Proxy Re-Encryption-Based Traceability and Sharing Mechanism of the Power Material Data in Blockchain Environment

Abstract

:1. Introduction

- The power material supply deployment and application structures based on blockchain technology are established based on the applicability analysis of blockchain technology in the power material supply chain, which realizes the data exchange and business transmission between different units in the power material supply chain.

- The traceability and sharing mechanism of the power material data are designed based on the proxy re-encryption method and blockchain technology, which provides a meaningful reference for the problem of sharing private data on the blockchain.

2. Power Material Supply Chain and Blockchain Technology

- Data traceability and authenticity guarantee: Consensus mechanisms are used by the nodes to generate blocks with timestamps, which ensures the immutability and traceability of the data on the chain. The accurate traceability of the data in various links such as material processing and distribution is still difficult to achieve in the current material supply chain. Additionally, there is also the problem that the material inspection reports cannot be completely trusted by suppliers. Therefore, the power material supply can be combined with blockchain to realize the decentralized processing of the data in the supply chain. By storing the power material supply data recorded by suppliers, warehousing systems, and logistics systems on the blockchain through consensus mechanisms, the whole process of the material information can be traced back, which improves the interaction efficiency of information flow between the material company and suppliers and strengthens the interaction between different subjects in the power material supply chain.

- Process simplification: A smart contract on the blockchain is a computer transaction protocol with the characteristics of being intermediary free, self-verification, and automatic execution. Based on the trusted and tamper-proof data on blockchain, the pre-defined rules and terms can be automatically implemented by the smart contract to realize the efficiency and irreversibility of transactions. At present, there are still many cumbersome and complicated procedures in the power material supply chain that require offline executions and layered approvals, which greatly reduce the efficiency of information flow and business execution. The business process can be stored by the smart contract on the blockchain in the form of contract terms. Additionally, the relevant procedures can be automatically executed by calling the corresponding smart contract, which reduces the consumption of human and material resources, the uncertainty in the business process, and improves the business execution efficiency on the power material supply chain. Moreover, the smart contract is deployed on the blockchain, which realizes its openness, transparency, and traceability in the process of deployment, invocation, and execution, and ensures the legal compliance of procedures in the power material supply.

- Protection of data privacy and system security: Asymmetric encryption, used in the blockchain to ensure data privacy, uses a public key and private key to encrypt and verify the data on the blockchain, which can ensure the confidentiality of the transactions on the blockchain. At present, there is still a large vacancy in the application of cryptography algorithms in the power material smart supply chain. Therefore, asymmetric encryption algorithms can be used to avoid the risk of privacy disclosure caused by the single point failure or the design vulnerability of management authority in multiple links such as demand declaration, bidding, procurement, inspection, and distribution.

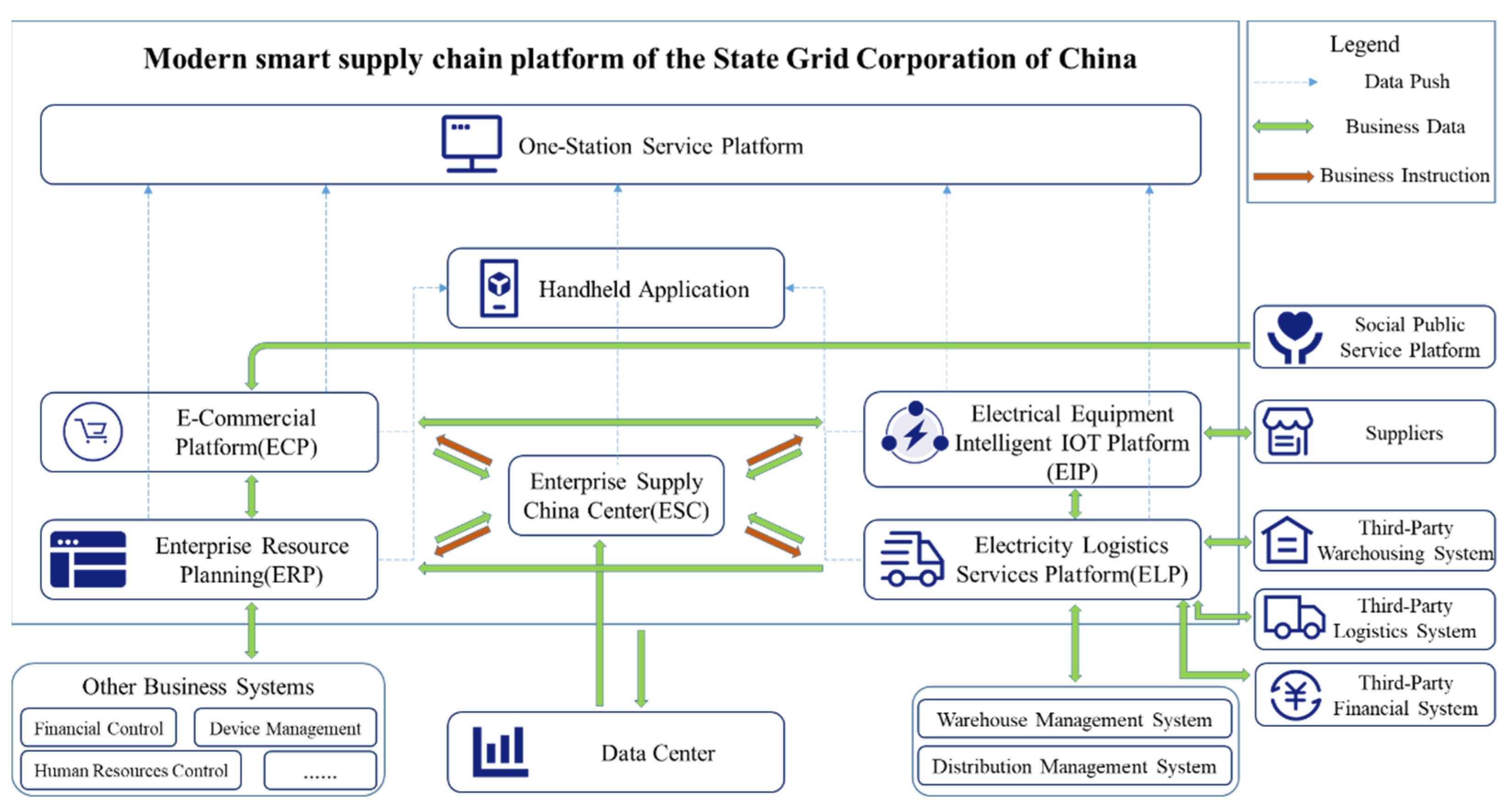

3. Structure of the Power Material Supply Chain Based on Blockchain

- The subject of responsibility in the power material supply chain: There are frequent and complex information interactions among the subjects in the power material supply chain, such as the material company, suppliers, testing organization, and judiciary. Therefore, on the power material supply consortium blockchain, the control and management of nodes and transaction data are usually completed by multiple responsible subjects, which not only ensures the data on the chain are non-tampering, but also reduces the operation cost of the blockchain.

- The channel layer for information interaction: As the main support for external data access and data circulation, the channel layer, with intranet PC, extranet PC, mobile APP, a large screen display, and data interface included, can realize data exchange between different business platforms and between three-party units and the material company. Among them, the intranet PC can realize the data access of various departments in the power material company on the blockchain and provide channels for data interaction between multiple management platforms. The external PC is applied to provide data interfaces connected to the blockchain for suppliers, testing organization, supervision company, and judiciary. Additionally, the mobile app can provide convenient operation and management methods for handheld applications. Additionally, the data interface is designed to summarize the various information in the data layer for blockchain services and integrated support services.

- Application layer for function design: The application layer mainly includes six modules: electricity logistics services platform, enterprise resource planning, handheld application, e-commercial platform, enterprise supply chain center, and electrical equipment intelligent IoT platform, which can realize the application mode design and function customization of blockchain in the power material supply chain. After receiving the instructions from the power material company or other entities in the power material supply chain, the application layer will use different blockchain services or integrated support services according to the preset process, and the results obtained after the program execution will be fed back to the user.

- Service layer for supporting various applications. Through the hash pointer and consensus mechanism, all transaction information is stored in the database of each participating node in a chain structure by the blockchain service. Additionally, the transactions on the blockchain are also executed by the blockchain service according to the preset logic through the smart contract composed of an automatic script code, which realizes the trust-free, traceability, and non-tampering characteristics of data. An integration support service is an auxiliary service necessary for business integrity and process automation, and is paperless, which provides the services and functions required for the normal operation of the structure together with the blockchain service. The service layer receives instructions from the application layer, obtains real-time data from the data layer, and executes specific services according to requirements, and then the execution results will be fed back to the service layer.

- The data layer for dealing with power material data and blockchain data: With business data, contract data, monitoring data, cross-chain data included, the data layer is the basis for the operation of the blockchain and the realization of various application services, which can be used to meet various data requirements of the service layer.

4. Traceability and Sharing Mechanism of the Power Material Data Based on PRE in the Blockchain Environment

4.1. Preliminary Definitions of Blockchain and PRE

- Key generation algorithm: . Input the system public parameter par, and the algorithm will output (pk, sk) as a user’s public–private key pair.

- Encryption algorithm: . Input the system public parameter par, plaintext m, and the delegator’s public key pki, the algorithm will output the ciphertext Ci encrypted by the public key pki.

- Conversion key generation algorithm: . Input the private key ski of the delegator and the public key pkj of the delegatee, the algorithm will output the conversion key rki→j, which is used for one-way re-encryption from delegator to delegate.

- Re-encryption algorithm: . Input the proxy re-encryption key rki→j and the delegator’s ciphertext, and the proxy re-encryption algorithm will output the re-encrypted ciphertext Cj for the delegate.

- Decryption algorithm: . Input the delegate’s private key skj and the ciphertext Cj corresponding to the delegate, and the algorithm will output the corresponding plaintext m.

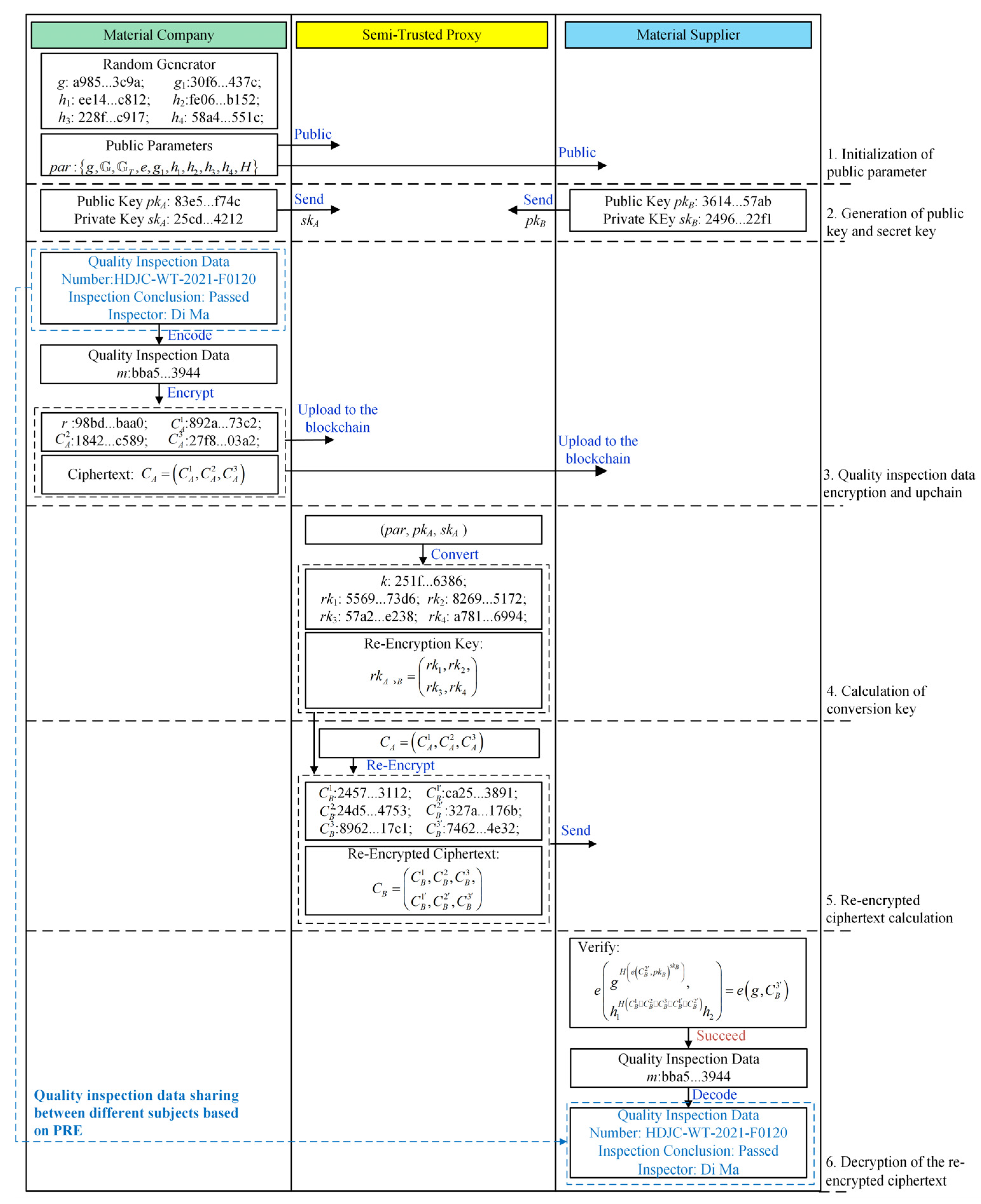

4.2. Power Material Data Traceability and Sharing Mechanism

- 1.

- Initialization of public parameter:

- 2.

- Generation of the public key and private key:

- 3.

- Quality inspection data encryption and upchain:

- 4.

- Calculation of conversion key:

- 5.

- Re-encrypted ciphertext calculation:

- 6.

- Decryption of the re-encrypted ciphertext:

5. Case Study

5.1. Hyperledger Fabric Platform

5.2. Traceability Mechanism of Power Material Supply Data Based on Hyperledger Fabric

5.3. Power Material Data Sharing Mechanism Based on PRE

6. Conclusions

- The blockchain-based power material supply deployment and application structures meet the different application needs of the power material supply chain and provide relevant services for data exchange with external and cross chains.

- The data traceability mechanism based on blockchain can track the historical power material supply chain data and confirm the authenticity of the data.

- The combination of proxy re-encryption and blockchain technology in the power material supply chain can realize the data sharing and keep the private data of the mate-rial company confidential. Additionally, the corresponding power material supply data cannot be obtained by the supplier without the conversion key, which requires the permission of the material company.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Aitzhan, N.Z.; Svetinovic, D. Security and Privacy in Decentralized Energy Trading Through Multi-Signatures, Blockchain and Anonymous Messaging Streams. IEEE Trans. Dependable Secur. Comput. 2018, 15, 840–852. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, X.; Wang, H. Consensus-Based Decentralized Energy Trading for Distributed Energy Resources. Energy Convers. Econ. 2021, 2, 221–234. [Google Scholar] [CrossRef]

- Hassan, M.U.; Rehmani, M.H.; Chen, J. DEAL: Differentially Private Auction for Blockchain-Based Microgrids Energy Trading. IEEE Trans. Serv. Comput. 2020, 13, 263–275. [Google Scholar] [CrossRef]

- Gai, K.; Wu, Y.; Zhu, L.; Qiu, M.; Shen, M. Privacy-Preserving Energy Trading Using Consortium Blockchain in Smart Grid. IEEE Trans. Ind. Inform. 2019, 15, 3548–3558. [Google Scholar] [CrossRef]

- Pop, C.; Cioara, T.; Antal, M.; Anghel, I.; Salomie, I.; Bertoncini, M. Blockchain Based Decentralized Management of Demand Response Programs in Smart Energy Grids. Sensors 2018, 18, 162. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chang, Y.; Iakovou, E.; Shi, W. Blockchain in Global Supply Chains and Cross Border Trade: A Critical Synthesis of the State-of-the-Art, Challenges and Opportunities. Int. J. Prod. Res. 2019, 58, 2082–2099. [Google Scholar] [CrossRef] [Green Version]

- Choi, T.M. Blockchain-Technology-Supported Platforms for Diamond Authentication and Certification in Luxury Supply Chains. Transp. Res. Part E-Logist. Transp. Rev. 2019, 128, 17–29. [Google Scholar] [CrossRef]

- Chang, S.E.; Chen, Y.C.; Lu, M.F. Supply Chain Re-Engineering Using Blockchain Technology: A Case of Smart Contract Based Tracking Process. Technol. Forecast. Soc. Change 2019, 144, 1–11. [Google Scholar] [CrossRef]

- Choi, T.M.; Wen, X.; Sun, X.; Chung, S.H. The Mean-Variance Approach for Global Supply Chain Risk Analysis with Air Logistics in the Blockchain Technology Era. Transp. Res. Part E-Logist. Transp. Rev. 2019, 127, 178–191. [Google Scholar] [CrossRef]

- Vaio, A.D.; Varriale, L. Blockchain Technology in Supply Chain Management for Sustainable Performance: Evidence from the Airport Industry. Int. J. Inf. Manag. 2019, 52, 102014. [Google Scholar] [CrossRef]

- Dubey, R.; Gunasekaran, A.; Bryde, D.J.; Dwivedi, Y.K.; Papadopoulos, T. Credit Evaluation System Based on Blockchain for Multiple Stakeholders in the Food Supply Chain. Int. J. Environ. Res. Public Health 2018, 15, 1627. [Google Scholar]

- Mao, D.; Wang, F.; Hao, Z.; Li, H. Blockchain Technology for Enhancing Swift-Trust, Collaboration and Resilience within a Humanitarian Supply Chain Setting. Int. J. Prod. Res. 2020, 58, 3381–3398. [Google Scholar]

- Cheng, J.; Qiu, W.; Mei, J.; Xu, C.; Zhou, G.; Ding, H.; Chu, Z.; Liu, B.; Tan, W.; Lin, Z. Evaluation Index System of Blockchain Technology Feasibility Towards Power Material Supply Chain. Energy Rep. 2021, 7, 968–978. [Google Scholar] [CrossRef]

- Obour Agyekum, K.O.B.; Xia, Q.; Sifah, E.B.; Gao, J.; Xia, H.; Du, X.; Guizani, M. A Secured Proxy-Based Data Sharing Module in IoT Environments Using Blockchain. Sensors 2019, 19, 1235. [Google Scholar] [CrossRef] [Green Version]

- Liu, Q.; Wang, G.; Wu, J. Time-Based Proxy Re-Encryption Scheme for Secure Data Sharing in A Cloud Environment. Inf. Sci. 2014, 258, 355–370. [Google Scholar] [CrossRef]

- Kim, S.K.; Huh, J.H. A Study on the Improvement of Smart Grid Security Performance and Blockchain Smart Grid Perspective. Energies 2018, 11, 1973. [Google Scholar] [CrossRef] [Green Version]

- Dong, Z.; Luo, F.; Liang, G. Blockchain: A Secure, Decentralized, Trusted Cyber Infrastructure Solution for Future Energy Systems. J. Mod. Power Syst. Clean Energy 2018, 6, 958–967. [Google Scholar] [CrossRef] [Green Version]

- Feng, Y.; Fan, J.; Chen, H.; Wang, Q.; Wang, B.; Wang, J. Transnational Power-Transaction Model Considering Transaction Costs Under the Support of Consortium Blockchain. Energy Convers. Econ. 2020, 1, 251–263. [Google Scholar] [CrossRef]

- Wang, J.; Wang, Q.; Zhou, N.; Chi, Y. A Novel Electricity Transaction Mode of Microgrids Based on Blockchain and Continuous Double Auction. Energies 2017, 10, 1971. [Google Scholar] [CrossRef] [Green Version]

- Zhang, T.; Liu, S.; Qiu, W. KPI-Based Real-Time Situational Awareness for Power Systems with High Proportion of Renewable Energy Sources. CSEE J. Power Energy Syst. 2020, 1–13. [Google Scholar] [CrossRef]

- Yang, Y.; Ma, M. Conjunctive Keyword Search with Designated Tester and Timing Enabled Proxy Re-Encryption Function for E-Health Clouds. IEEE Trans. Inf. Forensics Secur. 2016, 11, 746–759. [Google Scholar] [CrossRef]

- Blaze, M.; Bleumer, G.; Strauss, M. Divertible Protocols and Atomic Proxy Cryptography. In International Conference on the Theory and Applications of Cryptographic Techniques; Springer: Berlin/Heidelberg, Germary, 1998; Volume 1403, pp. 127–144. [Google Scholar]

- Liu, H.; Wang, Q.; Tang, Y. Architecture and Function Analysis of Integrated Energy Service Stations Considering Cyber-Physical Integration. Energy Convers. Econ. 2021, 2, 186–196. [Google Scholar] [CrossRef]

- Oliver, D.; Bessie, M.; Lindokhuhle, S. Proposed Framework for Blockchain Technology in a Decentralised Energy Network. Prot. Control. Mod. Power Syst. 2021, 6, 396–406. [Google Scholar]

- Piotr, F.B. Digitization, Digital Twins, Blockchain, and Industry 4.0 as Elements of Management Process in Enterprises in the Energy Sector. Energies 2021, 14, 1885. [Google Scholar]

- Wang, Y.; Qiu, W.; Dong, L.; Zhou, W.; Pei, Y.; Yang, L.; Nian, H.; Lin, Z. Proxy Signature-Based Management Model of Sharing Energy Storage in Blockchain Enviorment. Appl. Sci. 2020, 10, 7502. [Google Scholar] [CrossRef]

- Baek, J.; Vu, Q.H.; Liu, J.K.; Huang, X.; Xiang, Y. A Secure Cloud Computing Based Framework for Big Data Information Management of Smart Grid. IEEE Trans. Cloud Comput. 2021, 3, 233–244. [Google Scholar] [CrossRef]

- Shao, J.; Cao, Z.; Liang, X.; Lin, H. Proxy Re-Encryption with Keyword Search. Inf. Sci. 2010, 180, 2576–2587. [Google Scholar] [CrossRef]

- Sun, W.; Yu, S.; Lou, W.; Hou, Y.; Li, H. Secure Outsourced Blockchain-Based Medical Data Sharing System Using Proxy Re-Encryption. IEEE Trans. Parallel Distrib. Syst. 2016, 27, 1187–1198. [Google Scholar] [CrossRef]

- Beatrice, M.; Simone, Z. Supply Chain Management for Improved Energy Efficiency: Review and Opportunities. Energies 2017, 10, 1618. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, J.; Yang, Y.; Mei, J.; Zhou, G.; Qiu, W.; Wang, Y.; Xu, L.; Liu, Y.; Jiang, J.; Chu, Z.; et al. Proxy Re-Encryption-Based Traceability and Sharing Mechanism of the Power Material Data in Blockchain Environment. Energies 2022, 15, 2570. https://doi.org/10.3390/en15072570

Song J, Yang Y, Mei J, Zhou G, Qiu W, Wang Y, Xu L, Liu Y, Jiang J, Chu Z, et al. Proxy Re-Encryption-Based Traceability and Sharing Mechanism of the Power Material Data in Blockchain Environment. Energies. 2022; 15(7):2570. https://doi.org/10.3390/en15072570

Chicago/Turabian StyleSong, Jien, Yang Yang, Jie Mei, Gaofeng Zhou, Weiqiang Qiu, Yixing Wang, Lu Xu, Yanran Liu, Jinyu Jiang, Zhenyue Chu, and et al. 2022. "Proxy Re-Encryption-Based Traceability and Sharing Mechanism of the Power Material Data in Blockchain Environment" Energies 15, no. 7: 2570. https://doi.org/10.3390/en15072570