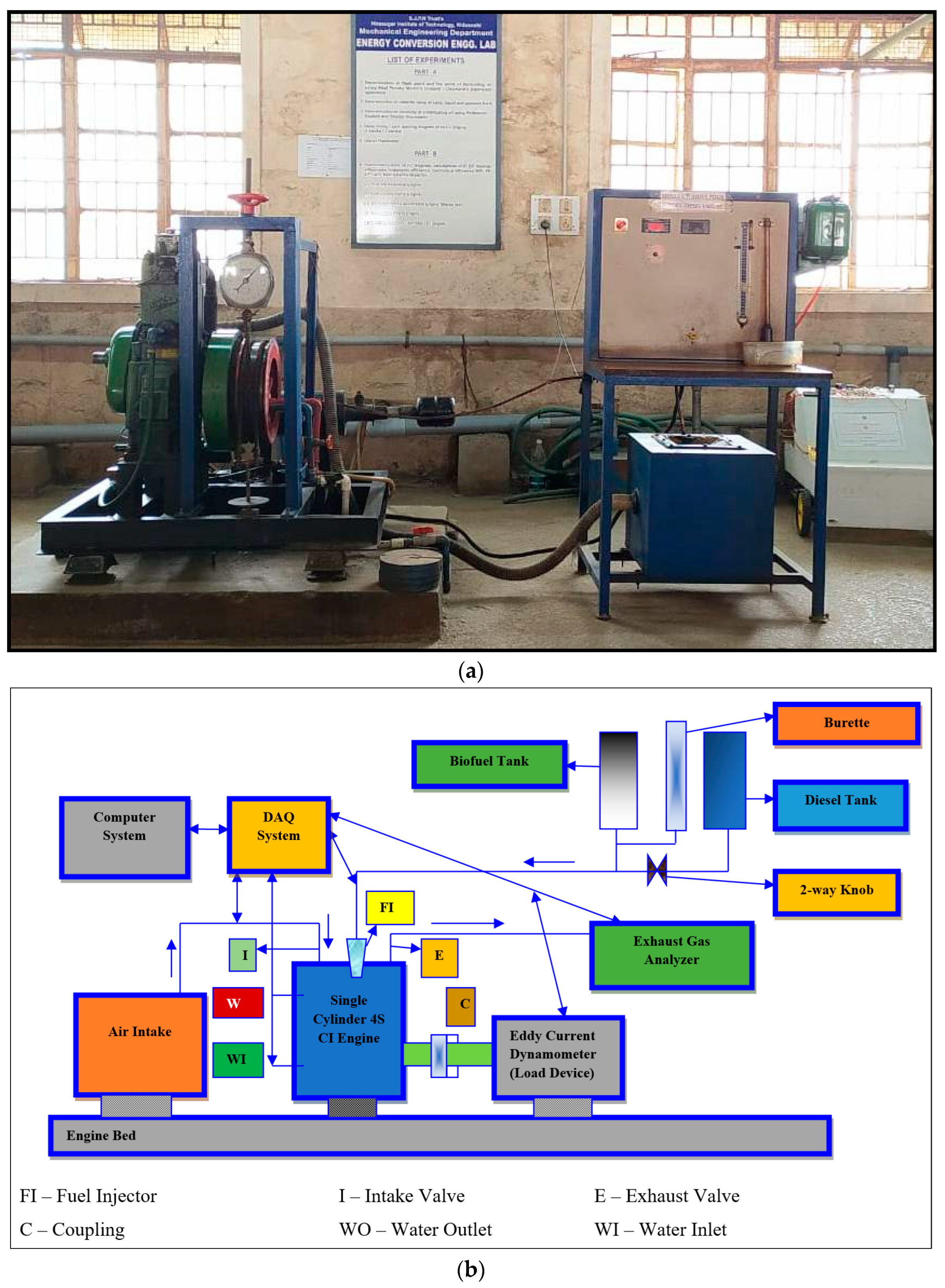

3. Experimental Setup

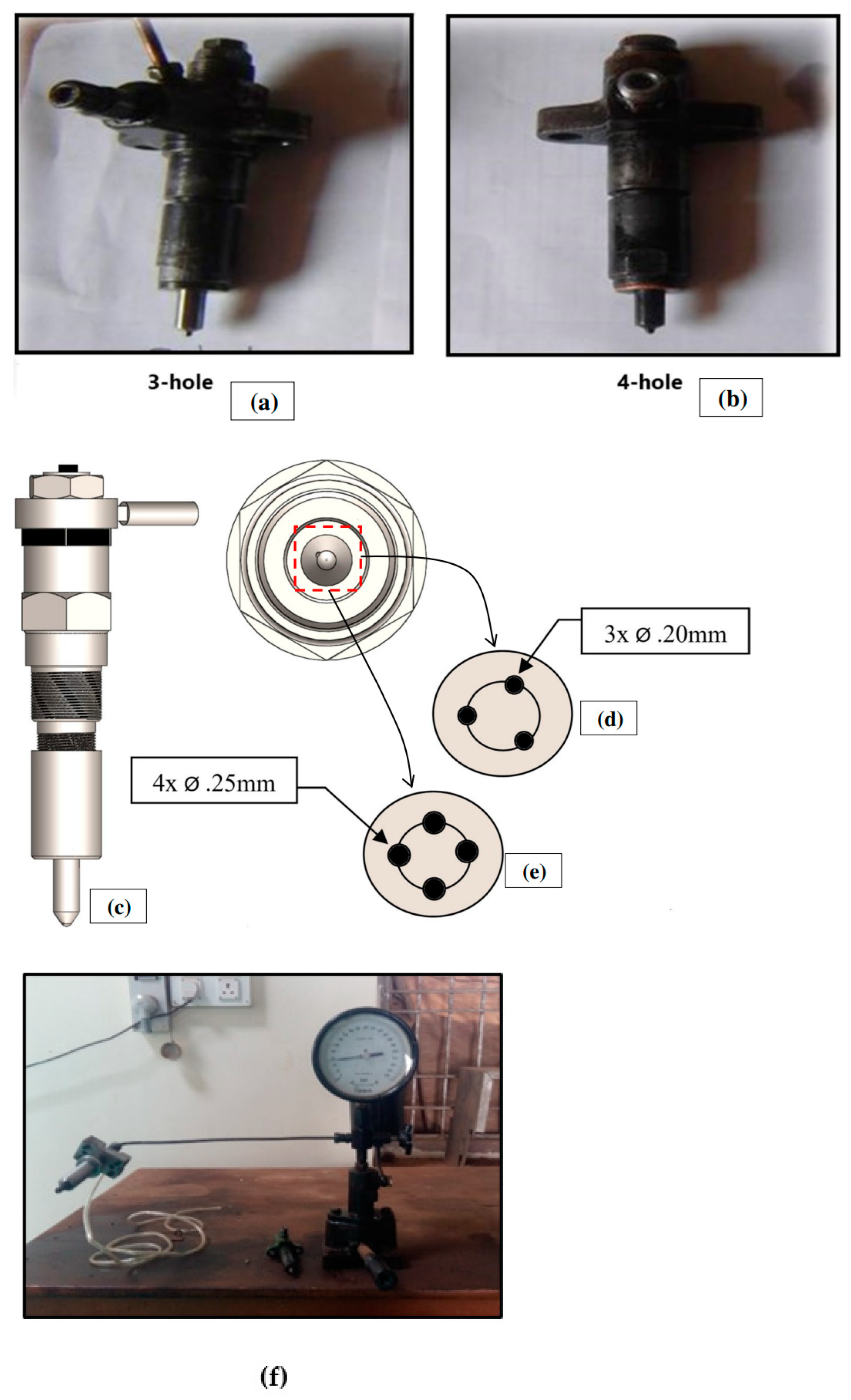

3.1. Fuel Injector

3.2. Test Fuel Blends and Nano-Biodiesel Blend Preparation

3.3. Experimental Procedure

3.4. Analysis of Uncertainty

4. Results and Discussion

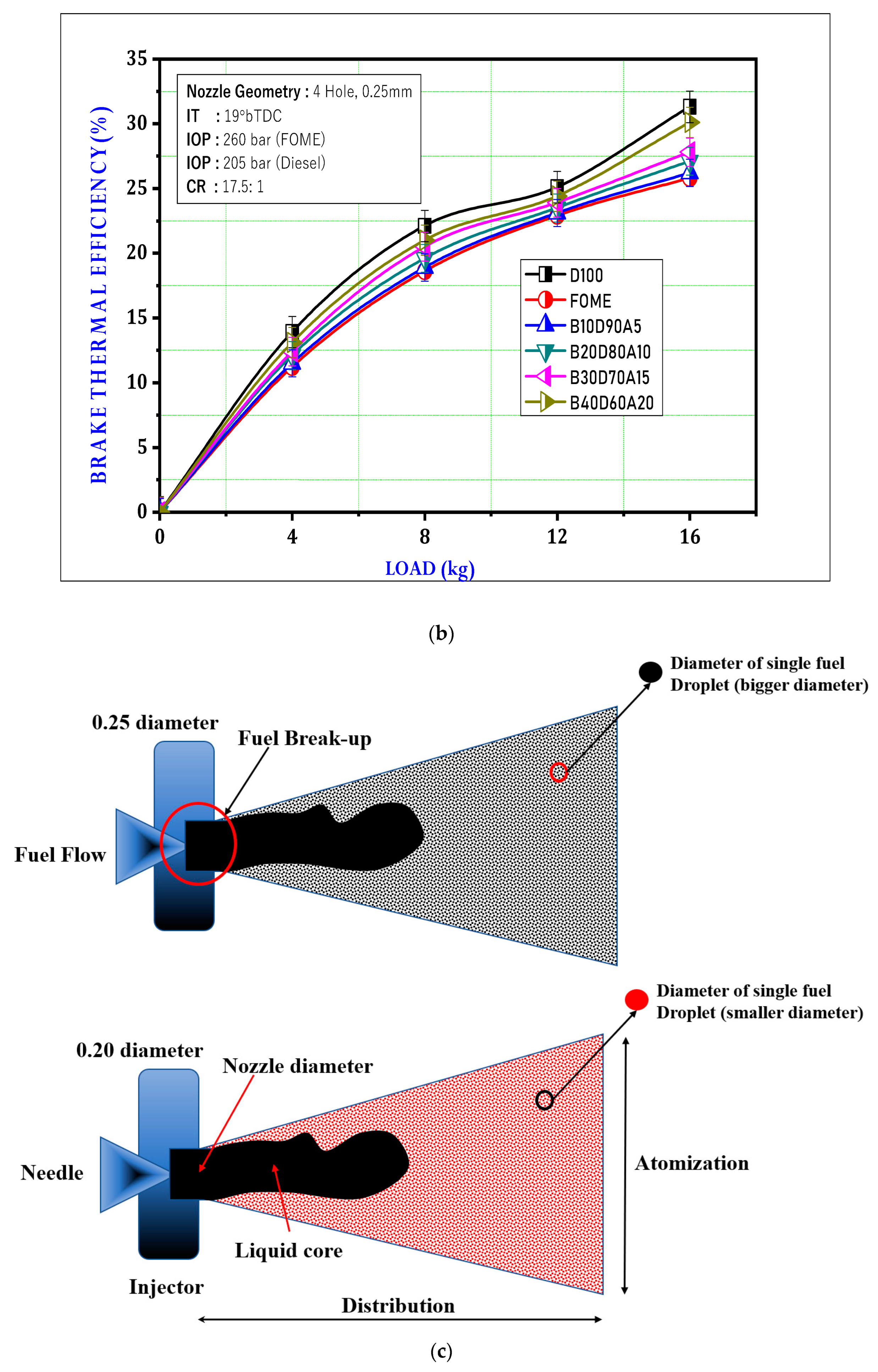

4.1. Performance Analysis—Brake Thermal Efficiency Variation with Load

4.2. Performance Analysis—Brake Thermal Efficiency Variation with Load

4.3. Emission Comparison—Carbon Monoxide Emission

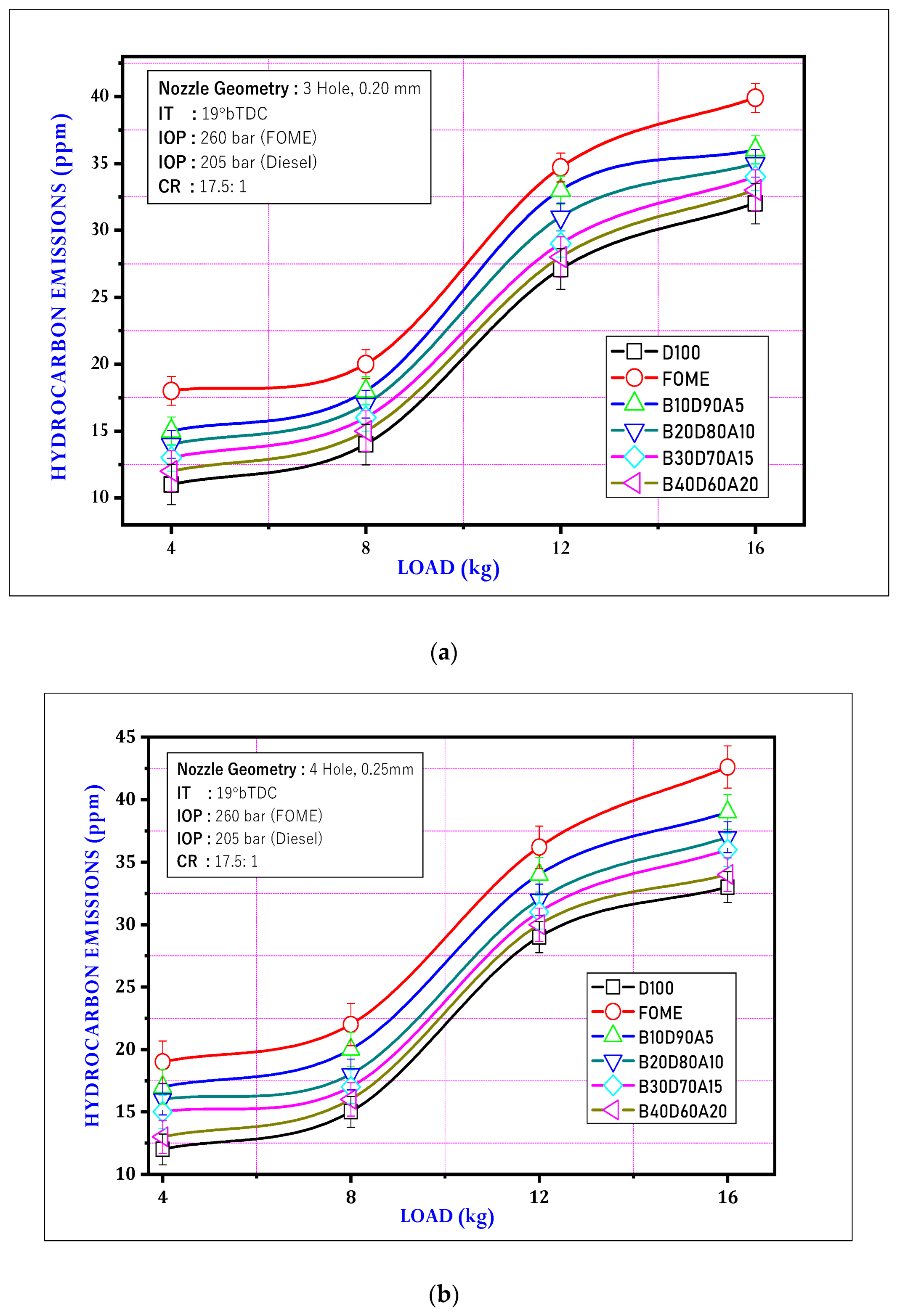

4.4. Emission Comparison—Hydrocarbon Emission

4.5. Emission Comparison—Nitrogen Oxide Emissions

4.6. Emission Comparison—Smoke Opacity

4.7. Combustion Characteristics: In-Cylinder Pressure and Heat Release Rate

5. Conclusions

- The B40D60A20 mixture exhibited optimised results for a three-hole nozzle geometry with a 0.20mm orifice diameter and 260 bar pressure injection, wherein a reasonable increase in the BTE and reduced emissions were achieved.

- Due to the catalytic character of Al2O3, the addition of Al2O3 nanoparticles at 20 mg/L in the FOME mixtures, i.e., the B40D60A20 mixture, provided the highest thermal efficiency of 30.9%, which is about 15.53% greater than the 100% FOME and 3.43% lower than the diesel, and also revealed a decrease in CO of 45.46%, HC of 17.29% 5%, NOx, and smoke of 21.28% compared to raw FOME. Additionally, the emissions are comparable with diesel at all loads.

- Owing to the uneven nozzle geometry of the four-hole injector, there is a lower BTE and more emissions for the four-hole injector compared to the three-hole injector. As the nozzle diameter decreases, the injection pattern improves, resulting in an enhancement in the engine performance and emission parameters.

- While the engine operated with a larger-diameter nozzle, the NOx emissions were lower than those of the smaller diameter nozzle. The cause for this might be attributed to the deterioration of the injection parameter, resulting in the deterioration of the combustion course. With the deterioration of the combustion course, the fuel is not properly burned and the temperature in the cylinder does not increase. Thus, the NOx emissions were lower for the larger-diameter nozzle.

- A small-diameter nozzle achieves superior atomization by forming smaller-diameter fuel droplets, thereby enabling an improved air/fuel ratio and facilitating the combustion process. Therefore, a small-diameter injector leads to improved performance and emissions characteristics.

- Al2O3 potentiates an oxygen surge and further oxidises the unburned fuel inside the combustion cavity. As a result of the existence of Al2O3 in the test fuel, the levels of imperfect combustion products such as HC, CO, and smoke are significantly lowered for the B40D60A20 mixture.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Future Scope of Work

Abbreviations

| FOME | Fish Oil Methyl Ester |

| CI | Compression Ignition |

| BP | Brake Power |

| BSFC | Brake Specific Fuel Consumption |

| HC | Hydrocarbons |

| CO | Carbon Monoxide |

| CO2 | Carbon Dioxide |

| CV | Calorific Value |

| NO | Nitrous Oxide |

| NOx | Nitrogen Oxide |

| CRDI | Common Rail Direct Injection |

| CR | Compression Ratio |

| CNT | Carbon Nanotubes |

| BTE | Brake Thermal Efficiency |

| BSFC | Brake Specific Fuel Consumption |

| UHC | Unburnt Hydrocarbon |

| JBD | Jatropha Biodiesel |

| FFA | Free Fatty Acid |

| HCS | Hexagonal Crystal Structure |

| B10/B20 | FOME 10% + Diesel 90%/ FOME 20% + Diesel 80%/ |

| B30/B40 | FOME 30% + Diesel 70%/ FOME 40% + Diesel 60%/ |

| B10D90A5 | B10 + 5 ppm Al2O3 nanoparticles |

| B20D80A10 | B20 + 10 ppm Al2O3 nanoparticles |

| B30D70A15 | B10 + 15 ppm Al2O3 nanoparticles |

| B40D60A20 | B10 + 20 ppm Al2O3 nanoparticles |

References

- Sarıdemir, S.; Ağbulut, Ü. Combustion, performance, vibration and noise characteristics of cottonseed methyl ester–diesel blends fuelled engine. Biofuels 2019, 13, 201–210. [Google Scholar] [CrossRef]

- Ağbulut, Ü.; Elibol, E.; Demirci, T.; Sarıdemir, S.; Gürel, A.E.; Rajak, U.; Afzal, A.; Verma, T.N. Synthesis of graphene oxide nanoparticles and the influences of their usage as fuel additives on CI engine behaviors. Energy 2021, 244, 122603. [Google Scholar] [CrossRef]

- Sharma, P.; Sahoo, B.B. Precise prediction of performance and emission of a waste derived Biogas–Biodiesel powered Dual–Fuel engine using modern ensemble Boosted regression Tree: A critique to Artificial neural network. Fuel 2022, 321, 124131. [Google Scholar] [CrossRef]

- Bora, B.J.; Saha, U.K. Emission reduction operating parameters for a dual-fuel diesel engine run on biogas and rice-bran biodiesel. J. Energy Eng. 2017, 143, 04016064. [Google Scholar] [CrossRef]

- Rajak, U.; Ağbulut, Ü.; Veza, I.; Dasore, A.; Sarıdemir, S.; Verma, T.N. Numerical and experimental investigation of a CI engine behaviours supported by zinc oxide nanomaterial along with diesel fuel. Energy 2021, 239, 122424. [Google Scholar] [CrossRef]

- Ağbulut, Ü.; Karagöz, M.; Sarıdemir, S.; Öztürk, A. Impact of various metal-oxide based nanoparticles and biodiesel blends on the combustion, performance, emission, vibration and noise characteristics of a CI engine. Fuel 2020, 270, 117521. [Google Scholar] [CrossRef]

- Jha, S.; Nanda, S.; Acharya, B.; Dalai, A.K. A Review of Thermochemical Conversion of Waste Biomass to Biofuels. Energies 2022, 15, 6352. [Google Scholar] [CrossRef]

- Ağbulut, Ü.; Sarıdemir, S.; Karagöz, M. Experimental investigation of fusel oil (isoamyl alcohol) and diesel blends in a CI engine. Fuel 2020, 267, 117042. [Google Scholar] [CrossRef]

- Gürbüz, H.; Akçay, H.; Aldemir, M.; Akçay, I.H.; Topalcı, Ü. The effect of euro diesel-hydrogen dual fuel combustion on performance and environmental-economic indicators in a small UAV turbojet engine. Fuel 2021, 306, 121735. [Google Scholar] [CrossRef]

- Karagöz, M.; Ağbulut, Ü.; Sarıdemir, S. Waste to energy: Production of waste tire pyrolysis oil and comprehensive analysis of its usability in diesel engines. Fuel 2020, 275, 117844. [Google Scholar] [CrossRef]

- Jabbr, A.I.; Gaja, H.; Koylu, U.O. Multi-objective optimization of operating parameters for a H2/Diesel dual-fuel compression-ignition engine. Int. J. Hydrog. Energy 2020, 45, 19965–19975. [Google Scholar] [CrossRef]

- Ağbulut, Ü.; Sarıdemir, S.; Albayrak, S. Experimental investigation of combustion, performance and emission characteristics of a diesel engine fuelled with diesel–biodiesel–alcohol blends. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 1–12. [Google Scholar] [CrossRef]

- Kannan, B.T.; Sathish, T.; Sathyamurthy, R.; Erko, K.G. Use of waste fish oil biodiesel blended with aluminium oxide nanoparticle in IC engines: An experimental on performance, combustion and emission study. Sci. Rep. 2022, 12, 12930. [Google Scholar] [CrossRef]

- Attia, A.M.A.; El-Seesy, A.I.; El-Batsh, H.M.; Shehata, M.S. Effects of Alumina Nanoparticles Additives into Jojoba Methyl Ester-Diesel Mixture on Diesel Engine Performance. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Montreal, QC, Canada, 14–20 November 2014; American Society of Mechanical Engineers: New York, NY, USA, 2014. [Google Scholar]

- El-Seesy, A.I.; Abdel-Rahman, A.K.; Bady, M.; Ookawara, S. The influence of multi-walled carbon nanotubes additives into non-edible biodiesel-diesel fuel blend on diesel engine performance and emissions. Energy Procedia 2016, 100, 166–172. [Google Scholar] [CrossRef] [Green Version]

- Selvan, V.A.M.; Anand, R.; Udayakumar, M. Effects of cerium oxide nanoparticle addition in diesel and diesel-biodiesel-ethanol blends on the performance and emission characteristics of a CI engine. J. Eng. Appl. Sci. 2009, 4, 1819–6608. [Google Scholar]

- Jeryrajkumar, L.; Anbarasu, G.; Elangovan, T. Effects on nano additives on performance and emission characteristics of calophyllim inophyllum biodiesel. Int. J. ChemTech Res. 2016, 9, 210–219. [Google Scholar]

- Karthikeyan, S.; Elango, A.; Silaimani, S.M.; Prathima, A. Role of Al2O3 nano additive in GSOBiodiesel on the working characteristics of a CI engine. Indian J. Chem. Technol. 2014, 21, 285–289. [Google Scholar]

- Jayanthi, P.; Rao, M.S. Effects of nanoparticles additives on performance and emissions characteristics of a DI diesel engine fuelled with biodiesel. Int. J. Adv. Eng. Technol. 2016, 9, 689. [Google Scholar]

- Loganathan, C.S. Emission Reduction from A Diesel Engine Fueled By Cerium Oxide Nano-Additives Using Scr With Different Metal Oxides Coated Catalytic Converter. J. Eng. Sci. Technol. 2015, 10, 1404–1421. [Google Scholar]

- Sravani, K.; Ravindra Reddy, G. Performance and emission characteristics of CI engine when fuelled with Pongamia biodiesel and zinc oxide nano fluid as additive. Int. J. Eng. Res. 2016, 5, 684–687. [Google Scholar]

- Karthikeyan, S.; Elango, A.; Prathima, A. Diesel engine performance and emission analysis using canola oil methyl ester with the nano sized zinc oxide particles. Indian J. Eng. Mater. Sci. 2014, 21, 83–87. [Google Scholar]

- Mohan, N.; Sharma, M.; Singh, R.C.; Pandey, R.K. Performance study of diesel engine using nanofuel. Int. J. Adv. Res. Innov. 2015, 3, 665–668. [Google Scholar]

- Raj, N.M.; Gajendiran, M.; Pitchandi, K.; Nallusamy, N. Investigation on aluminium oxide nano particles blended diesel fuel combustion, performance and emission characteristics of a diesel engine. J. Chem. Pharm. Res. 2016, 8, 246–257. [Google Scholar]

- Prabhu, L.; Kumar, S.S.; Andrerson, A.; Rajan, K. Investigation on performance and emission analysis of TiO2 nanoparticle as an additive for biodiesel blends. J. Chem. Pharm. Sci. Spec. 2015, 7, 408–412. [Google Scholar]

- Ghogare, P.; Kale, N. Experimental investigation on single cylinder diesel engine fuelled with soya bean biodiesel blends with nano additives. Int. J. Pure Appl. Res. Eng. Technol. 2016, 4, 247–257. [Google Scholar]

- Arockiasamy, P.; Anand, R.B. Performance, combustion and emission characteristics of a DI diesel engine fuelled with nanoparticle blended jatropha biodiesel. Period. Polytech. Mech. Eng. 2015, 59, 88–93. [Google Scholar] [CrossRef] [Green Version]

- Raja, M.; Vijayan, R.; Suresh, S.; Vivekananthan, R. Effect of heat transfer enhancement and NO x emission using Al2O3/water nanofluid as coolant in CI engine. Indian J. Eng. Mater. Sci. 2013, 20, 443–449. [Google Scholar]

- Ramarao, K.; Rao, C.; Sreeramulu, D. The experimental investigation on performance and emission characteristics of a single cylinder diesel engine using nano additives in diesel and biodiesel. Indian J. Sci. Technol. 2015, 8, 1. [Google Scholar] [CrossRef]

- Saifuddin, M.; Boyce, A.N. Biodiesel Production from Fish (Cyprinus carpio) Waste and Evaluation of Engine Performance. Sains Malays. 2017, 46, 1771–1778. [Google Scholar] [CrossRef]

- Edgar, S. Alumina (Al2O3) Nanoparticles—Properties & Applications. In AZO Nano; AZO Nano: Manchester, UK, 2013. [Google Scholar]

- Basha, J.S.; Anand, R. Performance, emission and combustion characteristics of a diesel engine using Carbon Nanotubes blended Jatropha Methyl Ester Emulsions. Alex. Eng. J. 2014, 53, 259–273. [Google Scholar] [CrossRef] [Green Version]

- Anbarsooz, M. Combustion characteristics of nanofuels: A comprehensive review on diesel/biodiesel-based nanofuels. Fuel 2022, 126834. [Google Scholar] [CrossRef]

- Ahmed, S.A.; Soudagar, M.E.M.; Rahamathullah, I.; Basha, J.S.; Khan, T.Y.; Javed, S.; Elfasakhany, A.; Kalam, M. Investigation of ternary blends of animal fat biodiesel-diethyl ether-diesel fuel on CMFIS-CI engine characteristics. Fuel 2023, 332, 126200. [Google Scholar] [CrossRef]

- Kattimani, S.S.; Topannavar, S.; Shivashimpi, M.; Dodamani, B. Experimental investigation to optimize fuel injection strategies and compression ratio on single cylinder DI diesel engine operated with FOME biodiesel. Energy 2020, 200, 117336. [Google Scholar] [CrossRef]

- Kothiwale, G.R.; Akkoli, K.M.; Doddamani, B.M.; Kattimani, S.S.; Ağbulut, U.; Afzal, A.; Kaladgi, A.R.; Said, Z. Impact of injector nozzle diameter and hole number on performance and emission characteristics of CI engine powered by nanoparticles. Int. J. Environ. Sci. Technol. 2022, 1–22. [Google Scholar] [CrossRef]

- Gavhane, R.S.; Kate, A.M.; Pawar, A.; Safaei, M.R.; Soudagar, M.E.; Mujtaba Abbas, M.; Muhammad Ali, H.; Banapurmath, N.R.; Goodarzi, M.; Badruddin, I.A.; et al. Effect of zinc oxide nano-additives and soybean biodiesel at varying loads and compression ratios on VCR diesel engine characteristics. Symmetry 2020, 12, 1042. [Google Scholar] [CrossRef]

- Soudagar, M.E.M.; Mujtaba, M.A.; Safaei, M.R.; Afzal, A.; Ahmed, W.; Banapurmath, N.R.; Hossain, N.; Bashir, S.; Badruddin, I.A.; Goodarzi, M.; et al. Effect of Sr@ ZnO nanoparticles and Ricinus communis biodiesel-diesel fuel blends on modified CRDI diesel engine characteristics. Energy 2021, 215, 119094. [Google Scholar] [CrossRef]

- Ağbulut, Ü.; Polat, F.; Sarıdemir, S. A comprehensive study on the influences of different types of nano-sized particles usage in diesel-bioethanol blends on combustion, performance, and environmental aspects. Energy 2021, 229, 120548. [Google Scholar] [CrossRef]

- Raju, V.D.; Kishore, P.S.; Nanthagopal, K.; Ashok, B. An experimental study on the effect of nanoparticles with novel tamarind seed methyl ester for diesel engine applications. Energy Convers. Manag. 2018, 164, 655–666. [Google Scholar] [CrossRef]

- El-Seesy, A.I.; Abdel-Rahman, A.K.; Bady, M.; Ookawara, S. Performance, combustion, and emission characteristics of a diesel engine fueled by biodiesel-diesel mixtures with multi-walled carbon nanotubes additives. Energy Convers. Manag. 2017, 135, 373–393. [Google Scholar] [CrossRef]

- Wei, J.; He, C.; Lv, G.; Zhuang, Y.; Qian, Y.; Pan, S. The combustion, performance and emissions investigation of a dual-fuel diesel engine using silicon dioxide nanoparticle additives to methanol. Energy 2021, 230, 120734. [Google Scholar] [CrossRef]

- Muruganantham, P.; Pandiyan, P.; Sathyamurthy, R. Analysis on performance and emission characteristics of corn oil methyl ester blended with diesel and cerium oxide nanoparticle. Case Stud. Therm. Eng. 2021, 26, 101077. [Google Scholar]

- Al-Kheraif, A.A.; Syed, A.; Elgorban, A.M.; Divakar, D.D.; Shanmuganathan, R.; Brindhadevi, K. Experimental assessment of performance, combustion and emission characteristics of diesel engine fuelled by combined non-edible blends with nanoparticles. Fuel 2021, 295, 120590. [Google Scholar] [CrossRef]

- Rastogi, P.M.; Sharma, A.; Kumar, N. Effect of CuO nanoparticles concentration on the performance and emission characteristics of the diesel engine running on jojoba (Simmondsia Chinensis) biodiesel. Fuel 2021, 286, 119358. [Google Scholar] [CrossRef]

- Sivakumar, M.; Sundaram, N.S.; Kumar, R.R.; Thasthagir, M.H.S. Effect of aluminium oxide nanoparticles blended pongamia methyl ester on performance, combustion and emission characteristics of diesel engine. Renew. Energy 2018, 116, 518–526. [Google Scholar] [CrossRef]

- Hoseini, S.; Najafi, G.; Ghobadian, B.; Mamat, R.; Ebadi, M.; Yusaf, T. Novel environmentally friendly fuel: The effects of nanographene oxide additives on the performance and emission characteristics of diesel engines fuelled with Ailanthus altissima biodiesel. Renew. Energy 2018, 125, 283–294. [Google Scholar] [CrossRef]

- Hoseini, S.S.; Najafi, G.; Ghobadian, B.; Ebadi, M.T.; Mamat, R.; Yusaf, T. Performance and emission characteristics of a CI engine using graphene oxide (GO) nano-particles additives in biodiesel-diesel blends. Renew. Energy 2020, 145, 458–465. [Google Scholar] [CrossRef]

- Vigneswaran, R.; Balasubramanian, D.; Sastha, B.S. Performance, emission and combustion characteristics of unmodified diesel engine with titanium dioxide (TiO2) nano particle along with water-in-diesel emulsion fuel. Fuel 2021, 285, 119115. [Google Scholar] [CrossRef]

- Singh, V.K.; Ansari, N.A.; Arora, A. A review of ci engine performance and emissions with graphene nanoparticle additive in diesel and biodiesel blends. Adv. Manuf. Ind. Eng. 2021, 1065–1072. [Google Scholar] [CrossRef]

- Annamalai, M.; Dhinesh, B.; Nanthagopal, K.; SivaramaKrishnan, P.; Lalvani, J.I.J.; Parthasarathy, M. An assessment on performance, combustion and emission behavior of a diesel engine powered by ceria nanoparticle blended emulsified biofuel. Energy Convers. Manag. 2016, 123, 372–380. [Google Scholar] [CrossRef]

- Leach, F.C.; Davy, M.; Terry, B. Combustion and emissions from cerium oxide nanoparticle dosed diesel fuel in a high speed diesel research engine under low temperature combustion (LTC) conditions. Fuel 2021, 288, 119636. [Google Scholar] [CrossRef]

- Saridemir, S.; Yildiz, G.; Hanedar, E. Effect of diesel-biodiesel-methanol blends on performance and combustion characteristics of diesel engine. Düzce Üniversitesi Bilim Teknol. Derg. 2021, 9, 189–201. [Google Scholar] [CrossRef]

- Şen, M.; Emiroglu, A.O.; Keskin, A. Impact of pentanol addition and injection timing on the characteristics of a single-cylinder diesel engine. Energy Fuels 2019, 33, 9224–9231. [Google Scholar] [CrossRef]

- Jahanbakhshi, A.; Karami-Boozhani, S.; Yousefi, M.; Ooi, J.B. Performance of bioethanol and diesel fuel by thermodynamic simulation of the miller cycle in the diesel engine. Results Eng. 2021, 12, 100279. [Google Scholar] [CrossRef]

| S.No | Parameters | Specifications | ASTM |

|---|---|---|---|

| 01 | Composition | Oxide of Gamma aluminium (Al2O3) in the gamma stage (99.9%) | ASTM E3001-20 |

| 02 | Particle Size | 20 to 50 nm | |

| 03 | Colour | White | |

| 04 | Melting point | 2045 °C | |

| 05 | Density | 3.9 g/cm3 | |

| 06 | Boiling point | 2980 °C | |

| 07 | Surface Area | 155 m2/g |

| ASTM Standard | Property | Diesel | Fish Oil | Fish Oil Biodiesel |

|---|---|---|---|---|

| D445 | Kinematic viscosity at 40 °C | 3.08 | 24.32 | 3.78 |

| D4052 | Density, kg/m3 | 828 | 898 | 878 |

| D93 | Flashpoint, °C | 60 | 194 | 160 |

| D93 | Fire point, °C | 65 | 198 | 165 |

| D613 | Cetane number | 40 | 48 | 80 |

| D5865 | Calorific Value, MJ/kg | 46 | 3608 | 38 |

| TV1 Kirloskar Engine | Specifications |

|---|---|

| No. of cylinders | 1 |

| No. of strokes | 4 |

| Fuel type | Diesel |

| Speed | 1500 rpm |

| Rated power | 3.5 kW |

| Bore | 80 mm |

| Diameter of injector orifice | 0.20 mm, 0.25 mm |

| Length of Stroke | 110 mm |

| Connecting rod length | 234 mm |

| Type of Cooling | Water-cooled |

| Compression ratio | 17.5:1 |

| Arm length of the Dynamometer | 185 mm |

| Type of loading | Mechanical |

| S.No. | Number of Holes | diameter of Hole in mm |

|---|---|---|

| 1 | 3 holes | 0.20 mm |

| 2 | 4 holes | 0.25 mm |

| Type | DELTA 1600S |

|---|---|

| Object of Measurement | Carbon monoxide (CO), Carbon Dioxide (CO2) and Hydrocarbons (HC) |

| Range of Measurement | HC = 0 to 20,000 ppm as C3H8 (Propane) CO = 0 to 10%, CO2 = 0 to 16%, O2 = 0 to 21% NOx = 0 to 5000 ppm (as Nitric Oxide) |

| Accuracy | HC = +/− 30 ppm HC CO = +/− 0.2% CO, CO2 = +/− 1% CO2 O2 = +/− 0.2% O2 NOx = +/− 10 ppm NO |

| Resolution | HC = 1 ppm, CO = 0.01% Vol. CO2 = 0.1% Vol., O2 = 0.01% Vol. NOx = 1 ppm |

| Warm-up time | 10 min. (self-controlled) at 20 °C |

| Speed of Response Time | Within 15 sec. for 90% response |

| Sampling | Directly sampled from tail pipe |

| Power Source | 100 to 240 V AC/50 Hz |

| Weight | 800 g |

| Size | 100 mm × 210 mm × 50 mm |

| Parameters | Accuracy (±) |

|---|---|

| CO emission (%) | ±0.01% |

| NOx emission (ppm) | ±10 ppm |

| UBHC emission (ppm) | ±10 ppm |

| Exhaust gas temperature (°C) | ±1 °C |

| Smoke meter (HSU) | ±0.1% |

| Pressure Transducer (bar) | ±0.1 bar |

| Dynamometer load cell (g) | ±50 g |

| Engine speed (rpm) | ±10 rpm |

| Measuring Burette (cc) | ±0.25 |

| Crank angle encoder (°CA) | ±1° |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Akkoli, K.M.; Kamate, S.C.; Topannavar, S.N.; Bhavimani, A.R.; Banapurmath, N.R.; Veza, I.; Soudagar, M.E.M.; Khan, T.M.Y.; El-Shafay, A.S.; Kalam, M.A.; et al. Influence of Injection Pressure and Aluminium Oxide Nano Particle-Added Fish Oil Methyl Ester on the Performance and Emission of Compression Ignition Engine. Energies 2022, 15, 9491. https://doi.org/10.3390/en15249491

Akkoli KM, Kamate SC, Topannavar SN, Bhavimani AR, Banapurmath NR, Veza I, Soudagar MEM, Khan TMY, El-Shafay AS, Kalam MA, et al. Influence of Injection Pressure and Aluminium Oxide Nano Particle-Added Fish Oil Methyl Ester on the Performance and Emission of Compression Ignition Engine. Energies. 2022; 15(24):9491. https://doi.org/10.3390/en15249491

Chicago/Turabian StyleAkkoli, K. M., S. C. Kamate, S. N. Topannavar, A. R. Bhavimani, N. R. Banapurmath, Ibham Veza, Manzoore Elahi M. Soudagar, T. M. Yunus Khan, A. S. El-Shafay, M. A. Kalam, and et al. 2022. "Influence of Injection Pressure and Aluminium Oxide Nano Particle-Added Fish Oil Methyl Ester on the Performance and Emission of Compression Ignition Engine" Energies 15, no. 24: 9491. https://doi.org/10.3390/en15249491

APA StyleAkkoli, K. M., Kamate, S. C., Topannavar, S. N., Bhavimani, A. R., Banapurmath, N. R., Veza, I., Soudagar, M. E. M., Khan, T. M. Y., El-Shafay, A. S., Kalam, M. A., Shivashimpi, M. M., & Gulli, A. M. (2022). Influence of Injection Pressure and Aluminium Oxide Nano Particle-Added Fish Oil Methyl Ester on the Performance and Emission of Compression Ignition Engine. Energies, 15(24), 9491. https://doi.org/10.3390/en15249491