How Do We Learn about Drivers for Industrial Energy Efficiency—Current State of Knowledge

Abstract

:1. Introduction

2. Method

2.1. Literature Selection

- A single audit or calculation without providing new insights on drivers,

- Shipping or scheduling,

- Renewable energy sources,

- Electric vehicles.

2.2. Data Classification

- Data source,

- Role description of people contributing the raw data,

- Study scope,

- Company size,

- Energy intensity,

- Country.

2.3. Driver Mapping

3. Results

3.1. How Do We Learn about Drivers

3.2. Can Contemporary Drivers Be Authentically Represented Using Existing Taxonomies?

4. Discussion

4.1. Limitations

4.2. How Do We Learn about Drivers?

4.3. Can Contemporary Drivers Be Authentically Represented Using Existing Taxonomies?

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Database | Search Type | Full Search String |

|---|---|---|

| ABI Inform | Full text | ((("energy efficiency" OR "energy management") AND (driv* OR motivat*) AND (indust* OR utilit* OR manufactur*) NOT (household OR renewable* OR transport OR shipping OR grid OR distribut* OR solar OR bio* OR nuclear OR wind OR geothermal OR certificate OR construction)) AND peer(yes)) AND yr(2013-2019) and stype.exact("Conference Papers & Proceedings" OR "Reports" OR "Scholarly Journals" OR "Dissertations & Theses") |

| Scopus | Title, Key Word, Abstract | (TITLE-ABS-KEY ("energy efficiency") OR TITLE-ABS-KEY ("energy management") AND TITLE-ABS-KEY (indust* OR utilit* OR manufactur*) AND TITLE-ABS-KEY (driv* OR motivat*) AND NOT TITLE-ABS-KEY (household) AND NOT TITLE-ABS-KEY (storage) AND NOT TITLE-ABS-KEY (transport*) AND NOT TITLE-ABS-KEY (shipping) AND NOT TITLE-ABS-KEY (grid) AND NOT TITLE-ABS-KEY (renewable) AND NOT TITLE-ABS-KEY (solar) AND NOT TITLE-ABS-KEY (wind) AND NOT TITLE-ABS-KEY (geothermal) AND NOT TITLE-ABS-KEY (bio*) AND NOT TITLE-ABS-KEY (nuclear) AND NOT TITLE-ABS-KEY (certificate) AND NOT TITLE-ABS-KEY (distribution) AND NOT TITLE-ABS-KEY (construction)) AND PUBYEAR > 2006 AND (EXCLUDE (SUBJAREA, "COMP") OR EXCLUDE (SUBJAREA, "MATE") OR EXCLUDE (SUBJAREA, "PHYS") OR EXCLUDE (SUBJAREA, "CHEM") OR EXCLUDE (SUBJAREA, "MATH") OR EXCLUDE (SUBJAREA, "EART") OR EXCLUDE (SUBJAREA, "AGRI") OR EXCLUDE (SUBJAREA, "BIOC") OR EXCLUDE (SUBJAREA, "MEDI") OR EXCLUDE (SUBJAREA, "NURS") OR EXCLUDE (SUBJAREA, "IMMU") OR EXCLUDE (SUBJAREA, "VETE") OR EXCLUDE (SUBJAREA, "NEUR") OR EXCLUDE (SUBJAREA, "DENT")) AND (EXCLUDE (DOCTYPE, "ch") OR EXCLUDE (DOCTYPE, "bk") OR EXCLUDE (DOCTYPE, "sh") OR EXCLUDE (DOCTYPE, "no") OR EXCLUDE (DOCTYPE, "ab") OR EXCLUDE (DOCTYPE, "bz") OR EXCLUDE (DOCTYPE, "ed") OR EXCLUDE (DOCTYPE, "er") OR EXCLUDE (DOCTYPE, "le")) AND (LIMIT-TO (PUBYEAR, 2020)) |

| Web of Science | Topic | TS =("energy efficiency" OR "energy manage*") AND TS=(indust* OR utilit* OR manufactur*) AND TS=(driv* OR motivat*) NOT TS=(household) NOT TS=(storage) NOT TS=(tranport*) NOT TS=(shipping) NOT TS=(grid) NOT TS=(renewable) NOT TS=(solar) NOT TS=(wind) NOT TS=(geothermal) NOT TS=(bio*) NOT TS=(nuclear) NOT TS=(certificate) NOT TS=(distribut*) NOT TS=(construction) Indexes=SCI-EXPANDED, SSCI, A&HCI, CPCI-S, CPCI-SSH, BKCI-S, BKCI-SSH, ESCI, CCR-EXPANDED, IC Timespan=2020 |

Appendix B

| Reference | Year | Coded Data Source | Company Size | Energy Intensity | Coded Position | Economic Dev. | Scope | Participant Description from Pper |

|---|---|---|---|---|---|---|---|---|

| [41] | 2017 | Case study for analysis | Large | EI | Mixed | OECD | Technology only | Stakeholder, staff at the companies, plant manufacturers and governmental intuitions |

| [42] | 2016 | Case study for analysis | SME | Non-EI | Mixed | OECD | Managerial only | Management and employees and production associates and technical staff |

| [55] | 2017 | Case study for analysis | Not stated | EI | Not conducted | OECD | Technology only | No interviewing because answer was obvious |

| [56] | 2015 | Case study for analysis | Not stated | Non-EI | Frontline workers | OECD | Technology only | Plant and mine operators |

| [57] | 2016 | Case study for analysis | SME | Non-EI | Not conducted | OECD | All EEM | Not stated (interviewing was done) |

| [58] | 2020 | Case study for analysis | Large | Non-EI | Frontline workers | Non-OECD | All EEM | Maintenance and operational personnel |

| [23] | 2020 | Case study for analysis | Large | EI | Managers | OECD | All EEM | Talks to managers but also maintenance manager and technical controller |

| [59] | 2013 | Case study for intervention | Large | Non-EI | Not conducted | OECD | All EEM | No interview component |

| [60] | 2019 | Case study for intervention | Not stated | EI | Engineers | OECD | Managerial only | People with responsibility for energy—process engineers energy coordinators and manager |

| [61] | 2020 | Case study for intervention | Large | EI | Engineers | OECD | All EEM | Technical staff with significant knowledge about the operational and technical aspects of the refinery—multiple sorts of engineers |

| [62] | 2016 | Case study for intervention | Large | Non-EI | Managers | OECD | All EEM | Energy managers as well as independent energy audit experts |

| [43] | 2019 | Case study for intervention | Large | Non-EI | Mixed | OECD | Managerial only | Mixed energy specials, global leaders and project team members from different departments at the plant. |

| [63] | 2018 | Case study for intervention | Large | EI | Not conducted | BRIC | All EEM | No interview component |

| [49] | 2019 | Literature review | Not stated | Not stated | N/A | Not stated | All EEM | N/A |

| [24] | 2018 | Literature review | Not stated | EI | N/A | OECD | All EEM | N/A |

| [31] | 2016 | Literature review | Not stated | Not stated | N/A | Not stated | All EEM | N/A |

| [64] | 2018 | Literature review | Not stated | Not stated | N/A | Not stated | Managerial only | N/A |

| [65] | 2018 | Literature review | Not stated | Not stated | N/A | Not stated | All EEM | N/A |

| [16] | 2018 | Literature review | Not stated | Not stated | N/A | Not stated | All EEM | N/A |

| [15] | 2017 | Literature review | Not stated | Not stated | N/A | Not stated | All EEM | N/A |

| [66] | 2013 | Other | Mixed | Mixed | N/A | OECD | All EEM | N/A |

| [67] | 2017 | Other | Not stated | Mixed | N/A | Non-OECD | Technology only | N/A |

| [68] | 2018 | Other | Not stated | Mixed | N/A | OECD and Non-OECD | All EEM | N/A |

| [69] | 2018 | Other | Mixed | Mixed | N/A | OECD | All EEM | N/A |

| [70] | 2016 | Other | Mixed | Mixed | Managers | OECD | Technology only | Plant managers, manufacturing managers general managers |

| [71] | 2016 | Other | Mixed | Mixed | N/A | OECD | All EEM | N/A |

| [72] | 2018 | Other | Not stated | Mixed | N/A | BRIC | Not stated | N/A |

| [73] | 2014 | Other | Not stated | Not stated | N/A | OECD and Non-OECD | investment only | N/A |

| [74] | 2017 | Other | Not stated | Not stated | N/A | OECD and Non-OECD | All EEM | N/A |

| [75] | 2017 | Other | Not stated | Mixed | N/A | OECD | All EEM | Not Applicable |

Appendix C

| Ref. | Year | Coded Data Source | Size | Energy Intensity | Coded Position | Economic Dev. | Scope | Participant | 3 Most Prominent or Important Drivers | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| [44] | 2020 | Survey and/or interview | SME | EI | Mixed | Non-OECD | All EEM | Staff | Cost reduction from lowered energy use | Improved working conditions | Threat of rising energy prices |

| [20] | 2013 | Survey and/or interview | Not stated | Mixed | Managers | Non-OECD | All EEM | Middle managers or technical directors and engineering staff who dealt directly with energy issues at the firm | Cost reduction lowered energy use | Increasing energy prices | Requirements by government |

| [76] | 2014 | Survey and/or interview | Large | EI | Managers | OECD | All EEM | Mixed managers | Commitment from top management/energy management | Cost reduction lowered energy use | Long-term energy strategy |

| [39] | 2013 | Survey and/or interview | SME | Mixed | Person responsible for energy issues | OECD | All EEM | Person in charge of energy issues | Allowances or public finances | External pressures | Long term benefits |

| [77] | 2015 | Survey and/or interview | SME | Mixed | Person responsible for energy issues | OECD | All EEM | People know legible and responsible for energy issues. | Cost reduction lowered energy use | Long-term energy strategy | Clarity of information |

| [12] | 2017 | Survey and/or interview | SME | Mixed | Person responsible for energy issues | OECD | All EEM | Person in charge of energy-efficient investment | Information about real costs | Clarity and trustworthiness of information | Public investment subsidies |

| [78] | 2019 | Survey and/or interview | Mixed | Mixed | Not stated | OECD | investment only | Not stated | Cost reductions resulting from lower energy use | Enhancing the positive image and reputation | Enhanced competitiveness |

| [79] | 2019 | Survey and/or interview | Mixed | EI | Managers | OECD | All EEM | Energy managers or CEO or production manager but they could pass the survey on | People with real ambition | Full support from top management | Knowledge about daily operations |

| [80] | 2018 | Survey and/or interview | Large | EI | Managers | Non-OECD | All EEM | Production manager or plant manager | Cost reductions from lowered energy use | Long term energy strategy | Threat of rising energy prices |

| [50] | 2019 | Survey and/or interview | SME | Non-EI | Person responsible for energy issues | Non-OECD | All EEM | Person mainly responsible for energy-related issues | Owners requirement | Expense minimisation due to lower energy use | Risk of high energy prices in the future |

| [81] | 2019 | Survey and/or interview | Large | Non-EI | Managers | Non-OECD | All EEM | Concerned plant manager, chief engineer | Energy management Scheme | Risk of higher energy prices in the future | Assistance from energy professionals |

| [82] | 2020 | Survey and/or interview | Large | EI | Managers | Non-OECD | All EEM | Plant managers, manufacturing managers general managers | Risk of high energy prices in the future | Highly motivated employee | High demand from consumer and NGO |

| [83] | 2020 | Survey and/or interview | Large | Not stated | Managers | Non-OECD | Not stated | Lower, middle and upper level managers | Environmental strategies | Entrepreneurial innovation | Entrepreneurial orientation |

| [45] | 2020 | Survey and/or interview | SME | Mixed | Mixed | OECD | All EEM | Owner, energy management, Accounting production workers, maintenance engineering, human resources, marketing, trainee | Embedding of energy efficiency in corporate strategy | The use of a broad spectrum of different practices | The empowerment and involvement of employees |

| [24] | 2019 | Survey and/or interview | Mixed | EI | Managers | OECD | All EEM | Energy manager or similar | Cost reduction from lower energy use | Access to internal competence with knowledge of the processes | Voluntary agreements with tax exemptions |

| [84] | 2015 | Survey and/or interview | Not stated | EI | Managers | Non-OECD | All EEM | Senior executives and managers | Cost savings from lowered energy use | Demand from owner | Energy tax |

| [85] | 2017 | Survey and/or interview | Mixed | Not stated | Managers | OECD | All EEM | Senior managers who were in charge of implementing ISO50001 | Improve energy efficiency | Enhance employee awareness | The rise of energy prices/image improvement |

| [86] | 2013 | Survey and/or interview | Large | Non-EI | Not stated | OECD | All EEM | Not stated | Reductions of costs | Reduction of environmental impact | Image improvement due to enhanced reputation |

| [46] | 2015 | Survey and/or interview | Not stated | EI | Mixed | OECD | All EEM | Experienced workers in the field from mining companies vendors engineering companies and academia | Economic | Community expectation | |

| [87] | 2018 | Survey and/or interview | Large | Non-EI | Managers | OECD | All EEM | Industrial energy managers and audit experts | Commitment from top management | People with real ambition | Cost reductions from lowered energy use |

| [88] | 2014 | Survey and/or interview | Mixed | Mixed | Not stated | OECD | All EEM | Not stated | Cost reductions resulting from lower energy use | Increase in energy prices | Fiscal arrangement |

| [47] | 2016 | Survey and/or interview | Mixed | Mixed | Mixed | OECD | All EEM | Managers are the typical respondent but some shop floor information is represented | Recognition for personal contributions | Motivation | |

| [89] | 2013 | Survey and/or interview | Mixed | Not stated | Managers | Not stated | investment only | Managers (sustainability, energy, plant, presidents and vice president) | Competitive performance | Proactive risk containment | Top down direction |

| [14] | 2018 | Survey and/or interview | Mixed | EI | Mixed | OECD | Technology only | One from top management and one from the energy group | Cost reductions from lowered energy use | People with real ambition | Long term energy strategy |

| [25] | 2017 | Survey and/or interview | Mixed | Mixed | Mixed | OECD | All EEM | One from top management and one from the energy group | Drivers cannot be extracted. | ||

| [90] | 2015 | Survey and/or interview | Mixed | Non-EI | Person responsible for energy issues | Non-OECD | All EEM | Key person who is charge of energy efficiency of each company | Potential to reduce energy costs | ||

| [91] | 2020 | Survey and/or interview | Mixed | EI | Managers | BRIC | All EEM | Middle managers | Environment | Competitiveness | Economics |

| [19] | 2013 | Survey and/or interview | Mixed | EI | Person responsible for energy issues | OECD | All EEM | People responsible for energy at their site (interview) | Cost reductions resulting from lowered energy use | Threat of rising energy prices | Commitment from top management |

| [22] | 2016 | Survey and/or interview | SME | Mixed | Person responsible for energy issues | OECD | investment only | People responsible for energy efficiency investments | Economic external | Economic internal | Regulatory external |

| [92] | 2014 | Survey and/or interview | SME | Non-EI | Owner | OECD | All EEM | Owners/Managers | Economics internal | Economics external | Regulatory external |

| [48] | 2018 | Survey and/or interview | Not stated | Not stated | Mixed | BRIC | All EEM | Energy management personnel | Economic | Informative | Regulatory |

References

- Lovins, A.B. How big is the energy efficiency resource? Environ. Res. Lett. 2018, 13, 090401. [Google Scholar] [CrossRef] [Green Version]

- International Energy Agency. Net Zero by 2050. A Roadmap for the Global Energy Sector. Flagship Report, May 2021; IEA Publications: Paris, France, 2021. [Google Scholar]

- Finnerty, N.; Sterling, R.; Contreras, S.; Coakley, D.; Keane, M.M. Defining corporate energy policy and strategy to achieve carbon emissions reduction targets via energy management in non-energy intensive multi-site manufacturing organisations. Energy 2018, 151, 913–929. [Google Scholar] [CrossRef] [Green Version]

- International Energy Agency. Energy Efficiency Market Report 2018; International Energy Agency: Paris, France, 2018. [Google Scholar]

- Department of Resources Energy and Tourism. Energy Efficiency Opportunities—Continuing Opportunities 2011. Results of EEO Assessments Reported by Participating Corporations; Department of Resources, Energy and Tourism: Canberra, ACT, Australia, 2011. [Google Scholar]

- Backlund, S.; Thollander, P. Impact after three years of the Swedish energy audit program. Energy 2015, 82, 54–60. [Google Scholar] [CrossRef] [Green Version]

- Hirst, E.; Brown, M. Closing the efficiency gap: Barriers to the efficient use of energy. Resour. Conserv. Recycl. 1990, 3, 267–281. [Google Scholar] [CrossRef]

- Johansson, M.; Thollander, P. A review of barriers to and driving forces for improved energy efficiency in Swedish industry—Recommendations for successful in-house energy management. Renew. Sustain. Energy Rev. 2018, 82, 618–628. [Google Scholar] [CrossRef]

- Paramonova, S.; Thollander, P.; Ottosson, M. Quantifying the extended energy efficiency gap-evidence from Swedish electricity-intensive industries. Renew. Sustain. Energy Rev. 2015, 51, 472–483. [Google Scholar] [CrossRef] [Green Version]

- Jalo, N.; Johansson, I.; Kanchiralla, F.M.; Thollander, P. Do energy efficiency networks help reduce barriers to energy efficiency? -A case study of a regional Swedish policy program for industrial SMEs. Renew. Sustain. Energy Rev. 2021, 151, 111579. [Google Scholar] [CrossRef]

- Schützenhofer, C. Overcoming the efficiency gap: Energy management as a means for overcoming barriers to energy efficiency, empirical support in the case of Austrian large firms. Energy Effic. 2021, 14, 45. [Google Scholar] [CrossRef]

- Cagno, E.; Trianni, A.; Spallina, G.; Marchesani, F. Drivers for energy efficiency and their effect on barriers: Empirical evidence from Italian manufacturing enterprises. Energy Effic. 2017, 10, 855–869. [Google Scholar] [CrossRef]

- Dütschke, E.; Hirzel, S.; Idrissova, F.; Mai, M.; Mielicke, U.; Nabitz, L. Energy efficiency networks—What are the processes that make them work? Energy Effic. 2018, 11, 1177–1192. [Google Scholar] [CrossRef]

- Sa, A.; Thollander, P.; Cagno, E.; Rafiee, M. Assessing Swedish Foundries Energy Management Program. Energies 2018, 11, 2780. [Google Scholar] [CrossRef] [Green Version]

- Trianni, A.; Cagno, E.; Marchesani, F.; Spallina, G. Classification of drivers for industrial energy efficiency and their effect on the barriers affecting the investment decision-making process. Energy Effic. 2017, 10, 199–215. [Google Scholar] [CrossRef]

- Solnørdal, M.T.; Foss, L. Closing the Energy Efficiency Gap—A Systematic Review of Empirical Articles on Drivers to Energy Efficiency in Manufacturing Firms. Energies 2018, 11, 518. [Google Scholar] [CrossRef] [Green Version]

- Ren, T. Barriers and drivers for process innovation in the petrochemical industry: A case study. J. Eng. Technol. Manag. 2009, 26, 285–304. [Google Scholar] [CrossRef]

- Cagno, E.; Worrell, E.; Trianni, A.; Pugliese, G. A novel approach for barriers to industrial energy efficiency. Renew. Sustain. Energy Rev. 2013, 19, 290–308. [Google Scholar] [CrossRef]

- Thollander, P.; Backlund, S.; Trianni, A.; Cagno, E. Beyond barriers—A case study on driving forces for improved energy efficiency in the foundry industries in Finland, France, Germany, Italy, Poland, Spain, and Sweden. Appl. Energy 2013, 111, 636–643. [Google Scholar] [CrossRef] [Green Version]

- Apeaning, R.W.; Thollander, P. Barriers to and driving forces for industrial energy efficiency improvements in African industries—A case study of Ghana’s largest industrial area. J. Clean. Prod. 2013, 53, 204–213. [Google Scholar] [CrossRef] [Green Version]

- Bell, M.G.; Carrington, G.; Lawson, R.; Stephenson, J. Socio-technical barriers to the use of energy-efficient timber drying technology in New Zealand. Energy Policy 2014, 67, 747–755. [Google Scholar] [CrossRef]

- Trianni, A.; Cagno, E.; Farné, S. Barriers, drivers and decision-making process for industrial energy efficiency: A broad study among manufacturing small and medium-sized enterprises. Appl. Energy 2016, 162, 1537–1551. [Google Scholar] [CrossRef]

- Rasmussen, J. The Role of Structural Context in Making Business Sense of Investments for Sustainability–A Case Study. Sustainability 2020, 12, 7006. [Google Scholar] [CrossRef]

- Lawrence, A.; Nehler, T.; Andersson, E.; Karlsson, M.; Thollander, P. Drivers, barriers and success factors for energy management in the Swedish pulp and paper industry. J. Clean. Prod. 2019, 223, 67–82. [Google Scholar] [CrossRef]

- Sa, A.; Thollander, P.; Cagno, E. Assessing the driving factors for energy management program adoption. Renew. Sustain. Energy Rev. 2017, 74, 538–547. [Google Scholar] [CrossRef]

- Buettner, S.M.; Bottner, F.; Sauer, A.; Koenig, W.; Loebbe, S. Barriers to and Decisions for Energy Efficiency: What Do We Know So Far? A Theoretical and Empirical Overview. In Proceedings of the ECEE Industrial Summer Study Proceedings, Kalkscheune, Berlin, Germany, 11–13 June 2018. [Google Scholar]

- Johansson, I.; Mardan, N.; Cornelis, E.; Kimura, O.; Thollander, P. Designing Policies and Programmes for Improved Energy Efficiency in Industrial SMEs. Energies 2019, 12, 1338. [Google Scholar] [CrossRef] [Green Version]

- Johansson, M.T. Improved energy efficiency within the Swedish steel industry—The importance of energy management and networking. Energy Effic. 2015, 8, 713–744. [Google Scholar] [CrossRef] [Green Version]

- Pathirana, S.; Yarime, M. Introducing energy efficient technologies in small- and medium-sized enterprises in the apparel industry: A case study of Sri Lanka. J. Clean. Prod. 2018, 178, 247–257. [Google Scholar] [CrossRef]

- Lawrence, A.; Karlsson, M.; Thollander, P. Effects of firm characteristics and energy management for improving energy efficiency in the pulp and paper industry. Energy 2018, 153, 825–835. [Google Scholar] [CrossRef]

- May, G.; Stahl, B.; Taisch, M.; Kiritsis, D. Energy management in manufacturing: From literature review to a conceptual framework. J. Clean. Prod. 2016, 167, 1464–1489. [Google Scholar] [CrossRef]

- Smith, K.M.; Wilson, S.; Hassall, M.E. Could focusing on barriers to industrial energy efficiency create a new barrier to energy efficiency? J. Clean. Prod. 2021, 310, 127387. [Google Scholar] [CrossRef]

- Boland, A.; Cherry, M.G.; Dickson, R. Doing a Systematic Review: A Student’s Guide, 2nd ed.; SAGE Publications: Thousand Oakes, CA, USA, 2017. [Google Scholar]

- Petticrew, M. Systematic reviews from astronomy to zoology: Myths and misconceptions. BMJ 2001, 322, 98–101. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G.; The PRISMA Group. Preferred Reporting Items for Systematic Reviews and Meta-Analyses: The PRISMA Statement. J. Clin. Epidemiol. 2009, 62, 1006–1012. [Google Scholar] [CrossRef]

- Thollander, P.; Paramonova, S.; Cornelis, E.; Kimura, O.; Trianni, A.; Karlsson, M.; Cagno, E.; Morales, I.; Jiménez-Navarro, J.-P. International study on energy end-use data among industrial SMEs (small and medium-sized enterprises) and energy end-use efficiency improvement opportunities. J. Clean. Prod. 2015, 104, 282–296. [Google Scholar] [CrossRef] [Green Version]

- International Energy Agency. Energy efficiency 2017, Fuel Report, October 2017; IEA: Paris, France, 2017. [Google Scholar]

- International Energy Agency. World Energy Outlook 2020; IEA: Paris, France, 2020. [Google Scholar]

- Cagno, E.; Trianni, A. Exploring drivers for energy efficiency within small- and medium-sized enterprises: First evidences from Italian manufacturing enterprises. Appl. Energy 2013, 104, 276–285. [Google Scholar] [CrossRef]

- Sa, A.; Paramonova, S.; Thollander, P.; Cagno, E. Classification of Industrial Energy Management Practices: A Case Study of a Swedish Foundry. Energy Procedia 2015, 75, 2581–2588. [Google Scholar] [CrossRef] [Green Version]

- Arens, M.; Worrell, E.; Eichhammer, W. Drivers and barriers to the diffusion of energy-efficient technologies—A plant-level analysis of the German steel industry. Energy Effic. 2017, 10, 441–457. [Google Scholar] [CrossRef]

- Cosgrove, J.; Doyle, F.; O’Neill, M.; Littlewood, J.; Wilgeroth, P. A Methodology for Verified Energy Savings in Manufacturing Facilities through Changes in Operational Behaviour. In Proceedings of the ECEE Industrial Summer Study Proceedings, Kalkscheune, Berlin, Germany, 12–14 September 2016. [Google Scholar]

- Sannö, A.; Johansson, M.T.; Thollander, P.; Wollin, J.; Sjögren, B. Approaching Sustainable Energy Management Operations in a Multinational Industrial Corporation. Sustainability 2019, 11, 754. [Google Scholar] [CrossRef] [Green Version]

- Ahmad, I.; Arif, M.; Cheema, I.; Thollander, P.; Khan, M. Drivers and Barriers for Efficient Energy Management Practices in Energy-Intensive Industries: A Case-Study of Iron and Steel Sector. Sustainability 2020, 12, 7703. [Google Scholar] [CrossRef]

- König, W.; Löbbe, S.; Büttner, S.; Schneider, C. Establishing Energy Efficiency—Drivers for Energy Efficiency in German Manufacturing Small- and Medium-Sized Enterprises. Energies 2020, 13, 5144. [Google Scholar] [CrossRef]

- Napier-Munn, T. Is progress in energy-efficient comminution doomed? Miner. Eng. 2015, 73, 1–6. [Google Scholar] [CrossRef]

- Pusnik, M.; Al-Mansour, F.; Sucic, B.; Gubina, A. Gap analysis of industrial energy management systems in Slovenia. Energy 2016, 108, 41–49. [Google Scholar] [CrossRef]

- Wang, J.; Yang, F.; Zhang, X.; Zhou, Q. Barriers and drivers for enterprise energy efficiency: An exploratory study for industrial transfer in the Beijing-Tianjin-Hebei region. J. Clean. Prod. 2018, 200, 866–879. [Google Scholar] [CrossRef]

- Jabbour, A.B.L.D.S.; Jabbour, C.J.C.; Sarkis, J.; Gunasekaran, A.; Alves, M.W.F.M.; Ribeiro, D.A. Decarbonisation of operations management—Looking back, moving forward: A review and implications for the production research community. Int. J. Prod. Res. 2019, 57, 4743–4765. [Google Scholar] [CrossRef]

- Hasan, A.S.M.M.; Hossain, R.; Tuhin, R.A.; Sakib, T.H.; Thollander, P. Empirical Investigation of Barriers and Driving Forces for Efficient Energy Management Practices in Non-Energy-Intensive Manufacturing Industries of Bangladesh. Sustainability 2019, 11, 2671. [Google Scholar] [CrossRef] [Green Version]

- Virtanen, T.; Tuomaala, M.; Pentti, E. Energy efficiency complexities: A technical and managerial investigation. Manag. Account. Res. 2013, 24, 401–416. [Google Scholar] [CrossRef]

- Challis, C.; Tierney, M.; Todd, A.; Wilson, E. Human factors in dairy industry process control for energy reduction. J. Clean. Prod. 2017, 168, 1319–1334. [Google Scholar] [CrossRef] [Green Version]

- Sivill, L.; Manninen, J.; Hippinen, I.; Ahtila, P. Success factors of energy management in energy-intensive industries: Development priority of energy performance measurement. Int. J. Energy Res. 2013, 37, 936–951. [Google Scholar] [CrossRef]

- Schulze, M.; Nehler, H.; Ottosson, M.; Thollander, P. Energy management in industry—A systematic review of previous findings and an integrative conceptual framework. J. Clean. Prod. 2016, 112, 3692–3708. [Google Scholar] [CrossRef] [Green Version]

- Durocher, D.B.; Higginson, M. Successful technology upgrade reduces thermo-mechanical pulp mill energy footprint. In Proceedings of the IEEE Conference Record of Annual Pulp and Paper Industry Technical Conference, Tacoma, WA, USA, 18–23 June 2017. [Google Scholar]

- Durocher, D.B.; Putnam, R. Cleaner Coal: Improving Energy Efficiency at a Coal Preparation Plant in Western Canada. IEEE Ind. Appl. Mag. 2015, 21, 59–67. [Google Scholar] [CrossRef]

- Solberg Hjorth, S.; Brem, A.M. How to Assess Market Readiness for an Innovative Solution: The Case of Heat Recovery Technologies for SMEs. Sustainability 2016, 8, 1152. [Google Scholar] [CrossRef] [Green Version]

- Khumalo, E.; Telukdarie, A. Application of digital products in the water and wastewater industry. In Proceedings of the ASEM 41st International Annual Conference Proceedings “Leading Organizations through Uncertain Times”, Online, 28–30 October 2020. [Google Scholar]

- Aflaki, S.; Kleindorfer, P.R.; Polvorinos, V.S.D.M. Finding and Implementing Energy Efficiency Projects in Industrial Facilities. Prod. Oper. Manag. 2013, 22, 503–517. [Google Scholar] [CrossRef]

- Andersson, E.; Thollander, P. Key performance indicators for energy management in the Swedish pulp and paper industry. Energy Strat. Rev. 2019, 24, 229–235. [Google Scholar] [CrossRef]

- Marton, S.; Svensson, E.; Harvey, S. Operability and Technical Implementation Issues Related to Heat Integration Measures—Interview Study at an Oil Refinery in Sweden. Energies 2020, 13, 3478. [Google Scholar] [CrossRef]

- Parra, R.; Thollander, P.; Nehler, T. Barriers to, drivers for and non-energy benefits for industrial energy efficiency improvement measures in compressed air systems. In Proceedings of the Eceee Industrial Summer Study, Berlin, Germany, 12–14 September 2016. [Google Scholar]

- Zhang, Y.; Ma, S.; Yang, H.; Lv, J.; Liu, Y. A big data driven analytical framework for energy-intensive manufacturing industries. J. Clean. Prod. 2018, 197, 57–72. [Google Scholar] [CrossRef]

- Rotzek, J.N.; Scope, C.; Günther, E. What energy management practice can learn from research on energy culture? Sustain. Account. Manag. Policy J. 2018, 9, 515–551. [Google Scholar] [CrossRef]

- Sindhwani, R.; Mittal, V.K.; Singh, P.L.; Kalsariya, V.; Salroo, F. Modelling and analysis of energy efficiency drivers by fuzzy ISM and fuzzy MICMAC approach. Int. J. Product. Qual. Manag. 2018, 25, 225–244. [Google Scholar] [CrossRef]

- Abeelen, C.; Harmsen, R.; Worrell, E. Implementation of energy efficiency projects by Dutch industry. Energy Policy 2013, 63, 408–418. [Google Scholar] [CrossRef]

- Cantore, N. Factors affecting the adoption of energy efficiency in the manufacturing sector of developing countries. Energy Effic. 2017, 10, 743–752. [Google Scholar] [CrossRef]

- Fuchs, H.; Aghajanzadeh, A.; Therkelsen, P. Using Industry’s Own Words to Quantify the Benefits and Challenges of ISO 50001. In Proceedings of the ECEE Industrial Summer Study, Kalkscheune, Berlin, Germany, 11–13 June 2018. [Google Scholar]

- Garrone, P.; Grilli, L.; Mrkajic, B. The role of institutional pressures in the introduction of energy-efficiency innovations. Bus. Strat. Environ. 2018, 27, 1245–1257. [Google Scholar] [CrossRef]

- Gerstlberger, W.; Knudsen, M.P.; Dachs, B.; Schröter, M. Closing the energy-efficiency technology gap in European firms? Innovation and adoption of energy efficiency technologies. J. Eng. Technol. Manag. 2016, 40, 87–100. [Google Scholar] [CrossRef]

- Hrovatin, N.; Dolšak, N.; Zorić, J. Factors impacting investments in energy efficiency and clean technologies: Empirical evidence from Slovenian manufacturing firms. J. Clean. Prod. 2016, 127, 475–486. [Google Scholar] [CrossRef]

- Liao, N.; He, Y. Exploring the effects of influencing factors on energy efficiency in industrial sector using cluster analysis and panel regression model. Energy 2018, 158, 782–795. [Google Scholar] [CrossRef]

- Nepal, R.; Jamasb, T.; Tisdell, C.A. Market-related reforms and increased energy efficiency in transition countries: Empirical evidence. Appl. Econ. 2014, 46, 4125–4136. [Google Scholar] [CrossRef] [Green Version]

- Sineviciene, L.; Sotnyk, I.; Kubatko, O. Determinants of energy efficiency and energy consumption of Eastern Europe post-communist economies. Energy Environ. 2017, 28, 870–884. [Google Scholar] [CrossRef]

- Solnørdal, M.T.; Thyholdt, S.B. Drivers for energy efficiency: An empirical analysis of Norwegian manufacturing firms. Energy Procedia 2017, 142, 2802–2808. [Google Scholar] [CrossRef]

- Brunke, J.-C.; Johansson, M.; Thollander, P. Empirical investigation of barriers and drivers to the adoption of energy conservation measures, energy management practices and energy services in the Swedish iron and steel industry. J. Clean. Prod. 2014, 84, 509–525. [Google Scholar] [CrossRef] [Green Version]

- Cagno, E.; Trianni, A.; Abeelen, C.; Worrell, E.; Miggiano, F. Barriers and drivers for energy efficiency: Different perspectives from an exploratory study in the Netherlands. Energy Convers. Manag. 2015, 102, 26–38. [Google Scholar] [CrossRef] [Green Version]

- Cooremans, C.; Schonenberger, A. Energy management: A key driver of energy-efficiency investment? J. Clean. Prod. 2019, 230, 264–275. [Google Scholar] [CrossRef]

- Haraldsson, J.; Johansson, M.T. Barriers to and Drivers for Improved Energy Efficiency in the Swedish Aluminium Industry and Aluminium Casting Foundries. Sustainability 2019, 11, 2043. [Google Scholar] [CrossRef] [Green Version]

- Hasan, A.S.M.M.; Hoq, M.T.; Thollander, P. Energy management practices in Bangladesh’s iron and steel industries. Energy Strategy Rev. 2018, 22, 230–236. [Google Scholar] [CrossRef]

- Hasan, A.S.M.M.; Rokonuzzaman, M.; Tuhin, R.A.; Salimullah, S.M.; Ullah, M.; Sakib, T.H.; Thollander, P. Drivers and Barriers to Industrial Energy Efficiency in Textile Industries of Bangladesh. Energies 2019, 12, 1775. [Google Scholar] [CrossRef] [Green Version]

- Hossain, S.R.; Ahmed, I.; Azad, F.S.; Hasan, A.M. Empirical investigation of energy management practices in cement industries of Bangladesh. Energy 2020, 212, 118741. [Google Scholar] [CrossRef]

- Khalid, N.; Salykova, L.; Capar, N. The Contribution of Environmental Strategies, Entrepreneurial Innovation and Entrepreneurial Orientation in Enhancing Firm Environmental Performance and Energy Efficiency. Int. J. Energy Econ. Policy 2020, 10, 282–288. [Google Scholar] [CrossRef]

- Lee, K.-H. Drivers and Barriers to Energy Efficiency Management for Sustainable Development. Sustain. Dev. 2015, 23, 16–25. [Google Scholar] [CrossRef]

- Marimon, F.; Casadesús, M. Reasons to Adopt ISO 50001 Energy Management System. Sustainability 2017, 9, 1740. [Google Scholar] [CrossRef] [Green Version]

- May, G.; Taisch, M.; Stahl, B.; Sadr, V. Toward Energy Efficient Manufacturing: A Study on Practices and Viewpoint of the Industry 2013. In Proceedings of the IFIP Advances in Information and Communication Technology, Rhodes, Greece, 24–26 September 2012; pp. 1–8. [Google Scholar]

- Nehler, T.; Parra, R.; Thollander, P. Implementation of energy efficiency measures in compressed air systems: Barriers, drivers and non-energy benefits. Energy Effic. 2018, 11, 1281–1302. [Google Scholar] [CrossRef] [Green Version]

- Pereira, V.M.F.; Ferreira, J.J.M. Barriers to and Driving Forces for Energy Efficiency in the Portuguese Industrial SMEs. In Design a Pattern of Sustainable Growth: Innovation, Education, Energy and Environment; Schiliro, D., Ed.; ASERS Publishing: Craiova, Romania, 2014. [Google Scholar]

- Russell, C.; Fellow, V. Corporate Protocols for Capital Investment: Implications for Energy Efficiency. In Proceedings of the World Energy Engineering Congress, Washington, DC, USA, 25–27 September 2013. [Google Scholar]

- Sathitbun-Anan, S.; Fungtammasan, B.; Barz, M.; Sajjakulnukit, B.; Pathumsawad, S. An analysis of the cost-effectiveness of energy efficiency measures and factors affecting their implementation: A case study of Thai sugar industry. Energy Effic. 2015, 8, 141–153. [Google Scholar] [CrossRef]

- Sola, A.V.; Mota, C.M. Influencing factors on energy management in industries. J. Clean. Prod. 2020, 248, 119263. [Google Scholar] [CrossRef]

- Trianni, A.; Cagno, E.; Farnè, S. An Empirical Investigation of Barriers, Drivers and Practices for Energy Efficiency in Primary Metals Manufacturing SMEs. Energy Procedia 2014, 61, 1252–1255. [Google Scholar] [CrossRef] [Green Version]

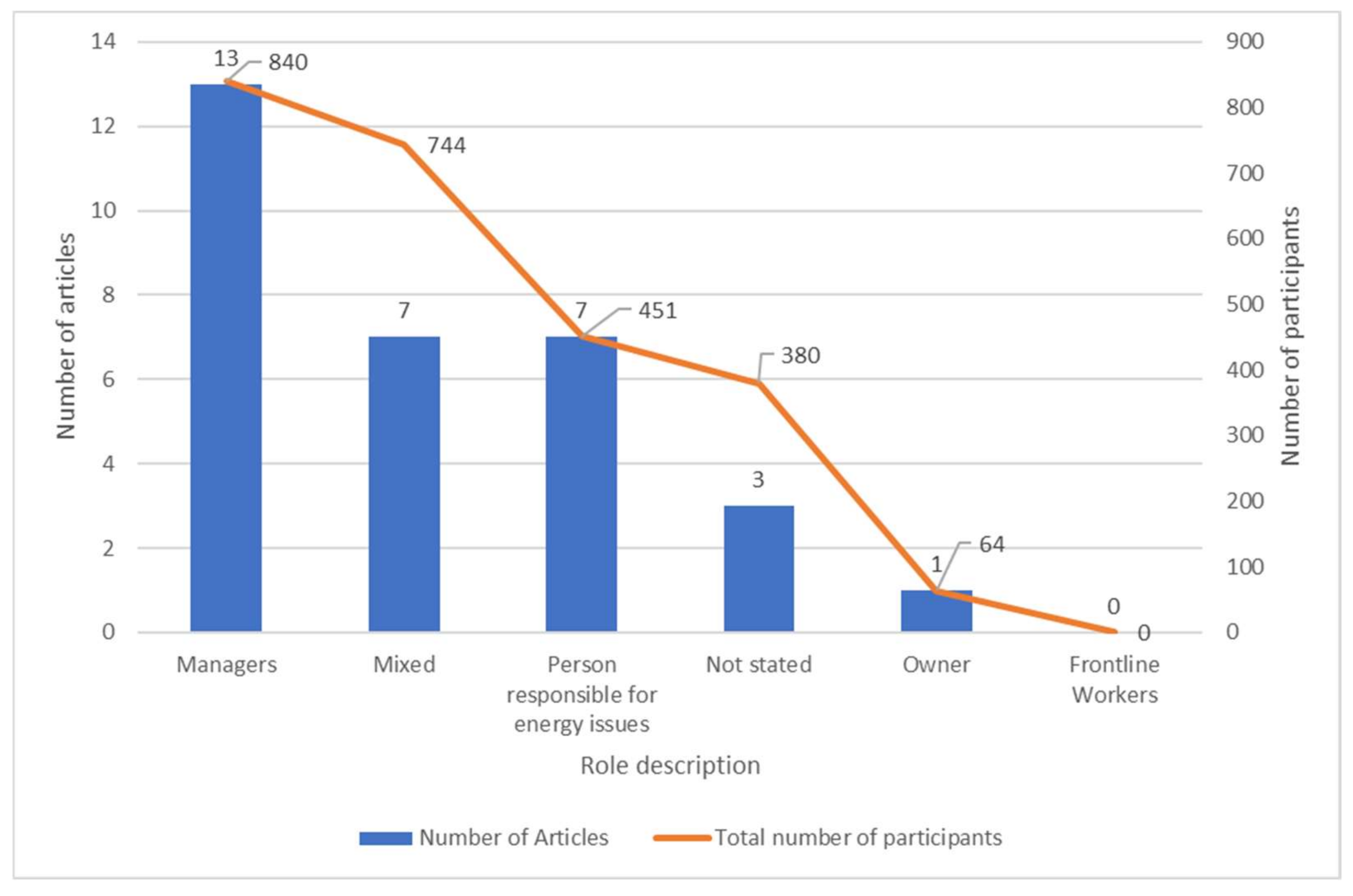

| Data Source (n = 61) | Role Description for Survey and Interview (n = 31) | Role Description for All Case Studies (n = 9) | Study Scope (n = 61) | Company Size (n = 61) | Energy-Intensity (n = 61) | Economic Dev. (n = 61). | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Survey or/and Interview | 31 | Manager | 13 | 2 | All energy efficiency measures | 45 | Small to medium enterprise | 10 | Energy-intensive | 18 | OECD | 36 |

| Case study for intervention | 6 | Frontline workers | 0 | 2 | Managerial only | 4 | Large enterprise | 15 | Non energy-intensive | 13 | Non-OECD | 11 |

| Case study for analysis | 7 | Person responsible for energy issues | 7 | 0 | Technology only | 6 | Multiple | 16 | Energy-intensive and Non energy-intensive | 18 | OECD and non-OECD | 3 |

| Literature Review | 7 | Mixed | 7 | 3 | Investment only | 4 | Not stated | 20 | Not stated | 12 | BRIC | 7 |

| Other | 10 | Owner | 1 | 0 | Not stated | 2 | Not stated | 11 | ||||

| Engineers | 0 | 2 | ||||||||||

| Not stated | 3 | 0 | ||||||||||

| Author | Data Source | Role Description | Participant |

|---|---|---|---|

| [41] | Case study for analysis | Mixed | Stakeholders—for example, staff at the companies, plant manufacturers and governmental institutions |

| [42] | Case study for analysis | Mixed | Management and employees and production associates and technical staff |

| [43] | Case study for intervention | Mixed | Mixed energy specialists, global leaders and project team members from different departments at the plant |

| [44] | Survey and/or interview | Mixed | Staff from production and quality departments |

| [45] | Survey and/or interview | Mixed | Owner, energy management, accounting production workers, maintenance engineering, human resources, marketing, trainees |

| [46] | Survey and/or interview | Mixed | Experienced workers in the field from mining companies vendors engineering companies and academia (field refers to field of study) |

| [47] | Survey and/or interview | Mixed | Managers are the typical respondent (comment is made on shop floor perspective) |

| [14] | Survey and/or interview | Mixed | One from top management and one from the energy group |

| [25] | Survey and/or interview | Mixed | One from top management and one from the energy group |

| [48] | Survey and/or interview | Mixed | Energy management personnel |

| Repeated Words and Phrases | Number of Papers | % of Total Drivers |

|---|---|---|

| Cost-saving/cost reductions | 14 | 16 |

| Rising/higher energy prices | 7 | 8 |

| Long term energy strategy | 5 | 6 |

| Company image or reputation | 4 | 5 |

| Information | 3 | 3 |

| Environment | 3 | 3 |

| Management commitment | 3 | 3 |

| Mapping to Lawrence, Nehler [24] | Mapping to Solnordal and Foss [16] | Mapping to Trianni, Cagno [15] | |||

|---|---|---|---|---|---|

| Driver Category | % of Drivers | Driver Category | % of Drivers | Driver Category | % of Drivers |

| Economic | 60 | Economic | 41 | Economic (internal and external) | 32 |

| Organisational | 16 | Organisational | 25 | Regulatory (internal) | 17 |

| Policy Instruments | 8 | Regulatory (external) | 19 | ||

| Knowledge-based | 14 | ||||

| Market | 18 | ||||

| Vocational Training (internal and external) | 0 | ||||

| Informative (internal and external) | 14 | ||||

| Not mapped | 10 (6 papers) | 8 (6 papers) | 18 (13 papers) | ||

| Size | Energy Intensity | Economic Development | Tot. l | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Driver Category | Driver Sub-Category | Small to Medium Enterprises (n = 8) | Large (n = 7) | Energy- Intensive (n = 11) | Non Energy- Intensive (n = 6) | OECD (n = 19) | Non-OECD (n = 9) | BRIC (n = 2) | |

| % | % | % | % | % | % | % | % | ||

| Economic | Technology | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Operating Costs | 33 | 33 | 41 | 39 | 33 | 44 | 33 | 35 | |

| Finance | 17 | 0 | 0 | 6 | 9 | 0 | 0 | 6 | |

| Organisational | Organisational Structure | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Management | 13 | 29 | 31 | 6 | 17 | 19 | 0 | 17 | |

| Competence | 0 | 5 | 10 | 0 | 8 | 4 | 17 | 8 | |

| Market | Market Forces | 4 | 19 | 6 | 22 | 13 | 7 | 0 | 10 |

| Ownership | 4 | 0 | 3 | 6 | 0 | 7 | 0 | 2 | |

| Network and Information | 13 | 5 | 0 | 5 | 6 | 4 | 17 | 6 | |

| Policy Instruments | Policy and Regulation | 8 | 0 | 6 | 11 | 6 | 11 | 17 | 8 |

| Not mapped | 8 | 9 | 3 | 5 | 8 | 4 | 16 | 8 | |

| Total | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Smith, K.M.; Wilson, S.; Lant, P.; Hassall, M.E. How Do We Learn about Drivers for Industrial Energy Efficiency—Current State of Knowledge. Energies 2022, 15, 2642. https://doi.org/10.3390/en15072642

Smith KM, Wilson S, Lant P, Hassall ME. How Do We Learn about Drivers for Industrial Energy Efficiency—Current State of Knowledge. Energies. 2022; 15(7):2642. https://doi.org/10.3390/en15072642

Chicago/Turabian StyleSmith, Kelly M., Stephen Wilson, Paul Lant, and Maureen E. Hassall. 2022. "How Do We Learn about Drivers for Industrial Energy Efficiency—Current State of Knowledge" Energies 15, no. 7: 2642. https://doi.org/10.3390/en15072642

APA StyleSmith, K. M., Wilson, S., Lant, P., & Hassall, M. E. (2022). How Do We Learn about Drivers for Industrial Energy Efficiency—Current State of Knowledge. Energies, 15(7), 2642. https://doi.org/10.3390/en15072642