Power Performance Analysis Based on Savonius Wind Turbine Blade Design and Layout Optimization through Rotor Wake Flow Analysis

Abstract

1. Introduction

2. Numerical Method

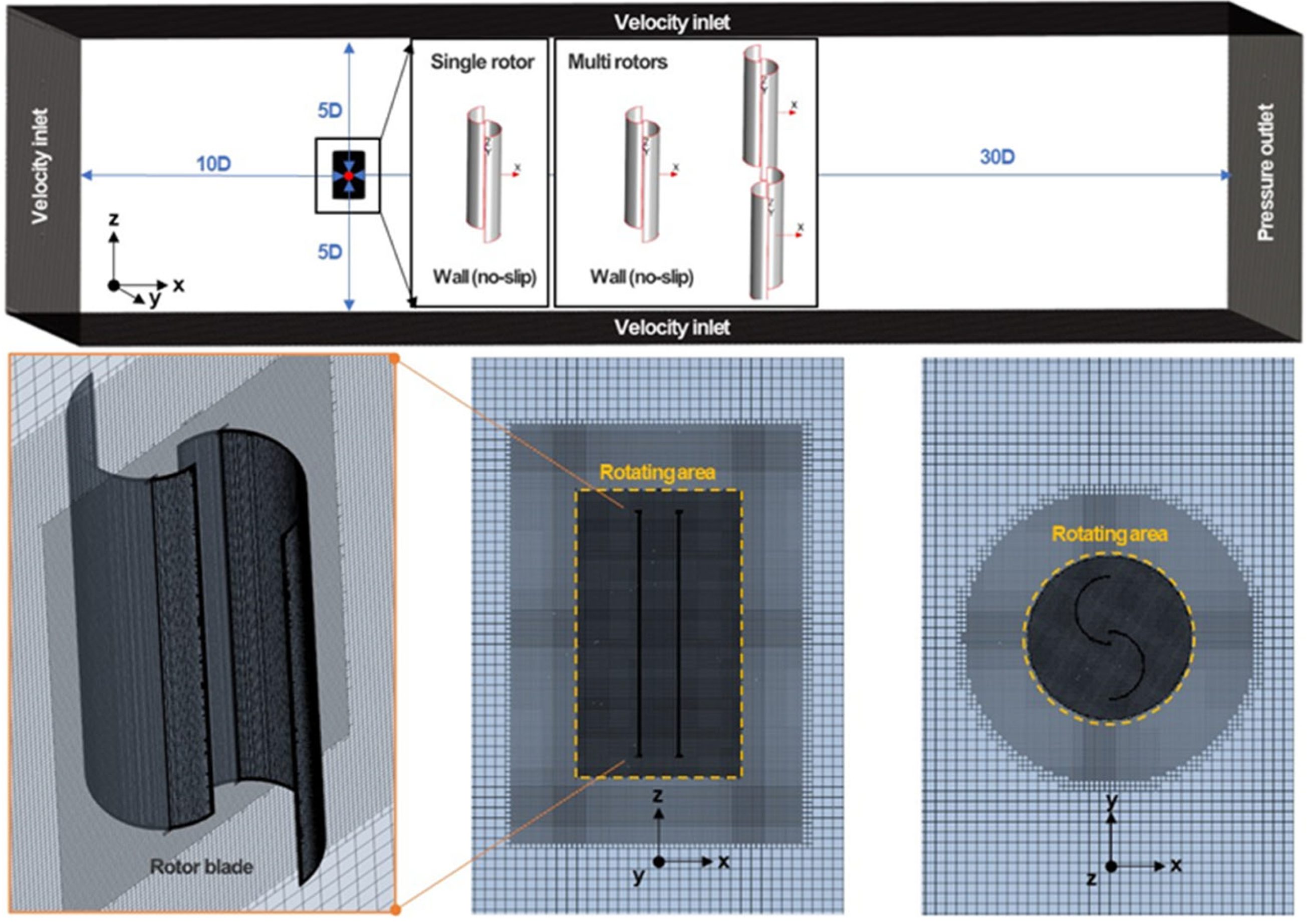

2.1. Boundary Condition and Grid Independence Test

2.2. Numerical Method Validation

3. Estimation of Rotor Power

3.1. Design Paramaters

3.2. Comparison of Various Rotor Types

4. Effect of Rotor Arrangement

4.1. Analysis of Single Rotor Wake

4.2. Multi Turbine Interaction Effect

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- GWEC. Global Wind Energy Council, Global wind report 2021. GWEA: Brussels, Belgium. Available online: https://gwec.net/wp-content/uploads/2021/03/GWEC-Global-Wind-Report-2021.pdf (accessed on 11 December 2022).

- Akwa, J.V.; Vielmo, H.A.; Petry, A.P. A review on the performance of Savonius wind turbines. Renew. Sustain. Energy Rev. 2012, 16, 3054–3064. [Google Scholar] [CrossRef]

- Savonius, S. The s-rotor and its applications. Mech. Eng. 1931, 53, 333–338. [Google Scholar]

- Saad, A.S.; Elwardany, A.; El-Sharkawy, I.I.; Ookawara, S.; Ahmed, M. Performance evaluation of a novel vertical axis wind turbine using twisted blades in multi-stage Savonius rotors. Energy Convers. Manag. 2021, 235, 114013. [Google Scholar] [CrossRef]

- Shikha; Bhatti,, T.S.; Kothari, D.P. Wind energy conversion systems as a distributed source of generation. J. Energy Eng. 2003, 129, 69–80. [Google Scholar]

- Mohamed, M.H.; Janiga, G.; Pap, E.; Thévenin, D. Optimal blade shape of a modified Savonius turbine using an obstacle shielding the returning blade. Energy Convers. Manag. 2011, 52, 236–242. [Google Scholar] [CrossRef]

- Roy, S.; Mukherjee, P.; Saha, U.K. Aerodynamic Performance Evaluation of a Novel Savonius-Style Wind Turbine Under an Oriented Jet. In Proceedings of the Gas Turbine India Conference, New Delhi, India, 15–17 December 2014. V001T08A001. [Google Scholar]

- Altan, B.D.; Atilgan, M. The use of a curtain design to increase the performance level of a Savonius wind rotors. Renew. Energy 2010, 35, 821–829. [Google Scholar] [CrossRef]

- Abraham, J.P.; Plourde, B.D.; Mowry, G.S.; Minkowycz, W.J.; Sparrow, E.M. Summary of Savonius wind turbine development and future applications for small-scale power generation. J. Renew. Sustain. Energy. 2012, 4, 042703. [Google Scholar] [CrossRef]

- El-Askary, W.A.; Nasef, M.H.; AbdEL-hamid, A.A.; Gad, H.E. Harvesting wind energy for improving performance of Savonius rotor. J. Wind Eng. Ind. Aerodyn. 2015, 139, 8–15. [Google Scholar] [CrossRef]

- Rahai, H.R.; Hefazi, H. Development of optimum design configuration and performance for vertical axis wind turbine. In Feasibility Analysis and Final EISG Report; California Energy Commission: Sacramento, CA, USA, 2005; CEC-500-2005-084. [Google Scholar]

- Al-Kayiem, H.H.; Bhayo, B.A.; Assadi, M. Comparative critique on the design parameters and their effect on the performance of s-rotors. Renew. Energy 2016, 99, 1306–1317. [Google Scholar] [CrossRef]

- Roy, S.; Saha, U.K. Review of experimental investigations into the design, performance and optimization of the Savonius rotor. Proc. Inst. Mech. Eng. A 2013, 227, 528–542. [Google Scholar] [CrossRef]

- Fujisawa, N. On the torque mechanism of Savonius rotors. J. Wind Eng. Ind. Aerodyn. 1992, 40, 277–292. [Google Scholar] [CrossRef]

- Blackwell, B.F.; Sheldahl, R.E.; Feltz, L.V. Wind Tunnel Performance Data for Two and Three-Bucket Savonius Rotors; Government Report; Journal of Energy: Albuquerque, NM, USA, 1977. [Google Scholar]

- Ushiyama, I.; Nagai, H. Optimum design configurations and performance of Savonius rotors. Wind Eng. 1988, 12, 59–75. [Google Scholar]

- Akwa, J.V.; Da Silva, G.A., Jr.; Petry, A.P. Discussion on the verification of the overlap ratio influence on performance coefficients of a Savonius wind rotor using computational fluid dynamics. Renew. Energy 2012, 38, 141–149. [Google Scholar] [CrossRef]

- Gupta, R.; Das, R.; Sharma, K.K. Experimental Study of a Savonius-Darrieus Wind Machine. In Proceedings of the International Conference on Renewable Energy for Developing Countries; University of Columbia: Washington, DC, USA, 2006. [Google Scholar]

- Roy, S.; Saha, U.K. Numerical Investigation to Assess an Optimal Blade Profile for the Drag Based Vertical Axis Wind Turbine. In ASME International Mechanical Engineering Congress and Exposition; American Society of Mechanical Engineers: San Diego, CA, USA, 2013; V06AT07A084. [Google Scholar]

- Banerjee, A.; Roy, S.; Mukherjee, P.; Saha, U.K. Unsteady Flow Analysis Around an Elliptic-Bladed Savonius-Style Wind Turbine. In Gas Turbine India Conference; American Society of Mechanical Engineers: New York, NY, USA, 2014; V001T05A001. [Google Scholar]

- Alon, N.; Saha, U.K. Influence of blade profiles on Savonius rotor performance: Numerical simulation and experimental validation. Energy Convers. Manag. 2019, 186, 267–277. [Google Scholar] [CrossRef]

- Zhang, B.; Song, B.; Mao, Z.; Tian, W. A novel wake energy reuse method to optimize the layout for Savonius-type vertical axis wind turbines. Energy 2017, 121, 341–355. [Google Scholar] [CrossRef]

- Kacprzak, K.; Liskiewicz, G.; Sobczak, K. Numerical investigation of conventional and modified Savonius wind turbines. Renew. Energy 2013, 60, 578–585. [Google Scholar] [CrossRef]

- Roy, S.; Saha, U.K. Wind tunnel experiments of a newly developed two-bladed Savonius-style wind turbine. Appl. Energy 2015, 137, 117–125. [Google Scholar] [CrossRef]

- Meri Ar, S.; Bin Salleh, H. Numerical investigation of Savonius rotor elliptical and the design modification on a blade shape. In Advances in Material Sciences and Engineering; Springer: Singapore, 2020; pp. 177–185. [Google Scholar]

- Le Gourieres, D. Wind Power Plants: Theory and Design; Elsevier: Amsterdam, The Netherlands, 2014. [Google Scholar]

- Shaheen, M.; El-Sayed, M.; Abdallah, S. Numerical study of two-bucket Savonius wind turbine cluster. J. Wing Eng. Ind. Aerodyn. 2015, 137, 78–89. [Google Scholar] [CrossRef]

| Rotor Type | D | H | d | A | AR | OR |

|---|---|---|---|---|---|---|

| mm | mm | mm | m2 | (H/D) | (e/d) | |

| RotorV1 | 800 | 1280 | 436.5 | 1 | 3.2 | 0.167 |

| RotorV2 | 600 | 1800 | 330 | 1.1 | 5.9 | 0.182 |

| RotorV3 | 600 | 1500 | 330 | 0.9 | 5.0 | 0.182 |

| RotorV4 | 600 | 1200 | 330 | 0.7 | 4.0 | 0.182 |

| RotorV5 | 500 | 1800 | 275 | 0.9 | 7.1 | 0.182 |

| RotorV6 | 600 | 1290 | 385 | 0.9 | 3.7 | 0.182 |

| RotorV7 | 700 | 1125 | 440 | 0.9 | 2.8 | 0.182 |

| RotorV8 | 500 | 1500 | 275 | 0.8 | 5.9 | 0.182 |

| RotorV9 | 550 | 1500 | 303 | 0.8 | 5.6 | 0.182 |

| RotorV10 | 650 | 1500 | 358 | 1 | 4.5 | 0.182 |

| RotorV11 | 400 | 2450 | 220 | 0.9 | 11.1 | 0.182 |

| RotorV12 | 450 | 2200 | 250 | 0.9 | 9.1 | 0.182 |

| RotorV13 | 550 | 1840 | 300 | 0.9 | 5.9 | 0.182 |

| Type | Power [W] | Power Coefficient [–] |

|---|---|---|

| Semi-circular (Rotor V10) | 151 | 0.15 |

| Bach | 114 | 0.11 |

| Elliptical | 155 | 0.16 |

| Type | a | Power (min) | Power (max) | Power | Power Coefficient | |

|---|---|---|---|---|---|---|

| m | ° | W | W | W | - | |

| Bach V1 | 0.24 | 135 | −16 | 324 | 151 | 0.15 |

| Bach V2 | 0.23 | 135 | −9 | 319 | 155 | 0.16 |

| Bach V3 | 0.22 | 135 | 2 | 304 | 158 | 0.16 |

| Bach V4 | 0.21 | 135 | 6 | 304 | 162 | 0.16 |

| Bach V5 | 0.2 | 135 | 11 | 298 | 165 | 0.17 |

| Bach V6 | 0.2 | 125 | 1 | 296 | 167 | 0.17 |

| Bach V7 | 0.2 | 130 | 8 | 300 | 167 | 0.17 |

| Bach V8 | 0.2 | 140 | 14 | 302 | 163 | 0.16 |

| Bach V9 | 0.2 | 145 | 4 | 314 | 159 | 0.16 |

| Bach V10 | 0.2 | 150 | −14 | 311 | 155 | 0.15 |

| Type | a | Power (min) | Power (max) | Power | Power Coefficient | |

|---|---|---|---|---|---|---|

| m | ° | W | W | W | - | |

| EllipticalV1 | 0.29 | 45 | 15 | 308 | 164 | 0.16 |

| EllipticalV2 | 0.28 | 45 | 22 | 307 | 173 | 0.17 |

| EllipticalV3 | 0.27 | 45 | 17 | 310 | 181 | 0.18 |

| EllipticalV4 | 0.26 | 45 | 22 | 309 | 180 | 0.18 |

| EllipticalV5 | 0.25 | 45 | 25 | 309 | 181 | 0.18 |

| EllipticalV6 | 0.27 | 30 | −5 | 304 | 175 | 0.18 |

| EllipticalV7 | 0.27 | 35 | 14 | 311 | 181 | 0.18 |

| EllipticalV8 | 0.27 | 40 | 19 | 315 | 183 | 0.18 |

| EllipticalV9 | 0.27 | 50 | 23 | 313 | 175 | 0.18 |

| EllipticalV10 | 0.270 | 55 | 32 | 313 | 170 | 0.17 |

| Case Number | Rotor 2 Position | Power Rotor 1 [W] | Power Rotor 2 [W] | Rotor 2 Power Reduction Rate [%] | |

|---|---|---|---|---|---|

| x Axis | y Axis | ||||

| Case 1 | 2D | 1D | 121.9 | 82.2 | −32.6 |

| Case 2 | 2D | 1.5D | 124.9 | 128.7 | 3 |

| Case 3 | 2D | 2D | 124.8 | 132.2 | 5.9 |

| Case 4 | 3D | 1D | 121.9 | 55.8 | −54.3 |

| Case 5 | 3D | 1.5D | 123.5 | 99 | −19.9 |

| Case 6 | 3D | 2D | 124.5 | 117.1 | −6 |

| Case Number | Rotor 2 Position | Rotor 3 Position | Power Rotor [W] | Power Rotor 2 [W] | Power Rotor 3 [W] | Power sum [W] | ||

|---|---|---|---|---|---|---|---|---|

| x Axis | y Axis | x Axis | y Axis | |||||

| Case 1 | 3.0 D | 2.0 D | 2.0 D | 1.0 D | 121.6 | 119.8 | 124.7 | 366.1 |

| Case 2 | 3.0 D | 2.0 D | 2.0 D | 1.5 D | 125.4 | 119 | 129.5 | 373.8 |

| Case 3 | 3.0 D | 2.0 D | 2.0 D | 2.0 D | 126.4 | 118.9 | 131 | 376.3 |

| Case 4 | 3.0 D | 2.0 D | 3.0 D | 1.0 D | 121.3 | 120.4 | 130.7 | 372.5 |

| Case 5 | 3.0 D | 2.0 D | 3.0 D | 1.5 D | 123.6 | 119.6 | 131.2 | 374.4 |

| Case 6 | 3.0 D | 2.0 D | 3.0 D | 2.0 D | 123.7 | 121 | 129.8 | 374.5 |

| Case 7 | 2,0 D | 2.0 D | 2.0 D | 1.0 D | 121.7 | 139.8 | 127.3 | 388.8 |

| Case 8 | 2.0 D | 2.0 D | 2.0 D | 1.5 D | 125.5 | 136.4 | 131.6 | 393.5 |

| Case 9 | 2.0 D | 2.0 D | 2.0 D | 2.0 D | 128.4 | 140.1 | 129.7 | 398.1 |

| Case 10 | 2.0 D | 2.0 D | 3.0 D | 1.0 D | 122.8 | 137.3 | 126 | 386 |

| Case 11 | 2.0 D | 2.0 D | 3.0 D | 1.5 D | 125 | 137.3 | 127.4 | 389.7 |

| Case 12 | 2.0 D | 2.0 D | 3.0 D | 2.0 D | 126.8 | 137 | 127 | 390.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Im, H.; Kim, B. Power Performance Analysis Based on Savonius Wind Turbine Blade Design and Layout Optimization through Rotor Wake Flow Analysis. Energies 2022, 15, 9500. https://doi.org/10.3390/en15249500

Im H, Kim B. Power Performance Analysis Based on Savonius Wind Turbine Blade Design and Layout Optimization through Rotor Wake Flow Analysis. Energies. 2022; 15(24):9500. https://doi.org/10.3390/en15249500

Chicago/Turabian StyleIm, Heejeon, and Bumsuk Kim. 2022. "Power Performance Analysis Based on Savonius Wind Turbine Blade Design and Layout Optimization through Rotor Wake Flow Analysis" Energies 15, no. 24: 9500. https://doi.org/10.3390/en15249500

APA StyleIm, H., & Kim, B. (2022). Power Performance Analysis Based on Savonius Wind Turbine Blade Design and Layout Optimization through Rotor Wake Flow Analysis. Energies, 15(24), 9500. https://doi.org/10.3390/en15249500