A Comprehensive Review on Efficiency Enhancement of Solar Collectors Using Hybrid Nanofluids

Abstract

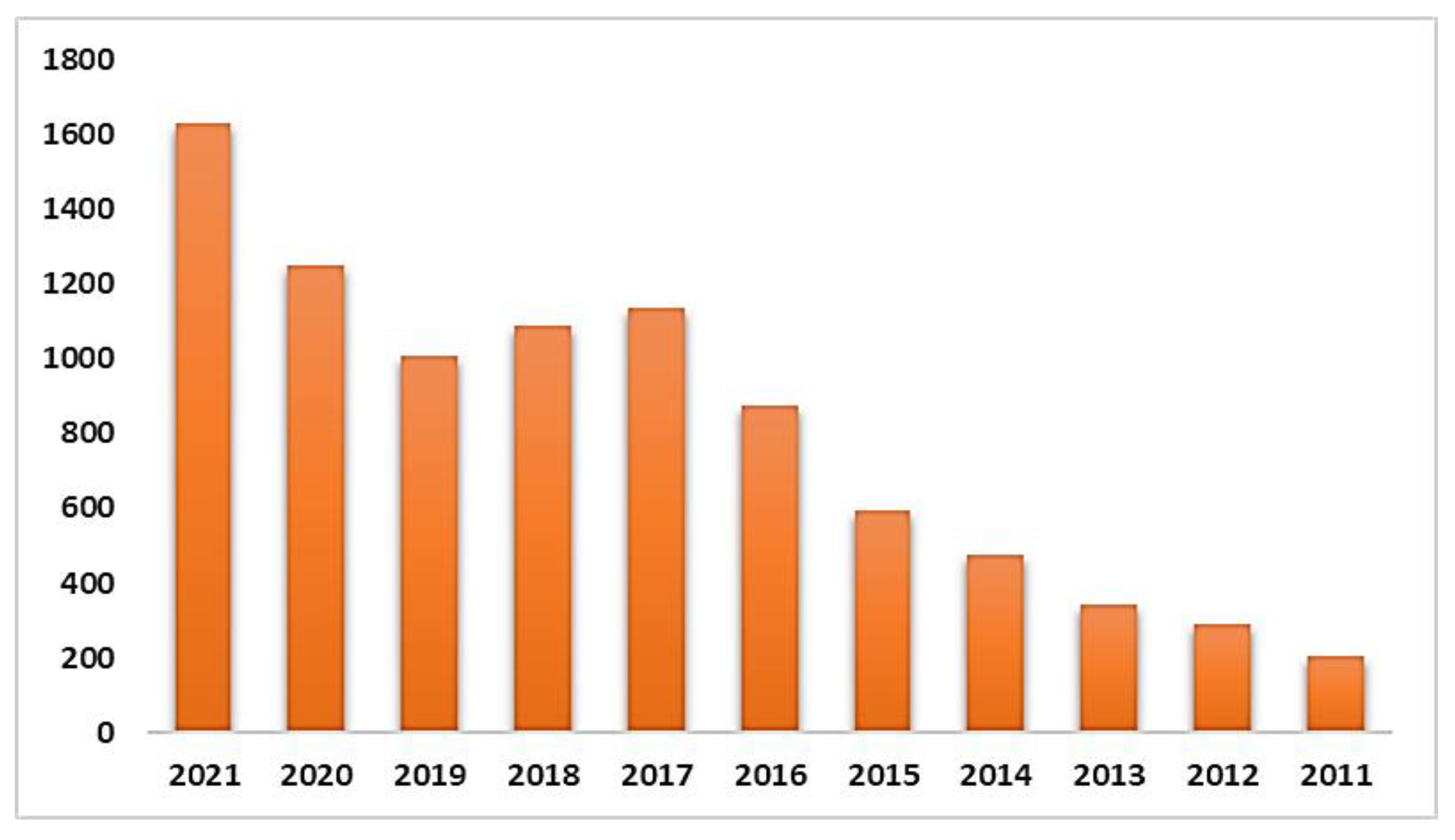

:1. Introduction

2. Historical Background

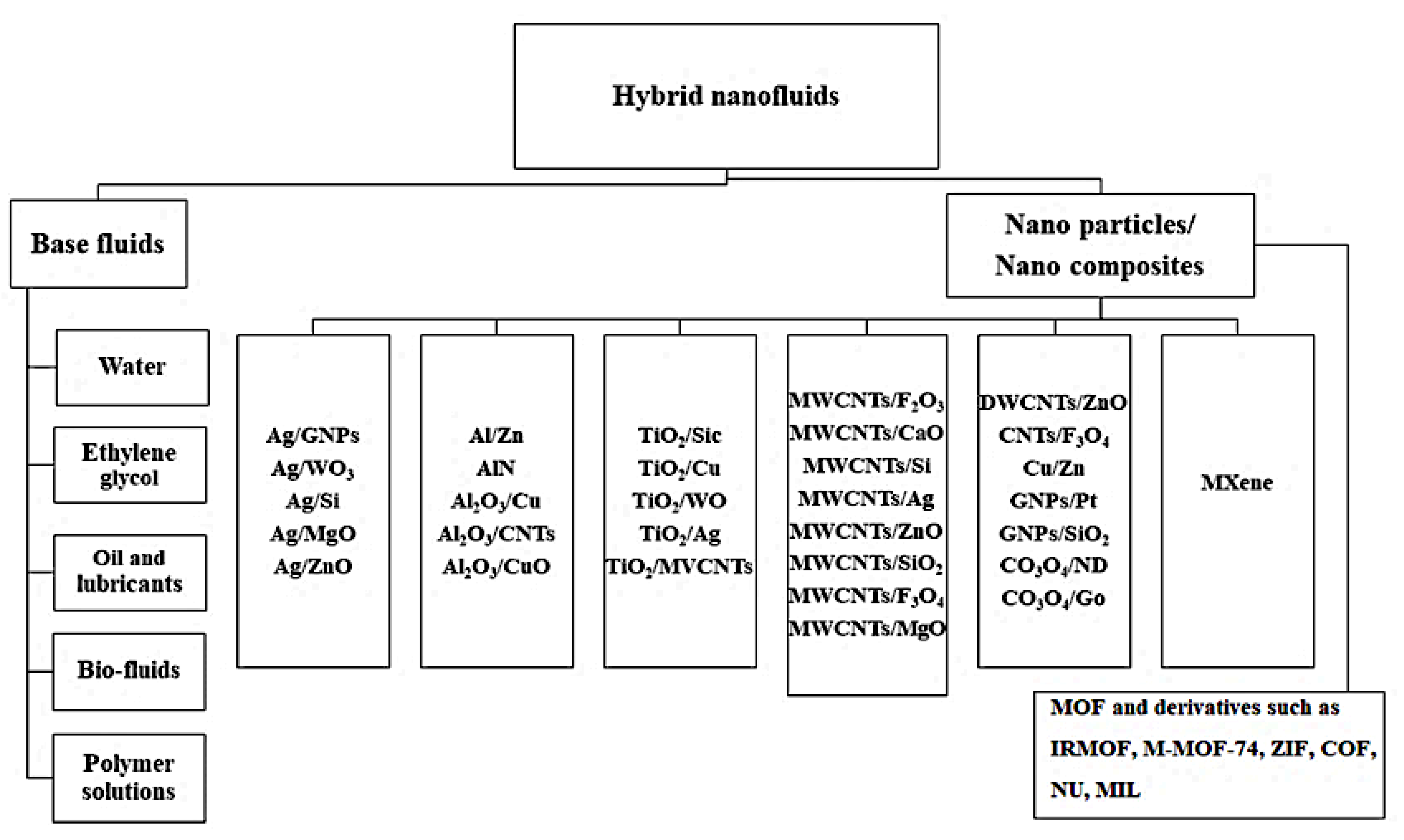

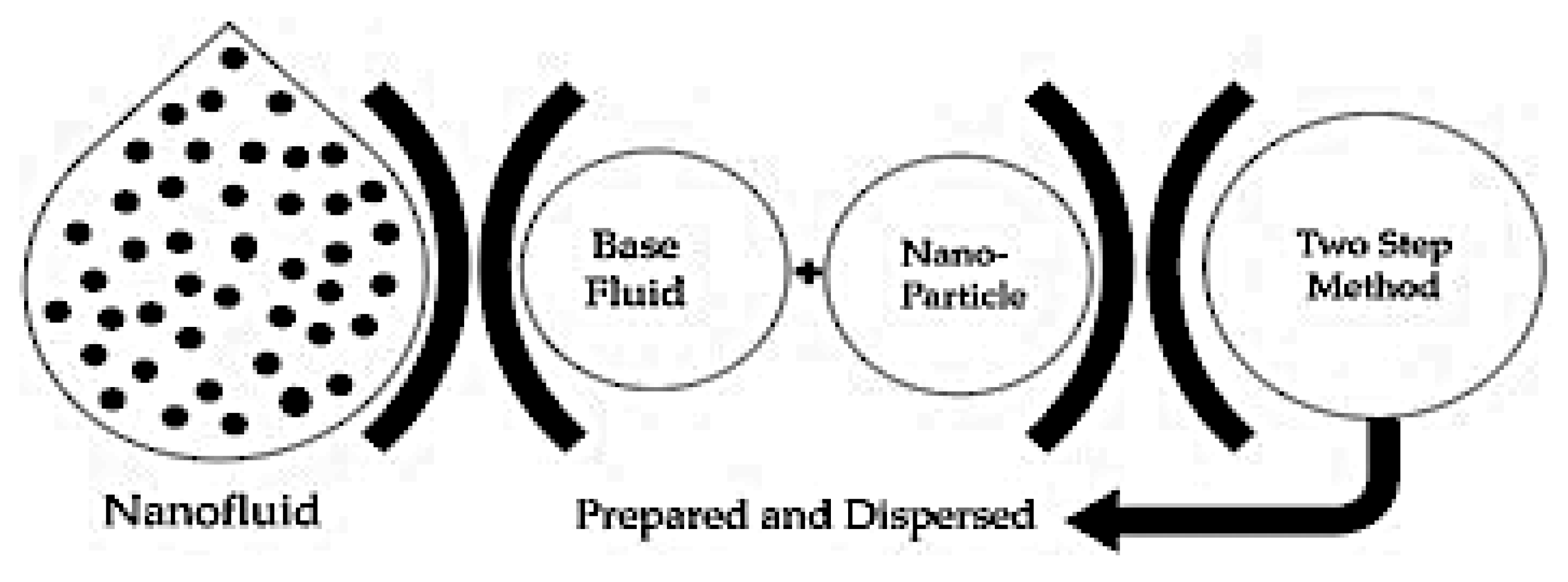

3. Preparation of Hybrid Nanofluids

4. Application of Hybrid Nanofluids in the Solar Collector

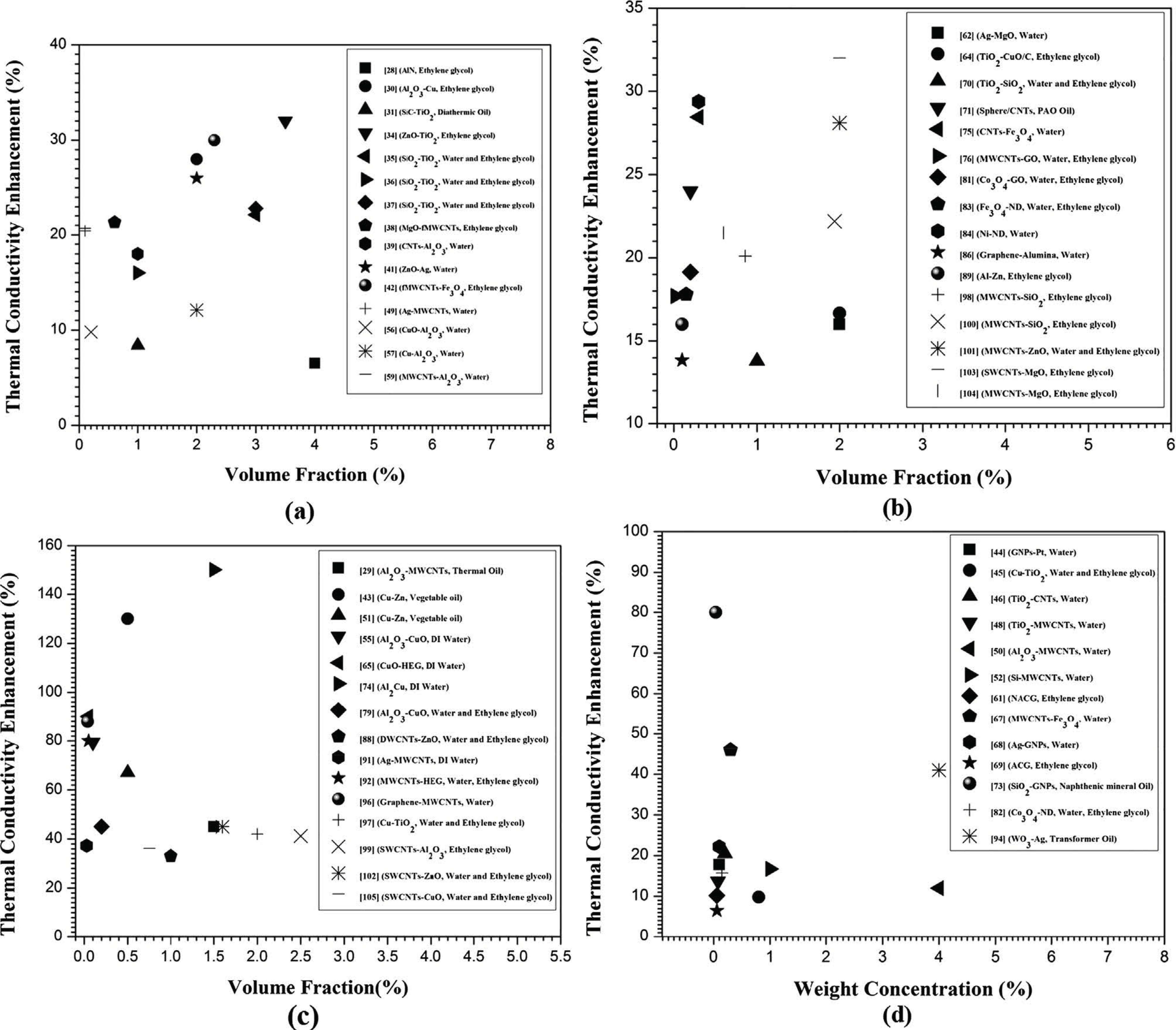

5. Efficiency Observations of Solar Collectors with Hybrid Nanofluids

6. Mathematical Analysis of Hybrid Nanofluids in Solar Collectors

7. Challenges Found Based on the Study

7.1. Physical Characteristics

7.2. Design and Mathematical Relationship

7.3. Cost and Economic Perspective

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Furlan, C.; Mortarino, C. Forecasting the impact of renewable energies in competition with non-renewable sources. Renew. Sustain. Energy Rev. 2018, 81, 1879–1886. [Google Scholar] [CrossRef]

- Elsaid, K.; Sayed, E.T.; Abdelkareem, M.A.; Baroutaji, A.; Olabi, A. Environmental impact of desalination processes: Mitigation and control strategies. Sci. Total Environ. 2020, 740, 140125. [Google Scholar] [CrossRef] [PubMed]

- Elsaid, K.; Sayed, E.T.; Abdelkareem, M.A.; Mahmoud, M.S.; Ramadan, M.; Olabi, A. Environmental impact of emerging desalination technologies: A preliminary evaluation. J. Environ. Chem. Eng. 2020, 8, 104099. [Google Scholar] [CrossRef]

- Olfian, H.; Ajarostaghi, S.S.M.; Ebrahimnataj, M. Development on evacuated tube solar collectors: A review of the last decade results of using nanofluids. Sol. Energy 2020, 211, 265–282. [Google Scholar] [CrossRef]

- Plante, R.H. Solar Energy, Photovoltaics, and Domestic Hot Water: A Technical and Economic Guide for Project Planners, Builders, and Property Owners; Academic Press: Cambridge, MA, USA, 2014. [Google Scholar]

- Wilberforce, T.; Baroutaji, A.; El Hassan, Z.; Thompson, J.; Soudan, B.; Olabi, A. Prospects and challenges of concentrated solar photovoltaics and enhanced geothermal energy technologies. Sci. Total Environ. 2018, 659, 851–861. [Google Scholar] [CrossRef] [Green Version]

- International Energy Agency. Renewable Energy Market Update; International Energy Agency: Paris, France, 2022. [Google Scholar]

- Olabi, A.; Elsaid, K.; Rabaia, M.K.H.; Askalany, A.A.; Abdelkareem, M.A. Waste heat-driven desalination systems: Perspective. Energy 2020, 209, 118373. [Google Scholar] [CrossRef]

- Brough, D.; Mezquita, A.; Ferrer, S.; Segarra, C.; Chauhan, A.; Almahmoud, S.; Khordehgah, N.; Ahmad, L.; Middleton, D.; Sewell, H.I.; et al. An experimental study and computational validation of waste heat recovery from a lab scale ceramic kiln using a vertical multi-pass heat pipe heat exchanger. Energy 2020, 208, 118325. [Google Scholar] [CrossRef]

- Bandyopadhyay, S.; Chakraborty, S. Thermophoretically driven capillary transport of nanofluid in a microchannel. Adv. Powder Technol. 2018, 29, 964–971. [Google Scholar] [CrossRef] [Green Version]

- Esmaeili, E.; Rounaghi, S.A.; Gruner, W.; Eckert, J. The preparation of surfactant-free highly dispersed ethylene glycol-based aluminum nitride-carbon nanofluids for heat transfer application. Adv. Powder Technol. 2019, 30, 2032–2041. [Google Scholar] [CrossRef]

- Al-Rashed, A.A.; Ranjbarzadeh, R.; Aghakhani, S.; Soltanimehr, M.; Afrand, M.; Nguyen, T.K. Entropy generation of boehmite alumina nanofluid flow through a minichannel heat exchanger considering nanoparticle shape effect. Phys. A Stat. Mech. Its Appl. 2019, 521, 724–736. [Google Scholar] [CrossRef]

- Purusothaman, A. Investigation of natural convection heat transfer performance of the QFN-PCB electronic module by using nanofluid for power electronics cooling applications. Adv. Powder Technol. 2018, 29, 996–1004. [Google Scholar] [CrossRef]

- Mahdi, J.M.; Lohrasbi, S.; Ganji, D.D.; Nsofor, E.C. Simultaneous energy storage and recovery in the triplex-tube heat exchanger with PCM, copper fins and Al2O3 nanoparticles. Energy Convers. Manag. 2018, 180, 949–961. [Google Scholar] [CrossRef]

- Mei, S.; Qi, C.; Luo, T.; Zhai, X.; Yan, Y. Effects of magnetic field on thermo-hydraulic performance of Fe3O4-water nanofluids in a corrugated tube. Int. J. Heat Mass Transf. 2018, 128, 24–45. [Google Scholar] [CrossRef]

- Wang, G.; Qi, C.; Liu, M.; Li, C.; Yan, Y.; Liang, L. Effect of corrugation pitch on thermo-hydraulic performance of nanofluids in corrugated tubes of heat exchanger system based on exergy efficiency. Energy Convers. Manag. 2019, 186, 51–65. [Google Scholar] [CrossRef]

- Qi, C.; Liu, M.; Tang, J. Influence of triangle tube structure with twisted tape on the thermo-hydraulic performance of nanofluids in heat-exchange system based on thermal and exergy efficiency. Energy Convers. Manag. 2019, 192, 243–268. [Google Scholar] [CrossRef]

- Farhana, K.; Kadirgama, K.; Rahman, M.M.; Noor, M.M.; Ramasamy, D.; Samykano, M.; Najafi, G.; Sidik, N.A.C.; Tarlochan, F. Significance of alumina in nanofluid technology. J. Therm. Anal. 2019, 138, 1107–1126. [Google Scholar] [CrossRef]

- Abu-Hamdeh, N.H.; Alazwari, M.A.; Salilih, E.M.; Sajadi, S.M.; Karimipour, A. Improve the efficiency and heat transfer rate’ trend prediction of a flat-plate solar collector via a solar energy installation by examine the Titanium Dioxide/Silicon Dioxide-water nanofluid. Sustain. Energy Technol. Assess. 2021, 48, 101623. [Google Scholar] [CrossRef]

- Ashour, A.F.; El-Awady, A.T.; Tawfik, M.A. Numerical investigation on the thermal performance of a flat plate solar collector using ZnO & CuO water nanofluids under Egyptian weathering conditions. Energy 2021, 240, 122743. [Google Scholar] [CrossRef]

- Khodadadi, H.; Aghakhani, S.; Majd, H.; Kalbasi, R.; Wongwises, S.; Afrand, M. A comprehensive review on rheological behavior of mono and hybrid nanofluids: Effective parameters and predictive correlations. Int. J. Heat Mass Transf. 2018, 127, 997–1012. [Google Scholar] [CrossRef]

- Arani, A.A.A.; Akbari, O.A.; Safaei, M.R.; Marzban, A.; Alrashed, A.A.; Ahmadi, G.R.; Nguyen, T.K. Heat transfer improvement of water/single-wall carbon nanotubes (SWCNT) nanofluid in a novel design of a truncated double-layered microchannel heat sink. Int. J. Heat Mass Transf. 2017, 113, 780–795. [Google Scholar] [CrossRef]

- Khodabandeh, E.; Safaei, M.R.; Akbari, S.; Akbari, O.A.; Alrashed, A.A. Application of nanofluid to improve the thermal performance of horizontal spiral coil utilized in solar ponds: Geometric study. Renew. Energy 2018, 122, 1–16. [Google Scholar] [CrossRef]

- Bahrami, M.; Akbari, M.; Karimipour, A.; Afrand, M. An experimental study on rheological behavior of hybrid nanofluids made of iron and copper oxide in a binary mixture of water and ethylene glycol: Non-Newtonian behavior. Exp. Therm. Fluid Sci. 2016, 79, 231–237. [Google Scholar] [CrossRef]

- Ranjbarzadeh, R.; Karimipour, A.; Afrand, M.; Isfahani, A.H.M.; Shirneshan, A. Empirical analysis of heat transfer and friction factor of water/graphene oxide nanofluid flow in turbulent regime through an isothermal pipe. Appl. Therm. Eng. 2017, 126, 538–547. [Google Scholar] [CrossRef]

- Dehkordi, R.A.; Esfe, M.H.; Afrand, M. Effects of functionalized single walled carbon nanotubes on thermal performance of antifreeze: An experimental study on thermal conductivity. Appl. Therm. Eng. 2017, 120, 358–366. [Google Scholar] [CrossRef]

- Nazir, U.; Nawaz, M.; Alharbi, S.O. Thermal performance of magnetohydrodynamic complex fluid using nano and hybrid nanoparticles. Phys. A Stat. Mech. Its Appl. 2020, 553, 124345. [Google Scholar] [CrossRef]

- Farhana, K.; Kadirgama, K.; Rahman, M.M.; Ramasamy, D.; Noor, M.M.; Najafi, G.; Samykano, M.; Mahamude, A.S.F. Improvement in the performance of solar collectors with nanofluids—A state-of-the-art review. Nano-Struct. Nano-Objects 2019, 18, 100276. [Google Scholar] [CrossRef]

- Shah, T.R.; Ali, H.M. Applications of hybrid nanofluids in solar energy, practical limitations and challenges: A critical review. Sol. Energy 2019, 183, 173–203. [Google Scholar] [CrossRef]

- Sarkar, J.; Ghosh, P.; Adil, A. A review on hybrid nanofluids: Recent research, development and applications. Renew. Sustain. Energy Rev. 2015, 43, 164–177. [Google Scholar] [CrossRef]

- Zainal, S.; Tan, C.; Sian, C.; Siang, T.J. ANSYS simulation for Ag/HEG hybrid nanofluid in turbulent circular pipe. J. Adv. Res. Appl. Mech. 2016, 23, 20–35. [Google Scholar]

- Li, H.; Ha, C.-S.; Kim, I.J. Fabrication of carbon nanotube/SiO2 and carbon nanotube/SiO2/Ag nanoparticles hybrids by using plasma treatment. Nanoscale Res. Lett. 2009, 4, 1384–1388. [Google Scholar] [CrossRef] [Green Version]

- Karthikeyan, N.; Philip, J.; Raj, B. Effect of clustering on the thermal conductivity of nanofluids. Mater. Chem. Phys. 2008, 109, 50–55. [Google Scholar] [CrossRef]

- Sastry, N.N.V.; Bhunia, A.; Sundararajan, T.; Das, S.K. Predicting the effective thermal conductivity of carbon nanotube based nanofluids. Nanotechnology 2008, 19, 055704. [Google Scholar] [CrossRef] [PubMed]

- Sidik, N.A.C.; Adamu, I.M.; Jamil, M.M. Preparation methods and thermal performance of hybrid nanofluids. J. Adv. Res. Appl. Mech. 2020, 66, 7–16. [Google Scholar] [CrossRef]

- Chakraborty, S.; Panigrahi, P.K. Stability of nanofluid: A review. Appl. Therm. Eng. 2020, 174, 115259. [Google Scholar] [CrossRef]

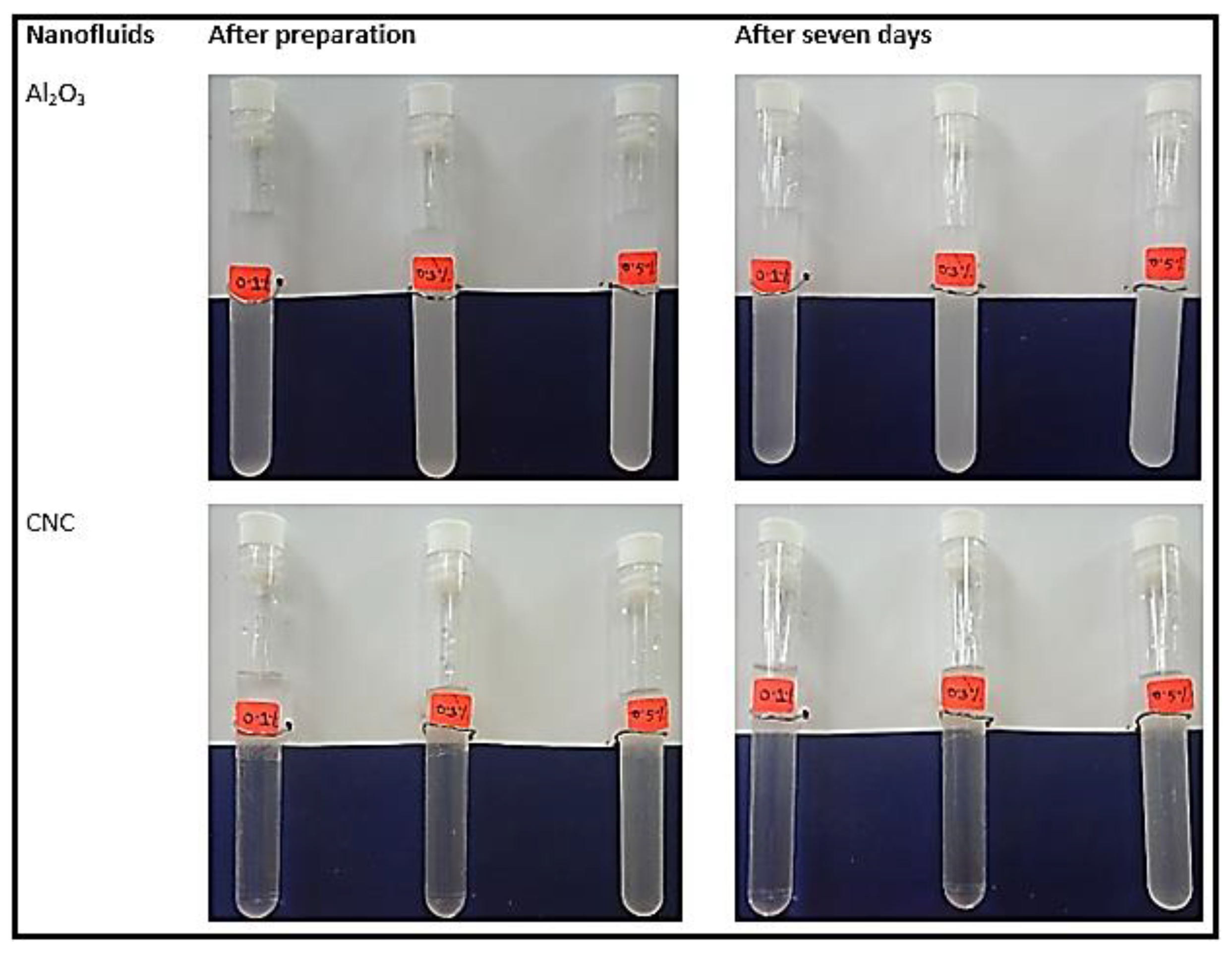

- Hussein, O.A.; Habib, K.; Muhsan, A.S.; Saidur, R.; Alawi, O.A.; Ibrahim, T.K. Thermal performance enhancement of a flat plate solar collector using hybrid nanofluid. Sol. Energy 2020, 204, 208–222. [Google Scholar] [CrossRef]

- Choi, S.U.S.; Zhang, Z.G.; Yu, W.; Lockwood, F.E.; Grulke, E.A. Anomalous thermal conductivity enhancement in nanotube suspensions. Appl. Phys. Lett. 2001, 79, 2252–2254. [Google Scholar] [CrossRef]

- Azwadi, C.N.; Adamu, I.J. Turbulent force convective heat transfer of hybrid nano fluid in a circular channel with constant heat flux. J. Adv. Res. Fluid Mech. Therm. Sci. 2016, 19, 1–9. [Google Scholar]

- Lee, Y.J. The use of nanofluids in domestic water heat exchanger. J. Adv. Res. Appl. Mech. 2014, 3, 9–24. [Google Scholar]

- Park, S.D.; Lee, S.W.; Kang, S.; Bang, I.C.; Kim, J.H.; Shin, H.S.; Lee, D.W. Effects of nanofluids containing graphene/graphene-oxide nanosheets on critical heat flux. Appl. Phys. Lett. 2010, 97, 023103. [Google Scholar] [CrossRef] [Green Version]

- Farhana, K.; Kadirgama, K.; Mohammed, H.A.; Ramasamy, D.; Samykano, M.; Saidur, R. Analysis of efficiency enhancement of flat plate solar collector using crystal nano-cellulose (CNC) nanofluids. Sustain. Energy Technol. Assess. 2021, 45, 101049. [Google Scholar] [CrossRef]

- Sidik, N.A.C.; Jamil, M.M.; Japar, W.M.A.A.; Adamu, I.M. A review on preparation methods, stability and applications of hybrid nanofluids. Renew. Sustain. Energy Rev. 2017, 80, 1112–1122. [Google Scholar] [CrossRef]

- Budihardjo, I.; Morrison, G.L.; Behnia, M. Natural circulation flow through water-in-glass evacuated tube solar collectors. Sol. Energy 2007, 81, 1460–1472. [Google Scholar] [CrossRef]

- Minardi, J.E.; Chuang, H.N. Performance of a “black” liquid flat-plate solar collector. Sol. Energy 1975, 17, 179–183. [Google Scholar] [CrossRef]

- Singh, A.K.J. A review study of solar desalting units with evacuated tube collectors. J. Clean. Prod. 2020, 279, 123542. [Google Scholar] [CrossRef]

- Zhou, Y.; Li, Q.; Wang, Q. Energy storage analysis of UIO-66 and water mixed nanofluids: An experimental and theoretical study. Energies 2019, 12, 2521. [Google Scholar] [CrossRef] [Green Version]

- McGrail, B.; Thallapally, P.K.; Blanchard, J.; Nune, S.; Jenks, J.; Dang, L. Metal-organic heat carrier nanofluids. Nano Energy 2013, 2, 845–855. [Google Scholar] [CrossRef]

- García, E.J.; Bahamon, D.; Vega, L.F. Systematic search of suitable metal–organic frameworks for thermal energy-storage applications with low global warming potential refrigerants. ACS Sustain. Chem. Eng. 2021, 9, 3157–3171. [Google Scholar] [CrossRef]

- Murshed, S.S.J. Correction and comment on “thermal conductance of nanofluids: Is the controversy over?”. J. Nanopart. Res. 2009, 11, 511–512. [Google Scholar] [CrossRef] [Green Version]

- Amrollahi, A.; Rashidi, A.; Meibodi, M.E.; Kashefi, K. Conduction heat transfer characteristics and dispersion behaviour of carbon nanofluids as a function of different parameters. J. Exp. Nanosci. 2009, 4, 347–363. [Google Scholar] [CrossRef]

- Suresh, S.; Venkitaraj, K.P.; Selvakumar, P.; Chandrasekar, M. Synthesis of Al2O3–Cu/water hybrid nanofluids using two step method and its thermo physical properties. Colloid. Surf. A Physicochem. Eng. Asp. 2011, 388, 41–48. [Google Scholar] [CrossRef]

- Sundar, L.S.; Singh, M.K.; Sousa, A.C.J. Enhanced heat transfer and friction factor of MWCNT–Fe3O4/water hybrid nanofluids. Int. Commun. Heat Mass Transf. 2014, 52, 73–83. [Google Scholar] [CrossRef]

- Baby, T.T.; Sundara, R.J. Synthesis and transport properties of metal oxide decorated graphene dispersed nanofluids. J. Phys. Chem. C 2011, 115, 8527–8533. [Google Scholar] [CrossRef]

- Amiri, A.; Shanbedi, M.; Eshghi, H.; Heris, S.Z.; Baniadam, M. Highly dispersed multiwalled carbon nanotubes decorated with Ag nanoparticles in water and experimental investigation of the thermophysical properties. J. Phys. Chem. C 2012, 116, 3369–3375. [Google Scholar] [CrossRef]

- Huang, D.; Wu, Z.; Sunden, B. Effects of hybrid nanofluid mixture in plate heat exchangers. Exp. Therm. Fluid Sci. 2016, 72, 190–196. [Google Scholar] [CrossRef]

- Yarmand, H.; Gharehkhani, S.; Ahmadi, G.; Shirazi, S.F.S.; Baradaran, S.; Montazer, E.; Zubir, M.N.M.; Alehashem, M.; Kazi, S.; Dahari, M. Graphene nanoplatelets–silver hybrid nanofluids for enhanced heat transfer. Energy Convers. Manag. 2015, 100, 419–428. [Google Scholar] [CrossRef]

- Harandi, S.S.; Karimipour, A.; Afrand, M.; Akbari, M.; D’Orazio, A.J. An experimental study on thermal conductivity of F-MWCNTs–Fe3O4/EG hybrid nanofluid: Effects of temperature and concentration. Int. Commun. Heat Mass Transf. 2016, 76, 171–177. [Google Scholar] [CrossRef] [Green Version]

- Ahammed, N.; Asirvatham, L.G.; Wongwises, S.J. Entropy generation analysis of graphene–alumina hybrid nanofluid in multiport minichannel heat exchanger coupled with thermoelectric cooler. Int. J. Heat Mass Transf. 2016, 103, 1084–1097. [Google Scholar] [CrossRef]

- Maddah, H.; Aghayari, R.; Mirzaee, M.; Ahmadi, M.H.; Sadeghzadeh, M.; Chamkha, A.J. Factorial experimental design for the thermal performance of a double pipe heat exchanger using Al2O3-TiO2 hybrid nanofluid. Int. Commun. Heat Mass Transf. 2018, 97, 92–102. [Google Scholar] [CrossRef]

- Tullius, T.K.; Bayazitoglu, Y. Analysis of a hybrid nanofluid exposed to radiation. Numer. Heat Transf. Part B Fundam. 2016, 69, 271–286. [Google Scholar] [CrossRef]

- Esfe, M.H.; Arani, A.A.A.; Badi, R.S.; Rejvani, M.J. ANN modeling, cost performance and sensitivity analyzing of thermal conductivity of DWCNT–SiO2/EG hybrid nanofluid for higher heat transfer. J. Therm. Anal. Calorim. 2018, 131, 2381–2393. [Google Scholar] [CrossRef]

- Esfe, M.H.; Rejvani, M.; Karimpour, R.; Arani, A.A.A. Estimation of thermal conductivity of ethylene glycol-based nanofluid with hybrid suspensions of SWCNT–Al2O3 nanoparticles by correlation and ANN methods using experimental data. J. Therm. Anal. 2017, 128, 1359–1371. [Google Scholar] [CrossRef]

- Ahmadi, M.H.; Ghazvini, M.; Sadeghzadeh, M.; Alhuyi Nazari, M.; Ghalandari, M. Utilization of hybrid nanofluids in solar energy applications: A review. Nano-Struct. Nano-Objects 2019, 20, 100386. [Google Scholar] [CrossRef]

- Sidik, N.A.C.; Adamu, I.M.; Jamil, M.M.; Kefayati, G.H.; Mamat, R.; Najafi, G. Recent progress on hybrid nanofluids in heat transfer applications: A comprehensive review. Int. Commun. Heat Mass Transf. 2016, 78, 68–79. [Google Scholar] [CrossRef]

- Ali, H.M.; Babar, H.; Shah, T.R.; Sajid, M.U.; Qasim, M.A.; Javed, S. Preparation techniques of TiO2 nanofluids and challenges: A review. Appl. Sci. 2018, 8, 587. [Google Scholar] [CrossRef] [Green Version]

- Chopkar, M.; Kumar, S.; Bhandari, D.; Das, P.; Manna, I. Development and characterization of Al2Cu and Ag2Al nanoparticle dispersed water and ethylene glycol based nanofluid. Mater. Sci. Eng. B 2007, 139, 141–148. [Google Scholar] [CrossRef]

- Moghadassi, A.; Ghomi, E.; Parvizian, F. A numerical study of water based Al2O3 and Al2O3–Cu hybrid nanofluid effect on forced convective heat transfer. Int. J. Therm. Sci. 2015, 92, 50–57. [Google Scholar] [CrossRef]

- Samylingam, L.; Aslfattahi, N.; Saidur, R.; Yahya, S.M.; Afzal, A.; Arifutzzaman, A.; Tan, K.; Kadirgama, K. Thermal and energy performance improvement of hybrid PV/T system by using olein palm oil with MXene as a new class of heat transfer fluid. Sol. Energy Mater. Sol. Cells 2020, 218, 110754. [Google Scholar] [CrossRef]

- Brailsford, A.D.; Major, K.G. The thermal conductivity of aggregates of several phases, including porous materials. Br. J. Appl. Phys. 1964, 15, 313–319. [Google Scholar] [CrossRef]

- Miles, J., Jr.; Robertson, H.J. The dielectric behavior of colloidal particles with an electric double-layer. Phys. Rev. 1932, 40, 583. [Google Scholar] [CrossRef]

- Takabi, B.; Salehi, S.J. Augmentation of the heat transfer performance of a sinusoidal corrugated enclosure by employing hybrid nanofluid. Adv. Mech. Eng. 2014, 6, 147059. [Google Scholar] [CrossRef]

- Yu, W.; Xie, H. A review on nanofluids: Preparation, stability mechanisms, and applications. J. Nanomater. 2012, 2012, 1–17. [Google Scholar] [CrossRef] [Green Version]

- Wong, K.V.; De Leon, O.J. Applications of nanofluids: Current and future. Adv. Mech. Eng. 2010, 2, 519659. [Google Scholar] [CrossRef] [Green Version]

- Wen, D.; Lin, G.; Vafaei, S.; Zhang, K. Review of nanofluids for heat transfer applications. Particuology 2009, 7, 141–150. [Google Scholar] [CrossRef]

- Saidur, R.; Leong, K.Y.; Mohammed, H.A. A review on applications and challenges of nanofluids. Renew. Sustain. Energy Rev. 2011, 15, 1646–1668. [Google Scholar] [CrossRef]

- Han, W.; Rhi, S. Thermal characteristics of grooved heat pipe with hybrid nanofluids. Therm. Sci. 2011, 15, 195–206. [Google Scholar] [CrossRef]

- He, Y.; Vasiraju, S.; Que, L. Hybrid nanomaterial-based nanofluids for micropower generation. RSC Adv. 2013, 4, 2433–2439. [Google Scholar] [CrossRef]

- Selvakumar, P.; Suresh, S. Use of Al2O3–Cu/water hybrid nanofluid in an electronic heat sink. IEEE Trans. Compon. Packag. Manuf. Technol. 2012, 2, 1600–1607. [Google Scholar] [CrossRef]

- Ho, C.; Huang, J.; Tsai, P.; Yang, Y. On laminar convective cooling performance of hybrid water-based suspensions of Al2O3 nanoparticles and MEPCM particles in a circular tube. Int. J. Heat Mass Transf. 2011, 54, 2397–2407. [Google Scholar] [CrossRef]

- Madhesh, D.; Parameshwaran, R.; Kalaiselvam, S. Experimental investigation on convective heat transfer and rheological characteristics of Cu–TiO2 hybrid nanofluids. Exp. Therm. Fluid Sci. 2014, 52, 104–115. [Google Scholar] [CrossRef]

- Li, G.; Xuan, Q.; Pei, G.; Su, Y.; Ji, J. Effect of non-uniform illumination and temperature distribution on concentrating solar cell—A review. Energy 2017, 144, 1119–1136. [Google Scholar] [CrossRef]

- Said, Z.; Ghodbane, M.; Sundar, L.S.; Tiwari, A.K.; Sheikholeslami, M.; Boumeddane, B.J. Heat transfer, entropy generation, economic and environmental analyses of linear Fresnel reflector using novel rGO-Co3O4 hybrid nanofluids. Renew. Energy 2021, 165, 420–437. [Google Scholar] [CrossRef]

- Aguilar, T.; Navas, J.; Sánchez-Coronilla, A.; Martín, E.I.; Gallardo, J.J.; Martínez-Merino, P.; Gómez-Villarejo, R.; Piñero, J.C.; Alcántara, R.; Fernández-Lorenzo, C.J. Investigation of enhanced thermal properties in NiO-based nanofluids for concentrating solar power applications: A molecular dynamics and experimental analysis. Appl. Energy 2018, 211, 677–688. [Google Scholar] [CrossRef]

- Bakhtiari, R.; Kamkari, B.; Afrand, M.; Abdollahi, A. Preparation of stable TiO2-graphene/water hybrid nanofluids and development of a new correlation for thermal conductivity. Powder Technol. 2021, 385, 466–477. [Google Scholar] [CrossRef]

- Tang, R.; Cheng, Y.; Wu, M.; Li, Z.; Yu, Y. Experimental and modeling studies on thermosiphon domestic solar water heaters with flat-plate collectors at clear nights. Energy Convers. Manag. 2010, 51, 2548–2556. [Google Scholar] [CrossRef]

- Arunkumar, T.; Velraj, R.; Denkenberger, D.; Sathyamurthy, R.; Kumar, K.V.; Ahsan, A. Productivity enhancements of compound parabolic concentrator tubular solar stills. Renew. Energy 2016, 88, 391–400. [Google Scholar] [CrossRef]

- Papadimitratos, A.; Sobhansarbandi, S.; Pozdin, V.; Zakhidov, A.; Hassanipour, F. Evacuated tube solar collectors integrated with phase change materials. Sol. Energy 2016, 129, 10–19. [Google Scholar] [CrossRef] [Green Version]

- Li, X.; Xu, E.; Ma, L.; Song, S.; Xu, L. Modeling and dynamic simulation of a steam generation system for a parabolic trough solar power plant. Renew. Energy 2019, 132, 998–1017. [Google Scholar] [CrossRef]

- Beltagy, H.; Semmar, D.; Lehaut, C.; Said, N. Theoretical and experimental performance analysis of a Fresnel type solar concentrator. Renew. Energy 2017, 101, 782–793. [Google Scholar] [CrossRef]

- Li, L.; Dubowsky, S. A new design approach for solar concentrating parabolic dish based on optimized flexible petals. Mech. Mach. Theory 2011, 46, 1536–1548. [Google Scholar] [CrossRef]

- Roca, L.; de la Calle, A.; Yebra, L.J.J. Heliostat-field gain-scheduling control applied to a two-step solar hydrogen production plant. Appl. Energy 2013, 103, 298–305. [Google Scholar] [CrossRef]

- Esfe, M.H.; Yan, W.-M.; Akbari, M.; Karimipour, A.; Hassani, M.J. Experimental study on thermal conductivity of DWCNT-ZnO/water-EG nanofluids. Int. Commun. Heat Mass Transf. 2015, 68, 248–251. [Google Scholar] [CrossRef]

- Suresh, S.; Venkitaraj, K.P.; Selvakumar, P.; Chandrasekar, M. Effect of Al2O3–Cu/water hybrid nanofluid in heat transfer. Exp. Therm. Fluid Sci. 2012, 38, 54–60. [Google Scholar] [CrossRef]

- Baghbanzadeh, M.; Rashidi, A.; Rashtchian, D.; Lotfi, R.; Amrollahi, A. Synthesis of spherical silica/multiwall carbon nanotubes hybrid nanostructures and investigation of thermal conductivity of related nanofluids. Thermochim. Acta 2012, 549, 87–94. [Google Scholar] [CrossRef]

- Chen, L.; Yu, W.; Xie, H. Enhanced thermal conductivity of nanofluids containing Ag/MWNT composites. Powder Technol. 2012, 231, 18–20. [Google Scholar] [CrossRef]

- Aravind, S.S.J.; Ramaprabhu, S. Graphene wrapped multiwalled carbon nanotubes dispersed nanofluids for heat transfer applications. J. Appl. Phys. 2012, 112, 124304. [Google Scholar] [CrossRef]

- Munkhbayar, B.; Tanshen, R.; Jeoun, J.; Chung, H.; Jeong, H. Surfactant-free dispersion of silver nanoparticles into MWCNT-aqueous nanofluids prepared by one-step technique and their thermal characteristics. Ceram. Int. 2013, 39, 6415–6425. [Google Scholar] [CrossRef]

- Labib, M.N.; Nine, J.; Afrianto, H.; Chung, H.; Jeong, H. Numerical investigation on effect of base fluids and hybrid nanofluid in forced convective heat transfer. Int. J. Therm. Sci. 2013, 71, 163–171. [Google Scholar] [CrossRef]

- Tomar, L.J.; Chakrabarty, B. Synthesis, structural and optical properties of TiO2-ZrO2 nanocomposite by hydrothermal method. Adv. Mater. Lett. 2013, 4, 64–67. [Google Scholar] [CrossRef]

- Suresh, S.; Venkitaraj, K.P.; Hameed, M.S.; Sarangan, J. Turbulent heat transfer and pressure drop characteristics of dilute water based Al2O3-Cu hybrid nanofluids. J. Nanosci. Nanotechnol. 2014, 14, 2563–2572. [Google Scholar] [CrossRef]

- Batmunkh, M.; Tanshen, R.; Nine, J.; Myekhlai, M.; Choi, H.; Chung, H.; Jeong, H. Thermal conductivity of TiO2 nanoparticles based aqueous nanofluids with an addition of a modified silver particle. Ind. Eng. Chem. Res. 2014, 53, 8445–8451. [Google Scholar] [CrossRef]

- Xuan, Y.; Duan, H.; Li, Q.J. Enhancement of solar energy absorption using a plasmonic nanofluid based on TiO2/Ag composite nanoparticles. RSC Adv. 2014, 4, 16206–16213. [Google Scholar] [CrossRef]

- Baghbanzadeh, M.; Rashidi, A.; Soleimanisalim, A.H.; Rashtchian, D. Investigating the rheological properties of nanofluids of water/hybrid nanostructure of spherical silica/MWCNT. Thermochim. Acta 2014, 578, 53–58. [Google Scholar] [CrossRef]

- Sundar, L.S.; Misganaw, A.H.; Singh, M.K.; Sousa, A.C.M.; Ali, H.M. Efficiency analysis of thermosyphon solar flat plate collector with low mass concentrations of ND–Co3O4 hybrid nanofluids: An experimental study. J. Therm. Anal. 2020, 143, 959–972. [Google Scholar] [CrossRef]

- Syam Sundar, L.; Sousa, A.; Singh, M.K. Heat transfer enhancement of low volume concentration of carbon nanotube-Fe3O4/water hybrid nanofluids in a tube with twisted tape inserts under turbulent flow. J. Therm. Sci. Eng. Appl. 2015, 7, 021015. [Google Scholar] [CrossRef]

- Esfe, M.H.; Wongwises, S.; Naderi, A.; Asadi, A.; Safaei, M.R.; Rostamian, H.; Dahari, M.; Karimipour, A. Thermal conductivity of Cu/TiO2–water/EG hybrid nanofluid: Experimental data and modeling using artificial neural network and correlation. Int. Commun. Heat Mass Transf. 2015, 66, 100–104. [Google Scholar] [CrossRef]

- Esfe, M.H.; Arani, A.A.A.; Rezaie, M.; Yan, W.-M.; Karimipour, A. Experimental determination of thermal conductivity and dynamic viscosity of Ag–MgO/water hybrid nanofluid. Int. Commun. Heat Mass Transf. 2015, 66, 189–195. [Google Scholar] [CrossRef]

- Afrand, M.; Toghraie, D.; Ruhani, B. Effects of temperature and nanoparticles concentration on rheological behavior of Fe3O4–Ag/EG hybrid nanofluid: An experimental study. Exp. Therm. Fluid Sci. 2016, 77, 38–44. [Google Scholar] [CrossRef]

- Eshgarf, H.; Afrand, M. An experimental study on rheological behavior of non-Newtonian hybrid nano-coolant for application in cooling and heating systems. Exp. Therm. Fluid Sci. 2016, 76, 221–227. [Google Scholar] [CrossRef]

- Sundar, L.S.; Ramana, E.V.; Graça, M.; Singh, M.K.; Sousa, A.C.J. Nanodiamond-Fe3O4 nanofluids: Preparation and measurement of viscosity, electrical and thermal conductivities. Int. Commun. Heat Mass Transf. 2016, 73, 62–74. [Google Scholar] [CrossRef]

- Soltani, O.; Akbari, M. Effects of temperature and particles concentration on the dynamic viscosity of MgO-MWCNT/ethylene glycol hybrid nanofluid: Experimental study. Phys. E Low-Dimens. Syst. Nanostruct. 2016, 84, 564–570. [Google Scholar] [CrossRef]

- Senniangiri, N.; Bensam Raj, J.; Sunil, J.J. Effects of temperature and particles concentration on the dynamic viscosity of graphene-NiO/coconut oil hybrid nanofluid: Experimental study. Int. J. Nanosci. 2020, 19, 1950016. [Google Scholar] [CrossRef]

- Nemade, K.; Waghuley, S.J. A novel approach for enhancement of thermal conductivity of CuO/H2O based nanofluids. Appl. Therm. Eng. 2016, 95, 271–274. [Google Scholar] [CrossRef]

- Verma, S.K.; Tiwari, A.K.; Tiwari, S.; Chauhan, D.S. Performance analysis of hybrid nanofluids in flat plate solar collector as an advanced working fluid. Sol. Energy 2018, 167, 231–241. [Google Scholar] [CrossRef]

- Arıkan, E.; Abbasoğlu, S.; Gazi, M. Experimental performance analysis of flat plate solar collectors using different nanofluids. Sustainability 2018, 10, 1794. [Google Scholar] [CrossRef] [Green Version]

- Sabiha, M.; Saidur, R.; Hassani, S.; Said, Z.; Mekhilef, S. Energy performance of an evacuated tube solar collector using single walled carbon nanotubes nanofluids. Energy Convers. Manag. 2015, 105, 1377–1388. [Google Scholar] [CrossRef]

- Mahendran, M.; Lee, G.; Sharma, K.; Shahrani, A. Performance of evacuated tube solar collector using water-based titanium oxide nanofluid. J. Mech. Eng. Sci. 2012, 3, 301–310. [Google Scholar] [CrossRef]

- Daghigh, R.; Zandi, P. Improving the performance of heat pipe embedded evacuated tube collector with nanofluids and auxiliary gas system. Renew. Energy 2018, 134, 888–901. [Google Scholar] [CrossRef]

- Peng, Y.; Zahedidastjerdi, A.; Abdollahi, A.; Amindoust, A.; Bahrami, M.; Karimipour, A.; Goodarzi, M. Investigation of energy performance in a U-shaped evacuated solar tube collector using oxide added nanoparticles through the emitter, absorber and transmittal environments via discrete ordinates radiation method. J. Therm. Anal. 2019, 139, 2623–2631. [Google Scholar] [CrossRef]

- Luo, Z.; Wang, C.; Wei, W.; Xiao, G.; Ni, M. Performance improvement of a nanofluid solar collector based on direct absorption collection (DAC) concepts. Int. J. Heat Mass Transf. 2014, 75, 262–271. [Google Scholar] [CrossRef]

- Hussain, H.A.; Jawad, Q.; Sultan, K.F. Experimental analysis on thermal efficiency of evacuated tube solar collector by using nanofluids. Sol. Energy 2015, 4, 19–28. [Google Scholar]

- Kim, H.; Ham, J.; Park, C.; Cho, H. Theoretical investigation of the efficiency of a U-tube solar collector using various nanofluids. Energy 2016, 94, 497–507. [Google Scholar] [CrossRef]

- Kaya, M.; Gürel, A.E.; Ağbulut, Ü.; Ceylan, İ.; Çelik, S.; Ergün, A.; Acar, B.J. Performance analysis of using CuO-Methanol nanofluid in a hybrid system with concentrated air collector and vacuum tube heat pipe. Energy Convers. Manag. 2019, 199, 111936. [Google Scholar] [CrossRef]

- Benkhedda, M.; Boufendi, T.; Touahri, S.J. Laminar mixed convective heat transfer enhancement by using Ag-TiO2-water hybrid Nanofluid in a heated horizontal annulus. Heat Mass Transf. 2018, 54, 2799–2814. [Google Scholar] [CrossRef]

- Rahman, M.R.A.; Leong, K.Y.; Idris, A.C.; Saad, M.R.; Anwar, M. Numerical analysis of the forced convective heat transfer on Al2O3–Cu/water hybrid nanofluid. Heat Mass Transf. 2016, 53, 1835–1842. [Google Scholar] [CrossRef]

- Gorji, T.B.; Ranjbar, A. A numerical and experimental investigation on the performance of a low-flux direct absorption solar collector (DASC) using graphite, magnetite and silver nanofluids. Sol. Energy 2016, 135, 493–505. [Google Scholar] [CrossRef]

- Li, X.; Chang, H.; Zeng, L.; Huang, X.; Li, Y.; Li, R.; Xi, Z. Numerical analysis of photothermal conversion performance of MXene nanofluid in direct absorption solar collectors. Energy Convers. Manag. 2020, 226, 113515. [Google Scholar] [CrossRef]

- Gupta, M.; Singh, V.; Said, Z. Heat transfer analysis using zinc Ferrite/water (Hybrid) nanofluids in a circular tube: An experimental investigation and development of new correlations for thermophysical and heat transfer properties. Sustain. Energy Technol. Assess. 2020, 39, 100720. [Google Scholar] [CrossRef]

- Abdelrazik, A.S.; Tan, K.H.; Aslfattahi, N.; Saidur, R.; Al-Sulaiman, F.A. Optical properties and stability of water-based nanofluids mixed with reduced graphene oxide decorated with silver and energy performance investigation in hybrid photovoltaic/thermal solar systems. Int. J. Energy Res. 2020, 44, 11487–11508. [Google Scholar] [CrossRef]

- Kasaeian, A.; Daneshazarian, R.; Pourfayaz, F. Comparative study of different nanofluids applied in a trough collector with glass-glass absorber tube. J. Mol. Liq. 2017, 234, 315–323. [Google Scholar] [CrossRef]

- Loni, R.; Pavlovic, S.; Bellos, E.; Tzivanidis, C.; Asli-Ardeh, E.A. Thermal and exergy performance of a nanofluid-based solar dish collector with spiral cavity receiver. Appl. Therm. Eng. 2018, 135, 206–217. [Google Scholar] [CrossRef]

- Esfe, M.H.; Alirezaie, A.; Rejvani, M.J. An applicable study on the thermal conductivity of SWCNT-MgO hybrid nanofluid and price-performance analysis for energy management. Appl. Therm. Eng. 2017, 111, 1202–1210. [Google Scholar] [CrossRef]

- Asadi, M.; Asadi, A.J. Dynamic viscosity of MWCNT/ZnO–engine oil hybrid nanofluid: An experimental investigation and new correlation in different temperatures and solid concentrations. Int. Commun. Heat Mass Transf. 2016, 76, 41–45. [Google Scholar] [CrossRef]

- Afrand, M. Experimental study on thermal conductivity of ethylene glycol containing hybrid nano-additives and development of a new correlation. Appl. Therm. Eng. 2017, 110, 1111–1119. [Google Scholar] [CrossRef]

- Sundar, L.S.; Singh, M.K.; Ferro, M.; Sousa, A. Experimental investigation of the thermal transport properties of graphene oxide/Co3O4 hybrid nanofluids. Int. Commun. Heat Mass Transf. 2017, 84, 1–10. [Google Scholar] [CrossRef]

- Nine, J.; Batmunkh, M.; Kim, J.-H.; Chung, H.-S.; Jeong, H.-M. Investigation of Al2O3-MWCNTs hybrid dispersion in water and their thermal characterization. J. Nanosci. Nanotechnol. 2012, 12, 4553–4559. [Google Scholar] [CrossRef] [PubMed]

- Khan, M.S.; Abid, M.; Ali, H.M.; Amber, K.P.; Bashir, M.A.; Javed, S. Comparative performance assessment of solar dish assisted s-CO2 Brayton cycle using nanofluids. Appl. Therm. Eng. 2018, 148, 295–306. [Google Scholar] [CrossRef]

- Zadeh, P.M.; Sokhansefat, T.; Kasaeian, A.; Kowsary, F.; Akbarzadeh, A. Hybrid optimization algorithm for thermal analysis in a solar parabolic trough collector based on nanofluid. Energy 2015, 82, 857–864. [Google Scholar] [CrossRef]

- Huang, W.; Marefati, M. Energy, exergy, environmental and economic comparison of various solar thermal systems using water and Thermia Oil B base fluids, and CuO and Al2O3 nanofluids. Energy Rep. 2020, 6, 2919–2947. [Google Scholar] [CrossRef]

- Loni, R.; Asli-Ardeh, E.A.; Ghobadian, B.; Kasaeian, A.; Bellos, E. Energy and exergy investigation of alumina/oil and silica/oil nanofluids in hemispherical cavity receiver: Experimental study. Energy 2018, 164, 275–287. [Google Scholar] [CrossRef]

- Potenza, M.; Milanese, M.; Colangelo, G.; de Risi, A. Experimental investigation of transparent parabolic trough collector based on gas-phase nanofluid. Appl. Energy 2017, 203, 560–570. [Google Scholar] [CrossRef]

- Aslfattahi, N.; Samylingam, L.; Abdelrazik, A.; Arifutzzaman, A.; Saidur, R. MXene based new class of silicone oil nanofluids for the performance improvement of concentrated photovoltaic thermal collector. Sol. Energy Mater. Sol. Cells 2020, 211, 110526. [Google Scholar] [CrossRef]

- Soltani, S.; Kasaeian, A.; Lavajoo, A.; Loni, R.; Najafi, G.; Mahian, O. Exergetic and enviromental assessment of a photovoltaic thermal-thermoelectric system using nanofluids: Indoor experimental tests. Energy Convers. Manag. 2020, 218, 112907. [Google Scholar] [CrossRef]

- Sardarabadi, M.; Passandideh-Fard, M.; Heris, S.Z. Experimental investigation of the effects of silica/water nanofluid on PV/T (photovoltaic thermal units). Energy 2014, 66, 264–272. [Google Scholar] [CrossRef]

- Arora, S.; Singh, H.P.; Sahota, L.; Arora, M.K.; Arya, R.; Singh, S.; Jain, A.; Singh, A. Performance and cost analysis of photovoltaic thermal (PVT)-compound parabolic concentrator (CPC) collector integrated solar still using CNT-water based nanofluids. Desalination 2020, 495, 114595. [Google Scholar] [CrossRef]

- Wahab, A.; Khan, M.A.Z.; Hassan, A. Impact of graphene nanofluid and phase change material on hybrid photovoltaic thermal system: Exergy analysis. J. Clean. Prod. 2020, 277, 123370. [Google Scholar] [CrossRef]

- Soltani, S.; Kasaeian, A.; Sarrafha, H.; Wen, D. An experimental investigation of a hybrid photovoltaic/thermoelectric system with nanofluid application. Sol. Energy 2017, 155, 1033–1043. [Google Scholar] [CrossRef]

- Sardarabadi, M.; Hosseinzadeh, M.; Kazemian, A.; Passandideh-Fard, M. Experimental investigation of the effects of using metal-oxides/water nanofluids on a photovoltaic thermal system (PVT) from energy and exergy viewpoints. Energy 2017, 138, 682–695. [Google Scholar] [CrossRef]

- Sardarabadi, M.; Passandideh-Fard, M.J.S.E.M.; Cells, S. Experimental and numerical study of metal-oxides/water nanofluids as coolant in photovoltaic thermal systems (PVT). Energy 2016, 157, 533–542. [Google Scholar] [CrossRef]

- Sakhaei, S.A.; Valipour, M.S. Performance enhancement analysis of the flat plate collectors: A comprehensive review. Renew. Sustain. Energy Rev. 2018, 102, 186–204. [Google Scholar] [CrossRef]

- Duffie, J.A.; Beckman, W.A. Solar Engineering of Thermal Processes; John Wiley & Sons: Hoboken, NJ, USA, 2013. [Google Scholar]

- Salman, A.; Hamdi, R.J. Theoretical technique for studying the effecting factors for loss coefficients theoretical technique for studying the effecting factors for loss coefficients in solar collectors. Int. J. Trend Res. Dev. 2018, 5, 1–6. [Google Scholar]

- Ward, G.T. Performance of a flat-plate solar heat collector. Proc. Inst. Mech. Eng. 1955, 169, 1091–1112. [Google Scholar] [CrossRef]

- Klein, S. Calculation of flat-plate collector loss coefficients. Sol. Energy 1975, 17, 79–80. [Google Scholar] [CrossRef]

- Fudholi, A.; Sopian, K. A review of solar air flat plate collector for drying application. Renew. Sustain. Energy Rev. 2018, 102, 333–345. [Google Scholar] [CrossRef]

- Golneshan, A.; Nemati, H. Exergy analysis of unglazed transpired solar collectors (UTCs). Sol. Energy 2014, 107, 272–277. [Google Scholar] [CrossRef]

- Badache, M.; Hallé, S.; Rousse, D. A full 34 factorial experimental design for efficiency optimization of an unglazed transpired solar collector prototype. Sol. Energy 2012, 86, 2802–2810. [Google Scholar] [CrossRef]

- Leon, M.A.; Kumar, S. Mathematical modeling and thermal performance analysis of unglazed transpired solar collectors. Sol. Energy 2007, 81, 62–75. [Google Scholar] [CrossRef]

- Kutscher, C.F. Heat exchange effectiveness and pressure drop for air flow through perforated plates with and without crosswind. J. Heat Transf. 1994, 116, 391–399. [Google Scholar] [CrossRef]

- Esfe, M.H.; Behbahani, P.M.; Arani, A.A.A.; Sarlak, M.R. Thermal conductivity enhancement of SiO2–MWCNT (85: 15%)–EG hybrid nanofluids. J. Therm. Anal. Calorim. 2017, 128, 249–258. [Google Scholar] [CrossRef]

- Esfahani, N.N.; Toghraie, D.; Afrand, M.J. A new correlation for predicting the thermal conductivity of ZnO–Ag (50–50%)/water hybrid nanofluid: An experimental study. Powder Technol. 2018, 323, 367–373. [Google Scholar] [CrossRef]

- Toghraie, D.; Chaharsoghi, V.A.; Afrand, M.J. Measurement of thermal conductivity of ZnO–TiO2/EG hybrid nanofluid. J. Therm. Anal. Calorim. 2016, 125, 527–535. [Google Scholar] [CrossRef]

- Alirezaie, A.; Saedodin, S.; Esfe, M.H.; Rostamian, S.H. Investigation of rheological behavior of MWCNT (COOH-functionalized)/MgO-engine oil hybrid nanofluids and modelling the results with artificial neural networks. J. Mol. Liq. 2017, 241, 173–181. [Google Scholar] [CrossRef]

- Moldoveanu, G.M.; Ibanescu, C.; Danu, M.; Minea, A.A. Viscosity estimation of Al2O3, SiO2 nanofluids and their hybrid: An experimental study. J. Mol. Liq. 2018, 253, 188–196. [Google Scholar] [CrossRef]

- Motahari, K.; Moghaddam, M.A.; Moradian, M. Experimental investigation and development of new correlation for influences of temperature and concentration on dynamic viscosity of MWCNT-SiO2 (20–80)/20W50 hybrid nano-lubricant. Chin. J. Chem. Eng. 2018, 26, 152–158. [Google Scholar] [CrossRef]

- Sajid, M.U.; Ali, H.M.J. Thermal conductivity of hybrid nanofluids: A critical review. Int. J. Heat Mass Transf. 2018, 126, 211–234. [Google Scholar] [CrossRef]

- Choi, C.; Yoo, H.; Oh, J. Preparation and heat transfer properties of nanoparticle-in-transformer oil dispersions as advanced energy-efficient coolants. Curr. Appl. Phys. 2007, 8, 710–712. [Google Scholar] [CrossRef]

- Otanicar, T.P.; Phelan, P.E.; Prasher, R.S.; Rosengarten, G.; Taylor, R.A. Nanofluid-based direct absorption solar collector. J. Renew. Sustain. Energy 2010, 2, 33102. [Google Scholar] [CrossRef] [Green Version]

- Khullar, V.; Tyagi, H.; Phelan, P.; Otanicar, T.; Singh, H.; Taylor, R.A. Solar energy harvesting using nanofluids-based concentrating solar collector. J. Nanotechnol. Eng. Med. 2012, 3, 31003. [Google Scholar] [CrossRef]

- Sundar, L.S.; Kirubeil, A.; Punnaiah, V.; Singh, M.K.; Sousa, A. Effectiveness analysis of solar flat plate collector with Al2O3 water nanofluids and with longitudinal strip inserts. Int. J. Heat Mass Transf. 2018, 127, 422–435. [Google Scholar] [CrossRef]

- Khaleduzzaman, S.; Sohel, M.; Saidur, R.; Selvaraj, J. Stability of Al2O3-water nanofluid for electronics cooling system. Procedia Eng. 2015, 105, 406–411. [Google Scholar] [CrossRef] [Green Version]

- Shao, X.; Chen, Y.; Mo, S.; Cheng, Z.; Yin, T. Dispersion stability of TiO2-H2O nanofluids containing mixed nanotubes and nanosheets. Energy Procedia 2015, 75, 2049–2054. [Google Scholar] [CrossRef] [Green Version]

- Gorjian, S.; Ebadi, H.; Calise, F.; Shukla, A.; Ingrao, C. A review on recent advancements in performance enhancement techniques for low-temperature solar collectors. Energy Convers. Manag. 2020, 222, 113246. [Google Scholar] [CrossRef]

- Hamzah, M.H.; Sidik, N.A.C.; Ken, T.L.; Mamat, R.; Najafi, G. Factors affecting the performance of hybrid nanofluids: A comprehensive review. Int. J. Heat Mass Transf. 2017, 115, 630–646. [Google Scholar] [CrossRef]

- Ma, M.; Zhai, Y.; Yao, P.; Li, Y.; Wang, H. Synergistic mechanism of thermal conductivity enhancement and economic analysis of hybrid nanofluids. Powder Technol. 2020, 373, 702–715. [Google Scholar] [CrossRef]

- Alirezaie, A.; Hajmohammad, M.H.; Ahangar, M.R.H.; Esfe, M.H. Price-performance evaluation of thermal conductivity enhancement of nanofluids with different particle sizes. Appl. Therm. Eng. 2018, 128, 373–380. [Google Scholar] [CrossRef]

| Reference | Types | Schematic Image | Applications |

|---|---|---|---|

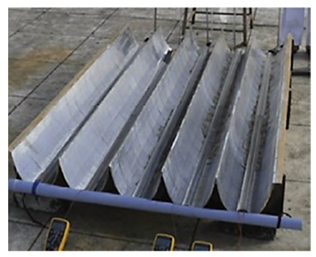

| Tang, Cheng [86] | Flat-plate solar collector (FPSC) |  | Solar collector of this sort is abruptly utilized in residential hot water. Additionally, in manufacturing air deicer. 20–80 °C is the working temperature. Thus, it acts as foremost common sort of collector in different kinds of sun-oriented collector frameworks. Provides higher productivity and outlet temperatures when there is less warmth through the cover of glass in collector and the requirement of sunlight. Customary sorts are for the most part planned for warm climates. Efficiencies for 500 and 1000 W/m2 are 0.71–0.75 and 0.72–0.75 separately. |

| Arunkumar, Velraj [87] | Compound parabolic collector (CPC) |  | In terms of flow, these types are rather proficient in collection and concentration of far-off light sources, with a few acceptance points. Basic components in sun-oriented vitality collection, remote contact, sun-focused drying, water purification, biomedical, or any device involving condensation of a disparate source of light. It covers a temperature of 60–240 °C. 500 and 1000 W/m2, with different efficiencies 0.45–0.73 and 0.58–0.72. |

| Papadimitratos, Sobhansarbandi [88] | Evacuated tube solar collector (ETSC) |  | These types are rather communal in residential hot water. Competent as air deicer. The working temperature of ETSC is 50–200 °C. They are more prudent than routine. In the cold weather, they provide more than FPC. Efficiencies of 500 W/m2 and 1000 W/m2 are between 0.44–0.82 and 0.62–0.82. |

| Li, Xu [89] | Parabolic trough collector (PTC) |  | Presently, as the most commercially used and most progressed, these types are rather proficient in control plants. Their capacity leads to the utilization of hybridization and vitality capacity by warm-vitality capacity. The preferences of PTC innovation incorporate the guarantee of the temperate venture, progressed innovation, ample operational involvement, and fossil-filling office and green energy sources. These have a temperature range of 400–500 °C. |

| Beltagy, Semmar [90] | Linear fresnel collector |  | These types play crucial roles in controlling plants. Currently, in the coordinated steam era, there is a predominance of utilizing this innovation compared to other sun-based frameworks, thereby reducing the cost of heat shift. The frame can be concentrated to provide surcharged steam. Significantly lower than the illustrative trough concentrators of 30–100, the defensive concentration variables are 10–40. Temperatures range between 100–450 °C. |

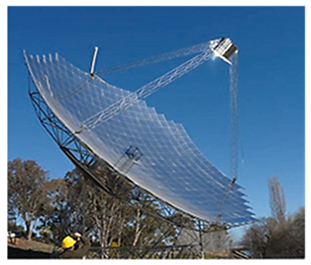

| Li, Dubowsky [91] | Parabolic dish reflector |  | This is simply defined as an electrical generator that generates daylight rather than coal or unrefined oil to create power. It was prepared with a dynamic following framework that can indicate the sun reliably. Temperatures can reach as high as 1500 °C. |

| Roca, de la Calle [92] | Heliostat field collector |  | Overheating during operation; costly choice for a broad range of operating applications including the development of solar energy, solar power, solar assist, carbon capture, water, and home applications. Temperature range of 12–85 °C. |

| Author | Nanoparticles | Base Fluids | Research Study |

|---|---|---|---|

| Ho, Huang [80] | Al2O3, MEPCM | Water | Crossbreed water, primarily based nanoparticle laminar in a round deportation |

| Han and Rhi [77] | Ag, Al2O3 | Water | Considered warm characteristics for hybrid nanofluids on a notched warm channel. |

| Baby and Sundara [54] | Ag, HEG | HEG–Deionized water and Ethylene glycol (EG) | Improvement of heat physical phenomenon and warmth transfer for the arranged hybrid nanoparticle. |

| Esfe, Yan [93] | Ag, Al2O3 | Water | Arrangement and characterization considered. |

| Selvakumar, Suresh [79], Suresh, Venkitaraj [94] | Cu, Al2O3 | Water | Exploratory considerations of convective warm exchange and weight drop for crossbreed nanofluids in an electronic warm sink. |

| Baghbanzadeh, Rashidi [95] | Silica, MWCNT | Distilled water | Heat transfer and weight drop for hybrid nanofluids in the associated electronic heat sink. |

| Chen, Yu [96] | Ag, MWCNT | Water | Considered the upgrade of compelling thermal conductivity. |

| Chen, Yu [96] | Graphene, MWCNT | Deionized water and Ethylene glycol (EG) | Upgrade of warm properties for hybrid nanofluids. |

| Jyothirmayee Aravind and Ramaprabhu [97] | Al2O3, MWCNT | water | Improvement of warm conductivity for single and half-breed nanofluids. |

| Munkhbayar, Tanshen [98] | Ag, MWCNT | Water | Examined the warm characteristics for the prepared cross breed nanofluids. |

| Labib, Nine [99] | CNT, Al2O3 | Water | Analytical examination along with the impact of associate fluids and cross-breed nanofluid in constrained convective heat exchange. |

| Tomar and Chakrabarty [100] | TiO2, ZrO2 | - | Considered the auxiliary and optical properties for the arranged nanocomposite. |

| Suresh, Venkitaraj [101] | Cu, Al2O3 | Distilled water | Turbulent warm exchange and weight sip for hybrid nanofluids in a consistently warmed round tube. |

| Madhesh, Parameshwaran [81] | Cu, TiO2 | Water | Test considers convective heat transfer and natural philosophy characteristics of hybrid nanofluids in the tube heat exchanger. |

| Batmunkh, Tanshen [102] | MWCNT, Fe2O3 | Water | Tests consider heat-convective transfer and touch calculates nanofluids in a continuously warmed circular tube for a fully formed, turbulent stream on a crossover. |

| Xuan, Duan [103] | TiO2, Ag | Water | Upgrade in sun-based assimilation. |

| Takabi and Salehi [73] | Cu, Al2O3 | Water | Considered the enlargement of the warm transfer performance of a sinusoidal corrugated enclosure by utilizing crossover nanofluid. |

| Baghbanzadeh, Rashidi [104] | Silica, MWCNT | Water | Considered the examination of an upgrade of rheological properties (thickness and density) for crossover nanofluids. |

| Sundar, Misganaw [105] | ND, NI | Water and EG | Examined the upgrade of thermal conductivity and thickness for the hybrid nanofluid with distinctive base liquids. |

| Syam Sundar, Sousa [106] | CNT, Fe3O4 | Water | Examined the warm exchange upgrade in low-quality awareness for the arranged hybrid nanofluids in a tube with bent tape inserts beneath turbulent steam. |

| Esfe, Wongwises [107] | Cu, TiO2 | Water | Test examination of warm conductivity for the arranged crossover Nanofluids and created Artificial Neural Network (ANN) simulation and correlation for heat conductivity. |

| Esfe, Yan [93] | DWCNT, ZnO | Water | The heat conductivity improvement for the organized nanofluids examined for different temperatures (25 °C to 50 °C) and strong volume division of (0.25% to 1%). |

| Esfe, Arani [108] | Ag, MgO | Water | Exploratory investigation on warm conductivity and energetic consistency for the arranged crossover Nanofluids with different volume divisions run from (0% to 2%) and created a relationship for warm conductivity and energetic thickness for the arranged cross breed nanofluids. |

| Afrand, Toghraie [109] | Fe3O4, Ag | EG | In particular, the effect on the rheological activity of the arranged blended nano-fluid is checked for temperature and nanoparticulate concentration. |

| Eshgarf, Afrand [110] | MWCNT, SiO2 | EG-water | Experimental change of the temperature range (25 °C to 50 °C) from different suspensions to strong volume distribution and of the rheological behavior of non-Newtonian hybrid nano-coolants in heating and cooling frame applications from (0.0625% to 2%). |

| Harandi, Karimipour [58] | f-MWCNT, Fe3O4 | EG | The test considers the influence of temperature and concentration on the thermal conductivity of the arranged cross nanofluid from 25 °C to 50 °C, to test different tests of nanofluids with a volume fraction from 0.1% to 2.3% and unused produce. The relationship of the thermal conductivity of the fluid is considered for testing. |

| Sundar, Ramana [111] | ND, Fe3O4 | Water | Considered the improvement of warm conductivity, thickness for the arranged half-breed nanofluid by shifting the temperature ranges (20 °C to 60 °C) and the volume concentration (0.05 to 0.2%). Additionally, an unused relationship was established for the thermal conductivity and consistency of the semi-aligned nanofluid with exploratory information. |

| Soltani, Akbari [112] | MgO, MWCNT | EG | Exploratory consideration of energetic thickness for their arranged half-breed nanofluid with different volume concentrations (0.1% to 1%) by shifting the temperature (30 °C to 60 °C) and created an unused relationship for the energetic consistency from their experimental work. |

| Senniangiri, Bensam Raj [113,114] | Graphene/NiO | Coconut oil | The high nanomaterial concentration regenerates the formation of lamellar agglomerated particles and increases the complex viscosity of the basic fluid. To estimate the dynamism of the hybrid nanofluid with a limited deviation margin, it is suggested to use the theoretical correlation artificially (ANN). |

| Hussein, Habib [37] | Covalent functionalized graphene nanoplatelets | water | Found that when the mixed hybrid nanofluid was used as the absorption medium and the flow rate was 4 L/min, the solar collector with the highest thermal efficiency increased by as much as 85%. |

| Author | Base Fluid | Nanoparticles | Mass Volume % | Solar Collectors | Efficiency Observation |

|---|---|---|---|---|---|

| Harandi, Karimipour [58] | H2O | Al2O3/Fe, Al2O3 | 0.05–0.2 wt. | FPSC | Maximum 6.9% increase |

| Sundar, Misganaw [105] | H2O | ND–CO3O4 | 0.05–0.15 wt. | FPSC | Maximum 59% increase if 0.15 wt. |

| Hussein, Habib [37] | H2O | MWCNTs/GNPs/h-BN | 0.05–0.1 wt. | FPSC | Maximum 89% increase |

| [115] | H2O | MWCNTs/MgO, MWCNTs/CuO | 0.25–2 vol. | FPSC | Performance of CuO-MWCNT was 18.05%, while MgO-MWCNT was 20.52%. |

| Arıkan, Abbasoğlu [116] | H2O/EG | Al2O3, ZnO | 0.25 vol. | FPSC | Performance was 15.13% positive |

| [117] | H2O | SWCNT | 0.2 vol. | ETSC | Optium productivity at 93.43% |

| [118] | H2O | Al2O3, TiO2 | 0.3 wt. | ETSC | Compared to its based liquid, the system’s performance improved by 16.67% |

| Daghigh and Zandi [119] | H2O | MWCNT, CuO and TiO2 | Different | ETSC | Performance of the collector using nanoparticles MWCNT, CuO, and TiO2, compared to water, increased by 25%, 12%, and 5%, respectively. |

| Peng, Zahedidastjerdi [120] | Water | Al2O3, CuO, TiO2 | Different | ETSC | CuO has 1.5% higher collector thermal efficiency than Al203, TiO2-water fluid |

| Luo, Wang [121] | Oil | C, Ag, SiO2, Al2O3, Cu | 0.01–0.025 wt. | DAC | Efficiency improves by 30–100 K and by 2–25% than the base oil |

| Hussain, Jawad [122] | H2O | Ag and ZrO2 | 5 vol. | ETSC | Efficiency % not mentioned but improved. |

| Kim, Ham [123] | 20% propylene glycol-water | MWCNT, Al2O3, CuO, SiO2, and TiO2 | 0.2 vol. | ETSC | Performance 20% increase |

| Kaya, Gürel [124,125] | Methanol | CuO | 0.3 vol. | Tube | Performance 63% increase |

| Gorji and Ranjbar [126,127] | water | Graphite, Magnetite—15 nm, Silver—20 nm | 5–40 ppm | DAC | According to the results, nanofluids promoted thermal and exergy efficiencies by 33–57% and 13–20%, respectively, compared to base fluid. |

| Li, Chang [128] | Di-water | Ti3AlC2, hydrochloric acid, triton X—100 | 100 ppm | DAC | For MXene loading, the maximum photothermal conversion efficiency of 77.49% is achieved. |

| Samylingam, Aslfattahi [69] | Di-water | Ti3AlC2, plum oil—MXene-OPO | 0.2 wt. | DAC | A 40% efficiency increase with respect to Al2O3-water-based nanofluid. |

| Gupta, Singh [129] | Water | ZnFe2O4 | 0.02–0.5 wt. | DAC | Performance enhancement of 42.99% |

| Abdelrazik, Tan [130] | Di-water | rGO-Ag, graphene oxide | 0.0005 to 0.05 wt. | DAC | Hybrid system displays improved efficiency at concentrations of less than 0.0235 wt. percent compared to the PV system without integration with optical filtration. The hybrid solar PV/T system with OF using water/rGO-Ag nanofluid can produce thermal energy with efficiencies between 24 percent and 30 percent. |

| Kasaeian, Daneshazarian [131] | EG | Nano silica | 0.3 wt. | PTC | Maximum outlet temperature of MWCNT is 338.3 K, and the thermal performance reaches 74.9%. |

| Loni, Pavlovic [132] | Water | TiO2, SiO2, Fe2O3, ZnO, Al2O3. | N/A | PTC | Use pure water to enhance the energy performance of low enthalpy parabolic trough collectors. |

| Esfe, Alirezaie [133] | EG | SWCNT-MgO | 0.05–2 vol. | PTC | Thermal conductivity enhancement of 18%. |

| Bahrami, Akbari [24] | EG-water | Fe-CuO | 0.05–1.5 wt. | PTC | Efficiency increases in the different conditions in different types. |

| [134] | Engine oil | MWCNT-ZnO | 0.125–1.0 wt. | PTC | If the viscosity increases then the efficiency increases. |

| Afrand [135] | EG | MgO-MWCNT | 0.6 vol. | PTC | Performance increase—21% |

| Sundar, Singh [136] | EG-water | graphene oxide/CO3O4 | 0.2 vol. | PTC | Performance increase—water based—19.14% Performance increase—EG based 11.75% |

| Nine, Batmunkh [137] | Water | Al2O3-MWCNT | 1–6 wt. | PTC | Increasing thermal conductivity is not sharp when compared to simple nanofluids |

| Baby and Sundara [54] | Water and EG | CuO-HEG | 0.05 vol. | PTC | Increasing thermal conductivity with volume fraction |

| Khan, Abid [138] | Oil-based | Al2O3, CuO and TiO2 | 1 wt. | Solar dish collector | Performance increased by 33.73% and 36.27% |

| Loni, Pavlovic [132] | Thermal oil | Cu, CuO, TiO2, and Al2O3 | 0–5 wt. | Solar dish collector | Thermal efficiency is found to be equivalent to 35% and up to 10% of the exergy efficiency. |

| Zadeh, Sokhansefat [139] | Synthesis oil/thermal oil | Al2O3 | N/A | Tube | Improve the mean efficiency by 4.25%. |

| Huang and Marefati [140] | Thermal oil and water | CuO and Al2O3 | N/A | Solar dish collector | Efficiency increase—28.7% |

| Loni, Asli-Ardeh [141] | Thermal oil | Al2O3/thermal, SiO2/thermal | N/A | Solar dish collector | Improve efficiency |

| Potenza, Milanese [142] | Airflow | CuO, nanopowder | N/A | Transparent receiver tube | Mean efficiency of about 65% |

| Aslfattahi, Samylingam [143] | Silicon oil | MXene with a chemical formula of Ti3C2 | 0.1 wt. | Photovoltaic thermal collector | Thermal conductivity improvement of 64%. |

| Soltani, Kasaeian [144] | Water | SiO2, Fe3O4 | N/A | Photovoltaic thermal-thermoelectric system | Maximum energy efficiency at the fixed irradiation of 900 W/m2. |

| Sardarabadi, Passandideh-Fard [145] | Water | SiO2 | 1–3 wt. | Photovoltaic thermal-thermoelectric system | Total exergy of the PV/T system with nanofluids was increased by up to 24.31%. |

| Arora, Singh [146] | Water | SWCNT, MWCNT NP | Different | Photovoltaic thermal-thermoelectric system | Percentage enhancement in total yield obtained using SWCNT and MWCNT was 65.7% and 28.1%, respectively. |

| Wahab, Khan [147] | Water | Graphene hybrid | 0.05–0.15 vol. | Hybrid photovoltaic thermal system. | Maximum sustainability index of 1.17 is shown at optimum conditions. |

| Soltani, Kasaeian [148] | Water | SiO2, Fe3O4 | Mass ratio 0.5 vol. | Photovoltaic thermal collector | Improvement of 54.29% and 1.72% in both power production and efficiency. |

| Sardarabadi, Hosseinzadeh [149] | Water | Al2O3, TiO2, ZnO | 0.2 wt. | Photovoltaic thermal collector | Results indicate that the overall exergy efficiencies for the cases of PVT/water, PVT/TiO2, PVT/Al2O3, and PVT/ZnO are enhanced by 12.34%, 15.93%, 18.27%, and 15.45%, respectively |

| Sardarabadi, Passandideh-Fard [150] | Water | TiO2, ZnO, Al2O3 | 0.2 | Photovoltaic thermal collector | Performance of ZnO is better than for the other types. The numerical model shows that the mass fraction of hybrid nanofluid has a significant impact on the thermal performance of PVT collectors. |

| References | Specification | Correlation | Remarks |

|---|---|---|---|

| Esfe, Behbahani [161] | Functioning fluid: SiO2-MWCNT/EG Temperature field: 30–50 °C Volume area: 0.05–1.95 vol. % | Two design methods and a feed-forward neural network have been provided to model the thermal conductivity of the hybrid nanofluid. R2 values of 0.9864 and 0.9981 were obtained for new methods and the artificial neural network (ANN). When these two measurement methods were compared to experimental data, both methods proved to be effective in predicting data. However, ANN’s correlation findings have a much lower error. | |

| Afrand [135] | Functioning fluid: MgO-MWCNT/EG Temperature field: 25–50 °C Volume area: 0–0.6 vol. % | Maximum increase in nanofluid thermal conductivity is 21.3%. A new connection was proposed to estimate the nanofluid thermal conductivity. | |

| Sardarabadi, Passandideh-Fard [150] | Functioning fluid: f-MWCNTs-Fe3O4/EG Temperature field: 25–50 °C Volume range: 0–2.3 vol. % | Numerical simulation has been validated and used for the effects of mass ZnO-nanoparticles on TiO2, ZnO, Al2O3/water nanofluids (0.2 wt.%). | |

| Esfahani, Toghraie [162] | Functioning fluid: ZnO-Ag/H2O Temperature range: 25–50 °C Volume range: 0.125–2 vol. % | Effect on thermal conductivity of hybrid nanofluid of volume fractions and temperatures is demonstrated. | |

| Toghraie, Chaharsoghi [163] | Functioning fluid: ZnO-Ag/H2O Temperature field: 25–50 °C Volume percentage: 0–3.5 vol. % | Increase in thermal conductivity variance of nano-fluids with a higher solid volume fraction temperature is also greater than that of a lower solid volume fraction. | |

| Alirezaie, Saedodin [164] | Functioning fluid: f-MWCNT-MgO/engine oil Volume percentage: 0.0625–1 vol. % Heat range: 25–50 °C Shear rate: 50–650 rpm | Experimental data were calculated with a three-variable correlation, with artificial neural networks modeling the experimental results. The comparison of experimental results with the simulations shows that neural-network modeling is highly accurate. | |

| Asadi, Asadi [134] | Functioning fluid: f-MWCNT-ZnO/engine oil Volume percentage: 0.125–1 vol. % Heat variable: 5–55 °C | At a solid concentration of 2 percent and a temperature of 40 °C, a maximal increase in dynamic viscosity was achieved at 65% while a minimum increase in solid concentration was achieved at 0.25% and a temperature of 25 °C was achieved at 14.4%. | |

| Esfe, Arani [62] | Functioning fluid: MWCNT-ZnO/10W40 engine oil Volume percentage: 0.05–1 vol. % Temperature difference: 5–55 °C | Thermal conductivity at some temperatures was 38% higher than that of ethylene glycol. A new correlation of volume concentration and temperature (R2 = 0.9925) is proposed to forecast experimental thermal conductivity. | |

| Moldoveanu, Ibanescu [165] | Functioning fluid: Al2O3-SiO2/H2O | Temperature variation in viscosity for hybrid nanofluid, which underpins viscosity reduction as the temperature increase rises and the action of low hysteresis, has been studied experimentally, proposing two viscosity variation equations as the temperature increases. | |

| Motahari, Moghaddam [166,167] | Functioning fluid: MWCNT-SiO2/20W50 oil Volume range: 0.05–1 vol. % Heat range: 40–100 °C | Increase in solid volume fraction and temperature-improved hybrid nano-lubricant viscosity. Nano viscosity was 171 percent higher than pure 20W50, at its maximum solid volume fraction and temperature. Current models are not capable of predicting the hybrid viscosity of nano-lubricants. A new correlation was thus suggested with an R-squared of 0.9943 with regard to solid volume fraction and temperature. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mahamude, A.S.F.; Kamarulzaman, M.K.; Harun, W.S.W.; Kadirgama, K.; Ramasamy, D.; Farhana, K.; Bakar, R.A.; Yusaf, T.; Subramanion, S.; Yousif, B. A Comprehensive Review on Efficiency Enhancement of Solar Collectors Using Hybrid Nanofluids. Energies 2022, 15, 1391. https://doi.org/10.3390/en15041391

Mahamude ASF, Kamarulzaman MK, Harun WSW, Kadirgama K, Ramasamy D, Farhana K, Bakar RA, Yusaf T, Subramanion S, Yousif B. A Comprehensive Review on Efficiency Enhancement of Solar Collectors Using Hybrid Nanofluids. Energies. 2022; 15(4):1391. https://doi.org/10.3390/en15041391

Chicago/Turabian StyleMahamude, Abu Shadate Faisal, Muhamad Kamal Kamarulzaman, Wan Sharuzi Wan Harun, Kumaran Kadirgama, Devarajan Ramasamy, Kaniz Farhana, Rosli Abu Bakar, Talal Yusaf, Sivarao Subramanion, and Belal Yousif. 2022. "A Comprehensive Review on Efficiency Enhancement of Solar Collectors Using Hybrid Nanofluids" Energies 15, no. 4: 1391. https://doi.org/10.3390/en15041391

APA StyleMahamude, A. S. F., Kamarulzaman, M. K., Harun, W. S. W., Kadirgama, K., Ramasamy, D., Farhana, K., Bakar, R. A., Yusaf, T., Subramanion, S., & Yousif, B. (2022). A Comprehensive Review on Efficiency Enhancement of Solar Collectors Using Hybrid Nanofluids. Energies, 15(4), 1391. https://doi.org/10.3390/en15041391