The Effects of Nano-Additives Added to Diesel-Biodiesel Fuel Blends on Combustion and Emission Characteristics of Diesel Engine: A Review

Abstract

:1. Introduction

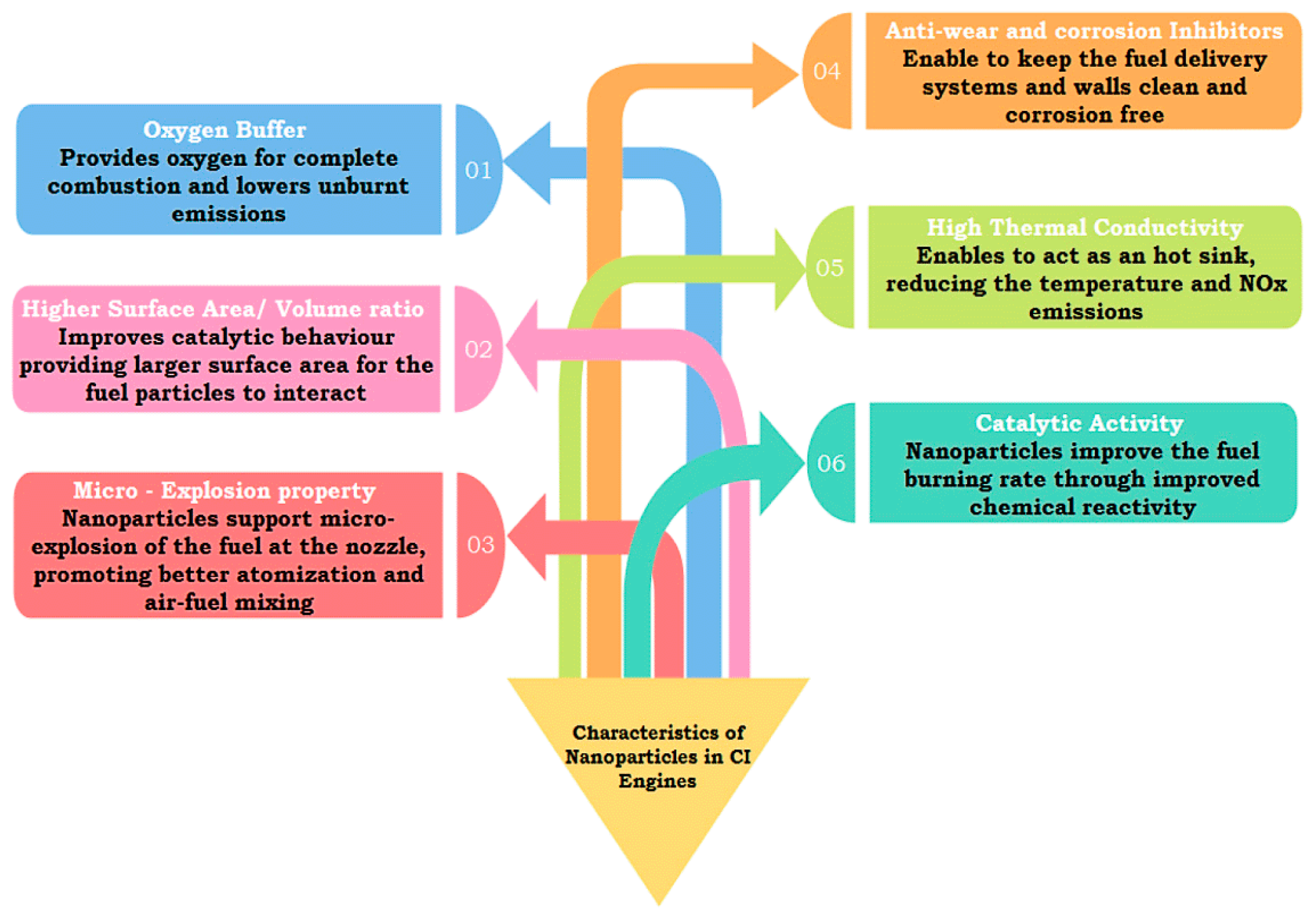

2. Nano-Additives: A Very Promising Fuel Additive

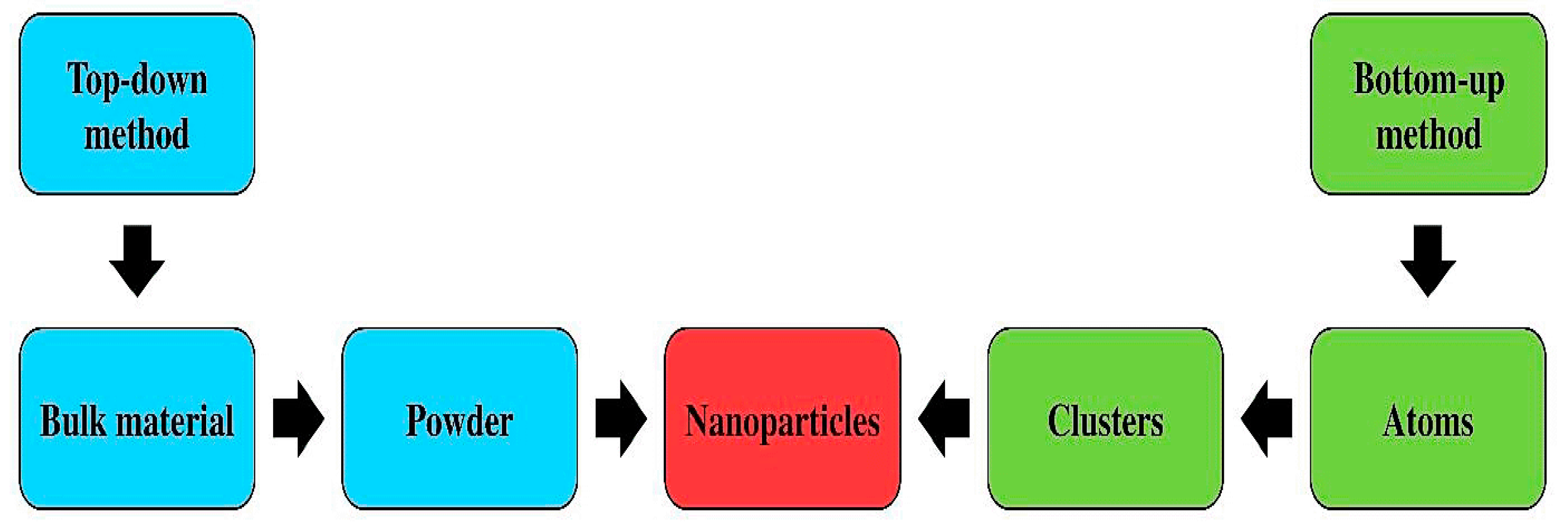

3. Different Preparation Methods to Obtain Stable Nanoparticles

3.1. One-Step Preparation Method

3.2. Two-Step Preparation Method

3.3. Some New Techniques

4. Nano-Additives in the Diesel-Biodiesel Fuel Blends

| Diesel Blended with | Blended Percentage | Nanoparticle | NPs Dosage and Size | Main Effect | Refs. |

|---|---|---|---|---|---|

| Neochloris oleoabundans methyl ester | 5–15% | CuO2 | 60 ppm | Nanoparticle-added fuel has higher BTE, EGT and lower BSFC, showing higher peak cylinder pressure | [38] |

| <50 nm | |||||

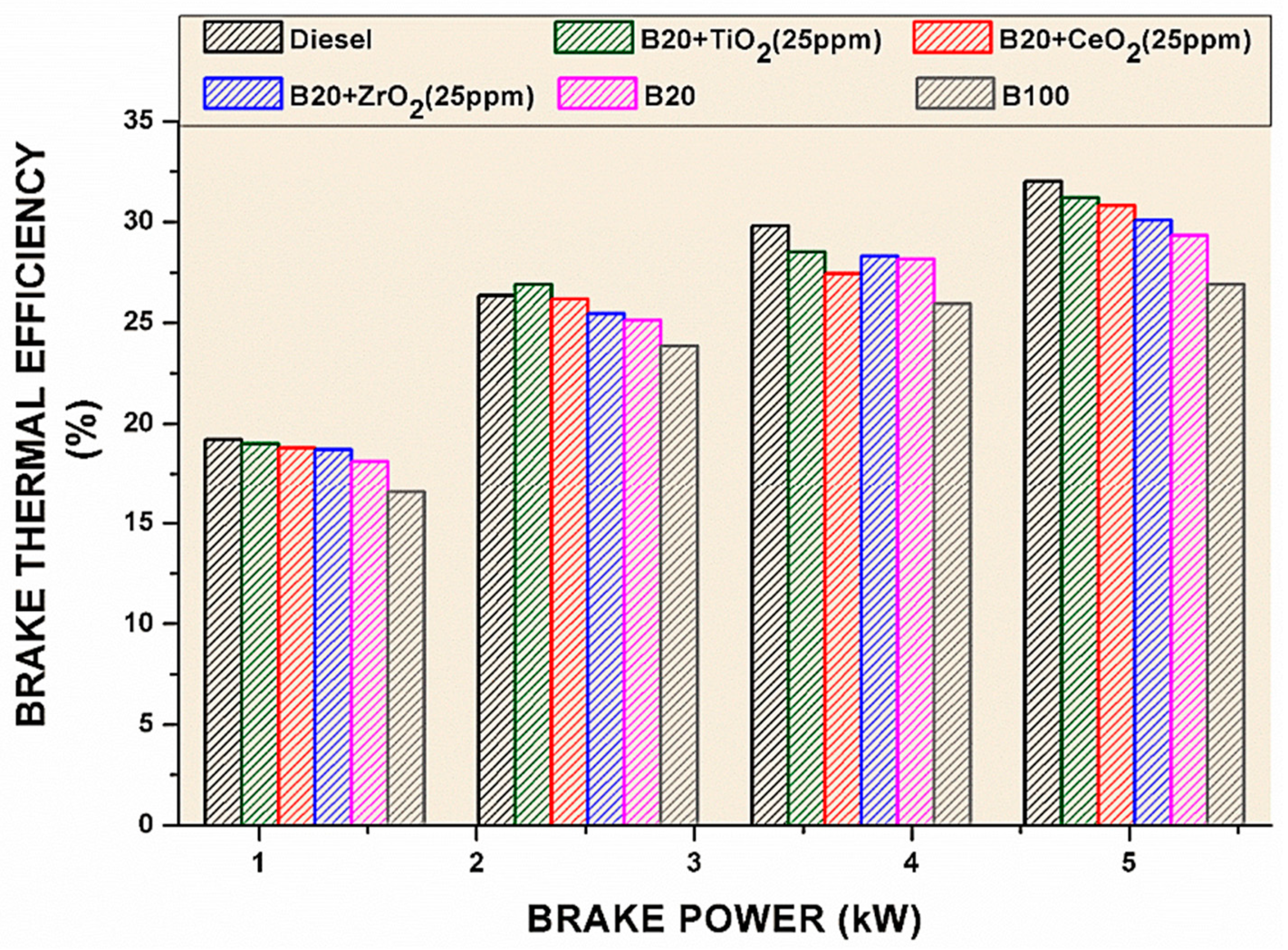

| Garcinia gummi-gutta | 20% | CeO2, ZrO2 and TiO2 | 25 ppm | CO, UBHC and smog emissions are reduced NOx and CO2 emissions increase sharply at peak loads. | [62] |

| biodiesel–ethanol | 30% | CeO2 nd CNT | 25–100 ppm | CO emission increased to 22.2%, while HC and smog emissions decreased to 7.2% and 47.6%, respectively. | [80] |

| Jatropha | 20% | Al2O3 | 10–30 ppm | BSFC decreased by 4.93%, BTE increased by 7.8% and emissions of HC, CO, flue gas decreased and nitrogen oxides by 5.69%, 11.24%, 6.48% and 9.39%. Respectively. | [91] |

| biodiesel | 10% | 28–30 nm | |||

| Oenothera Lamarckian biodiesel | 20% | GO | 30–90 ppm | Power and EGT increased significantly, and CO and UHC emissions were significantly reduced. However, carbon dioxide emission and nitrogen oxide emission increased slightly. | [92] |

| 150 nm | |||||

| Botryococcus braunii algae oil | 20% | CuO2 | 50 ppm | Shows higher BTE, lower BSFC and EGT, and increases the fuel mixture in the combustion chamber | [93] |

| 50–100 nm | |||||

| methyl ester | |||||

| Dairy scum oil methyl ester | 20% | GO | 20–60 | BSFC was decreased by 8.34%, BTE was increased by 11.56%, unburned HC decreased by 21.68%, and smoke decreased by 24.88%, which was significantly improved. | [94] |

| 23–27 mm | |||||

| tamanu biodiesel | 0–30% | TiO2 | 25–100 ppm | Various reductions in CO, nitrogen, CO2, HC, oxygen and flue gas opacity were found. | [95] |

| Waste cooking oil | 20% | CeO2-WCNT | 90 ppm | BSFC decreased by 0.2501 (kg/ kW-h), NOx was reduced by 18.90%, CO by 38.8% and HC by 71.40%. | [96] |

| Waste cooking oil | 5–20% | Al2O3 and TiO2 | 50–100 ppm | Performance parameters such as BTE and BFSC improved significantly, NOx, UHC and CO emissions decreased, while CO2 emissions increased. | [97] |

| Jatropha-n-Butanol | 50% | GNP- Multi-walled carbon nanotubes (MWCNT) | 50 ppm | NOx, CO and UHC were reduced by 45%, 55% and 50% respectively | [98] |

| (JME40B) | |||||

| Jojoba (JB20D) | 40% | Al2O3 | 50 ppm | 12% reduction in BFSC, 4.5% increase in peak cylinder pressure, 4% increase in maximum pressure | [99] |

| waste frying oil | 20% | Mn2O3 | 25–50 ppm | The engine consumes less fuel while producing the same power output. BTE has been improved. Both reduce emissions of NOx and CO | [100] |

| Co3O4 | |||||

| 10% astor oil +20%Ethanol | 30% | cerium oxide | 25 ppm | Increased BTE and IMEP, CO, reduced ignition delay, lower HC emissions, and lower smoke levels | [101] |

| Algae oil | 20% | SiO2 and TiO2 | 50–100 ppm | BSFC, BTH, CO, CH and CO2 are well improved in performance characteristics and emission reduction. | [102] |

| 50 nm | |||||

| water | 10% | Al2O3, CuO, MgO, MnO and ZnO | 100 ppm | The BSFC reduction rate of Al2O3 is high. 17% reduction in CO emission when using ZnO | [103] |

| 34 nm | |||||

| Lemon and orange peel oil | 20% | CNT, CeO2 | 50–100 ppm | Higher BTE and lower BSFCwith relatively low CO and HC emissions | [104] |

5. Effect of Different Nano-Additives on Combustion and Emissions of Biodiesel-Diesel Engines

5.1. Effect of Nano-Additives in Diesel-Biodiesel on Engine Combustion

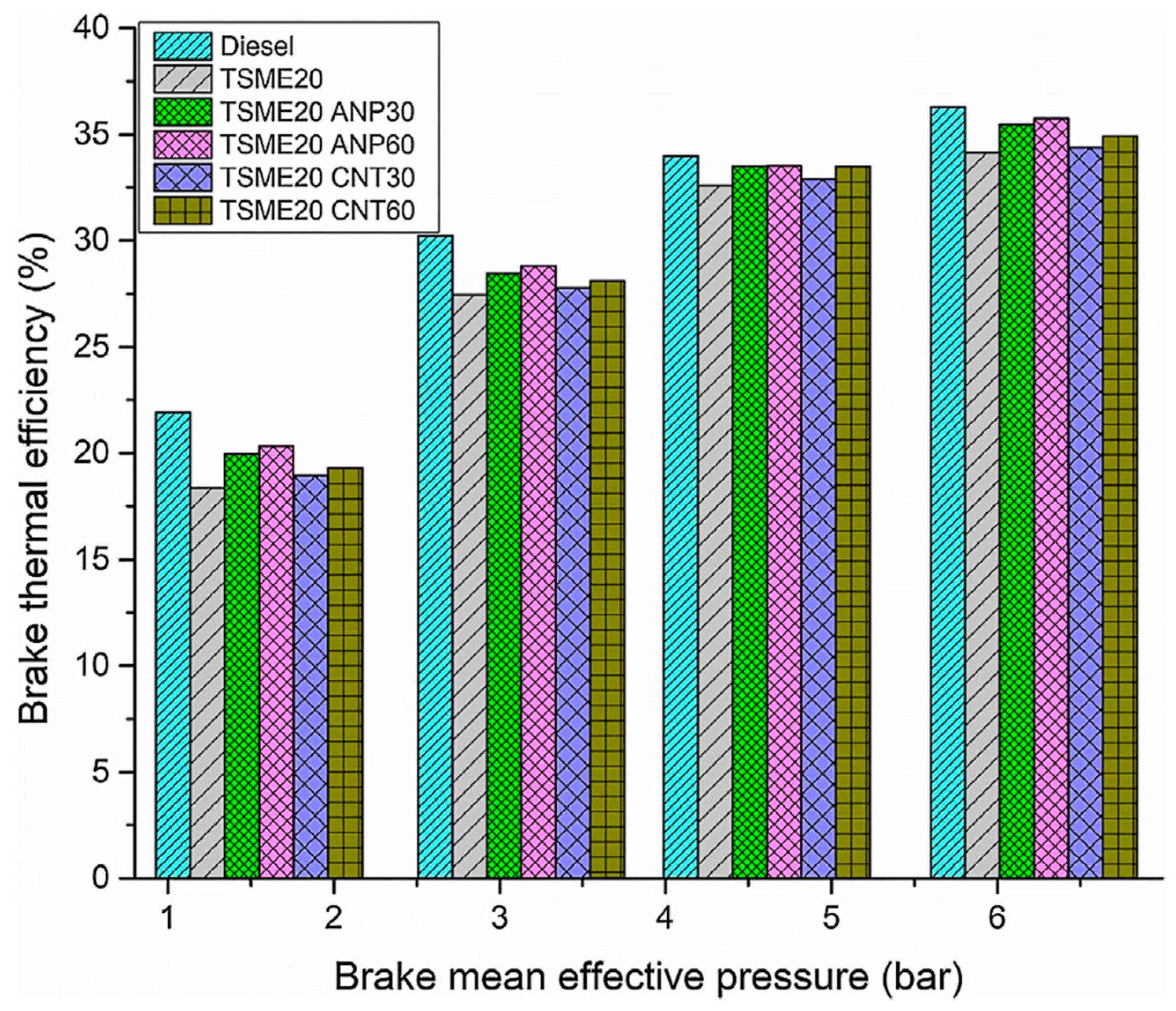

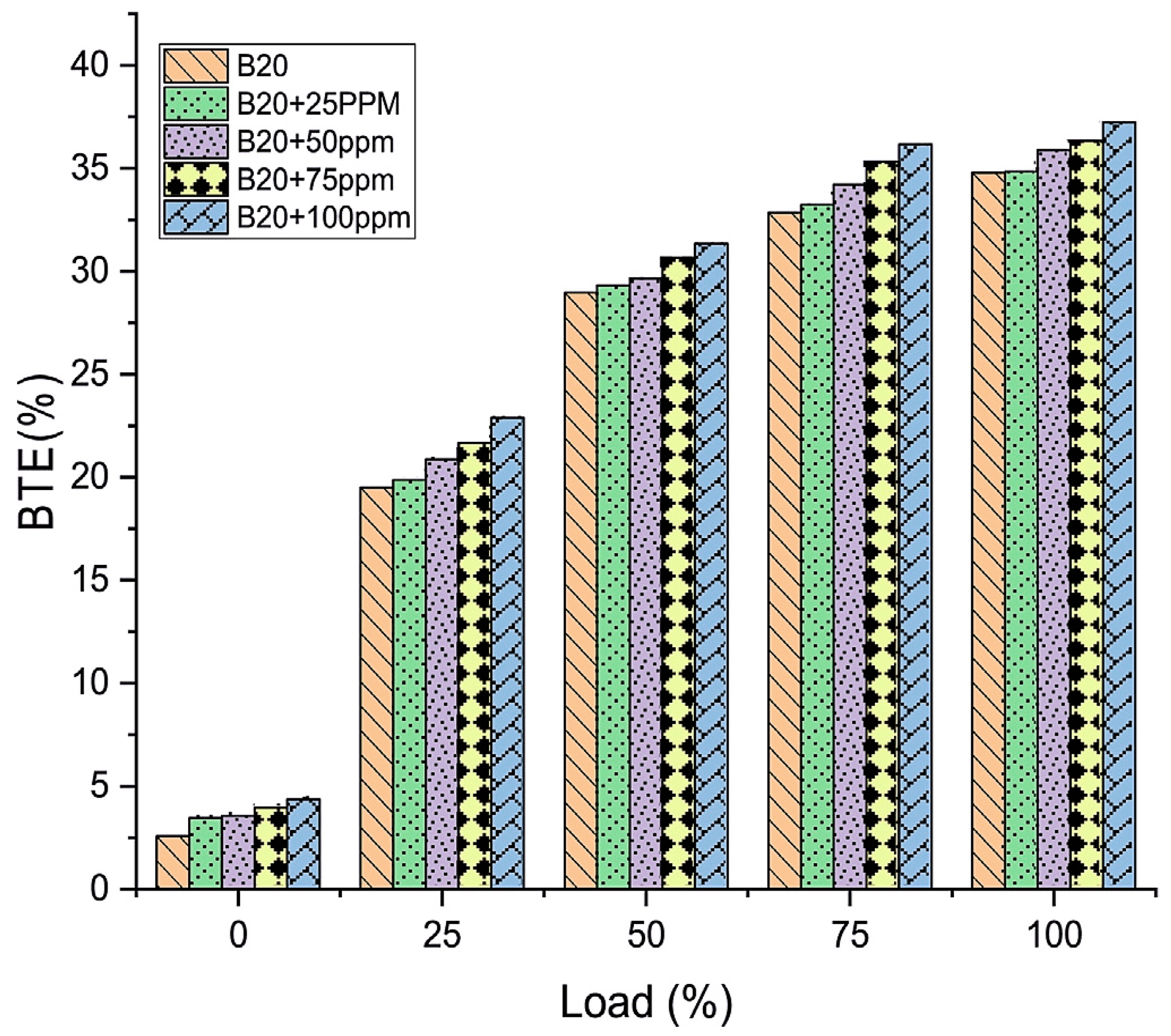

5.1.1. The Effect of Nano-Additives on Brake Thermal Efficiency

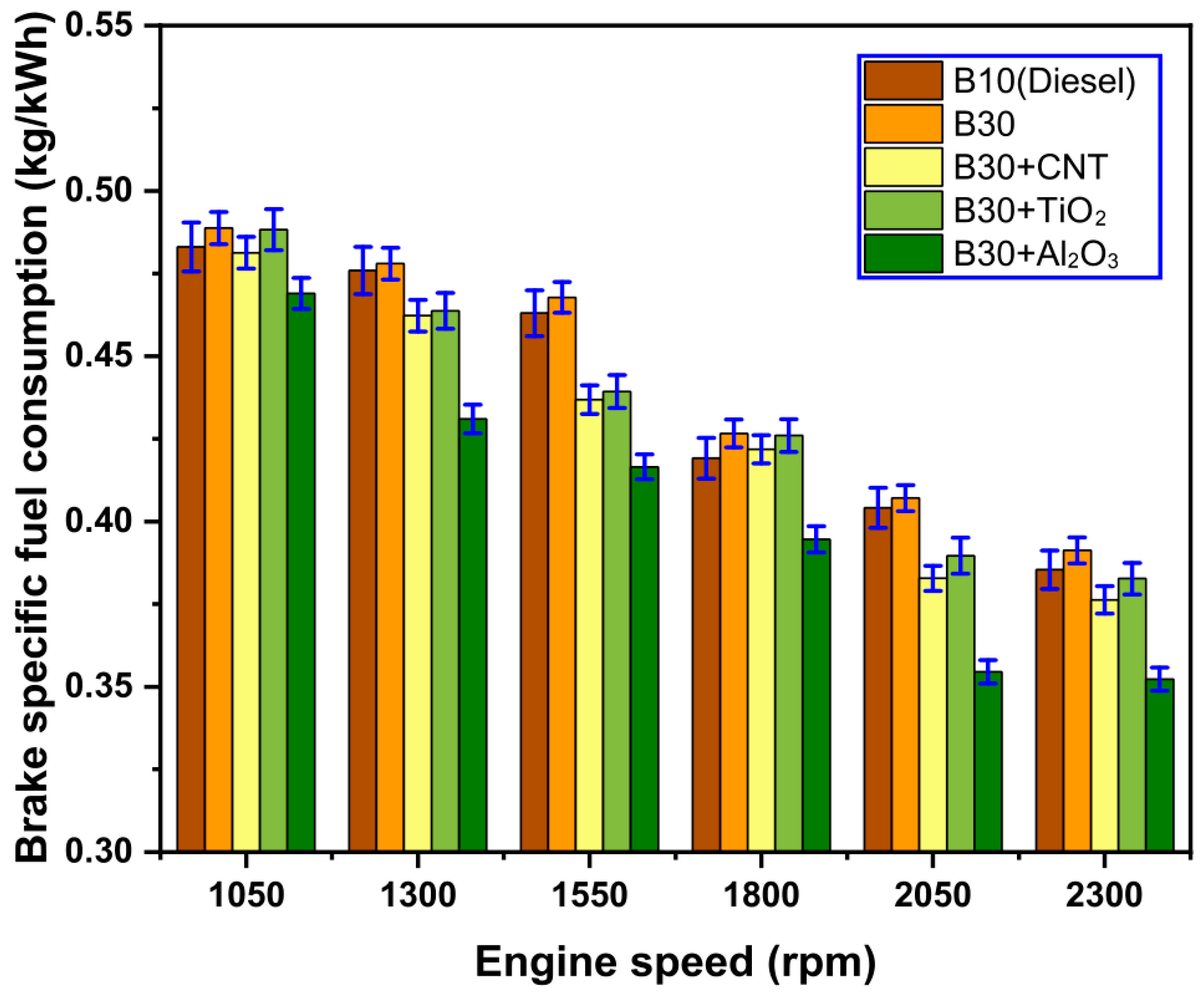

5.1.2. The effect of Nano-Additives on Brake Specific Fuel Consumption

5.2. Engine Emission Characteristics of Diesel-Biodiesel Fuel Blends with Nano-Additives

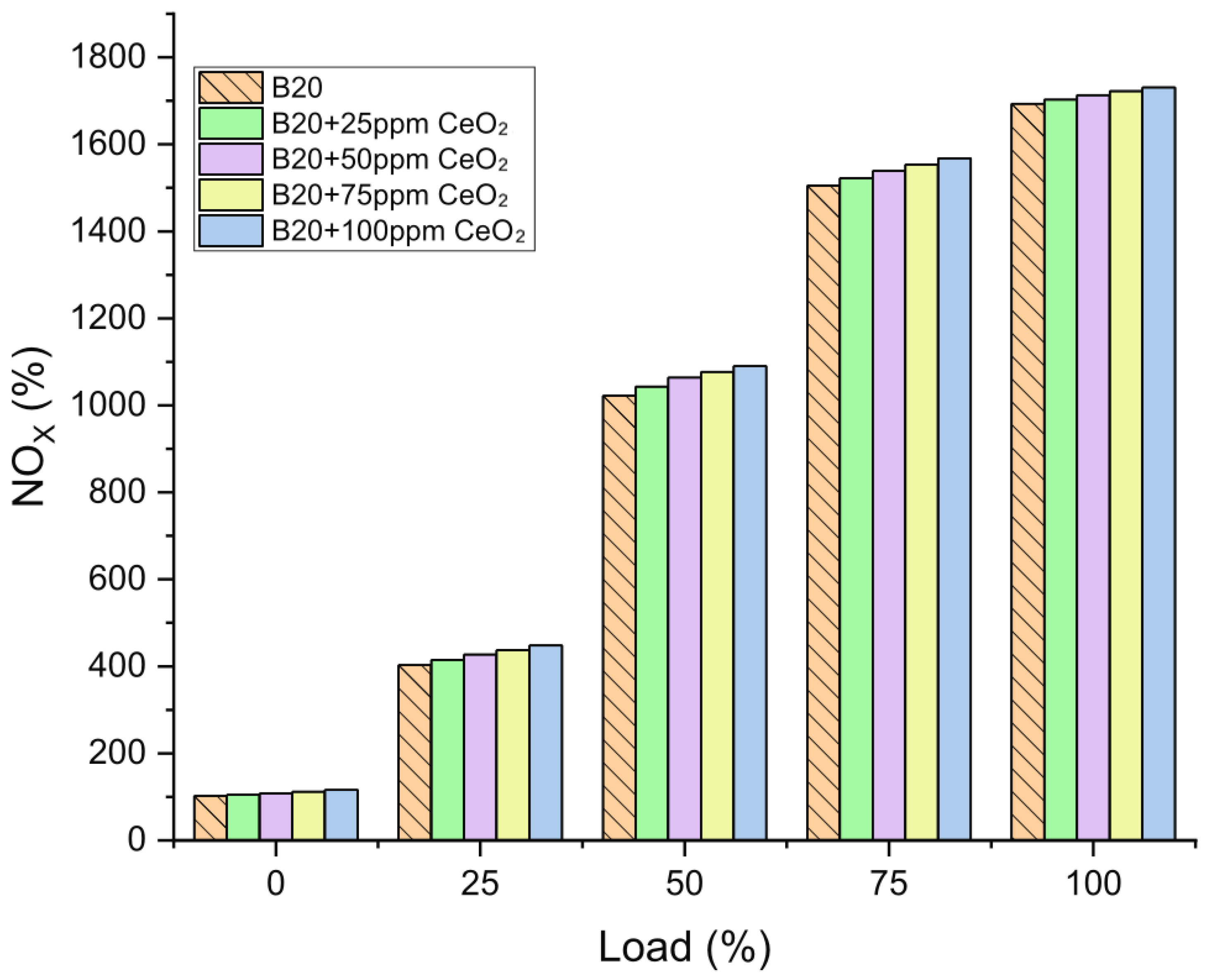

5.2.1. The Effect of Nano-Additives on Nitrogen Oxide Emissions

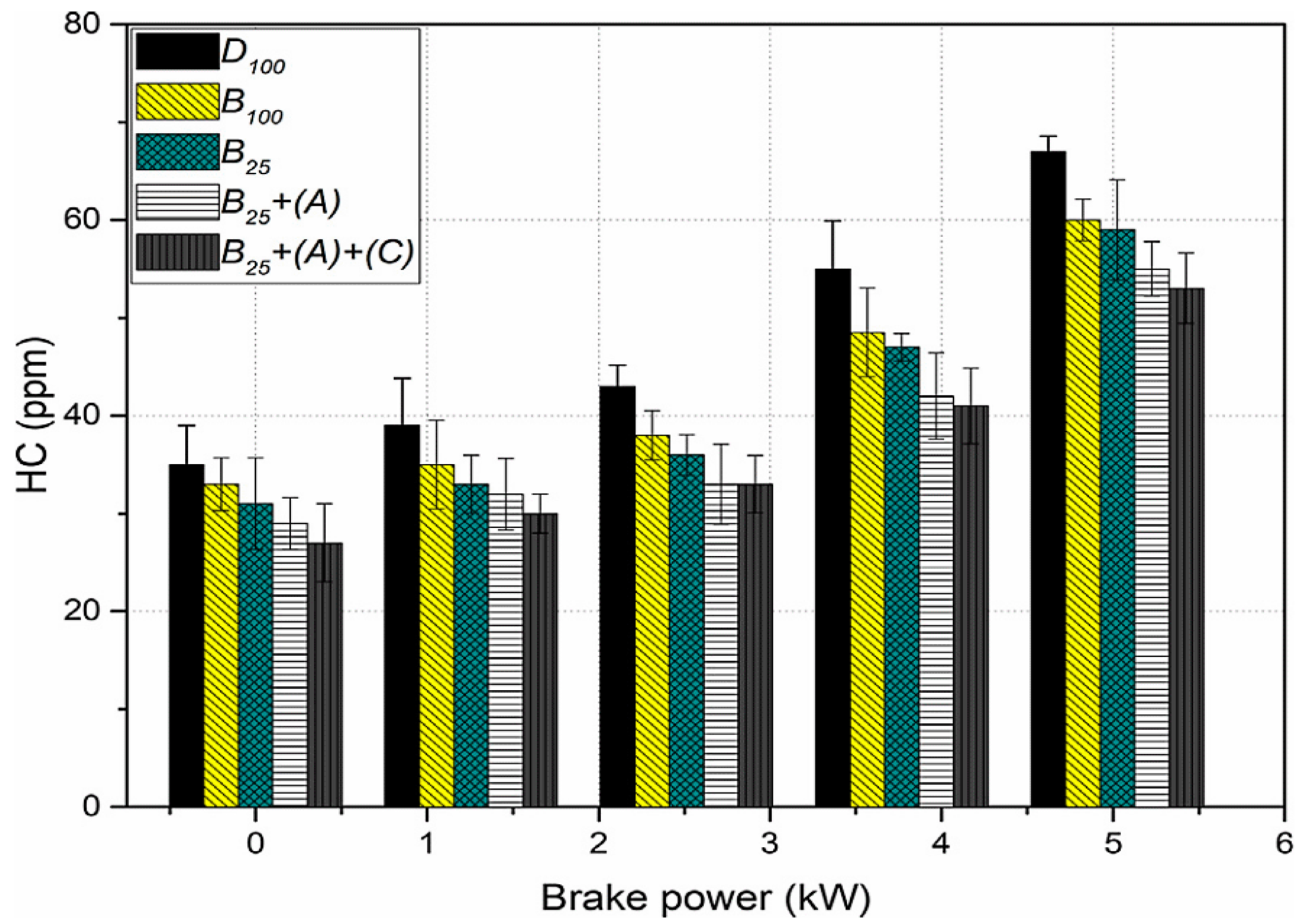

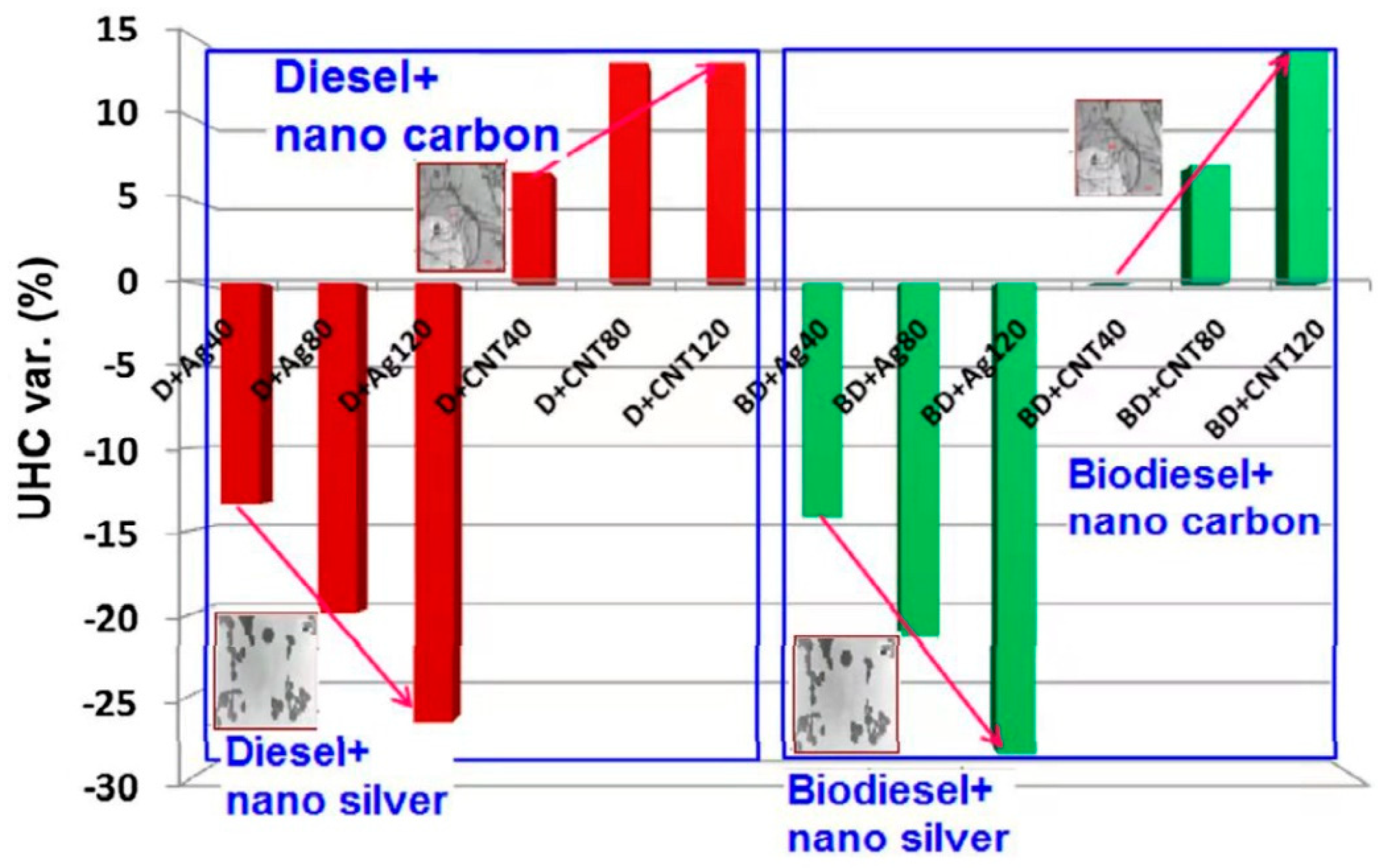

5.2.2. The Effect of Nano-Additives on HC Emission

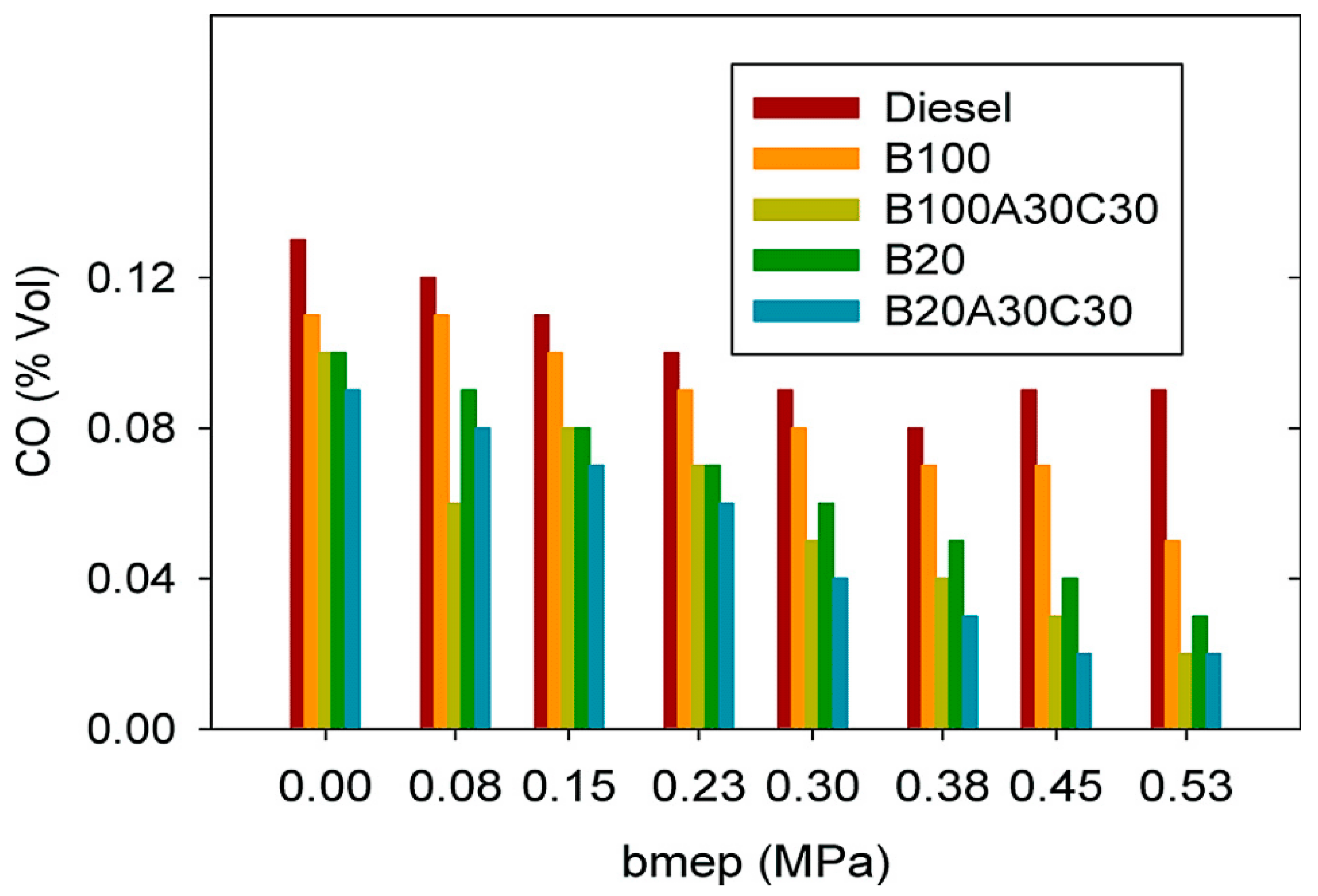

5.2.3. The Effect of Nano-Additives on CO Emission

6. Limitations of Nano Additive in Engine Applications

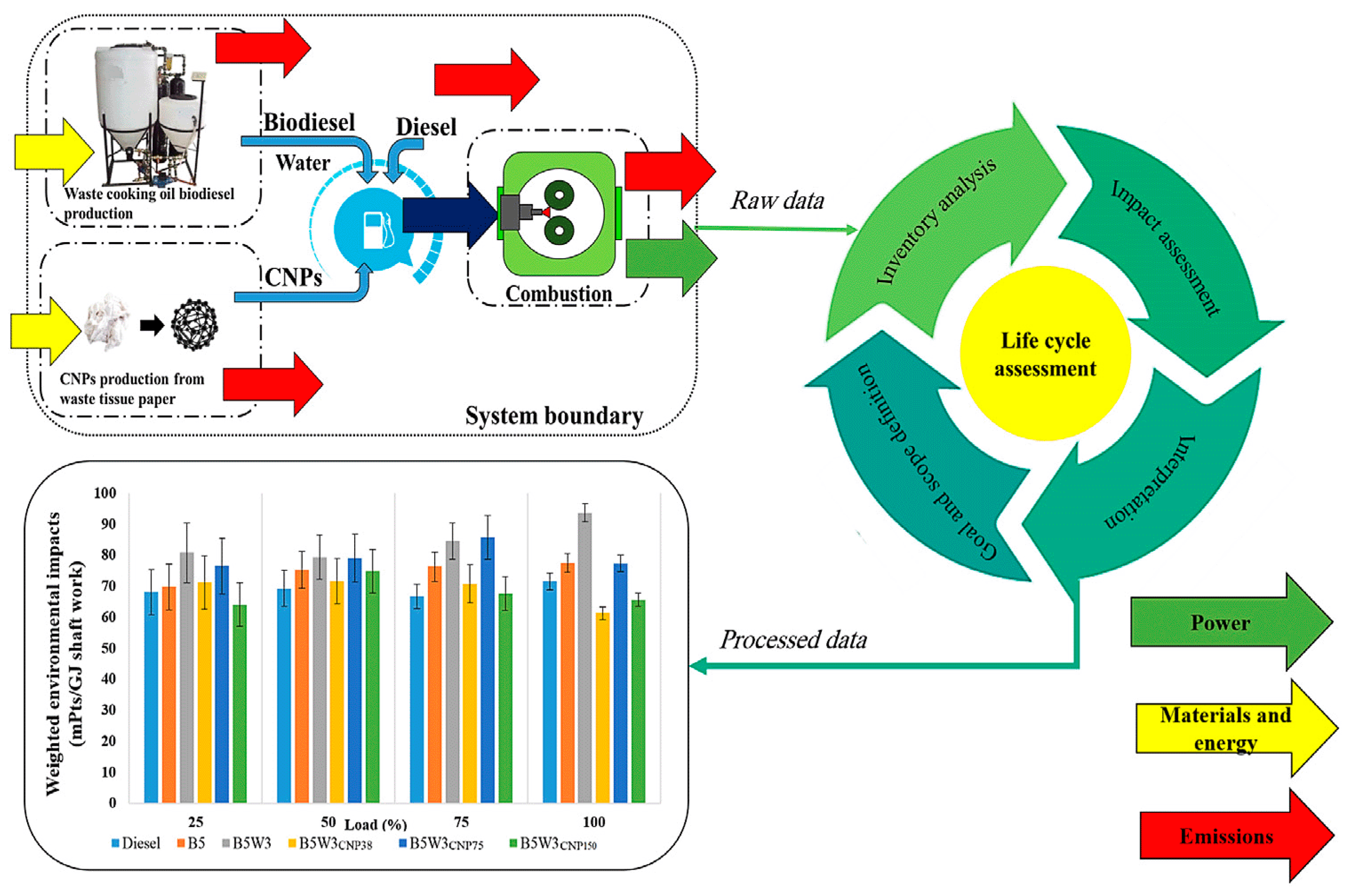

7. Comprehensive Evaluation of Nanoparticle-Doped Diesel-Biodiesel Using Life Cycle Assessment

8. Conclusions

- (1)

- Nano-additives have many excellent properties, such as large contact surface area, good stability, good catalytic performance, fast oxidation rate, high heat of combustion, etc. These advantages can be applied in the fuel field to improve the combustion of internal combustion engines and reduce harmful gas emissions.

- (2)

- The stable presence of nanoparticles in solution is significant, and among the two-step methods, sol-gel and mechanical grinding are relatively simple and less costly methods for making nanofluids.

- (3)

- In general, researchers have usually studied with CuO, Al2O3, MWCNT, CeO2, GO, CNT, and TiO2, which are nano-additives added to diesel-biodiesel fuel blends and have achieved remarkable results. In terms of engine performance, CeO2 was the most effective in reducing BFSC by as low as 30%, and MWCNT was the best in improving BTE by up to 36.81%. In terms of emission, TiO2 has the best effect in reducing NOx, with a minimum reduction of 22.57%, GNPs has the best effect in reducing CO, with a minimum reduction of 65%, GO has the best impact in reducing HC, with a minimum decrease of 70%.

- (4)

- Nano-additives in the field of internal combustion engines should be concerned about their harmful effects when they achieve significant results. After the engine combustion process, the nano-particles left behind that are not involved in combustion are released into the atmosphere; atmospheric pollution and human toxicity are severe. Moreover, the introduction of LCA to fully evaluate the benefits and hazards of biofuels to human health and the environment is described in detail.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Cai, T.; Becker, S.M.; Cao, F.; Wang, B.; Tang, A.; Fu, J.; Han, L.; Sun, Y.; Zhao, D. NOx Emission Performance Assessment on a Perforated Plate-Implemented Premixed Ammonia-Oxygen Micro-Combustion System. Chem. Eng. J. 2021, 417, 128033. [Google Scholar] [CrossRef]

- Li, Y.; Tang, W.; Chen, Y.; Liu, J.; Lee, C. Potential of acetone-butanol-ethanol (ABE) as a biofuel. Fuel 2019, 242, 673–686. [Google Scholar] [CrossRef]

- Cai, T.; Zhao, D.; Sun, Y.; Ni, S.; Li, W.; Guan, D.; Wang, B. Evaluation of NO Emissions Characteristics in a CO2-Free Micro-Power System by Implementing a Perforated Plate. Renew. Sustain. Energy Rev. 2021, 145, 111150. [Google Scholar] [CrossRef]

- Zhao, D. A Review of Cavity-Based Trapped Vortex, Ultra-Compact, High-g, Inter-Turbine Combustors. Prog. Energy Combust. Sci. 2018, 66, 42–82. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Z.; E, J.; Chen, J.; Zhu, H.; Zhao, X.; Han, D.; Zuo, W.; Peng, Q.; Gong, J.; Yin, Z. Effects of low-level water addition on spray, combustion and emission characteristics of a medium speed diesel engine fueled with biodiesel fuel. Fuel 2019, 239, 245–262. [Google Scholar] [CrossRef]

- Tan, D.; Chen, Z.; Li, J.; Luo, J.; Yang, D.; Cui, S.; Zhang, Z. Effects of swirl and boiling heat transfer on the performance enhancement and emission reduction for a medium diesel engine fueled with biodiesel. Processes 2021, 9, 568. [Google Scholar] [CrossRef]

- Zhang, Z.; E, J.; Chen, J.; Zhao, X.; Zhang, B.; Deng, Y.; Peng, Q.; Yin, Z. Effects of Boiling Heat Transfer on the Performance Enhancement of a Medium Speed Diesel Engine Fueled with Diesel and Rapeseed Methyl Ester. Appl. Therm. Eng. 2020, 169, 114984. [Google Scholar] [CrossRef]

- Cai, T.; Zhao, D.; Wang, B.; Li, J.; Guan, Y. NO Emission and Thermal Performances Studies on Premixed Ammonia-Oxygen Combustion in a CO2-Free Micro-Planar Combustor. Fuel 2020, 280, 11855. [Google Scholar] [CrossRef]

- E, J.; Pham, M.; Deng, Y.; Nguyen, T.; Duy, V.; Le, D.; Zuo, W.; Peng, Q.; Zhang, Z. Effects of Injection Timing and Injection Pressure on Performance and Exhaust Emissions of a Common Rail Diesel Engine Fueled by Various Concentrations of Fish-Oil Biodiesel Blends. Energy 2018, 149, 979–989. [Google Scholar] [CrossRef]

- E, J.; Liu, T.; Yang, W.M.; Li, J.; Gong, J.; Deng, Y. Effects of Fatty Acid Methyl Esters Proportion on Combustion and Emission Characteristics of a Biodiesel Fueled Diesel Engine. Energy Convers. Manag. 2016, 117, 410–419. [Google Scholar] [CrossRef]

- Liu, T.; E., J.; Yang, W.; Hui, A.; Cai, H. Development of a Skeletal Mechanism for Biodiesel Blend Surrogates with Varying Fatty Acid Methyl Esters Proportion. Appl. Energy 2016, 162, 278–288. [Google Scholar] [CrossRef]

- Li, Y.; Meng, L.; Nithyanandan, K.; Lee, T.H.; Lin, Y.; Lee, C.F.; Liao, S. Combustion, performance and emissions characteristics of a spark-ignition engine fueled with isopropanol-n-butanol-ethanol and gasoline blends. Fuel 2016, 184, 864–872. [Google Scholar] [CrossRef] [Green Version]

- Cai, T.; Zhao, D. Temperature Dependence of Laminar Burning Velocity in Ammonia/Dimethyl Ether-Air Premixed Flames. J. Therm. Sci. 2022, 31, 189–197. [Google Scholar] [CrossRef]

- Huang, Z.; Huang, J.; Luo, J.; Hu, D.; Yin, Z. Performance enhancement and emission reduction of a diesel engine fueled with different biodiesel-diesel blending fuel based on the multi-parameter optimization theory. Fuel 2021, 122753. [Google Scholar] [CrossRef]

- Li, Y.; Chen, Y.; Wu, G.; Liu, J. Experimental evaluation of water-containing isopropanol-n-butanol-ethanol and gasoline blend as a fuel candidate in spark-ignition engine. Appl. Energy 2018, 219, 42–52. [Google Scholar] [CrossRef]

- Cai, T.; Zhao, D. Enhancing and assessing ammonia-air combustion performance by blending with dimethyl ether. Renew. Sustain. Energy Rev. 2022, 156, 112003. [Google Scholar] [CrossRef]

- Lee, J.; Jung, J.-M.; Park, C.; Jeon, B.-H.; Wang, C.-H.; Lee, S.-R.; Kwon, E.E. Rapid Conversion of Fat, Oil and Grease (FOG) into Biodiesel without Pre-Treatment of FOG. J. Clean. Prod. 2017, 168, 1211–1216. [Google Scholar] [CrossRef]

- Adewale, P.; Dumont, M.-J.; Ngadi, M. Recent Trends of Biodiesel Production from Animal Fat Wastes and Associated Production Techniques. Renew. Sustain. Energy Rev. 2015, 45, 574–588. [Google Scholar] [CrossRef]

- E, J.; Pham, M.; Zhao, D.; Deng, Y.; Le, D.; Zuo, W.; Zhu, H.; Liu, T.; Peng, Q.; Zhang, Z. Effect of Different Technologies on Combustion and Emissions of the Diesel Engine Fueled with Biodiesel: A Review. Renew. Sustain. Energy Rev. 2017, 80, 620–647. [Google Scholar] [CrossRef]

- Zhang, Z.; E, J.; Deng, Y.; Pham, M.; Zuo, W.; Peng, Q.; Yin, Z. Effects of Fatty Acid Methyl Esters Proportion on Combustion and Emission Characteristics of a Biodiesel Fueled Marine Diesel Engine. Energy Convers. Manag. 2018, 159, 244–253. [Google Scholar] [CrossRef]

- Gad, M.S.; El-Shafay, A.S.; Abu Hashish, H.M. Assessment of Diesel Engine Performance, Emissions and Combustion Characteristics Burning Biodiesel Blends from Jatropha Seeds. Process Saf. Environ. Prot. 2021, 147, 518–526. [Google Scholar] [CrossRef]

- Zhang, Z.; Ye, J.; Lv, J.; Xu, W.; Tan, D.; Jiang, F.; Huang, H. Investigation on the effects of non-uniform porosity catalyst on SCR characteristic based on the field synergy analysis. J. Environ. Chem. Eng. 2022, 10, 107056. [Google Scholar] [CrossRef]

- Zhang, Z.; Ye, J.; Feng, Z.; Tan, D.; Luo, J.; Tan, Y.; Huang, Y. The effects of Fe2O3 based DOC and SCR catalyst on the combustion and emission characteristics of a diesel engine fueled with biodiesel. Fuel 2021, 290, 120039. [Google Scholar] [CrossRef]

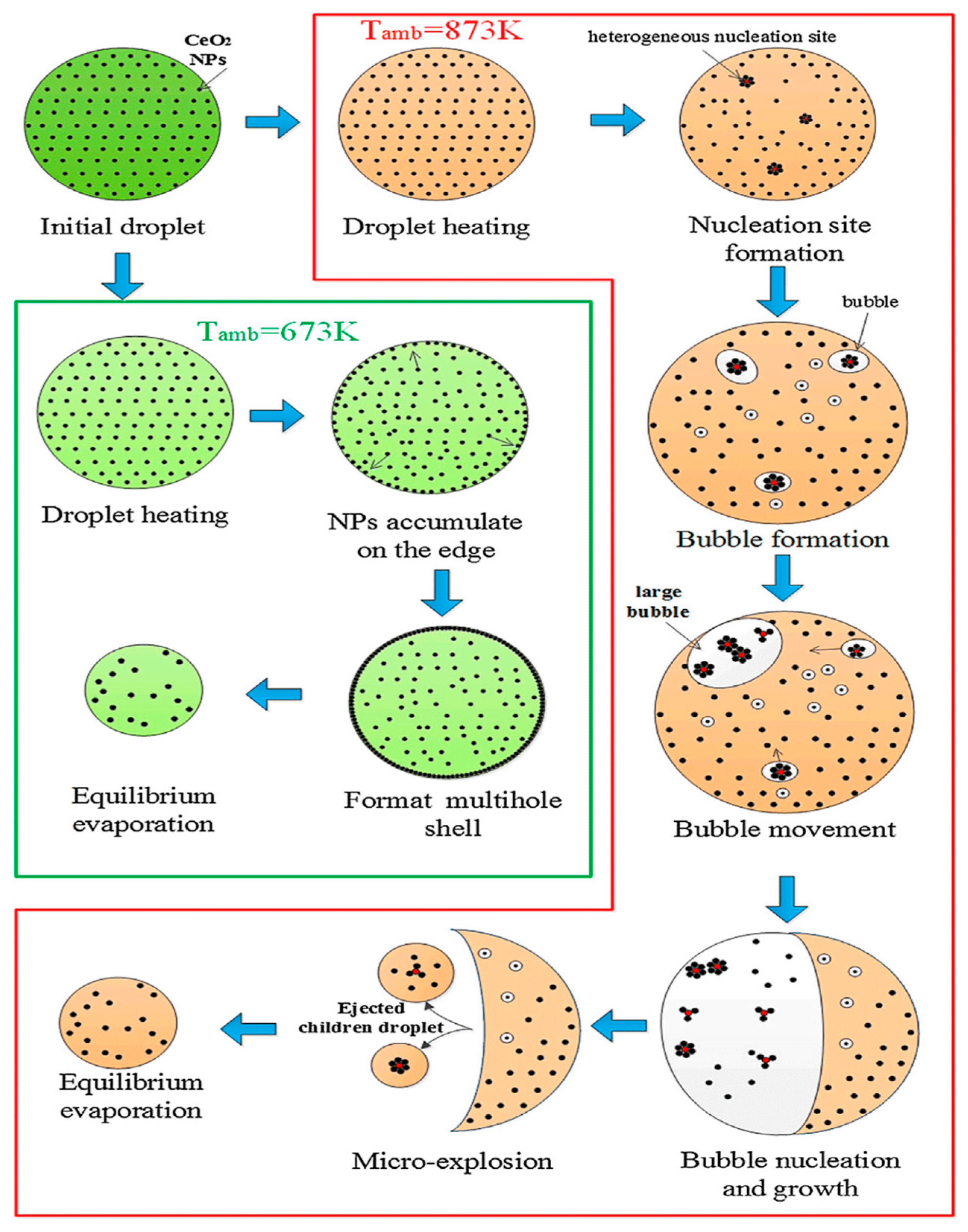

- Jiang, G.; Yan, J.; Wang, G.; Dai, M.; Xu, C.; Wang, J. Effect of Nanoparticles Concentration on the Evaporation Characteristics of Biodiesel. Appl. Surf. Sci. 2019, 492, 150–156. [Google Scholar] [CrossRef]

- Zhang, Z.; Tian, J.; Xie, G.; Li, J.; Xu, W.; Jiang, F.; Huang, Y.; Tan, D. Investigation on the combustion and emission characteristics of diesel engine fueled with diesel/methanol/n-butanol blends. Fuel 2022, 314, 123088. [Google Scholar] [CrossRef]

- Cernat, A.; Pana, C.; Negurescu, N.; Lazaroiu, G.; Nutu, C.; Fuiorescu, D.; Toma, M.; Nicolici, A. Combustion of Preheated Raw Animal Fats-Diesel Fuel Blends at Diesel Engine. J. Therm. Anal. Calorim. 2020, 140, 2369–2375. [Google Scholar] [CrossRef]

- Raju, V.D.; Venu, H.; Subramani, L.; Kishore, P.S.; Prasanna, P.L.; Kumar, D.V. An Experimental Assessment of Prospective Oxygenated Additives on the Diverse Characteristics of Diesel Engine Powered with Waste Tamarind Biodiesel. Energy 2020, 203, 117821. [Google Scholar] [CrossRef]

- Žaglinskis, J.; Lukács, K.; Bereczky, Á. Comparison of Properties of a Compression Ignition Engine Operating on Diesel–Biodiesel Blend with Methanol Additive. Fuel 2016, 170, 245–253. [Google Scholar] [CrossRef]

- Kegl, T.; Kovač Kralj, A.; Kegl, B.; Kegl, M. Nanomaterials as Fuel Additives in Diesel Engines: A Review of Current State, Opportunities, and Challenges. Prog. Energy Combust. Sci. 2021, 83, 100897. [Google Scholar] [CrossRef]

- Ghanbari, M.; Najafi, G.; Ghobadian, B.; Yusaf, T.; Carlucci, A.P.; Kiani Deh Kiani, M. Performance and Emission Characteristics of a CI Engine Using Nano Particles Additives in Biodiesel-Diesel Blends and Modeling with GP Approach. Fuel 2017, 202, 699–716. [Google Scholar] [CrossRef]

- Eroglu, E.; Eggers, P.K.; Winslade, M.; Smith, S.M.; Raston, C.L. Enhanced Accumulation of Microalgal Pigments Using Metal Nanoparticle Solutions as Light Filtering Devices. Green Chem. 2013, 15, 3155. [Google Scholar] [CrossRef]

- Contreras, J.E.; Rodriguez, E.A.; Taha-Tijerina, J. Nanotechnology Applications for Electrical Transformers—A Review. Electr. Power Syst. Res. 2017, 143, 573–584. [Google Scholar] [CrossRef]

- Soudagar, M.E.M.; Nik-Ghazali, N.-N.; Kalam, M.A.; Badruddin, I.A.; Banapurmath, N.R.; Bin Ali, M.A.; Kamangar, S.; Cho, H.M.; Akram, N. An Investigation on the Influence of Aluminium Oxide Nano-Additive and Honge Oil Methyl Ester on Engine Performance, Combustion and Emission Characteristics. Renew. Energy 2020, 146, 2291–2307. [Google Scholar] [CrossRef]

- Hosseini, S.H.; Taghizadeh-Alisaraei, A.; Ghobadian, B.; Abbaszadeh-Mayvan, A. Performance and Emission Characteristics of a CI Engine Fuelled with Carbon Nanotubes and Diesel-Biodiesel Blends. Renew. Energy 2017, 111, 201–213. [Google Scholar] [CrossRef]

- Sajith, V.; Sobhan, C.B.; Peterson, G.P. Experimental Investigations on the Effects of Cerium Oxide Nanoparticle Fuel Additives on Biodiesel. Adv. Mech. Eng. 2010, 2, 581407. [Google Scholar] [CrossRef]

- Heidari-Maleni, A.; Gundoshmian, T.M.; Karimi, B.; Jahanbakhshi, A.; Ghobadian, B. A Novel Fuel Based on Biocompatible Nanoparticles and Ethanol-Biodiesel Blends to Improve Diesel Engines Performance and Reduce Exhaust Emissions. Fuel 2020, 276, 118079. [Google Scholar] [CrossRef]

- Bet-Moushoul, E.; Farhadi, K.; Mansourpanah, Y.; Nikbakht, A.M.; Molaei, R.; Forough, M. Application of CaO-Based/Au Nanoparticles as Heterogeneous Nanocatalysts in Biodiesel Production. Fuel 2016, 164, 119–127. [Google Scholar] [CrossRef]

- Kalaimurugan, K.; Karthikeyan, S.; Periyasamy, M.; Dharmaprabhakaran, T. Combustion Analysis of CuO2 Nanoparticles Addition with Neochloris Oleoabundans Algae Biodiesel on CI Engine. Mater. Today Proc. 2020, 33, 2573–2576. [Google Scholar] [CrossRef]

- Hosseinzadeh-Bandbafha, H.; Tabatabaei, M.; Aghbashlo, M.; Khanali, M.; Khalife, E.; Roodbar Shojaei, T.; Mohammadi, P. Consolidating Emission Indices of a Diesel Engine Powered by Carbon Nanoparticle-Doped Diesel/Biodiesel Emulsion Fuels Using Life Cycle Assessment Framework. Fuel 2020, 267, 117296. [Google Scholar] [CrossRef]

- Debbarma, S.; Misra, R.D. Effects of Iron Nanoparticle Fuel Additive on the Performance and Exhaust Emissions of a Compression Ignition Engine Fueled with Diesel and Biodiesel. J. Therm. Sci. Eng. Appl. 2018, 10, 041002. [Google Scholar] [CrossRef]

- Keskin, A.; Yaşar, A.; Yıldızhan, Ş.; Uludamar, E.; Emen, F.M.; Külcü, N. Evaluation of Diesel Fuel-Biodiesel Blends with Palladium and Acetylferrocene Based Additives in a Diesel Engine. Fuel 2018, 216, 349–355. [Google Scholar] [CrossRef]

- Hawi, M.; Elwardany, A.; Ismail, M.; Ahmed, M. Experimental Investigation on Performance of a Compression Ignition Engine Fueled with Waste Cooking Oil Biodiesel–Diesel Blend Enhanced with Iron-Doped Cerium Oxide Nanoparticles. Energies 2019, 12, 798. [Google Scholar] [CrossRef] [Green Version]

- Sadhik Basha, J. Impact of Carbon Nanotubes and Di-Ethyl Ether as Additives with Biodiesel Emulsion Fuels in a Diesel Engine—An Experimental Investigation. J. Energy Inst. 2018, 91, 289–303. [Google Scholar] [CrossRef]

- Elwardany, A.E.; Marei, M.N.; Eldrainy, Y.; Ali, R.M.; Ismail, M.; El-kassaby, M.M. Improving Performance and Emissions Characteristics of Compression Ignition Engine: Effect of Ferrocene Nanoparticles to Diesel-Biodiesel Blend. Fuel 2020, 270, 117574. [Google Scholar] [CrossRef]

- Syed Aalam, C. Investigation on the Combustion and Emission Characteristics of CRDI Diesel Engine Fuelled with Nano Al2O3 and Fe3O4 Particles Blended Biodiesel. Mater. Today Proc. 2020, 33, 2540–2546. [Google Scholar] [CrossRef]

- Gardy, J.; Hassanpour, A.; Lai, X.; Ahmed, M.H. Synthesis of Ti(SO4)O Solid Acid Nano-Catalyst and Its Application for Biodiesel Production from Used Cooking Oil. Appl. Catal. Gen. 2016, 527, 81–95. [Google Scholar] [CrossRef]

- Zou, X.; Wang, N.; Liao, L.; Chu, Q.; Shi, B. Prediction of Nano/Micro Aluminum Particles Ignition in Oxygen Atmosphere. Fuel 2020, 266, 116952. [Google Scholar] [CrossRef]

- Saxena, V.; Kumar, N.; Saxena, V.K. A Comprehensive Review on Combustion and Stability Aspects of Metal Nanoparticles and Its Additive Effect on Diesel and Biodiesel Fuelled C.I. Engine. Renew. Sustain. Energy Rev. 2017, 70, 563–588. [Google Scholar] [CrossRef]

- E, J.; Jin, Y.; Deng, Y.; Zuo, W.; Zhao, X.; Han, D.; Peng, Q.; Zhang, Z. Wetting models and working mechanisms of typical surfaces existed in nature and its application on super-hydrophobic surfaces: A review. Adv. Mater. Interfaces 2018, 5, 1701052. [Google Scholar] [CrossRef]

- Panneerselvam, S.; Choi, S. Nanoinformatics: Emerging Databases and Available Tools. Int. J. Mol. Sci. 2014, 15, 7158–7182. [Google Scholar] [CrossRef] [Green Version]

- Zhang, D.; Cao, C.-Y.; Lu, S.; Cheng, Y.; Zhang, H.-P. Experimental Insight into Catalytic Mechanism of Transition Metal Oxide Nanoparticles on Combustion of 5-Amino-1H-Tetrazole Energetic Propellant by Multi Kinetics Methods and TG-FTIR-MS Analysis. Fuel 2019, 245, 78–88. [Google Scholar] [CrossRef]

- Manigandan, S.; Sarweswaran, R.; Booma Devi, P.; Sohret, Y.; Kondratiev, A.; Venkatesh, S.; Rakesh Vimal, M.; Jensin Joshua, J. Comparative Study of Nanoadditives TiO2, CNT, Al2O3, CuO and CeO2 on Reduction of Diesel Engine Emission Operating on Hydrogen Fuel Blends. Fuel 2020, 262, 116336. [Google Scholar] [CrossRef]

- Hao, W.; Niu, L.; Gou, R.; Zhang, C. Influence of Al and Al2O3 Nanoparticles on the Thermal Decay of 1,3,5-Trinitro-1,3,5-Triazinane (RDX): Reactive Molecular Dynamics Simulations. J. Phys. Chem. C 2019, 123, 14067–14080. [Google Scholar] [CrossRef] [Green Version]

- Singh, G.; Esmaeilpour, M.; Ratner, A. Effect of Carbon-Based Nanoparticles on the Ignition, Combustion and Flame Characteristics of Crude Oil Droplets. Energy 2020, 197, 117227. [Google Scholar] [CrossRef] [Green Version]

- Sharma, P.; Baek, I.-H.; Cho, T.; Park, S.; Lee, K.B. Enhancement of Thermal Conductivity of Ethylene Glycol Based Silver Nanofluids. Powder Technol. 2011, 208, 7–19. [Google Scholar] [CrossRef]

- Alawi, O.A.; Sidik, N.A.C.; Kazi, S.N.; Abdolbaqi, M.K. Comparative Study on Heat Transfer Enhancement and Nanofluids Flow over Backward and Forward Facing Steps. J. Adv. Res. Fluid Mech. Therm. Sci. 2016, 23, 25. [Google Scholar]

- Venkatesan, H.; Sivamani, S.; Sampath, S. A Comprehensive Review on the Effect of Nano Metallic Additives on Fuel Properties. Int. J. Renew. Energy Res. 2017, 7, 825–843. [Google Scholar]

- Devi, R.S.; Venckatesh, R.; Sivaraj, R. Synthesis of Titanium Dioxide Nanoparticles by Sol-Gel Technique. Int. J. Innov. Res. Sci. Eng. Technol. 2014, 3, 15206–15211. [Google Scholar] [CrossRef]

- Lee, C.C.; Tran, M.-V.; Tan, B.T.; Scribano, G.; Chong, C.T. A Comprehensive Review on the Effects of Additives on Fundamental Combustion Characteristics and Pollutant Formation of Biodiesel and Ethanol. Fuel 2021, 288, 119749. [Google Scholar] [CrossRef]

- Kuppusamy, P.; Yusoff, M.M.; Maniam, G.P.; Govindan, N. Biosynthesis of Metallic Nanoparticles Using Plant Derivatives and Their New Avenues in Pharmacological Applications—An Updated Report. Saudi Pharm. J. 2016, 24, 473–484. [Google Scholar] [CrossRef]

- Janakiraman, S.; Lakshmanan, T.; Chandran, V.; Subramani, L. Comparative Behavior of Various Nano Additives in a DIESEL Engine Powered by Novel Garcinia Gummi-Gutta Biodiesel. J. Clean. Prod. 2020, 245, 118940. [Google Scholar] [CrossRef]

- Rai, R.K.; Sahoo, R.R. Impact of Different Shape Based Hybrid Nano Additives in Emulsion Fuel for Exergetic, Energetic, and Sustainability Analysis of Diesel Engine. Energy 2021, 214, 119086. [Google Scholar] [CrossRef]

- Prasad Yadav, T.; Manohar Yadav, R.; Pratap Singh, D. Mechanical Milling: A Top Down Approach for the Synthesis of Nanomaterials and Nanocomposites. Nanosci. Nanotechnol. 2012, 2, 22–48. [Google Scholar] [CrossRef] [Green Version]

- Amendola, V.; Meneghetti, M. Laser Ablation Synthesis in Solution and Size Manipulation of Noble Metal Nanoparticles. Phys. Chem. Chem. Phys. 2009, 11, 3805. [Google Scholar] [CrossRef]

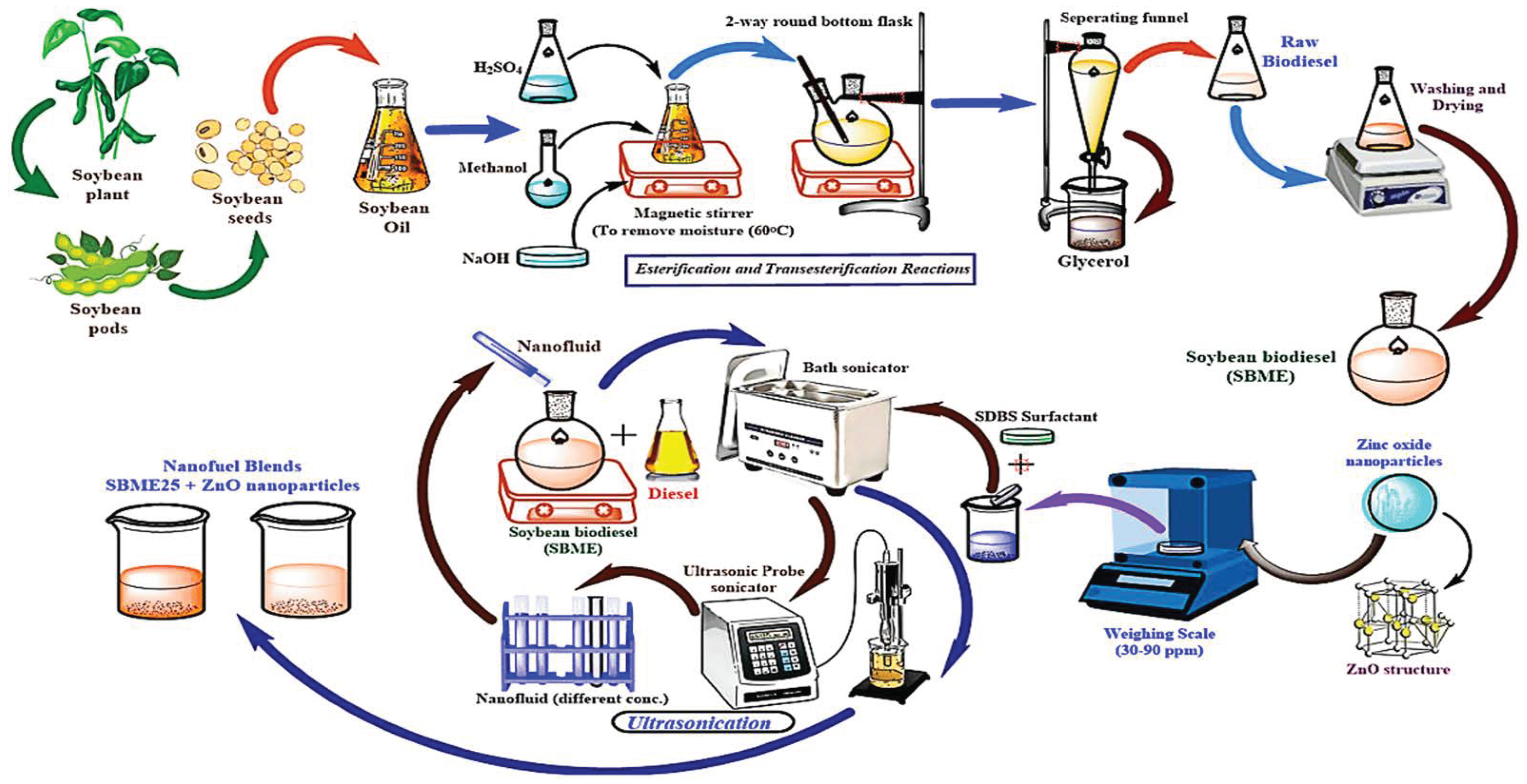

- Gavhane, R.; Kate, A.; Pawar, A.; Safaei, M.R.; Soudagar, M.E.; Mujtaba Abbas, M.; Muhammad Ali, H.; Banapurmath, N.; Goodarzi, M.; Badruddin, I.A.; et al. Effect of Zinc Oxide Nano-Additives and Soybean Biodiesel at Varying Loads and Compression Ratios on VCR Diesel Engine Characteristics. Symmetry 2020, 12, 1042. [Google Scholar] [CrossRef]

- Akoh, H.; Tsukasaki, Y.; Yatsuya, S.; Tasaki, A. Magnetic Properties of Ferromagnetic Ultrafine Particles Prepared by Vacuum Evaporation on Running Oil Substrate. J. Cryst. Growth 1978, 45, 495–500. [Google Scholar] [CrossRef]

- Tran, P.X.; Soong, Y. Preparation of Nanofluids Using Laser Ablation in Liquid Technique. United States: N. p., 2007. Available online: https://www.osti.gov/biblio/915607-preparation-nanofluids-using-laser-ablation-liquid-technique (accessed on 1 December 2021).

- Lo, C.-H.; Tsung, T.-T.; Chen, L.-C. Shape-Controlled Synthesis of Cu-Based Nanofluid Using Submerged Arc Nanoparticle Synthesis System (SANSS). J. Cryst. Growth 2005, 277, 636–642. [Google Scholar] [CrossRef]

- Mann, S.; Burkett, S.L.; Davis, S.A.; Fowler, C.E.; Mendelson, N.H.; Sims, S.D.; Walsh, D.; Whilton, N.T. Sol−Gel Synthesis of Organized Matter. Chem. Mater. 1997, 9, 2300–2310. [Google Scholar] [CrossRef]

- Adachi, M.; Tsukui, S.; Okuyama, K. Nanoparticle Synthesis by Ionizing Source Gas in Chemical Vapor Deposition. Jpn. J. Appl. Phys. 2003, 42, L77–L79. [Google Scholar] [CrossRef]

- Anu Mary Ealia, S.; Saravanakumar, M.P. A Review on the Classification, Characterisation, Synthesis of Nanoparticles and Their Application. IOP Conf. Ser. Mater. Sci. Eng. 2017, 263, 032019. [Google Scholar] [CrossRef]

- Singh, G.; Singh, S.P. Synthesis of Zinc Oxide by Sol-Gel Method and to Study It’s Structural Properties. AIP Conf. Proc. 2020, 2220, 020184. [Google Scholar]

- Alagiri, M.; Ponnusamy, S.; Muthamizhchelvan, C. Synthesis and Characterization of NiO Nanoparticles by Sol–Gel Method. J. Mater. Sci. Mater. Electron. 2012, 23, 728–732. [Google Scholar] [CrossRef]

- Bhaviripudi, S.; Mile, E.; Steiner, S.A.; Zare, A.T.; Dresselhaus, M.S.; Belcher, A.M.; Kong, J. CVD Synthesis of Single-Walled Carbon Nanotubes from Gold Nanoparticle Catalysts. J. Am. Chem. Soc. 2007, 129, 1516–1517. [Google Scholar] [CrossRef]

- Shen, L.; Bao, N.; Yanagisawa, K.; Domen, K.; Gupta, A.; Grimes, C.A. Direct Synthesis of ZnO Nanoparticles by a Solution-Free Mechanochemical Reaction. Nanotechnology 2006, 17, 5117–5123. [Google Scholar] [CrossRef]

- Pimpin, A.; Srituravanich, W. Review on Micro- and Nanolithography Techniques and Their Applications. Eng. J. 2012, 16, 37–56. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.; Chaker, M.; Ma, D. Pulsed Laser Ablation Based Synthesis of Colloidal Metal Nanoparticles for Catalytic Applications. J. Colloid Interface Sci. 2017, 489, 138–149. [Google Scholar] [CrossRef] [PubMed]

- Hussain, F.; Soudagar, M.E.M.; Afzal, A.; Mujtaba, M.A.; Fattah, I.M.R.; Naik, B.; Mulla, M.H.; Badruddin, I.A.; Khan, T.M.Y.; Raju, V.D.; et al. Enhancement in Combustion, Performance, and Emission Characteristics of a Diesel Engine Fueled with Ce-ZnO Nanoparticle Additive Added to Soybean Biodiesel Blends. Energies 2020, 13, 4578. [Google Scholar] [CrossRef]

- Karisathan Sundararajan, N.; Ammal, A.R.B. Improvement Studies on Emission and Combustion Characteristics of DICI Engine Fuelled with Colloidal Emulsion of Diesel Distillate of Plastic Oil, TiO2 Nanoparticles and Water. Environ. Sci. Pollut. Res. 2018, 25, 11595–11613. [Google Scholar] [CrossRef]

- Arul Mozhi Selvan, V.; Anand, R.B.; Udayakumar, M. Effect of Cerium Oxide Nanoparticles and Carbon Nanotubes as Fuel-Borne Additives in Diesterol Blends on the Performance, Combustion and Emission Characteristics of a Variable Compression Ratio Engine. Fuel 2014, 130, 160–167. [Google Scholar] [CrossRef]

- Yu, W.; Zhang, Z.; Liu, B. Investigation on the Performance Enhancement and Emission Reduction of a Biodiesel Fueled Diesel Engine Based on an Improved Entire Diesel Engine Simulation Model. Processes 2021, 9, 104. [Google Scholar] [CrossRef]

- Abomohra, A.E.-F.; Elsayed, M.; Esakkimuthu, S.; El-Sheekh, M.; Hanelt, D. Potential of Fat, Oil and Grease (FOG) for Biodiesel Production: A Critical Review on the Recent Progress and Future Perspectives. Prog. Energy Combust. Sci. 2020, 81, 100868. [Google Scholar] [CrossRef]

- Lam, M.K.; Lee, K.T. Potential of Using Organic Fertilizer to Cultivate Chlorella Vulgaris for Biodiesel Production. Appl. Energy 2012, 94, 303–308. [Google Scholar] [CrossRef]

- Wang, X.; Dai, M.; Wang, J.; Xie, Y.; Ren, G.; Jiang, G. Effect of Ceria Concentration on the Evaporation Characteristics of Diesel Fuel Droplets. Fuel 2019, 236, 1577–1585. [Google Scholar] [CrossRef]

- Basu, S.; Agarwal, A.K.; Mukhopadhyay, A.; Patel, C. Introduction to Droplets and Sprays: Applications for Combustion and Propulsion. In Droplets and Sprays: Applications for Combustion and Propulsion; Basu, S., Agarwal, A.K., Mukhopadhyay, A., Patel, C., Eds.; Energy, Environment, and Sustainability; Springer: Singapore, 2018; pp. 3–6. ISBN 978-981-10-7449-3. [Google Scholar]

- Xi, X.; Liu, H.; Cai, C.; Jia, M.; Ma, X. Analytical and Experimental Study on Boiling Vaporization and Multi-Mode Breakup of Binary Fuel Droplet. Int. J. Heat Mass Transf. 2021, 165, 120620. [Google Scholar] [CrossRef]

- Yang, W.M.; An, H.; Chou, S.K.; Chua, K.J.; Mohan, B.; Sivasankaralingam, V.; Raman, V.; Maghbouli, A.; Li, J. Impact of Emulsion Fuel with Nano-Organic Additives on the Performance of Diesel Engine. Appl. Energy 2013, 112, 1206–1212. [Google Scholar] [CrossRef]

- Yang, W.M.; An, H.; Chou, S.K.; Vedharaji, S.; Vallinagam, R.; Balaji, M.; Mohammad, F.E.A.; Chua, K.J.E. Emulsion Fuel with Novel Nano-Organic Additives for Diesel Engine Application. Fuel 2013, 104, 726–731. [Google Scholar] [CrossRef]

- Sazhin, S.S.; Rybdylova, O.; Crua, C.; Heikal, M.; Ismael, M.A.; Nissar, Z.; Aziz, A.R.B.A. A Simple Model for Puffing/Micro-Explosions in Water-Fuel Emulsion Droplets. Int. J. Heat Mass Transf. 2019, 131, 815–821. [Google Scholar] [CrossRef]

- Ooi, J.B.; Ismail, H.M.; Swamy, V.; Wang, X.; Swain, A.K.; Rajanren, J.R. Graphite Oxide Nanoparticle as a Diesel Fuel Additive for Cleaner Emissions and Lower Fuel Consumption. Energy Fuels 2016, 5, 02162. [Google Scholar] [CrossRef]

- Venu, H.; Raju, V.D.; Lingesan, S.; Elahi Soudagar, M. Influence of Al2O3 nano Additives in Ternary Fuel (Diesel-Biodiesel-Ethanol) Blends Operated in a Single Cylinder Diesel Engine: Performance, Combustion and Emission Characteristics. Energy 2021, 215, 119091. [Google Scholar] [CrossRef]

- Hoseini, S.S.; Najafi, G.; Ghobadian, B.; Ebadi, M.T.; Mamat, R.; Yusaf, T. Performance and Emission Characteristics of a CI Engine Using Graphene Oxide (GO) Nano-Particles Additives in Biodiesel-Diesel Blends. Renew. Energy 2020, 145, 458–465. [Google Scholar] [CrossRef]

- Dharmaprabhakaran, T.; Karthikeyan, S.; Periyasamy, M.; Mahendran, G. Combustion Analysis of CuO2 Nanoparticle Addition with Blend of Botryococcus Braunii Algae Biodiesel on CI Engine. Mater. Today Proc. 2020, 33, 2874–2876. [Google Scholar] [CrossRef]

- Soudagar, M.E.M.; Nik-Ghazali, N.-N.; Kalam, M.A.; Badruddin, I.A.; Banapurmath, N.R.; Yunus Khan, T.M.; Bashir, M.N.; Akram, N.; Farade, R.; Afzal, A. The Effects of Graphene Oxide Nanoparticle Additive Stably Dispersed in Dairy Scum Oil Biodiesel-Diesel Fuel Blend on CI Engine: Performance, Emission and Combustion Characteristics. Fuel 2019, 257, 116015. [Google Scholar] [CrossRef]

- Karthikeyan, P.; Viswanath, G. Effect of Titanium Oxide Nanoparticles in Tamanu Biodiesel Operated in a Two Cylinder Diesel Engine. Mater. Today Proc. 2020, 22, 776–780. [Google Scholar] [CrossRef]

- Mirzajanzadeh, M.; Tabatabaei, M.; Ardjmand, M.; Rashidi, A.; Ghobadian, B.; Barkhi, M.; Pazouki, M. A Novel Soluble Nano-Catalysts in Diesel–Biodiesel Fuel Blends to Improve Diesel Engines Performance and Reduce Exhaust Emissions. Fuel 2015, 139, 374–382. [Google Scholar] [CrossRef]

- Hussain Vali, R.; Marouf Wani, M. The Effect of Mixed Nano-Additives on Performance and Emission Characteristics of a Diesel Engine Fuelled with Diesel-Ethanol Blend. Mater. Today Proc. 2021, 43, 3842–3846. [Google Scholar] [CrossRef]

- EL-Seesy, A.I.; Hassan, H. Investigation of the Effect of Adding Graphene Oxide, Graphene Nanoplatelet, and Multiwalled Carbon Nanotube Additives with n-Butanol-Jatropha Methyl Ester on a Diesel Engine Performance. Renew. Energy 2019, 132, 558–574. [Google Scholar] [CrossRef]

- El-Seesy, A.I.; Attia, A.M.A.; El-Batsh, H.M. The Effect of Aluminum Oxide Nanoparticles Addition with Jojoba Methyl Ester-Diesel Fuel Blend on a Diesel Engine Performance, Combustion and Emission Characteristics. Fuel 2018, 224, 147–166. [Google Scholar] [CrossRef]

- Mehregan, M.; Moghiman, M. Effects of Nano-Additives on Pollutants Emission and Engine Performance in a Urea-SCR Equipped Diesel Engine Fueled with Blended-Biodiesel. Fuel 2018, 222, 402–406. [Google Scholar] [CrossRef]

- Selvan, V.A.M.; Anand, R.B.; Udayakumar, M. Effects of Cerium Oxide Nanoparticle Addition in Diesel and Diesel-Biodiesel-Ethanol Blends on the Performance and Emission Characteristics of a CI Engine. J. Eng. Appl. Sci. 2009, 4, 6. [Google Scholar]

- Karthikeyan, S.; Prathima, A. Environmental Effect of CI Engine Using Microalgae Methyl Ester with Doped Nano Additives. Transp. Res. Part Transp. Environ. 2017, 50, 385–396. [Google Scholar] [CrossRef]

- Hasannuddin, A.K.; Yahya, W.J.; Sarah, S.; Ithnin, A.M.; Syahrullail, S.; Sidik, N.A.C.; Abu Kassim, K.A.; Ahmad, Y.; Hirofumi, N.; Ahmad, M.A.; et al. Nano-Additives Incorporated Water in Diesel Emulsion Fuel: Fuel Properties, Performance and Emission Characteristics Assessment. Energy Convers. Manag. 2018, 169, 291–314. [Google Scholar] [CrossRef]

- Sheriff, S.A.; Kumar, I.K.; Mandhatha, P.S.; Jambal, S.S.; Sellappan, R.; Ashok, B.; Nanthagopal, K. Emission Reduction in CI Engine Using Biofuel Reformulation Strategies through Nano Additives for Atmospheric Air Quality Improvement. Renew. Energy 2020, 147, 2295–2308. [Google Scholar] [CrossRef]

- Soudagar, M.E.M.; Nik-Ghazali, N.-N.; Abul Kalam, M.; Badruddin, I.A.; Banapurmath, N.R.; Akram, N. The Effect of Nano-Additives in Diesel-Biodiesel Fuel Blends: A Comprehensive Review on Stability, Engine Performance and Emission Characteristics. Energy Convers. Manag. 2018, 178, 146–177. [Google Scholar] [CrossRef]

- Venu, H.; Appavu, P. Al2O3 Nano Additives Blended Polanga Biodiesel as a Potential Alternative Fuel for Existing Unmodified DI Diesel Engine. Fuel 2020, 279, 118518. [Google Scholar] [CrossRef]

- Rajasekar, R.; Naveenchandran, P. Performance and Emission Analysis of Di Diesel Engine Fuelled by Biodiesel with Al2o3 Nano Additives. Mater. Today Proc. 2021, 47, 345–350. [Google Scholar] [CrossRef]

- Venu, H.; Subramani, L.; Raju, V.D. Emission Reduction in a DI Diesel Engine Using Exhaust Gas Recirculation (EGR) of Palm Biodiesel Blended with TiO2 Nano Additives. Renew. Energy 2019, 140, 245–263. [Google Scholar] [CrossRef]

- Badawy, T.; Mansour, M.S.; Daabo, A.M.; Abdel Aziz, M.M.; Othman, A.A.; Barsoum, F.; Basouni, M.; Hussien, M.; Ghareeb, M.; Hamza, M.; et al. Selection of Second-Generation Crop for Biodiesel Extraction and Testing Its Impact with Nano Additives on Diesel Engine Performance and Emissions. Energy 2021, 237, 121605. [Google Scholar] [CrossRef]

- El-Seesy, A.I.; Hassan, H.; Ookawara, S. Effects of Graphene Nanoplatelet Addition to Jatropha Biodiesel–Diesel Mixture on the Performance and Emission Characteristics of a Diesel Engine. Energy 2018, 147, 1129–1152. [Google Scholar] [CrossRef]

- Kumar Patel, H.; Kumar, S. Experimental Analysis on Performance of Diesel Engine Using Mixture of Diesel and Bio-Diesel as a Working Fuel with Aluminum Oxide Nanoparticle Additive. Therm. Sci. Eng. Prog. 2017, 4, 252–258. [Google Scholar] [CrossRef]

- Hoseini, S.S.; Najafi, G.; Ghobadian, B.; Mamat, R.; Ebadi, M.T.; Yusaf, T. Novel Environmentally Friendly Fuel: The Effects of Nanographene Oxide Additives on the Performance and Emission Characteristics of Diesel Engines Fuelled with Ailanthus Altissima Biodiesel. Renew. Energy 2018, 125, 283–294. [Google Scholar] [CrossRef]

- Jumaa, H.; Mashkour, M.A. The Effect of Variable Engine Parameters on Performance and Emissions of DI Diesel Engine Running on Diesel-Biodiesel Blended with Nano Additives. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1094, 012122. [Google Scholar] [CrossRef]

- Gavhane, R.S.; Kate, A.M.; Soudagar, M.E.M.; Wakchaure, V.D.; Balgude, S.; Rizwanul Fattah, I.M.; Nik-Ghazali, N.-N.; Fayaz, H.; Khan, T.M.Y.; Mujtaba, M.A.; et al. Influence of Silica Nano-Additives on Performance and Emission Characteristics of Soybean Biodiesel Fuelled Diesel Engine. Energies 2021, 14, 1489. [Google Scholar] [CrossRef]

- Campli, S.; Acharya, M.; Channapattana, S.V.; Pawar, A.A.; Gawali, S.V.; Hole, J. The Effect of Nickel Oxide Nano-Additives in Azadirachta Indica Biodiesel-Diesel Blend on Engine Performance and Emission Characteristics by Varying Compression Ratio. Environ. Prog. Sustain. Energy 2021, 40, e13514. [Google Scholar] [CrossRef]

- Kalaimurugan, K.; Karthikeyan, S.; Periyasamy, M.; Mahendran, G. Experimental Investigations on the Performance Characteristics of CI Engine Fuelled with Cerium Oxide Nanoparticle Added Biodiesel-Diesel Blends. Mater. Today Proc. 2020, 33, 2882–2885. [Google Scholar] [CrossRef]

- Vinukumar, K.; Azhagurajan, A.; Vettivel, S.C.; Vedaraman, N.; Haiter Lenin, A. Biodiesel with Nano Additives from Coconut Shell for Decreasing Emissions in Diesel Engines. Fuel 2018, 222, 180–184. [Google Scholar] [CrossRef]

- Ghanbari, M.; Mozafari-Vanani, L.; Dehghani-Soufi, M.; Jahanbakhshi, A. Effect of Alumina Nanoparticles as Additive with Diesel–Biodiesel Blends on Performance and Emission Characteristic of a Six-Cylinder Diesel Engine Using Response Surface Methodology (RSM). Energy Convers. Manag. X 2021, 11, 100091. [Google Scholar] [CrossRef]

- Soudagar, M.E.M.; Mujtaba, M.A.; Safaei, M.R.; Afzal, A.; Raju, V.D.; Ahmed, W.; Banapurmath, N.R.; Hossain, N.; Bashir, S.; Badruddin, I.A.; et al. Effect of Sr@ZnO Nanoparticles and Ricinus Communis Biodiesel-Diesel Fuel Blends on Modified CRDI Diesel Engine Characteristics. Energy 2021, 215, 119094. [Google Scholar] [CrossRef]

- Hosseini, S.H.; Taghizadeh-Alisaraei, A.; Ghobadian, B.; Abbaszadeh-Mayvan, A. Effect of Added Alumina as Nano-Catalyst to Diesel-Biodiesel Blends on Performance and Emission Characteristics of CI Engine. Energy 2017, 124, 543–552. [Google Scholar] [CrossRef]

- Perumal, V.; Ilangkumaran, M. The Influence of Copper Oxide Nano Particle Added Pongamia Methyl Ester Biodiesel on the Performance, Combustion and Emission of a Diesel Engine. Fuel 2018, 232, 791–802. [Google Scholar] [CrossRef]

- Annamalai, M.; Dhinesh, B.; Nanthagopal, K.; SivaramaKrishnan, P.; Isaac JoshuaRamesh Lalvani, J.; Parthasarathy, M.; Annamalai, K. An Assessment on Performance, Combustion and Emission Behavior of a Diesel Engine Powered by Ceria Nanoparticle Blended Emulsified Biofuel. Energy Convers. Manag. 2016, 123, 372–380. [Google Scholar] [CrossRef]

- El-Seesy, A.I.; Hassan, H.; Ookawara, S. Performance, Combustion, and Emission Characteristics of a Diesel Engine Fueled with Jatropha Methyl Ester and Graphene Oxide Additives. Energy Convers. Manag. 2018, 166, 674–686. [Google Scholar] [CrossRef]

- Tyagi, H.; Phelan, P.E.; Prasher, R.; Peck, R.; Lee, T.; Pacheco, J.R.; Arentzen, P. Increased Hot-Plate Ignition Probability for Nanoparticle-Laden Diesel Fuel. Nano Lett. 2008, 8, 1410–1416. [Google Scholar] [CrossRef]

- Ramarao, K.; Rao, C.J.; Sreeramulu, D. The Experimental Investigation on Performance and Emission Characteristics of a Single Cylinder Diesel Engine Using Nano Additives in Diesel and Biodiesel. Indian J. Sci. Technol. 2015, 8, 8. [Google Scholar] [CrossRef]

- Liu, T.; E, J.; Yang, W.M.; Den, Y.; An, H.; Zhang, Z.; Pham, M. Investigation on the applicability for adjusting reaction rates of the optimized biodiesel skeletal mechanism. Energy 2018, 150, 1031–1038. [Google Scholar] [CrossRef]

- Dhana Raju, V.; Kishore, P.S.; Nanthagopal, K.; Ashok, B. An Experimental Study on the Effect of Nanoparticles with Novel Tamarind Seed Methyl Ester for Diesel Engine Applications. Energy Convers. Manag. 2018, 164, 655–666. [Google Scholar] [CrossRef]

- Aalam, C.S.; Saravanan, C.G.; Kannan, M. Experimental Investigations on a CRDI System Assisted Diesel Engine Fuelled with Aluminium Oxide Nanoparticles Blended Biodiesel. Alex. Eng. J. 2015, 54, 351–358. [Google Scholar] [CrossRef] [Green Version]

- Sadhik Basha, J.; Anand, R.B. Role of Nanoadditive Blended Biodiesel Emulsion Fuel on the Working Characteristics of a Diesel Engine. J. Renew. Sustain. Energy 2011, 3, 023106. [Google Scholar] [CrossRef]

- EL-Seesy, A.I.; Kosaka, H.; Hassan, H.; Sato, S. Combustion and Emission Characteristics of a Common Rail Diesel Engine and RCEM Fueled by N-Heptanol-Diesel Blends and Carbon Nanomaterial Additives. Energy Convers. Manag. 2019, 196, 370–394. [Google Scholar] [CrossRef]

- Ooi, J.B.; Rajanren, J.R.; Ismail, H.M.; Swamy, V.; Wang, X. Improving Combustion Characteristics of Diesel and Biodiesel Droplets by Graphite Oxide Addition for Diesel Engine Applications. Int. J. Energy Res. 2017, 41, 2258–2267. [Google Scholar] [CrossRef]

- Qi, D.H.; Chen, H.; Geng, L.M.; Bian, Y.Z.H. Experimental Studies on the Combustion Characteristics and Performance of a Direct Injection Engine Fueled with Biodiesel/Diesel Blends. Energy Convers. Manag. 2010, 51, 2985–2992. [Google Scholar] [CrossRef]

- Chen, A.F.; Akmal Adzmi, M.; Adam, A.; Othman, M.F.; Kamaruzzaman, M.K.; Mrwan, A.G. Combustion Characteristics, Engine Performances and Emissions of a Diesel Engine Using Nanoparticle-Diesel Fuel Blends with Aluminium Oxide, Carbon Nanotubes and Silicon Oxide. Energy Convers. Manag. 2018, 171, 461–477. [Google Scholar] [CrossRef]

- Dhahad, H.A.; Chaichan, M.T. The Impact of Adding Nano-Al2O3 and Nano-ZnO to Iraqi Diesel Fuel in Terms of Compression Ignition Engines’ Performance and Emitted Pollutants. Therm. Sci. Eng. Prog. 2020, 18, 100535. [Google Scholar] [CrossRef]

- Fayaz, H.; Mujtaba, M.A.; Soudagar, M.E.M.; Razzaq, L.; Nawaz, S.; Nawaz, M.A.; Farooq, M.; Afzal, A.; Ahmed, W.; Khan, T.M.Y.; et al. Collective Effect of Ternary Nano Fuel Blends on the Diesel Engine Performance and Emissions Characteristics. Fuel 2021, 293, 120420. [Google Scholar] [CrossRef]

- Tomar, M.; Kumar, N. Effect of Multi-Walled Carbon Nanotubes and Alumina Nano-Additives in a Light Duty Diesel Engine Fuelled with Schleichera Oleosa Biodiesel Blends. Sustain. Energy Technol. Assess. 2020, 42, 100833. [Google Scholar] [CrossRef]

- Elkelawy, M.; Etaiw, S.E.H.; Ayad, M.I.; Marie, H.; Dawood, M.; Panchal, H.; Bastawissi, H.A.-E. An Enhancement in the Diesel Engine Performance, Combustion, and Emission Attributes Fueled by Diesel-Biodiesel and 3D Silver Thiocyanate Nanoparticles Additive Fuel Blends. J. Taiwan Inst. Chem. Eng. 2021, 124, 369–380. [Google Scholar] [CrossRef]

- Hoseini, S.S.; Najafi, G.; Ghobadian, B.; Ebadi, M.T.; Mamat, R.; Yusaf, T. Biodiesels from Three Feedstock: The Effect of Graphene Oxide (GO) Nanoparticles Diesel Engine Parameters Fuelled with Biodiesel. Renew. Energy 2020, 145, 190–201. [Google Scholar] [CrossRef]

- Gad, M.S.; Jayaraj, S. A Comparative Study on the Effect of Nano-Additives on the Performance and Emissions of a Diesel Engine Run on Jatropha Biodiesel. Fuel 2020, 267, 117168. [Google Scholar] [CrossRef]

- EL-Seesy, A.I.; Nour, M.; Hassan, H.; Elfasakhany, A.; He, Z.; Mujtaba, M.A. Diesel-Oxygenated Fuels Ternary Blends with Nano Additives in Compression Ignition Engine: A Step towards Cleaner Combustion and Green Environment. Case Stud. Therm. Eng. 2021, 25, 100911. [Google Scholar] [CrossRef]

- Kumar, A.R.M.; Kannan, M.; Nataraj, G. A Study on Performance, Emission and Combustion Characteristics of Diesel Engine Powered by Nano-Emulsion of Waste Orange Peel Oil Biodiesel. Renew. Energy 2020, 146, 1781–1795. [Google Scholar] [CrossRef]

- Chandrasekaran, V.; Arthanarisamy, M.; Nachiappan, P.; Dhanakotti, S.; Moorthy, B. The Role of Nano Additives for Biodiesel and Diesel Blended Transportation Fuels. Transp. Res. Part Transp. Environ. 2016, 46, 145–156. [Google Scholar] [CrossRef]

- Kumar, S.; Dinesha, P.; Bran, I. Influence of Nanoparticles on the Performance and Emission Characteristics of a Biodiesel Fuelled Engine: An Experimental Analysis. Energy 2017, 140, 98–105. [Google Scholar] [CrossRef]

- Srinidhi, C.; Madhusudhan, A.; Channapattana, S.V. Effect of NiO Nanoparticles on Performance and Emission Characteristics at Various Injection Timings Using Biodiesel-Diesel Blends. Fuel 2019, 235, 185–193. [Google Scholar] [CrossRef]

- Jaikumar, S.; Srinivas, V.; Rajasekhar, M. Influence of Dispersant Added Nanoparticle Additives with Diesel-Biodiesel Blend on Direct Injection Compression Ignition Engine: Combustion, Engine Performance, and Exhaust Emissions Approach. Energy 2021, 224, 120197. [Google Scholar] [CrossRef]

- Sachuthananthan, B.; Vinoth, R.; Reddy, D.R.; Reddy, K.H. Role of Non Metallic Nano Additive in the Behavior of a Diesel Engine Fueled with Blends of Waste Plastic Oil. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1130, 012041. [Google Scholar] [CrossRef]

- Razzaq, L.; Mujtaba, M.A.; Soudagar, M.E.M.; Ahmed, W.; Fayaz, H.; Bashir, S.; Fattah, I.M.R.; Ong, H.C.; Shahapurkar, K.; Afzal, A.; et al. Engine Performance and Emission Characteristics of Palm Biodiesel Blends with Graphene Oxide Nanoplatelets and Dimethyl Carbonate Additives. J. Environ. Manag. 2021, 282, 111917. [Google Scholar] [CrossRef]

- Kalaimurugan, K.; Karthikeyan, S.; Periyasamy, M.; Mahendran, G. Emission Analysis of CI Engine with CeO2 Nanoparticles Added Neochloris Oleoabundans Biodiesel-Diesel Fuel Blends. Mater. Today Proc. 2020, 33, 2877–2881. [Google Scholar] [CrossRef]

- Vellaiyan, S. Enhancement in Combustion, Performance, and Emission Characteristics of a Diesel Engine Fueled with Diesel, Biodiesel, and Its Blends by Using Nanoadditive. Environ. Sci. Pollut Res. 2019, 26, 9561–9573. [Google Scholar] [CrossRef]

- Balamurugan, K.; Tamilvanan, A.; Anbarasu, M.; Mohamed, S.A.; Srihari, S. Nano-Copper Additive for Reducing NOx Emission in Soya Bean Biodiesel-Fuelled CI Engine. J. Biofuels 2013, 4, 1. [Google Scholar] [CrossRef]

- Sahoo, P.K.; Das, L.M.; Babu, M.K.G.; Arora, P.; Singh, V.P.; Kumar, N.R.; Varyani, T.S. Comparative Evaluation of Performance and Emission Characteristics of Jatropha, Karanja and Polanga Based Biodiesel as Fuel in a Tractor Engine. Fuel 2009, 88, 1698–1707. [Google Scholar] [CrossRef]

- Özgünay, H.; Çolak, S.; Zengin, G.; Sari, Ö.; Sarikahya, H.; Yüceer, L. Performance and Emission Study of Biodiesel from Leather Industry Pre-Fleshings. Waste Manag. 2007, 27, 1897–1901. [Google Scholar] [CrossRef]

- Al-Widyan, M.I.; Tashtoush, G.; Abu-Qudais, M. Utilization of Ethyl Ester of Waste Vegetable Oils as Fuel in Diesel Engines. Fuel Process. Technol. 2002, 76, 91–103. [Google Scholar] [CrossRef]

- Knothe, G. “Designer” Biodiesel: Optimizing Fatty Ester Composition to Improve Fuel Properties. Energy Fuels 2008, 22, 1358–1364. [Google Scholar] [CrossRef]

- Dhinesh, B.; Maria Ambrose Raj, Y.; Kalaiselvan, C.; KrishnaMoorthy, R. A Numerical and Experimental Assessment of a Coated Diesel Engine Powered by High-Performance Nano Biofuel. Energy Convers. Manag. 2018, 171, 815–824. [Google Scholar] [CrossRef]

- Kataria, J.; Mohapatra, S.K.; Kundu, K. Biodiesel Production from Waste Cooking Oil Using Heterogeneous Catalysts and Its Operational Characteristics on Variable Compression Ratio CI Engine. J. Energy Inst. 2019, 92, 275–287. [Google Scholar] [CrossRef]

- Han, D.; E, J.; Deng, Y.; Zhao, X.; Feng, C.; Chen, J.; Leng, E.; Liao, G.; Zhang, F. A review of studies using hydrocarbon reduction measures for reducing hydrocarbon emissions from cold start of gasoline engine. Renew. Sustain. Energy Rev. 2021, 135, 110079. [Google Scholar] [CrossRef]

- Zhang, Z.; Lu, Y.; Wang, Y.; Yu, X.; Smallbone, A.; Dong, C.; Roskilly, A.P. Comparative Study of Using Multi-Wall Carbon Nanotube and Two Different Sizes of Cerium Oxide Nanopowders as Fuel Additives under Various Diesel Engine Conditions. Fuel 2019, 256, 115904. [Google Scholar] [CrossRef]

- Nanthagopal, K.; Kishna, R.S.; Atabani, A.E.; Al-Muhtaseb, A.H.; Kumar, G.; Ashok, B. A Compressive Review on the Effects of Alcohols and Nanoparticles as an Oxygenated Enhancer in Compression Ignition Engine. Energy Convers. Manag. 2020, 203, 112244. [Google Scholar] [CrossRef]

- E, J.; Zhang, Z.; Chen, J.; Pham, M.H.; Zhao, X.; Peng, Q.; Zhang, B.; Yin, Z. Performance and emission evaluation of a marine diesel engine fueled by water biodiesel-diesel emulsion blends with a fuel additive of a cerium oxide nanoparticle. Energy Convers. Manag. 2018, 169, 194–205. [Google Scholar] [CrossRef]

- Chaichan, M.T.; Kadhum, A.A.H.; Al-Amiery, A.A. Novel Technique for Enhancement of Diesel Fuel: Impact of Aqueous Alumina Nano-Fluid on Engine’s Performance and Emissions. Case Stud. Therm. Eng. 2017, 10, 611–620. [Google Scholar] [CrossRef]

- Chacko, N.; Jeyaseelan, T. Comparative Evaluation of Graphene Oxide and Graphene Nanoplatelets as Fuel Additives on the Combustion and Emission Characteristics of a Diesel Engine Fuelled with Diesel and Biodiesel Blend. Fuel Process. Technol. 2020, 204, 106406. [Google Scholar] [CrossRef]

- Gowtham, M.; Prakash, R. Control of Regulated and Unregulated Emissions from a CI Engine Using Reformulated Nano Fuel Emulsions. Fuel 2020, 271, 117596. [Google Scholar] [CrossRef]

- Lenin, M.A.; Swaminathan, M.R.; Kumaresan, G. Performance and Emission Characteristics of a DI Diesel Engine with a Nanofuel Additive. Fuel 2013, 109, 362–365. [Google Scholar] [CrossRef]

- Basha, S.A.; Raja Gopal, K. A Review of the Effects of Catalyst and Additive on Biodiesel Production, Performance, Combustion and Emission Characteristics. Renew. Sustain. Energy Rev. 2012, 16, 711–717. [Google Scholar] [CrossRef]

- Demirbas, A. Importance of Biodiesel as Transportation Fuel. Energy Policy 2007, 35, 4661–4670. [Google Scholar] [CrossRef]

- Hirkude, J.; Padalkar, A.S. Experimental Investigation of the Effect of Compression Ratio on Performance and Emissions of CI Engine Operated with Waste Fried Oil Methyl Ester Blend. Fuel Process. Technol. 2014, 128, 367–375. [Google Scholar] [CrossRef]

- Prabu, A. Nanoparticles as Additive in Biodiesel on the Working Characteristics of a DI Diesel Engine. Ain Shams Eng. J. 2018, 9, 2343–2349. [Google Scholar] [CrossRef]

- Bazooyar, B.; Hosseini, S.Y.; Moradi Ghoje Begloo, S.; Shariati, A.; Hashemabadi, S.H.; Shaahmadi, F. Mixed Modified Fe2O3-WO3 as New Fuel Borne Catalyst (FBC) for Biodiesel Fuel. Energy 2018, 149, 438–453. [Google Scholar] [CrossRef]

- Shaafi, T.; Velraj, R. Influence of Alumina Nanoparticles, Ethanol and Isopropanol Blend as Additive with Diesel–Soybean Biodiesel Blend Fuel: Combustion, Engine Performance and Emissions. Renew. Energy 2015, 80, 655–663. [Google Scholar] [CrossRef]

- Pantzali, M.N.; Kanaris, A.G.; Antoniadis, K.D.; Mouza, A.A.; Paras, S.V. Effect of Nanofluids on the Performance of a Miniature Plate Heat Exchanger with Modulated Surface. Int. J. Heat Fluid Flow 2009, 30, 691–699. [Google Scholar] [CrossRef]

- Wu, Q.; Xie, X.; Wang, Y.; Roskilly, T. Effect of Carbon Coated Aluminum Nanoparticles as Additive to Biodiesel-Diesel Blends on Performance and Emission Characteristics of Diesel Engine. Appl. Energy 2018, 221, 597–604. [Google Scholar] [CrossRef] [Green Version]

- Mei, D.; Li, X.; Wu, Q.; Sun, P. Role of Cerium Oxide Nanoparticles as Diesel Additives in Combustion Efficiency Improvements and Emission Reduction. J. Energy Eng. 2016, 142, 04015050. [Google Scholar] [CrossRef]

- Gantt, B.; Hoque, S.; Fahey, K.M.; Willis, R.D.; Delgado-Saborit, J.M.; Harrison, R.M.; Zhang, K.M.; Jefferson, D.A.; Kalberer, M.; Bunker, K.L.; et al. Factors Affecting the Ambient Physicochemical Properties of Cerium-Containing Particles Generated by Nanoparticle Diesel Fuel Additive Use. Aerosol Sci. Technol. 2015, 49, 371–380. [Google Scholar] [CrossRef] [Green Version]

- Möller, P.; Morteani, G.; Dulski, P. Anomalous Gadolinium, Cerium, and Yttrium Contents in the Adige and Isarco River Waters and in the Water of Their Tributaries (Provinces Trento and Bolzano/Bozen, NE Italy). Acta Hydrochim. Hydrobiol. 2003, 31, 225–239. [Google Scholar] [CrossRef]

- Keller, A.A.; Lazareva, A. Predicted Releases of Engineered Nanomaterials: From Global to Regional to Local. Environ. Sci. Technol. Lett. 2014, 1, 65–70. [Google Scholar] [CrossRef] [Green Version]

- Norhafana, M.; Noor, M.M.; Hairuddin, A.A.; Harikrishnan, S.; Kadirgama, K.; Ramasamy, D. The Effects of Nano-Additives on Exhaust Emissions and Toxicity on Mankind. Mater. Today Proc. 2020, 22, 1181–1185. [Google Scholar] [CrossRef]

- Fan, L.; Cheng, F.; Zhang, T.; Liu, G.; Yuan, J.; Mao, P. Visible-light photoredox-promoted desilylative allylation of a-silylamines: An efficient route to synthesis of homoallylic amines. Tetrahedron Lett. 2021, 81, 153357. [Google Scholar] [CrossRef]

- Nemmar, A.; Hoet, P.H.M.; Thomeer, M.; Nemery, B.; Vanquickenborne, B.; Vanbilloen, H.; Mortelmans, L.; Hoylaerts, M.; Verbruggen, A.; Dinsdale, A. Passage of Inhaled Particles into the Blood Circulation in Humas (Reply to W.M. Burch). Circulation 2002, 106, E141–E142. [Google Scholar]

- Gatti, A.M. Biocompatibility of Micro- and Nano-Particles in the Colon. Part II. Biomaterials 2004, 25, 385–392. [Google Scholar] [CrossRef] [Green Version]

- Jolliet, O.; Margni, M.; Charles, R.; Humbert, S.; Payet, J.; Rebitzer, G.; Rosenbaum, R. IMPACT 2002+: A New Life Cycle Impact Assessment Methodology. Int. J. Life Cycle Assess. 2003, 8, 324. [Google Scholar] [CrossRef] [Green Version]

- E, J.; Liu, G.; Zhang, Z.; Han, D.; Chen, J.; Wei, K.; Gong, J.; Yin, Z. Effect analysis on cold starting performance enhancement of a diesel engine fueled with biodiesel fuel based on an improved thermodynamic model. Appl. Energy 2019, 243, 321–335. [Google Scholar] [CrossRef]

- Qin, J.; Du, J. Robust adaptive asymptotic trajectory tracking control for underactuated surface vessels subject to unknown dynamics and input saturation. J. Mar. Sci. Technol. 2021, 212, 835–839. [Google Scholar] [CrossRef]

- Mukhopadhyay, P.; Chakraborty, R. LCA of Sustainable Biodiesel Production from Fried Borassus Flabellifer Oil in Energy-Proficient Reactors: Impact Assessment of Multi Fuel-Additives on Pour Point, NOx and Engine Performance. Sustain. Energy Technol. Assess. 2021, 44, 100994. [Google Scholar] [CrossRef]

- Hosseinzadeh-Bandbafha, H.; Tabatabaei, M.; Aghbashlo, M.; Khanali, M.; Khalife, E.; Roodbar Shojaei, T.; Mohammadi, P. Data Supporting Consolidating Emission Indices of a Diesel Engine Powered by Carbon Nanoparticle-Doped Diesel/Biodiesel Emulsion Fuels Using Life Cycle Assessment Framework. Data Brief 2020, 30, 105428. [Google Scholar] [CrossRef]

| Category | Method | Nanoparticles |

|---|---|---|

| Bottom-up | Sol-gel | Carbon metal and metal oxide based |

| Spinning | Organic polymers | |

| Chemical Vapour Deposition | Carbon and metal based | |

| Pyrolysis | Carbon and metal oxide based | |

| Biosynthesis | Organic polymers and metal-based | |

| Top-down | Mechanical milling | Metal, oxide and polymer-based |

| Nanolithography | Metalbased | |

| Laser ablation | Carbon based and metal oxide based | |

| Sputtering | Metal-based | |

| Thermal decomposition | Carbon and metal oxide based |

| Diesel Blended with | Nanoparticle | BTE | BFSC | Power | Refs. |

|---|---|---|---|---|---|

| Waste cooking oil | CNT and silver | ─ | −7.08% | +2% | [30] |

| Honge oil | Al2O3 | +10.57% | −11.65% | ─ | [33] |

| cooking oil | CNTs | +8.12% | −7.12% | +3.67% | [34] |

| Soybean | ZnO | +23.2% | −26.66% | ─ | [65] |

| Dairy scum oil | graphene oxide | +11.56% | −8.34% | ─ | [94] |

| Cooking oil | MWCNT | ─ | −4.5% | +7.81% | [96] |

| Jatropha methyl ester | GNPs | +25% | −20% | ─ | [110] |

| Jatropha | Al2O3 | +24.7% | Decrease | +3.85% | [111] |

| Ailanthus altissima | GO | ─ | −14.48% | +14.3% | [112] |

| Cooking oil | Fe2O3 | +15.05% | −10.73% | ─ | [113] |

| Soybean | SiO2 | +6.39% | +9.88% | ─ | [114] |

| Neem | NiO | +2.9% | −1.8% | ─ | [115] |

| Algae oil | CeO2 | increase | decrease | ─ | [116] |

| Pungamia pinnata | coconut shell | increase | decrease | +0.65% | [117] |

| Waste Cooking Oil | Al2O3 | increase | decrease | increase | [118] |

| Ricinus communis | Sr@ZnO | +20.83% | −20.07% | increase | [119] |

| Waste cooking oil | Al2O3 | +5.80% | −14.66% | +5.36% | [120] |

| Pongamia | CuO | +4.01% | −1.0% | ─ | [121] |

| Lemongrass Oil | CeO2 | +3.55% | −5.87% | ─ | [122] |

| Jatropha Methyl Ester | GO | +17% | −20% | ─ | [123] |

| Diesel Blended with | Nanoparticle | NOx | CO | HC | Refs. |

|---|---|---|---|---|---|

| Honge oil | HOME | +11.27% | −47.43% | −37.72% | [33] |

| Garcinia gummi-gutta | TiO2 | −22.57% | −35.89% | −6.39% | [61] |

| Oenothera lamarckiana | GO | +9% | −22% | −26% | [92] |

| Jatropha methyl | GNPs | −55% | −65% | −65% | [110] |

| Cooking oil | MWCNT | +8% | −20% | +28% | [114] |

| Pongamia | CuO | −9.8% | −29% | −7.9% | [121] |

| Jatropha | GO | −13% | −60% | −70% | [140] |

| Orange peel oil | TiO2 | −9.7% | −18.4% | −16.0% | [141] |

| Mahua | CuO | +3.2% | −33% | −5.33% | [142] |

| Pongamia | Fe3O4 | −8% | decrease | +16.6% | [143] |

| Azadirachta indica | NiO | +6.1% | −25.4% | −10.8% | [144] |

| Flaxseed oil | Cr2O3 | −6.66% | −14.05% | −12.93% | [145] |

| Waste Plastic Oil | rice husk | +14.1% | −7% | −15.3% | [146] |

| Palm oil | GNPs | +3.65% | −4.41% | −25% | [147] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lv, J.; Wang, S.; Meng, B. The Effects of Nano-Additives Added to Diesel-Biodiesel Fuel Blends on Combustion and Emission Characteristics of Diesel Engine: A Review. Energies 2022, 15, 1032. https://doi.org/10.3390/en15031032

Lv J, Wang S, Meng B. The Effects of Nano-Additives Added to Diesel-Biodiesel Fuel Blends on Combustion and Emission Characteristics of Diesel Engine: A Review. Energies. 2022; 15(3):1032. https://doi.org/10.3390/en15031032

Chicago/Turabian StyleLv, Junshuai, Su Wang, and Beibei Meng. 2022. "The Effects of Nano-Additives Added to Diesel-Biodiesel Fuel Blends on Combustion and Emission Characteristics of Diesel Engine: A Review" Energies 15, no. 3: 1032. https://doi.org/10.3390/en15031032