Environmental Impact Analysis of Portland Cement (CEM1) Using the Midpoint Method

Abstract

:1. Introduction

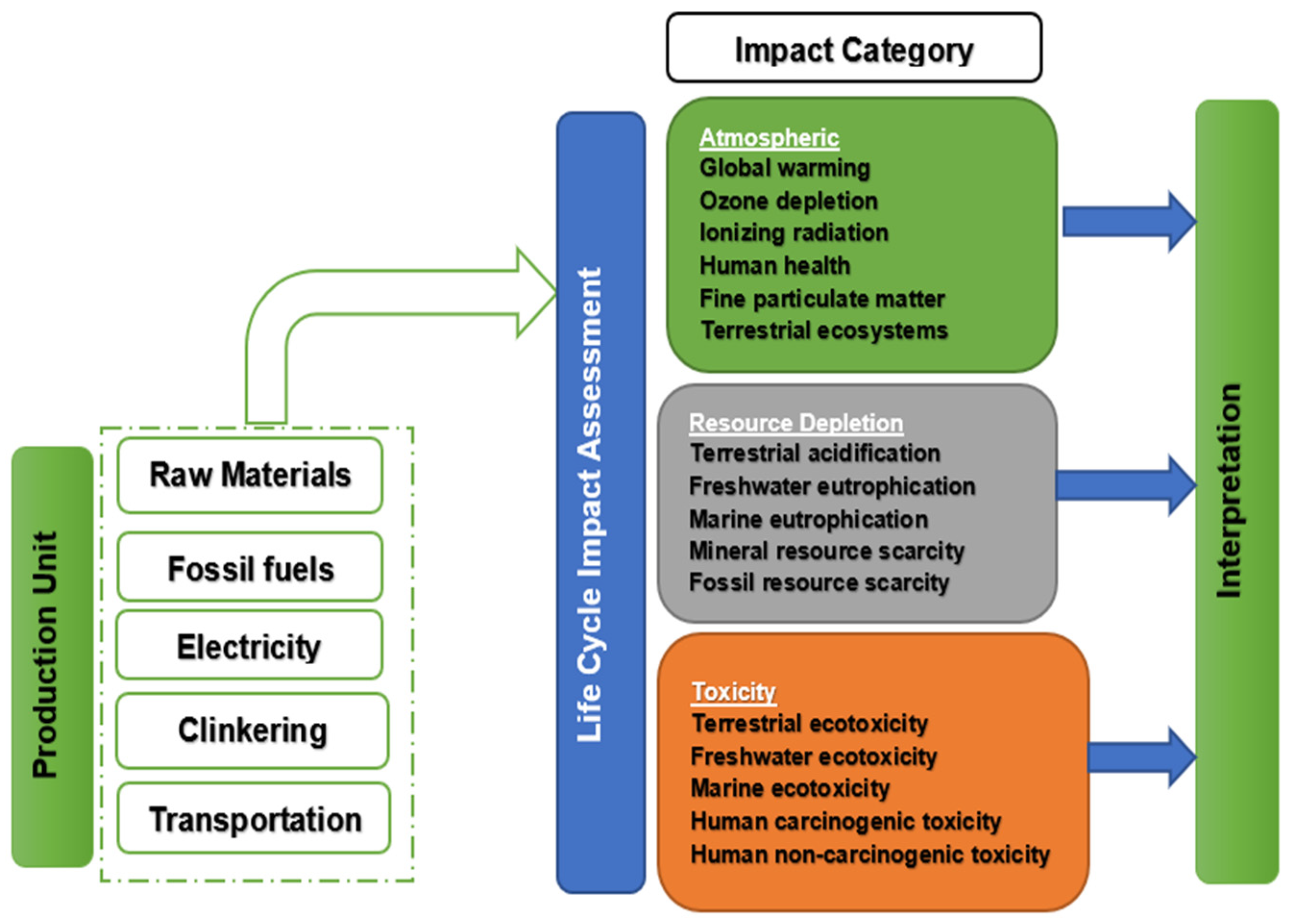

2. A Recipe

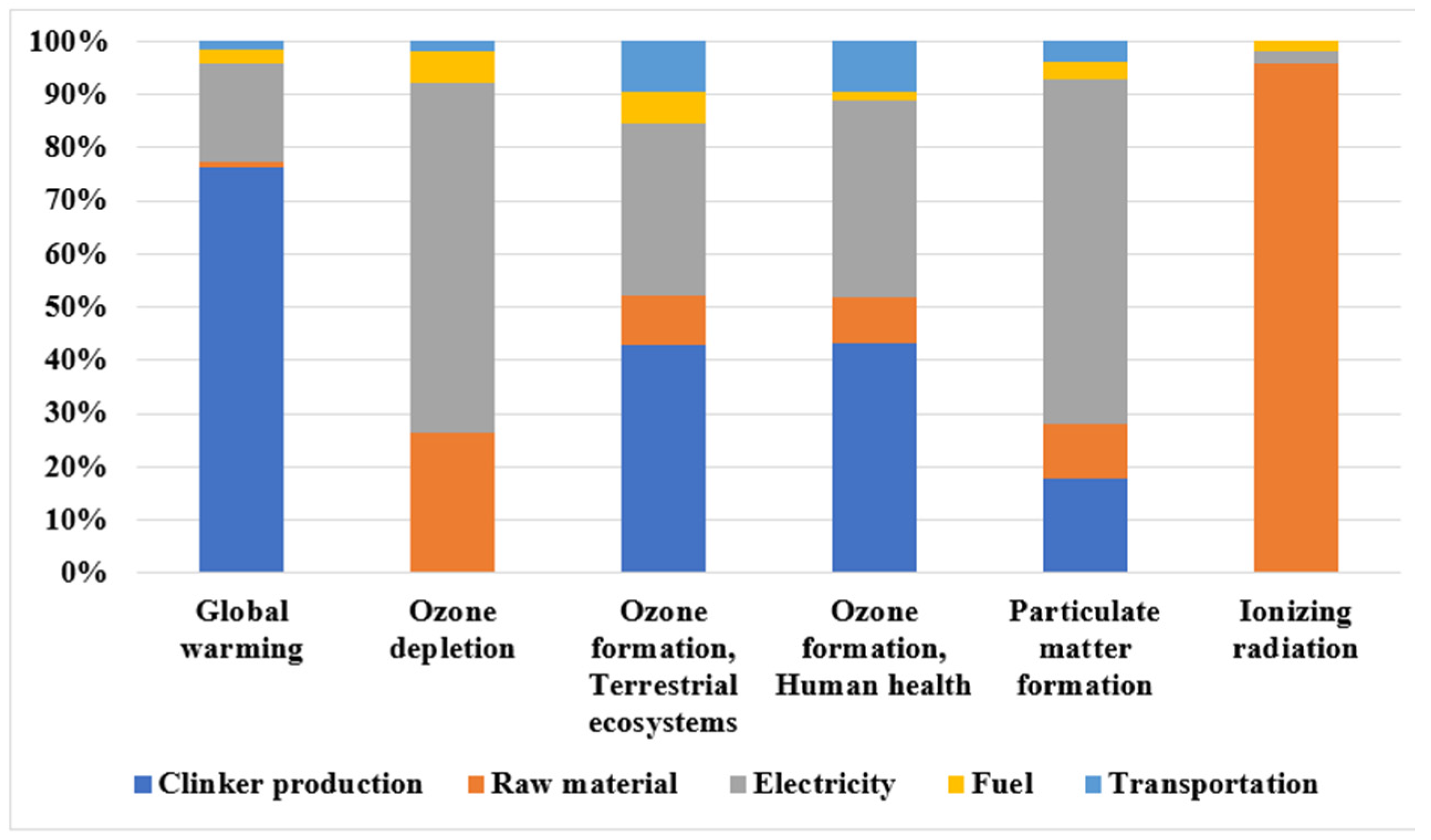

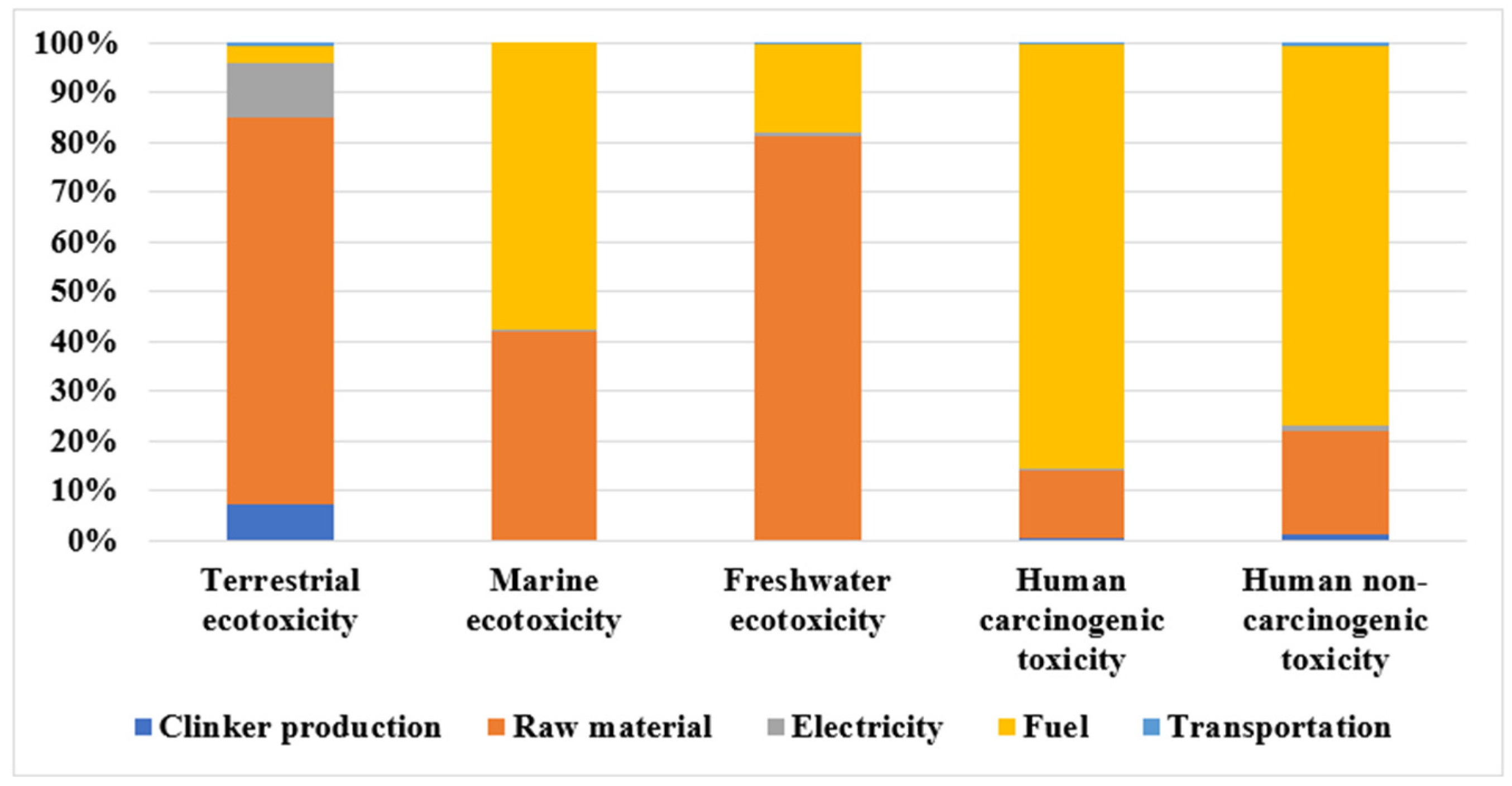

3. Methodology

3.1. Goal and Scope Definition

3.2. Life Cycle Inventory

3.3. Life Cycle Impact Assessment

- = impact category j indicator

- = size of the intervention of type i

- subscript i = substance,

- s = location of the emission,

- l = related exposure area of the receptor

- t = period during which the potential contribution to the impact is considered [93].

- k = impact category

- N = normalized indicator

- S = category indicator from the characterization phase

- R = reference value.

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Worrell, E.; Price, L.; Martin, N.; Hendriks, C.; Meida, L.O. Carbon dioxide emissions from the global cement industry. Annu. Rev. Energy Environ. 2001, 26, 303–329. [Google Scholar] [CrossRef]

- WBCSD. The Cement Sustainability Initiative (CSI) Recycling Concrete Excutive Summary; World Business Council for Sustainable Development: Geneva, Switzerland, 2009. [Google Scholar]

- IEA; WBCSD. Cement Technology Roadmap 2009—Carbon Emissions Reductions up to 2050; Energy Agency (IEA): Paris, France, 2021; pp. 1–2. [Google Scholar]

- Miccoli, S.; Finucci, F.; Murro, R. Criteria and procedures for regional environmental regeneration: A European strategic project. In Applied Mechanics and Materials; Trans Tech Publications Ltd.: Bäch, Switzerland, 2014; Volume 675, pp. 401–405. [Google Scholar]

- Usón, A.A.; Ferreira, G.; López-Sabirón, A.M.; Sastresa, E.L.; De Guinoa, A.S. Characterisation and environmental analysis of sewage sludge as secondary fuel for cement manufacturing. Chem. Eng. Trans. 2012, 29, 457–462. [Google Scholar]

- Summerbell, D.L.; Barlow, C.Y.; Cullen, J.M. Potential reduction of carbon emissions by performance improvement: A cement industry case study. J. Clean. Prod. 2016, 135, 1327–1339. [Google Scholar] [CrossRef]

- Nadal, M.; Schuhmacher, M.; Domingo, J.L. Cost–benefit analysis of using sewage sludge as alternative fuel in a cement plant: A case study. Environ. Sci. Pollut. Res. 2009, 16, 322–328. [Google Scholar] [CrossRef] [PubMed]

- Feiz, R.; Ammenberg, J.; Baas, L.; Eklund, M.; Helgstrand, A.; Marshall, R. Improving the CO2 performance of cement, part I: Utilizing life-cycle assessment and key performance indicators to assess development within the cement industry. J. Clean. Prod. 2015, 98, 272–281. [Google Scholar] [CrossRef] [Green Version]

- Cao, Z.; Shen, L.; Zhao, J.; Liu, L.; Zhong, S.; Sun, Y.; Yang, Y. Toward a better practice for estimating the CO2 emission factors of cement production: An experience from China. J. Clean. Prod. 2016, 139, 527–539. [Google Scholar] [CrossRef]

- IEA. “Cement”, IEA Report. 2020. Available online: https://www.iea.org/reports/cement (accessed on 15 January 2022).

- Pacheco-Torgal, F.; Cabeza, L.F.; Labrincha, J.; De Magalhaes, A.G. Eco-Efficient Construction and Building Materials: Life Cycle Assessment (LCA), Eco-Labelling and Case Studies; Woodhead Publishing: Cambridge, UK, 2014. [Google Scholar]

- IEA. Enrgy Technology Transitions for Industry, Paris, France. 2009. Available online: https://www.iea.org/publications/freepublications/publication/industry2009.pdf (accessed on 15 January 2022).

- IEAGHG. CO2 Capture in the Cement Industry. IEA Greenhouse Gas R&D Programme, Technical Study, Report, UK 2008/3; IEA Greenhouse Gas R & D Programme: Cheltenham, UK, 2008. [Google Scholar]

- Madlool, N.; Saidur, R.; Hossain, M.; Rahim, N. A critical review on energy use and savings in the cement industries. Renew. Sustain. Energy Rev. 2011, 15, 2042–2060. [Google Scholar] [CrossRef]

- Ali, M.; Saidur, R.; Hossain, M. A review on emission analysis in cement industries. Renew. Sustain. Energy Rev. 2011, 15, 2252–2261. [Google Scholar] [CrossRef]

- Ige, O.E. Energy Efficiency in the South African Cement Finishing Plant: Drivers, Barriers and Improvement; UKZN: Durban, South Africa, 2018. [Google Scholar]

- Ige, O.E.; Inambao, F.L.; Olanrewaju, O.A.; Duffy, K.J.; Collins, O.C. Drivers and Barriers to Industrial Energy Efficiency: A Case Study of South Africa’s Cement Finishing Mill Plant; Acosta, M.J., Ed.; Nova Science Publishers: New York, NY, USA, 2020; Volume 33, p. 45. [Google Scholar]

- Ige, O.E.; Olanrewaju, O.A.; Duffy, K.J.; Collins, O.C. A review of the effectiveness of Life Cycle Assessment for gauging environmental impacts from cement production. J. Clean. Prod. 2021, 324, 129213. [Google Scholar] [CrossRef]

- Wang, J.; Dai, Y.; Gao, L. Exergy analyses and parametric optimizations for different cogeneration power plants in cement industry. Appl. Energy 2009, 86, 941–948. [Google Scholar] [CrossRef]

- Singhi, M.; Bhargava, R. Sustainable Indian cement industry. In Proceedings of the Workshop on International comparison of Industrial Energy Efficiency, New Delhi, India, 27–28 January 2010; pp. 27–28. [Google Scholar]

- Lidbetter, R.T. Demand Side Management Opportunities for a Typical South African Cement Plant; North-West University: Pochefstrum, South Africa, 2010. [Google Scholar]

- Kumar, A. Global warming, climate change and greenhouse gas mitigation. In Biofuels: Greenhouse Gas Mitigation and Global Warming; Springer: New Delhi, India, 2018; pp. 1–16. [Google Scholar]

- O’Connor, R.E.; Bord, R.J.; Yarnal, B.; Wiefek, N. Who wants to reduce greenhouse gas emissions? Soc. Sci. Q. 2002, 83, 1–17. [Google Scholar] [CrossRef]

- Dodman, D. Blaming cities for climate change? An analysis of urban greenhouse gas emissions inventories. Environ. Urban. 2009, 21, 185–201. [Google Scholar] [CrossRef] [Green Version]

- Statistics, I. Key World Energy Statistics; Paris International Energy Agency: Paris, France, 2014. [Google Scholar]

- Arto, I.; Capellán-Pérez, I.; Lago, R.; Bueno, G.; Bermejo, R. The energy requirements of a developed world. Energy Sustain. Dev. 2016, 33, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Anand, S.; Vrat, P.; Dahiya, R. Application of a system dynamics approach for assessment and mitigation of CO2 emissions from the cement industry. J. Environ. Manag. 2006, 79, 383–398. [Google Scholar] [CrossRef] [PubMed]

- Bekun, F.V.; Emir, F.; Sarkodie, S.A. Another look at the relationship between energy consumption, carbon dioxide emissions, and economic growth in South Africa. Sci. Total Environ. 2019, 655, 759–765. [Google Scholar] [CrossRef] [PubMed]

- DEA. GHG Inventory for South Africa 2000–2010; Forestry, Fisheries and the Environment, Republic of South Africa: Pretoria, South Africa, 2013.

- DEA. GHG National Inventory Report For South Africa 2000–2010; Department of Environmental Affairs (DEA): Pretoria, South Africa, 2014. Available online: http://www.saaqis.org.za (accessed on 9 January 2022).

- Mann, M.; Spath, P. A life cycle assessment of biomass cofiring in a coal-fired power plant. Clean Prod. Process. 2001, 3, 81–91. [Google Scholar] [CrossRef]

- Whitaker, M.; Heath, G.A.; O’Donoughue, P.; Vorum, M. Life cycle greenhouse gas emissions of coal-fired electricity generation: Systematic review and harmonization. J. Ind. Ecol. 2012, 16, S53–S72. [Google Scholar] [CrossRef]

- Inglesi, R.; Pouris, A. Forecasting electricity demand in South Africa: A critique of Eskom’s projections. S. Afr. J. Sci. 2010, 106, 50–53. [Google Scholar] [CrossRef]

- Gross, C. Electricity Generation Options considered by Eskom. In Presentation at the Energy Planning Colloquium; Eskom Holding: Johannesburg, South Africa, 2012; Volume 30. [Google Scholar]

- Swanepoel, J.A.; Mathews, E.H.; Vosloo, J.; Liebenberg, L. Integrated energy optimisation for the cement industry: A case study perspective. Energy Convers. Manag. 2014, 78, 765–775. [Google Scholar] [CrossRef]

- Humphreys, K.; Mahasenan, M. Towards a Sustainable Cement Industry. Substudy 8: Climate Change; World Business Conuncil for Sustainable Development: Geneva, Switzerland, 2002. [Google Scholar]

- Karagiannidis, A. Waste to Energy; Opportunities and Challenges for Developing and Transition Economies; Springer: London, UK, 2012. [Google Scholar]

- Scalet, B.M. Best Available Techniques (BAT) Reference Document for the Production of Cement, Lime and Magnesium Oxide (CLM BREF); European Commission Joint Research Centre Institute for Prospective Technological Studies: Luxembourg, 2013. [Google Scholar]

- Phair, J.W. Green chemistry for sustainable cement production and use. Green Chem. 2006, 8, 763–780. [Google Scholar] [CrossRef]

- Josa, A.; Aguado, A.; Cardim, A.; Byars, E. Comparative analysis of the life cycle impact assessment of available cement inventories in the EU. Cem. Concr. Res. 2007, 37, 781–788. [Google Scholar] [CrossRef] [Green Version]

- Al-Dadi, M.; Hassan, H.; Sharshar, T.; Arida, H.; Badran, H. Environmental impact of some cement manufacturing plants in Saudi Arabia. J. Radioanal. Nucl. Chem. 2014, 302, 1103–1117. [Google Scholar] [CrossRef]

- Galvez-Martos, J.-L.; Schoenberger, H. An analysis of the use of life cycle assessment for waste co-incineration in cement kilns. Resour. Conserv. Recycl. 2014, 86, 118–131. [Google Scholar] [CrossRef]

- ISO/TS 14072:2014; Environmental Management Life Cycle Assessment Requirements and Guidelines for Organizational Life Cycle Assessment. International Organization for Standardization: Geneva, Switzerland, 2014. Available online: https://www.iso.org/obp/ui/#iso:std:iso:ts:14072:ed-1:v1:en (accessed on 1 March 2022).

- ISO. 14040 Environmental Management: Life Cycle Assessment; Principles and Framework; International Organization for Standardization: Geneva, Switzerland, 2006. [Google Scholar]

- ISO. 14044 Environmental Management: Life Cycle Assessment; Requirements and Guidelines; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- Petek Gursel, A.; Masanet, E.; Horvath, A.; Stadel, A. Life-cycle inventory analysis of concrete production: A critical review. Cem. Concr. Compos. 2014, 51, 38–48. [Google Scholar] [CrossRef]

- Centre, J. ILCD Handbook: Analysing of Existing Environmental Impact Assessment Methodologies for Use in Life Cycle Assessment; Euronpean Union: Rome, Italy, 2010. [Google Scholar]

- Huntzinger, D.N.; Eatmon, T.D. A life-cycle assessment of Portland cement manufacturing: Comparing the traditional process with alternative technologies. J. Clean. Prod. 2009, 17, 668–675. [Google Scholar] [CrossRef]

- Boesch, M.E.; Hellweg, S. Identifying improvement potentials in cement production with life cycle assessment. Environ. Sci. Technol. 2010, 44, 9143–9149. [Google Scholar] [CrossRef]

- Amrina, E.; Vilsi, A.L. Key performance indicators for sustainable manufacturing evaluation in cement industry. Procedia Cirp 2015, 26, 19–23. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Chan, H.K.; Li, D. A case study of an integrated fuzzy methodology for green product development. Eur. J. Oper. Res. 2015, 241, 212–223. [Google Scholar] [CrossRef]

- Blengini, G.A.; Busto, M.; Fantoni, M.; Fino, D. Eco-efficient waste glass recycling: Integrated waste management and green product development through LCA. Waste Manag. 2012, 32, 1000–1008. [Google Scholar] [CrossRef] [PubMed]

- Mazari, M.; Aval, S.F.; Satani, S.M.; Corona, D.; Garrido, J. Developing Guidelines for Assessing the Effectiveness of Intelligent Compaction Technology; Mineta Transportation Institute Publication: San Jose, CA, USA, 2021. [Google Scholar] [CrossRef]

- Satani, S.; Aval, S.; Garrido, J.; Mazari, M. Preliminary evaluation of using intelligent compaction for life cycle assessment and life cycle cost analysis of pavement structures. In Pavement, Roadway, and Bridge Life Cycle Assessment 2020; Taylor & Franscis Group: London, UK, 2020; pp. 460–468. [Google Scholar]

- Boughrara, S.; Aksas, H.; Louhab, K. Comparative Study of Wet and Dry Process of Cement Manufacturing Using Life Cycle Assessment Approach; University of Boumerdes: Boumerdes, Algeria, 2014. [Google Scholar]

- García-Gusano, D.; Garraín, D.; Herrera, I.; Cabal, H.; Lechón, Y. Life Cycle Assessment of applying CO2 post-combustion capture to the Spanish cement production. J. Clean. Prod. 2015, 104, 328–338. [Google Scholar] [CrossRef]

- Stafford, F.N.; Raupp-Pereira, F.; Labrincha, J.A.; Hotza, D. Life cycle assessment of the production of cement: A Brazilian case study. J. Clean. Prod. 2016, 137, 1293–1299. [Google Scholar] [CrossRef]

- Morsali, S. Emissions from portland cement production using life cycle assessment inventory and method. Environ. Energy Econ 2016, 1, 1–8. [Google Scholar]

- Chen, W.; Hong, J.; Xu, C. Pollutants generated by cement production in China, their impacts, and the potential for environmental improvement. J. Clean. Prod. 2015, 103, 61–69. [Google Scholar] [CrossRef]

- Hong, J.; Li, X. Environmental assessment of sewage sludge as secondary raw material in cement production—A case study in China. Waste Manag. 2011, 31, 1364–1371. [Google Scholar] [CrossRef] [PubMed]

- Strazza, C.; Del Borghi, A.; Gallo, M.; Del Borghi, M. Resource productivity enhancement as means for promoting cleaner production: Analysis of co-incineration in cement plants through a life cycle approach. J. Clean. Prod. 2011, 19, 1615–1621. [Google Scholar] [CrossRef]

- Valderrama, C.; Granados, R.; Cortina, J.L.; Gasol, C.M.; Guillem, M.; Josa, A. Implementation of best available techniques in cement manufacturing: A life-cycle assessment study. J. Clean. Prod. 2012, 25, 60–67. [Google Scholar] [CrossRef]

- Dabbaghi, F.; Sadeghi-Nik, A.; Libre, N.A.; Nasrollahpour, S. Characterizing fiber reinforced concrete incorporating zeolite and metakaolin as natural pozzolans. In Structures; Elsevier: Amsterdam, The Netherlands, 2021; pp. 2617–2627. [Google Scholar]

- Mousavi, M.A.; Sadeghi-Nik, A.; Bahari, A.; Jin, C.; Ahmed, R.; Ozbakkaloglu, T.; de Brito, J. Strength optimization of cementitious composites reinforced by carbon nanotubes and Titania nanoparticles. Constr. Build. Mater. 2021, 303, 124510. [Google Scholar] [CrossRef]

- Mazari, M.; Aval, S.F.; Rodriguez-Nikl, T. Evaluating the Use of Recycled and Sustainable Materials in Self-Consolidating Concrete for Underground Infrastructure Applications; U.S. Department of Transportation. Office of the Assistant Secretary for Research and Technology: Washington, DC, USA, 2020.

- Bahari, A.; Sadeghi-Nik, A.; Cerro-Prada, E.; Sadeghi-Nik, A.; Roodbari, M.; Zhuge, Y. One-step random-walk process of nanoparticles in cement-based materials. J. Cent. South Univ. 2021, 28, 1679–1691. [Google Scholar] [CrossRef]

- Bahari, A.; Sadeghi-Nik, A.; Shaikh, F.U.A.; Sadeghi-Nik, A.; Cerro-Prada, E.; Mirshafiei, E.; Roodbari, M. Experimental studies on rheological, mechanical, and microstructure properties of self-compacting concrete containing perovskite nanomaterial. Struct. Concr. 2021, 29, 19262–19272. [Google Scholar] [CrossRef]

- Askarian, M.; Fakhretaha Aval, S.; Joshaghani, A. A comprehensive experimental study on the performance of pumice powder in self-compacting concrete (SCC). J. Sustain. Cement-Based Mater. 2018, 7, 340–356. [Google Scholar] [CrossRef]

- Vahabi, M.Y.; Tahmouresi, B.; Mosavi, H.; Aval, S.F. Effect of pre-coating lightweight aggregates on the self-compacting concrete. Struct. Concr. 2021, 1–12. [Google Scholar] [CrossRef]

- Tüfekçi, M.; Demirbaş, A.; Genc, H. Evaluation of steel furnace slags as cement additives. Cem. Concr. Res. 1997, 27, 1713–1717. [Google Scholar] [CrossRef]

- Xu, X.; Tian, Y. Application of Electric Arc Furnace Dust in Cement Production. Iron Steel 1998, 33, 61–64. [Google Scholar]

- Hilton, R.G. Use of Stabilized EAFD as a Raw Material in the Production of a Portland Cement Clinker. U.S. Patent 5,853,474, 29 December 1998. [Google Scholar]

- Yüksel, İ. A review of steel slag usage in construction industry for sustainable development. Environ. Dev. Sustain. 2017, 19, 369–384. [Google Scholar] [CrossRef]

- Zhang, X.; Zhao, S.; Liu, Z.; Wang, F. Utilization of steel slag in ultra-high performance concrete with enhanced eco-friendliness. Constr. Build. Mater. 2019, 214, 28–36. [Google Scholar] [CrossRef]

- Josa, A.; Aguado, A.; Heino, A.; Byars, E.; Cardim, A. Comparative analysis of available life cycle inventories of cement in the EU. Cem. Concr. Res. 2004, 34, 1313–1320. [Google Scholar] [CrossRef] [Green Version]

- Chen, C.; Habert, G.; Bouzidi, Y.; Jullien, A. Environmental impact of cement production: Detail of the different processes and cement plant variability evaluation. J. Clean. Prod. 2010, 18, 478–485. [Google Scholar] [CrossRef]

- Beltran, L.; Arnesh, T. Uses of Alternative Fuels as Best Practices to Reduce CO2 Emissions from the South African Cement Industry. In Proceedings of the International Conference on Industrial Engineering and Operations Management Pretoria/Johannesburg, Bogota, Colombia, 29 October–1 November 2018. [Google Scholar]

- Benhelal, E.; Zahedi, G.; Shamsaei, E.; Bahadori, A. Global strategies and potentials to curb CO2 emissions in cement industry. J. Clean. Prod. 2013, 51, 142–161. [Google Scholar] [CrossRef]

- Hasanbeigi, A.; Springer, C. California’s Cement Industry: Failing the Climate Challenge; Global Efficiency Intelligence: San Francisco, CA, USA, 2019. [Google Scholar]

- Wang, Y.; Zhu, Q.; Geng, Y. Trajectory and driving factors for GHG emissions in the Chinese cement industry. J. Clean. Prod. 2013, 53, 252–260. [Google Scholar] [CrossRef]

- Sagastume Gutiérrez, A.; Cabello Eras, J.J.; Gaviria, C.A.; Van Caneghem, J.; Vandecasteele, C. Improved selection of the functional unit in environmental impact assessment of cement. J. Clean. Prod. 2017, 168, 463–473. [Google Scholar] [CrossRef]

- Tun, T.Z.; Bonnet, S.; Gheewala, S.H. Life cycle assessment of Portland cement production in Myanmar. Int. J. Life Cycle Assess. 2020, 25, 2106–2121. [Google Scholar] [CrossRef]

- Marceau, M.; Nisbet, M.A.; Van Geem, M.G. Life Cycle Inventory of Portland Cement Manufacture; Portland Cement Association: Skokie, IL, USA, 2006. [Google Scholar]

- Thwe, E.; Khatiwada, D.; Gasparatos, A. Life cycle assessment of a cement plant in Naypyitaw, Myanmar. Clean. Environ. Syst. 2021, 2, 100007. [Google Scholar] [CrossRef]

- Rosyid, A.; Boedisantoso, R.; Iswara, A. Environmental impact studied using life cycle assessment on cement industry. In Proceedings of IOP Conference Series: Earth and Environmental Science; IOP Publishing: Philadelphia, PA, USA, 2020; Volume 506, p. 012024. [Google Scholar]

- Goedkoop, M.; De Schryver, A.; Oele, M.; Durksz, S.; de Roest, D. Introduction to LCA with SimaPro 7; PRé Consultants: San Francisco, CA, USA, 2008. [Google Scholar]

- PRé Sustainability. “SimaPro”, Software to Measure and Improve the Impact of Your Product Life Cycle. 2017. Available online: Pre-sustainability.com/simapro (accessed on 13 June 2017).

- Goedkoop, M.; Heijungs, R.; Huijbregts, M.; De Schryver, A.; Struijs, J.; Van Zelm, R. ReCiPe 2008: A life Cycle Impact Assessment Method which Comprises Harmonised Category Indicators at the Midpoint and the Endpoint Level; PRé Consultants: Amersfoort, The Netherland, 2009; Volume 1, pp. 1–126. [Google Scholar]

- Moreno Ruiz, E.; Valsasina, L.; FitzGerald, D.; Symeonidis, A.; Turner, D.; Müller, J.; Minas, N.; Bourgault, G.; Vadenbo, C.; Ioannidou, D. Cement Production: Documentation of Changes Implemented in Ecoinvent Database v3. 7 & v3. 7.1. Documentation Cement Production, Portland-ZA”, Ecoinvent Association, Allocation, Cut-off ed. Identifying Improvement Potentials in Cement Production with Life Cycle Assessment 2010, 2019; Ecoinvent Association: Zürich, Switzerland, 2020. [Google Scholar]

- Dreyer, L.C.; Niemann, A.L.; Hauschild, M.Z. Comparison of three different LCIA methods: EDIP97, CML2001 and Eco-indicator 99. Int. J. Life Cycle Assess. 2003, 8, 191–200. [Google Scholar] [CrossRef]

- Azapagic, A.; Clift, R. The application of life cycle assessment to process optimisation. Comput. Chem. Eng. 1999, 23, 1509–1526. [Google Scholar] [CrossRef]

- Huijbregts, M.A.J.; Thissen, U.; Guinée, J.B.; Jager, T.; Kalf, D.; van de Meent, D.; Ragas, A.M.J.; Wegener Sleeswijk, A.; Reijnders, L. Priority assessment of toxic substances in life cycle assessment. Part I: Calculation of toxicity potentials for 181 substances with the nested multi-media fate, exposure and effects model USES–LCA. Chemosphere 2000, 41, 541–573. [Google Scholar] [CrossRef]

- Pennington, D.W.; Potting, J.; Finnveden, G.; Lindeijer, E.; Jolliet, O.; Rydberg, T.; Rebitzer, G. Life cycle assessment Part 2: Current impact assessment practice. Environ. Int. 2004, 30, 721–739. [Google Scholar] [CrossRef] [PubMed]

- Finnveden, G.; Hofstetter, P.; Bare, J.; Basson, L.; Ciroth, A.; Mettier, T.; Seppälä, J.; Johansson, J.; Norris, G.; Volkwein, S. Normalization, grouping and weighting in life cycle impact assessment. In Life Cycle Impact Assessment: Striving towards Best Practice. Society of Environmental Toxicology and Chemistry (SETAC); SETAC Press: Pensacola, FL, USA, 2002; pp. 177–208. [Google Scholar]

- Pré Consultants, B. SimaPro. 2016. Available online: https://network.simapro.com/esuservices (accessed on 15 December 2021).

- Uwasu, M.; Hara, K.; Yabar, H. World cement production and environmental implications. Environ. Dev. 2014, 10, 36–47. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, G.; Chen, B.; Song, D.; Qi, J.; Liu, X. Analysis of CO2 emission for the cement manufacturing with alternative raw materials: A LCA-based framework. Energy Procedia 2014, 61, 2541–2545. [Google Scholar] [CrossRef] [Green Version]

- Feiz, R.; Ammenberg, J.; Baas, L.; Eklund, M.; Helgstrand, A.; Marshall, R. Improving the CO2 performance of cement, part II: Framework for assessing CO2 improvement measures in the cement industry. J. Clean. Prod. 2015, 98, 282–291. [Google Scholar] [CrossRef] [Green Version]

- Vatopoulos, K.; Tzimas, E. Assessment of CO2 capture technologies in cement manufacturing process. J. Clean. Prod. 2012, 32, 251–261. [Google Scholar] [CrossRef]

- Ammenberg, J.; Baas, L.; Eklund, M.; Feiz, R.; Helgstrand, A.; Marshall, R. Improving the CO2 performance of cement, part III: The relevance of industrial symbiosis and how to measure its impact. J. Clean. Prod. 2015, 98, 145–155. [Google Scholar] [CrossRef] [Green Version]

- Güereca, L.P.; Torres, N.; Juárez-López, C.R. The co-processing of municipal waste in a cement kiln in Mexico. A life-cycle assessment approach. J. Clean. Prod. 2015, 107, 741–748. [Google Scholar] [CrossRef]

- Hu, D.; Guo, Z.; Wang, Z.; Xiao, Q. Metabolism analysis and eco-environmental impact assessment of two typical cement production systems in Chinese enterprises. Ecol. Inform. 2015, 26, 70–77. [Google Scholar] [CrossRef]

- Zhang, J.; Cheng, J.C.; Lo, I.M. Life cycle carbon footprint measurement of Portland cement and ready mix concrete for a city with local scarcity of resources like Hong Kong. Int. J. Life Cycle Assess. 2014, 19, 745–757. [Google Scholar] [CrossRef]

- García-Gusano, D.; Herrera, I.; Garraín, D.; Lechón, Y.; Cabal, H. Life cycle assessment of the Spanish cement industry: Implementation of environmental-friendly solutions. Clean Technol. Environ. Policy 2015, 17, 59–73. [Google Scholar] [CrossRef]

- Li, C.; Cui, S.; Nie, Z.; Gong, X.; Wang, Z.; Itsubo, N. The LCA of Portland cement production in China. Int. J. Life Cycle Assess. 2015, 20, 117–127. [Google Scholar] [CrossRef]

- Huijbregts, M.A.; Steinmann, Z.J.; Elshout, P.M.; Stam, G.; Verones, F.; Vieira, M.; Zijp, M.; Hollander, A.; Van Zelm, R. ReCiPe2016: A harmonised life cycle impact assessment method at midpoint and endpoint level. Int. J. Life Cycle Assess. 2017, 22, 138–147. [Google Scholar] [CrossRef]

- Neuffer, B.; Laney, M. Alternative Control Techniques Document Update: NOX Emissions from New Cement Kilns; US Environmental Protection Agency, Office of Air Quality Planning and Standards: Washington, DC, USA, 2007.

- Ottermann, E.W. Energy management challenges and opportunities in the South African cement industry. In Proceedings of the 2011 Proceedings of the 8th Conference on the Industrial and Commercial Use of Energy, Cape Town, South Africa, 16–17 August 2011; pp. 34–39. [Google Scholar]

- Ohanyere, C.; Alexander, M. The South African Cement Industry: A Review of Its Energy Efficiency and Environmental Performance Since 1980; University of Cape Town: Cape Town, South Africa, 2012. [Google Scholar]

- WBCSD. Guidelines for co-processing fuels and raw materials in cement manufacturing. In Cement Sustainability Initiative (CSI); World Business Council for Sustainable Development Geneva: Geneva, Switzerland, 2014. [Google Scholar]

- Tun, T.Z.; Bonnet, S.; Gheewala, S.H. Emission reduction pathways for a sustainable cement industry in Myanmar. Sustain. Prod. Consum. 2021, 27, 449–461. [Google Scholar] [CrossRef]

- Chatziaras, N.; Psomopoulos, C.; Themelis, N. Use of alternative fuels in cement industry. In Proceedings of the 12th International Conference on Protection and Restoration of the Environment, Skiathos Island, Greece, 29 June–3 July 2014; Volume 1, pp. 521–529. [Google Scholar]

| Amount | |

|---|---|

| Cement Factory | 5.36 × 10−11 unit |

| Input | |

| Clinker | 0.902 kg |

| Gypsum, mineral | 0.0475 kg |

| Limestone | 0.05 kg |

| Ethylene glycol | 0.00019 kg |

| Steel, low-alloyed | 5.25 × 10−5 kg |

| Electricity | 0.0376 kWh |

| Output | |

| Emissions to air (Heat, waste) | 0.135 MJ |

| Products (Cement, Portland) | 1 kg |

| Atmospheric | ||

|---|---|---|

| Environmental Indicator | Abbreviation | Unit |

| Global warming | GWP | kg CO2 eq |

| Ozone depletion | ODP | kg CFC11 eq |

| Ozone formation, Terrestrial ecosystem | EOFP | kg NOx eq |

| Ozone formation, Human health | HOFP | kg NOx eq |

| Particulate matter formation | PMFP | kg PM2.5 eq |

| Ionization radiation | IRP | kBq Co-60 eq |

| Resource Depletion | ||

| Terrestrial acidification | TAP | kg SO2 eq |

| Freshwater eutrophication | FEP | kg P eq |

| Marine eutrophication | MEP | kg N eq |

| Mineral resource scarcity | SOP | kg Cu eq |

| Fossil resource scarcity | FFP | kg oil eq |

| Toxicity | ||

| Human carcinogenic toxicity | HTPc | kg 1,4-DCB eq |

| Terrestrial ecotoxicity | TETP | kg 1,4-DCB eq |

| Freshwater ecotoxicity | FETP | kg 1,4-DCB eq |

| Marine ecotoxicity | METP | kg 1,4-DCB eq |

| Human non-carcinogenic toxicity | HTPnc | kg 1,4-DCB eq |

| Production Unit | Processes Considered |

|---|---|

| Raw materials | Limestone and steel. Clinker and ethylene glycol, including the inputs and outputs |

| Fossil fuels | Diesel, coal, light fuel oil and lubrication oil, including inputs and outputs. |

| Electricity | Electricity used in mills and other equipment, in agreement with South Africa production and distribution regulation |

| Transportation | The transportation of raw materials, fuels and energy resources from the extraction site up to the gate of the plant |

| Clinker production | Particulate matter, NOx, CO2, emitted by the kiln during clinker production |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ige, O.E.; Olanrewaju, O.A.; Duffy, K.J.; Collins, O.C. Environmental Impact Analysis of Portland Cement (CEM1) Using the Midpoint Method. Energies 2022, 15, 2708. https://doi.org/10.3390/en15072708

Ige OE, Olanrewaju OA, Duffy KJ, Collins OC. Environmental Impact Analysis of Portland Cement (CEM1) Using the Midpoint Method. Energies. 2022; 15(7):2708. https://doi.org/10.3390/en15072708

Chicago/Turabian StyleIge, Oluwafemi E., Oludolapo A. Olanrewaju, Kevin J. Duffy, and Obiora C. Collins. 2022. "Environmental Impact Analysis of Portland Cement (CEM1) Using the Midpoint Method" Energies 15, no. 7: 2708. https://doi.org/10.3390/en15072708

APA StyleIge, O. E., Olanrewaju, O. A., Duffy, K. J., & Collins, O. C. (2022). Environmental Impact Analysis of Portland Cement (CEM1) Using the Midpoint Method. Energies, 15(7), 2708. https://doi.org/10.3390/en15072708