Regression Models for Performance Prediction of Internally-Cooled Liquid Desiccant Dehumidifiers

Abstract

:1. Introduction

2. Methods

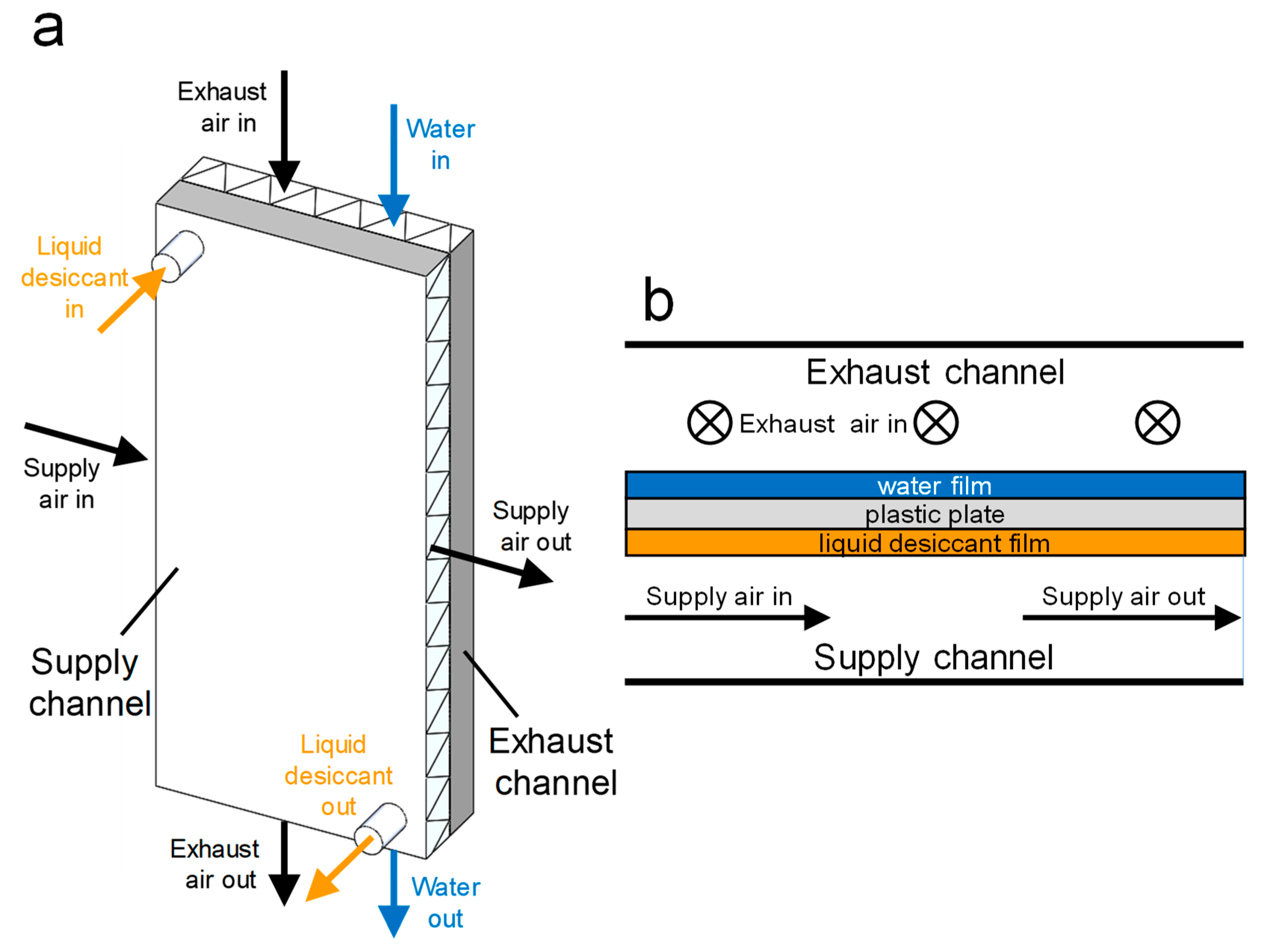

2.1. Experiments

2.2. Heat and Mass Transfer Model

- The system is insulated; therefore, no heat transfer occurs between the device and the surroundings.

- The thickness of the channels is small relative to the channels’ length and width; therefore, the variations of temperature and humidity ratio normal to the flow are neglected, reducing the problem to be two-dimensional.

- The flow is laminar, fully developed, and steady.

- The mass flow rate is constant in each channel.

- The heat and mass transfer coefficients are constant.

- The heat and mass transfer analogy holds.

2.2.1. Governing Equations

2.2.2. Boundary Conditions

2.2.3. Heat and Mass Transfer Coefficients

2.2.4. Computational Grid

2.3. Regression Models

3. Results and Discussion

3.1. Validation of the Heat and Mass Transfer Model

3.2. Regression Models

3.2.1. Supply Air Outlet Humidity Ratio

3.2.2. Supply Air Outlet Temperature

3.3. Model–Experiments Comparison

3.4. Performance Assessment of the Dehumidification Process

3.5. Example of Using the Regression Models

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| liquid desiccant concentration, kgsalt kgsolution−1 | |

| specific heat, J kg−1 K−1 | |

| hydraulic diameter, m | |

| membrane diffusivity, m2 s−1 | |

| binary diffusion coefficient of water vapor in air, m2 s−1 | |

| convective heat transfer coefficient, W m−2 K−1 | |

| enthalpy of dilution of aqueous solutions of lithium chloride, J kg−1 | |

| enthalpy of evaporation of water, J kg−1 | |

| mass transfer coefficient, m s−1 | |

| thermal conductivity, W m−1 K−1 | |

| length of the channel, m | |

| mass flow rate, kg s−1 | |

| mass flow rate per channel, kg s−1 | |

| Nusselt number | |

| atmospheric pressure, Pa | |

| saturated vapor pressure, Pa | |

| saturated vapor pressure above the liquid desiccant, Pa | |

| exhaust air to supply air mass flow rate ratio | |

| Sherwood number | |

| temperature, °C | |

| thickness, mm | |

| overall heat transfer coefficient, W m−2 K−1 | |

| overall mass transfer coefficient, kg m−2 s−1 | |

| volume flow rate, mL min−1 | |

| volume flow rate per channel, mL min−1 | |

| width of the channel, m | |

| space coordinates | |

| Greek letters | |

| density, kg m−3 | |

| humidity ratio, kg kgdry air−1 | |

| Subscripts | |

| exhaust channel | |

| inlet | |

| liquid desiccant | |

| outlet | |

| supply channel | |

| water film |

Appendix A

| Test No. | Ts, in (°C) | ωs, in (kg kg−1) | Te, in (°C) | ωe, in (kg kg−1) | (kg kg−1) | (kg s−1) | TLD,in (°C) | CLD (kg kg−1) | (mL min−1) |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 20.9 | 0.0146 | - | - | 0.152 | - | 31.4 | 0.380 | 337 |

| 2 | 20.9 | 0.0146 | - | - | 0.106 | - | 29.0 | 0.383 | 310 |

| 3 | 20.9 | 0.0146 | - | - | 0.197 | - | 30.9 | 0.380 | 337 |

| 4 | 26.7 | 0.0146 | 35.0 | 0.0186 | 0.152 | 0.061 | 30.4 | 0.373 | 337 |

| 5 | 26.7 | 0.0146 | 26.7 | 0.0186 | 0.152 | 0.061 | 31.7 | 0.375 | 360 |

| 6 | 26.7 | 0.0146 | 26.7 | 0.0132 | 0.152 | 0.061 | 31.2 | 0.378 | 337 |

| 7 | 26.7 | 0.0146 | 35.0 | 0.0132 | 0.152 | 0.061 | 31.1 | 0.380 | 337 |

| 8 | 35.0 | 0.0186 | 35.0 | 0.0186 | 0.152 | 0.061 | 34.8 | 0.385 | 360 |

| 9 | 26.7 | 0.0146 | 35.0 | 0.0186 | 0.152 | 0.046 | 32.0 | 0.380 | 337 |

| 10 | 26.7 | 0.0146 | 35.0 | 0.0186 | 0.152 | 0.030 | 31.3 | 0.378 | 337 |

| 11 | 26.7 | 0.0146 | 35.0 | 0.0186 | 0.106 | 0.042 | 32.8 | 0.381 | 310 |

| 12 | 26.7 | 0.0146 | 35.0 | 0.0186 | 0.182 | 0.073 | 30.7 | 0.379 | 337 |

| 13 | 26.7 | 0.0146 | 35.0 | 0.0186 | 0.152 | 0.061 | 32.9 | 0.380 | 337 |

| 14 | 35.0 | 0.0186 | 35.0 | 0.0186 | 0.152 | 0.061 | 38.2 | 0.424 | 299 |

| 15 | 44.2 | 0.0146 | 35.0 | 0.0186 | 0.152 | 0.061 | 36.1 | 0.430 | 299 |

| 16 | 26.7 | 0.0146 | 35.0 | 0.0186 | 0.152 | 0.061 | 32.2 | 0.380 | 583 |

| 17 | 26.7 | 0.0146 | 35.0 | 0.0186 | 0.152 | 0.061 | 25.9 | 0.330 | 572 |

| 18 | 26.7 | 0.0146 | 35.0 | 0.0171 | 0.152 | 0.061 | 25.2 | 0.360 | 443 |

| 19 | 26.7 | 0.0146 | 35.0 | 0.0146 | 0.152 | 0.061 | 29.3 | 0.340 | 515 |

| 20 | 26.7 | 0.0146 | 35.0 | 0.0132 | 0.152 | 0.046 | 30.3 | 0.340 | 515 |

| Source | Coded Coefficient × 10−5 | DF | Adj SS × 10−10 | Adj MS × 10−5 | F-Value | p-Value |

|---|---|---|---|---|---|---|

| Model | 60 | 53,742,256 | 895,704.3 | 3677.432 | 0.000 | |

| Linear | 12 | |||||

| Ts,in | 23.58 | 1 | 289,105.9 | 289,105.9 | 1186.96 | 0.000 |

| ωs,in | 193.56 | 1 | 19,481,938 | 19,481,938 | 79,985.66 | 0.000 |

| Te,in | 10.42 | 1 | 56,475.98 | 56,475.98 | 231.87 | 0.000 |

| ωe,in | 15.88 | 1 | 131,123.1 | 131,123.1 | 538.34 | 0.000 |

| TLD,in | 7.69 | 1 | 30,730.78 | 30,730.78 | 126.17 | 0.000 |

| CLD | −124.66 | 1 | 8,080,975 | 8,080,975 | 33,177.5 | 0.000 |

| vLD | −0.38 | 1 | 76.78 | 76.78 | 0.32 | 0.575 |

| 85.83 | 1 | 3,830,366 | 3,830,366 | 15,726.07 | 0.000 | |

| r | −23.23 | 1 | 280,592.4 | 280,592.4 | 1152.01 | 0.000 |

| t | 80.84 | 1 | 3,398,203 | 3,398,203 | 13,951.77 | 0.000 |

| L | −122.5 | 1 | 7,803,524 | 7,803,524 | 32,038.4 | 0.000 |

| W | −121.81 | 1 | 7,715,903 | 7,715,903 | 31,678.66 | 0.000 |

| Square | 6 | |||||

| CLD2 | 13.83 | 1 | 7010.6 | 7010.6 | 28.78 | 0.000 |

| −17.23 | 1 | 10,872.96 | 10,872.96 | 44.64 | 0.000 | |

| r2 | 29.96 | 1 | 32,870.27 | 32,870.27 | 134.95 | 0.000 |

| t2 | −15.6 | 1 | 8915.74 | 8915.74 | 36.6 | 0.000 |

| L2 | 12.02 | 1 | 5288.41 | 5288.41 | 21.71 | 0.000 |

| W2 | 11.85 | 1 | 5143.08 | 5143.08 | 21.12 | 0.000 |

| 2-Way Interaction | 42 | |||||

| Ts,inωs,in | 1.49 | 1 | 1131.63 | 1131.63 | 4.65 | 0.032 |

| Ts,inCLD | −8.07 | 1 | 33,330.72 | 33,330.72 | 136.84 | 0.000 |

| −2.31 | 1 | 2743.74 | 2743.74 | 11.26 | 0.001 | |

| Ts,inr | −3.51 | 1 | 6309.72 | 6309.72 | 25.91 | 0.000 |

| Ts,int | −4.34 | 1 | 9655.98 | 9655.98 | 39.64 | 0.000 |

| Ts,inL | 4.05 | 1 | 8408.94 | 8408.94 | 34.52 | 0.000 |

| Ts,inW | 3.98 | 1 | 8099.78 | 8099.78 | 33.25 | 0.000 |

| ωs,inCLD | −9.31 | 1 | 44,363.64 | 44,363.64 | 182.14 | 0.000 |

| 21.03 | 1 | 226,454.4 | 226,454.4 | 929.74 | 0.000 | |

| ωs,inr | −4.98 | 1 | 12,704.38 | 12,704.38 | 52.16 | 0.000 |

| ωs,int | 19.39 | 1 | 192,575.3 | 192,575.3 | 790.64 | 0.000 |

| ωs,inL | −29.45 | 1 | 443,914 | 443,914 | 1822.55 | 0.000 |

| ωs,inW | −29.28 | 1 | 438,928.3 | 438,928.3 | 1802.08 | 0.000 |

| Te,inCLD | −3.66 | 1 | 6846.26 | 6846.26 | 28.11 | 0.000 |

| Te,int | −1.37 | 1 | 955.12 | 955.12 | 3.92 | 0.048 |

| Te,inL | 2.07 | 1 | 2192.54 | 2192.54 | 9 | 0.003 |

| Te,inW | 2.07 | 1 | 2198.43 | 2198.43 | 9.03 | 0.003 |

| ωe,inCLD | −5.59 | 1 | 15,970.64 | 15,970.64 | 65.57 | 0.000 |

| −1.93 | 1 | 1909 | 1909 | 7.84 | 0.005 | |

| ωe,inr | 1.7 | 1 | 1475.81 | 1475.81 | 6.06 | 0.014 |

| ωe,int | −1.99 | 1 | 2032.19 | 2032.19 | 8.34 | 0.004 |

| ωe,inL | 3.05 | 1 | 4774.97 | 4774.97 | 19.6 | 0.000 |

| ωe,inW | 3.05 | 1 | 4753.86 | 4753.86 | 19.52 | 0.000 |

| TLD,inCLD | −2.79 | 1 | 3976.76 | 3976.76 | 16.33 | 0.000 |

| TLD,invLD | 2.4 | 1 | 2939.05 | 2939.05 | 12.07 | 0.001 |

| −1.85 | 1 | 1758.02 | 1758.02 | 7.22 | 0.007 | |

| TLD,inr | −1.39 | 1 | 985.79 | 985.79 | 4.05 | 0.045 |

| 16.93 | 1 | 146,756 | 146,756 | 602.53 | 0.000 | |

| CLDr | 4.96 | 1 | 12,587.89 | 12,587.89 | 51.68 | 0.000 |

| CLDt | 16.79 | 1 | 144,343 | 144,343 | 592.62 | 0.000 |

| CLDL | −23.91 | 1 | 292,820 | 292,820 | 1202.21 | 0.000 |

| CLDW | −23.73 | 1 | 288,329 | 288,329 | 1183.77 | 0.000 |

| r | 5.34 | 1 | 14,616.65 | 14,616.65 | 60.01 | 0.000 |

| t | −3.34 | 1 | 5724.1 | 5724.1 | 23.5 | 0.000 |

| L | 5.61 | 1 | 16,123.14 | 16,123.14 | 66.2 | 0.000 |

| W | 5.55 | 1 | 15,755.57 | 15,755.57 | 64.69 | 0.000 |

| rt | 5.27 | 1 | 14,223.52 | 14,223.52 | 58.4 | 0.000 |

| rL | −8.22 | 1 | 34,587.46 | 34,587.46 | 142 | 0.000 |

| rW | −8.2 | 1 | 34,408.51 | 34,408.51 | 141.27 | 0.000 |

| tL | 4.98 | 1 | 12,697.8 | 12,697.8 | 52.13 | 0.000 |

| tW | 5.07 | 1 | 13,167.6 | 13,167.6 | 54.06 | 0.000 |

| LW | −8.17 | 1 | 34,146.68 | 34,146.68 | 140.19 | 0.000 |

| Error | 485 | 118,130.4 | 243.5679 | |||

| Total | 545 | 53,860,387 |

| Source | Coded Coefficient | DF | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|---|

| Model | 59 | 7503.37 | 127.18 | 1747.11 | 0.000 | |

| Linear | 12 | |||||

| Ts,in | 3.2351 | 1 | 5442.19 | 5442.19 | 74,763.64 | 0.000 |

| ωs,in | 0.9002 | 1 | 421.37 | 421.37 | 5788.68 | 0.000 |

| Te,in | 0.3522 | 1 | 64.52 | 64.52 | 886.33 | 0.000 |

| ωe,in | 0.5377 | 1 | 150.33 | 150.33 | 2065.14 | 0.000 |

| TLD,in | 0.2616 | 1 | 35.58 | 35.58 | 488.82 | 0.000 |

| CLD | 0.7573 | 1 | 298.19 | 298.19 | 4096.41 | 0.000 |

| vLD | −0.0142 | 1 | 0.1 | 0.1 | 1.44 | 0.231 |

| −0.0772 | 1 | 3.1 | 3.1 | 42.54 | 0.000 | |

| r | −0.7296 | 1 | 276.84 | 276.84 | 3803.12 | 0.000 |

| t | −0.2364 | 1 | 29.07 | 29.07 | 399.38 | 0.000 |

| L | 0.1461 | 1 | 11.1 | 11.1 | 152.45 | 0.000 |

| W | 0.1378 | 1 | 9.88 | 9.88 | 135.67 | 0.000 |

| Square | 7 | |||||

| ωs,in2 | −0.1034 | 1 | 0.39 | 0.39 | 5.3 | 0.022 |

| ωe,in2 | −0.0987 | 1 | 0.35 | 0.35 | 4.82 | 0.029 |

| CLD2 | −0.1894 | 1 | 1.29 | 1.29 | 17.77 | 0.000 |

| −0.1068 | 1 | 0.41 | 0.41 | 5.65 | 0.018 | |

| r2 | 0.7185 | 1 | 18.61 | 18.61 | 255.61 | 0.000 |

| L2 | −0.1428 | 1 | 0.73 | 0.73 | 10.1 | 0.002 |

| W2 | −0.1404 | 1 | 0.71 | 0.71 | 9.76 | 0.002 |

| 2-Way Interaction | 40 | |||||

| 0.4097 | 1 | 85.95 | 85.95 | 1180.82 | 0.000 | |

| Ts,inr | −0.0738 | 1 | 2.79 | 2.79 | 38.33 | 0.000 |

| Ts,int | 0.4953 | 1 | 125.6 | 125.6 | 1725.4 | 0.000 |

| Ts,inL | −0.5692 | 1 | 165.87 | 165.87 | 2278.63 | 0.000 |

| Ts,inW | −0.5647 | 1 | 163.28 | 163.28 | 2243.11 | 0.000 |

| ωs,inωe,in | −0.0254 | 1 | 0.33 | 0.33 | 4.53 | 0.034 |

| ωs,inCLD | 0.0427 | 1 | 0.94 | 0.94 | 12.85 | 0.000 |

| −0.0854 | 1 | 3.73 | 3.73 | 51.27 | 0.000 | |

| ωs,inr | −0.0771 | 1 | 3.04 | 3.04 | 41.77 | 0.000 |

| ωs,int | −0.1566 | 1 | 12.55 | 12.55 | 172.38 | 0.000 |

| ωs,inL | 0.1477 | 1 | 11.17 | 11.17 | 153.44 | 0.000 |

| ωs,inW | 0.1453 | 1 | 10.8 | 10.8 | 148.42 | 0.000 |

| −0.0418 | 1 | 0.89 | 0.89 | 12.29 | 0.000 | |

| Te,inr | 0.0503 | 1 | 1.29 | 1.29 | 17.79 | 0.000 |

| Te,int | −0.0579 | 1 | 1.72 | 1.72 | 23.58 | 0.000 |

| Te,inL | 0.0662 | 1 | 2.24 | 2.24 | 30.82 | 0.000 |

| Te,inW | 0.0662 | 1 | 2.24 | 2.24 | 30.82 | 0.000 |

| −0.0616 | 1 | 1.95 | 1.95 | 26.72 | 0.000 | |

| ωe,inr | 0.0835 | 1 | 3.57 | 3.57 | 49.07 | 0.000 |

| ωe,int | −0.0855 | 1 | 3.74 | 3.74 | 51.44 | 0.000 |

| ωe,inL | 0.0979 | 1 | 4.9 | 4.9 | 67.38 | 0.000 |

| ωe,inW | 0.0977 | 1 | 4.89 | 4.89 | 67.13 | 0.000 |

| TLD,invLD | 0.0344 | 1 | 0.61 | 0.61 | 8.33 | 0.004 |

| −0.0607 | 1 | 1.89 | 1.89 | 25.95 | 0.000 | |

| TLD,inr | −0.0404 | 1 | 0.84 | 0.84 | 11.48 | 0.001 |

| −0.0557 | 1 | 1.59 | 1.59 | 21.81 | 0.000 | |

| CLDr | −0.108 | 1 | 5.97 | 5.97 | 82.08 | 0.000 |

| CLDt | −0.1272 | 1 | 8.28 | 8.28 | 113.74 | 0.000 |

| CLDL | 0.1076 | 1 | 5.92 | 5.92 | 81.37 | 0.000 |

| CLDW | 0.1042 | 1 | 5.56 | 5.56 | 76.33 | 0.000 |

| r | 0.1533 | 1 | 12.04 | 12.04 | 165.37 | 0.000 |

| t | −0.0426 | 1 | 0.93 | 0.93 | 12.78 | 0.000 |

| L | 0.0607 | 1 | 1.89 | 1.89 | 25.91 | 0.000 |

| W | 0.0612 | 1 | 1.92 | 1.92 | 26.32 | 0.000 |

| rt | 0.1762 | 1 | 15.89 | 15.89 | 218.28 | 0.000 |

| rL | −0.2396 | 1 | 29.38 | 29.38 | 403.67 | 0.000 |

| rW | −0.239 | 1 | 29.24 | 29.24 | 401.75 | 0.000 |

| tL | 0.0512 | 1 | 1.34 | 1.34 | 18.47 | 0.000 |

| tW | 0.0493 | 1 | 1.25 | 1.25 | 17.12 | 0.000 |

| LW | −0.0774 | 1 | 3.07 | 3.07 | 42.16 | 0.000 |

| Error | 486 | 35.38 | 0.07 | |||

| Total | 545 | 7538.75 |

References

- IEA. World Energy Outlook 2018; OECD: Paris, France, 2018. [Google Scholar] [CrossRef]

- International Energy Agency. The Future of Cooling; OECD: Paris, France, 2018. [Google Scholar] [CrossRef]

- Lowenstein, A.; Slayzak, S.; Kozubal, E. A zero carryover liquid-desiccant air conditioner for solar applications. In Proceedings of the ASME 2006 International Solar Energy Conference, Denver, CO, USA, 8–13 July 2006; pp. 397–407. [Google Scholar] [CrossRef] [Green Version]

- Lu, H.; Lu, L. CFD simulation of liquid desiccant dehumidifier performance with smooth and rough plates. Int. J. Refrig. 2021, 124, 1–12. [Google Scholar] [CrossRef]

- Gao, W.Z.; Shi, Y.R.; Cheng, Y.P.; Sun, W.Z. Experimental study on partially internally cooled dehumidification in liquid desiccant air conditioning system. Energy Build. 2013, 61, 202–209. [Google Scholar] [CrossRef]

- Jafarian, H.; Sayyaadi, H.; Torabi, F. Numerical modeling and comparative study of different membrane-based liquid desiccant dehumidifiers. Energy Convers. Manag. 2019, 184, 735–747. [Google Scholar] [CrossRef]

- Woods, J.; Kozubal, E. A desiccant-enhanced evaporative air conditioner: Numerical model and experiments. Energy Convers. Manag. 2013, 65, 208–220. [Google Scholar] [CrossRef]

- Park, J.Y.; Kim, B.J.; Yoon, S.Y.; Byon, Y.S.; Jeong, J.W. Experimental analysis of dehumidification performance of an evaporative cooling-assisted internally cooled liquid desiccant dehumidifier. Appl. Energy 2019, 235, 177–185. [Google Scholar] [CrossRef]

- Huang, S.M.; Zhong, Z.; Yang, M. Conjugate heat and mass transfer in an internally-cooled membrane-based liquid desiccant dehumidifier (IMLDD). J. Memb. Sci. 2016, 508, 73–83. [Google Scholar] [CrossRef]

- Li, W.; Yao, Y. Thermodynamic analysis of internally-cooled membrane-based liquid desiccant dehumidifiers of different flow types. Int. J. Heat Mass Transf. 2021, 166, 120802. [Google Scholar] [CrossRef]

- Guan, B.; Liu, X.; Zhang, T.; Liu, J. Optimal flow type in internally-cooled liquid-desiccant system driven by heat pump: Component level vs. System level. Appl. Therm. Eng. 2021, 183, 116208. [Google Scholar] [CrossRef]

- McDonald, B.; Waugaman, D.G.; Kettleborough, C.F. A statistical analysis of a packed tower dehumidifier. Dry. Technol. 1992, 10, 223–237. [Google Scholar] [CrossRef]

- Abdul-Wahab, S.A.; Zurigat, Y.H.; Abu-Arabi, M.K. Predictions of moisture removal rate and dehumidification effectiveness for structured liquid desiccant air dehumidifier. Energy 2004, 29, 19–34. [Google Scholar] [CrossRef]

- Gandhidasan, P.; Mohandes, M.A. Artificial neural network analysis of liquid desiccant dehumidification system. Energy 2011, 36, 1180–1186. [Google Scholar] [CrossRef]

- Mohammad, A.T.; Bin Mat, S.; Sulaiman, M.Y.; Sopian, K.; Al-Abidi, A.A. Implementation and validation of an artificial neural network for predicting the performance of a liquid desiccant dehumidifier. Energy Convers. Manag. 2013, 67, 240–250. [Google Scholar] [CrossRef]

- Park, J.Y.; Yoon, D.S.; Lee, S.J.; Jeong, J.W. Empirical model for predicting the dehumidification effectiveness of a liquid desiccant system. Energy Build. 2016, 126, 447–454. [Google Scholar] [CrossRef]

- Lin, J.; Huang, S.M.; Wang, R.; Jon Chua, K. On the in-depth scaling and dimensional analysis of a cross-flow membrane liquid desiccant dehumidifier. Appl. Energy 2019, 250, 786–800. [Google Scholar] [CrossRef]

- Sohani, A.; Sayyaadi, H.; Hasani Balyani, H.; Hoseinpoori, S. A novel approach using predictive models for performance analysis of desiccant enhanced evaporative cooling systems. Appl. Therm. Eng. 2016, 107, 227–252. [Google Scholar] [CrossRef]

- Pakari, A.; Ghani, S. Comparison of 1D and 3D heat and mass transfer models of a counter flow dew point evaporative cooling system: Numerical and experimental study. Int. J. Refrig. 2019, 99, 114–125. [Google Scholar] [CrossRef]

- Conde, M.R. Properties of aqueous solutions of lithium and calcium chlorides: Formulations for use in air conditioning equipment design. Int. J. Therm. Sci. 2004, 43, 367–382. [Google Scholar] [CrossRef]

- Buck, A.L. New Equations for Computing Vapor Pressure and Enhancement Factor. J. Appl. Meteorol. 1981, 20, 1527–1532. [Google Scholar] [CrossRef]

- Buck, A.L. CR-1A Hygrometer Operating Manual. 2012. Available online: https://www.hygrometers.com/wp-content/uploads/CR-1A-users-manual-2009-12.pdf (accessed on 10 January 2022).

- Sharqawy, M.H.; Lienhard, V.J.H.; Zubair, S.M. The thermophysical properties of seawater: A review of existing correlations and data accessed thermophysical properties of seawater: A review of existing correlations and data. Desalin. Water Treat. 2010, 16, 354–380. [Google Scholar] [CrossRef]

- Shah, R.K.; London, A.L. Chapter VI—Parallel plates. In Laminar Flow Forced Convection in Ducts; Shah, R.K., London, A.L., Eds.; Academic Press: Cambridge, MA, USA, 1978; pp. 153–195. [Google Scholar] [CrossRef]

- Pakari, A.; Ghani, S. Regression models for performance prediction of counter flow dew point evaporative cooling systems. Energy Convers. Manag. 2019, 185, 562–573. [Google Scholar] [CrossRef]

| Parameter | Symbol | Value | Unit |

|---|---|---|---|

| Supply channel thickness | 3.175 | mm | |

| Exhaust channel thickness | 3.175 | mm | |

| Channel length | 0.24 | m | |

| Channel width | 0.535 | m | |

| Plate thickness | 0.4 | mm | |

| Wick thickness | 0.3 | mm | |

| Membrane thickness | 20 | μm | |

| Membrane diffusivity | 1.48 × 10−6 | m2 s−1 | |

| Membrane thermal conductivity | 0.06 | W m−1 K−1 |

| No. | Factor | Description | Unit | Levels | ||||

|---|---|---|---|---|---|---|---|---|

| 1 | Ts,in | Supply air inlet temperature | °C | 20 | 26.5 | 33 | 39.5 | 46 |

| 2 | ωs,in | Supply air inlet humidity ratio | kg/kg | 0.011 | 0.0145 | 0.018 | 0.0215 | 0.025 |

| 3 | Te,in | Exhaust air inlet temperature | °C | 24 | 29.5 | 35 | 40.5 | 46 |

| 4 | ωe,in | Exhaust air inlet humidity ratio | kg/kg | 0.011 | 0.0145 | 0.018 | 0.0215 | 0.025 |

| 5 | TLD,in | Liquid desiccant inlet temperature | °C | 24 | 29.5 | 35 | 40.5 | 46 |

| 6 | CLD | Liquid desiccant concentration | kg/kg | 0.32 | 0.375 | 0.43 | 0.485 | 0.54 |

| 7 | vLD | Liquid desiccant flow rate per channel | mL/min | 7 | 9.75 | 12.5 | 15.25 | 18 |

| 8 | Supply air mass flow rate per channel | kg/s | 0.0024 | 0.0033 | 0.0042 | 0.0051 | 0.006 | |

| 9 | r | Ratio of exhaust to supply mass flow rate | - | 0 | 0.25 | 0.5 | 0.75 | 1 |

| 10 | t | Thickness of the channels | mm | 2 | 3 | 4 | 5 | 6 |

| 11 | L | Channel length | m | 0.15 | 0.2625 | 0.375 | 0.4875 | 0.6 |

| 12 | W | Channel width | m | 0.15 | 0.2625 | 0.375 | 0.4875 | 0.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pakari, A.; Ghani, S. Regression Models for Performance Prediction of Internally-Cooled Liquid Desiccant Dehumidifiers. Energies 2022, 15, 1758. https://doi.org/10.3390/en15051758

Pakari A, Ghani S. Regression Models for Performance Prediction of Internally-Cooled Liquid Desiccant Dehumidifiers. Energies. 2022; 15(5):1758. https://doi.org/10.3390/en15051758

Chicago/Turabian StylePakari, Ali, and Saud Ghani. 2022. "Regression Models for Performance Prediction of Internally-Cooled Liquid Desiccant Dehumidifiers" Energies 15, no. 5: 1758. https://doi.org/10.3390/en15051758

APA StylePakari, A., & Ghani, S. (2022). Regression Models for Performance Prediction of Internally-Cooled Liquid Desiccant Dehumidifiers. Energies, 15(5), 1758. https://doi.org/10.3390/en15051758