Development of a Low-Depth Modular GHX through a Real-Scale Experiment

Abstract

:1. Introduction

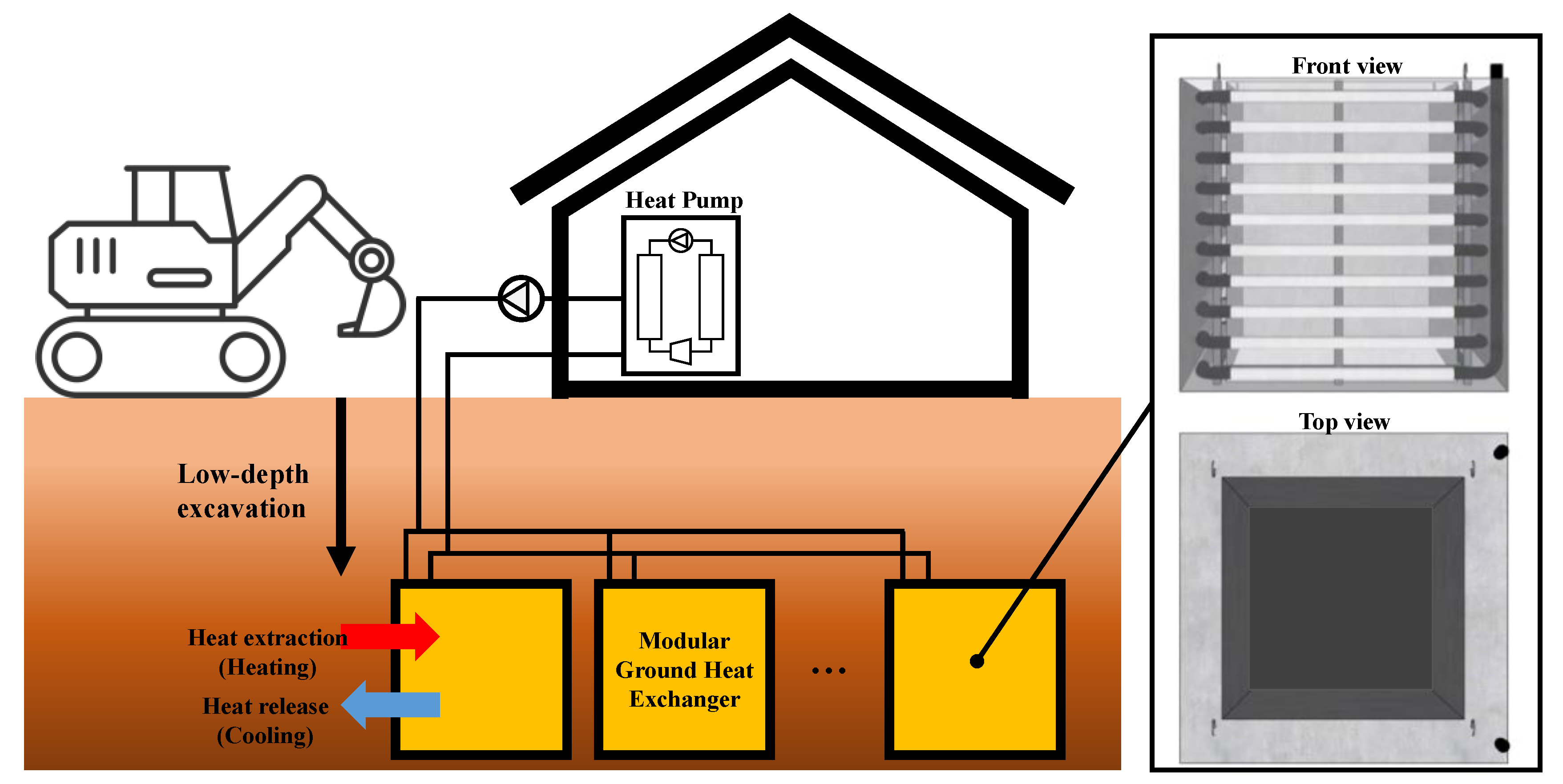

2. Low-Depth Modular GHX

3. Research Method

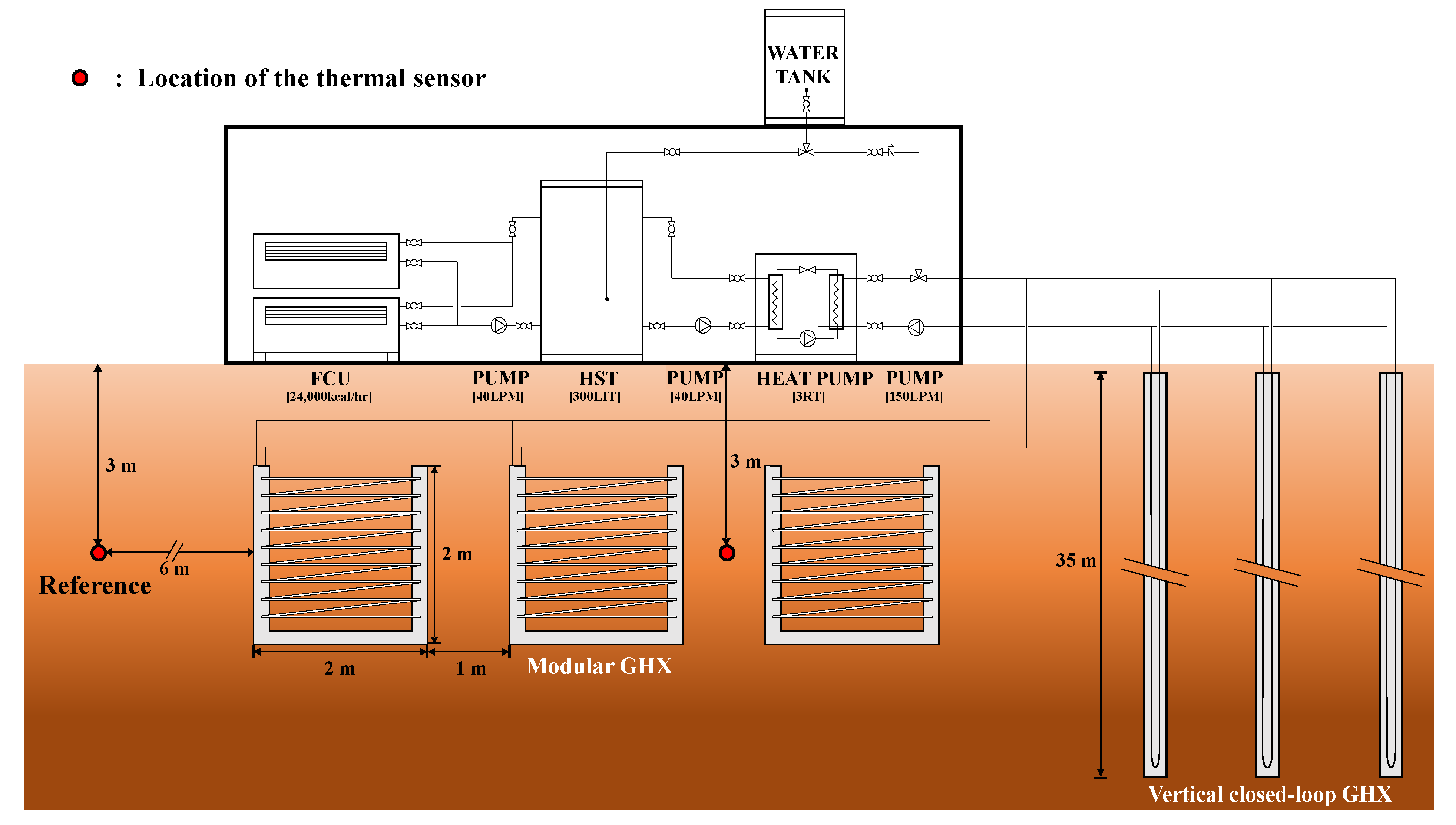

Set-Up of Real-Scale Experiment

4. Experiment Result

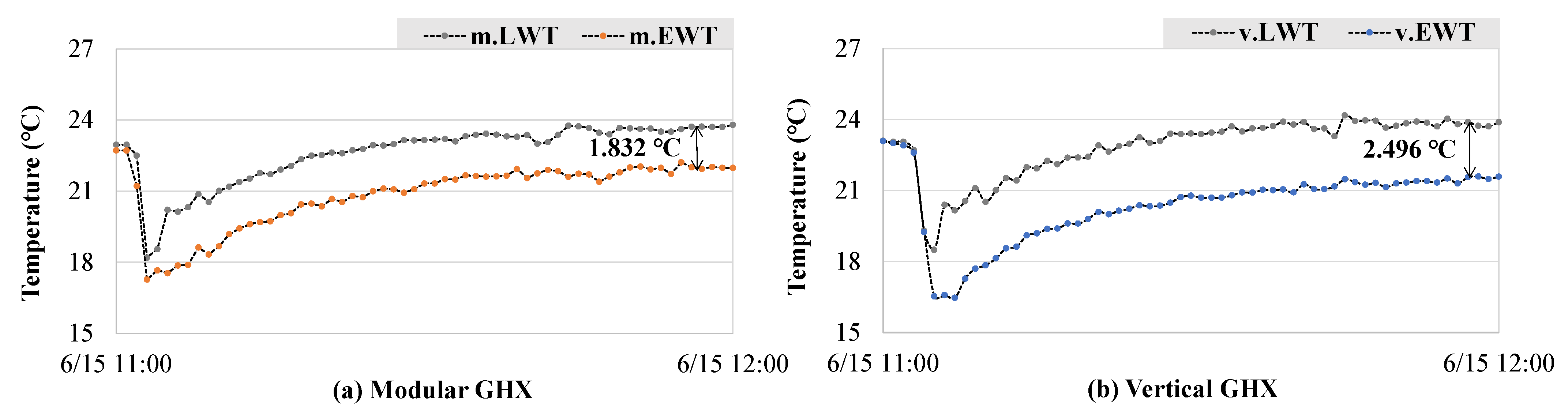

4.1. EWT Temperature Change Analysis

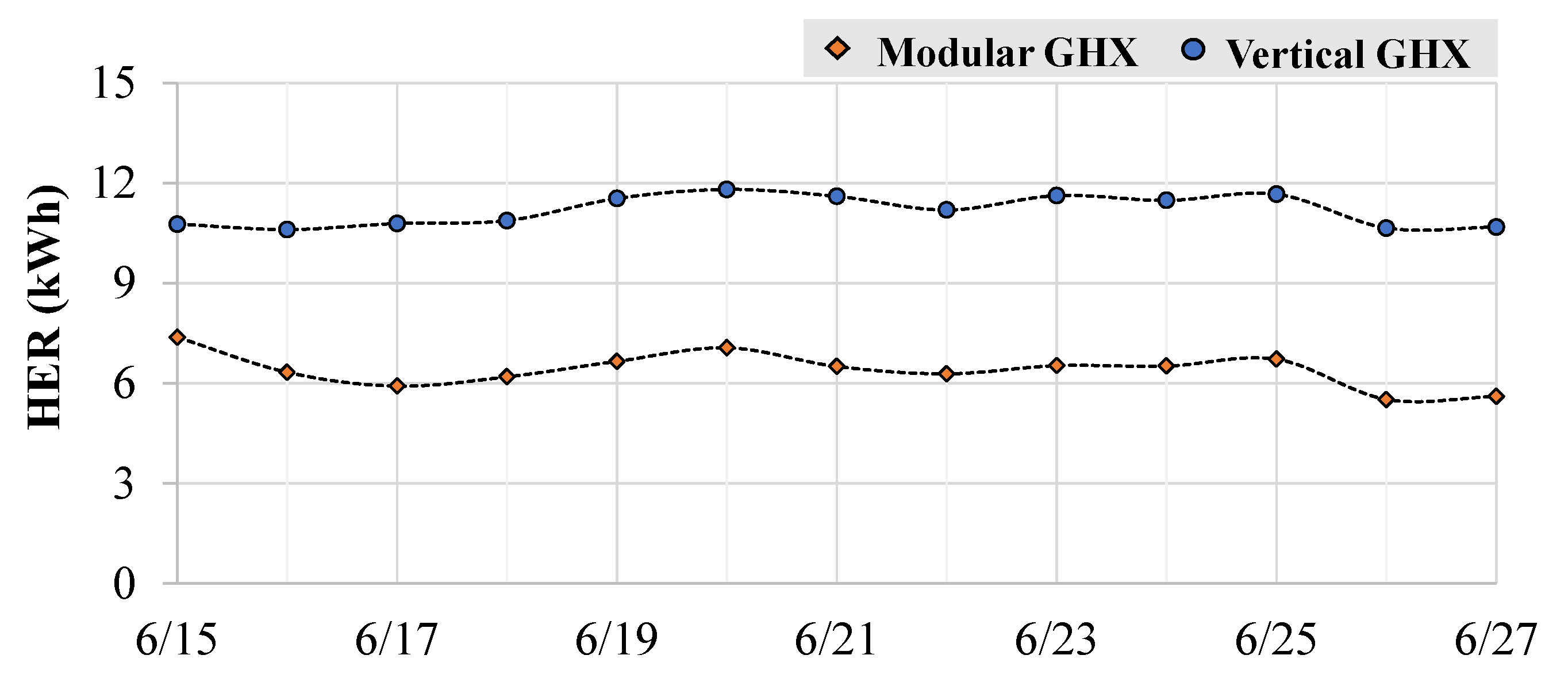

4.2. HER Analysis

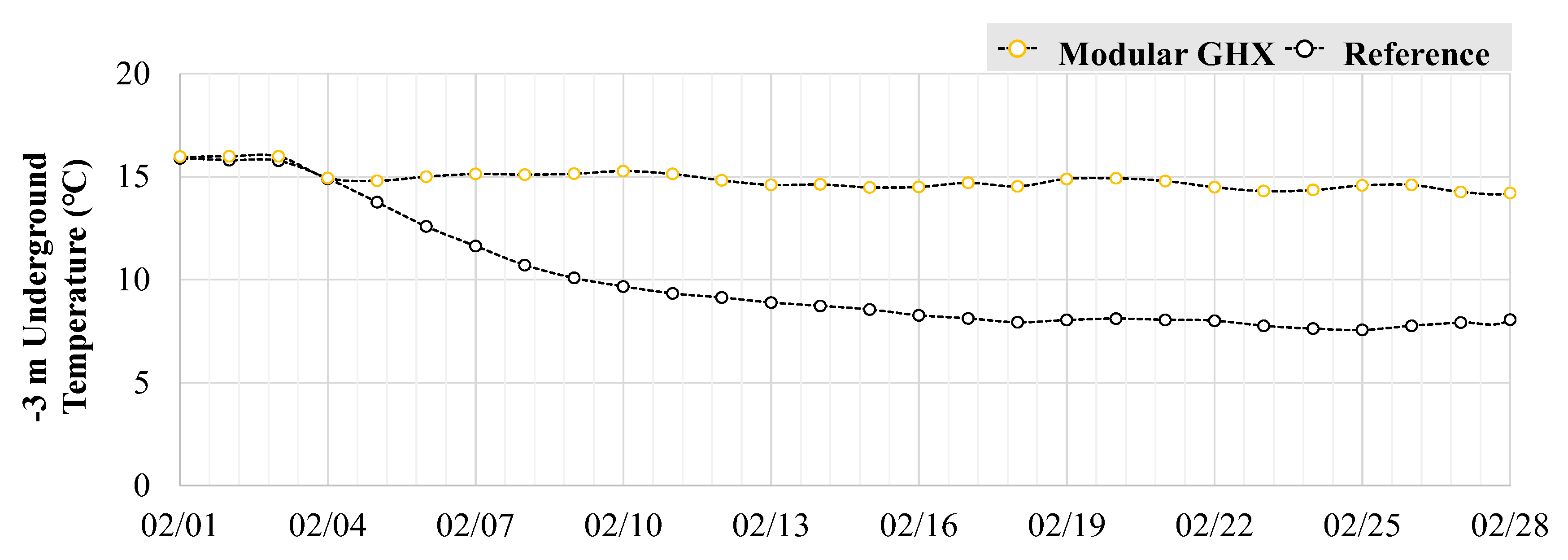

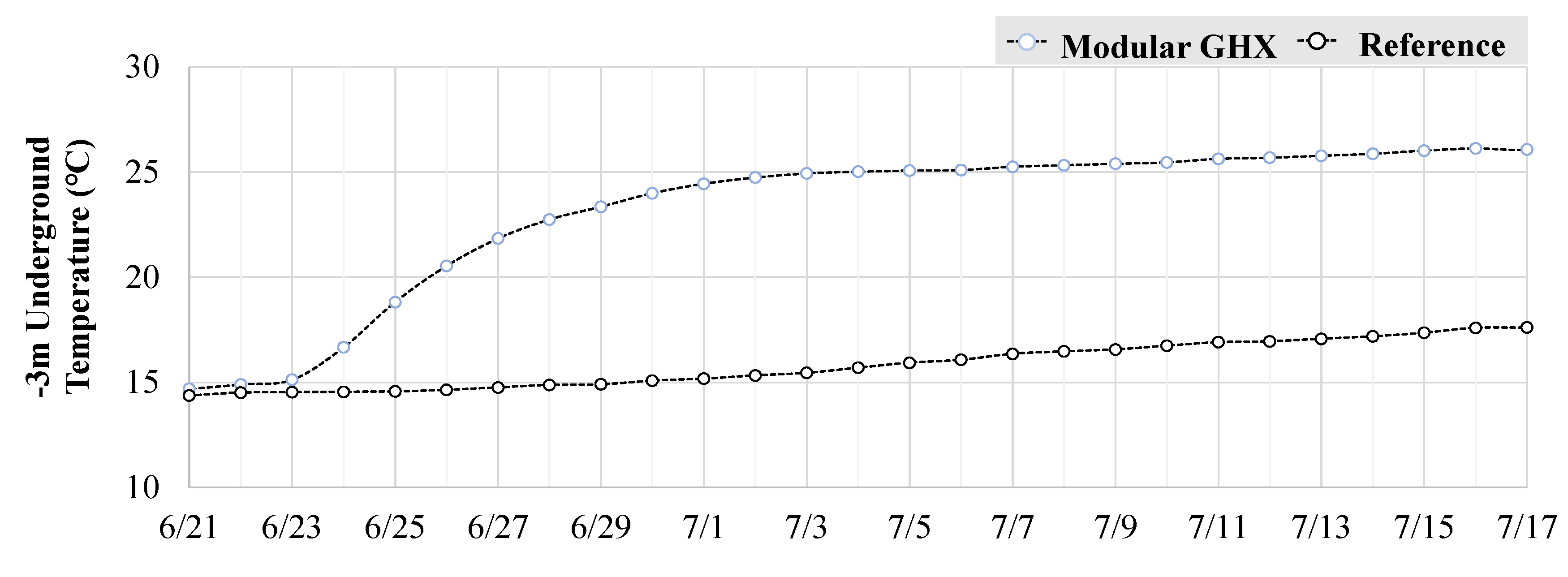

4.3. Underground Temperature Analysis

4.4. Performance Comparison and COP Analysis

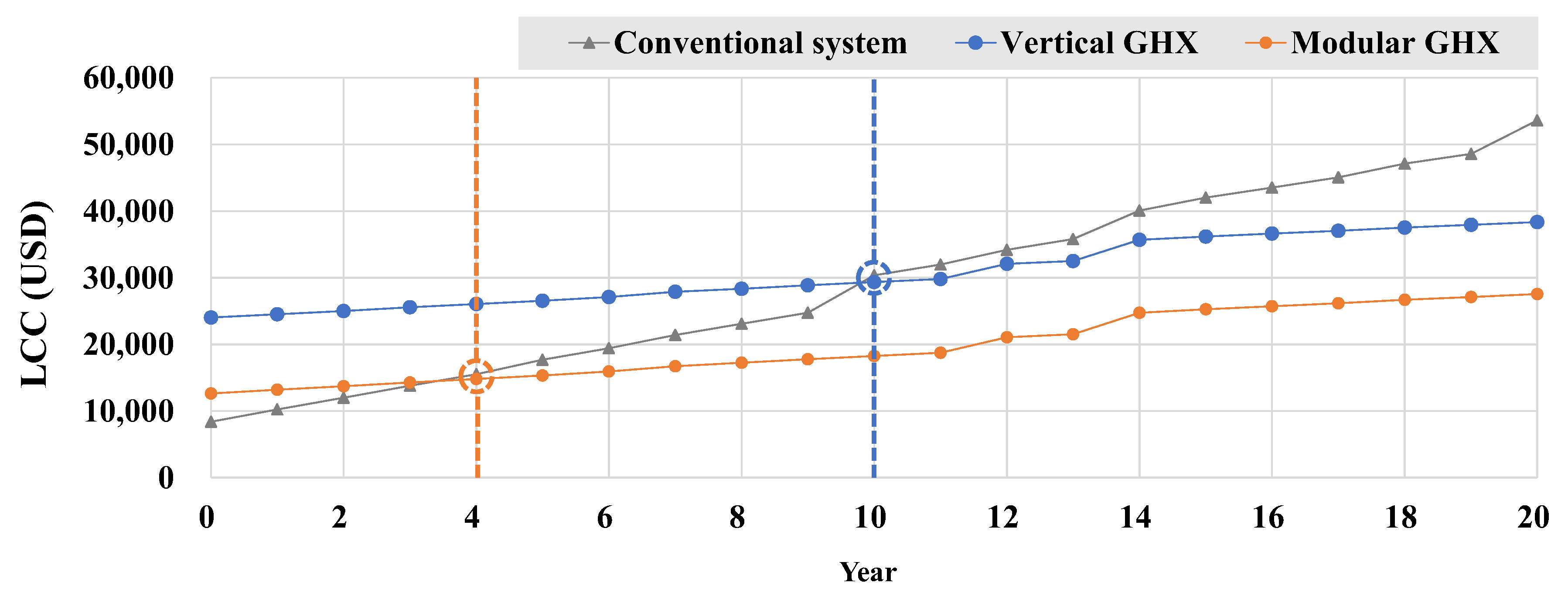

5. Feasibility Analysis

5.1. Introduction Feasibility Overview

5.2. Estimating Initial Investment Costs

5.3. Estimating Annual Operation Costs

5.4. Introduced Feasibility Analysis Results

6. Conclusions

- (1)

- During heating, the HER test results of the modular GHX and the vertical GHX was 5.14 kWh and 5.63 kWh, respectively, showing that the modular GHX can perform at 91% of the level of the vertical GHX. During cooling, the HER test results of the modular GHX and the vertical GHX were 7.38 kWh and 10.77 kWh, respectively, showing that the modular GHX can perform at 70% of the level of the vertical GHX.

- (2)

- During continuous operation experiments, the 3 m temperature of the load on the modular side was lowered by 8.4 °C when heating; however, the temperature increased by 11.6 °C during cooling operation. With the introduction of optimal control or a combined-heat-source system, higher efficiency can be expected if the ground temperature recovery is considered for operation.

- (3)

- The initial investment cost per unit was a saving of 55% with the modular GHX at 3100 USD and the vertical GHX at 6890 USD.

- (4)

- The COPc for the modular GHX and vertical GHX was 4.04 and 4.24, respectively. The annual operation cost was 6% higher for the modular GHX at 542 USD, with that of the vertical GHX at 510 USD.

- (5)

- The feasibility of introducing the modular GHX was analyzed, and it was found that the initial investment cost recovery period for the vertical GHX and the modular GHX is 10 and 4 years, respectively. Therefore, introducing the modular GHX was valid, and the factor that had the largest impact on economic feasibility was the initial investment cost.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| GSHP | Ground source heat pump |

| GHX | Ground heat exchanger |

| EWT | Entering water temperature |

| LWT | Leaving water temperature |

| HDPE | High-density polyethylene |

| HP | Heat pump |

| FCU | Fan coil unit |

| HST | Heat storage tank |

| LPM | Liter per meter |

| RT | Refrigeration ton |

| COP | Coefficient of performance |

| NPV | Net present value |

| PNNL | Pacific Northwest National Laboratory |

| LCC | Life cycle cost |

References

- Global Alliance for Buildings and Construction. 2020 Global Status Report for Buildings and Construction 2020-12; Un Environment Programme: Nairobi, Kenya, 2020. [Google Scholar]

- The Ministry of Trade, Industry and Energy. Announcement of the 5th Renewable Energy Master Plan (2020–2034); Government of Republic of Korea, 2020; Available online: https://www.korea.kr/news/pressReleaseView.do?newsId=156429610 (accessed on 2 December 2021).

- Chen, S.; Mao, J.; Han, X.; Li, C.; Liu, L. Numerical analysis of the factors influencing a vertical U-tube ground heat exchanger. Sustainability 2016, 8, 882. [Google Scholar] [CrossRef] [Green Version]

- Kim, H.; Nam, Y.; Bae, S.; Choi, J.; Kim, S. A study on the effect of performance factor on GSHP System through real-scale experiments in Korea. Energies 2020, 13, 554. [Google Scholar] [CrossRef] [Green Version]

- Eswiasi, A.; Mukhopadhyaya, P. Performance of conventional and innovative single U-tube pipe configuration in vertical ground heat exchanger (VGHE). Sustainability 2021, 13, 6384. [Google Scholar] [CrossRef]

- Selamat, S.; Miyara, A.; Kariya, K. Analysis of short time period of operation of horizontal ground heat exchangers. Resources 2015, 4, 507–523. [Google Scholar] [CrossRef] [Green Version]

- Ali, M.; Kariya, K.; Miyara, A. Performance analysis of slinky horizontal ground heat exchangers for a ground source heat pump system. Resources 2017, 6, 56. [Google Scholar] [CrossRef]

- Piselli, C.; Guastaveglia, A.; Romanelli, J.; Cotana, F.; Pisello, A. Facility energy management application of HBIM for historical low-carbon communities: Design, modelling and operation control of geothermal energy retrofit in a real Italian case study. Energies 2020, 13, 6338. [Google Scholar] [CrossRef]

- Kim, J.; Bae, S.; Nam, Y. Performance and feasibility analysis on the unit-type ground heat exchanger under a building. Korean J. Air-Cond. Refrig. Eng. 2018, 30, 228–236. [Google Scholar]

- Kim, J.; Nam, Y. Development of the performance prediction equation for a modular ground heat exchanger. Energies 2020, 13, 6005. [Google Scholar] [CrossRef]

- Cho, J.H.; Nam, Y.J. Analysis of the initial cost payback period on the open-loop geothermal system using two wells. Korean J. Air-Cond. Refrig. Eng. 2017, 29, 119–126. [Google Scholar]

- ASHRAE Standard 90.1-2004; Energy Standard for Buildings Except Low-Rise Residential Buildings. 2004. Available online: https://www.techstreet.com/ashrae/standards/ashrae-90-1-2019-i-p?gateway_code=ashrae&product_id=2088527 (accessed on 2 December 2021).

- ASHRAE Standard 90.2-2004; Energy-Efficient Design of Low-Rise Residential Buildings. 2004. Available online: https://www.techstreet.com/ashrae/standards/ashrae-90-2-2018?product_id=2030773 (accessed on 2 December 2021).

- Ministry of Land. Manual of Building Energy Saving Design, MLIT Criteria 2017-71. 2017. Available online: https://www.mlit.go.jp/jutakukentiku/jutakukentiku_house_tk4_000103.html (accessed on 2 December 2021).

- ASHRAE Standard 55-2013; Thermal Environmental Conditions for Human Occupancy. 2013. Available online: https://www.ashrae.org/technical-resources/bookstore/standard-55-thermal-environmental-conditions-for-human-occupancy (accessed on 2 December 2021).

- New & Renewable Energy Center, Korea Energy Agency. Unit Price per Renewable Energy Source, Criteria, 2012–2013; New & Renewable Energy Center, Korea Energy Agency: Yongin-si, Korea, 2012. [Google Scholar]

- Ministry of Land. Standard on Construction Estimate. 2017. Available online: https://www.codil.or.kr/helpdesk/read.do;jsessionid=1DrQsuDCUMEnnR8db1pAYUCraZx2QQHElPgb0mRlsOQ65aIhyuz9s2yl7fKC6Ga9.codil_servlet_engine1?bbsId=BBSMSTR_900000000202&nttId=10908&searchWrd= (accessed on 2 December 2021).

| Modular GHX | Vertical GHX | |

|---|---|---|

| Pipe diameter | 40 A | |

| Pipe length | 67.27 m | 70 m |

| Heat transfer area/Unit | 8.45 m2 (25.36 m2) | 8.80 m2 (26.40 m2) |

| Pipe material | HDPE (High-density polyethylene) | |

| Case | GHX | Operating Period | Mode | Flow Rate | FCU Capabilities | Purpose |

|---|---|---|---|---|---|---|

| 1 | Modular | 3rd February–28th February | Heating | 85 LPM | Heating: 24,600 kcal/h Cooling: 17,600 kcal/h | For analyzing the underground temperature |

| 2 | Modular | 23rd June–18th July | Cooling | 85 LPM | ||

| 3 | Modular + Vertical | 3rd February–28th February | Heating | Modular: 70 LPM Vertical: 70 LPM | For comparison of the heat exchange rate between the modular and vertical GHX | |

| 4 | Modular + Vertical | 15th June–27th June | Cooling | Modular: 70 LPM Vertical: 75 LPM | ||

| 5 | Modular | 3th June–8th June | Cooling | 54 LPM | For COP comparison of each GHX | |

| 6 | Vertical | 31st May–3rd June | Cooling | 50 LPM |

| Mode | Limited Temperature of the Heat Source | Limited Temperature of HST |

|---|---|---|

| Heating | 4 °C | 50 °C |

| Cooling | 30 °C | 10 °C |

| Parameter | Assumption |

|---|---|

| Conditioned floor area | 220.7 m² |

| Height | two-story, 2.59 m |

| Perimeter length | 42.5 m |

| Window area | Fifteen percent equally distributed to the four cardinal directions |

| Door area | 3.71 m² |

| Parameter | Input Value |

|---|---|

| People | 2.7/100 m² |

| People sensible heat gain | 70 W/person |

| People latent heat gain | 45 W/person |

| Lighting power density (LPD) | 10.76 W/m² |

| Electric power density (EPD) | 2.69 W/m² |

| Infiltration flow | 0.7/h |

| Heating setting temperature | 20 °C |

| Cooling setting temperature | 26 °C |

| Insulation condition | Energy-saving design standard |

| Modular GHX | Vertical GHX | |

|---|---|---|

| Excavation | 620 USD | 4770 USD |

| Pipe casing | - | 350 USD |

| Grouting | 440 USD | 620 USD |

| Making | 1770 USD | 620 USD |

| Labor | 270 USD | 530 USD |

| Total | 3100 USD | 6890 USD |

| Annual Operation Cost | |||

|---|---|---|---|

| Conventional System | Vertical GHX | Modular GHX | |

| Heat pump COP | 2.50 | 4.24 | 4.04 |

| Annual operation cost | 1830 USD | 510 USD | 542 USD |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, K.; Bae, S.; Nam, Y.; Lee, E.; Entchev, E. Development of a Low-Depth Modular GHX through a Real-Scale Experiment. Energies 2022, 15, 698. https://doi.org/10.3390/en15030698

Kim K, Bae S, Nam Y, Lee E, Entchev E. Development of a Low-Depth Modular GHX through a Real-Scale Experiment. Energies. 2022; 15(3):698. https://doi.org/10.3390/en15030698

Chicago/Turabian StyleKim, Kwonye, Sangmu Bae, Yujin Nam, Euyjoon Lee, and Evgueniy Entchev. 2022. "Development of a Low-Depth Modular GHX through a Real-Scale Experiment" Energies 15, no. 3: 698. https://doi.org/10.3390/en15030698

APA StyleKim, K., Bae, S., Nam, Y., Lee, E., & Entchev, E. (2022). Development of a Low-Depth Modular GHX through a Real-Scale Experiment. Energies, 15(3), 698. https://doi.org/10.3390/en15030698