Recent Advances in Two-Phase Immersion Cooling with Surface Modifications for Thermal Management

Abstract

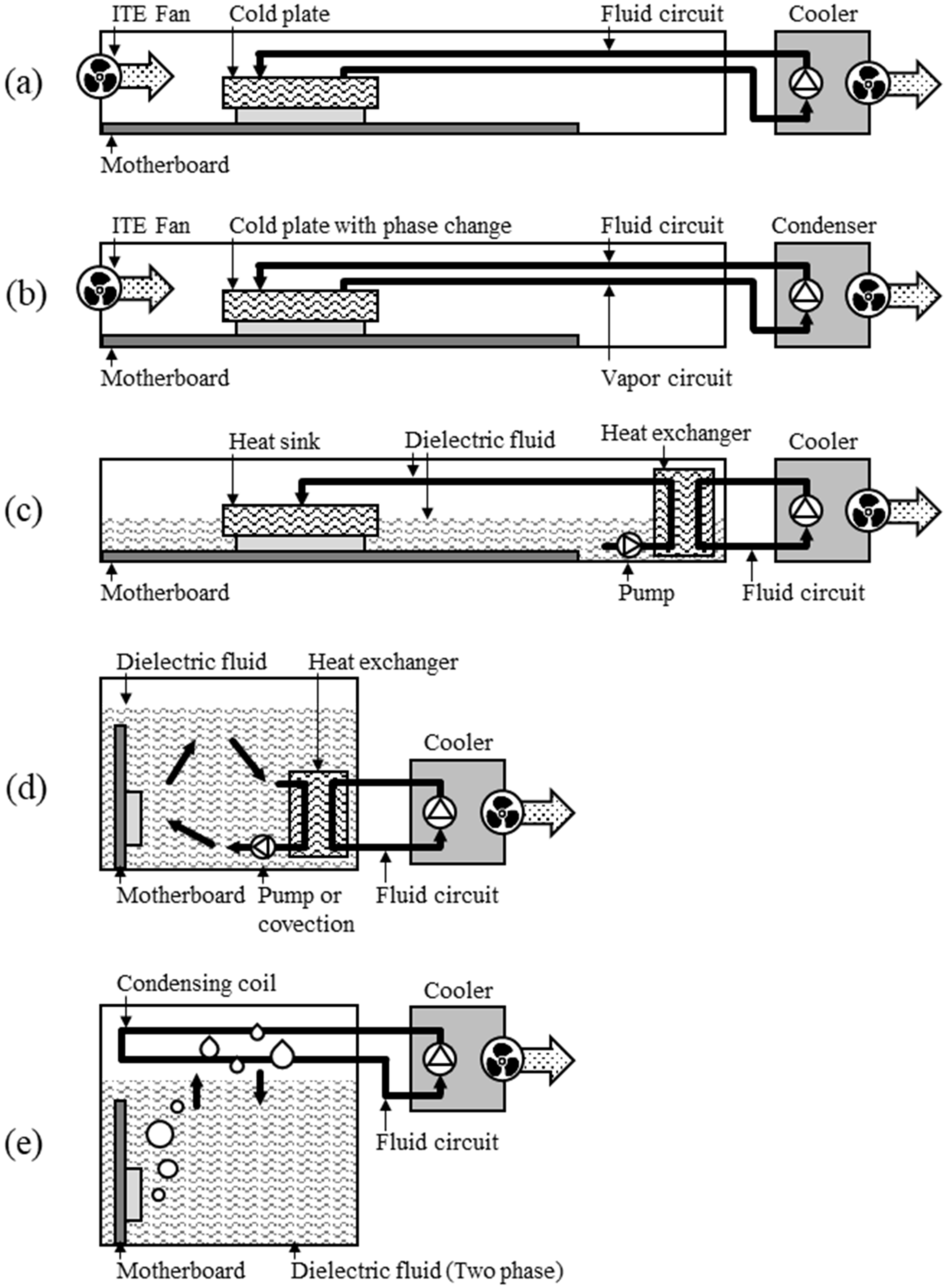

:1. Introduction

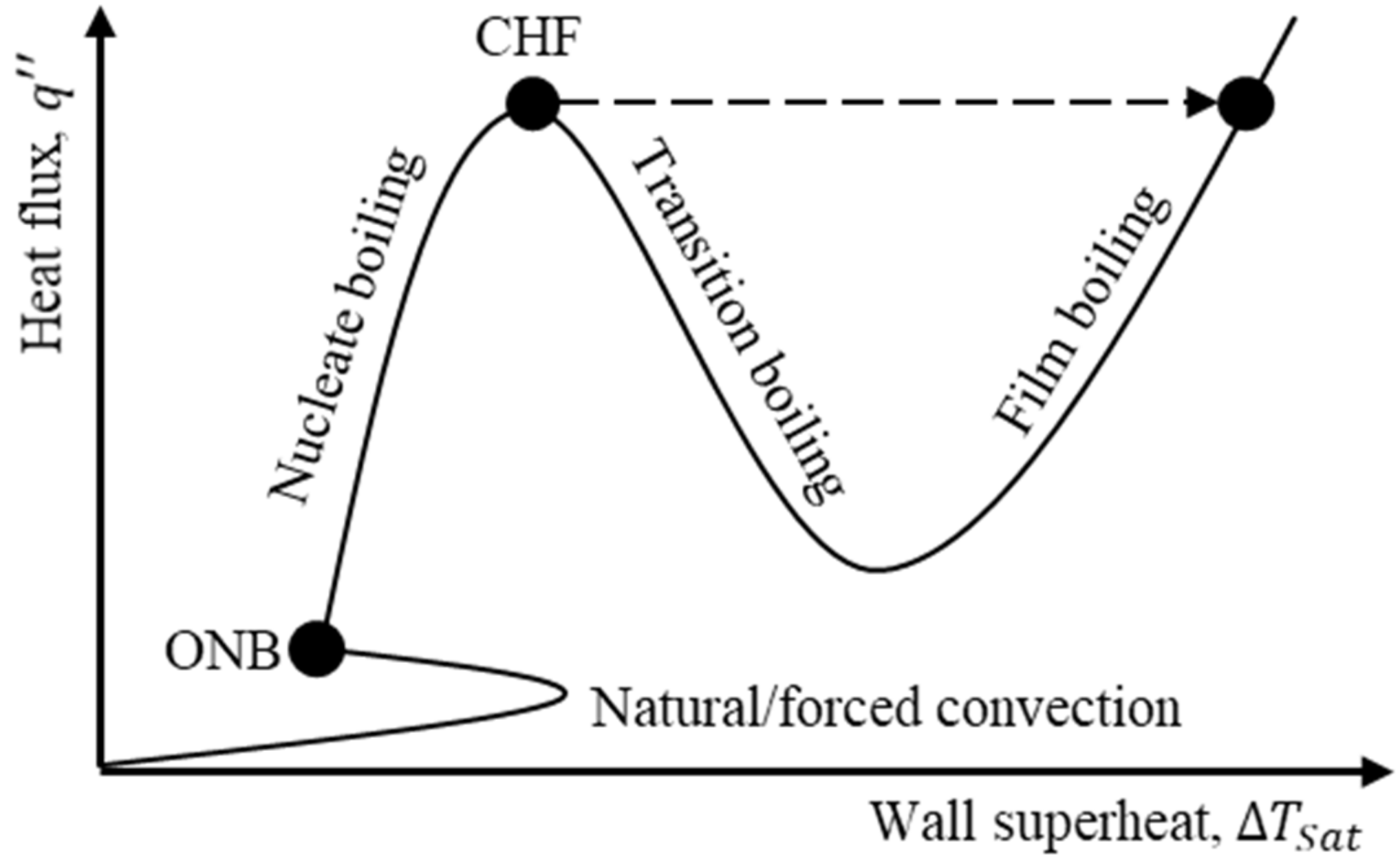

2. Two-Phase Boiling Heat Transfer Depending on the Morphology of the Heat Dissipating Structure

3. Surface Treatment

4. Porous Foam

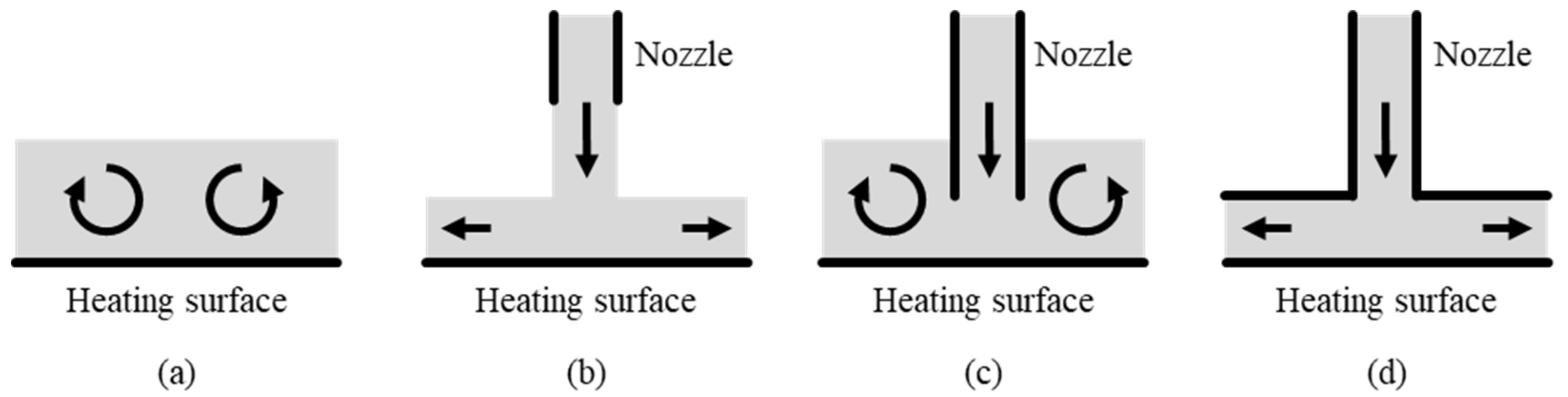

4.1. Effect of the Porous Foam

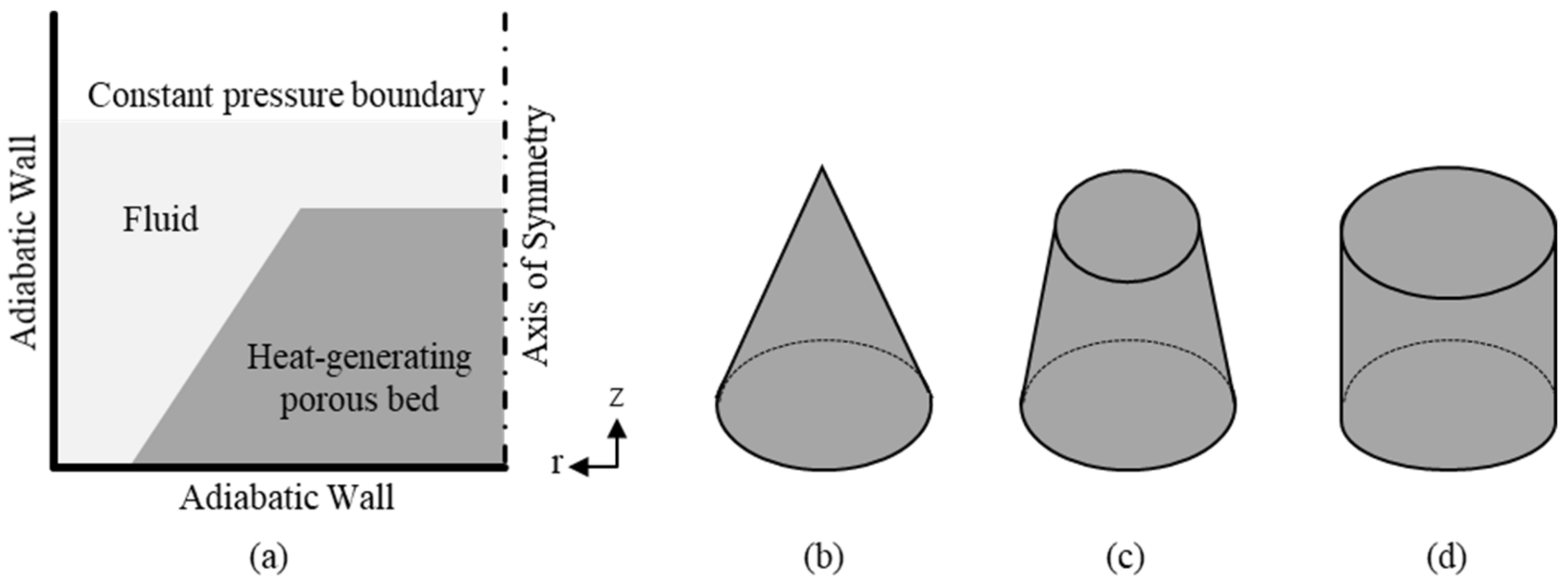

4.2. Modeling and Experimental Study

4.3. Applied Subjects

5. Sub-Structure Fabrication

5.1. Shape and Surface Conditions of Channels

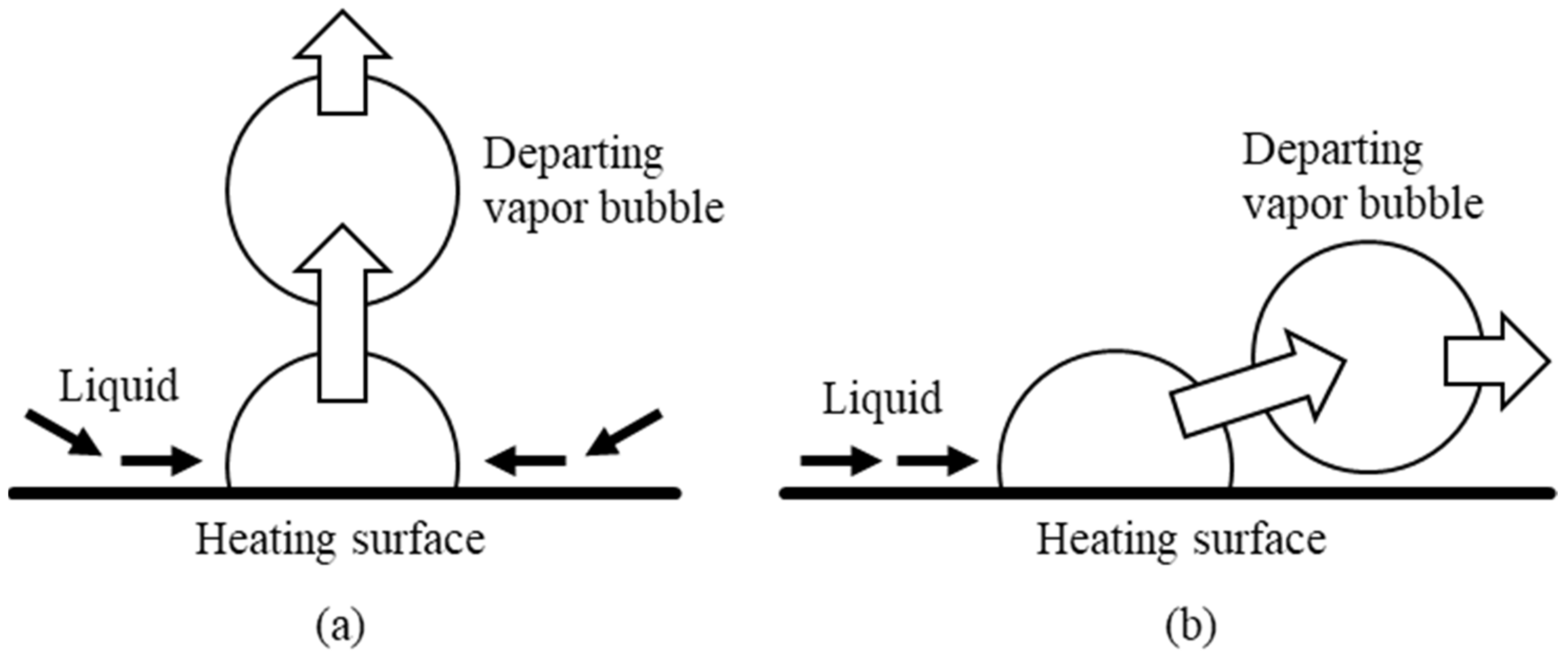

5.2. Buoyancy and Surface Tension

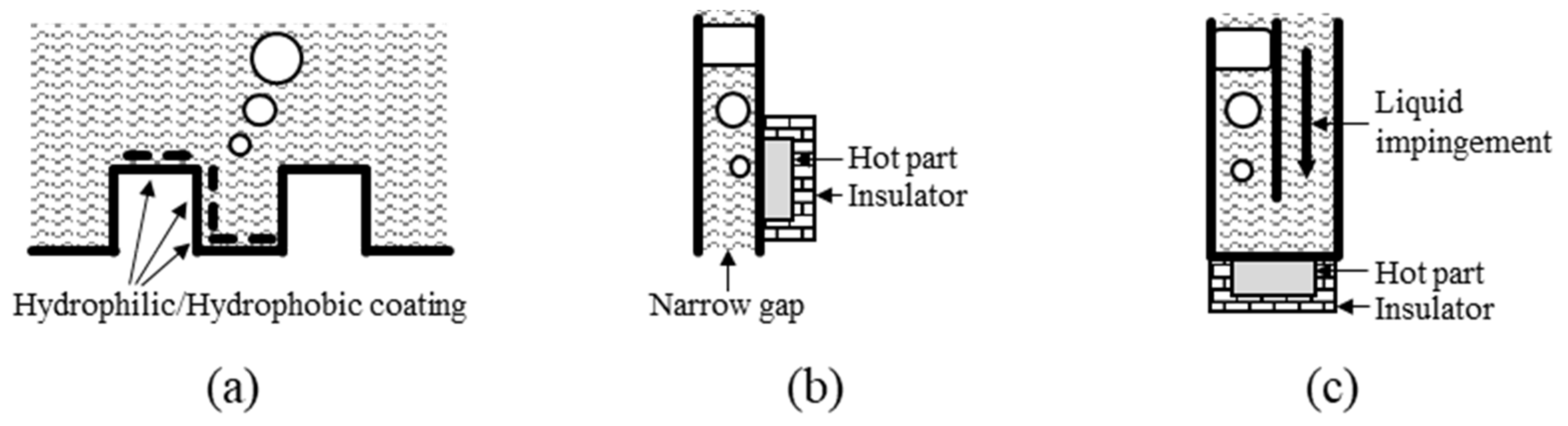

6. Convection Scheme by CHF and HTC

7. Patents

8. Future Research Needs

- (1)

- The bubble dynamics and energetic analysis of the chip level are well developed. However, economic analysis of the rack level is at an early stage.

- (2)

- PF liquids are prohibited by regulation. Experiments using new dielectric liquids under previous conditions are required. Water shows good heat transfer performance, but it is not dielectric.

- (3)

- The experimental conditions for the porous foam do not vary. Various combinations of pore size, particle size, porosity, and thickness may be possible.

- (4)

- There is concern that the porous foam or coating on the surface will fall off and the metal powder will harm the device. Research addressing these concerns is required.

- (5)

- The advantage of using a two-phase pool boiling immersion tub is the absence of a moving or controlling device. Therefore, it is important to show how the tub condition changes in a variable heat situation rather than a constant heat. The dynamic control of the condensing coil can be studied.

- (6)

- The boiling curve depends on the pressure applied to the fluid and not only on the surface condition. It is necessary to check whether there are benefits to increasing the performance by pressurizing the tanks rather than operating under atmospheric pressure. The idea of balancing the pressure between the auxiliary condensing space and the multi-tank can be studied.

- (7)

- Tall structures using gravity and buoyancy show a heat transfer performance as high as when using a pump. However, compared to the surface-level treatment, the volume becomes larger. Research is required to determine the economic feasibility of using a large volume versus improved heat transfer performance.

- (8)

- Methods to prevent leakage of dielectric liquid can be studied.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| C | Zuber Constant |

| CHF | Critical heat flux |

| COP | Coefficient of Performance |

| CRAC | Computer room air conditioner |

| CRAH | Computer room air handler |

| g | Gravity (m/s2) |

| GWP | Global Warming Point |

| h | Enthalpy (kJ/kg) |

| HTC | Heat transfer coefficient |

| ONB | Onset of nucleate boiling |

| PUE | Power usage effectiveness |

| q″ | Heat flux (kW/m2) |

| Ra | Surface average roughness (μm) |

| Temp. | Temperature |

| Greek letter | |

| ρ | Density (kg/m3) |

| σ | Surface tension (N/m) |

| Subscripts | |

| fg | Liquid to gas |

| l | Saturated liquid |

| v | Saturated vapor |

References

- Andrae, A.; Edler, T. On Global Electricity Usage of Communication Technology: Trends to 2030. Challenges 2015, 6, 117–157. [Google Scholar] [CrossRef] [Green Version]

- Uptime Institute. 2019 Annual Data Center Survey Results. 2019. Available online: https://datacenter.com/wp-content/uploads/2019/06/data-center-survey-2019.pdf (accessed on 13 December 2021).

- Habibi Khalaj, A.; Halgamuge, S.K. A Review on Efficient Thermal Management of Air- and Liquid-Cooled Data Centers: From Chip to the Cooling System. Appl. Energy 2017, 205, 1165–1188. [Google Scholar] [CrossRef]

- Fan, S.; Duan, F. A Review of Two-Phase Submerged Boiling in Thermal Management of Electronic Cooling. Int. J. Heat Mass Transf. 2020, 150, 119324. [Google Scholar] [CrossRef]

- Birbarah, P.; Gebrael, T.; Foulkes, T.; Stillwell, A.; Moore, A.; Pilawa-Podgurski, R.; Miljkovic, N. Water Immersion Cooling of High Power Density Electronics. Int. J. Heat Mass Transf. 2020, 147, 118918. [Google Scholar] [CrossRef]

- Ruch, P.; Brunschwiler, T.; Paredes, S.; Meijer, I.; Michel, B. Road Map Towards Ultimately Efficient Zeta-Scale Datacenters. In Proceedings of the 2013 Design, Automation & Test in Europe Conference & Exhibition (DATE), Grenoble, France, 18 March 2013. [Google Scholar] [CrossRef]

- Lin, P.; Day, T. Five Reasons to Adopt Liquid Cooling. 2019. Available online: https://download.schneider-electric.com/files?p_File_Name=WTOL-B9RKEA_R0_EN.pdf&p_Doc_Ref=SPD_WTOL-B9RKEA_EN&CFID=77719264&CFTOKEN=c7487997ff23526f-466392B3-C887-7624-3065912EA269F77B (accessed on 13 December 2021).

- Bennion, K.; Nrel, G.M. Thermal Management of Power Semiconductor Packages—Matching Cooling Technologies with Packaging Technologies (Presentation). National Renewable Energy Laboratory. 2010. Available online: https://www.nrel.gov/docs/fy10osti/48147.pdf (accessed on 13 December 2021).

- Moreno, G.; Bennion, K.; King, C.; Narumanchi, S. Evaluation of Performance and Opportunities for Improvements in Automotive Power Electronics Systems. In Proceedings of the 2016 15th IEEE Intersociety Conference Thermal and Thermomechanical Phenomena in Electronic Systems (ITherm), Las Vegas, NV, USA, 31 May 2016; pp. 185–192. [Google Scholar] [CrossRef] [Green Version]

- Burress, T.; Campbell, S. Benchmarking EV and HEV Power Electronics and Electric Machines. In Proceedings of the 2013 IEEE Transportation Electrification Conference and Expo. (ITEC), Detroit, MI, USA, 16 June 2013; pp. 1–6. [Google Scholar] [CrossRef]

- U.S. Department of Energy. FY 2016 Annual Progress Report for Electric Drive Technologies Program. 2017. Available online: https://www.osti.gov/biblio/1413876-fy2016-electric-drive-technologies-annual-progress-report (accessed on 13 December 2021).

- Lee, J.; Ki, S.; Seo, D.; Kim, J.; Nam, Y. Liquid Cooling Module Incorporating a Metal Foam and Fin Hybrid Structure for High Power Insulated Gate Bipolar Transistors (IGBTs). Appl. Therm. Eng. 2020, 173, 115230. [Google Scholar] [CrossRef]

- Ki, S.; Lee, J.; Ryu, S.; Bang, S.; Kim, K.; Nam, Y. A Bio-Inspired, Low Pressure Drop Liquid Cooling System for High-Power I.G.B.T. Modules for E.V./H.E.V. Applications. Int. J. Therm. Sci. 2021, 161, 106708. [Google Scholar] [CrossRef]

- Deng, Z.; Shen, J.; Dai, W.; Liu, Y.; Song, Q.; Gong, W.; Ke, L.; Gong, M. Flow and Thermal Analysis of Hybrid Mini-Channel and Slot Jet Array Heat Sink. Appl. Therm. Eng. 2020, 171, 115063. [Google Scholar] [CrossRef]

- Gould, K.; Cai, S.Q.; Neft, C.; Bhunia, A. Liquid Jet Impingement Cooling of a Silicon Carbide Power Conversion Module for Vehicle Applications. IEEE Trans. Power Electron. 2015, 30, 2975–2984. [Google Scholar] [CrossRef]

- Chen, D.; Jiang, J.; Kim, G.H.; Yang, C.; Pesaran, A. Comparison of Different Cooling Methods for Lithium Ion Battery Cells. Appl. Therm. Eng. 2016, 94, 846–854. [Google Scholar] [CrossRef] [Green Version]

- Rao, Z.; Qian, Z.; Kuang, Y.; Li, Y. Thermal Performance of Liquid Cooling Based Thermal Management System for Cylindrical Lithium-Ion Battery Module with Variable Contact Surface. Appl. Therm. Eng. 2017, 123, 1514–1522. [Google Scholar] [CrossRef]

- Jiaqiang, E.; Han, D.; Qiu, A.; Zhu, H.; Deng, Y.; Chen, J.; Zhao, X.; Zuo, W.; Wang, H.; Chen, J.; et al. Orthogonal Experimental Design of Liquid-Cooling Structure on the Cooling Effect of a Liquid-Cooled Battery Thermal Management System. Appl. Therm. Eng. 2018, 132, 508–520. [Google Scholar] [CrossRef]

- Alibaba Group, Immersion Cooling for Green Computing. 2018. Available online: https://www.opencompute.org/files/Immersion-Cooling-for-Green-Computing-V1.0.pdf (accessed on 13 December 2021).

- American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), American National Standards Institute (ANSI). Standard 34-2019 Designation and Safety Classification of Refrigerants. 2019. Available online: https://www.ashrae.org/technical-resources/standards-and-guidelines/ashrae-refrigerant-designations (accessed on 13 December 2021).

- Tschudi, B. Electronics Take a Bath. Lawrence Berkeley National Laboratory. 2014. Available online: https://datacenters.lbl.gov/sites/default/files/SVLG2014TSCHUDI10-24-2014.pdf (accessed on 7 January 2022).

- Jaikumar, A.; Kandlikar, S.G. Ultra-High Pool Boiling Performance and Effect of Channel Width with Selectively Coated Open Microchannels. Int. J. Heat Mass Transf. 2016, 95, 795–805. [Google Scholar] [CrossRef] [Green Version]

- Suszko, A.; El-Genk, M.S. Saturation Boiling of PF-5060 on Rough Cu Surfaces: Bubbles Transient Growth, Departure Diameter and Detachment Frequency. Int. J. Heat Mass Transf. 2015, 91, 363–373. [Google Scholar] [CrossRef]

- Theodore, D.P.D.; Bergman, L.; Lavine, A.S.; Incropera, F.P. Fundamentals of Heat and Mass Transfer, 8th ed.; Wiley & Sons: Hoboken, NJ, USA, 2018. [Google Scholar]

- White, C.S.; Nelms, R.M.; Johnson, R.W.; Grzybowski, R.R. High Temperature Electronic Systems Using Silicon Semiconductors. IEEE Ind. Appl. 1998, 2, 967–976. [Google Scholar] [CrossRef]

- El-Genk, M.S.; Bostanci, H. Saturation Boiling of HFE-7100 from a Copper Surface, Simulating a Microelectronic Chip. Int. J. Heat Mass Transf. 2003, 46, 1841–1854. [Google Scholar] [CrossRef]

- El-Genk, M.S.; Suszko, A. Saturation Nucleate Boiling and Correlations for PF-5060 Dielectric Liquid on Inclined Rough Copper Surfaces. J. Heat Transf. 2014, 136, 081503. [Google Scholar] [CrossRef]

- Suszko, A.; El-Genk, M.S. Dielectric Liquids Natural Convection on Small Rough Cu Surfaces at Different Orientations. Int. J. Heat Mass Transf. 2015, 81, 289–296. [Google Scholar] [CrossRef]

- Fan, S.; Jiao, L.; Wang, K.; Duan, F. Pool Boiling Heat Transfer of Saturated Water on Rough Surfaces with the Effect of Roughening Techniques. Int. J. Heat Mass Transf. 2020, 159, 120054. [Google Scholar] [CrossRef]

- Kanbur, B.B.; Wu, C.; Fan, S.; Tong, W.; Duan, F. Two-Phase Liquid-Immersion Data Center Cooling System: Experimental Performance and Thermoeconomic Analysis. Int. J. Refrig. 2020, 118, 290–301. [Google Scholar] [CrossRef]

- Ho, J.Y.; Wong, K.K.; Leong, K.C. Saturated Pool Boiling of FC-72 from Enhanced Surfaces Produced by Selective Laser Melting. Int. J. Heat Mass Transf. 2016, 99, 107–121. [Google Scholar] [CrossRef]

- Wong, K.K.; Leong, K.C. Saturated Pool Boiling Enhancement Using Porous Lattice Structures Produced by Selective Laser Melting. Int. J. Heat Mass Transf. 2018, 121, 46–63. [Google Scholar] [CrossRef]

- El-Genk, M.S.; Suszko, A. Effects of Inclination Angle and Liquid Subcooling on Nucleate Boiling on Dimpled Copper Surfaces. Int. J. Heat Mass Transf. 2016, 95, 650–661. [Google Scholar] [CrossRef]

- El-Genk, M.S.; Pourghasemi, M. Experimental Investigation of Saturation Boiling of HFE-7000 Dielectric Liquid on Rough Copper Surfaces. Therm. Sci. Eng. Prog. 2020, 15, 100428. [Google Scholar] [CrossRef]

- El-Genk, M.S.; Parker, J.L. Enhanced Boiling of HFE-7100 Dielectric Liquid on Porous Graphite. Energy Convers. Manag. 2005, 46, 2455–2481. [Google Scholar] [CrossRef]

- Jin, L.W.; Leong, K.C.; Pranoto, I. Saturated Pool Boiling Heat Transfer from Highly Conductive Graphite Foams. Appl. Therm. Eng. 2011, 31, 2685–2693. [Google Scholar] [CrossRef]

- El-Genk, M.S.; Parker, J.L. Nucleate Boiling of FC-72 and HFE-7100 on Porous Graphite at Different Orientations and Liquid Subcooling. Energy Convers. Manag. 2008, 49, 733–750. [Google Scholar] [CrossRef]

- El-Genk, M.S. Immersion Cooling Nucleate Boiling of High Power Computer Chips. Energy Convers. Manag. 2012, 53, 205–218. [Google Scholar] [CrossRef]

- Suszko, A.; El-Genk, M.S. Thermally Anisotropic Composite Heat Spreaders for Enhanced Thermal Management of High-Performance Microprocessors. Int. J. Therm. Sci. 2016, 100, 213–228. [Google Scholar] [CrossRef]

- Kiyomura, I.S.; Mogaji, T.S.; Manetti, L.L.; Cardoso, E.M. A Predictive Model for Confined and Unconfined Nucleate Boiling Heat Transfer Coefficient. Appl. Therm. Eng. 2017, 127, 1274–1284. [Google Scholar] [CrossRef] [Green Version]

- Chakravarty, A.; Datta, P.; Ghosh, K.; Sen, S.; Mukhopadhyay, A. Numerical Analysis of a Heat-Generating, Truncated Conical Porous Bed in a Fluid-Filled Enclosure. Energy 2016, 106, 646–661. [Google Scholar] [CrossRef]

- Chakravarty, A.; Datta, P.; Ghosh, K.; Sen, S.; Mukhopadhyay, A. Characteristics of Thermal Energy Removal from Heat-Generating Porous Media Considering Liquid–Vapour Phase Change. Int. J. Heat Mass Transf. 2020, 148, 119073. [Google Scholar] [CrossRef]

- El-Genk, M.S.; Ali, A.F. Enhancement of Saturation Boiling of PF-5060 on Microporous Copper Dendrite Surfaces. J. Heat Transf. 2010, 132, 071501. [Google Scholar] [CrossRef]

- El-Genk, M.S.; Ali, A.F. Enhanced Nucleate Boiling on Copper Micro-Porous Surfaces. Int. J. Multiph. Flow 2010, 36, 780–792. [Google Scholar] [CrossRef]

- Ali, A.F.; El-Genk, M.S. Effect of Inclination on Saturation Boiling of PF-5060 Dielectric Liquid on 80- and 137-μm Thick Copper Micro-Porous Surfaces. Int. J. Therm. Sci. 2012, 53, 42–48. [Google Scholar] [CrossRef]

- Ho, J.Y.; Leong, K.C.; Yang, C. Saturated Pool Boiling from Carbon Nanotube Coated Surfaces at Different Orientations. Int. J. Heat Mass Transf. 2014, 79, 893–904. [Google Scholar] [CrossRef]

- Manetti, L.L.; Ribatski, G.; de Souza, R.R.; Cardoso, E.M. Pool Boiling Heat Transfer of HFE-7100 on Metal Foams. Exp. Therm. Fluid Sci. 2020, 113, 110025. [Google Scholar] [CrossRef]

- Manetti, L.L.; Moita, A.S.O.H.; de Souza, R.R.; Cardoso, E.M. Effect of Copper Foam Thickness on Pool Boiling Heat Transfer of HFE-7100. Int. J. Heat Mass Transf. 2020, 152, 119547. [Google Scholar] [CrossRef]

- Xu, Z.G.; Zhao, C.Y. Thickness Effect on Pool Boiling Heat Transfer of Trapezoid-Shaped Copper Foam Fins. Appl. Therm. Eng. 2013, 60, 359–370. [Google Scholar] [CrossRef]

- Pranoto, I.; Leong, K.C.; Jin, L.W. The Role of Graphite Foam Pore Structure on Saturated Pool Boiling Enhancement. Appl. Therm. Eng. 2012, 42, 163–172. [Google Scholar] [CrossRef]

- Xu, Z.G.; Zhao, C.Y. Enhanced Boiling Heat Transfer by Gradient Porous Metals in Saturated Pure Water and Surfactant Solutions. Appl. Therm. Eng. 2016, 100, 68–77. [Google Scholar] [CrossRef]

- Kandlikar, S.G. Enhanced Macroconvection Mechanism with Separate Liquid–Vapor Pathways to Improve Pool Boiling Performance. J. Heat Transf. 2017, 139, 051501. [Google Scholar] [CrossRef]

- Cooke, D.; Kandlikar, S.G. Pool Boiling Heat Transfer and Bubble Dynamics over Plain and Enhanced Microchannels. J. Heat Transf. 2011, 133, 052902. [Google Scholar] [CrossRef]

- Cooke, D.; Kandlikar, S.G. Effect of Open Microchannel Geometry on Pool Boiling Enhancement. Int. J. Heat Mass Transf. 2012, 55, 1004–1013. [Google Scholar] [CrossRef]

- Kandlikar, S.G. Controlling Bubble Motion over Heated Surface Through Evaporation Momentum Force to Enhance Pool Boiling Heat Transfer. Appl. Phys. Lett. 2013, 102, 051611. [Google Scholar] [CrossRef] [Green Version]

- Patil, C.M.; Kandlikar, S.G. Pool Boiling Enhancement Through Microporous Coatings Selectively Electrodeposited on Fin Tops of Open Microchannels. Int. J. Heat Mass Transf. 2014, 79, 816–828. [Google Scholar] [CrossRef]

- Jaikumar, A.; Kandlikar, S.G. Enhanced Pool Boiling for Electronics Cooling Using Porous Fin Tops on Open Microchannels with FC-87. Appl. Therm. Eng. 2015, 91, 426–433. [Google Scholar] [CrossRef] [Green Version]

- Jaikumar, A.; Kandlikar, S.G. Pool Boiling Enhancement Through Bubble Induced Convective Liquid Flow in Feeder Microchannels. Appl. Phys. Lett. 2016, 108, 094107. [Google Scholar] [CrossRef]

- Raghupathi, P.A.; Kandlikar, S.G. Bubble Growth and Departure Trajectory Under Asymmetric Temperature Conditions. Int. J. Heat Mass Transf. 2016, 95, 824–832. [Google Scholar] [CrossRef]

- Wang, X.; Fadda, D.; Godinez, J.C.; Lee, J.; You, S.M. Capillary Evaporation of Water from Aluminum High-Temperature Conductive Microporous Coating. Int. J. Heat Mass Transf. 2020, 153, 119660. [Google Scholar] [CrossRef]

- Wang, X.; Fadda, D.; Godinez, J.C.; Lee, J.; You, S.M. Evaporation of Highly Wetting Fluids on Aluminum Microporous Coating. Int. J. Heat Mass Transf. 2020, 163, 120451. [Google Scholar] [CrossRef]

- Kim, J.S.; Shin, D.H.; You, S.M.; Lee, J. Pool Boiling Heat Transfer on Bare and Microporous Surfaces Confined in a Narrow Gap. Int. J. Heat Mass Transf. 2020, 162, 120329. [Google Scholar] [CrossRef]

- Dong, L.; Quan, X.; Cheng, P. An Analysis of Surface-Microstructures Effects on Heterogeneous Nucleation in Pool Boiling. Int. J. Heat Mass Transf. 2012, 55, 4376–4384. [Google Scholar] [CrossRef]

- Yuan, L.; Hong, F.; Cheng, P. Pool Boiling Enhancement Through a Guidance Structure Mounted Above Heating Surface. Int. J. Heat Mass Transf. 2019, 139, 751–763. [Google Scholar] [CrossRef]

- Law, K.W. Immersion Cooling. U.S. Patent Application No. 20170325355A1, 12 February 2019. [Google Scholar]

- Law, K.W.; Yi, T. Filter for Immersion Cooling Apparatus. U.S. Patent Application No. 10765983B2, 7 August 2020. [Google Scholar]

- Law, K.W. Two-phase Immersion Cooling Apparatus with Active Vapor Management. U.S. Patent Application No. 10966349B1, 30 March 2021. [Google Scholar]

- Enright, J.D.; Mertel, J. Liquid Immersion Cooling Platform. U.S. Patent Application No. 10477726B1, 12 November 2019. [Google Scholar]

- Enright, J.D.; Mertel, J. Liquid Immersion Cooling Platform. U.S. Patent Application No. 11102912B2, 24 August 2021. [Google Scholar]

- Enright, J.D.; Mertel, J. Robot for a Liquid Immersion Cooling System. U.S. Patent Application No. 10617032B1, 7 April 2020. [Google Scholar]

- Enright, J.D.; Mertel, J. Liquid Immersion Cooling Vessel and Components Thereof. U.S. Patent Application No. 10624237B2, 14 April 2020. [Google Scholar]

- Enright, J.D.; Mertel, J. Vapor Management System for a Liquid Immersion Cooling System. U.S. Patent Application No. 10653043B2, 12 May 2020. [Google Scholar]

- Enright, J.D.; Mertel, J.; Monnig, T.; Hadala, W. Absorption/Desorption Processes and Systems for Liquid Immersion Cooling. U.S. Patent Application No. 20210274677A1, 18 May 2021. [Google Scholar]

| Product Name | Chemical Formula | Boiling Temp. (°C) | GWP | Note |

|---|---|---|---|---|

| HFE-7000 | CF3CF2CF2OCH3 | 34 | 575 | |

| Novec-649 | C2F5C(O)CF(CF3)2 | 49 | 0.6 | |

| FC-72 | C6F14 | 56 | >5000 | High GWP |

| PF-5060 | CxFy | 56 | >5000 | High GWP |

| HFE-7100 | C4F9OCH3 | 61 | 320 | |

| HFE-7200 | C4F9OC2H5 | 76 | 55 | |

| HFE-7300 | C7H3F13O | 98 | 310 | |

| Water | H2O | 100 | - | Corrosive |

| Mineral oil | CnH2n+2 | >100 | - | Flammable |

| Ethylene Glycol | C2H4(OH)2 | >100 | 4 | Conductive |

| Surface | Liquid | CHF (W/cm2) | Max HTC (W/cm2K) | Reference |

|---|---|---|---|---|

| Smooth copper | HFE-7100 | 24.5 | - | 2003, El-Genk [26] |

| Roughened copper (Ra = 0.039–0.58 μm) | HFE-7000 | 30 | 1.9 | 2019, El-Genk [34] |

| PF-5060 | 20.6 | 1.44 | ||

| Roughened copper (Ra = 0.039–1.79 μm) | PF-5060 | 20.9 | 1.6 | 2014, El-Genk [27] |

| Roughened Copper (Ra = 0.039–1.79 μm) | PF-5060 | 21.5 | 1.67 | 2015, El-Genk [23] |

| Roughened copper (Ra = 0.045–1.22 μm) | Water | 120 | 10 | 2020, Duan [29] |

| Dimples on copper | PF-5060 | 19.3 | 1.06 | 2016, El-Genk [33] |

| Smooth copper | FC-72 | 47.9 | 1.27 | 2016, Leong [31] |

| Surface | Liquid | CHF (W/cm2) | Max HTC (W/cm2K) | Reference |

|---|---|---|---|---|

| Copper foam | PF-5060 | 3 | - | 2015, El-Genk [28] |

| Graphite foam | HFE-7100 | 66.4 | - | 2005, El-Genk [35] |

| Graphite foams | HFE-7000 | 112 | - | 2011, Leong [36] |

| FC-72 | 112 | - | ||

| Graphite foams | HFE-7000 | 112 | 3.58 | 2012, Leong [50] |

| FC-72 | 112 | 4.19 | ||

| Graphite foam | HFE-7100 | 33 | - | 2012, El-Genk [38] |

| FC-72 | 30 | 3.4 | ||

| Graphite foam | PF-5060 | 20.5 | 1.4 | 2016, El-Genk [39] |

| Copper foam Nickel foam | Water, n-pentane, FC-72, FC-87 | - | 0.6 | 2017, Manetti [40] |

| Copper foam | Water | - | - | 2016, Chakravarty [41] |

| Copper foam | Water | - | - | 2020, Chakravarty [42] |

| Graphite foam | HFE-7100 | 70 | 2.53 | 2008, El-Genk [37] |

| FC-72 | 60 | 3.79 | ||

| Copper foam | PF-5060 | 25.27 | 8.76 | 2010, El-Genk [43] |

| Copper foam | PF-5060 | 27.8 | 13.5 | 2010, El-Genk [44] |

| Copper foam | PF-5060 | 24.9 | 6.7 | 2012, El-Genk [45] |

| Coating on Silicon | FC-72 | 16.3 | 0.48 | 2014, Leong [46] |

| Copper foam Nickel foam | HFE-7100 | 27 | 1.24 | 2020, Manetti [47] |

| Copper foam | HFE-7100 | 40 | 2 | 2020, Manetti [48] |

| Surface | Liquid | CHF (W/cm2) | Max HTC (W/cm2K) | Reference |

|---|---|---|---|---|

| Silicon channel | Water | 97 | 7.23 | 2011, Kandlikar [53] |

| Silicon channel | Water | 244 | 24.4 | 2012, Kandlikar [54] |

| Silicon channel | Water | 300 | 62.9 | 2013, Kandlikar [55] |

| Carbon coating | Water | 325 | 99.5 | 2014, Kandlikar [56] |

| Carbon coating | FC-87 | 37 | 2.0 | 2015, Kandlikar [57] |

| Carbon coating | Water | 420 | 290 | 2016, Kandlikar [22] |

| Carbon coating | Water | 394 | 71.3 | 2016, Kandlikar [58] |

| Silicon channel | Water | 300 | 62.9 | 2016, Kandlikar [59] |

| Aluminum | Water | 1.49 | - | 2020, Lee [60] |

| Aluminum | Hydrocarbon | 0.16 | - | 2020, Lee [61] |

| Copper | Water | 205 | - | 2020, Lee [62] |

| Copper foam | Water | 147 | - | 2013, Zhao [48] |

| Copper foam Nickel foam | Water | 140 | - | 2016, Zhao [50] |

| Copper | Water | 109 | 3.88 | 2019, Cheng [64] |

| Lattice structure of aluminum alloy | FC-72 | 107 | 1.35 | 2018, Leong [32] |

| Bitfury | TMGCore |

|---|---|

| 2016-06-15 GB2549946A 2017-11-09 US 20170325355A1 [65] 2019-02-12 US10206307B2 (abandoned) | 2018-10-19 US11102912B2 2019-11-12 US10477726B1 [68] |

| 2016-06-29 GB2550356B 2017-11-16 US20170326489A1 2020-09-08 US10765983B2 [66] | 2020-03-19 US20200093026A1 2020-04-07 US10617032B1 [70] |

| 2021-03-30 US10966349B1 [67] | 2020-03-19 US20200093025A1 2020-04-14 US10624237B2 [71] |

| 2020-03-19 US20200093038A1 2020-05-12 US10653043B2 [72] | |

| 2020-03-19 US20200093032A1 2020-08-24 US11102912B2 [69] | |

| 2021-01-21 US20210022263A1 2021-05-18 US11013144B2 2021-09-02 US20210274677A1 [73] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kang, D.; Lee, J.; Chakraborty, A.; Lee, S.-E.; Kim, G.; Yu, C. Recent Advances in Two-Phase Immersion Cooling with Surface Modifications for Thermal Management. Energies 2022, 15, 1214. https://doi.org/10.3390/en15031214

Kang D, Lee J, Chakraborty A, Lee S-E, Kim G, Yu C. Recent Advances in Two-Phase Immersion Cooling with Surface Modifications for Thermal Management. Energies. 2022; 15(3):1214. https://doi.org/10.3390/en15031214

Chicago/Turabian StyleKang, Daehoon, Jooyoung Lee, Anirban Chakraborty, Sang-Eui Lee, Gildong Kim, and Choongho Yu. 2022. "Recent Advances in Two-Phase Immersion Cooling with Surface Modifications for Thermal Management" Energies 15, no. 3: 1214. https://doi.org/10.3390/en15031214

APA StyleKang, D., Lee, J., Chakraborty, A., Lee, S.-E., Kim, G., & Yu, C. (2022). Recent Advances in Two-Phase Immersion Cooling with Surface Modifications for Thermal Management. Energies, 15(3), 1214. https://doi.org/10.3390/en15031214