Densification of Yak Manure Biofuel Pellets and Evaluation of Parameters: Effects on Properties

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Properties of Yak Manure

2.3. Testing Equipment

2.4. Experimental Design

2.4.1. Single Factor Test

2.4.2. Response Surface Methodology Analysis

2.5. Methods

2.5.1. Adjustment of Moisture Content

2.5.2. Preparation of Fuel Pellets

2.6. Determination of Quality Properties

2.6.1. Density

2.6.2. Durability

3. Results and Discussion

3.1. Yak Manure Characteristics

3.2. Analysis of Single-Factor Test Results

3.2.1. Effect of Pressure

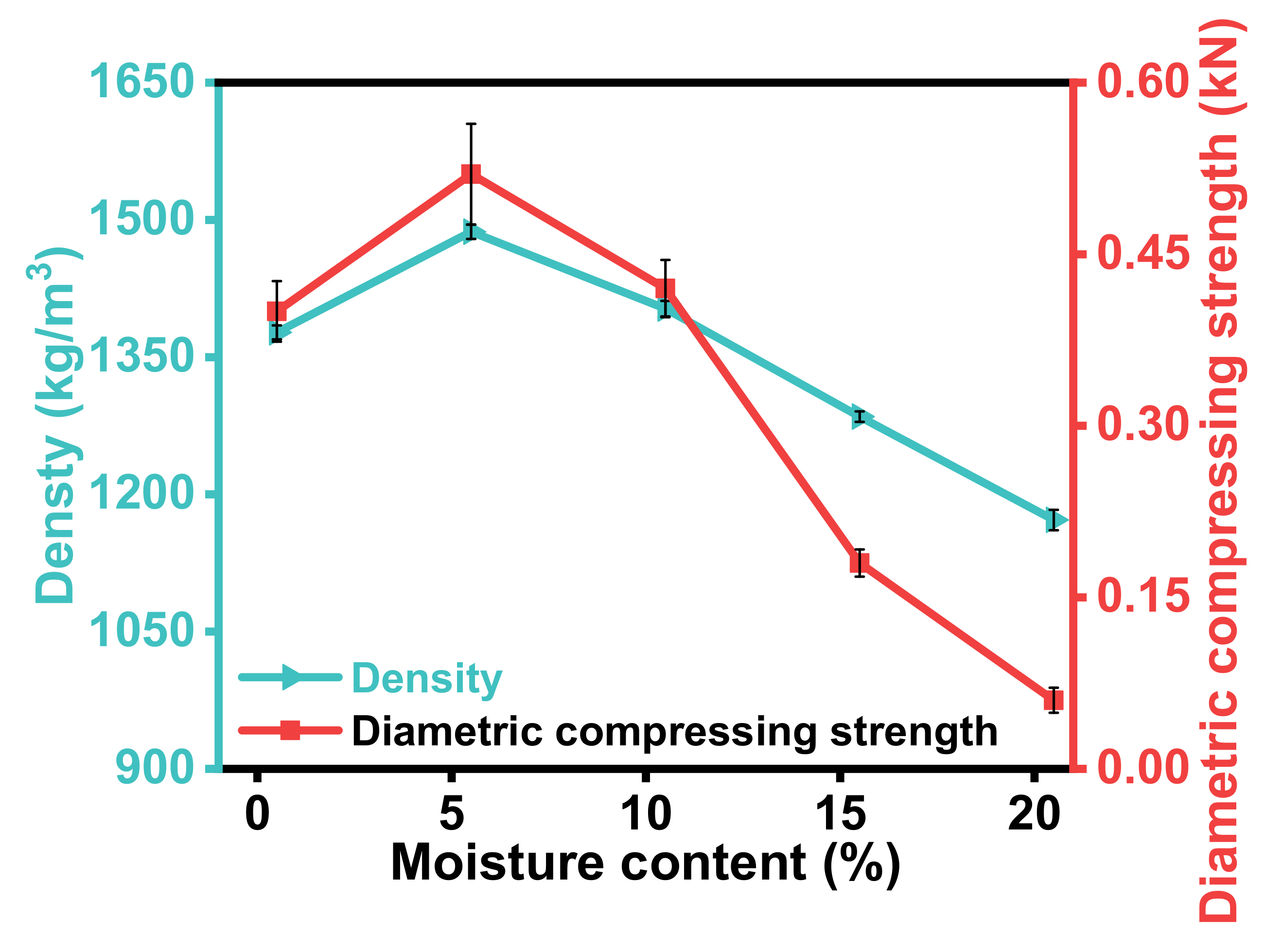

3.2.2. Effect of Moisture Content

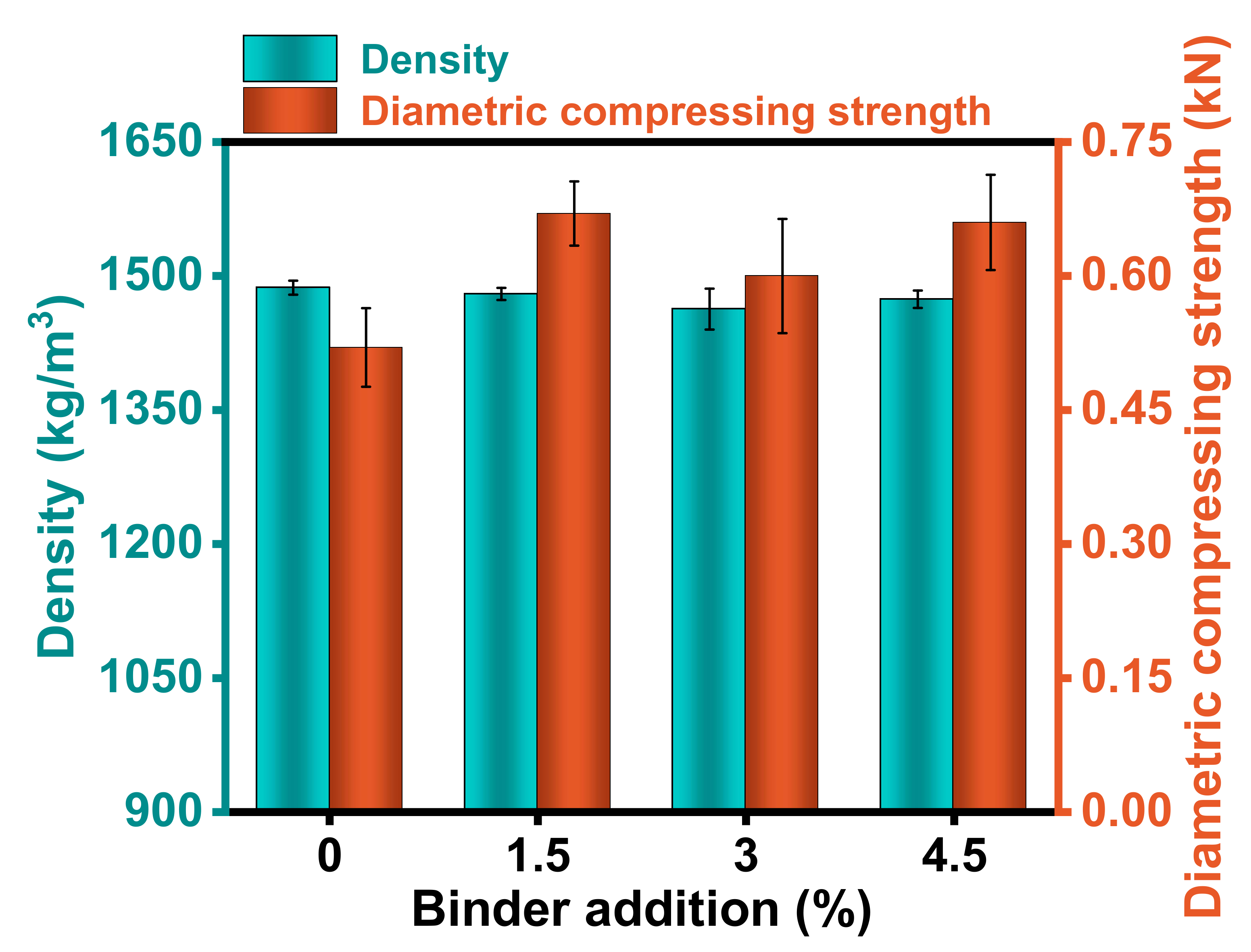

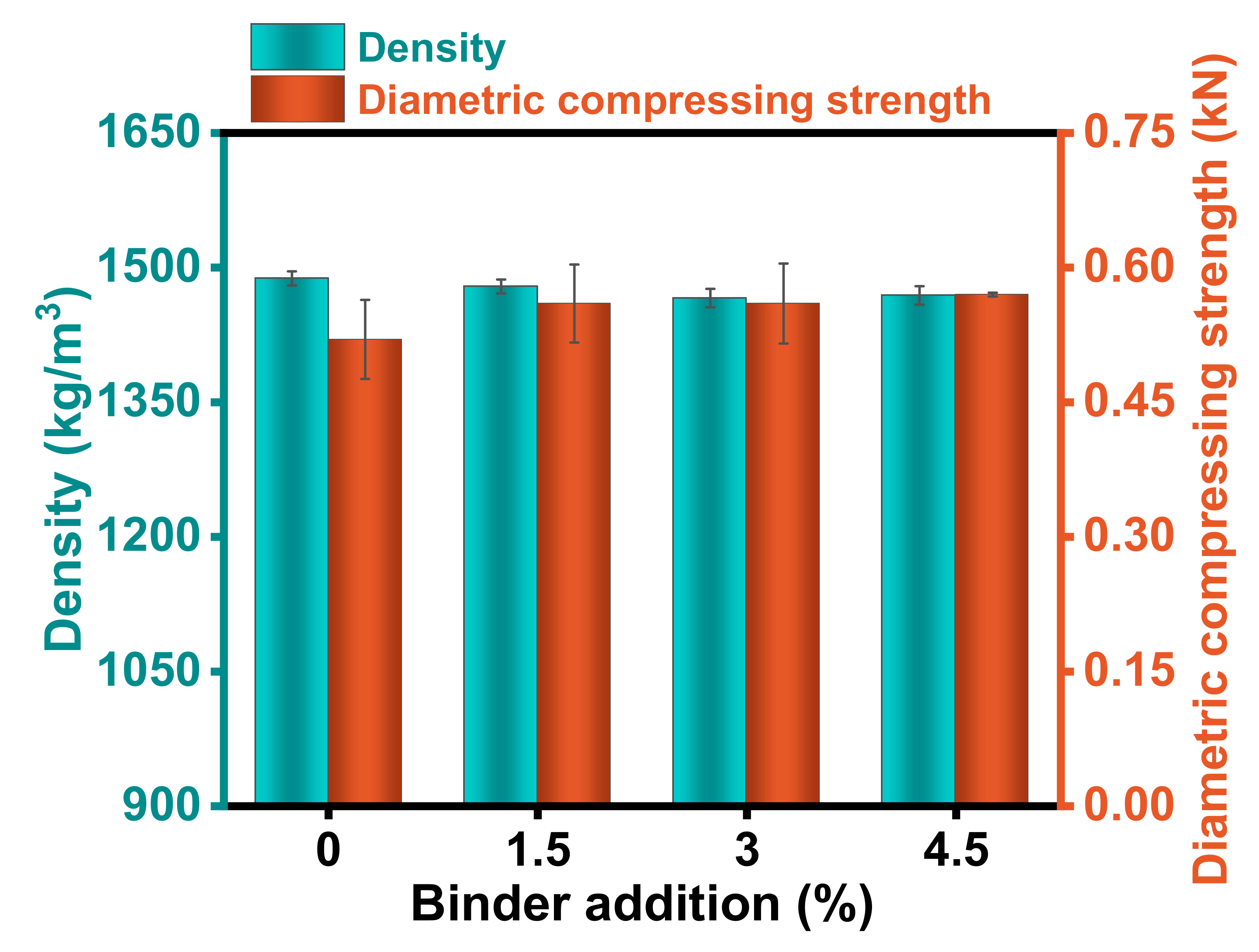

3.2.3. Effect of Binders

3.3. Response Surface Methodology Analysis

3.3.1. Statistical Analysis and Model Fitting

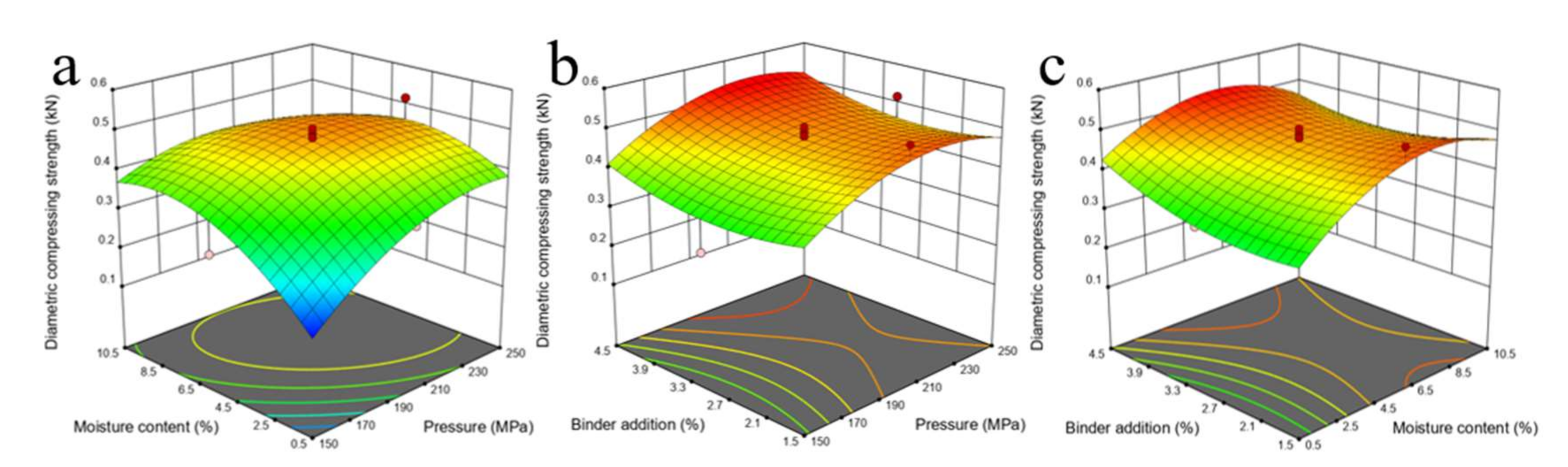

3.3.2. Three-D (3D) Surface Plot

3.3.3. Optimization of Process Variables and Validation of Result

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ibitoye, S.E.; Jen, T.C.; Mahamood, R.M.; Akinlabi, E.T. Densification of agro-residues for sustainable energy generation: An overview. Bioresour. Bioprocess. 2021, 8, 75. [Google Scholar] [CrossRef]

- Laougé, Z.B.; Merdun, H. Pyrolysis and combustion kinetics of Sida cordifolia L. using thermogravimetric analysis. Bioresour. Technol. 2020, 299, 122602. [Google Scholar] [CrossRef] [PubMed]

- Statistical Review of World Energy 2021. Available online: https://www.bp.com/en/global/corporate/energy-economics/statistical-review-of-world-energy.html (accessed on 9 July 2021).

- Liu, J.; Jiang, X.; Cai, H.; Gao, F. Study of Combustion Characteristics and Kinetics of Agriculture Briquette Using Thermogravimetric Analysis. ACS Omega 2021, 6, 15827–15833. [Google Scholar] [CrossRef]

- Anekwe, I.M.S.; Khotseng, L.; Isa, Y.M. The Place of Biofuel in Sustainable Living; Prospects and Challenges; Reference Module in Earth Systems and Environmental Sciences; Elsevier: Amsterdam, The Netherlands, 2021. [Google Scholar] [CrossRef]

- Gent, S.; Twedt, M.; Gerometta, C.; Almberg, E. (Eds.) Chapter Two—Introduction to Feedstocks. In Theoretical and Applied Aspects of Biomass Torrefaction; Butterworth-Heinemann: Burlington, MA, USA, 2017; pp. 17–39. [Google Scholar]

- Whittaker, C.; Shield, I. Factors affecting wood, energy grass and straw pellet durability—A review. Renew. Sustain. Energy Rev. 2017, 71, 1–11. [Google Scholar] [CrossRef]

- Pradhan, P.; Mahajani, S.M.; Arora, A. Production and utilization of fuel pellets from biomass: A review. Fuel Process. Technol. 2018, 181, 215–232. [Google Scholar] [CrossRef]

- Stolarski, M.J.; Szczukowski, S.; Tworkowski, J.; Krzyżaniak, M.; Gulczyński, P.; Mleczek, M. Comparison of quality and production cost of briquettes made from agricultural and forest origin biomass. Renew. Energy 2013, 57, 20–26. [Google Scholar] [CrossRef]

- Liu, J.; Cheng, W.; Jiang, X.; Muhammad, U.K.; Zhang, Q.; Cai, H. Effect of extractives on the physicochemical properties of biomass pellets: Comparison of pellets from extracted and non-extracted sycamore leaves. BioResources 2021, 15, 544–556. [Google Scholar] [CrossRef]

- Wang, Z.; Lei, T.; Chang, X.; Shi, X.; Xiao, J.; Li, Z.; He, X.; Zhu, J.; Yang, S. Optimization of a biomass briquette fuel system based on grey relational analysis and analytic hierarchy process: A study using cornstalks in China. Appl. Energy. 2015, 157, 523–532. [Google Scholar] [CrossRef]

- Iftikhar, M.; Asghar, A.; Ramzan, N.; Sajjadi, B.; Chen, W. Biomass densification: Effect of cow dung on the physicochemical properties of wheat straw and rice husk based biomass pellets. Biomass Bioenergy 2019, 122, 1–16. [Google Scholar] [CrossRef]

- Rajput, S.P.; Jadhav, S.V.; Thorat, B.N. Methods to improve properties of fuel pellets obtained from different biomass sources: Effect of biomass blends and binders. Fuel Process. Technol. 2020, 199, 106255. [Google Scholar] [CrossRef]

- Afra, E.; Abyaz, A.; Saraeyan, A. The production of bagasse biofuel briquettes and the evaluation of natural binders (LNFC, NFC, and lignin) effects on their technical parameters. J. Clean. Prod. 2021, 278, 123543. [Google Scholar] [CrossRef]

- Liang, M.; Lu, W.; Lei, P.; Wang, L.; Wang, B.; Li, B.; Shen, Y.; Zhang, K. Physical and Combustion Properties of Binder-Assisted Hydrochar Pellets from Hydrothermal Carbonization of Tobacco Stem. Waste Biomass Valorization 2020, 11, 6369–6382. [Google Scholar] [CrossRef]

- Lavergne, S.; Larsson, S.H.; Perez, D.D.S.; Marchand, M.; Campargue, M.; Dupont, C. Effect of process parameters and biomass composition on flat-die pellet production from underexploited forest and agricultural biomass. Fuel 2021, 302, 121076. [Google Scholar] [CrossRef]

- Yu, Y.; Lau, A.; Sokhansanj, S. Improvement of the pellet quality and fuel characteristics of agricultural residues through mild hydrothermal treatment. Ind. Crops Prod. 2021, 169, 113654. [Google Scholar] [CrossRef]

- Jiang, L.; Liang, J.; Yuan, X.; Li, H.; Li, C.; Xiao, Z.; Huang, H.; Wang, H.; Zeng, G. Co-pelletization of sewage sludge and biomass: The density and hardness of pellet. Bioresour. Technol. 2014, 166, 435–443. [Google Scholar] [CrossRef]

- Degen, A.A.; Meccawi, S.E.; Kam, M. Milk and Dung Production by Yaks (Poephagus grunniens): Important Products for the Livelihood of the Herders and for Carbon Recycling on the Qinghai-Tibetan Plateau. In Carbon Management for Promoting Local Livelihood in the Hindu Kush Himalayan (HKH) Region; Springer: Cham, Switzerland, 2020; pp. 145–162. [Google Scholar] [CrossRef]

- Bai, Y.; Rafiq, M.K.; Li, S.; Degen, A.A.; Masek, O.; Sun, H.; Han, H.; Wang, T.; Joseph, T.; Bachmann, R.T.; et al. Biochar from pyrolyzed Tibetan Yak dung as a novel additive in ensiling sweet sorghum: An alternate to the hazardous use of Yak dung as a fuel in the home. J. Hazard. Mater. 2021, 403, 123647. [Google Scholar] [CrossRef]

- Proximate Analysis of Solid Biofuels (GB/T 28731-2012). Available online: http://www.gb688.cn/bzgk/gb/newGbInfo?hcno=E2D830152F09E47F4F6F7FF84555C30B (accessed on 5 November 2012).

- Antony, J. (Ed.) Chapter 4—A Systematic Methodology for Design of Experiments. In Design of Experiments for Engineers and Scientists, 2nd ed.; Elsevier: Oxford, UK, 2014; pp. 33–50. [Google Scholar] [CrossRef]

- Radi, B.; Saadoune, N.; El Hami, A. Chapter 7—Probabilistic Study and Optimization of a Solder Interconnect. In Embedded Mechatronic Systems 2, 2nd ed.; El Hami, A., Pougnet, P., Eds.; ISTE: London, UK, 2020; pp. 189–220. [Google Scholar] [CrossRef]

- Siyal, A.A.; Liu, Y.; Mao, X.; Siyal, Z.A.; Ran, C.; Ao, W.; Fu, J.; Zhou, C.; Wang, L.; Li, X.; et al. Co-pelletization of sewage sludge, furfural residue and corn stalk: Characteristics and quality analysis of pellets. Biomass Bioenergy 2021, 150, 106121. [Google Scholar] [CrossRef]

- Xie, R.Y.; Zhang, H.; Zhang, P.; Han, L. Effects and mechanism of pyrolysis temperature on physicochemical properties of corn stalk pellet biochar based on combined characterization approach of microcomputed tomography and chemical analysis. Bioresour. Technol. 2021, 329, 124907. [Google Scholar] [CrossRef] [PubMed]

- Mostafa, M.E.; Hu, S.; Wang, Y.; Su, S.; Hu, X.; Elsayed, S.A.; Xiang, J. The significance of pelletization operating conditions: An analysis of physical and mechanical characteristics as well as energy consumption of biomass pellets. Renew. Sustain. Energy Rev. 2019, 105, 332–348. [Google Scholar] [CrossRef]

- Setter, C.; Costa, K.L.S.; Oliveira, T.J.P.; Mendes, R.F. The effects of kraft lignin on the physicomechanical quality of briquettes produced with sugarcane bagasse and on the characteristics of the bio-oil obtained via slow pyrolysis. Fuel Process. Technol. 2020, 210, 106561. [Google Scholar] [CrossRef]

- Cheng, J.; Zhou, F.; Si, T.; Zhou, J.; Cen, K. Mechanical strength and combustion properties of biomass pellets prepared with coal tar residue as a binder. Fuel Process. Technol. 2018, 179, 229–237. [Google Scholar] [CrossRef]

- Sarker, T.R.; Nanda, S.; Meda, V.; Dalai, A.K. Pelletization of torrefied canola residue: Effects of microwave power, residence time and bio-additives on fuel pellet quality. Fuel 2022, 312, 122728. [Google Scholar] [CrossRef]

- Wang, T.; Tang, L.; Feng, X.; Xu, J.; Ding, L.; Chen, X. Influence of organic binders on the pyrolysis performance of rice straw pellets. J. Anal. Appl. Pyrolysis 2022, 161, 105366. [Google Scholar] [CrossRef]

- McKendry, P. Energy production from biomass (part 1): Overview of biomass. Bioresour. Technol. 2002, 83, 37–46. [Google Scholar] [CrossRef]

- Moliner, C.; Lagazzo, A.; Bosio, B.; Botter, R.; Arato, E. Production, Characterization, and Evaluation of Pellets from Rice Harvest Residues. Energies 2020, 13, 479. [Google Scholar] [CrossRef] [Green Version]

- Larsson, S.H.; Thyrel, M.; Geladi, P.; Lestander, T.A. High quality biofuel pellet production from pre-compacted low density raw materials. Bioresour. Technol. 2008, 99, 7176–7182. [Google Scholar] [CrossRef] [PubMed]

- Kaliyan, N.; Vance, M.R. Factors affecting strength and durability of densified biomass products. Biomass Bioenergy 2009, 33, 337–359. [Google Scholar] [CrossRef]

- Lisowski, A.; Pajor, M.; Świętochowski, A.; Dąbrowska, M.; Klonowski, J.; Mieszkalski, L.; Ekielski, A.; Stasiak, M.; Piatek, M. Effects of moisture content, temperature, and die thickness on the compaction process, and the density and strength of walnut shell pellets. Renew. Energy 2019, 141, 770–781. [Google Scholar] [CrossRef]

- Espuelas, S.; Marcelino, S.; Echeverría, A.M.; Castillo, J.M.; Seco, A. Low energy spent coffee grounds briquetting with organic binders for biomass fuel manufacturing. Fuel 2020, 278, 118310. [Google Scholar] [CrossRef]

- Soleimani, M.; Tabil, X.L.; Grewal, R.; Tabil, L.G. Carbohydrates as binders in biomass densification for biochemical and thermochemical processes. Fuel 2017, 193, 134–141. [Google Scholar] [CrossRef]

- Hu, Q.; Shao, J.; Yang, H.; Yao, D.; Wang, X.; Chen, H. Effects of binders on the properties of bio-char pellets. Appl. Energy 2015, 157, 508–516. [Google Scholar] [CrossRef]

- Said, N.; Abdel, M.M.; Maraver, A.G.; Zamorano, M. Influence of densification parameters on quality properties of rice straw pellets. Fuel Process. Technol. 2015, 138, 56–64. [Google Scholar] [CrossRef]

- Azargohar, R.; Nanda, S.; Kang, K.; Bond, T.; Karunakaran, C.; Dalai, A.K.; Kozinski, J.A. Effects of bio-additives on the physicochemical properties and mechanical behavior of canola hull fuel pellets. Renew. Energy 2019, 132, 296–307. [Google Scholar] [CrossRef]

- Emadi, B.; Iroba, K.L.; Tabil, L.G. Effect of polymer plastic binder on mechanical, storage and combustion characteristics of torrefied and pelletized herbaceous biomass. Appl. Energy 2017, 198, 312–319. [Google Scholar] [CrossRef]

| Ultimate Analysis (%) | Proximate Analysis (%) | |||||||

|---|---|---|---|---|---|---|---|---|

| C | H | O | N | S | MC | VM | FC | AC |

| 31.88 | 4.43 | 62.32 | 1.37 | 0.00 | 7.89 | 47.43 | 10.32 | 34.36 |

| Parameters | Responses | ||||

|---|---|---|---|---|---|

| Run | Pressure (MPa) | Moisture Content (%) | Binder Addition (%) | Density (kg/m3) | Diametric Compressing Strength (kN) |

| 1 | 200 | 5.5 | 4.5 | 1479.86 | 0.46 |

| 2 | 250 | 10.5 | 4.5 | 1423.43 | 0.40 |

| 3 | 250 | 0.5 | 1.5 | 1417.06 | 0.35 |

| 4 | 150 | 0.5 | 4.5 | 1391.21 | 0.29 |

| 5 | 200 | 5.5 | 3 | 1466.89 | 0.49 |

| 6 | 150 | 10.5 | 1.5 | 1413.47 | 0.43 |

| 7 | 250 | 5.5 | 3 | 1474.40 | 0.52 |

| 8 | 200 | 5.5 | 3 | 1470.93 | 0.46 |

| 9 | 200 | 10.5 | 3 | 1402.34 | 0.41 |

| 10 | 250 | 10.5 | 1.5 | 1397.60 | 0.38 |

| 11 | 250 | 0.5 | 4.5 | 1463.56 | 0.46 |

| 12 | 200 | 5.5 | 3 | 1475.65 | 0.48 |

| 13 | 150 | 0.5 | 1.5 | 1303.40 | 0.17 |

| 14 | 200 | 5.5 | 3 | 1474.28 | 0.50 |

| 15 | 200 | 5.5 | 3 | 1473.86 | 0.48 |

| 16 | 150 | 10.5 | 4.5 | 1418.97 | 0.44 |

| 17 | 200 | 5.5 | 3 | 1483.22 | 0.48 |

| 18 | 200 | 0.5 | 3 | 1415.33 | 0.34 |

| 19 | 150 | 5.5 | 3 | 1450.73 | 0.28 |

| 20 | 200 | 5.5 | 1.5 | 1488.87 | 0.53 |

| Source | Sum of Squares | df | Mean Square | F Value | p Value | |

|---|---|---|---|---|---|---|

| Model | 37540.96 | 9 | 4171.22 | 18.71 | <0.0001 | Significant |

| 3930.39 | 1 | 3930.39 | 17.76 | 0.0018 | ||

| 425.75 | 1 | 425.75 | 1.91 | 0.1971 | ||

| 2453.37 | 1 | 2453.37 | 11.00 | 0.0078 | ||

| 4872.00 | 1 | 4872.00 | 21.85 | 0.0009 | ||

| 55.04 | 1 | 55.04 | 0.2469 | 0.6300 | ||

| 1325.66 | 1 | 1325.66 | 5.95 | 0.0349 | ||

| 464.37 | 1 | 464.37 | 2.08 | 0.1795 | ||

| 12241.49 | 1 | 12241.49 | 54.91 | <0.0001 | ||

| 213.34 | 1 | 213.34 | 0.9569 | 0.3510 | ||

| Residual | 2229.50 | 10 | 222.95 | |||

| Lack of fit | 2081.81 | 5 | 416.36 | 14.10 | 0.0057 | Significant |

| Pure error | 147.69 | 5 | 29.54 | |||

| Cor Total | 39770.46 | 19 |

| Source | Sum of Squares | df | Mean Square | F Value | p Value | |

|---|---|---|---|---|---|---|

| Model | 0.1429 | 9 | 0.0159 | 7.17 | 0.0025 | Significant |

| 0.0267 | 1 | 0.0267 | 12.05 | 0.0060 | ||

| 0.0194 | 1 | 0.0194 | 8.76 | 0.0143 | ||

| 0.0034 | 1 | 0.0034 | 1.56 | 0.2406 | ||

| 0.0235 | 1 | 0.0235 | 10.60 | 0.0086 | ||

| 0.0000 | 1 | 0.0000 | 0.0091 | 0.9259 | ||

| 0.0053 | 1 | 0.0053 | 2.41 | 0.1519 | ||

| 0.0117 | 1 | 0.0117 | 5.28 | 0.0444 | ||

| 0.0202 | 1 | 0.0202 | 9.14 | 0.0128 | ||

| 0.0039 | 1 | 0.0039 | 1.78 | 0.2114 | ||

| Residual | 0.0222 | 10 | 0.0022 | |||

| Lack of fit | 0.0208 | 5 | 0.0042 | 15.92 | 0.0043 | Significant |

| Pure error | 0.0013 | 5 | 0.0003 | |||

| Cor Total | 0.1650 | 19 |

| Density | Diametric Compressing Strength | |

|---|---|---|

| Standard Deviation (Std. Dev.) | 14.93 | 0.0471 |

| Mean | 1439.25 | 0.4178 |

| Coefficient of Variance (C.V.) | 1.04 | 11.27 |

| Coefficient of Determination (R2) | 0.9439 | 0.8658 |

| Adjusted R2 | 0.8935 | 0.7450 |

| Adequate Precision | 16.8177 | 10.8856 |

| Name | Goal | Lower Limit | Upper Limit | Lower Weight | Upper Weight | Importance |

|---|---|---|---|---|---|---|

| Pressure | is in range | 150 | 250 | 1 | 1 | 3 |

| Moisture content | is in range | 0.5 | 10.5 | 1 | 1 | 3 |

| Binder addition | is in range | 1.5 | 4.5 | 1 | 1 | 3 |

| Density | maximize | 1303.4 | 1488.87 | 1 | 1 | 3 |

| Diametric compressing strength | maximize | 0.1721 | 0.5327 | 1 | 1 | 3 |

| No. | Pressure (MPa) | Moisture Content (%) | Binder Addition (%) | Density (kg/m3) | Diametric Compressing Strength (kN) | Desirability | |

|---|---|---|---|---|---|---|---|

| 1 | 229.470 | 6.003 | 4.443 | 1500.880 | 0.543 | 1.000 | Selected |

| 2 | 216.068 | 5.497 | 4.435 | 1501.976 | 0.537 | 1.000 | |

| 3 | 233.397 | 4.961 | 4.473 | 1505.968 | 0.536 | 1.000 | |

| 4 | 229.398 | 6.493 | 4.491 | 1497.847 | 0.533 | 1.000 |

| No. | Density (kg/m3) | Diametric Compressing Strength (kN) | ||||

|---|---|---|---|---|---|---|

| Predicted | Experimental | Error | Predicted | Experimental | Error | |

| 1 | 1502.02 | 1436.21 | 4.38% | 0.57 | 0.55 | 3.51% |

| 2 | 1502.02 | 1434.93 | 4.47% | 0.57 | 0.58 | 1.75% |

| 3 | 1502.02 | 1446.45 | 3.70% | 0.57 | 0.58 | 1.75% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Jiang, X.; Yuan, Y.; Chen, H.; Zhang, W.; Cai, H.; Gao, F. Densification of Yak Manure Biofuel Pellets and Evaluation of Parameters: Effects on Properties. Energies 2022, 15, 1621. https://doi.org/10.3390/en15051621

Liu J, Jiang X, Yuan Y, Chen H, Zhang W, Cai H, Gao F. Densification of Yak Manure Biofuel Pellets and Evaluation of Parameters: Effects on Properties. Energies. 2022; 15(5):1621. https://doi.org/10.3390/en15051621

Chicago/Turabian StyleLiu, Jianbiao, Xuya Jiang, Yanhao Yuan, Huanhuan Chen, Wenbin Zhang, Hongzhen Cai, and Feng Gao. 2022. "Densification of Yak Manure Biofuel Pellets and Evaluation of Parameters: Effects on Properties" Energies 15, no. 5: 1621. https://doi.org/10.3390/en15051621

APA StyleLiu, J., Jiang, X., Yuan, Y., Chen, H., Zhang, W., Cai, H., & Gao, F. (2022). Densification of Yak Manure Biofuel Pellets and Evaluation of Parameters: Effects on Properties. Energies, 15(5), 1621. https://doi.org/10.3390/en15051621