Image Detection of Insulator Defects Based on Morphological Processing and Deep Learning

Abstract

:1. Introduction

2. Materials and Methods

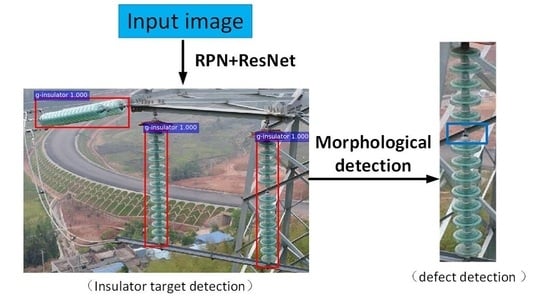

- A method for detecting the absence of insulator caps combined with neural networks and deep learning is proposed. The proposed method not only detects the location of defects but also counts the number of remaining insulator caps.

- A target detection method for insulator regions based on the Faster RCNN is proposed. The residual network performs feature extraction so that the detection accuracy is higher.

- According to the morphological characteristics of glass insulation, a pixel clustering algorithm for insulator image segmentation is proposed.

- A method for detecting the insulator inclination angle is proposed. The image is rotated according to the angle between the insulator and the horizontal line, and the inclined insulators are then placed horizontally.

- The detection problem regarding insulators that are installed side by side is transformed into a detection problem regarding single-row insulators. A method for separating side-by-side insulators is proposed.

3. Insulator Target Detection

3.1. The Faster RCNN

3.2. Residual Network

4. Defect Detection

4.1. Insulator Image Segmentation

- According to the median element’s value in, the elements are divided into two groups. For both groups, the median is found and used as the group’s cluster center. In this way, cluster centers C1 and C2 are obtained.

- All pixels are mapped to a six-dimensional coordinate system. The coordinate system’s information primarily includes the pixel’s RGB characteristics, the position of the image (X, Y) and the corresponding value in .

- The Euclidean distance from each pixel to the cluster center is calculated, and the pixel and the nearest cluster center are grouped into a cluster.

- For each cluster, the mean value of all included samples is used as the new cluster center.

- Repeat steps (3) and (4) until the cluster center no longer changes or the set number of iterations is reached. One cluster of pixels whose cluster center is more similar to the insulator color feature is marked as “1”, and the other cluster is marked as “0”.

4.2. Insulator Space Feature Conversion

- The image is divided into N equal parts, the connected region in each part is found, and its center of gravity is marked.

- The least-squares method is used to fit the straight line according to the center of gravity. According to the angle between the line and the horizontal line, the angle between the line and the horizontal line is the angle of rotation for the binary image.

- The rotation angle obtained using this method is also suitable for insulators installed side by side.

- The image is rotated, and the blank spaces are filled with pixel values of 0. The image is then cut according to the insulator position. The acquired image is shown in Figure 7d.

4.3. Location of the Insulator Defect

5. Experiment

5.1. Data Set and Experimental Environment

5.2. Insulator Identification

5.2.1. Training and Testing of the Deep Neural Network

5.2.2. Comparison with Other Target Detection Methods

5.3. Insulator Defect Detection

5.3.1. Verification of Defect Detection Algorithm

5.3.2. Robustness Test

5.3.3. Comparison with Other Defect Detection Methods

6. Conclusions

7. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Castillo, A. Risk Analysis and Management in Power Outage and Restoration: A Literature Survey. Electr. Power Syst. Res. 2014, 107, 9–15. [Google Scholar] [CrossRef]

- Wu, Y.; Zhao, G.; Hu, J.; Ouyang, Y.; Wang, S.; He, J.; Gao, F.; Wang, S. Overhead Transmission Line Parameter Reconstruction for UAV Inspection Based on Tunneling Magnetoresistive Sensors and Inverse Models. IEEE Trans. Power Deliv. 2019, 34, 819–827. [Google Scholar] [CrossRef]

- Chen, D.-Q.; Guo, X.-H.; Huang, P.; Li, F.-H. Safety Distance Analysis of 500kV Transmission Line Tower UAV Patrol Inspection. IEEE Lett. Electromagn. Compat. Pr. Appl. 2020, 2, 124–128. [Google Scholar] [CrossRef]

- Shao, G.; Liu, Z.; Fu, J.; Tan, J.; Chen, Y.; Zhou, L. Progress in Unmanned Aerial Vehicle Inspection Technology on Overhead Transmission Lines. High Volt. Eng. 2020, 46, 14–22. [Google Scholar] [CrossRef]

- Han, S.; Yang, F.; Yang, G.; Gao, B.; Zhang, N.; Wang, D. Electrical Equipment Identification in Infrared Images Based on ROI-Selected CNN Method. Electr. Power Syst. Res. 2020, 188, 106534. [Google Scholar] [CrossRef]

- Zhang, S.; Qi, L.; Han, W.; Zhu, X.; Xi, X.; Wang, C.; Wang, P.; Nie, S. Danger Tree Detection and Tree Number Estimation Based on UAV Lidar Data. J. Univ. Chin. Acad. Sci. 2020, 37, 760–766. [Google Scholar]

- Serikbay, A.; Bagheri, M.; Zollanvari, A.; Phung, B.T. Accurate Surface Condition Classification of High Voltage Insulators based on Deep Convolutional Neural Networks. IEEE Trans. Dielectr. Electr. Insul. 2021, 28, 2126–2133. [Google Scholar] [CrossRef]

- Yue, S.; Yuan, M.; Lu, T.; Shivakumara, P.; Blumenstein, M.; Shi, J.; Kumar, G.H. Rotation Invariant Angle-Density Based Features for An Ice Image Classification System. Expert Syst. Appl. 2020, 162, 113744. [Google Scholar] [CrossRef]

- Zhao, Z.; Qi, H.; Qi, Y.; Zhang, K.; Zhai, Y.; Zhao, W. Detection Method Based on Automatic Visual Shape Clustering for Pin-Missing Defect in Transmission Lines. IEEE Trans. Instrum. Meas. 2020, 69, 6080–6091. [Google Scholar] [CrossRef] [Green Version]

- Huang, X.; Zhang, X.; Zhang, Y.; Zhao, L. A Method of Identifying Rust Status of Dampers Based on Image Processing. IEEE Trans. Instrum. Meas. 2020, 69, 5407–5417. [Google Scholar] [CrossRef]

- Jenssen, R.; Roverso, D. Intelligent Monitoring and Inspection of Power Line Components Powered by UAVs and Deep Learning. IEEE Power Energy Technol. Syst. J. 2019, 6, 11–21. [Google Scholar] [CrossRef]

- Huang, X.; Liu, X.; Zhang, Y.; Li, J.; Zhang, H.; Xing, X. Classification Recognition Method of Insulator in Aerial Image Based on the Red-blue Difference and Developed K-means Algorithm. High Volt. Eng. 2018, 44, 1528–1534. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, Y. Insulator Identification from Aerial Images Using Support Vector Machine with Background Suppression. In Proceedings of the International Conference on Unmanned Aircraft Systems (ICUAS), Arlington, VA, USA, 7–10 June 2016; pp. 892–897. [Google Scholar]

- Zhu, S.; Gao, Q.; Liu, Y.; Sun, D. Identification and Location of Insulator String Based on Frequency-Tuned. Trans. China Electrotech. Soc. 2018, 33, 5573–5580. [Google Scholar] [CrossRef]

- Girshick, R.; Donahue, J.; Darrell, T.; Malik, J. Rich Feature Hierarchies for Accurate Object Detection and Semantic Segmentation. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Columbus, OH, USA, 23–28 June 2014; pp. 580–587. [Google Scholar]

- Cui, Z.; Lu, N. Feature Selection Accelerated Convolutional Neural Networks for Visual Tracking. Appl. Intell. 2021, 51, 8230–8244. [Google Scholar] [CrossRef]

- Zhao, Z.; Zhen, Z.; Zhang, L.; Qi, Y.; Kong, Y.; Zhang, K. Insulator Detection Method in Inspection Image Based on Improved Faster R-CNN. Energies 2019, 12, 1204. [Google Scholar] [CrossRef] [Green Version]

- Gawande, U.; Hajari, K.; Golhar, Y. SIRA: Scale Illumination Rotation Affine Invariant Mask R-CNN for Pedestrian Detection. Appl. Intell. 2022, 2022, 1–19. [Google Scholar] [CrossRef]

- Sadykova, D.; Pernebayeva, D.; Bagheri, M.; James, A. IN-YOLO: Real-Time Detection of Outdoor High Voltage Insulators Using UAV Imaging. IEEE Trans. Power Deliv. 2020, 35, 1599–1601. [Google Scholar] [CrossRef]

- Liu, Y.; Ji, X.; Pei, S.; Ma, Z.; Zhang, G.; Lin, Y.; Chen, Y. Research on Automatic Location and Recognition of Insulators in Substation Based on YOLOv3. High Volt. 2020, 5, 62–68. [Google Scholar] [CrossRef]

- Zhao, W.; Cheng, X.; Zhao, Z.; Zhai, Y. Insulator Recognition Based on Attention Mechanism and Faster RCNN. CAAI Trans. Intell. Syst. 2020, 15, 92–98. [Google Scholar] [CrossRef]

- Zhang, Q.; Li, W.; Li, H.; Wang, J. Self-blast State Detection of Glass Insulators Based on Stochastic Configuration Networks and A Feedback Transfer Mechanism. Inf. Sci. 2020, 522, 259–274. [Google Scholar] [CrossRef]

- Prates, R.M.; Cruz, R.; Marotta, A.P.; Ramos, R.P.; Filho, E.F.D.S.; Cardoso, J. Insulator Visual Non-Conformity Detection in Overhead Power Distribution Lines Using Deep Learning. Comput. Electr. Eng. 2019, 78, 343–355. [Google Scholar] [CrossRef]

- Shi, C.; Huang, Y. Cap-Count Guided Weakly Supervised Insulator Cap Missing Detection in Aerial Images. IEEE Sens. J. 2021, 21, 685–691. [Google Scholar] [CrossRef]

- Kang, G.; Gao, S.; Yu, L.; Zhang, D. Deep Architecture for High-Speed Railway Insulator Surface Defect Detection: Denoising Autoencoder with Multitask Learning. IEEE Trans. Instrum. Meas. 2019, 68, 2679–2690. [Google Scholar] [CrossRef]

- Tao, X.; Zhang, D.; Wang, Z.; Liu, X.; Zhang, H.; Xu, D. Detection of Power Line Insulator Defects Using Aerial Images Analyzed With Convolutional Neural Networks. IEEE Trans. Syst. Man, Cybern. Syst. 2020, 50, 1486–1498. [Google Scholar] [CrossRef]

- Zhang, Y.; Huang, X.; Jia, J.; Zhu, Y.; Zhao, L.; Zhang, X. Detection and Condition Assessment of Icicle Bridging for Suspension Glass Insulator by Image Analysis. IEEE Trans. Instrum. Meas. 2020, 69, 7458–7471. [Google Scholar] [CrossRef]

- Jin, L.; Tian, Z.; Ai, J.; Zhang, Y.; Gao, K. Condition Evaluation of the Contaminated Insulators by Visible Light Images Assisted With Infrared Information. IEEE Trans. Instrum. Meas. 2018, 67, 1349–1358. [Google Scholar] [CrossRef]

- Xin, L.; Jin, H.; Tu, Y.; Yuan, Z.; Lv, Z.; Wang, C. Defect Detection and Characterization of RTV Silicone Rubber Coating on Insulator Based on Visible Spectrum Image. IEEE Trans. Power Deliv. 2020, 35, 2734–2736. [Google Scholar] [CrossRef]

- Chen, W.; Yao, L.; Li, F. Insulator Defect Detection and Location in UAV Grid Inspection. J. Comput. Appl. 2019, 39, 210–214. [Google Scholar]

- Chen, W.; Li, C.; Yuan, B.; Jiang, X. Effective Method to Locate Self-Explosion Defects of Insulators. Comput. Eng. Des. 2019, 40, 2346–2352. [Google Scholar] [CrossRef]

- Ren, S.; He, K.; Girshick, R.; Sun, J. Faster R-CNN: Towards Real-Time Object Detection with Region Proposal Networks. IEEE Trans. Pattern Anal. Mach. Intell. 2017, 39, 1137–1149. [Google Scholar] [CrossRef] [Green Version]

- He, K.; Zhang, X.; Ren, S.; Sun, J. Deep Residual Learning for Image Recognition. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition (CVPR), Las Vegas, NV, USA, 27–30 June 2016; pp. 770–778. [Google Scholar]

| Hardware/Software | Parameter |

|---|---|

| CPU | Intel Core i7-8700K @3.7 GHz |

| GPU | GeForce GTX 1080Ti (11G) |

| RAM | 16G(DDR4 3200MHz) |

| Hard disk | 1T (SSD SN750) |

| System | ubuntu16.04 |

| Language | Python 3.5.2 |

| Deep learning framework | TensorFlow-gpu-1.13.2 |

| Detection Method | AP (insulator) | Recall |

|---|---|---|

| Faster RCNN + Res152 (Our method) | 0.9175 | 0.98 |

| Faster RCNN + Res101 | 0.9119 | 0.96 |

| Faster RCNN + res50 | 0.9088 | 0.95 |

| Faster RCNN + Vgg16 | 0.9113 | 0.95 |

| YOLO v3 | 0.9119 | 0.97 |

| Sliding window + LBP + SVM | 0.8012 | 0.85 |

| Voltage | Arrangement of Caps | Omission | False | Accuracy |

|---|---|---|---|---|

| 35 kV | 1·4 | 0 | 0 | 100% |

| 35 kV | 1·5 | 0 | 0 | 100% |

| 35 kV | 2·5 | 0 | 0 | 100% |

| 110 kV | 1·7 | 1 | 0 | 98% |

| 110 kV | 1·8 | 1 | 0 | 98% |

| 110 kV | 2·8 | 1 | 2 | 94% |

| 220 kV | 1·13 | 1 | 0 | 98% |

| 220 kV | 1·15 | 1 | 1 | 96% |

| 220 kV | 2·16 | 1 | 3 | 92% |

| Type | Noise | Accuracy |

|---|---|---|

| Short insulator [35 kV, 110 kV] | None | 0.98 |

| Gaussian (v = 0.005) | 0.98 | |

| Gaussian (v = 0.01) | 0.98 | |

| Long insulator [220 kV, 550 kV] | None | 0.94 |

| Gaussian (v = 0.005) | 0.94 | |

| Gaussian (v = 0.01) | 0.90 |

| Method | False | Omission | Accuracy |

|---|---|---|---|

| Our method | 1 | 1 | 0.98 |

| Method 1 | 6 | 3 | 0.91 |

| Method 2 | 3 | 1 | 0.96 |

| Method 3 | 16 | 1 | 0.83 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Huang, S.; Li, Y.; Li, H.; Hao, H. Image Detection of Insulator Defects Based on Morphological Processing and Deep Learning. Energies 2022, 15, 2465. https://doi.org/10.3390/en15072465

Zhang Z, Huang S, Li Y, Li H, Hao H. Image Detection of Insulator Defects Based on Morphological Processing and Deep Learning. Energies. 2022; 15(7):2465. https://doi.org/10.3390/en15072465

Chicago/Turabian StyleZhang, Zhaoyun, Shihong Huang, Yanxin Li, Hui Li, and Houtang Hao. 2022. "Image Detection of Insulator Defects Based on Morphological Processing and Deep Learning" Energies 15, no. 7: 2465. https://doi.org/10.3390/en15072465