Reduction of the Information Gap Problem in Industry 4.0 Projects as a Way to Reduce Energy Consumption by the Industrial Sector

Abstract

1. Introduction

G1: The identification of information components over the life cycle of the project from the client’s perspective.

G2: A characteristic of information gaps to identify information components.

2. The Development of Industry 4.0 Considering Sustainable Growth and Reduction of Energy Consumption—Literature Review

2.1. Energy Consumption Review

2.2. Sustainable Development and Energy-Consuming

- 1.

- Ecology—IT solutions allow for a switch from an energy-intensive economy to a model that considers the protection of the environment. This type of solution may concern

- Limiting the energy intensity of ICT (e.g., cloud data migration); and

- Limiting the energy intensity of industry solutions through ICT (e.g., using artificial intelligence)

In this area, we need to consider the results of research into information ecology. - 2.

- Society—allowing direct communication between employees and contractors and taking action in real time; and

- 3.

- Economy—leading to benefits in a way that does not eliminate the social and ecological benefits of stakeholders.

2.3. Project Management in Industry 4.0

- A hypothesis that can refer to information components that may be characterized by the users’ information gap;

- A business result, along with benefits, when the hypothesis is proven to be true; and

- Conditions that allow for the hypothesis to be fulfilled.

2.4. Information Gap in Industry 4.0 Projects

3. Research Methods

3.1. Research Goals

G1: The identification of information components in the entire life cycle of the researched project from the client’s perspective.

G2: A characteristic of information gaps for the identified information components.

3.2. Research Method

- A desire to perform a qualitative description of the entire life cycle of an ICT project spanning many years;

- The relevant characteristics of the projects resulting from the characteristics of Industry 4.0 projects and sustainably developing enterprises;

- The interdisciplinary character of the ICT projects;

- The observation of the information gap areas that cannot be studied using interviews during the project life cycle;

- The possibility of tracking the dynamics of the information gap during the project life cycle.

- Be concerned with ICT solutions belonging to the Industry 4.0 project group;

- Be implemented in enterprises that paid particular attention to sustainable growth;

- Be avant-garde; i.e., employees had no experience in implementing this type of projects; and

- Be implemented in a relatively large diversification of industries.

- The observed knew that the study was being carried out by a researcher from the Warsaw University of Technology conducting studies in IT project management;

- The strong requirement for privacy and confidentiality by the enterprises where the research was carried out was respected. The research description did not name the enterprises and the context described was at times slightly modified while ensuring credibility;

- The observed were treated as subjects;

- The majority of data characterizing the project over its life cycle was accessible.

4. Results

4.1. Information Components

- Pre-implementation—The creation of the problem domain model, a user-needs analysis and definition of the system’s functional requirements, analysis of the organization’s IT infrastructure, project group definition, identification of significant risk factors, ex ante economic analysis of the investment and preliminary definition of the implementation project;

- System and supplier selection—The preparation of a potential suppliers’ list, creation of Request for Proposal (RFP) forms, analysis and evaluation of offers according to established criteria, substantive and trade negotiations, and contract formulation. The result of the first, preparatory stage was a selection of a system and a supplier; the completion of Phase 2 was a multi-dimensional task where many organizational, legal, social, and technical factors needed to be considered.

- Initiation—An implementation planning session as an initial meeting and a technological project consisting of the installation and configuration of components in the hardware layer, system software and application software layer;

- Analysis—Training for key users and a functional analysis that included analytical workshops and the designing of a theoretical prototype;

- Design—Customization of the project;

- Implementation—Preliminary data migration and acceptance testing for the completed customization along with tuning, developing workplace instructions and training for key users; and

- Go-live—System go-live and post-go-live support during system stabilization.

- Post-implementation analysis and identification of operational needs—covering tasks linked to an ex-post analysis of the implemented IT project and an identification of needs linked to system operation;

- Selection of an appropriate supplier of post-implementation services linked to system operation—covering the preparation of a potential suppliers’ list, creation of RFP forms, analysis and evaluation of offers according to established criteria, substantive and trade negotiations, and creation of Service Level Agreements (SLAs) [71].

- Managing the TCO of an IT system,

- Implementing functional and technological requirements linked to Green IT, and

- Managing risk and uncertainty in an IT project.

- The character of the project resulting from the energy consumption reduction and sustainable growth concept,

- The functional-technological character of the customization based on the technical possibilities of the parameterization and software,

- The level of investment in the knowledge of the project group regarding the project and the concept of reduced energy consumption (sustainable growth) during the first stage, and

- The level of trust between among members of the project group.

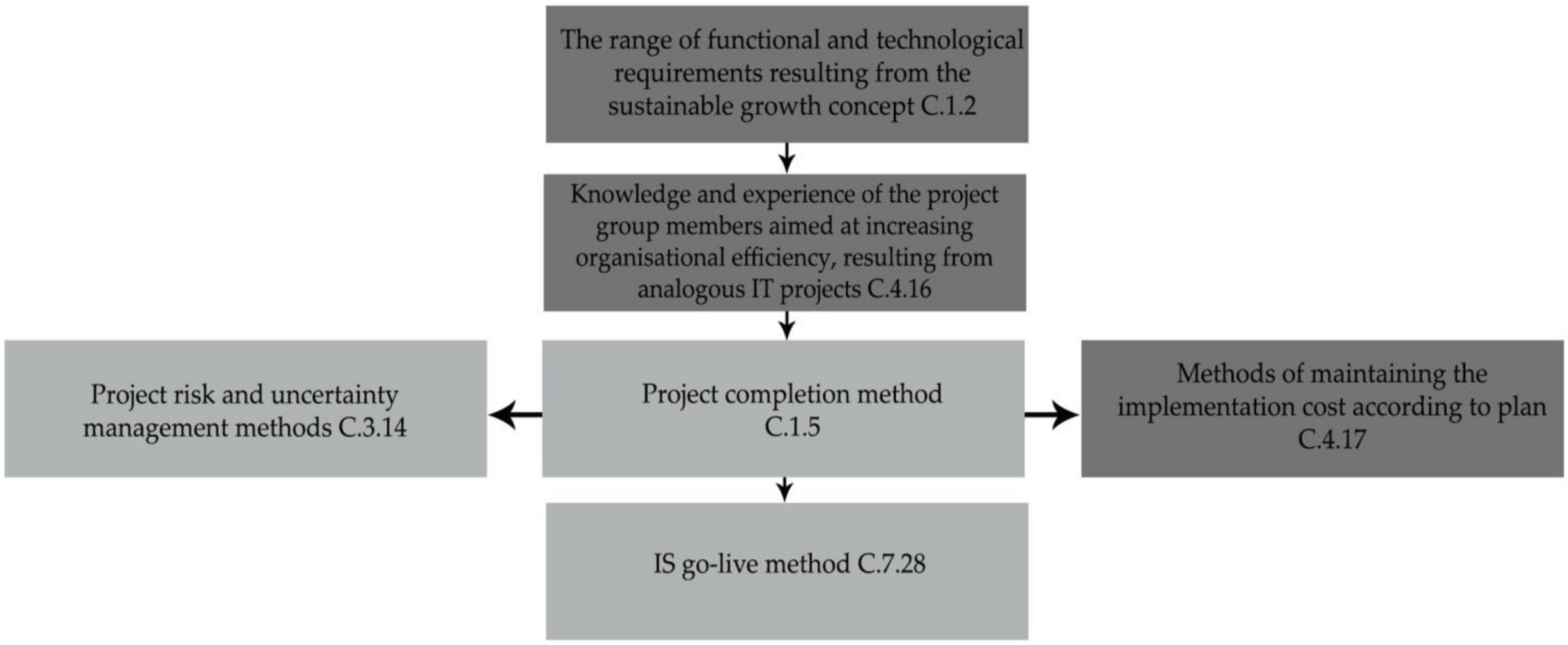

4.2. Inheriting Information Gaps

- Agreeing on advantageous trade conditions of license purchases of the software and external outsourcing services, both for Stage 2 and 3 of the project life cycle,

- Recommendations resulting from reduced energy consumption and the sustainable growth concept (Green IT) regarding Industry 4.0 project completion,

- The security of business activity in influencing development possibilities of the IT system and security of data access.

- The knowledge and experience of project group members regarding the concept of sustainable growth and

- Risk and uncertainty management following the concept of sustainable growth.

5. Discussion

- Structured issues (solving resource problems, scheduling turbulence, or choosing an optimal type of services or license in the context of the project’s TCO) and

- More abstract issues, based on Big Data, scientific theories, empirical knowledge, as well as contextual knowledge and understanding, i.e., selecting a model structure, completing a prognosis, or formulating a policy.

- The shaping of beneficial economic relations between the supplier and the recipient of services,

- Maintaining the TCO of the implemented IT system on the planned level,

- Defining the functional and business requirements of the system and confronting them with the Green IT concept, and

- Managing risk and uncertainty.

6. Conclusions

- The surveyed enterprises operated in Poland;

- The projects were implemented in a mixed manner by both specialized suppliers and customers, but the information gap was only studied from the perspective of the client’s project manager; and

- The projects were implemented in medium enterprises and the SME group

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- International Energy Outlook. 2019. Available online: https://www.eia.gov/outlooks/ieo/pdf/IEO2021_Narrative.pdf (accessed on 1 December 2021).

- Hermann, M.; Pentek, T.; Otto, B. Design Principles for Industry 4.0 Scenarios: A Literature Review; Working Paper No. 01, 2015; Technische Universität Dortmund: Dortmund, Germany, 2015. [Google Scholar]

- Rajkumar, R.; Lee, I.; Sha, L.; Stankovic, J. Cyber-physical systems: The next computing revolution. In Proceedings of the 47th Design Automation Conference (DAC ‘10), Anaheim, CA, USA, 13–18 June 2010; Association for Computing Machinery: New York, NY, USA, 2010; pp. 731–736. [Google Scholar] [CrossRef]

- Buxmann, P.; Hess, T.; Ruggaber, R. Internet of Services. Bus. Inf. Syst. Eng. 2009, 1, 341. [Google Scholar] [CrossRef]

- Eurostat. [NRG_BAL_S]. Available online: http://eurostat.ec.europa.eu (accessed on 1 December 2021).

- Madlool, N.A.; Saidur, R.; Rahim, N.A.; Kamalisarvestani, M. An overview of energy savings measures for cement industries. Renew. Sustain. Energy Rev. 2013, 19, 18–29. [Google Scholar] [CrossRef]

- Madlool, N.A.; Saidur, R.; Hossain, M.S.; Rahim, N.A. A critical review on energy use and savings in the cement industries. Renew. Sustain. Energy Rev. 2011, 15, 2042–2060. [Google Scholar] [CrossRef]

- Ke, J.; Zheng, N.; Fridley, D.; Price, L.; Zhou, N. Potential energy savings and CO2 emissions reduction of China’s cement industry. Energy Policy 2012, 45, 739–751. [Google Scholar] [CrossRef]

- Thirugnanasambandam, M.; Hasanuzzaman, M.; Saidur, R.; Ali, M.B.; Rajakarunakaran, S.; Devaraj, D.; Rahim, N.A. Analysis of electrical motors load factors and energy savings in an Indian cement industry. Energy 2011, 36, 4307–4314. [Google Scholar] [CrossRef]

- Galitsky, C.; Price, L.; Zhou, N.; Fuqiu, Z.; Huawen, X.; Xuemin, Z.; Lan, W. Guidebook for Using the Tool BEST Cement: Benchmarking and Energy Savings Tool for the Cement Industry; (No. LBNL-1989E); Lawrence Berkeley National Lab. (LBNL): Berkeley, CA, USA, 2008. [Google Scholar]

- Czosnyka, M.; Wnukowska, B.; Karbowa, K. Energy efficiency as a base of the energy economy in a modern industrial plants. In Proceedings of the 2018 Progress in Applied Electrical Engineering (PAEE), Koscielisko, Poland, 18–22 June 2018; IEEE: New York, NY, USA, 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Leites, I.L.; Sama, D.A.; Lior, N. The theory and practice of energy saving in the chemical industry: Some methods for reducing thermodynamic irreversibility in chemical technology processes. Energy 2003, 28, 55–97. [Google Scholar] [CrossRef]

- Bujak, J. Energy savings and heat efficiency in the paper industry: A case study of a corrugated board machine. Energy 2008, 33, 1597–1608. [Google Scholar] [CrossRef]

- Johnsson, S.; Andersson, E.; Thollander, P.; Karlsson, M. Energy savings and greenhouse gas mitigation potential in the Swedish wood industry. Energy 2019, 187, 115919. [Google Scholar] [CrossRef]

- Shao, Y. Analysis of energy savings potential of China’s nonferrous metals industry. Resour. Conserv. Recycl. 2017, 117, 25–33. [Google Scholar] [CrossRef]

- Wolniak, R.; Saniuk, S.; Grabowska, S.; Gajdzik, B. Identification of energy efficiency trends in the context of the development of industry 4.0 using the polish steel sector as an example. Energies 2020, 13, 2867. [Google Scholar] [CrossRef]

- Xu, Y.; Szmerekovsky, J. System dynamic modeling of energy savings in the US food industry. J. Clean. Prod. 2017, 165, 13–26. [Google Scholar] [CrossRef]

- Diaz, N.; Ninomiya, K.; Noble, J.; Dornfeld, D. Environmental impact characterization of milling and implications for potential energy savings in industry. Procedia CIRP 2012, 1, 518–523. [Google Scholar] [CrossRef]

- Price, L. Voluntary Agreements for Energy Efficiency or GHG Emissions Reduction in Industry: An Assessment of Programs Around the World. Presented at the Proceedings of the 2005 ACEEE Summer Study on Energy Efficiency in Industry, New York, NY, USA, June 2005. Available online: https://www.osti.gov/servlets/purl/881402 (accessed on 1 December 2021).

- Modig, G. Evaluation of the Industrial Energy Efficiency Network in Norway. Report Prepared within the AID-EE Project, Ecofys. Available online: www.aid-ee.org/documents (accessed on 1 June 2017).

- Schüle, R. Evaluation of Energy Concepts for Trade and Industry Sectors (ECTIS) in North Rhine-Westphalia. ECOFYS/Active Implementation of the European Directive on Energy Efficiency. 2006. Available online: https://www.academia.edu/50048010/Evaluation_of_Energy_Concepts_for_Trade_and_Industry_Sectors_Ectis_in_North_Rhine_Westphalia (accessed on 1 December 2021).

- Rezessy, S.; Bertoldi, P. Top down energy efficiency indicators in the scope of Directive 2006/32/EC. In Proceedings of the ODYSSEE—MURE Workshop, Madrid, Spain, 21–22 June 2010. [Google Scholar]

- SenterNovem. Long-Term Agreement on Energy Efficiency in the Netherlands LTA3. Results of 2009; SenterNovem: The Hague, The Netherlands, 2010.

- Mingay, S. Green IT: The New Industry Shock Wave. Gartner Inc., 2007. Available online: http://download.microsoft.com/download/E/F/9/EF9672A8-592C-4FA2-A3BF-528E93DF44EA/VirtualizationPublicSafety_GreenITWhitepaper.pdf (accessed on 1 December 2021).

- Murugesan, S. Harnessing green IT: Principles and practices. IT Prof. 2008, 10, 24–33. [Google Scholar] [CrossRef]

- Murugesan, S. Making IT green. IT Prof. 2010, 12, 4–5. [Google Scholar] [CrossRef]

- Chou, D.C.; Chou, A.Y. Awareness of Green IT and its value model. Comput. Stand. Interfaces 2012, 34, 447–451. [Google Scholar] [CrossRef]

- Chou, D.C. Risk identification in Green IT practice. Comput. Stand. Interfaces 2013, 35, 231–237. [Google Scholar] [CrossRef]

- Solow, R. A contribution to the theory of economic growth. Q. J. Econ. 1956, 70, 65–94. [Google Scholar] [CrossRef]

- Baumol, W.J.; Litan, R.E.; Schramm, C.J. Good Capitalism, Bad Capitalism, and the Economics of Growth and Prosperity; Yale University Press: New Haven, CT, USA, 2009; ISBN 978-0-300-15832-8. [Google Scholar]

- Mazur-Wierzbicka, E. Koncepcja zrównoważonego rozwoju jako podstawa gospodarowania środowiskiem przyrodniczym. In Funkcjonowanie Gospodarki Polskiej w Warunkach Integracji i Globalizacji; Kopycińska, W.D., Ed.; Wydawnictwo Uniwersytetu Szczecińskiego: Szczecin, Poland, 2005. [Google Scholar]

- Rudyk, T.; Szczepański, E.; Jacyna, M. Safety factor in the sustainable fleet management model. Arch. Transp. 2019, 49, 103–114. [Google Scholar] [CrossRef]

- Jacyna, M.; Wasiak, M.; Lewczuk, K.; Chamier-Gliszczyński, N.; Dąbrowski, T. Decision problems in developing proecological transport system. Rocz. Ochr. Srodowiska 2018, 20, 1007–1025. [Google Scholar]

- Pyza, D.; Jacyna-Gołda, I.; Gołda, P.; Gołębiowski, P. Alternative fuels and their impact on reducing pollution of the natural environment. Rocz. Ochr. Srodowiska 2018, 20, 819–836. [Google Scholar]

- Pearce, D.W.; Turner, R.K. Economics of Natural Resources and the Environment; Harvester Wheatsheaf: London, UK, 1990; ISBN 0-7450-0225-0. [Google Scholar]

- Molla, A.; Cooper, V. Green IT readiness: A framework and preliminary proof of concept. Australas. J. Inf. Syst. 2009, 16, 5–23. [Google Scholar] [CrossRef]

- Howard, G.R.; Lubbe, S. Synthesis of Green IS Frameworks for Achieving Strong Environmental Sustainability in Organisations. In Proceedings of the South African Institute for Computer Scientists and Information Technologists Conference, Pretoria, South Africa, 1–3 October 2012. [Google Scholar] [CrossRef]

- Izdebski, M.; Jacyna-Gołda, I.; Gołebiowski, P.; Pyza, D.; Żak, J. Decision problems in designing database architecture for the assessment of logistics services. Zesz. Nauk. Transp. Politech. Śląska 2020, 108, 53–71. [Google Scholar] [CrossRef]

- Penzenstadler, B. Infusing Green: Requirements Engineering for Green in and through Software Systems; University of California: Irvine, CA, USA, 2015; Available online: http://ceur-ws.org/Vol-1216/paper8.pdf (accessed on 16 April 2021).

- Andreopoulou, Z.S. Green informatics: ICT for green and sustainability. J. Agric. Inform. 2012, 3, 1–8. [Google Scholar] [CrossRef]

- Lewczuk, K.; Kłodawski, M. Logistics information processing systems on the threshold of IoT. Zesz. Nauk. Transp. Politech. Śląska 2020, 107, 85–94. [Google Scholar] [CrossRef]

- Lewczuk, K.; Kłodawski, M.; Gepner, P. Energy consumption in a distributional warehouse: A practical case study for different warehouse technologies. Energies 2021, 14, 2709. [Google Scholar] [CrossRef]

- Cieśla, M.; Sobota, A.; Jacyna, M. Multi-Criteria decision making process in metropolitan transport means selection based on the sharing mobility idea. Sustainability 2020, 12, 7231. [Google Scholar] [CrossRef]

- Stypułkowski, K.; Gołda, P.; Lewczuk, K.; Tomaszewska, J. Monitoring system for railway infrastructure elements based on thermal imaging analysis. Sensors 2021, 21, 3819. [Google Scholar] [CrossRef]

- Radu, S. Poland Graduates to Developed Status. U.S. News, 2 October 2018. Available online: https://www.usnews.com/news/best-countries/articles/2018-10-02/poland-reclassified-as-a-developed-economy-by-the-ftse (accessed on 16 April 2021).

- Cao, J.Q.; Zhang, S.H. ITIL Incident management process reengineering in industry 4.0 environments. In Proceedings of the 2nd International Conference on Advances in Mechanical Engineering and Industrial Informatics (AMEII 2016), Hangzhou, China, 9–10 April 2016; Volume 73, pp. 1011–1016. [Google Scholar] [CrossRef][Green Version]

- Izdebski, M.; Jacyna-Gołda, I.; Wasiak, M.; Jachimowski, R.; Kłodawski, M.; Pyza, D.; Żak, J. The application of the genetic algorithm to multi-criteria warehouses location problems on the logistics network. Transport 2018, 33, 741–750. [Google Scholar] [CrossRef]

- Walker, W.E.; Marchau, V.A.W.J.; Swanson, D. Addressing deep uncertainty using adaptive policies: Introduction to section 2. Technol. Soc. Change 2010, 77, 917–923. [Google Scholar] [CrossRef]

- Jacyna, M.; Semenov, I. Models of vehicle service system supply under information uncertainty. Eksploat. I Niezawodn. Maint. Reliab. 2020, 22, 694–704. [Google Scholar] [CrossRef]

- Bland, D.J.; Osterwalder, A. Testing Business Ideas: Field Guide for Rapid Experimentation; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2019. [Google Scholar]

- Geissdoerfer, M.; Bocken, N.M.P.; Hultink, E.J. Design thinking to enhance the sustainable business modelling process—A workshop based on a value mapping process. J. Clean. Prod. 2016, 135, 1218–1232. [Google Scholar] [CrossRef]

- Cosenz, F.; Noto, G. A dynamic business modelling approach to design and experiment new business venture strategies. Long Range Plann. 2018, 51, 127–140. [Google Scholar] [CrossRef]

- Marchau, V.A.W.J.; Walker, W.E.; Bloemen, P.J.T.M.; Popper, S.W. Decision Making under Deep Uncertainty from Theory to Practice; Springer International Publishing: Berlin/Heidelberg, Germany, 2019; ISBN 978-3-030-05252-2. [Google Scholar]

- Ben-Haim, Y. Info-Gap Decision Theory: Decisions under Severe Uncertainty; Academic Press: London, UK, 2006; ISBN 978-149-330-098-3. [Google Scholar]

- Oleński, J. Ekonomika Informacji. Metody; PWE: Warsaw, Poland, 2003; p. 20. [Google Scholar]

- Wachnik, B. Luka Informacyjna w Przedsięwzięciach Informatycznych. Problemy i Rozwiązania; Polskie Wydawnictwo Ekonomiczne: Warszawa, Poland, 2020; ISBN 978-83-208-2416-2. [Google Scholar]

- Babik, W. Zarządzanie Informacją we Współczesnych Systemach Informacyjno-Wyszukiwawczych—Nowe Wyzwania Współczesności. Zag. Inf. Nauk. 2000, 1, 51–63. [Google Scholar]

- The Big6. Available online: http://www.big6.com (accessed on 16 April 2021).

- The Society of College, National and University Libraries (SCONUL). Available online: http://www.sconul.ac.uk (accessed on 16 April 2021).

- Ciesielska, M.; Wolnia-Bostrom, K.; Ohlander, M. Obserwacja. In Badania Jakościowe. Metody i Narzędzia; Jemielniak, D., Ed.; Wydawnictwo Naukowe PWN: Warszawa, Poland, 2012; Volume 2, pp. 41–67. [Google Scholar]

- Czakon, W. Podstawy Metodologii Badań w Naukach o Zarządzaniu; Oficyna Wolters Kluwer Business: Warszawa, Poland, 2011. [Google Scholar]

- Microsoft. Available online: https://www.microsoft.com (accessed on 16 April 2021).

- SAP. Available online: http://www.sap.com (accessed on 16 April 2021).

- Bradley, K. Podstawy Metodyki PRINCE II CRM S.A.; Centrum Rozwiązań Menadżerskich: Warszawa, Poland, 2002. [Google Scholar]

- Esteves, J.; Bohorquez, V. An Updated ERP Systems Annotated Bibliography: 2001–2005. Commun. Assoc. Inf. Syst. 2007, 19, 1–59. [Google Scholar]

- Esteves, J.; Pastor, J.A. Organizational and technological critical success factors behavior along the ERP implementation phases. In Proceedings of the 6th International Conference on Enterprise Information Systems, Porto, Portugal, 14–17 April 2004; Seruca, I., Filipe, J., Hammoudi, S., Cordeiro, J., Eds.; pp. 45–53. [Google Scholar] [CrossRef]

- Chang, S.I. ERP Life cycle implementation, management and support. Implications for practice and research. In Proceedings of the 37th Annual Hawaii International Conference on System Sciences, Hawaii, HI, USA, 5–8 January 2004. [Google Scholar] [CrossRef][Green Version]

- Nguyen, T.H.; Sherif, J.S.; Newby, M. Strategies for Successful CRM Implementation. Inf. Manag. Comput. Secur. 2007, 15, 102–115. [Google Scholar] [CrossRef]

- Best Practice Solutions. Available online: https://www.axelos.com/best-practice-solutions/prince2 (accessed on 16 April 2021).

- Itil. Available online: https://www.itlibrary.org/ (accessed on 16 April 2021).

- Auksztol, J. Outsourcing Informatyczny w Teorii i Praktyce Zarządzania; Wydawnictwo Uniwersytetu Gdańskiego: Gdańsk, Poland, 2008. [Google Scholar]

- Deng, Q.; Ji, S. Organizational Green IT adoption: Concept and evidence. Sustainability 2015, 7, 16737–16755. [Google Scholar] [CrossRef]

- Bayo-Moriones, A.; Lera-López, F. A firm-level analysis of determinants of ICT adoption in Spain. Technovation 2007, 27, 352–366. [Google Scholar] [CrossRef]

- Greenpeace International. Make IT Green: Cloud Computing and Its Contribution to Climate Change. Greenpeace International: Amsterdam, The Netherlands, 30 March 2010. Available online: http://www.greenpeace.org/international/Global/international/planet-2/report/2010/3/makeit-green-cloud-computing.pdf (accessed on 27 February 2016).

- Wall, T.A.; Walker, W.E.; Marchau, V.A.W.J.; Bertolini, L. Dynamic adaptive approach to transportation-infrastructure planning for climate change: San-Francisco-Bay-Area case study. J. Infrastruct. Syst. 2015, 21, 05015004. [Google Scholar] [CrossRef]

- U.S. Army Heritage and Education Center. Who First Originated the Term VUCA (Volatility, Uncertainty, Complexity and Ambiguity)? Available online: https://usawc.libanswers.com/faq/84869 (accessed on 27 August 2021).

- Ben-Haim, Y. Info-Gap Economics. An Operational Introduction; Palgrave Macmillan: London, UK, 2010. [Google Scholar]

- Ben-Haim, Y. What Strategic Planners Need to Know, Workshop on Strategic Uncertainty in National Security, Samuel Neaman Institute, Technion, 26 June 2018. Available online: https://info-gap.technion.ac.il/files/2018/06/stpl007.pdf (accessed on 7 September 2020).

- Ben-Haim, Y. Robust satisficing and the probability of survival. Int. J. Syst. Sci. 2014, 45, 3–19. [Google Scholar] [CrossRef]

- Regev, S.; Shtub, A.; Ben-Haim, Y. Managing project risks as knowledge gaps. Proj. Manag. J. 2006, 37, 17–25. [Google Scholar] [CrossRef]

| Stage 1 | Formulating the research question |

| Stage 2 | Selection of cases |

| Stage 3 | Development of data-collection tools |

| Stage 4 | Fieldwork |

| Stage 5 | Data analysis |

| Stage 6 | Formulating generalizations |

| Stage 7 | Confrontation with the literature |

| Stage 8 | Study conclusion—generalization |

| A | B | C | D | E | |

|---|---|---|---|---|---|

| Enterprise description | Furniture production | Food manufacturing | Transport services | Production of car components | Financial services |

| Project description | Infrastructure transfer to Cloud | Using Big Data to identify business-marketing data | Using IoT to monitor the work of the transport fleet | Implementation of an AI-based system identifying defective products | Digitization of the invoice documents introduced into the financial module of the ERP system |

| Benefits resulting from the project that has an impact on sustainable development | Limiting the use of Resources | Making better decisions | Extending the life cycle of the transport fleet | Limiting the number of defective components being released into the market | Lower paper usage |

| Number of participants | 50 | 40 | 120 | 5 | 25 |

| Studied project duration (phase/completion time) | F 1—3 months F 2—1 month F 3—2 years | F 1—6 months F 2—6 months F 3—1 year | F 1—6 months F 2—2 months F 3—2 years | F 1—6 months F 2—1 month F 3—2 years | F 1—3 months F 2—3 months F 3—2 years |

| Stage 1 | Phase 1 | Competence in estimating the TCO in the entire project life cycle C.1.1 | Functional and technological requirements range resulting from the sustainable growth concept C.1.2 | The structure of the IT implementation project group and the role and responsibility of its members during the project completion C.1.3 | A precise definition of the technological and functional requirements for the system C.1.4 | Project completion method C.1.5 | |||

| Stage 2 | Phase 2 | Security of data access C.2.6 | Methods of charging the license fee C.2.7 | The right to modify the completed customization, inc. the right to source code modification C.2.8 | Integration with other IT systems C.2.9 | Project schedule C.2.10 | Project completion method C.1.5 | Future SI development of the producer and future license price policy C.2.11 | Functional and technological requirements |

| Stage 2 | Phase 3 | Project documentation and completion methods C.3.13 | Methods of risk and project uncertainty management C.3.14 | Project schedule C.2.10 | The role and responsibility of the project group members during the implementation C.3.15 | Project completion method C.1.5 | - |

| Stage 2 | Phase 4 | Knowledge and experience of the project group members that can make the organization more efficient, resulting from analogous IT projects C.4.16 | Methods of maintaining implementation costs according to plan C.4.17 | Functional and technological requirements range resulting from the sustainable growth concept C.2.13 | Methods of collecting functional requirements by the project group members during the functional analysis C.4.18 | Methods of functional and technological knowledge transfer C.4.19 | Methods of risk and project uncertainty management C.3.14 |

| Stage 2 | Phase 5 | Internal testing methods for the completed customization C.5.20 | Documentation methods of the completed customization C.5.21 | The impact of customization method selection on the TCO of the IS C.5.22 | Functional and technological requirements range resulting from the sustainable growth concept C.2.13 | Competence in the area of communication in a project based on remote working C.5.23 | Methods of risk and project uncertainty management C.3.14 |

| Stage 2 | Phase 6 | Data migration methods C.6.24 | Knowledge transfer methods C.6.25 | Functional and technological requirements range resulting from the sustainable growth concept C.2.13 | Methods of system tuning completion after receiving the results of acceptance testing C.6.26 | Competence in the area of communication in a project based on remote working C.5.23 | Methods of acceptance testing completion C.6.27 |

| Stage 2 | Phase 7 | System go-live method C.7.28 | Methods of risk and project uncertainty management C.3.14 | Project schedule C.2.10 | Competence in the area of communication in a project based on remote working C.5.23 | Functional and technological requirements range resulting from the sustainable growth concept C.2.13 | - |

| Stage 3 | Phase 8 | Identification of needs linked to the system’s functional development C.8.29 | Economic evaluation (ex-post) of the IT project completion C.8.30 | Methods of risk and project uncertainty management C.3.14 | Project schedule C.2.10 | Functional and technological requirements range resulting from the sustainable growth concept C.2.13 |

| Stage 3 | Phase 9 | Range of development tasks C.9.30 | Operational task range C.9.31 | Methods of risk and project uncertainty management C.3.14 | Project schedule C.2.10 | Functional and technological requirements range resulting from the sustainable growth concept C.2.13 |

| A | B | C | D | E | |

|---|---|---|---|---|---|

| Enterprise type | Furniture production | Food manufacturing | Transport services | Production of car components | Financial services |

| Project type | Cloud migration of infrastructure | The use of Big Data for the identification of business-marketing data | The use of IoT to monitor the work of the transport fleet | Implementation of an AI-based system to identify poor quality products | Digitization of invoice documents introduced into the financial module of the ERP system |

| Time | ☑ | ☑ | ⚪ | ☑ | ☑ |

| Business range | ☑ | ⚪ | ☑ | ☑ | ☑ |

| Project completion cost | ☑ | ⚪ | ⚪ | ☑ | ☑ |

| Functional-technological requirements | ☑ | ☑ | ☑ | ☑ | ☑ |

| ☑ Criterion met | ⚪—Criterion not met | ||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wachnik, B.; Kłodawski, M.; Kardas-Cinal, E. Reduction of the Information Gap Problem in Industry 4.0 Projects as a Way to Reduce Energy Consumption by the Industrial Sector. Energies 2022, 15, 1108. https://doi.org/10.3390/en15031108

Wachnik B, Kłodawski M, Kardas-Cinal E. Reduction of the Information Gap Problem in Industry 4.0 Projects as a Way to Reduce Energy Consumption by the Industrial Sector. Energies. 2022; 15(3):1108. https://doi.org/10.3390/en15031108

Chicago/Turabian StyleWachnik, Bartosz, Michał Kłodawski, and Ewa Kardas-Cinal. 2022. "Reduction of the Information Gap Problem in Industry 4.0 Projects as a Way to Reduce Energy Consumption by the Industrial Sector" Energies 15, no. 3: 1108. https://doi.org/10.3390/en15031108

APA StyleWachnik, B., Kłodawski, M., & Kardas-Cinal, E. (2022). Reduction of the Information Gap Problem in Industry 4.0 Projects as a Way to Reduce Energy Consumption by the Industrial Sector. Energies, 15(3), 1108. https://doi.org/10.3390/en15031108