Research on Multi-Objective Compound Energy Management Strategy Based on Fuzzy Control for FCHEV

Abstract

:1. Introduction

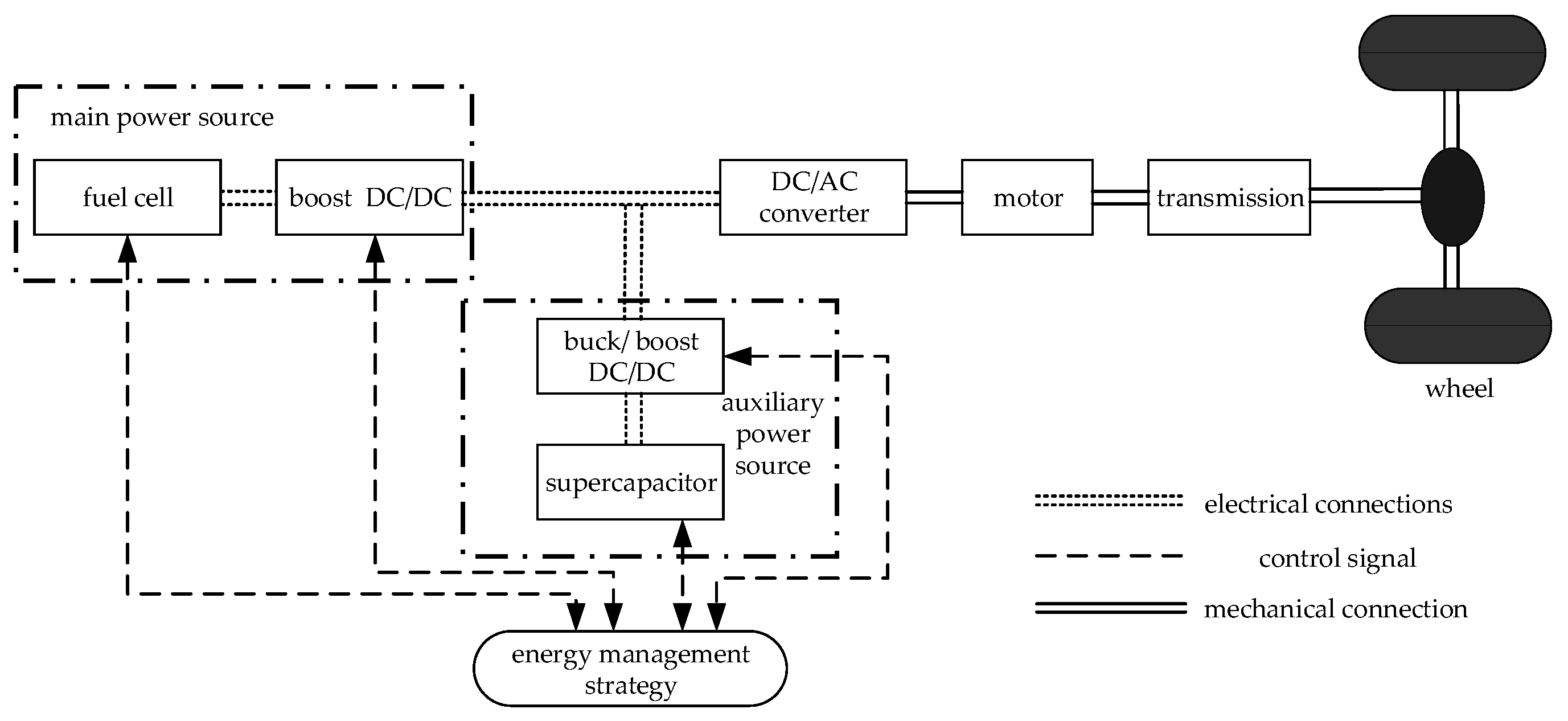

2. Powertrain Structure and Key Component Characteristics of FCHEV

2.1. Powertrain Structure of FCHEV

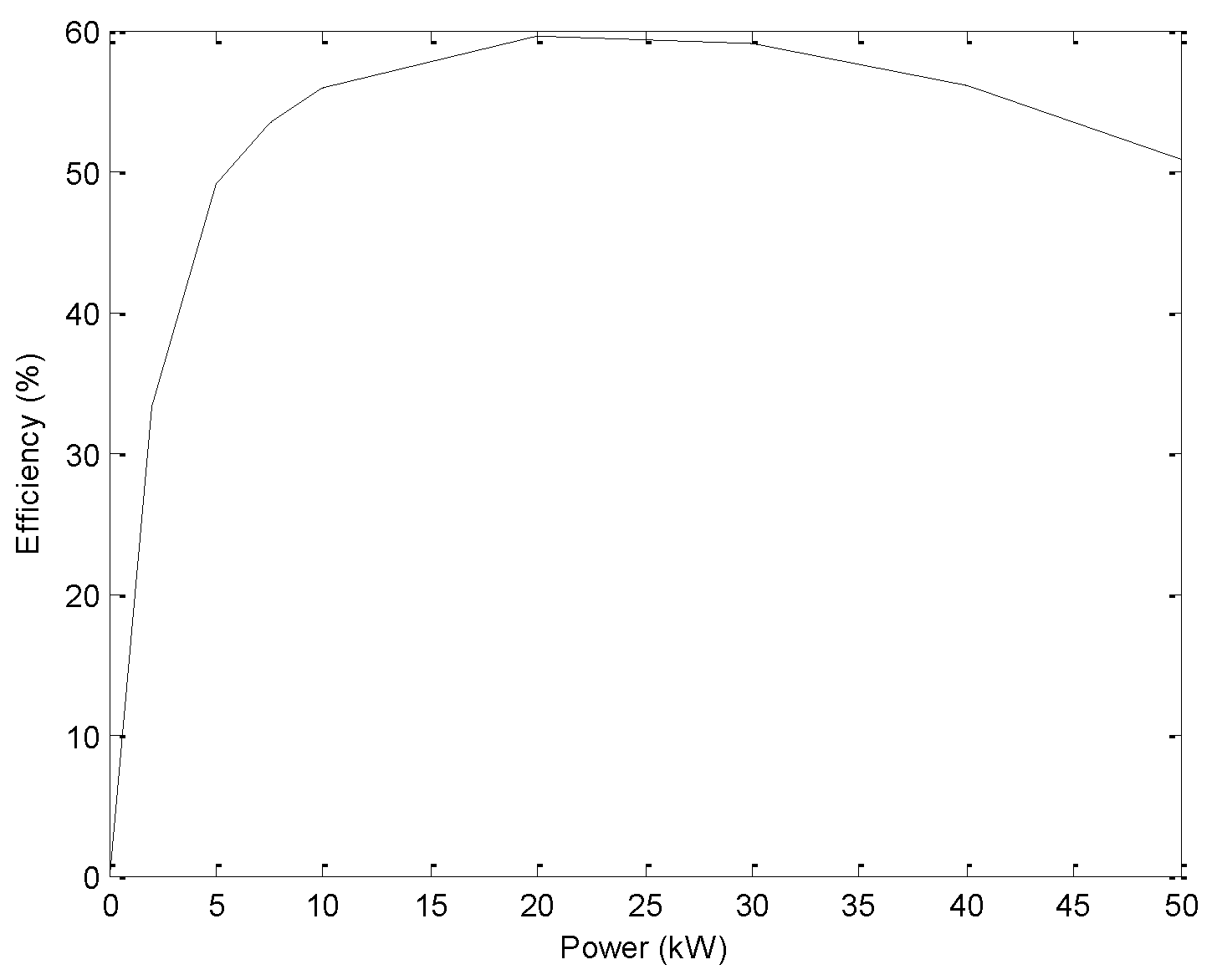

2.2. Fuel Cell Model

2.3. Supercapacitor Park Model

2.4. DC/DC Model

2.5. Motor Model

2.6. Complete Vehicle Model

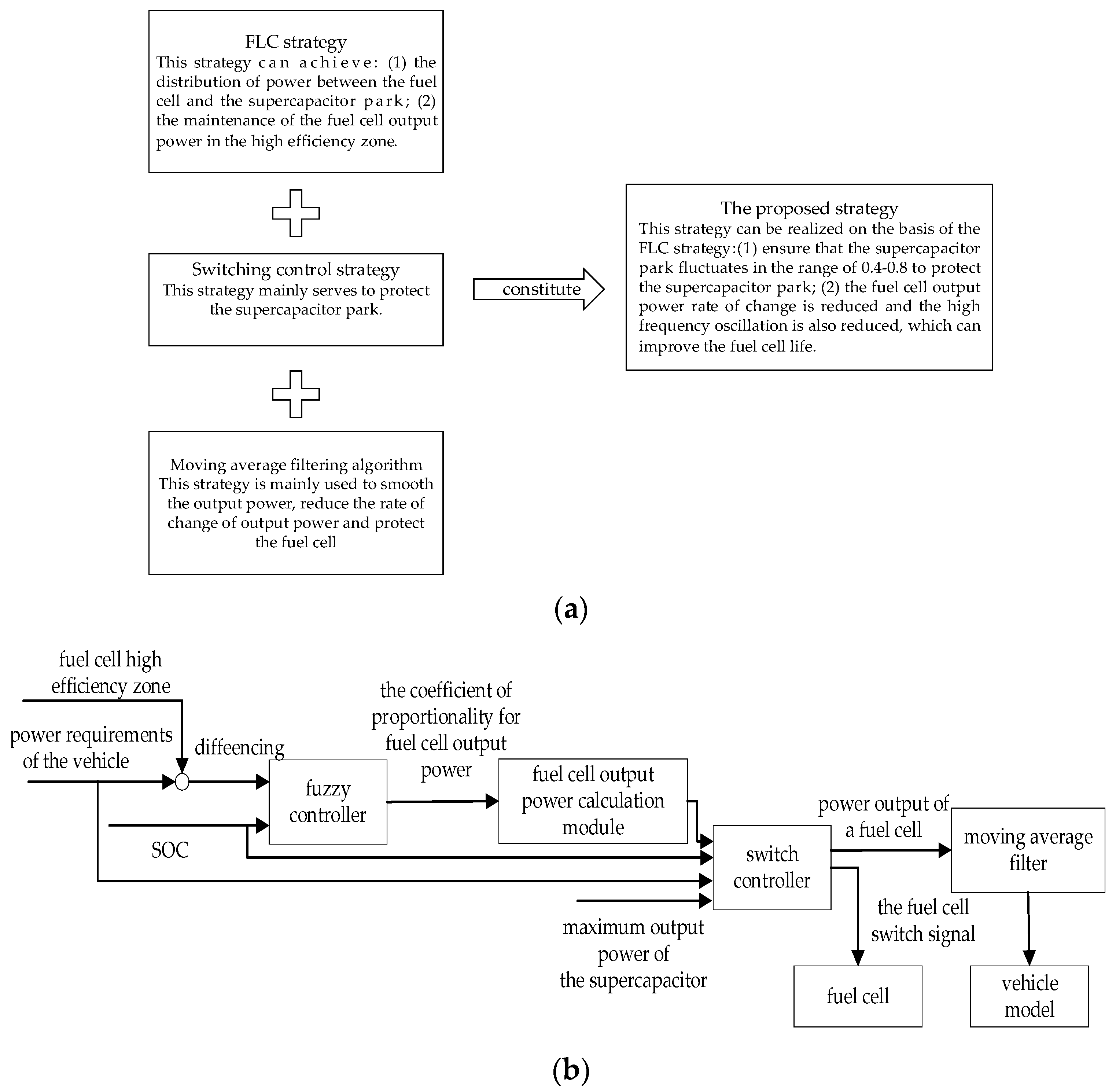

3. Energy Management Strategy

3.1. Influencing Factors of Fuel Cell Durability

- Start–stop condition

- 2.

- Idling condition

- 3.

- Frequent load changes condition

- 4.

- Overload condition

3.2. Design of Compound Energy Management Strategy

3.2.1. Fuzzy Logic Control Strategy

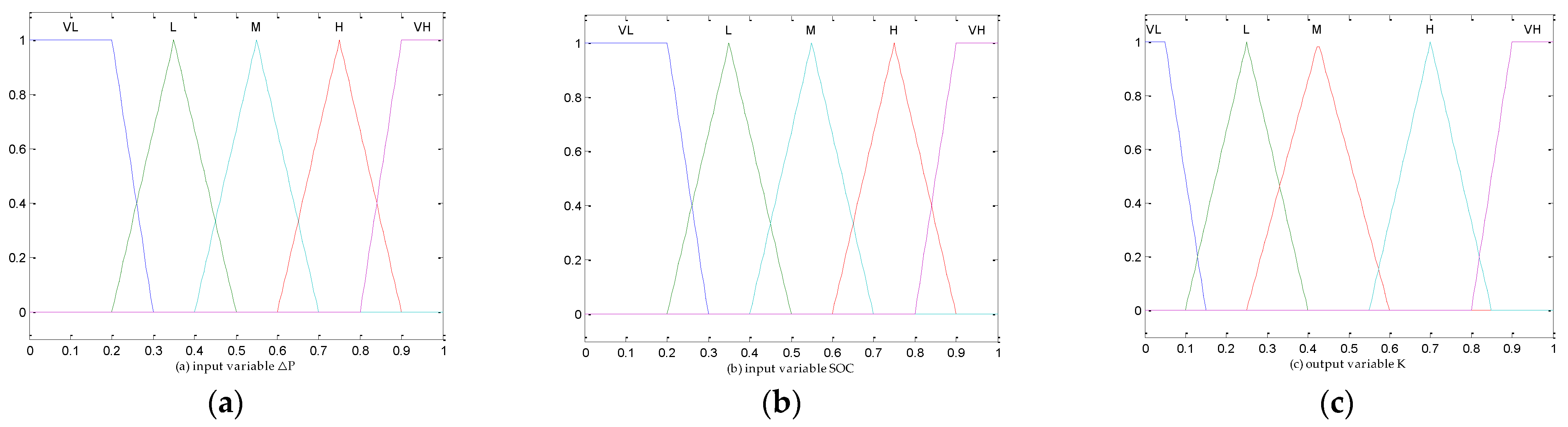

Variable Design for Inputs and Outputs

Fuzzy Distribution of Input and Output Variables

Formulation of Fuzzy Rules

- Meet the overall vehicle dynamics requirements: the sum of the fuel cell and supercapacitor park’s output power should be sufficient to fulfill the total vehicle required power of the FCHEV.

- Meet the economy requirements of FCHEV: to improve the vehicle’s working efficiency, the fuel cell’s output power should be controlled in the high-efficiency zone; simultaneously, the supercapacitor park should also absorb the braking energy as much as possible.

- Meet the fuel cell’s durability requirements: minimize frequent start–stop situations with fuel cells.

- Meet the SOC requirements of supercapacitor parks: control the SOC of supercapacitors to fluctuate within a reasonable range (0.4–0.8).

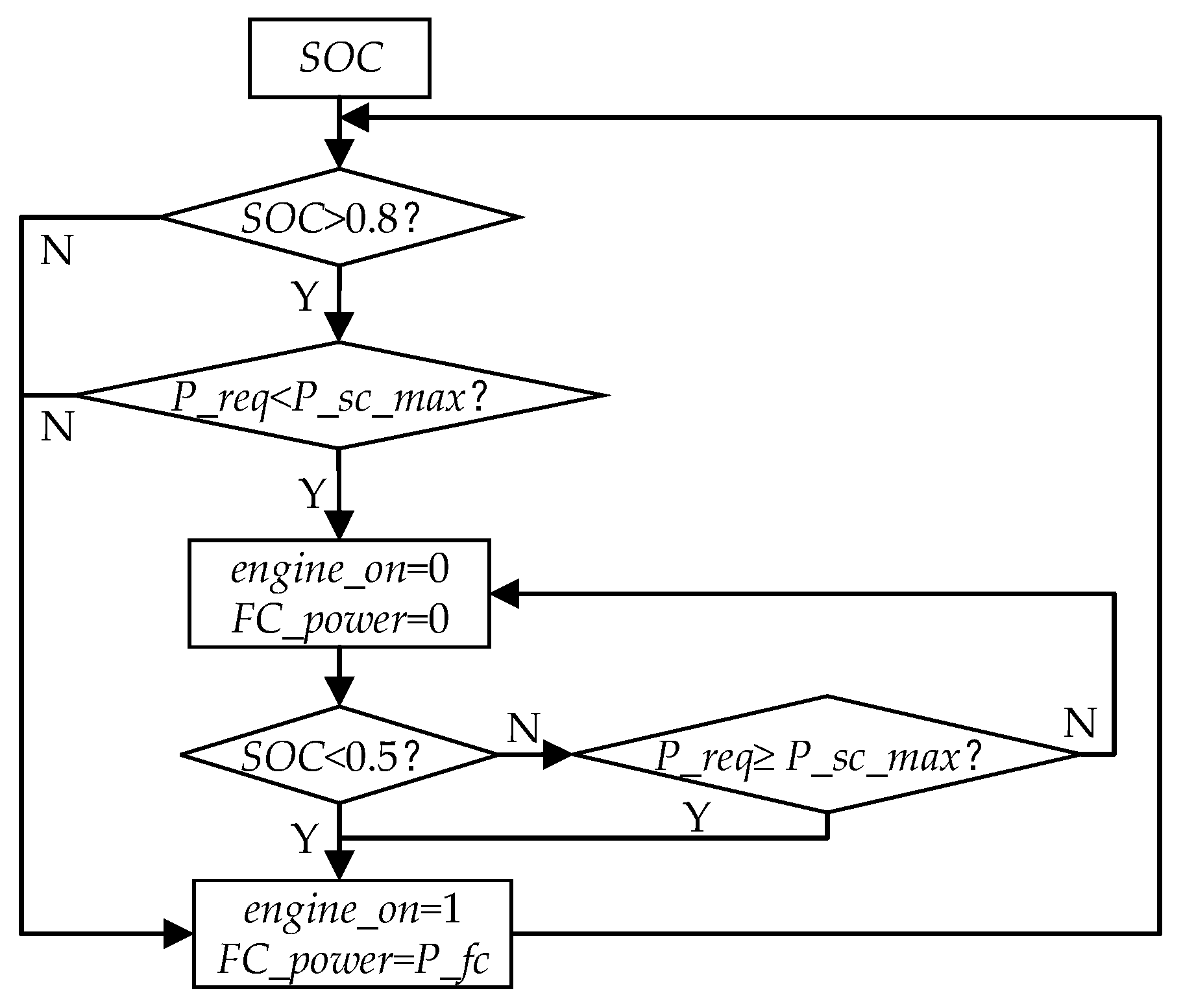

3.2.2. Switching Control Strategy

3.2.3. Smoothing Fuel Cell Output Power

4. Modeling and Simulation Analysis

4.1. Establishment of Simulation Model

- Modify the module control library: open the Advisor control module database, save the original <vc>fuel cell as <vc>fuel cell_new, and finally embed the designed control strategy into <vc>fuel cell_new to complete the control module modification.

- Modify the top-level module: open the original Advisor top-level module BD_FUELCELL.mdl and save it as BD_FUELCELL_new.mdl, replace <vc>fuel cell in this module with <vc>fuel cell _new.

- Modify the m file: first save the original FUELCELL_defaults_in.m as FUECELL_new_defaults_in.m and modify the first two sentences of the file to the top-level module of your own name; then, to make the module recognizable to the Advisor, add the following statement to the driver chain field of the global variable Vinf:

4.2. Simulation Comparison and Analysis

5. Conclusions

- All control strategies can meet the power requirements of the whole vehicle, but the proposed compound energy management strategy ensures that the supercapacitor park SOC fluctuates within a reasonable range on the basis of the advantages of conventional fuzzy control, and effectively avoids the overcharge of the supercapacitor park, to protect the supercapacitor park.

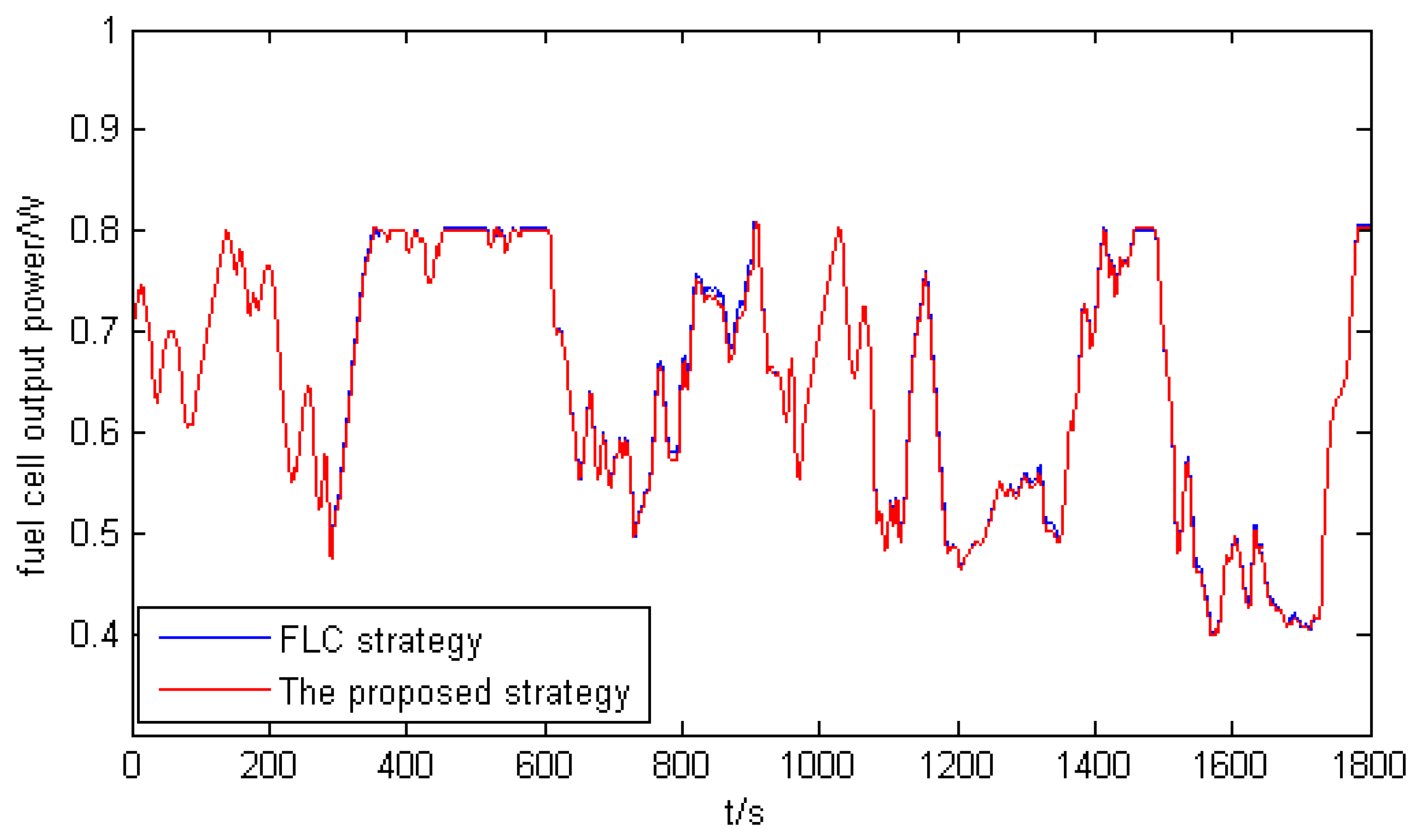

- The proposed compound energy management strategy smooths the output power of the fuel cell through the moving average filtering algorithm, which improves the smoothness of the output power of the fuel cell, reduces the rate of change of the power of the fuel cell and improves the durability of the fuel cell.

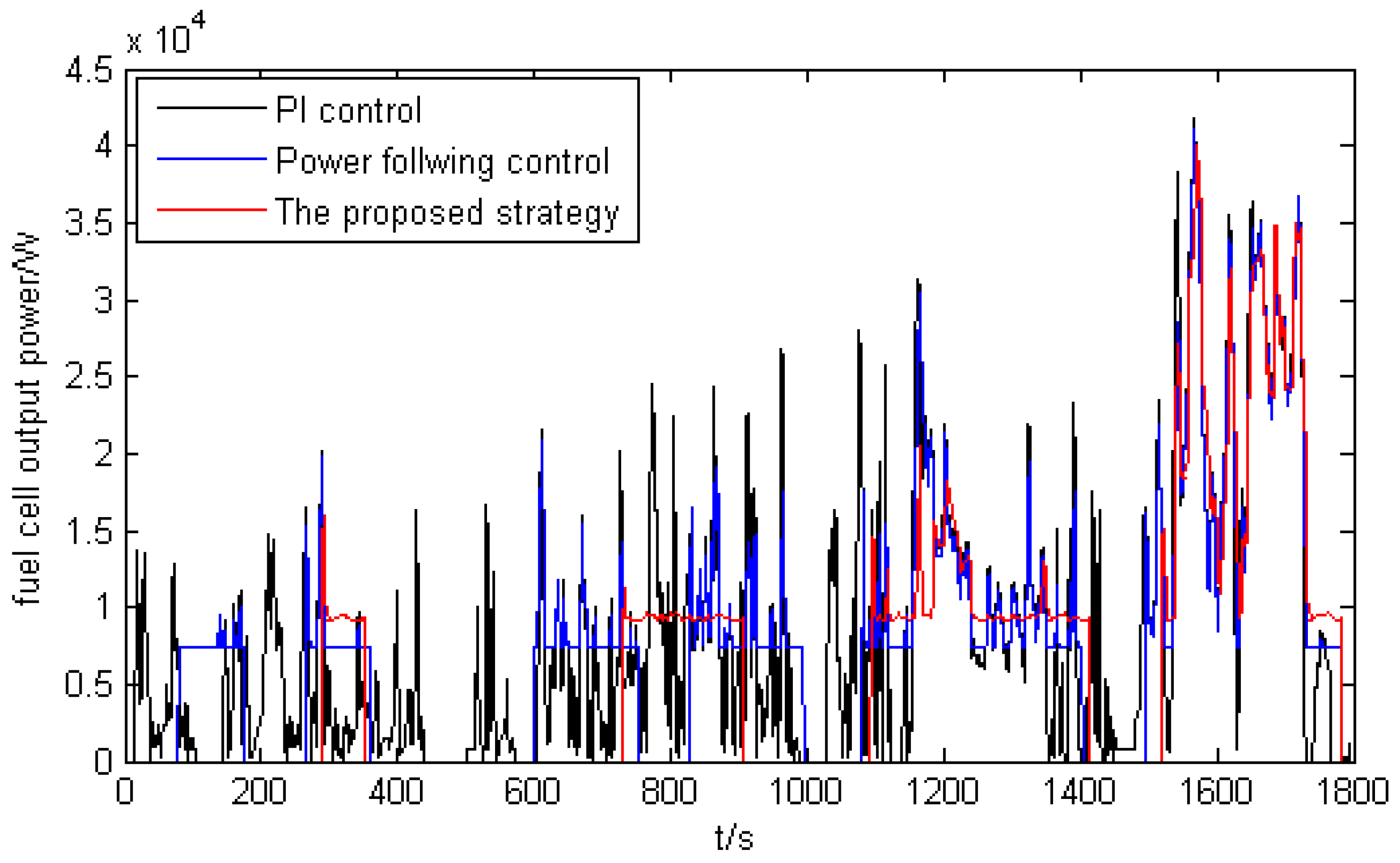

- Compared with the PI control and power-following control strategy, the compound energy management strategy reduces the number of starts and stops of the fuel cell and effectively avoids the reduction of the life of the fuel cell.

- The compound energy management strategy can fully consider the operating states of the fuel cell and supercapacitor park, which can effectively utilize the high power density of the supercapacitor park to ensure a smooth fuel cell output power while effectively improving the economy of the fuel cell hybrid vehicle. Compared with the PI control and power-following control strategy, the equivalent hydrogen consumption per 100 km under the compound energy management strategy is reduced by 13.15% and 9.18%, respectively, and the number of starts and stops is also reduced by 11 and 2 times, respectively. Therefore, this strategy can effectively reduce the hydrogen consumption of FCHEV and improve the durability of the fuel cell.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhu, D.B.; Wang, X.Y.; Li, Y.W. Progress on energy management strategies for hybrid electric vehicles. Mach. Des. Manuf. 2020, 293–296. [Google Scholar] [CrossRef]

- Liu, Y.D.; Guo, H.X.; Ouyang, X.P. Development status and future prospects of hydrogen fuel cell technology. Strateg. Study CAE 2021, 23, 162–171. [Google Scholar] [CrossRef]

- Shao, Z.G.; Yi, B.L. Developing trend and present status of hydrogen energy and fuel cell development. Bull. Chin. Acad. Sci. 2019, 34, 469–477. [Google Scholar]

- Han, L. Research on optimal power distribution strategy of vehicle hybrid energy storage power system. Foreign Electron. Meas. Technol. 2020, 39, 94–98. [Google Scholar]

- Cui, P.F.; Shen, Y.; Zhao, K.Y. Energy management for fuel cell vehicle power system based on fuzzy control. Mach. Build. Autom. 2020, 49, 177–179, 187. [Google Scholar]

- Li, D.X.; Xu, B.; Jie, T.; Ma, Z. Energy management strategy for fuel cell and battery hybrid vehicle based on fuzzy logic. Processes 2020, 8, 882. [Google Scholar] [CrossRef]

- Siab, S.; Hamouda, Z.; Marouani, K. Energy Management in a Fuel Cell Hybrid Electric Vehicle Using a Fuzzy Logic Approach. In Proceedings of the 2017 5th International Conference on Electrical Engineering, Boumerdes, Algeria, 29–31 October 2017. [Google Scholar]

- Wang, Q.; Li, D.G.; Miao, H.C. Research on energy management strategy of fuel cell vehicle based on fuzzy logic control. Automot. Eng. 2019, 41, 1347–1355. [Google Scholar]

- Zhang, G.R.; Chen, W.R.; Li, Q. Modeling, optimization and control of a FC/battery hybrid locomotive based on ADVISOR. Int. J. Hydrogen Energy 2017, 42, 18568–18583. [Google Scholar] [CrossRef]

- Chen, J.; Xu, C.F.; Wu, C.S. Adaptive fuzzy logic control of fuel-cell-battery hybrid systems for electric vehicles. IEEE Trans. Ind. Inform. 2018, 14, 292–300. [Google Scholar] [CrossRef]

- Lv, X.Q.; Wu, Y.B.; Lian, J. Energy management of hybrid electric vehicles: A review of energy optimization of fuel cell hybrid power system based on genetic algorithm. Energy Convers. Manag. 2020, 205, 112474. [Google Scholar]

- Ahmadi, S.; Bthaee, S.M.T.; Hosseinpour, A.H. Improving fuel economy and performance of a fuel-cell hybrid electric vehicle (fuel-cell, battery, and ultra-capacitor) using optimized energy management strategy. Energy Convers. Manag. 2018, 160, 74–84. [Google Scholar] [CrossRef]

- Munoz, P.M.; Correa, G.; Gaudiano, M.E.; Fernandez, D. Energy management control design for fuel cell hybrid electric vehicles using neural networks. Int. J. Hydrogen Energy 2017, 42, 28932–28944. [Google Scholar] [CrossRef]

- Chen, H.; Chen, J.; Lu, H.; Yan, C.; Liu, Z. A modified MPC-based optimal strategy of power management for fuel cell hybrid vehicles. IEEE/ASME Trans. Mechatron. 2020, 25, 2009–2018. [Google Scholar] [CrossRef]

- Shi, J.W.; Xie, J.F.; Zhao, Y. Research on durability control strategy of vehicle fuel cell. Mod. Manuf. Eng. 2021, 56–63. [Google Scholar] [CrossRef]

- Li, Q.; Chen, W.; Liu, Z.; Li, M.; Ma, L. Development of energy management system based on a power sharing strategy for a fuel cell-battery-supercapacitor hybrid tramway. J. Power Sources 2015, 279, 267–280. [Google Scholar] [CrossRef]

- Flosescu, A.; Bacha, S.; Munteanu, I.; Bratcu, A.I.; Rumeau, A. Adaptive frequency-separation-based energy management system for electric vehicles. J. Power Sources 2015, 280, 410–421. [Google Scholar] [CrossRef]

- Wang, Z.; Xie, Y.; Sun, W.; Zang, P. Modeling and energy management strategy research of fuel cell bus. J. Tongji Univ. (Nat. Sci.) 2019, 47, 97–103, 123. [Google Scholar]

- Xu, L.; Mueller, C.D.; Li, J. Multi-objective component sizing based on optimal energy management strategy of fuel cell electric vehicles. Appl. Energy 2015, 157, 664–674. [Google Scholar] [CrossRef]

- Lin, X.Y.; Xia, Y.T.; Li, X.F.; Lin, H.B. Equivalent consumption minimization strategy adaptive to various driving ranges for fuel cell. Automot. Eng. 2019, 41, 750–756. [Google Scholar]

- Yan, Z.F.; Wang, H.L.; Wu, J.L.; Zhang, N. Modeling and energy management strategy optimization for the drive system of a fuel cell based bus. J. Chongqing Univ. Technol. (Nat. Sci.) 2021, 35, 8–16. [Google Scholar]

- Zhao, Z.; Wang, T.; Li, M.; Wang, H.; Wang, Y.Q. Optimization of fuzzy control energy management strategy for fuel cell vehicle power system using a multi-slandgenetic algorithm. Energy Sci. Eng. 2020, 9, 548–564. [Google Scholar] [CrossRef]

- Zhou, J.H.; Gu, C.; Liu, J.; Hai, B.; Sai, Y.H. Energy management strategy of a fuel cell hybrid electric vehicle based on fuzzy logic and improved IGWO. J. Chongqing Univ. Technol. (Nat. Sci.) 2021, 35, 33–41. [Google Scholar]

- Liu, Q.; Zhan, Y.D.; Li, R.Q. Research on a multiobjective optimization energy management strategy for fuel cell electric vehicles. Electron. Meas. Technol. 2020, 43, 31–36. [Google Scholar]

- Li, Z.H.; Fu, Z.M.; Tao, F.Z. Hierarchical energy management strategy of fuel cell hybrid electrical vehicle. Fire Control. Command. Control. 2019, 44, 113–118. [Google Scholar]

- Chan, C.C.; Bouscayrol, A.; Chen, K. Electric, hybrid, and fuel-cell vehicles: Architectures and modeling. IEEE Trans. Veh. Technol. 2010, 59, 589–598. [Google Scholar] [CrossRef]

| Name | Parameter | Value | Unit |

|---|---|---|---|

| vehicle part | mass | 1138 | |

| drag coefficient | 0.335 | ||

| frontal area | 2 | ||

| wheel | wheel radius | 0.282 | |

| rolling coefficient | 0.009 | ||

| drive motor | power max | 75 | |

| max efficiency | 0.92 | - | |

| fuel cell | power max | 50 | |

| max efficiency | 0.6 | - | |

| supercapacitor park | rated voltage | 2 | |

| group number | 80 | - | |

| capacity | 2.1 |

| K | ||||||||

|---|---|---|---|---|---|---|---|---|

| VL | L0 | L1 | M | H0 | H1 | VH | ||

| SOC | VL | M | H | VH | VH | VH | VH | VH |

| L | M | M | M | H | H | VH | VH | |

| M | VL | VL | VL | M | M | H | H | |

| H | VL | VL | VL | L | L | L | M | |

| VH | VL | VL | VL | VL | VL | VL | VL | |

| Statistical Results | PI Control | Power Following Control Strategy | Compound Energy Management Strategy |

|---|---|---|---|

| 52.39 | 50.1 | 45.5 | |

| start and stop times | 15 | 6 | 4 |

| fuel cell efficiency | 0.54 | 0.53 | 0.55 |

| supercapacitor park efficiency | 0.97 | 0.98 | 0.98 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, C.; Luo, W.; Lan, H.; Hu, C. Research on Multi-Objective Compound Energy Management Strategy Based on Fuzzy Control for FCHEV. Energies 2022, 15, 1721. https://doi.org/10.3390/en15051721

Lin C, Luo W, Lan H, Hu C. Research on Multi-Objective Compound Energy Management Strategy Based on Fuzzy Control for FCHEV. Energies. 2022; 15(5):1721. https://doi.org/10.3390/en15051721

Chicago/Turabian StyleLin, Cuixia, Wenguang Luo, Hongli Lan, and Cong Hu. 2022. "Research on Multi-Objective Compound Energy Management Strategy Based on Fuzzy Control for FCHEV" Energies 15, no. 5: 1721. https://doi.org/10.3390/en15051721

APA StyleLin, C., Luo, W., Lan, H., & Hu, C. (2022). Research on Multi-Objective Compound Energy Management Strategy Based on Fuzzy Control for FCHEV. Energies, 15(5), 1721. https://doi.org/10.3390/en15051721