1. Introduction

Climate change is a major challenge for the world community. European countries aim to achieve zero net emissions by 2050 [

1,

2]. Buildings, which account for up to 36% of final energy consumption, can make an important contribution to achieving this goal [

3,

4]. The issue of the environment, and especially global warming, has become one of the most serious problems that threaten all living creatures on Earth. Global warming has been increasing since the industrial revolution [

5]. The most important factor in man-made global warming is the unprecedentedly high concentration of greenhouse gases in the atmosphere, mainly due to the combustion of fossil fuels such as oil, gas and coal, as shown in the recently published IPCC report [

6].

Despite increasing energy efficiency requirements, the full potential of energy efficiency is still unlimited; many buildings in the EU use more energy than expected. Data collection and the development of models to predict residents’ behavior are seen as the next frontier in sustainable design [

7]. The use of fossil fuels as the main source of energy in most countries has caused a number of negative environmental effects, such as global warming and air pollution [

8].

The construction sector has great potential to improve energy efficiency thanks to modernization measures, including insulation and the use of modern HVAC systems (heating, ventilation, air conditioning) that are managed intelligently [

9,

10]. Rational operation of the HVAC system, consisting of the reduction of energy losses, operating costs, pollutant and dust emissions, while maintaining thermal comfort, should be based on the prediction of the heat load. The heating load is influenced by several factors, including the building’s energy efficiency standard, its heating power and the location of the rooms in relation to each other or to the external walls. Another important aspect is the location of the building in relation to world directions and the density of buildings in the surroundings [

11,

12,

13,

14]. Scientific studies have shown that the operating habits and routine of residents with respect to their temperature preferences also have a significant impact on the heat demand [

15,

16,

17]. The energy efficiency of a building depends not only on the structure of the building itself, but also on the behavior of its inhabitants. After occupancy, energy consumption changes depend only on the activities of the occupants. This can be understood from the evidence that similar households in similar buildings can have significant differences in energy consumption and that a change in the household population can lead to significant changes in energy consumption. Thanks to the use of new technologies and services in the housing sector, it is possible to thoroughly examine the impact of dynamic changes in user activity on energy consumption [

18,

19,

20]. To estimate the amount of heat consumed in buildings, analyses usually try to find empirical correlations between weather conditions and heat demand. Among the basic meteorological parameters, the outside air temperature is the most important element in calculating heat demand, which is the basis for designing heating systems and heating sources for buildings [

21,

22,

23]. Moreover, it is also used in forecasting thermal comfort in rooms [

24,

25,

26]. Another issue that arises in the course of research is the importance of applying computational intelligence methods (including the neural approach) in broadly understood engineering [

27,

28,

29].

The use of Model Predictive Control (MPC) for energy management in buildings is of great interest to the scientific community. MPC is becoming more and more profitable due to the increase in the computing power of building automation systems and the availability of a significant amount of monitored data about buildings. Although the use of MPC algorithms in building control has been thoroughly tested in various works, there is still no unified structure that fully describes and formulates the implementation [

30,

31,

32]. With the rapid advancement of machine learning [

33,

34,

35] and data mining technologies [

36,

37], especially deep learning [

38,

39,

40] and reinforcement learning [

41,

42], building structure HVAC will become smarter based on historical data such as temperature, humidity and energy consumption. In addition to the above-mentioned research, many other cases have been investigated on HVAC [

43,

44,

45,

46,

47,

48,

49,

50,

51,

52,

53,

54].

In this study, the MPC method was used for temperature and humidity control, which was previously only introduced for temperature control in [

55,

56,

57,

58,

59]. By creating an optimized space for the MPC design problem of energy consumption in construction, especially in the cooling and heating sector, which is the main factor of energy consumption in buildings, a multi-criteria optimization function can be introduced to minimize the total energy consumption [

60,

61,

62,

63,

64,

65,

66,

67,

68,

69,

70,

71,

72].

Forecasting air temperature is one of the main topics in the field of meteorology and climatology, which explains why it is fairly well researched. However, this applies to daily, monthly or annual time series of temperature measured with low and medium time resolution (long- and medium-term forecasts) [

73,

74,

75,

76,

77]. Typically, the prediction of meteorological parameters is used at an early stage of the heat load estimation without going into its methodology [

78]. The implementation of MPCs in buildings presents an important opportunity to reduce energy consumption and apply a demand-side management strategy [

79,

80,

81,

82].

Air pollution is one of the most important environmental problems affecting health and well-being [

83]. This is associated with increased mortality from cardiovascular and respiratory diseases including lung cancer and chronic obstructive pulmonary disease (COPD), reducing life expectancy [

84]. In 2019, it is estimated that around 307,000 premature deaths in Europe were caused by chronic exposure to coarse particles 10 μm or less in diameter (PM10) and fine particles 2.5 μm or less in diameter (PM2.5). In addition, approximately 40,000 premature deaths have been attributed to chronic exposure to nitrogen dioxide (NO

2) [

85].

Despite improvements in air quality in Europe, air pollution is one of the greatest environmental threats to health and continues to be a major health problem for Europeans [

84]. Despite a downward trend in annual average concentrations of primary pollutants (e.g., NO

2, SO

2, etc.) in Europe, the European limit values for PM10, PM2.5 and NO

2 are still exceeded in some zones, especially in urban areas. In 2019, the EU urban population exposed to concentrations of PM2.5, PM10 and NO

2 above EU standards was 4%, 15% and 4%, respectively [

86]. European countries have committed to further reducing their annual pollutant emissions (National Emission Ceilings Directive (NEC), 2016/2884/EU) to meet EU standards regulated by the Ambient Air Quality and Cleaner Air Directive for Europe (Air Quality Directive, 2008/50/EC).

It is commonly said that the population of developing countries may be exposed to various harmful gases from the combustion of fossil fuels from production, transport and energy generation due to limited access to clean energy sources [

87].

According to the World Bank Group, 36 of the 50 most polluted cities in the European Union are in Poland [

88]. Moreover, Polish cities are among the urban areas with the highest estimated PM mortality burden [

89]. Despite the steady decline in annual outdoor PM concentrations in the most polluted Polish cities, the current values still do not meet the guidelines of the World Health Organization (WHO) [

90,

91]. According to the WHO, 7 million deaths annually are related to global air pollution [

92], and 4.2 million of them are related to outdoor air pollution, which occurs in large cities. The most important types of air pollution in cities are nitrogen dioxide (NO

2), particulate matter (PM), ozone (O

3) and sulfur dioxide (SO

2). Road transport, power plants, heating and cooling, cooking and landfills are the main sources of pollution for city dwellers.

Huizong et al. [

93] completed a very in-depth and critical review of the emission factors. They analyzed 270 scientific articles, included and extracted for data analysis. They checked and grouped the emission factors (EF) of common air pollutants, including CO, PM2.5, SO

2, NO

x and polycyclic aromatic hydrocarbons (PAHs). Emission factors are divided into laboratory and field groups for different fuels burnt in natural and forced draft furnaces and different combustion chambers.

In Poland, the main sources of air pollution are emissions from fuel combustion, mainly from the energy sector and households, and emissions from transport. Polish air protection policy is largely reactive—the decrease in air pollution emitted by industry and energy was in response to EU requirements for these sectors. However, there are no regulations for installations used in households, i.e., solid fuel stoves, boilers or fireplaces. Additionally, in the field of transport, there are no significant legal solutions limiting old vehicles, which are responsible for the production of harmful air pollutants [

94].

The research presented in the article concerns heat supply in the Polish construction sector (multi-family buildings). The results of the research can be used in the optimization of the heating system control strategy by using the outside air temperature forecast over a period of several hours, which allows for the improvement of the heating system control process and the implementation of an effective and rational fuel management strategy [

95]. Due to the climate in Poland, a significant part of the energy sold to households (65.1% in 2018) is used for space heating in the winter [

96].

As shown in the paper, the implementation of deep thermal modernization contributes to a real reduction of greenhouse gas emissions [

97], in combination with the use of advanced control systems of the heating installation [

98,

99], it is possible to lead to a state in which it is possible to use renewable energy sources for heating buildings [

100]. However, you need to be careful, because if the main operating parameters of the system are not correctly defined (e.g., thermal conductivity of the ground); for example, excessive cooling of the lower heat source may occur [

101], which will deteriorate the operating conditions of the installation, extend the operating hours of electric motors and, hence, increasing the emissions of pollutants. This is especially relevant in countries such as Poland, where electricity is obtained by burning coal.

The process and results of this study can help to achieve a more accurate energy performance evaluation by considering all the users together when predicting the energy consumption of a building, and it can serve as a basis to facilitate the transmission of energy information to users in energy management. As can be seen in Europe, any armed conflict or war between countries is able to completely delay or stop the decarbonization process, e.g., the “Fit for 55” package, which, in the face of the war in Ukraine, is currently being modified to avoid the period of natural gas burning on the way to renewable energy sources.

2. Materials and Methods

2.1. Object and Place of Research

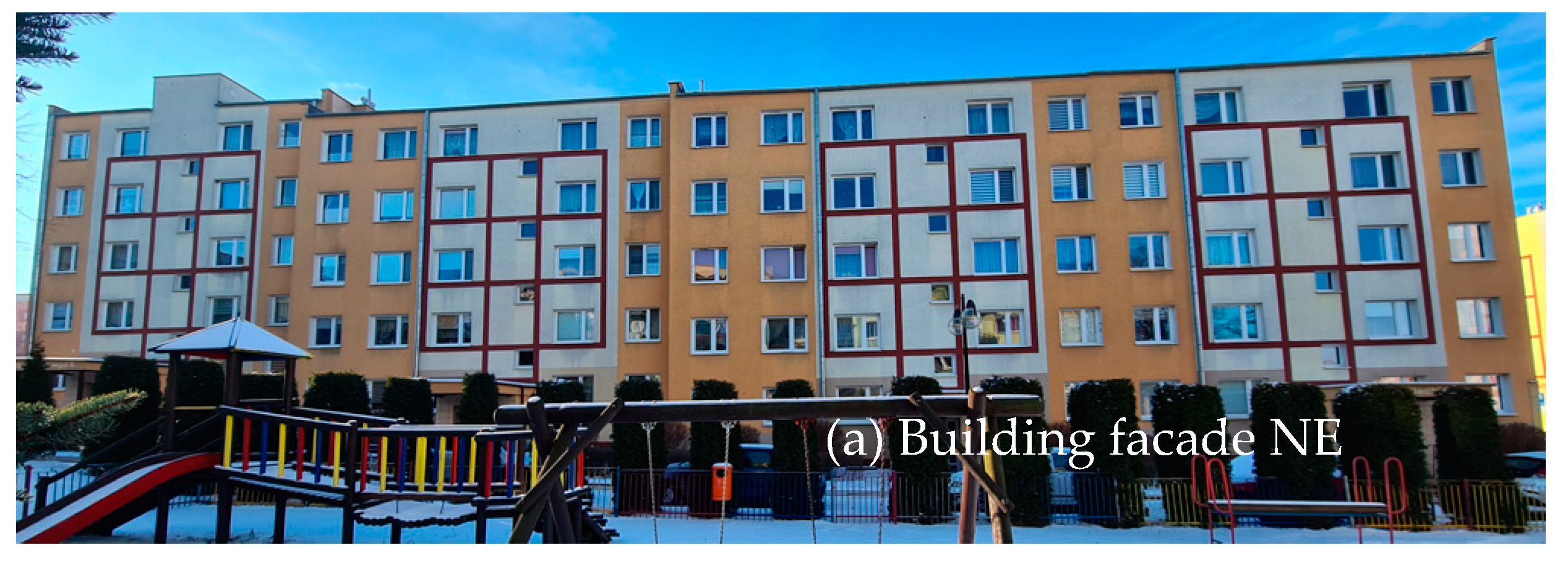

In total, 10 multi-family buildings made in the OWT-67N prefabricated panel technology were selected for the research. The buildings are very similar in terms of area and cubature. The A/V shape factor for the examined buildings ranges from 0.37 to 0.38. These are five-story buildings with a full basement, eight of them (BU1–BU2; BU4–BU6; BU8–BU10) have four staircases and the other two have three (BU3 and BU7). The arrangement of the load-bearing walls is cross-shaped. These buildings are located in the northeastern part of Poland in the city of Łomża. The geographical coordinates are as follows: longitude 53°10′35″ N, and latitude 22°04′23″ E.

This was one of the most popular construction systems in Poland. However, it had many drawbacks and shortcomings, which meant that buildings made in this technology require constant supervision of their technical condition, including the need for modernization. It is important here that the characteristic feature of large-panel objects is their low thermal insulation.

The standard heating season in this region of Poland lasts 222 days. The number of heating degree-days in the standard heating season (

) based on multi-year outdoor temperatures (1991–2020) is 3413.1 day·K/year, and the mean annual outdoor temperature is +7.7 °C [

102]. The heating seasons in 2002–2020 differed among themselves. Recent years were characterized by very mild winters, compared to the statistical long-term climatic conditions, which translates into the actual amount of thermal energy used for heating the building.

Figure 1 shows the view of an example building under test.

Table 1 presents the basic technical parameters of the 10 analyzed buildings, marked as BU1–BU10.

Buildings are supplied with heat from the municipal heat network. After the thermal modernization of the building, the heat source is an individual dual-function heat distribution center operating for central heating and hot water purposes, and previously, buildings were supplied from group district stations. Before the introduction of the forecast regulation in heat stations, weather regulation was performed, which consisted in controlling the temperature of the heating medium on the supply, depending on changes in the outside temperature, with a constant flow of the installation medium. Quality regulation was implemented in the buildings.

The analysis of thermal energy consumption for heating buildings was carried out for the period from 2002 to 2020. All buildings underwent deep thermal modernization (

Table 1). Thermo-modernization was carried out in two stages and did not take place at the same time in all facilities. In the first stage, the gable walls were insulated. These partitions were insulated with 10 cm thick polystyrene,

λ = 0.04 W/m·K, with a thermal insulation layer with a thermal resistance of R = 2.50 m

2 K/W.

Then, in 2005–2011, thermo-modernization works consisted of:

External curtain walls above the ground insulation with 12 cm thick polystyrene,

λ = 0.04 W/m·K, with a thermal insulation layer with a thermal resistance of R = 3.00 m

2·K/W (year of insulation is given in

Table 1).

Ventilated roof insulation with 14 cm thick mineral wool granulate, λ = 0.04 W/m·K, with a thermal insulation layer with a thermal resistance of R = 3.50 m2·K/W.

External walls of basements insulation of extruded polystyrene (XPS), λ = 0.04 W/m·K, with a 15 cm thermal insulation layer with thermal resistance R = 3.75 m2·K/W.

Windows in staircases and basements replacement of windows with new PVC with a heat transfer coefficient of U = 1.70 W/(m2·K).

The heat transfer coefficients U of building partitions (walls, windows, doors, etc.) after thermal modernization in BU1–BU10 buildings, calculated in accordance with PN-EN ISO 6946:2008 [

103], are as follows: 0.26 W/(m

2·K) for gable walls, 0.24 W/(m

2·K) for longitudinal walls, 0.18 W/(m

2·K) for a ventilated flat roof, 1.5 W/(m

2·K) for entrance doors and 1.1 W/(m

2·K) for windows in staircases and 1.3 W/(m

2·K) for windows in basements.

In all buildings after thermal modernization, apart from BU4, hydraulic adjustment of the central heating system was performed in order to adjust the distribution of the heating medium flow in the central heating system to individual radiators, after reducing the heat demand of the rooms.

Table 2 presents data on thermal parameters characterizing each of the buildings.

In the assessed buildings, the central heating installation is a two-pipe, multi-tiered installation with a lower distribution with parameters of 80/60 °C, equipped with panel heaters. Next to the radiators, there are thermostatic radiator valves with thermostatic heads. The use of thermostatic heads allows you to adjust the efficiency of the radiators and use the gains from insolation, as well as enable automatic closing of the valve head when the temperature in the room reaches a value higher than the required one. This type of improvement allows for additional reduction of thermal energy consumption in the building. In 1999, central heating cost allocators were installed in flats, aimed at improving the settlement of residents for the heat consumed and intended to constitute an effective financial mechanism motivating users to rationally manage heat energy.

Before deep thermal modernization, the calculated temperature on the inner surface of curtain walls in BU1–BU10 buildings, assuming an internal air temperature of +20 °C, was +16 °C, and after thermal modernization it was +18.32 °C [

105]. Thermal insulation of curtain walls resulted in an increase in temperature by +2.32 °C, which translated into lower heat losses through the external partition, and thus a reduction in thermal energy consumption in the building. Thermal insulation of the remaining external partitions included load-bearing walls and the flat roof in the building, which improved not only insulation, but also increased the temperature on their internal surface.

Table 3 presents a summary of temperatures on the internal surfaces of building partitions before and after thermal modernization. The listed temperatures apply to all buildings from BU1 to BU10, because the technology of building partitions is the same, the heat transfer coefficient U before and after thermal modernization does not differ in individual buildings.

A statistical measure describing the heat demand in a building is the number of the heating degree-days in the heating season (

), which determines the energy consumption for heating buildings. In order to be able to compare the studied heating seasons, the number of degree-days for each of them was determined based on Equation (1):

where

is the number of heating degree-days calculated for each year, (day·K/year);

is the average temperature of indoor air in the heating zone, accepted for calculations established +18 °C, (°C);

is the average monthly temperature of outdoor air for the particular year, adopted on the basis of the data of the Municipal Thermal Power Company (

MTPC) for the city of Łomża, (°C); and

is the number of heating days in the particular month for each year, (day).

The monthly average outside air temperature in Equation (1) was calculated on the basis of the temperature data provided by MTPC in Łomża. During the heating season, the outside air temperature was continuously recorded every 1 h throughout the day. Based on hourly measurements of outside air temperatures, the average daily outside air temperature was calculated, and then the average monthly temperature was used to calculate the number of degree-days in the heating season. The calculations were made for the years 2002–2020.

Table 4 includes the number of

calculated according to Equation (1) that characterize a given heating season. The duration of the heating season is closely related to the consumption of thermal energy for heating purposes.

The longer the heating season lasts, the greater the energy consumption to meet the building’s energy needs. Based on the years 1991–2020 outdoor temperatures, the number of degree-days in the standard heating season is

= 3413.1 day·K/year, and the number of days in the heating season is 222 days [

102].

One of the important values for energy storage in buildings is the time constant, which describes the speed of the facility’s response to changes in weather and changes in internal temperatures in the building. In the case of the analyzed buildings constructed in the large-panel system, the time constant is about 78 h. The calculations were made in accordance with the PN-EN ISO 13790:2008 standard [

106].

After deep thermal modernization, the buildings were covered by the “Egain Edge” forecast regulation system. The forecast control system was launched in buildings BU1, BU2 and BU4 on 16 September 2013; BU3 on 17 September 2013; BU5 and BU6 on 23 September 2014; and BU7–BU10 on 27 January 2015.

2.2. Forecast Regulation System

The forecast control system consists of components that are integral with each other. The system includes, among others, the “Egain Hub” weather forecast receiver, eGain 905 climate recorders installed in apartments and wireless temperature sensors in the heating station in each building.

The system uses predictive control that replaces the external temperature sensor that controls traditional systems by a receiver that receives local weather. It is the weather forecast, in conjunction with the information obtained both during the initial inventory of the building’s components, as well as with data collected on an ongoing basis, via internal climate recorders in apartments, that constitutes a fundamental component of the algorithm that calculates the so-called equivalent temperature. The variable in the form of the equivalent temperature replaces the outdoor temperature signal supplied to the central heating controller and takes into account other parameters (apart from the outdoor temperature component) that affect the perceived temperature. The dominant role of the weather forecast in the calculation of the equivalent temperature allows for an adequately early reaction of the heating system, consisting in shortening the reaction time, related to the hydraulic and thermal inertia of the object.

The weather forecast, together with the building data important for the operation of the system (glazed area, location in relation to the directions of the world, type of windows, ventilation system), is treated as an input data for the calculation of the so-called equivalent temperature. It is a fundamental parameter that determines the amount of heat consumed by a building. The “Egain Hub” weather forecast receiver continuously registers the following climate parameters: outside temperature, sunshine, wind direction and speed, precipitation. Thanks to the registration of climate parameters, it is possible to control the position of the control valves in the heating station in advance, adjusting the temperature of the heating medium to the changing weather conditions.

Figure 2 shows the “Egain Hub” weather forecast receiver mounted on the outer wall of one of the examined buildings together with a temperature sensor installed in the heating station.

Via the GSM network, the system’s servers communicate with the weather forecast receiver installed in the building in order to generate and send the equivalent temperature value for the next 5 days several times a day. The equivalent temperature then replaces the outdoor temperature as the control parameter. The “Egain Hub” receiver also has a built-in sensor that measures the outside temperature in real time in the range from −50 °C to +50 °C, with an accuracy of ±0.5K. In the event of a break in the reception of the equivalent temperature, e.g., as a result of a failure, the external temperature sensor becomes a guide, and the control is based on its measurements.

The main tasks of the weather forecast receiver “Egain Hub” include the following: increasing energy efficiency, optimization and remote control of heating systems, data collection from M-Bus sensors, transmission of the equivalent temperature, measurement of outside temperature and forecast calibration.

The Edge Hub uses a high-performance wireless M-Bus receiver module that supports C, T and S modes.

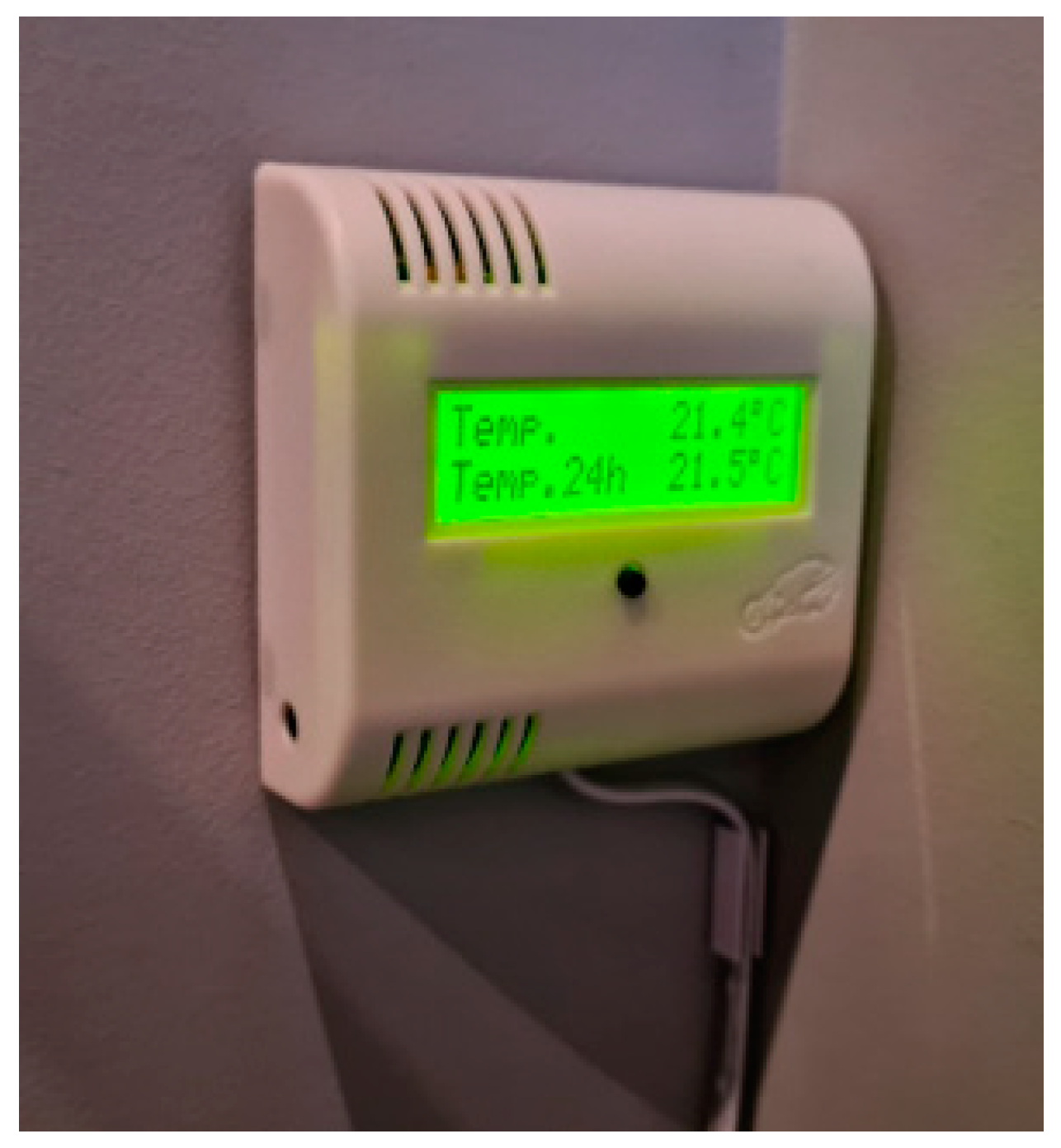

The “Egain Edge 905” climate recorders installed in buildings can measure temperatures ranging from −40 °C to +50 °C, with an accuracy of ±0.5 K, and humidity from 5% to 90%, with an accuracy of ±3%. Climate recorders ensure proper control over thermal comfort in the building and can also play a dominant role in the algorithm for calculating the equivalent temperature supplied to the controller.

Figure 3 shows the “Egain Edge 905” climate recorder installed in an apartment.

The constant analysis of air humidity and temperature in the apartments enables the system manager to determine the correct slope of the heating curve through the appropriate settings of the control system. It enables the reduction of heat consumption and improves thermal comfort in residential premises.

2.3. Measurement Methodology

Measurement of thermal energy for central heating in each of the BU1–BU10 buildings was measured with ultrasonic heat meters located in individual heat substations in each building. The study of heat consumption solely for heating purposes covered the years 2002–2020.

In order to eliminate seasonal temperature fluctuations that occurred in individual years, the measured consumption of thermal energy for heating purposes, marked as

, was converted in the study into the standard heating season, in accordance with Equation (2):

where

is the annual heat energy consumption (final energy) for heating, adjusted to standard conditions (GJ/year);

is the measured actual annual thermal energy consumption (final energy) for heating purposes (GJ/year);

is the degree-day energy index, calculated according to Equation (3) [-]:

where

is the number of degree-days calculated in standard year (day·K/year),

[

102]; and

is the number of degree-days calculated for each year (day·K/year), according to

Table 4.

The calculated degree-day energy index γ used to correct the actual final energy consumption

for the standard heating season is shown in

Table 5.

The indicator of the annual final energy demand (kWh/(m

2·year)) for heating buildings

covering the period before and after thermal modernization and the period including the installation of the forecast regulation was calculated from dependence (4):

where

is the annual final energy demand index for heating adjusted to standard conditions (kWh/(m

2·year));

is the annual final energy consumption for heating adjusted to standard conditions (GJ/year); and

is the heated area of the usable part of the building (with regulated temperature), (m

2), according to

Table 1.

The indicator of the annual demand for non-renewable primary energy (adjusted to the conditions of the standard heating season) for heating buildings covering the period before and after thermo-modernization and the period including the installation of the forecast regulation was calculated from Equation (5):

where

indicator of the annual demand for non-renewable primary energy for heating purposes (kWh/(m

2·year));

is the coefficient of expenditure of non-renewable primary energy for the production and delivery of the final energy carrier to buildings (GJ/year), and

heat from a heating plant burning coal in the form of fine coal in accordance with Polish regulations [

107].

The energy effects obtained as a result of deep thermal modernization in buildings were determined based on Equation (6):

where

is the percentage saving of final energy used for heating the building after deep thermal modernization (%),

is the average annual final energy consumption for heating purposes before thermal modernization (GJ/year) and

is the average annual final energy consumption for heating the building after thermal modernization (GJ/year).

On the other hand, the energy effects resulting from the installation of a central heating system control system based on weather prediction were determined based on Equation (7):

where

is the percentage savings of the final energy used for heating the building after the application of the central heating system regulation system based on weather prediction (%);

is the average annual final energy consumption for heating the building after the thermal modernization, but before the start of the inspection of the building equipped with a predictive system (GJ/year); and

is the average annual final energy consumption for heating purposes after the introduction of the forecast regulation in the building (GJ/year).

2.4. Methodology for Determining the Emission of Harmful Substances in Buildings before and after the Introduction of the Forecast Regulation

The calculation of the amount of pollutant emissions, i.e., SO

2, NO

x, CO

2, CO and benzo(a)pyrene, introduced into the air during energy combustion of fuel in the

MTPC Łomża Heat Plant before thermal modernization in each building was calculated from Equation (8):

where

is the amount of pollutant emissions before thermo-modernization in (Mg/year),

is the average annual final energy consumption before thermo-modernization (GJ/year) and

is the emission factor of the

i-th pollutant during the combustion of hard coal in the fine coal sort (kg/GJ).

The amount of pollutant emissions released into the atmosphere after deep thermal modernization was calculated from Equation (9):

where

is the amount of pollutant emissions after thermal modernization (Mg/year), and

is the average annual final energy consumption after thermal modernization (GJ/year).

The amount of emissions of the

i-th pollutants introduced into the atmosphere after the introduction of predictions in the building was calculated from Equation (10):

where

is the amount of pollutant emissions after the use of weather prediction in the building (Mg/year), and

is the average annual final energy consumption after the introduction of the forecast regulation in the building (GJ/year).

The indicator of the emission of the i-th pollutants during the combustion of hard coal in the sorting fine coal before and after thermo-modernization and after the application of forecast regulation in buildings was adopted according to Equations (8)–(10) with the following values measured and given by MTPC Łomża: for sulfur dioxide, ; for nitrogen dioxide, ; for carbon dioxide, ; for benzo(a)pyrene, ; and for carbon monoxide,

The reduction of pollutant emissions after the implementation of deep thermal modernization of buildings and after the introduction of the forecast regulation was calculated on the basis of Equations (11) and (12):

where

is the reduction of pollutant emissions after deep thermal modernization (Mg/year),

reduction of pollutant emissions after the introduction of the forecast regulation (Mg/year),

is the amount of pollutant emissions before thermo-modernization (Mg/year),

is the amount of pollutant emissions after thermal modernization (Mg/year) and

is the amount of pollutant emissions after using the prediction in the building (Mg/year).

The ecological effects obtained as a result of carrying out deep thermal modernization in buildings and the effects resulting only from the installation of the forecast regulation system were determined based on Equations (13) and (14):

where

percentage reduction in pollutant emissions after deep thermal modernization (%), and

the percentage reduction in pollutant emissions after the introduction of the forecast regulation (%).

3. Results and Discussion

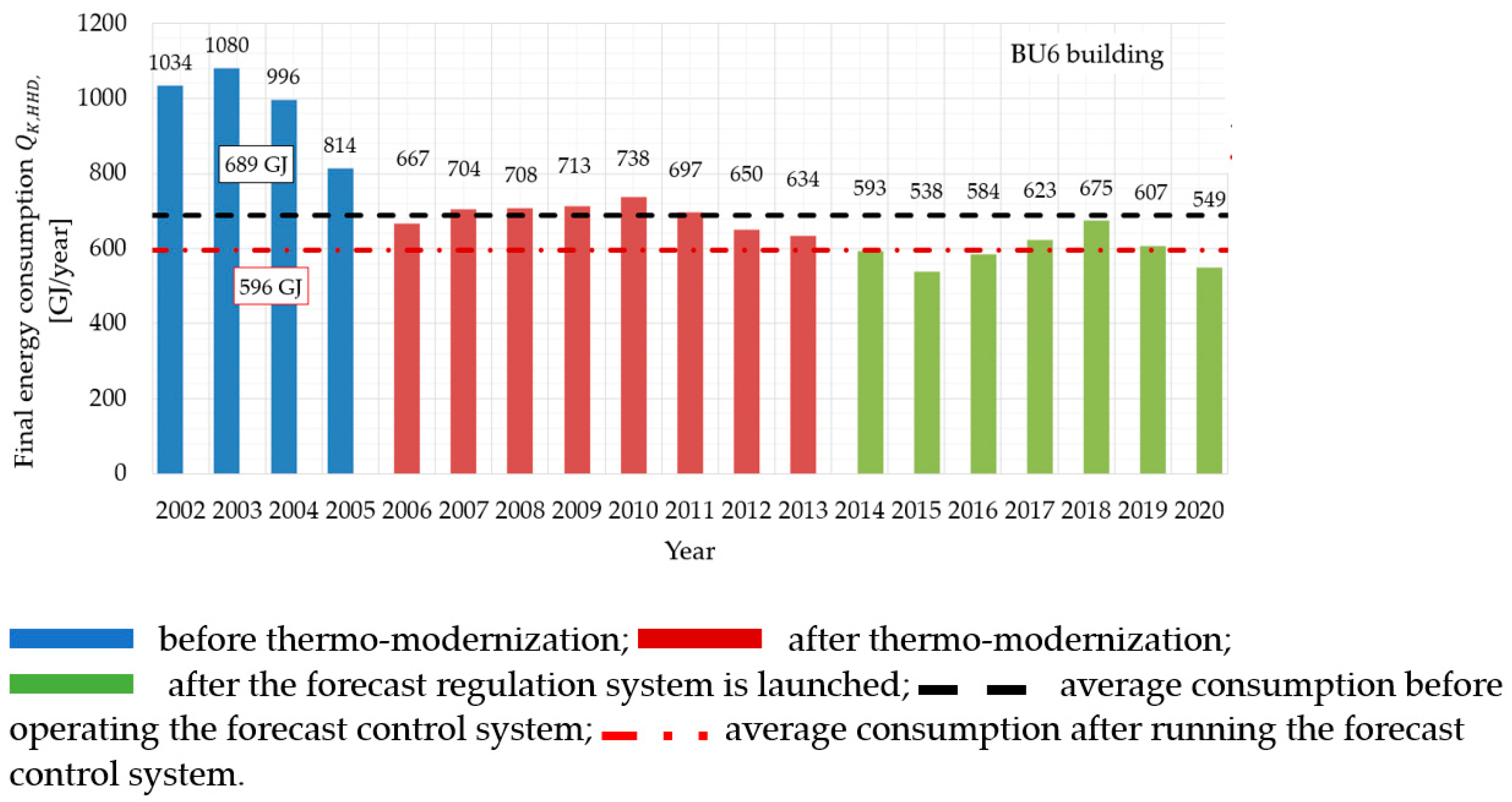

The study of thermal energy consumption (final energy) for heating a building covers three periods. The first one is the time before the thermo-modernization is carried out, the second one is years after the implementation of deep thermal modernization and the third one covers the years after the installation of the forecast regulation system.

The period before deep thermal modernization (

Table 1) covers the years 2003–2007 for BU1–BU3 buildings, 2002–2007 for BU4 buildings, 2001–2005 for BU5-BU6 buildings, 2001–2011 for BU7 buildings and 2003–2009 for buildings BU9 and BU10.

The assessment of the annual final energy consumption in the examined buildings in relation to the standard season in the years 2002–2020 is shown in

Figure 4,

Figure 5,

Figure 6,

Figure 7,

Figure 8,

Figure 9,

Figure 10,

Figure 11,

Figure 12 and

Figure 13. The final energy consumption measured by means of ultrasonic heat meters was corrected by the

degree-day energy indicator given in

Table 5 and calculated in accordance with Equations (2) and (3). The duration of the research covered 18 years.

The heating seasons in 10 buildings between 2002 and 2020 were thoroughly analyzed. A typical heating season in the research area lasts 222 days. Based on the values of heating degree-days of the heating season and the number of days presented in

Table 4, it can be seen that the heating seasons in 2009, 2011, 2014 or 2018 were shorter than the standard season and lasted from 195 days to 205 days. It was related to warmer winters and higher average monthly temperatures than the outdoor temperatures from the years 1991–2020. In the process of interpreting the heat energy consumption data in buildings, information on outdoor air temperatures provided by the MTPC Łomża thermal energy company was used. The average number of days in the heating season recorded in the years 2002–2020 was 214 days.

The average final energy consumption in all analyzed BU1–BU10 buildings before thermal modernization was 855 GJ/year, after thermal modernization it was 607 GJ/year and after introducing the forecast regulation it decreased to an average of 538 GJ/year. The average final energy consumption in each building after thermal modernization (black dotted line) presented in

Figure 4,

Figure 5,

Figure 6,

Figure 7,

Figure 8,

Figure 9,

Figure 10,

Figure 11,

Figure 12 and

Figure 13 was adopted as a reference value for determining the energy effects after the introduction of the forecast regulation in each of the buildings. The dashed red line shows the average final energy consumption in each building after the introduction of the forecast regulation.

Based on the data in

Figure 4,

Figure 5,

Figure 6,

Figure 7,

Figure 8,

Figure 9,

Figure 10,

Figure 11,

Figure 12 and

Figure 13, and taking into account the heated area (with regulated temperature) of each building presented in

Table 1, the annual final energy demand indicator

in buildings BU1–BU10 was calculated according to Equation (4). The results of the index calculations are presented in

Table 6.

In prefabricated buildings BU1–BU10 built in the years 1983–1986 in the technology of large slab, the seasonal energy demand indicator

in the period 2002–2020 varied from 130 to 52 kWh/(m

2·year), as shown in

Table 6. The changes in the index were influenced by the thermo-modernization of buildings and the application of forecast regulation in individual years.

Determining the value index of the seasonal heat demand in Poland allows us to determine the energy consumption of a building. For multi-family buildings in large-panel or traditional technology, the indicators of seasonal final energy demand were as follows: for buildings erected in the years 1970–1984, they were 180–250 kWh/(m

2·year); for buildings erected after 1984, 140–180 kWh/(m

2·year); for buildings erected after 1993, 70–140 kWh/(m

2·year); and for energy-efficient buildings they were at the level of 15–70 kWh/(m

2·year) [

108].

The results of the indicators of seasonal demand for final energy in buildings in the years after the introduction of the forecast regulation, presented in

Table 6, allow us to define buildings as buildings of good energy quality, and even as energy efficient.

The calculation of the average rate of demand for final energy and non-renewable primary energy for heating for a given period before and after thermo-modernization and after the introduction of the forecast regulation of the central heating installation in the building is presented in

Table 7.

When calculating non-renewable primary energy in 2002–2020 according to Equation (5), it was assumed in accordance with Polish regulations that, in the case of heat supplied from a coal-fired heating plant, the coefficient of non-renewable primary energy expenditure on the production and delivery of the final energy carrier to the building is

[

107].

The average indicator of final energy demand before thermal modernization for the examined buildings was 103 kWh/(m2·year), with the highest indicator in buildings BU2 and BU3 being 113–114 kWh/(m2·year), and the lowest indicators in buildings BU7 93 kWh/(m2·year) and BU10 87 kWh/(m2·year).

After the thermo-modernization works were performed, the average final energy demand indicator in all buildings decreased, and on average it was 73 kWh/(m2·year). It was the lowest in BU8-BU10 and amounted to 59–68 kWh/(m2·year).

After introducing the forecast regulation, the average final energy ratio, taking into account all buildings, was 64 kWh/(m2·year). The lowest average final energy indicator was recorded in the BU7 building and it was 57 kWh/(m2·year), while in the BU10 building, the indicator increased by an average of 2 kWh/(m2·year) after the prediction was introduced.

The range of the average final energy ratio before the thermal modernization was 87–113 kWh/(m2·year), after the thermal modernization it was 59–85 kWh/(m2·year) and after the introduction of the forecast regulation it was 57–72 kWh/(m2·year).

The average index of non-renewable primary energy before thermal modernization for the examined buildings was 134 kWh/(m2·year), with the highest index in buildings BU2 and BU3 being 147–148 kWh/(m2·year), and the lowest rates in buildings BU1 (113 kWh/(m2·year)) and BU7 (121 kWh/(m2·year)).

After the thermo-modernization works were performed, the average index of non-renewable primary energy in all buildings also decreased, with the average being 95 kWh/(m2·year). It was the lowest in buildings BU7-BU10 and amounted to 74–79 kWh/(m2·year). After introducing the forecast regulation, the average primary energy ratio, taking into account all buildings, was 84 kWh/(m2·year).

The range of the average value of the non-renewable primary energy index for heating purposes before thermal modernization was 113–148 kWh/(m2·year), after thermal modernization it was 77–111 kWh/(m2·year) and after introducing the forecast regulation it was 74–94 kWh/(m2·year).

In Poland, the values of the index of non-renewable primary energy EP for heating and ventilation, cooling and preparation of domestic hot water were at different levels in different years. In 2014, for multi-family residential buildings, the indicator was 105 kWh/(m

2·year); in 2017, the indicator was 85 kWh/(m

2·year); from 2021, the value of the indicator is to be no more than 65 kWh/(m

2·year) [

108].

Table 8 summarizes the energy effects

(%) in buildings BU1–BU10 obtained as a result of thermal modernization works, calculated in accordance with Equation (6). The average final energy savings after thermo-modernization works in 10 prefabricated buildings was 29.2%.

In all buildings, a deep thermal modernization was carried out, consisting in thermal insulation of external gable and shield walls, insulation of the flat roof, replacement of basement and staircase windows, replacement of external entrance doors and replacement of windows in apartments by residents. This allowed for final energy savings ranging from 19.8 to 35.0%. Lower thermal energy savings in the BU4 building result from the failure to adjust the hydraulic heating system after deep thermal modernization of buildings. As a result of thermo-modernization works, 183–303 GJ/year were saved, on average 248 GJ/year.

The use of an innovative forecast control system in 10 buildings, instead of weather regulation, allows for additional energy savings of an average of 10.9%.

Table 9 presents the energy effects

, (%) in each building as a result of introducing a system of forecasting central heating installation consisting in the continuous prediction of weather conditions, i.e., outside temperature, humidity, sunlight and wind. Thanks to the use of forecast regulation, it is possible to save energy without lowering the internal temperature of heated rooms and ensuring the thermal comfort of residents.

The introduction of an innovative forecast control system in BU1–BU9 buildings allowed for additional heat energy savings from 4.8% to 23.5%. It allowed them to save an additional 21–174 GJ/year of thermal energy, on average about 69 GJ/year.

The highest energy effects were achieved in buildings BU4 23.5% (174 GJ/year) and BU3 18.4% (101 GJ/year). The introduction of forecast regulation made it possible to adjust the parameters of the central heating installation to the needs of residents while maintaining thermal comfort in the rooms.

The use of forecast control in the case of BU10 building did not reduce the consumption of thermal energy for heating purposes, but increased energy. The energy effect was not achieved, as in the case of other buildings, as shown in

Table 9. It was probably due to the fact that the heating energy consumption in the BU10 building was at a very low level, both after thermo-modernization and after the introduction of regulations forecast, compared to other buildings (

Table 6 and

Table 7 and

Figure 4,

Figure 5,

Figure 6,

Figure 7,

Figure 8,

Figure 9,

Figure 10,

Figure 11,

Figure 12 and

Figure 13). The final energy indicator before thermo-modernization in the BU10 building was 87 kWh/(m

2·year), after thermo-modernization it was 59 kWh/(m

2·year) and after applying the forecast regulation it already increased and amounted to 61 kWh/(m

2·year) (

Table 7).

The internal temperatures in the building at BU10 in the heating season in 2017–2020 were maintained in the range of average daily temperatures from +18.8 °C to +22.6 °C. The average seasonal temperature from 4 years was +20.3 °C. Taking into account only the coldest months in Poland, XII–II, the average temperature was +20.1 °C.

According to the SET scale, known as the standard effective temperature, the thermal comfort index is in the temperature range from +22.2 °C to +25.6 °C; then, we feel pleasant warmth and feel comfortable. Maintaining the indoor temperature in the rooms in the range of +17.5 °C to +22.2 °C causes a feeling of slight discomfort and perceptible slight coolness according to the SET scale [

109].

Increasing the temperature of the heating medium in the central heating system in order to ensure greater thermal comfort in rooms only resulted in greater heat losses on uninsulated central heating risers and heat losses in staircases, as in most apartments the thermostatic heads were still closed. Unfortunately, the use of radiator central heating cost allocators causes the residents to save heat energy at the expense of their thermal comfort, as could be the case with the BU10 building. Hence, in this building, despite the use of forecast regulation, no reduction in heat consumption for central heating purposes was achieved, only an increase, because the system tried to provide a higher internal temperature in the rooms, in order to improve the thermal comfort of the residents.

Figure 14 shows the daily indoor temperatures (orange) maintained in the BU10 building, measured in 2017–2020 during the heating season, and the average monthly indoor temperatures (red) along with the distribution of daily and monthly average outdoor temperatures.

In order to show the different internal temperatures maintained in buildings, which have a significant impact on the final energy consumption,

Figure 15 shows the average daily indoor temperatures (orange) maintained in the BU4 building, measured in 2017–2020 during the heating season, and the average monthly indoor temperatures (red).

The internal temperatures in the building at BU4 during the heating season in 2017–2020 were maintained in the range of average daily temperatures from +19.7 °C to +23.6 °C. The average seasonal temperature from 4 years was +21.4 °C. Taking into account only the coldest months in Poland, XII–II, the average temperature was +20.3 °C.

The internal temperature in the BU4 building in comparison to the BU10 building in the heating season in 2017–2020 was higher by +1.1 °C, and while taking into account only the coldest months in Poland, it was by +1.2 °C.

Insolation also has a great influence on the indoor temperature in rooms. During the heating season in the BU10 building, the sum of the total solar radiation intensity on the surface with SE orientation and an inclination to the level of 90°, i.e., the building facade with balconies and large glazing, was 320.5 kWh/(m2·season), while in the BU4 building, the facade with balconies facing SW was 300.6 kWh/(m2·season). This is especially visible in April in the BU10 building, where the internal temperature in the rooms is increased and amounts to approximately +21 °C.

Figure 16 shows the total final energy savings as a result of the implementation of deep thermal modernization in BU1–BU10 buildings with the introduction of the forecast regulation of the “Egain Edge” system.

Percentage savings in thermal energy used for heating buildings after deep thermal modernization and after the introduction of forecast regulation in the examined facilities BU1–BU10 ranged from 36.4% to 45.9%, and on average it was about 40.1%.

The emission of NOx, CO2, SOx and CO pollutants, as well as organic pollutants and volatile organic compounds, is strictly dependent on the combustion technology and the type of fuel used. The existing MTPC Municipal Heating Plant in Łomża is a high-parameter heat source that burns hard coal in the fine coal sort. Buildings BU1–BU10 are supplied with heat through the municipal heating network. The emission of pollutants and the obtained ecological effects related to the implementation of deep thermal modernization of buildings and the introduction of the forecast regulation in buildings were calculated based on the indicator data of pollutant emissions for hard coal obtained from MTPC Łomża.

Table 10 presents the amount of pollutant emissions in buildings BU1–BU10 before thermal modernization works. The calculations were made according to Equation (8). The period before thermo-modernization for each building is shown in

Table 6 and in

Figure 4,

Figure 5,

Figure 6,

Figure 7,

Figure 8,

Figure 9,

Figure 10,

Figure 11,

Figure 12 and

Figure 13. Before the thermo-modernization of buildings, the total emission of CO

2 was 1020.25 Mg/year, SO

x was 5.47 Mg/year, NO

x was 1.63 Mg/year and carbon monoxide was 0.43 Mg/year.

By carrying out the thermo-modernization of buildings BU1–BU10, the emission of pollutants was reduced, i.e., NOx, CO2, SOx, CO and b(a)p introduced into the atmosphere during the combustion of hard coal in the assortment of fine coal.

Table 11 presents the results of the pollutant emission calculations together with the reduction in the amount of pollutant emissions compared to the period before deep thermal modernization. The calculations were made in accordance with Equations (9) and (11).

As a result of deep thermo-modernization, an average reduction of emissions of CO2, NOx, SOx and CO pollutants introduced into the atmosphere as a result of combustion of fine coal in the MTPC Heat Plant was achieved in the following amounts: CO2 of 296.28 Mg/year, NOx of 0.49 Mg/year, SOx of 1.59 Mg/year and CO 0.13 of Mg/year; in the case of b(a)p, emission reduction was achieved by 6.5 × 10−5 Mg/year.

The use of forecast regulation in all buildings allowed for an additional reduction of pollutant emissions, except for the BU10 building, where the demand for final energy increased, and thus the pollutant emissions increased, on average by 3.1%.

Table 12 shows the results of calculations of pollutant emissions along with the reduction of pollutant emissions after the introduction of the forecast regulation as compared to the period after deep thermal modernization. The calculations were made in accordance with Equations (10) and (12).

After the implementation of the heating system regulation system based on weather prediction in the buildings, an additional reduction in the emission of pollutants introduced into the atmosphere as a result of the combustion of fine coal in the MPEC Heat Plant, except the BU10 building.

The total reduction of pollutant emissions was as follows: CO2 by 82.22 Mg/year, NOx by 0.11 Mg/year, SOx by 0.45 Mg/year and CO by 0.034 Mg/year; in the case of b(a)p, an additional emission reduction was obtained by 1.8 × 10−5 Mg/year.

Table 13 summarizes the percentage reduction of emissions of individual pollutants, broken down by buildings, after deep thermal modernization and after the application of forecast regulation in buildings, calculated in accordance with Equations (13) and (14).

As a result of deep thermal modernization, in each building a reduction in the emission of pollutants introduced into the atmosphere as a result of the combustion of fine coal in the MTPC Heat Plant in Łomża was achieved. The emission of carbon dioxide was reduced by 29%, the emission of nitrogen oxides by 30.1%, the emission of sulfur oxides by 29.1%, the emission of carbon monoxide by 30.2% and, in the case of b(a)p, the emission was reduced by 30%.

Based on

Table 13, it can be seen that the implementation of modern technologies, in this case forecast regulation, in most buildings allows for an additional reduction of pollutant emissions, and thus the reduction of final energy for heating purposes. On average, the emission of carbon dioxide was reduced by an additional 11.4%, the emission of nitrogen oxides by 9.6%, the emission of sulfur oxides by 11.6%, the emission of carbon monoxide by 11.2% and, in the case of b(a)p, the emission was reduced by 11.8%.

4. Conclusions

The study analyzes the consumption of thermal energy for heating in the years 2002–2020 in 10 buildings made in the OWT-67N prefabricated panel technology in three periods: before and after thermo-modernization and after the use of an innovative heating system control system based on weather prediction in buildings. The impact of deep thermo-modernization and the installation of an innovative forecast regulation system in terms of reducing heat energy consumption for central heating purposes, as well as reducing greenhouse gas emissions of CO2, SOx, NOx, CO and b(a)p to the atmosphere, was assessed.

Each analyzed building created a specific spatial structure with an individual physical character and was subjected to the influence of many climatic variables over the years, including solar radiation intensity, wind force and people’s behavior; hence, the final energy consumption in individual buildings differed.

The average rate of the annual final energy demand before thermo-modernization for the studied buildings was 103 kWh/(m2·year) and ranged from 87 to 113 kWh/(m2·year), and the average index of non-renewable primary energy was 134 kWh/(m2·year) and ranged from 113 to 148 kWh/(m2·year).

Implementation of deep thermal modernization in buildings, consisting in thermal insulation of external walls (gable and curtain), insulation of basement walls, insulation of flat roofs, replacement of windows and doors and hydraulic adjustment of central heating installation allowed for savings in the range of 19.8% to 35% of thermal energy consumption for heating, which gives an average of 29.2% savings in final energy consumption.

After the thermal-modernization works were performed, the average indicator of the annual demand for final energy in all buildings decreased, and on average it was 73 kWh/(m2·year) and ranged from 59 to 85 kWh/(m2·year), and the indicator of non-renewable primary energy on average was 95 kWh/(m2·year) and ranged from 77 to 111 kWh/(m2·year).

The use of additional regulation of the central heating system based on the prediction allowed buildings to save from 4.8 to 23.5% of energy, on average 10.9%, and in buildings made in large-panel technology, except for one BU10 building, where there was an increase in final energy consumption by 2.1%.

On the basis of the analysis, it was noticed that, in buildings equipped with radiator cost allocators, when using the central heating system temperature prediction system, the algorithm for determining the equivalent temperature (alternatively instead of the actual outside temperature given to the controller) should not prioritize the temperature in apartments (e.g., building BU10). The function is very good, provided that the recorders are installed in apartments, where heat is rationally and not exaggerated. In the BU10 building, the controller tried to increase the internal temperature in the room by increasing the temperature of the heating medium in order to provide thermal comfort to the residents, and this increased the final energy consumption.

The average indicator of the annual final energy demand after the introduction of the forecast regulation for the examined buildings was 64 kWh/(m2·year) and ranged from 57 to 72 kWh/(m2·year), and the average indicator of non-renewable primary energy was 84 kWh/(m2·year) and ranged from 74 to 94 kWh/(m2·year).

Reducing final energy consumption through thermal modernization and forecast regulation is the most effective way to reduce the emission of harmful substances to the atmosphere, such as sulfur dioxide, nitrogen oxides, dust or carbon dioxide, because it is a direct method. Replacing the weather regulation in district heating stations with the forecast regulation additionally reduced the emission of pollutants by 11.1%, compared to the reduction of pollution obtained as a result of the thermal modernization of buildings alone, amounting to an average of 29.7%.

Summing up, the percentage savings of final energy used for heating buildings after deep thermal modernization and after the introduction of forecast regulation in the examined buildings BU1–BU10 ranged from 36.4% to 45.9%, on average it was about 40.1%.

The obtained results suggest that the deep thermal modernization of buildings in combination with the use of an innovative forecast control system for central heating systems, instead of weather regulation, fully contributes to the reduction of heat energy consumption for central heating purposes and reducing the emission of pollutants into the atmosphere, thus protecting the natural environment.

The article may make a significant contribution to the construction of models used to determine the demand for thermal energy in multi-family buildings, because one of the important stages of model construction is its verification based on real results. The article presents the research results of 18 years of final energy consumption in a group of 10 buildings constructed with the same technology.

Research has shown that the use of thermal modernization, as well as additionally introducing a forecast control system in buildings, is a good tool for controlling a thermal source.

On the example of the presented buildings, it can be seen that in the OWT-67 large-panel buildings it is possible to obtain the average value of the final energy indicator on the average level of 57–72 kWh/(m2·year) after the implementation of modern technologies and projects limiting the consumption of thermal energy.