Technical and Economic Analysis of the Implementation of a Self-Sustainable Briquetting Process for Electric Generation

Abstract

1. Introduction

2. Materials and Methods

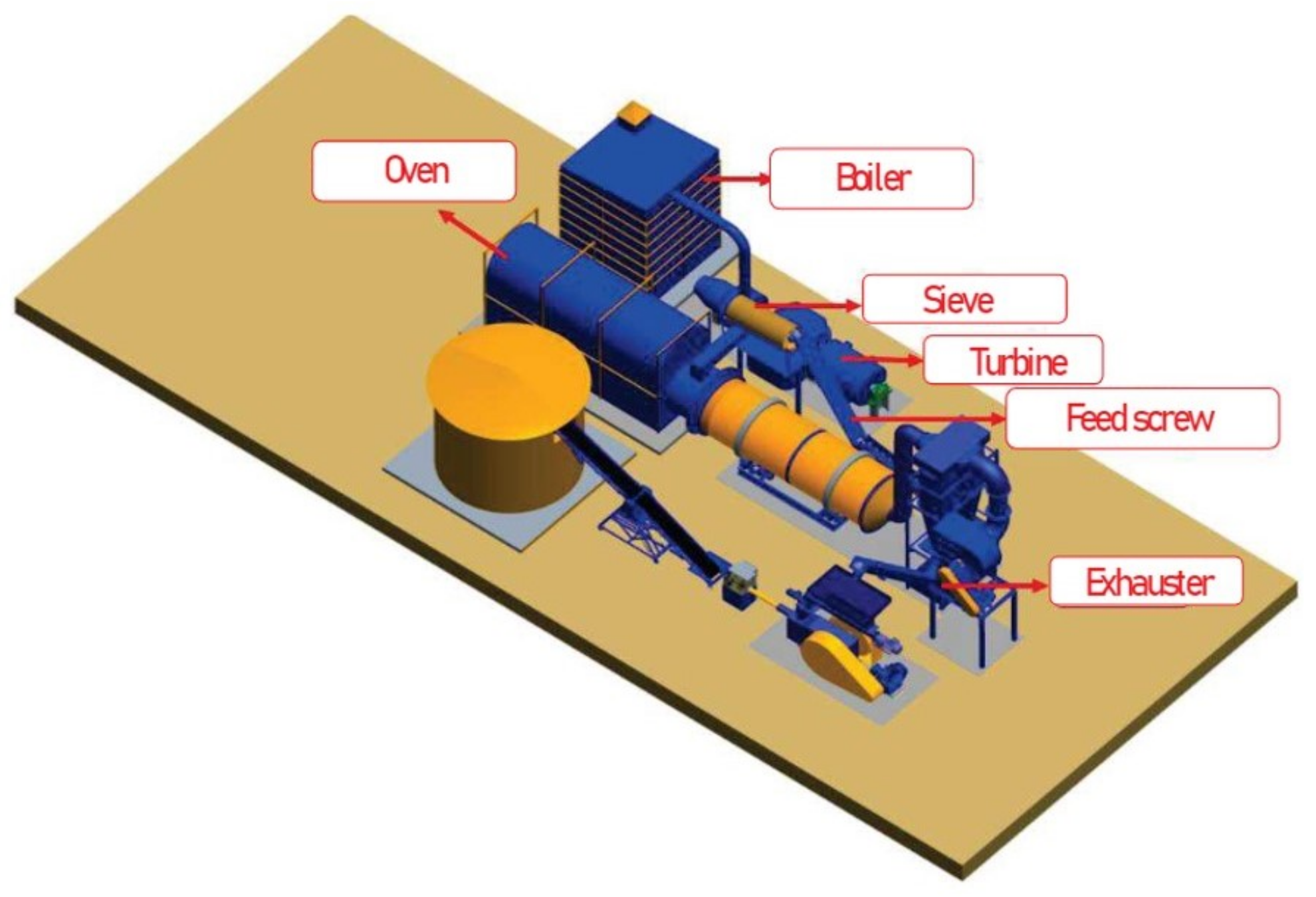

- Turbo Condenser Generator of 33 MVA.

- Boiler (130 TVH rotary grill boiler with a pressure of 67 kgf/cm, heating temperature of 2495 ºC with an average consumption os wood residue—46,000 kg/h or 144 m3/h and maximum consumption—55,000 kg/h or 172 m3/h).

- Interconnection pipes for high and low pressure steam lines.

2.1. Energetic Properties of in Natura Residues

Determination of the Heating Value of the Residues

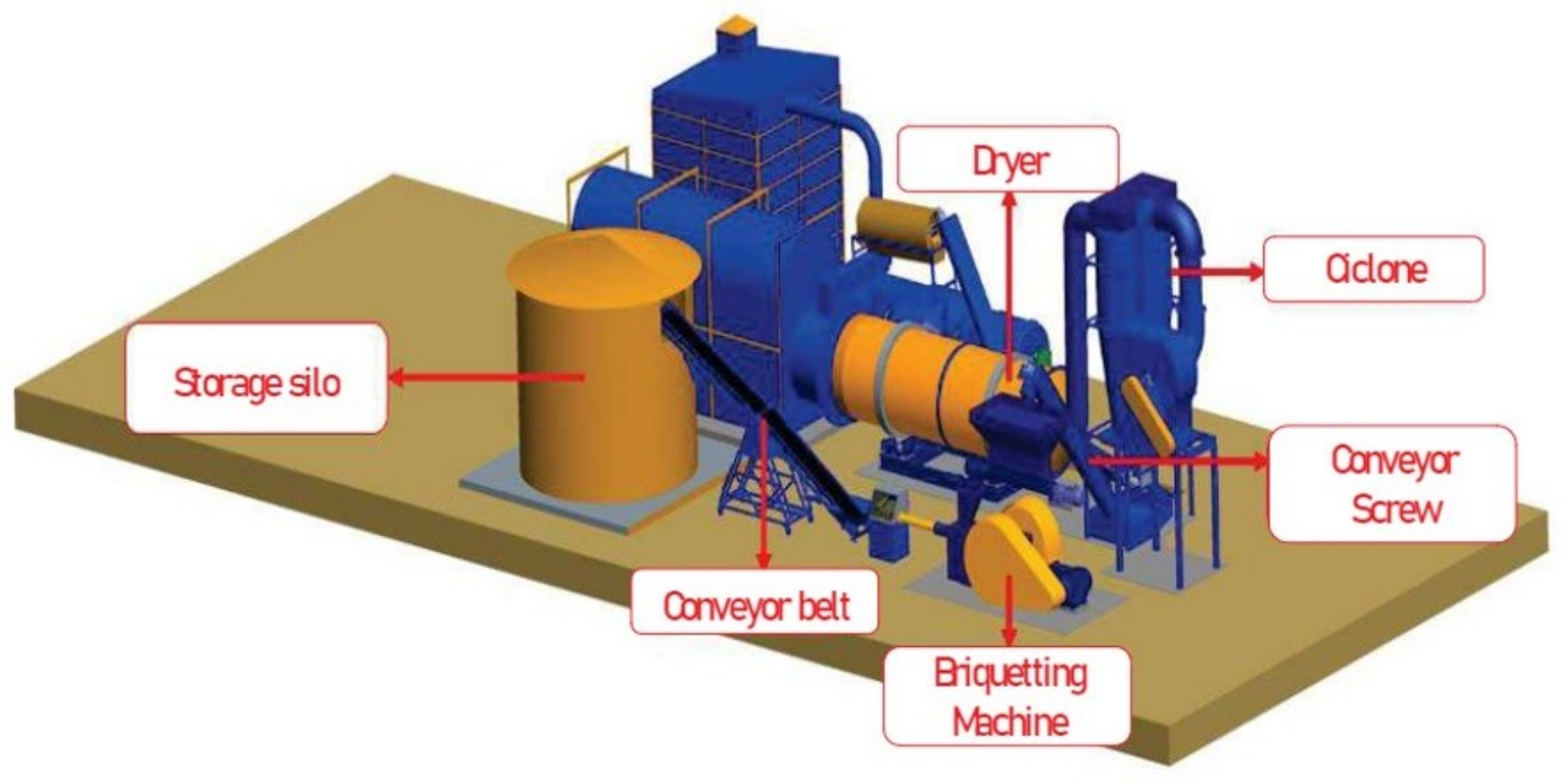

2.2. Production Process of Briquettes

2.3. Evaluation of Briquettes Apparent Density

3. Results and Discussion

3.1. Heating Value of the Wood Residues and Briquettes

3.2. Electrical Energy Storage

3.3. Case Study

3.3.1. Investment Costs

3.3.2. Operational/Production Costs

3.3.3. Transportation Costs

3.3.4. Energy and Transport Savings

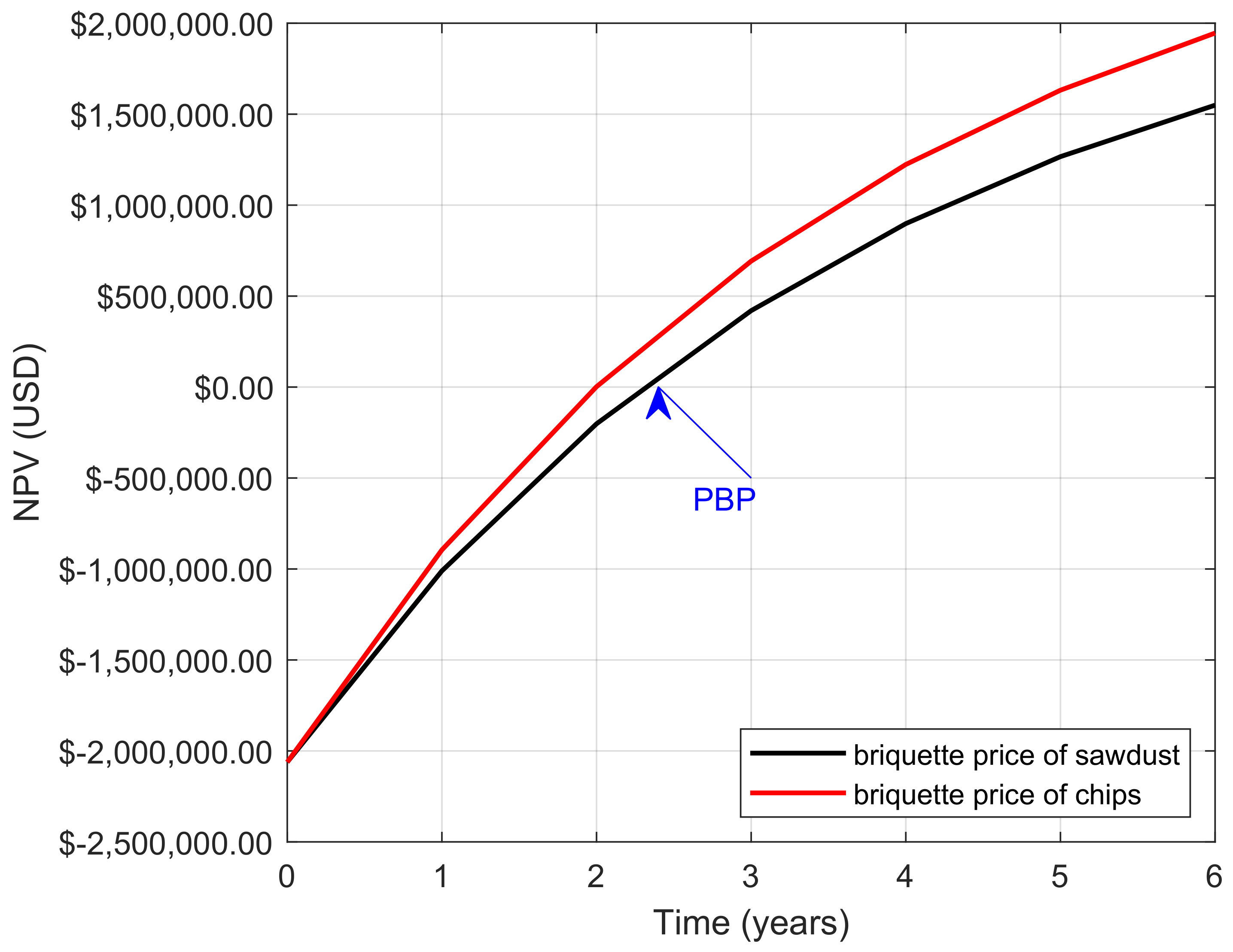

3.3.5. NPV, IRR and Pay Back Period Estimation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| LAPEM | Laboratório de Painéis e Energia da Madeira (Wood Panels and Energy Laboratory) |

| NP | Necessary power |

References

- Araujo, S.D.O.; Neiva, D.M.; Carneiro, A.D.C.; Esteves, B.; Pereira, H. Potential of Mild Torrefaction for Upgrading the Wood Energy Value of Different Eucalyptus Species. Forests 2018, 9, 535. [Google Scholar] [CrossRef]

- Marafon, A.C.; Santiago, A.D.; Amaral, A.F.C.; Bierhals, A.N.; Paiva, H.L.; Guimarães, V.d.S. Uso da Biomassa para a Geração de Energia; Embrapa Tabuleiros Costeiros-Documentos (INFOTECA-E): Aracaju, Brazil, 2016. [Google Scholar]

- Alanya-Rosenbaum, S.; Bergman, R.D. Life-cycle impact and exergy based resource use assessment of torrefied and non-torrefied briquette use for heat and electricity generation. J. Clean. Prod. 2019, 233, 918–931. [Google Scholar] [CrossRef]

- Canto, J.L.d.; Machado, C.C.; Seixas, F.; Souza, A.P.d.; Sant’Anna, C.d.M. Avaliação de um sistema de cavaqueamento de ponteiras de eucalipto para aproveitamento energético. Revista Árvore 2011, 35, 1327–1334. [Google Scholar] [CrossRef][Green Version]

- Simpkins, D.; Allard, N.; Patrick, J. Clean Energy from Wood Residues in Michigan. 2006. Available online: https://www.michigan.gov/documents/wood_energy_in_michigan–final1_169999_7.pdf (accessed on 5 December 2021).

- Muniz, H.C.; Correia, J.M.F.; Lucato, W.C.; de Oliveira Neto, G.C. Ganho Economico e Reducao de Emissao de Gases de Efeito Estufa com a Utilizacao de Briquete como Fonte de Energia Calorifica para Fornos: Estudo de Caso em duas Pizzarias. 2018. Available online: https://www.aedb.br/seget/arquivos/artigos18/17526182.pdf (accessed on 17 December 2021).

- Ungureanu, N.; Vladut, V.; Voicu, G.; Dinca, M.N.; Zabava, B.S. Influence of biomass moisture content on pellet properties—Review. Eng. Rural Dev. 2018, 17, 1876–1883. [Google Scholar]

- Tenu, I.; Roman, C.; Senila, L.; Roşca, R.; Cârlescu, P.; Băetu, M.; Arsenoaia, V.; Dumitrachi, E.P.; Corduneanu, O.R. Valorization of Vine Tendrils Resulted from Pruning as Densified Solid Biomass Fuel (Briquettes). Processes 2021, 9, 1409. [Google Scholar] [CrossRef]

- Sahoo, K.; Alanya-Rosenbaum, S.; Bergman, R.; Abbas, D.; Bilek, E.M.T. Environmental and Economic Assessment of Portable Systems: Production of Wood-Briquettes and Torrefied-Briquettes to Generate Heat and Electricity. Fuels 2021, 2, 20. [Google Scholar] [CrossRef]

- Akolgo, G.A.; Awafo, E.A.; Essandoh, E.O.; Owusu, P.A.; Uba, F.; Adu-Poku, K.A. Assessment of the potential of charred briquettes of sawdust, rice and coconut husks: Using water boiling and user acceptability tests. Sci. Afr. 2021, 12, e00789. [Google Scholar] [CrossRef]

- Kpalo, S.Y.; Zainuddin, M.F.; Manaf, L.A.; Roslan, A.M. A Review of Technical and Economic Aspects of Biomass Briquetting. Sustainability 2020, 12, 4609. [Google Scholar] [CrossRef]

- Trubetskaya, A.; Leahy, J.J.; Yazhenskikh, E.; Müller, M.; Layden, P.; Johnson, R.; Ståhl, K.; Monaghan, R.F. Characterization of woodstove briquettes from torrefied biomass and coal. Energy 2019, 171, 853–865. [Google Scholar] [CrossRef]

- Furtado, T.S.; Valin, M.; Brand, M.A.; Bellote, A.F.J. Variáveis do processo de briquetagem e qualidade de briquetes de biomassa florestal. Pesquisa Florestal Brasileira 2010, 30, 101. [Google Scholar] [CrossRef]

- Quirino, W.F.; Brito, J.O. Características e Índice de Combustão de Briquetes de Carvão Vegetal; IBAMA, Laboratório de Produtos Florestais: Brasilia, Brazil, 1991. [Google Scholar]

- Dias, J. Utilização da Biomassa: Avaliação dos Resíduos e Utilização de Pellets em Caldeiras Domésticas; Universidade Técnica de Lisboa: Lisboa, Portugal, 2002. [Google Scholar]

- Filippetto, D. Briquetagem de Residuos Vegetais: Viabilidade Tecnico-Economica e Potencial de Mercado; Unicamp: Campinas, Brazil, 2008. [Google Scholar]

- Figueira, F.V.; Martinazzo, A.P.; de Souza Teodoro, C.E. Estimativa da viabilidade econômica da produção de briquetes a partir de resíduos de grãos beneficiados. Engevista 2015, 17, 95–104. [Google Scholar] [CrossRef]

- Onchieku, J. Cost benefit analysis of making charcoal briquettes using screw press machine locally designed and fabricated. Int. Adv. Res. J. Sci. Eng. Technol. 2018, 5, 57–65. [Google Scholar]

- Cardenas-Rodriguez, H.d.N.; Martins, R.; Oliveira, L.E.L.; Bonaldi, E.L.; Assuncao, F.d.O.; Lambert-Torres, G.; Villa-Nova, H.F.; Sant’Ana, W.C.; Borges-da Silva, L.E.; Bomfin, C.B.; et al. Analysis on the Use of Briquettes as an Alternative to Improve the Generation of Thermal Energy in the Locality of Aripuana-Brazil. Energies 2021, 14, 6355. [Google Scholar] [CrossRef]

- De Souza, M.M.; Silva, D.A.; Rochadelli, R.; dos Santos, R.C. Estimativa de poder calorífico e caracterização para uso energético de resíduos da colheita e do processamento de Pinus taeda. Floresta 2012, 42, 325–334. [Google Scholar] [CrossRef]

- Domingos, I.; Ayata, U.; Ferreira, J.; Cruz-Lopes, L.; Sen, A.; Sahin, S.; Esteves, B. Calorific Power Improvement of Wood by Heat Treatment and Its Relation to Chemical Composition. Energies 2020, 13, 5322. [Google Scholar] [CrossRef]

- Campos, M.M.; Borges-da Silva, L.E.; Arantes, D.d.A.; Teixeira, C.E.; Bonaldi, E.L.; Lambert-Torres, G.; Ribeiro Junior, R.F.; Krupa, G.P.; Sant’Ana, W.C.; Oliveira, L.E.L.; et al. An Ultrasonic-Capacitive System for Online Characterization of Fuel Oils in Thermal Power Plants. Sensors 2021, 21, 7979. [Google Scholar] [CrossRef] [PubMed]

- De Carvalho-Junior, R.M. Desenvolvimento e Analise Energetica do Processo de Obtencao do Biodiesel de Microalga por Metanolise In Situ; Universidade Federal do Parana: Curitiba, Brazil, 2010. [Google Scholar]

- Neto, A.d.P.M.; Lins, C.F.; Brandão, S.; Duarte, B.; Almir, J.; Marangon, L.C.; Feliciano, A.L.P. Densidade e poder calorífico como base para prevenção de incêndios florestais sob linhas de transmissão. Nativa 2015, 3, 10–15. [Google Scholar] [CrossRef][Green Version]

- Phyllis Online Database. Available online: https://phyllis.nl/Home/Help (accessed on 3 January 2022).

- Associação Brasileira de Normas Técnicas. Carvão Vegetal: Determinação do Poder Calorífico; NBR 8633; Associação Brasileira de Normas Técnicas: Rio do Janeiro, Brazil, 1984. [Google Scholar]

- Matúš, M.; Križan, P.; Beniak, J.; Šooš, L. Effects of initial moisture content on the production and quality properties of solid biofuel. Acta Polytech. 2015, 55, 335–341. [Google Scholar] [CrossRef]

- Garrido, S.G. Centrales Termoeléctricas de Biomasa; Renovetec: Fuenlabrada, Madrid, Spain, 2014. [Google Scholar]

- Jean de Dieu, K.H.; Kim, H.T. Peat briquette as an alternative to cooking fuel: A techno-economic viability assessment in Rwanda. Energy 2016, 102, 453–464. [Google Scholar]

| Granulometry | Mass |

|---|---|

| wood chips | 31.3 ton |

| sawdust | 22.76 ton |

| Equipments | Units | Capacity [ton/h] | Power [CV] |

|---|---|---|---|

| Briquetting machine (B 95/210) | 1 | 2 | 75 |

| Oven (1,000,000) Kcal/h | 1 | 0.166 | - |

| Dryer | 1 | 2 | 2 × 7.5 |

| Ciclone | 1 | 2 | - |

| Exhauster | 1 | 2 | 30 |

| Feed screw | 4 | - | 2 × 3 |

| Sieve | 1 | 4 | 2 |

| turbo-generator | 1 | - | 201 |

| Boiler | 1 | 6 | - |

| Productive capacity | 2 ton/h |

| Equipment weight | 7.6 ton |

| Diameter of the matrix | 93 mm |

| Main engine power | 75 CV–380 V three-phase |

| vertical propeller power | 7.5 CV |

| Dimensions | 2840 mm × 1170 mm × 1830 mm |

| Flywheel diameter | 1390 mm (2 units) |

| Granulometry | HHV | LHV | UHV | |||

|---|---|---|---|---|---|---|

| [kcal/kg] | [kJ/kg] | [kcal/kg] | [kJ/kg] | [kcal/kg] | [kJ/kg] | |

| wood chips | 4742 | 19,847.6 | 4418 | 18,491.5 | 2310.44 | 9668.5 |

| sawdust | 4176 | 17,478.6 | 3852 | 16,122.5 | 1982.16 | 8295.6 |

| Granulometry | HHV | LHV | UHV | |||

|---|---|---|---|---|---|---|

| [kcal/kg] | [kJ/kg] | [kcal/kg] | [kJ/kg] | [kcal/kg] | [kJ/kg] | |

| Briquette | 4949 | 20,714 | 4625 | 19,358 | 4207 | 17,608.3 |

| Granulometry | kg/h |

|---|---|

| briquette | 1022 |

| wood chips | 1861.1 |

| sawdust | 1833.5 |

| Equipment | Units | Unit Cost [USD] | Total Cost [USD] |

|---|---|---|---|

| B95/210 Briquetting machine | 9 | 59,600 | 536,400 |

| Sieve | 9 | 9600 | 86,400 |

| Oven | 9 | 35,000 | 315,000 |

| Drying system * | 9 | 55,430 | 498,870 |

| turbo-generator | 1 | 400,000 | 400,000 |

| Boiler | 1 | 198,000 | 198,000 |

| Briquette Plant Automation System | 1 | 27,397 | 27,397 |

| Total | 2,061,667 |

| Item | Units | Unit Cost [USD/Year] | Total Cost [USD/Year] |

|---|---|---|---|

| Maintenance briquetting machine | 1 | 515 | 515 |

| Maintenance miscellaneous | 1 | 12,000 | 12,000 |

| Cost of manpower | 4 | 7354 | 29,417 |

| Total set-up | 41,932 |

| Granulometry | Cost [USD/ton] |

|---|---|

| wood chips | 10.00 |

| sawdust | 7.5 |

| briquette | 10.00 or 7.5 |

| Granulometry | Residue/Briquette Qty [ton/Day] | Daily Transport Cost [USD/ton] | Cost Saving [USD/Month] | Cost Savings [USD/Year] |

|---|---|---|---|---|

| wood chips | 803.952 (25.7 trucks) | 8039 | - | |

| sawdust | 791,856 (34.8 trucks) | 5939 | - | |

| Briquette (chips transport cost) | 441,504 (5.8 trucks) | 4415 | 185,909 | 2,230,911 (77 %) |

| Briquette (sawdust transport cost) | 147,968 | 1,775,624 (83 %) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martins, R.; Cardenas-Rodriguez, H.d.N.; Oliveira, L.E.L.; Bonaldi, E.L.; Assuncao, F.d.O.; Lambert-Torres, G.; Villa-Nova, H.F.; Sant’Ana, W.C.; Borges-da-Silva, L.E.; Bomfin, C.B.; et al. Technical and Economic Analysis of the Implementation of a Self-Sustainable Briquetting Process for Electric Generation. Energies 2022, 15, 2146. https://doi.org/10.3390/en15062146

Martins R, Cardenas-Rodriguez HdN, Oliveira LEL, Bonaldi EL, Assuncao FdO, Lambert-Torres G, Villa-Nova HF, Sant’Ana WC, Borges-da-Silva LE, Bomfin CB, et al. Technical and Economic Analysis of the Implementation of a Self-Sustainable Briquetting Process for Electric Generation. Energies. 2022; 15(6):2146. https://doi.org/10.3390/en15062146

Chicago/Turabian StyleMartins, Rosa, Haylemar de Nazaret Cardenas-Rodriguez, Levy Ely Lacerda Oliveira, Erik Leandro Bonaldi, Frederico de Oliveira Assuncao, Germano Lambert-Torres, Helcio Francisco Villa-Nova, Wilson Cesar Sant’Ana, Luiz Eduardo Borges-da-Silva, Clodoaldo Barboza Bomfin, and et al. 2022. "Technical and Economic Analysis of the Implementation of a Self-Sustainable Briquetting Process for Electric Generation" Energies 15, no. 6: 2146. https://doi.org/10.3390/en15062146

APA StyleMartins, R., Cardenas-Rodriguez, H. d. N., Oliveira, L. E. L., Bonaldi, E. L., Assuncao, F. d. O., Lambert-Torres, G., Villa-Nova, H. F., Sant’Ana, W. C., Borges-da-Silva, L. E., Bomfin, C. B., Haddad, J., & Santos, A. H. M. (2022). Technical and Economic Analysis of the Implementation of a Self-Sustainable Briquetting Process for Electric Generation. Energies, 15(6), 2146. https://doi.org/10.3390/en15062146