Abstract

The interest in passive construction that has low demand for thermal energy continues to grow every year. It is related to both the reduction in maintenance costs of buildings and the growing environmental awareness in societies. Passive houses are characterised by very good thermal insulation properties of their external partitions. This paper presents the results of tests on the thermal conductivity for three different types of building materials, assuming their use as thermal insulation. The materials were subjected to water absorption tests during long-term immersion. The purpose of this study was to simulate water absorption caused by long-term water exposure. The tests were carried out on a perlite concrete block, a sheet of polyurethane foam applied by spraying and expanded clay in a loose form in three different fractions. The tested insulation materials were selected due to their different form, structure, and porosity characteristics, which largely determined the value of the thermal conductivity. A perlite concrete block is a new, innovative product, of which manufacturer’s data are not yet available as the product is currently at the stage of detailed research. The results were analysed statistically and used in graphs to show the dependence of the value of the thermal conductivity on moisture content of the samples. The purpose of this study was to indicate the importance of the proper incorporation of insulation materials into buildings, their storage before construction and use in the post-construction phase. Building standards for passive houses place high demands on materials used. In order to fully enjoy the advantages of passive buildings, i.e., lower energy consumption and benefits for the natural environment due to lower consumption of energy generated from non-renewable energy sources, it is necessary to use certified building materials and ensure proper use of objects. The studies quoted in this paper indicate to what extent the influence of moisture content negatively affects the properties of insulation materials in external partitions.

1. Introduction

The more prosperous the society, the greater the environmental awareness and the greater the interest in passive construction, which continues to grow every year. This interest also results from an increase in fossil fuel prices as well as from political instability in numerous countries in the world. Another key factor is climate change and violent weather phenomena that occur globally, which clearly indicate the need to reduce pollutant emissions into the atmosphere, including pollution caused by the heating of buildings. The construction industry consumes almost 40% of the total energy in the world, which, moreover, comes from non-renewable energy sources and contributes to greenhouse gas emissions [1,2,3,4,5,6]. The demand for climate protection affects the necessity to apply such material, technological and organisational solutions at the design stage, thanks to which new and modernized buildings will use less energy for heating, ventilation and hot water preparation.

Passive buildings are the latest generation of energy-efficient buildings [7,8,9]. They offer the highest thermal comfort and satisfy extremely low demand for thermal energy, maximum 15 kWh/m2/year (less than 1.5 litres of heating oil or 1.5 m3 of natural gas per m2/year), or 5 kWh of electricity generated with a heat pump [10].

The idea of a passive house compliant with the Passive House Institute standards combines high living comfort for its residents with very low consumption of energy [11,12,13]. Passive houses are characterised by very good insulation properties of their external partitions. The selection of materials based on their thermal characteristics and the necessary thickness of insulation layers are fundamental issues to be solved at the design stage. Materials should be chosen so that the amount of energy consumption during the use of buildings will be as low as possible, which will also ensure lower operating costs [14,15,16,17,18].

Therefore, over the last few years, technical regulations [19] and standard requirements [20] have changed, reducing the maximum permissible values of the thermal conductance Umax required for external partitions in new and modernised buildings. The thermal conductance determines heat transfer through thermal partitions. For flat surfaces, it determines the amount of heat penetrating through a partition with a unit surface area when there is a temperature difference between the surfaces equal to the temperature unit. The lower the coefficient, the more efficient the thermal insulation of the partition is. The thermal conductance is not a material characteristic, yet it describes a given partition, i.e., a wall, roof, floor, foundation [21,22]. Its value depends on the type of partition and internal temperature in the room [19].

In recent years, very important research has also been developed on in situ hygrothermal measurement in dynamic conditions for existing historic buildings, for which there is no information about the properties of the materials from which they were built. [23,24]. These studies are important in the process of designing solutions that increase thermal insulation of walls in historic buildings. In many European countries, historic buildings account for a significant percentage of the total number of buildings and the improvement of their thermal insulation properties is of particular importance from reduction of energy consumption point of view [25,26].

Technical regulations [19] provide guidelines on the maximum permissible values of the thermal conductance, which are correlated to the thermal conductivity λ of materials constituting the layers of a given partition. Therefore, when selecting building materials, it is worth following the results of studies conducted on the thermal conductivity of materials used in construction. It particularly concerns the studies on thermal conductivity, thermal diffusivity, and specific heat of materials [27,28,29,30,31,32,33,34,35,36]. The value of the thermal conductivity is a property of a given material; it is a physical property of the body that describes the ability of the substance to transmit its internal energy. Under the same conditions, more heat will be transmitted through a substance with greater thermal conductivity. The thermal conductivity is not a constant value and depends on factors such as body structure, pressure, temperature, density, moisture content or time from production [27,28,29,30,31,32,33,34,35,36].

Materials used in passive and energy-efficient construction should be characterised by the lowest possible thermal conductivity. The use of insulation materials ensures that partitions in buildings achieve the thermal conductance required by standards and regulations. Typical insulation materials include polystyrene, mineral and wood wool, cellulose, air gels, foam glass, resole and polyurethane foams. The thermal conductivity of insulation and building materials is low. This is because they are usually porous materials whose pores are filled with air. These in turn act as an insulator. The lower the bulk weight of the material, the lower the thermal conductivity. However, when the pores are large and filled with air, this can cause convection in the pores and increase the thermal conductivity of the material. An important feature of the research presented in the paper is the attempt to reproduce the natural humidity conditions in laboratory conditions and the diversity of the tested materials in terms of their physical properties. In addition to the well-known materials, such as expanded clay and PUR foam, tests of a completely new material—perlite concrete—were carried out. Perlite concrete in the form of blocks has not yet been subjected to thermal conductivity tests and in this respect these results are unique.

The tests presented in the article were carried out on a perlite concrete block, a sheet of polyurethane foam applied by spraying and expanded clay in a loose form in three different fractions (0–4 mm, 4–10 mm, 10–20 mm). The tested materials were selected due to their different form, structure, and porosity, which largely determined the value of the thermal conductivity. Interestingly, a perlite concrete block is a new, innovative product, for which the manufacturer’s data are not yet available, as the product is currently at the stage of detailed research. However, it is also designed to thermally insulate buildings.

This paper presents the results of tests on the thermal conductivity of three different types of building materials, assuming their use as thermal insulation. The materials were subjected to water absorption tests during long-term immersion. The tests simulated water absorption caused by long-term water exposure. The purpose of this study was to show how important it is to properly incorporate insulation materials into buildings, how to store them before construction, as well as how to use them in the post-construction phase.

2. Materials and Methods

The tests of water absorption caused by long-term water exposure were conducted on a perlite concrete block, a sheet of polyurethane foam applied by spraying and expanded clay in a loose form in three different fractions.

The main component of perlite concrete blocks is perlite. It is a base product or an additive in the production of thermal and acoustic insulation materials. Perlite is an igneous rock made of acidic volcanic rhyolite glaze, formed as a result of rapid cooling of volcanic lava in the aquatic environment. The structure of solidified lava encloses water droplets that make up 2% to 5% of its volume. Expanded perlite has many uses, and as of present day 90% of its consumption is assigned to the building materials industry and the remaining 10% to agriculture and horticulture. Most applications of expanded perlite are related to its thermal insulation properties [37,38,39,40,41,42,43]. The perlite concrete block used for the study is a new product, currently in the testing phase, designed to function as a self-supporting wall with the thermal conductance determined by the regulations and adopted for passive and energy-efficient buildings.

The sample of polyurethane foam taken for the study was made by spraying, in situ, in the place of its later incorporation. Polyurethane insulation products have one of the lowest levels of chemical emissions compared to other materials available on the market, even classified as organic, mineral, or natural. Polyurethanes are a plastic material consisting of gas bubbles surrounded by integrated polyurethane cells. According to their cellular structure, they can be divided into flexible (light) (12 kg/m3), rigid (heavy) (30–60 kg/m3) or medium (semi-rigid). When applied by spraying, they form a uniform, seamless layer that precisely fills every gap and hard-to-reach places [44,45,46,47].

The third material accepted for the study was expanded clay in three fractions: 0–4 mm, 4–10 mm, 10–20 mm. Expanded clay is a lightweight, artificial aggregate obtained from mineral raw materials, which is subjected to thermal treatment. Its production uses low-melting raw materials, such as compact clay shales of plastic properties, heavy loams with an addition of organic admixtures in the form of sawdust or a mixture of crude oil with brown coal, which expanded clay raw: plastic processing (forming roller-shaped granules), grinding in a semi-dry state, or creating a sludge. Sintering takes place at a temperature of 900 to 1300 °C in rotary kilns, then the raw material is swollen increasing its volume by 2–3 times. Lightweight expanded clay aggregates of an oval or spherical shape obtain a glazed tight coating 0.5–2.0 mm-thick and is 90% pores in the inner part. Aggregates’ diameters range from 0–2 mm, 2–4 mm, 4–10 mm and 10–20 mm [48,49,50].

Test methods of materials for thermal conductivity can be divided into two main groups:

- −

- stationary methods, carried out at a fixed heat flux;

- −

- non-stationary methods, carried out at a transient heat flux.

In stationary methods, the density of heat flux, and the temperature on the surface of tested material should be constant. It is assumed that the heat flow is one-dimensional, i.e., a homogeneous and one-dimensional temperature field occurs in the entire volume of the material sample.

The thermal conductivity in solids is quantified by the empirical Fourier’s law (1).

where:

- —vector of heat flux density,

- Λ—thermal conductivity,

- T—temperature.

According to the Fourier’s law, the heat flux density is proportional to the temperature gradient measured along the heat flow direction (2).

The minus sign results from the fact that the direction of the heat flux density vector is directed opposite to the direction of the axis x (heat flows from a place with higher temperature to a place with lower temperature, so the section dx measured along the direction of the heat flow corresponds to its negative value).

By accepting

where

the formula describing the thermal conductance is U (5) [20,51].

where:

- R—thermal resistance of the material layer,

- t1, t2—air temperature on external and internal surfaces of the material,

- d—thickness of the material layer,

- λ—design thermal conductivity of the material,

- U—thermal conductance.

The thermal conductance U is the ratio of the determined heat flux density to the air temperature difference on both sides of the partition. It is the inverse of the thermal resistance coefficient.

Measurement with the stationary method can be taken using a plate apparatus with heat flux sensors. The device consists of a fixed upper plate and a movable lower plate. Heat meters with thermocouples are attached to the surface of both plates, and they are equipped with a cooling and heating system. The value of the thermal is determined on the basis of the thickness of the sample, the values of temperature and heat flux on both its edges. Measurement with a plate apparatus is possible to be taken only in laboratory conditions.

Non-stationary measurement methods are based on transient thermal conductivity and consists in determining thermal diffusivity based on the measurement of the temperature change over time during heating or cooling of the sample. Non-stationary measurement can be made with a portable device that allows for making quick measurements in the field at any location. The device is used for measuring the thermal conductivity of isotropic materials. It is also used to designate other thermal parameters of materials, such as: thermal diffusivity, volumetric thermal capacity, and temperature. Measurement consists in analysing the thermal response to the thermal signal reaching the surface of the sample, assuming that the spread occurs in an unlimited medium. The heat flux is generated by heating with an electric resistor, a heater, placed in the probe in direct contact with the tested sample. What is recorded is the thermal response of the tested material as a function of time. The device is equipped with two types of measuring probes: a needle probe for measuring soft materials and a surface probe for hard materials [51,52].

Thermal conductivity of materials increases with an increase in their moisture content. Water that fills the pores of the material has a thermal conductivity almost 20 times higher than air.

Moisture content of a given material is the ratio of the mass of physically bound water and free water to the mass of the dry material (6) [53].

where wm is the mass moisture, mm is the wet mass, ms is the dry mass, and mw is water.

3. Results

Two methods are used to study the thermal conductivity of materials: the stationary method (carried out with a fixed heat flux) and non-stationary method (carried out with a transient heat flux). The tests, the results of which are cited in the article, were performed using the non-stationary method. The measurement was taken dynamically with the use of a portable device–ISOMET 2114 [54]. The device’s small dimensions allow for testing in the field. Measurement consists in analysing the thermal response of the sample to which the thermal signal is sent by the probe, assuming that the heat is spread in an unlimited medium. The heat flux is sent through an electric resistor, a heater located in the probe, which is in direct contact with the sample. The device has two probes: a surface probe, used for hard materials, and a needle probe, used for soft materials. The test consisted in recording the thermal response of the tested material as a function of time. The measurement range depends on the probe and covers the values from 0.015 W/mK to 6.0 W/mK in seven sub-ranges for different measuring probes. The device can measure not only the thermal conductivity λ but also thermal diffusivity, volumetric thermal capacity, and temperature [54].

The water absorption test of three selected types of materials was carried out in accordance with the standard [55]. The samples with expanded clay of 0–4 mm, 4–10 mm, 10–20 mm grain sizes and a block of perlite concrete no. 1 were completely immersed in water for 21 days. Due to its high buoyancy, the PUR foam sample was partially immersed in order to check whether it would be completely saturated with water over a certain time. After the samples were taken out of water, they were left for 4 days to drain. Measurements of the thermal conductivity were carried out for each sample twice in each measurement series. The materials were left to self-dry for ten weeks, and measurements were taken every week with the non-stationary method using the ISOMET 2114, produced by Applied Precision s.r.o. from Slovakia.

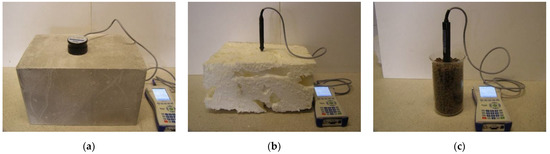

Figure 1 shows testing of the perlite concrete block with a surface probe (a), testing of the PUR foam with a needle probe (b) and testing of the expanded clay with a needle probe (c).

Figure 1.

Testing of perlite concrete with a surface probe (a), testing of PUR foam with a needle probe (b), and testing of expanded clay with a needle probe (c).

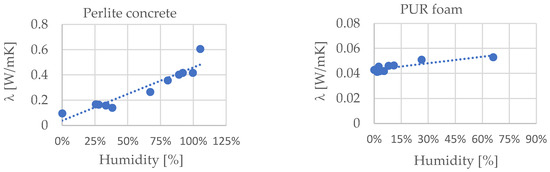

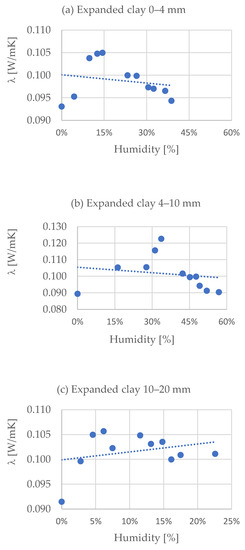

The measurement results for individual insulation materials are presented in Table 1 and Figure 2 and Figure 3.

Table 1.

Measurement results of the thermal conductivity λ for mass moisture content for different insulation materials.

Figure 2.

Measurement results of the thermal conductivity for perlite concrete and PUR foam.

Figure 3.

Measurement results of the thermal conductivity for expanded clay, (a) expanded clay 0–4 mm, (b) expanded clay 4–10 mm, (c) expanded clay 10–20 mm.

Statistical Analysis of the Results

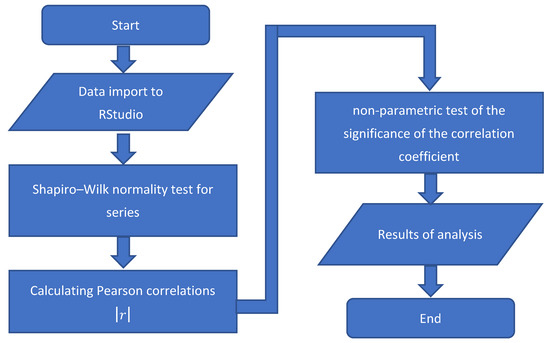

In order to determine the influence of moisture content of individual materials on their thermal conductivity, the obtained results were analysed statistically. The main steps of the statistical analysis are shown in Figure 4.

Figure 4.

Main steps of statistical analysis.

The analyses were performed using the Pearson correlation coefficient, which is expressed by the Formula (7) taken from [56].

and the Spearman’s rank correlation coefficient

where:

- —squares of differences between ranks of corresponding values xi i yi,

- n—number of data pairs.

The criterion of normal distribution for individual measurement series was tested using the Shapiro–Wilk test. The well-known and widely used RStudio software was used as a tool for performing statistical calculations [57].

In the first stage, the Shapiro–Wilk normality test [56] was carried out, the aim of which was to check whether all selected series met the criterion of a normal distribution. The results of calculations are summarised in Table 2. The parameters V and p-value indicate that the data for perlite, PUR foam, and expanded clay with fractions of 0–4 mm and 4–10 mm meet the normal distribution criterion (p-value > 0.05).

Table 2.

Shapiro–Wilk test results for selected data series.

The analysis of the Pearson’s correlation presented in Table 3 shows that two data series indicate very strong correlation. The highest correlation was obtained for perlite (), then PUR foam (). Expanded clay shows poor correlation for all three data series. The Spearman analysis confirms correlation relationships for the series. It is also worth noting that the correlation coefficient for expanded clay fractions 0–4 mm and 4–10 mm has a negative value, which could indicate that thermal conductivity decreases with an increase in moisture content. However, this is unlikely because the higher the water content in the material, the greater its thermal conductivity. By analysing the graphs shown in Figure 3, it can be seen that the pattern of points has a shape similar to an inverted parabola. Therefore, there is no linear relationship here and correlation relationships must be described with non-linear functions. For all series of measurements taken for expanded clay, a statistical analysis was carried out, assuming a second-degree polynomial as the correlation function. The diagram of the correlation function with its parameters and the value of the correlation coefficient is shown in Figure 5

Table 3.

Results of the non-parametric test of the correlation coefficient significance.

Figure 5.

Example of the nonlinear correlation for measurements of expanded clay, (a) expanded clay 0–4 mm, (b) expanded clay 4–10 mm, (c) expanded clay 10–20 mm.

Calculations were made for the remaining series of measurement data for expanded clay. The summary of correlation coefficients for each series is presented in Table 4.

Table 4.

Correlation coefficients for the polynomial correlation function.

The values of correlation coefficients in Table 4 indicate that for the conducted experiment, the thermal conductivity of expanded clay as a function of moisture content can be described by a second-degree polynomial.

4. Discussion

Climate change is one of the major problems affecting our planet. The atmosphere is overloaded with carbon dioxide released by fossil fuels when they are burned to produce energy. The authors of the work [6] examined whether a specific project optimised with regard to energy consumption in the current climatic conditions can effectively respond to future climate challenges. They considered it important to provide for nearly net zero energy buildings proper thermal insulation, which is particularly vital for buildings in cooler climates.

The results obtained from the tests carried out by the authors of this study confirm the dependence of the values of material conductivity and moisture content. When designing and then building objects as passive buildings, several requirements must be met, including requirements regarding the value of the thermal conductivity, defined by adequate regulations. Traditional thermal insulation materials do not have all the desired properties. Therefore, it is very important to develop new thermal insulation materials.

The tests of this study were carried out on a new product—a perlite concrete block—the production of which is under development. It is designed to be used as an element of wall filling with load-bearing and thermal insulation capabilities. A sheet of polyurethane foam applied by spraying was a sample taken during the execution of the floor, used as thermal insulation. Loose expanded clay aggregate is used as an insulation material in floors, ceilings, and roofs. None of these materials can be damp or wet during installation and use, as this leads to a sharp decrease in their insulating properties. Table 5 summarizes the obtained results for the thermal conductivity of the tested materials by comparing them with the values for similar materials under medium-humidity conditions corresponding to the temperature of 20 °C and 50% humidity specified in the standards [20,58].

Table 5.

Summary of the values of the thermal conductivity of the tested samples and corresponding materials according to [20,58] at the temperature of 20 °C and humidity 50%.

The values of the thermal conductivity presented in Table 1 were obtained from measurements based on the transient heat flux taken with the use of the ISOMET 2114. The advantage of this instrument is its functionality to take measurements in any place, in a much shorter time than by means of stationary methods.

By analysing the values provided in Table 1, it can be concluded that the tests of the thermal conductivity were carried out correctly. The obtained values are similar to those included in generally available construction standards, wherein a cellular concrete wall was adopted as a reference for a perlite concrete block, and a 4–10 mm fraction for expanded clay. The relevant standard does not specify the grain size of this material.

For the purpose of the paper [52], the authors conducted an analysis which showed that in regard to thermal insulation materials, the accuracy of the non-stationary method can be considered high only for the layers that are 10 cm thick. For thinner layers (4–6 cm), the obtained results may be subject to a significant degree of error. On the basis of the tests carried out for selected thermal insulation materials, it was observed that the results of measurements taken with the Isomet device were in most cases overestimated (compared to the results of measurements taken with the plate device and the values included in manufacturers’ specifications).

The interest in using perlite for building materials is related to its thermal insulation properties, resulting from the low thermal conductivity λ, which for pure expanded perlite is 0.045–0.059 W/mK, and for products in which it is one of the components (mortars, plasters, concrete mixes)—approx. 0.08–0.25 W/mK [37]. The work [38] includes tests showing that the use of light fine-grained aggregate such as perlite in mortar results in a decrease in the values of bending strength and compressive strength, but at the same time, they obtain a much more favourable value for the thermal conductivity. Such mortars can be used as thermal insulation materials to increase the energy efficiency of building partitions and reduce the occurrence of thermal bridges.

The work [32] considers a thermal insulation material based on expanded perlite as an alternative to traditional insulation materials. The composition of the developed material was designed and prepared using theoretical models for predicting thermal conductivity. The prepared material was formed into a rectangular plate. The thermal conductivity of the plate was measured experimentally, and the results were compared with the results of calculations. The experimental tests provided the lowest value of the thermal conductivity obtained for plates consisting of expanded perlite, equal to 0.0435 W/mK.

The purpose of the experimental tests presented in [41] was to develop high-strength and light concrete suitable for structural applications. The study investigated the effect of replacing standard aggregate partially or completely with expanded perlite aggregate. Expanded perlite aggregate was used in concrete in 20%, 40%, 60%, 80% and 100% share instead of natural aggregate. The six concrete mixtures were tested in terms of material characteristics: compressive strength, bending strength and thermal conductivity. After 28 days, the proposed concrete mixture with a 100% share of expanded perlite aggregate and a unit weight of kg/m3 obtained a percentage reduction of thermal conductivity by approx. 62% (1.81 to 0.69 W/mK) and a reduction in compressive strength (42 MPa). It was found to be an ideal material for structural applications with enhanced thermal insulation properties.

Spray-applied polyurethane foam is widely used in the construction industry, particularly in hard-to-reach places of irregular shapes. Its possible tendency to absorb water may result in, for instance, destruction (rotting) present in structures or their elements, i.e., wooden roofs. Based on the tests performed, the paper [28] indicates that the value of the thermal conductivity of polyurethane foam depends on its density and temperature. The authors state that in temperatures between 10 and 40 °C, the relationship between the thermal conductivity and temperature is the same and does not affect the obtained results of the thermal conductivity during water absorption tests.

The authors [59] studied mineral wool and polystyrene as these materials have a low density and, as a consequence, store a large amount of air in the pores. Moisture saturation was achieved during immersion. The authors showed a difference between the values read from the manufacturer’s public website and the measurements of moisture saturation of the materials. The greatest differences between moisture content for dry and wet materials were demonstrated by polystyrene: despite partially closed pores, water penetrated it successfully. The thermal conductivity of both materials increased sharply with an increase in moisture content. When the material was wet, the value of the coefficient was 0.7–0.9 W/mK. It had a typical value of 0.10–0.14 W/mK only with a low moisture content, 5–20%. As an anisotropic material with a fibrous structure, mineral wool showed significant differences in the values of the coefficient λ measured in vertical and horizontal directions. Both wool and polystyrene demonstrated a low absorption capacity of moisture from the air. Moreover, the authors of the work [59] claim, based on their own studies, that data provided by manufacturers regarding the value of the coefficient λ are highly overestimated and may lead to adopting erroneous design solutions.

The paper [36] presents the results of research on the influence of moisture content in mature expanded clay concrete on some of its physical and mechanical properties. The tests considered six states of moisture content in concrete: dry state, full saturation with water under normal atmospheric pressure, and four intermediate states. The tests for intermediate states were carried out after the liquidation of moisture gradients formed in the drying process and the homogeneous and uniform moisture field in the samples. A clear dependence of concrete properties on its moisture content was demonstrated. It was found that the nature of these changes is non-linear, determined by the durability of the bond between water and expanded clay at a given moisture content.

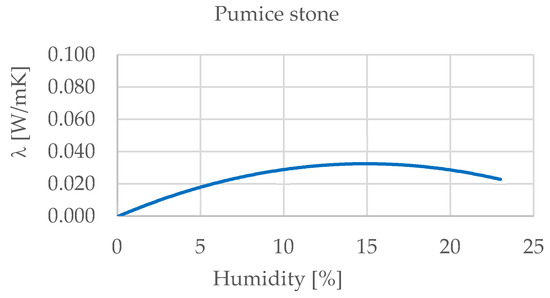

The authors [51] state that in porous bodies, the thermal conductivity of the material skeleton is greater than the thermal conductivity of air. The thermal conductivity of porous bodies increases with an increase in moisture content. For many porous building materials, the coefficient λ increases linearly with an increase to approximately 10% moisture content. It is related to an increase in the intermolecular contact of water, which, filling pores, removes the air from them. For the thermal conductivity of porous materials, the so-called effective thermal conductivity λef should be taken. Its value is determined by the values of thermal conductivity of the porous body skeleton λs and the fluid filling its pores λp (liquid, gas, mixture of liquid and gas) [60]. The work [60] presents a graph of the dependence of the thermal conductivity on moisture content, among others, for pumice stone. The graph shows, as in the case of the results from the tests carried out by the authors of this paper, the tendency consisting in an initial increase in the value of the coefficient λ with an increase in moisture content to 15%, then with increasing moisture, a decrease in the value of the thermal conductivity. The graph has a parabolic shape with a clear tendency for the conductivity to decrease with an increase in material moisture. Similar results were also obtained in the tests for expanded clay described above (Figure 6).

Figure 6.

Effect of humidity on thermal conductivity of pumice [author’s figure based on [60]].

In a porous material, heat mainly passes through the constrictions (skeleton). With negligible heat transport by pore air convection and radiation, it can be assumed that the heat conducting surface is the sum of the surfaces of the constrictions [61]. In the work [62], the authors carried out a study of the thermal conductivity of ash cellular concretes, conducted for three supersorptive moisture contents of approximately 150%, 200% and 300% of the maximum sorption moisture of a given sample. Water was introduced into the samples during total immersion. The aim of the study was to determine the value of the thermal conductivity depending on the location of moisture in the sample. The highest thermal conductivity occurred with even distribution of moisture; it decreased with an increasingly uneven distribution, and the lowest thermal conductivity was achieved with all the moisture on the cold side of the sample. The movement of moisture in the sample during the test was proportional to its uneven distribution, and the greatest occurred when initially all the moisture was located on the warm side of the sample. The graphs in [61] show a parabolic, similar relationship between the coefficient λ and water content in the upper half of the sample. With an increase in moisture content, the value of the conductivity was lower.

5. Conclusions

Contemporary trends in the construction industry aim at reducing thermal energy consumption—therefore, towards minimising heat losses and tightening the regulations on insulation requirements. The current standards force investors to use very thick layers of thermal insulation. Thus, even a slight decrease in the thermal conductivity may result in a reduction in the required minimum insulation thickness.

The study investigated the influence of variable moisture conditions on the value of the thermal conductivity of selected insulation materials used in passive buildings. On the basis of the conducted tests, it can be stated that:

- −

- Measurements of the thermal conductivity λ on a perlite concrete block were taken with a portable device, ISOMET 2114, equipped with a surface probe. Before the tests, the sample had been immersed in water for 21 days; thus, its weight more than doubled. It proves the high porosity and high water absorption capacity of perlite concrete. The measured maximum thermal conductivity λ for the sample before the experiment was 0.0956 W/mK, while for the water-saturated sample, it was 0.6063 W/mK, which increased the value of the coefficient λ by more than six times. The obtained measurement results were interpreted as a graph (Figure 2) showing the correlation between the thermal conductivity and moisture content. The level of moisture content in a perlite concrete block has a great influence on the value of the coefficient λ, i.e., with moisture content w = 30%, the thermal conductivity λ increases to 0.160 W/mK (approx. 70%), and with moisture content w = 50%, it increases by more than 100%. Therefore, using perlite concrete blocks, walls should be built in an air-dry state and sorption moisture. Moreover, during construction, they require protection against rainfall.

- −

- Measurements of the thermal conductivity λ of the sample prepared from spray-applied polyurethane foam were taken with a portable device, ISOMET 2114, equipped with a needle probe. Although the sample was kept in water for 21 days, it did not completely soak. Its weight increased only by 0.158 kg, and moisture content was 66.11%, at which the thermal conductivity was 0.0539 W/mK. The value of the coefficient λ of the sample tested before the experiment was 0.0467 W/mK, which gave an increase of 15%. The obtained measurement results were interpreted as a graph (Figure 2) showing the correlation between the thermal conductivity and moisture content. Therefore, it can be concluded that moisture content has a less significant effect on the value of the thermal conductivity of polyurethane foam. Nevertheless, there is a noticeable tendency for the thermal conductivity to increase when the moisture content of the sample increases.

- −

- Measurements of the thermal conductivity λ of the samples prepared of expanded clay samples were taken with a portable device, ISOMET 2114, equipped with a needle probe. In the case of expanded clay, a porous material commonly described as non-absorbent, there was a tendency for an initial linear increase in the thermal conductivity at moisture content, depending on fractions, amounting to 10–20%. The obtained measurement results were interpreted as a graph (Figure 3) showing the correlation between the thermal conductivity and moisture content. Then, with increasing moisture content, the value of the thermal coefficient decreased. The authors explain this result by the uneven occurrence of moisture (Figure 5) (as in the case of ash concretes described above) and different values of the coefficient λ for the skeleton of a porous body and for the liquid filling its pores (as for the above-mentioned pumice stone as a porous material). It would be scientifically valuable to prepare a further study on expanded clay with samples prepared from mixed fractions, which would result in a greater densification of the sample material and therefore less space between its aggregates than in the case of a homogeneous fraction.

Author Contributions

Conceptualization, A.S.-G. and I.L.; methodology, A.S.-G., I.L.; software, G.G.; validation, W.K. and A.S.-G.; formal analysis, A.S-G.; investigation, I.L.; resources, G.G.; data curation, G.G. and W.K.; writing—original draft preparation, A.S.-G. and I.L; writing—review and editing, A.S.-G.; visualization, A.S-G.; supervision, A.S.-G.; project administration, A.S.-G.; funding acquisition, A.S.-G. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Acknowledgments

The publication was co-financed within the framework of Ministry of Science and Higher Education programme as “Regional Initiative Excellence” in years 2019–2022, Project No. 005/RID/2018/19.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Zhai, Z.J.; Helman, J.M. Implications of climate changes to building energy and design. Sustain. Cities Soc. 2019, 44, 511–519. [Google Scholar] [CrossRef]

- Dino, I.G.; Akgül, C.M. Impact of climate change on the existing residential building stock in Turkey: An analysis on energy use, greenhouse gas emissions and occupant comfort. Renew. Energy 2019, 141, 828–846. [Google Scholar] [CrossRef]

- Wan, K.K.; Li, D.H.; Pan, W.; Lam, J.C. Impact of climate change on building energy use in different climate zones and mitigation and adaptation implications. Appl. Energy 2012, 97, 274–282. [Google Scholar] [CrossRef]

- Ciancio, V.; Salata, F.; Falasca, S.; Curci, G.; Golasi, I.; de Wilde, P. Energy demands of buildings in the framework of climate change: An investigation across Europe. Sustain. Cities Soc. 2020, 60, 102213. [Google Scholar] [CrossRef]

- Chai, J.; Huang, P.; Sun, Y. Investigations of climate change impacts on net-zero energy building lifecycle performance in typical Chinese climate regions. Energy 2019, 185, 176–189. [Google Scholar] [CrossRef]

- Aram, K.; Taherkhani, R.; Šimelytė, A. Multi-Stage Optimization towards Nearly Net Zero Energy Building Due to Climate Change. Energies 2022, 15, 983. [Google Scholar] [CrossRef]

- Radomski, B.; Mróz, T. The Methodology for Designing Residential Buildings with a Positive Energy Balance—General Approach. Energies 2021, 14, 4715. [Google Scholar] [CrossRef]

- Radomski, B.; Mróz, T. The Methodology for Designing Residential Buildings with a Positive Energy Balance—Case Study. Energies 2021, 14, 5162. [Google Scholar] [CrossRef]

- Rodriguez-Ubinas, E.; Rodriguez, S.; Voss, K.; Todorovic, M.S. Energy efficiency evaluation of zero energy houses. Energy Build. 2014, 83, 23–35. [Google Scholar] [CrossRef] [Green Version]

- Feist, W. Active for More Comfort: Passive House; International Passive House Association: Darmstadt, Germany, 2018. [Google Scholar]

- Passive House Institute (PHI). Passive House Planning Package, Energy Balance and Passive House Design Tool for Quality Approved Passive Houses and EnerPHit Retrofits, Version 9; Passive House Institute (PHI): Darmstadt, Germany, 2015. [Google Scholar]

- Passive House Institute (PHI). Criteria for the Passive House, EnerPHit and PHI Low Energy Building Standard, Version 9f; Passive House Institute (PHI): Darmstadt, Germany, 2016. [Google Scholar]

- Moreno-Rangel, A. Passivhaus. Encyclopedia 2021, 1, 5. [Google Scholar] [CrossRef]

- Liu, L.; Moshfegh, B.; Akander, J.; Cehlin, M. Comprehensive investigation on energy retrofits in eleven multi-family buildings in Sweden. Energy Build. 2014, 84, 704–715. [Google Scholar] [CrossRef]

- Arumägi, E.; Kalamees, T. Analysis of energy economic renovation for historic wooden apartment buildings in cold climates. Appl. Energy 2014, 115, 540–548. [Google Scholar] [CrossRef]

- Piccardo, C.; Dodoo, A.; Gustavsson, L.; Tettey, U.Y.A. Retrofitting with different building materials: Life-cycle primary energy implications. Energy 2020, 192, 116648. [Google Scholar] [CrossRef]

- Piccardo, C.; Dodoo, A.; Gustavsson, L. Retrofitting a building to passive house level: A life cycle carbon balance. Energy Build. 2020, 223, 110135. [Google Scholar] [CrossRef]

- Gustavsson, L.; Piccardo, C. Cost Optimized Building Energy Retrofit Measures and Primary Energy Savings under Different Retrofitting Materials, Economic Scenarios, and Energy Supply. Energies 2022, 15, 1009. [Google Scholar] [CrossRef]

- Rozporządzenie Ministra Infrastruktury z Dnia 12 Kwietnia 2002 r. w Sprawie Warunków Technicznych, Jakim Powinny Odpowiadać Budynki i ich Usytuowanie (z późn. Zmianami) Regulation of the Minister of Infrastructure of April 12, 2002 on Technical Conditions to be Met by Buildings and Their Location. Available online: https://www.piib.org.pl/akty-prawne/przepisy-i-warunki-techniczno-budowlane/593-rozporzadzenie-ministra-infrastruktury-z-dnia-12-kwietnia-2002-r-w-sprawie-warunkow-technicznych-jakim-powinny-odpowiadac-budynki-i-ich-usytuowanie (accessed on 20 February 2022).

- Building components and building elements. Thermal resistance and thermal transmittance. Calculation methods. In PN-EN ISO 6946:2017-10; International Organization for Standardization: Geneva, Switzerland, 2017.

- Godlewski, T.; Mazur, Ł.; Szlachetka, O.; Witowski, M.; Łukasik, S.; Koda, E. Design of Passive Building Foundations in the Polish Climatic Conditions. Energies 2021, 14, 7855. [Google Scholar] [CrossRef]

- Sadłowska-Sałęga, A.; Wąs, K. Moisture Risk Analysis for Three Construction Variants of a Wooden Inverted Flat Roof. Energies 2021, 14, 7898. [Google Scholar] [CrossRef]

- Andreotti, M.; Calzolari, M.; Davoli, P.; Dias Pereira, L.; Lucchi, E.; Malaguti, R. Design and Construction of a New Metering Hot Box for the In Situ Hygrothermal Measurement in Dynamic Conditions of Historic Masonries. Energies 2020, 13, 2950. [Google Scholar] [CrossRef]

- Andreotti, M.; Bottino-Leone, D.; Calzolari, M.; Davoli, P.; Dias Pereira, L.; Lucchi, E.; Troi, A. Applied Research of the Hygrothermal Behaviour of an Internally Insulated Historic Wall without Vapour Barrier: In Situ Measurements and Dynamic Simulations. Energies 2020, 13, 3362. [Google Scholar] [CrossRef]

- Biseniece, E.; Freimanis, R.; Purvins, R.; Gravelsins, A.; Pumpurs, A.; Blumberga, A. Study of Hygrothermal Processes in External Walls with Internal Insulation. Environ. Clim. Technol. 2018, 22, 22–41. [Google Scholar] [CrossRef] [Green Version]

- Gianangeli, A.; DiGiuseppe, E.; D’Orazio, M. Mould growth risk evaluation of internal insulation solutions in a historic building under temperate climates. In Proceedings of the SER4SC2018 Seismic and Energy Renovation for Sustainable Cities Conference, Catania, Italy, 1–3 February 2018; pp. 508–517. [Google Scholar]

- Li, J.; Cao, W. The Heat Transfer Coefficient of Recycled Concrete Bricks Combination with EPS Insulation Board Wall. Math. Probl. Eng. 2015, 695962. [Google Scholar] [CrossRef]

- Jarfelt, U.; Ramnäs, O. Thermal conductivity of polyurethane foam—best performance. In Proceedings of the 10th International Symposium on District Heating and Cooling, Göteborg, Sweden, 3–5 September 2006. [Google Scholar]

- Ming, L.Y.; Sandu, A.V.; Yong, H.C.; Tajunnisa, Y.; Azzahran, S.F.; Bayuji, R.; Abdullah, M.M.A.; Vizureanu, P.; Hussin, K.; Jin, T.S.; et al. Compressive strength and thermal conductivity of fly ash geopolymer concrete incorporated with lightweight Aggregate, expanded clay aggregate and foaming agent. Rev. Chim. 2019, 70, 4021–4028. [Google Scholar] [CrossRef]

- Wu, J.-W.; Chu, H.-S. Heat transfer in open cell polyurethane foam insulation. Heat Mass Transf. 1998, 34, 247–254. [Google Scholar] [CrossRef]

- Wu, J.-W.; Sung, W.-F.; Chu, H.-S. Thermal conductivity of polyurethane foams. Int. J. Heat Mass Transf. 1999, 42, 2211–2217. [Google Scholar] [CrossRef]

- Uluer, O.; Aktaş, M.; Karaağaç, I.; Durmuş, G.; Khanlari, A.; Ağbulut, Ü.; Çelik, D.N. Mathematical calculation and experimental investigation of expanded perlite-based heat insulation materials’ thermal conductivity values. J. Therm. Eng. 2018, 4, 2274–2286. [Google Scholar]

- Suman, B.M.; Srivastava, R.K. Influence of thermal insulation on conductive heat transfer through roof ceiling construction. J. Sci. Ind. Res. 2009, 68, 248–251. [Google Scholar]

- Zhang, H.; Fang, W.-Z.; Li, Y.-M.; Tao, W.-Q. Experimental study of the thermal conductivity of polyurethane foams. Appl. Therm. Eng. 2017, 115, 528–538. [Google Scholar] [CrossRef]

- Tseng, C.-J.; Yamaguchi, M.; Ohmori, T. Thermal conductivity of polyurethane foams from room temperature to 20 K. Cryogenics 1997, 31, 305–312. [Google Scholar] [CrossRef]

- Bogucka, J. Influence of moisture content in expanded clay aggregate concrete on its strength, deformability, and thermal conductivity. Arch. Civ. Eng. 2004, 50, 625–642. [Google Scholar]

- Burkowicz, A. Perlit ekspandowany—materiał termoizolacyjny mało znany w Polsce. Zesz. Nauk. Inst. Gospod. Surowcami Miner. I Energią Pol. Akad. Nauk. 2016, 96, 7–22. [Google Scholar]

- Jakubowska, P. Influence of light aggregates—perlite and polystyrene granulate on the properties of building mortars. Builder 2020, 281, 30–35. [Google Scholar] [CrossRef]

- Łukowski, P. Polymer-Cement Composites Containing Waste Perlite Powder. Materials 2016, 9, 839. [Google Scholar] [CrossRef] [PubMed]

- Barnat-Hunek, D.; Góra, J.; Andrzejuk, W.; Łagód, G. The Microstructure-Mechanical Properties of Hybrid Fibres-Reinforced Self-Compacting Lightweight Concrete with Perlite Aggregate. Materials 2018, 11, 1093. [Google Scholar] [CrossRef] [Green Version]

- Mohammad, M.; Masad, E.; Seers, T.; Al-Ghamdi, S.G. Properties and Microstructure Distribution of High-Performance Thermal Insulation Concrete. Materials 2020, 13, 2091. [Google Scholar] [CrossRef]

- Drozdzol, K. Thermal and Mechanical Studies of Perlite Concrete Casing for Chimneys in Residential Buildings. Materials 2021, 14, 2011. [Google Scholar] [CrossRef]

- Kremieniewski, M.; Rzepka, M. Influence of perlite powder on technological properties of cement slurry. Nafta-Gaz 2017, 12, 943–952. [Google Scholar] [CrossRef]

- Szymczak-Graczyk, A. Numerical Analysis of the Impact of Thermal Spray Insulation Solutions on Floor Loading. Appl. Sci. 2020, 10, 1016. [Google Scholar] [CrossRef] [Green Version]

- Schneider, D.; Szymczak-Graczyk, A. Determination of the polyurethane foam shear modulus In Situ. Mater. Bud. 2019, 557, 62–63. [Google Scholar] [CrossRef] [Green Version]

- Deręgowska, B.; Szymczak-Graczyk, A. Evaluation of the suitability of polyurethane foam boards treated as underfloor elastic substrate. Mater. Bud. 2017, 537, 126–127. [Google Scholar] [CrossRef]

- Gajewska, G. Investigation of the Thermal Conductivity Coefficient in Various Humidity Conditions for Selected Insulation Materials. Bachelor’s Thesis, Poznan University of Life Sciences, Poznań, Poland, 2021. [Google Scholar]

- Hassan, A.; Ismail, N.; Mourad, A.-H.I.; Rashid, Y.; Laghari, M.S. Preparation and Characterization of Expanded Clay-Paraffin Wax-Geo-Polymer Composite Material. Materials 2018, 11, 2191. [Google Scholar] [CrossRef] [Green Version]

- Boarder, F.W.; Owens, P.L.; Khatib, J.M. 10—The sustainability of lightweight aggregates manufactured from clay wastes for reducing the carbon footprint of structural and foundation concrete. In Woodhead Publishing Series in Civil and Structural Engineering, Sustainability of Construction Materials, 2nd ed.; Khatib, J.M., Ed.; Woodhead Publishing: Sawston, UK, 2016; pp. 209–244. [Google Scholar] [CrossRef]

- Rashad, A.M. Lightweight expanded clay aggregate as a building material—An overview. Constr. Build. Mater. 2018, 170, 757–775. [Google Scholar] [CrossRef]

- Klemm, P. General Construction, T. 2. Building Physics; Arkady: Warsaw, Poland, 2010. [Google Scholar]

- Zastawna-Rumin, A.; Nowak, K. Measurement of thermal properties of building materials through the use of different measuring equipment—Analysis of. J. Civ. Eng. Environ. Archit. 2015, 62, 603–610. [Google Scholar]

- Monczyński, B. Humidity analyses of mineral construction materials. Izolacje 2019, 2, 78–84. [Google Scholar]

- Applied Precision, ISOMET 2114 User’s Guide. 2004. Available online: https://www.appliedp.com/download/manual/isomet2114_ug_en.pdf (accessed on 20 February 2022).

- Thermal insulation products in construction. Determination of water absorption during long-term immersion. In PN-EN 120807:2000; Polski Komitet Normalizacyjny: Warsaw, Poland, 2000.

- Rahman, N.A. A Course in Theoretical Statistics; Charles Griffin and Company: London, UK, 1968. [Google Scholar]

- Pebesma, E. Simple Features for R: Standardized Support for Spatial Vector Data. R J. 2018, 10, 439–446. [Google Scholar] [CrossRef] [Green Version]

- Thermal protection of buildings. Requirements and calculations. In PN-B-02020:1991; Polski Komitet Normalizacyjny: Warsaw, Poland, 1991.

- Jerman, M.; Černý, R. Effect of moisture content on heat and moisture transport and storage properties of thermal insulation materials. Energy Build. 2012, 53, 39–46. [Google Scholar] [CrossRef]

- Szumera, M. Advanced Research Methods. Determination of Thermal Conductivity of Selected Materials; Akademia Górniczo-Hutnicza: Krakow, Poland, 2011. [Google Scholar]

- Stefańczyk, B. General Construction, T. 1. Building Materials and Products; Arkady: Warsaw, Poland, 2010. [Google Scholar]

- Bobociński, A. Effect of superabsorbent moisture on the thermal conductivity of cellular concrete. Build. Res. Inst. 2004, 4, 3–12. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).