Splicing Method of Micro-Nano-Scale Pore Radius Distribution in Tight Sandstone Reservoir

Abstract

:1. Introduction

2. Materials and Methods

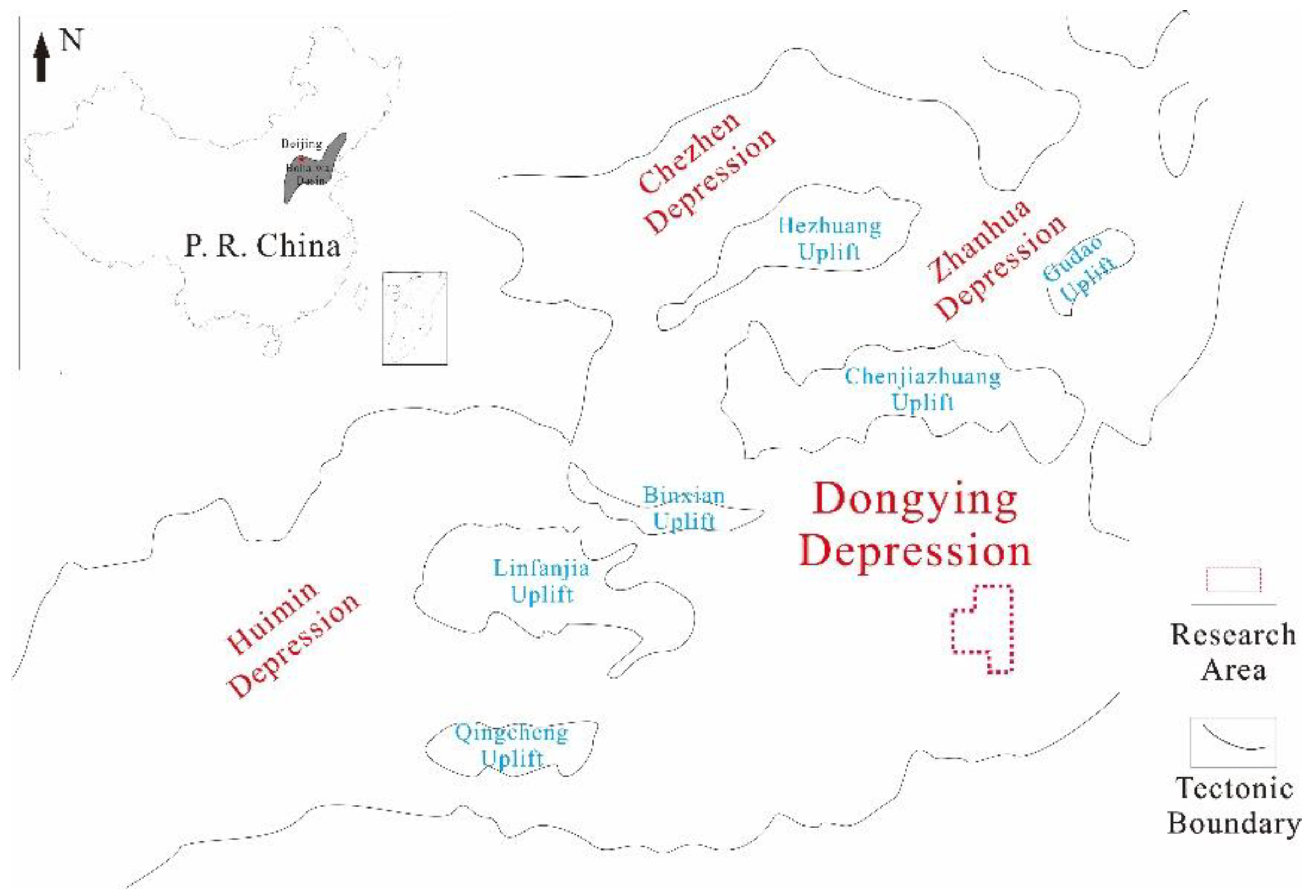

2.1. Geological Background and Experimental Pretreatment

2.2. High-Pressure Mercury Injection

2.3. Nuclear Magnetic Resonance

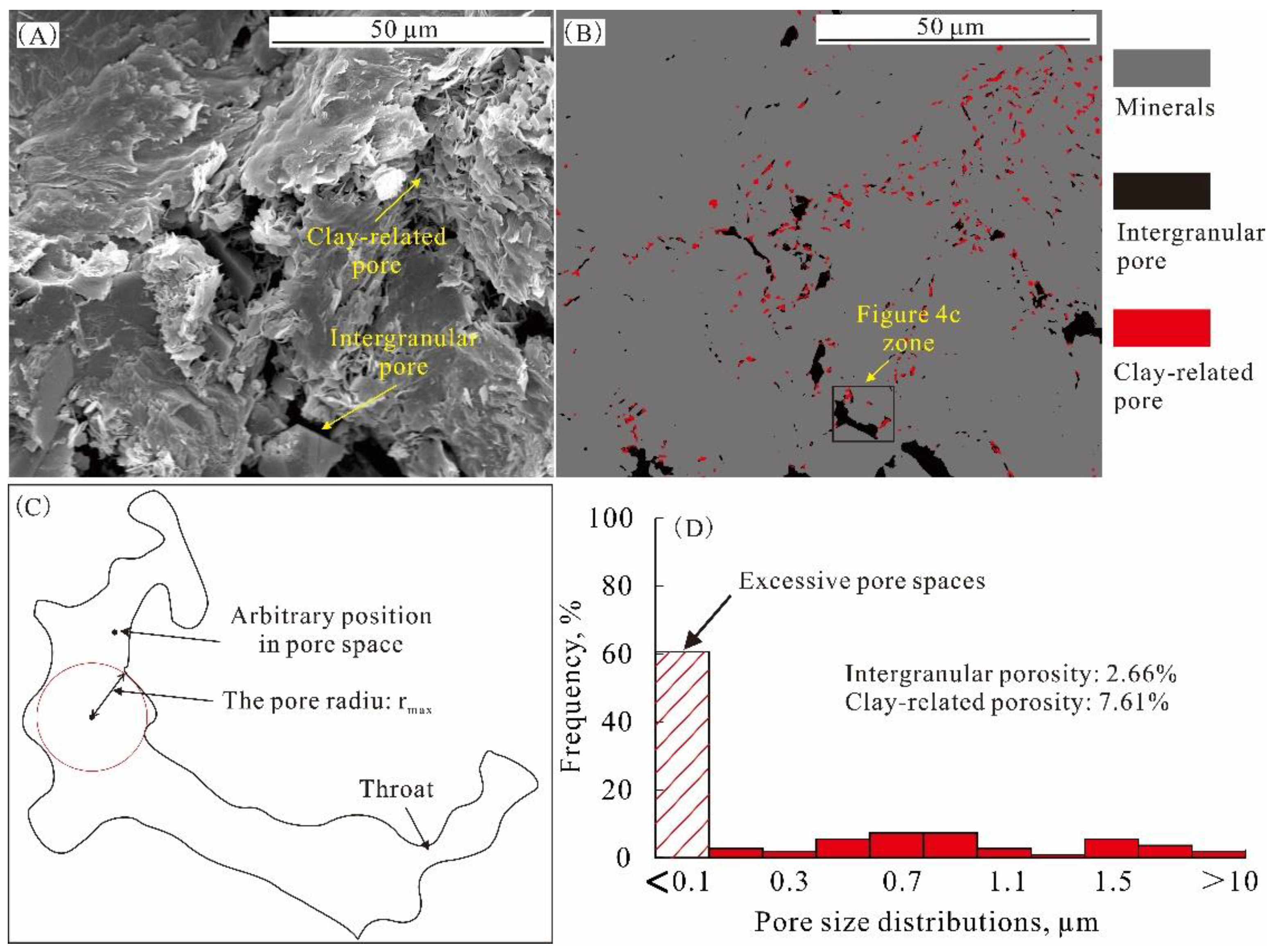

2.4. Scanning Electron Microscope

2.5. Helium Porosity

2.6. X-ray Diffraction

3. Results

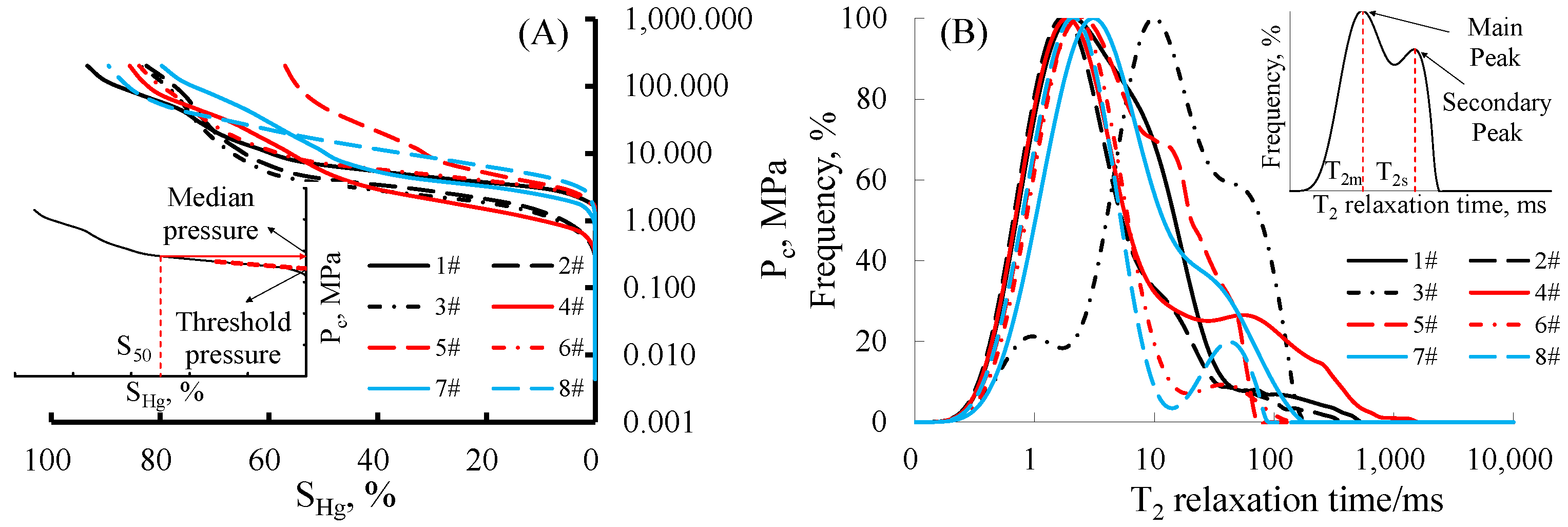

3.1. Capillary Pressure Curve of High-Pressure Mercury Injection

3.2. Nuclear Magnetic Resonance T2 Spectrum Curve

3.3. Microscopic Identification Results

3.4. X-ray Diffraction Results

4. Discussion

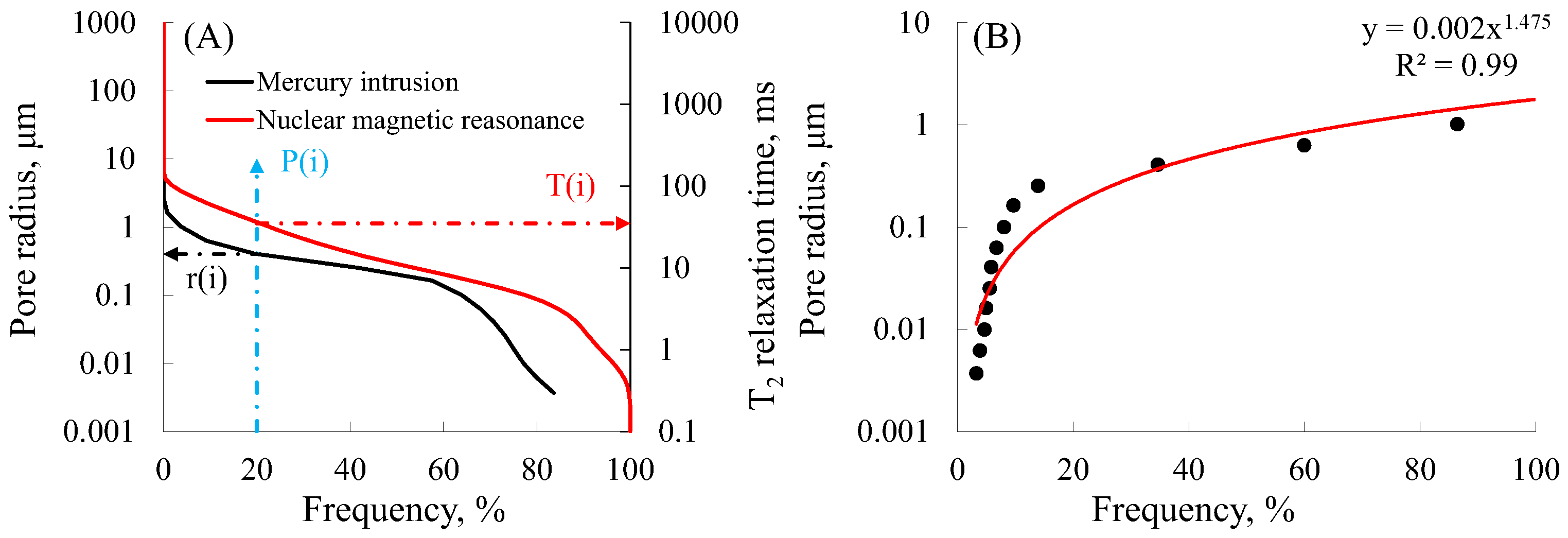

4.1. C Value Fitting of Capillary Pressure Curve and T2 Spectrum Curve

4.2. Interpolation Fitting of Capillary Pressure Curve and T2 Spectrum Curve

4.3. Morphological Fitting of Capillary Pressure Curve and T2 Spectrum Curve

4.4. Comparison of Three Fitting Methods and their Image Verification

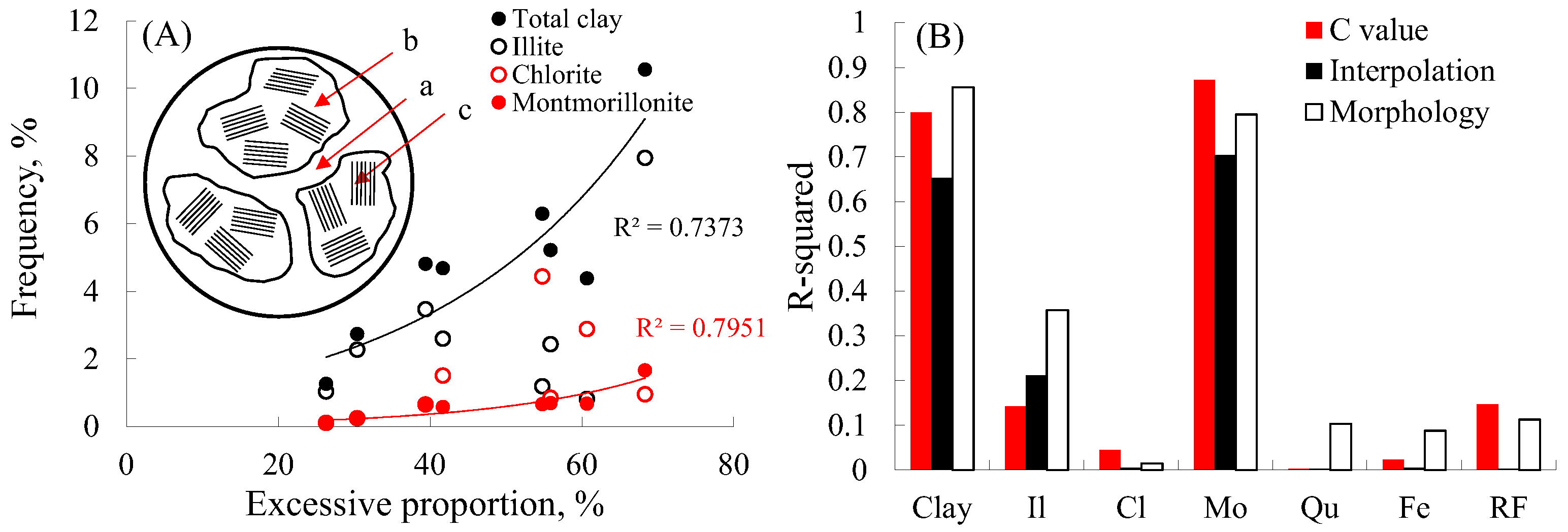

4.5. Study on the Formation Mechanism of Excess Porosity and Its Coupling Relationship with Mineral Composition

5. Conclusions

- (1)

- C-value fitting, interpolation fitting, and shape fitting are the three main ways of pore size splicing of tight sandstone. The three methods are mainly based on the similar extension trend of the gentle section curve by different experimental methods.

- (2)

- Different fitting methods have different application ranges. The C-value fitting method has high applicability for tight sandstone with few micro-pores. Shape fitting can effectively improve the efficiency of pore splicing.

- (3)

- A large number of clay mineral micro-pores are the main contributors to the pore space of tight sandstone, and they also play a decisive role in the selection of fitting methods and the control of fitting accuracy.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yu, Y.; Wang, Y.; Wang, H.; Zhao, Q.; Liu, D.; Zhan, L.; Wu, J.; Lin, W.; Shi, J. Examining and applying the theory of “exploring petroleum inside source kitchens” for continental shale oil: A case study from the Kong 2 member of the Cangdong sag in the Bohai Bay Basin, China. Energy Rep. 2022, 8, 1174–1190. [Google Scholar] [CrossRef]

- Verma, A.K.; Deb, D.; Dey, A.C.; Roy, S.; Singh, A.K.; Avadhani, V.L.N.; Tiwari, R.R. Development of one dimensional geomechanical model for a tight gas reservoir. Sci. Rep. 2021, 11, 21433. [Google Scholar] [CrossRef] [PubMed]

- Qiao, J.; Zeng, J.; Feng, X.; Yang, Z.; Zhang, Y.; Feng, S. Characteristics of nano-micro pore networks and petroleum microscopic occurrence state in ultra-low permeability (tight) sandstone reservoir. J. Nanosci. Nanotechnol. 2017, 17, 6039–6050. [Google Scholar] [CrossRef]

- Yu, S.; Bo, J.; Ming, L.; Chenliang, H.; Shaochun, X. A review on pore-fractures in tectonically deformed coals. Fuel 2020, 278, 118248. [Google Scholar] [CrossRef]

- Liu, D.; Ren, D.; Du, K.; Qi, Y.; Ye, F. Impacts of mineral composition and pore structure on spontaneous imbibition in tight sandstone. J. Pet. Sci. Eng. 2021, 201, 108397. [Google Scholar] [CrossRef]

- Ren, D.; Zhou, D.; Liu, D.; Dong, F.; Ma, S.; Huang, H. Formation mechanism of the Upper Triassic Yanchang Formation tight sandstone reservoir in Ordos Basin—Take Chang 6 reservoir in Jiyuan oil field as an example. J. Pet. Sci. Eng. 2019, 178, 497–505. [Google Scholar] [CrossRef]

- Qin, Y.; Yao, S.; Xiao, H.; Cao, J.; Hu, W.; Sun, L.; Tao, K.; Liu, X. Pore structure and connectivity of tight sandstone reservoirs in petroleum basins: A review and application of new methodologies to the Late Triassic Ordos Basin, China. Mar. Pet. Geol. 2021, 129, 105084. [Google Scholar] [CrossRef]

- Xu, Z.; Zhao, P.; Wang, Z.; Ostadhassan, M.; Pan, Z. Characterization and consecutive prediction of pore structures in tight oil reservoirs. Energies 2018, 11, 2705. [Google Scholar] [CrossRef] [Green Version]

- Krzyżak, A.T.; Habina-Skrzyniarz, I.; Machowski, G.; Mazur, W. Overcoming the barriers to the exploration of nanoporous shales porosity. Microporous Mesoporous Mater. 2020, 298, 110003. [Google Scholar] [CrossRef]

- Klewiah, I.; Berawala, D.S.; Walker, H.C.A.; Andersen, P.; Nadeau, P.H. Review of experimental sorption studies of CO2 and CH4 in shales. J. Nat. Gas Sci. Eng. 2020, 73, 103045. [Google Scholar] [CrossRef]

- Wang, H.; Kou, Z.; Bagdonas, D.A.; Phillips, E.H.; Alvarado, V.; Johnson, A.C.; Jiao, Z.; McLaughlin, J.F.; Quillinan, S.A. Multiscale Petrophysical Characterization and Flow Unit Classification of the Minnelusa Eolian Sandstones. J. Hydrol. 2022, 60, 127466. [Google Scholar] [CrossRef]

- Yu, H.; Xu, H.; Fan, J.; Zhu, Y.-B.; Wang, F.; Wu, H. Transport of shale gas in microporous/nanoporous media: Molecular to pore-scale simulations. Energy Fuels 2020, 35, 911–943. [Google Scholar] [CrossRef]

- Baveye, P.C.; Otten, W.; Kravchenko, A.; Balseiro-Romero, M.; Beckers, É.; Chalhoub, M.; Darnault, C.; Eickhorst, T.; Garnier, P.; Hapca, S.; et al. Emergent properties of microbial activity in heterogeneous soil microenvironments: Different research approaches are slowly converging, yet major challenges remain. Front. Microbiol. 2018, 9, 1929. [Google Scholar] [CrossRef] [PubMed]

- Singh, A.; Das, S.; Craciun, E.-M. Effect of thermomechanical loading on an edge crack of finite length in an infinite orthotropic strip. Mech. Compos. Mater. 2019, 55, 285–296. [Google Scholar] [CrossRef]

- Sun, Z.; Li, X.; Liu, W.; Zhang, T.; He, M.; Nasrabadi, H. Molecular dynamics of methane flow behavior through realistic organic nanopores under geologic shale condition: Pore size and kerogen types. Chem. Eng. J. 2020, 398, 124341. [Google Scholar] [CrossRef]

- Cristescu, N.D.; Craciun, E.-M.; Soós, E. Mechanics of Elastic Composites; Chapman and Hall/CRC: Boca Raton, Fl, USA, 2003. [Google Scholar]

- Cui, R.; Feng, Q.; Chen, H.; Zhang, W.; Wang, S. Multiscale random pore network modeling of oil-water two-phase slip flow in shale matrix. J. Pet. Sci. Eng. 2019, 175, 46–59. [Google Scholar] [CrossRef]

- Zhang, P.; Lu, S.; Li, J. Characterization of pore size distributions of shale oil reservoirs: A case study from Dongying sag, Bohai Bay basin, China. Mar. Pet. Geol. 2019, 100, 297–308. [Google Scholar] [CrossRef]

- Zhu, X.; Pan, R.; Li, S.; Wang, H.; Zhang, X.; Ge, J.; Lu, Z. Seismic sedimentology of sand-gravel bodies on the steep slope of rift basins—A case study of the Shahejie Formation, Dongying Sag, Eastern China. Interpretation 2018, 6, SD13–SD27. [Google Scholar] [CrossRef]

- Wang, Y.; Li, M.; Pang, X.; Zhang, S.; Shi, D. Fault-fracture mesh petroleum plays in the Zhanhua Depression, Bohai Bay Basin: Part 2. Oil-source correlation and secondary migration mechanisms. Org. Geochem. 2005, 36, 203–223. [Google Scholar] [CrossRef]

- Youshu, B.; Yongshi, W.; Zheng, L.; Shouchun, Z.; Rifang, Z.; Lianbo, W. Accumulation conditions for deep light oil and condensate gas from Member 4 of Shahejie Formation in Jiyang depression. Acta Pet. Sin. 2021, 42, 1615. [Google Scholar]

- Yu, C.; Wang, S.; Zhang, Y.; Wang, J. Study on two dimensional channeling distribution of unconsolidated sandstone reservoir. Geoscience 2016, 30, 1134–1140. [Google Scholar]

- Washburn, E.W. The dynamics of capillary flow. Phys. Rev. 1921, 17, 273. [Google Scholar] [CrossRef]

- Xie, Z.; Zhang, N.; Wang, J.; Xiang, Z.; Zhang, C. Study on magnetic resonance characteristics of coal sample under progressive loads. Appl. Sci. 2020, 10, 6526. [Google Scholar] [CrossRef]

- Wang, L.; Wang, S.; Zhang, R.; Wang, C.; Xiong, Y.; Zheng, X.; Li, S.; Jin, K.; Rui, Z. Review of multi-scale and multi-physical simulation technologies for shale and tight gas reservoirs. J. Nat. Gas Sci. Eng. 2017, 37, 560–578. [Google Scholar] [CrossRef]

| No. | IP, Pixel | CP, Pixel | M, Pixel | IPo, % | CPo, % | NP, % | RCPo, % | EP, % | EPP, % |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 27,930 | 29,015 | 852,545 | 3.07 | 3.19 | 7.09 | 4.02 | 0.83 | 11.69 |

| 2 | 21,345 | 18,093 | 870,052 | 2.35 | 1.99 | 8.74 | 6.39 | 4.40 | 50.39 |

| 3 | 24,204 | 12,528 | 872,758 | 2.66 | 1.38 | 10.27 | 7.61 | 6.23 | 60.67 |

| 4 | 23,456 | 14,398 | 871,636 | 2.58 | 1.58 | 9.43 | 6.85 | 5.27 | 55.86 |

| 5 | 22,987 | 18,766 | 867,737 | 2.53 | 2.06 | 8.88 | 6.35 | 4.29 | 48.30 |

| 6 | 25,873 | 27,897 | 855,720 | 2.84 | 3.07 | 8.02 | 5.18 | 2.11 | 26.28 |

| 7 | 21,098 | 15,793 | 872,599 | 2.32 | 1.74 | 8.97 | 6.65 | 4.91 | 54.78 |

| 8 | 23,098 | 29,887 | 856,505 | 2.54 | 3.29 | 8.25 | 5.71 | 2.42 | 29.38 |

| No. | Clay, % | Il, % | Cl, % | Ka, % | Mo, % | Q, % | F, % | Ot, % |

|---|---|---|---|---|---|---|---|---|

| 1 | 4.66 | 2.59 | 1.49 | 0.00 | 0.60 | 44.34 | 27.00 | 19.32 |

| 2 | 2.73 | 2.28 | 0.24 | 0.00 | 0.23 | 40.21 | 30.82 | 23.49 |

| 3 | 4.40 | 0.82 | 2.90 | 0.00 | 0.68 | 44.63 | 33.45 | 13.12 |

| 4 | 5.21 | 2.44 | 0.84 | 1.23 | 0.70 | 43.19 | 38.42 | 7.97 |

| 5 | 10.55 | 7.94 | 0.96 | 0.00 | 1.66 | 29.73 | 33.20 | 15.96 |

| 6 | 1.26 | 1.03 | 0.09 | 0.00 | 0.12 | 40.84 | 32.00 | 24.66 |

| 7 | 6.29 | 1.20 | 4.43 | 0.00 | 0.66 | 38.76 | 28.29 | 20.37 |

| 8 | 4.79 | 3.47 | 0.66 | 0.00 | 0.70 | 39.88 | 27.50 | 23.00 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, S.; Yu, C.; Su, J.; Liu, D. Splicing Method of Micro-Nano-Scale Pore Radius Distribution in Tight Sandstone Reservoir. Energies 2022, 15, 1642. https://doi.org/10.3390/en15051642

Zhang S, Yu C, Su J, Liu D. Splicing Method of Micro-Nano-Scale Pore Radius Distribution in Tight Sandstone Reservoir. Energies. 2022; 15(5):1642. https://doi.org/10.3390/en15051642

Chicago/Turabian StyleZhang, Shiming, Chunlei Yu, Junwei Su, and Dengke Liu. 2022. "Splicing Method of Micro-Nano-Scale Pore Radius Distribution in Tight Sandstone Reservoir" Energies 15, no. 5: 1642. https://doi.org/10.3390/en15051642

APA StyleZhang, S., Yu, C., Su, J., & Liu, D. (2022). Splicing Method of Micro-Nano-Scale Pore Radius Distribution in Tight Sandstone Reservoir. Energies, 15(5), 1642. https://doi.org/10.3390/en15051642