Simulation about the Effect of the Height-to-Stroke Ratios of Ports on Power and Emissions in an OP2S Engine Using Diesel/Methanol Blends

Abstract

:1. Introduction

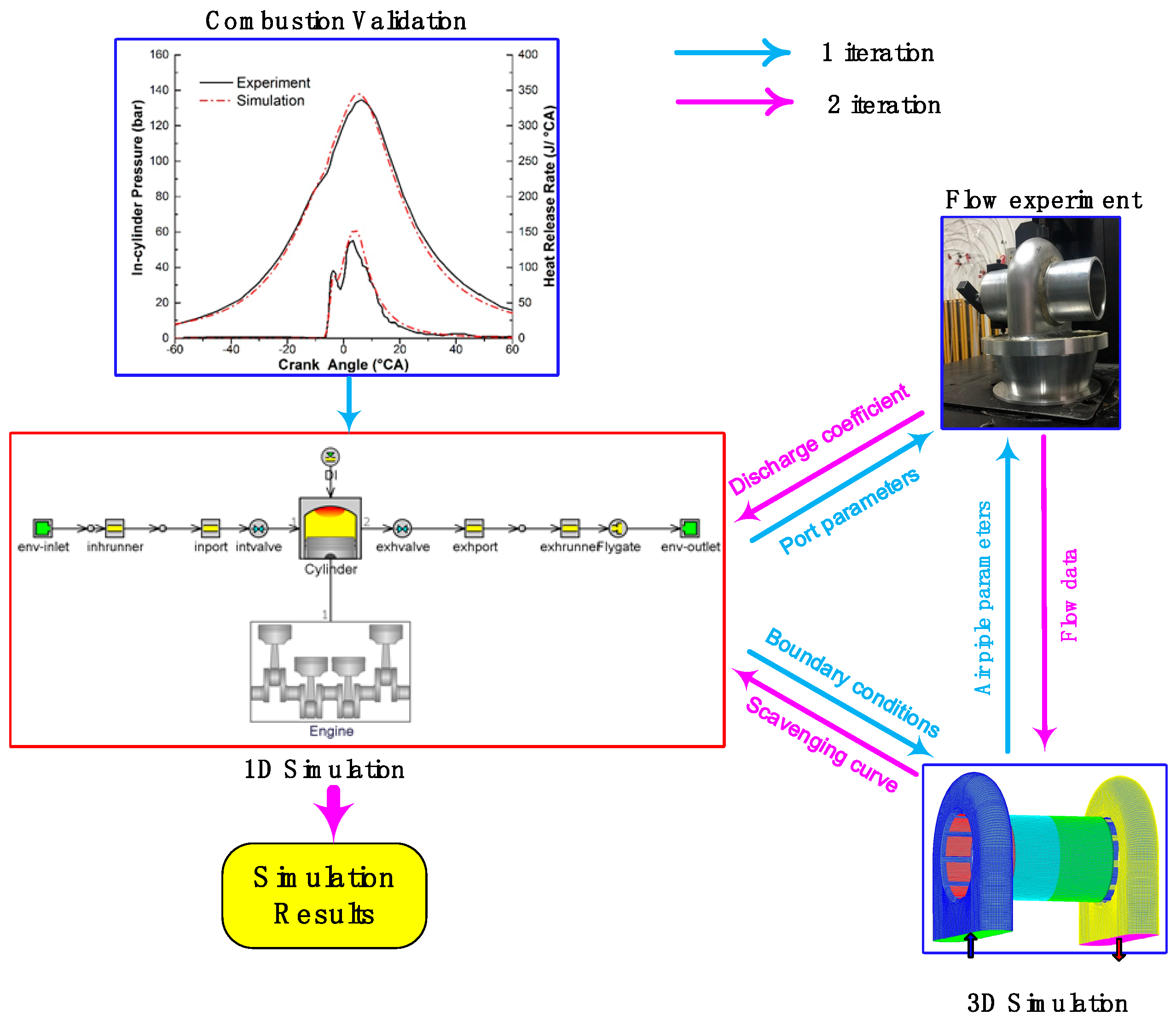

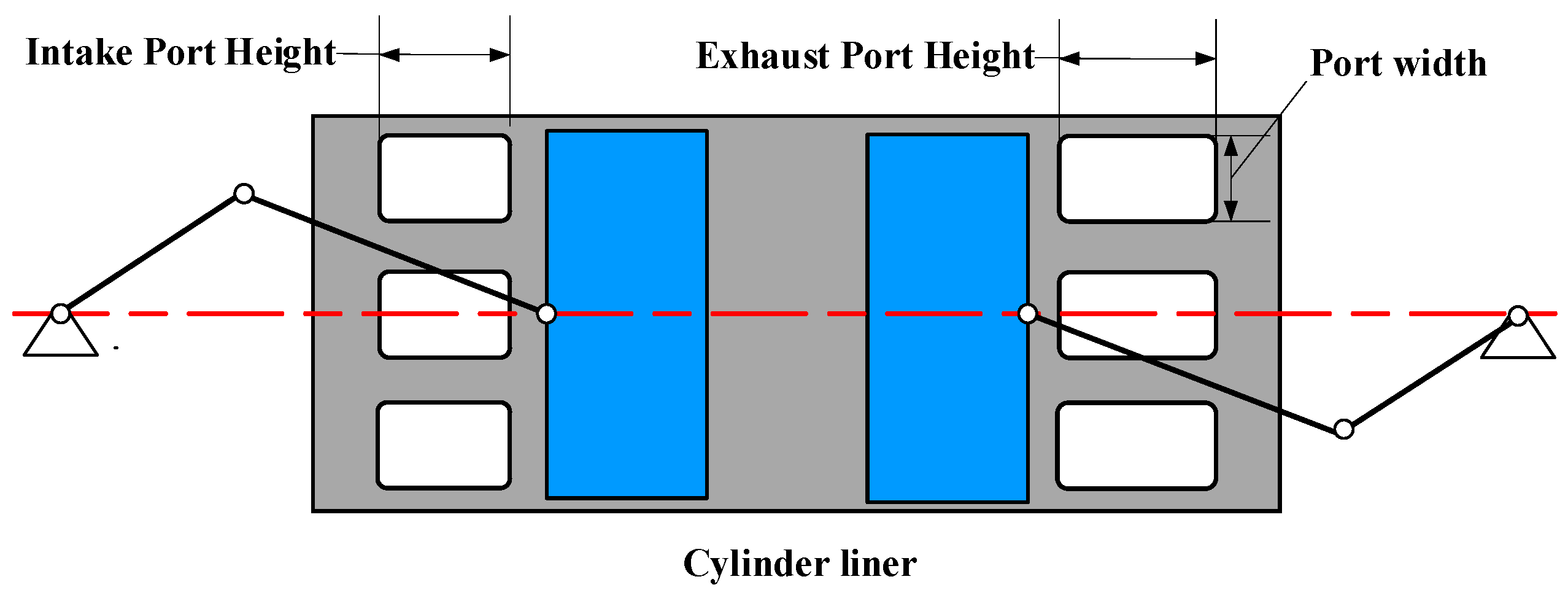

2. Simulation Setup

2.1. Simulation Model

2.2. Simulation Validation

2.3. Simulation Method

3. Results and Discussion

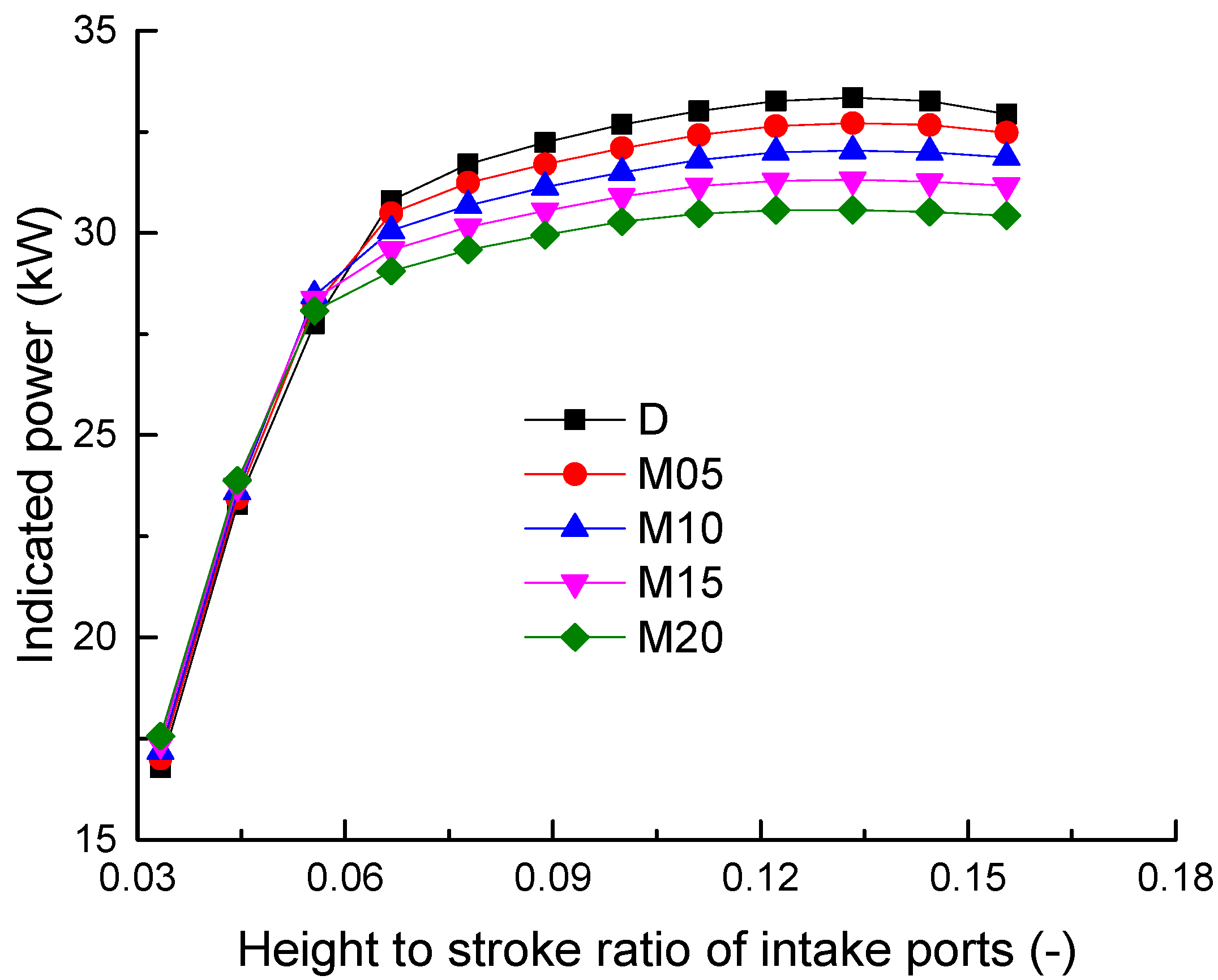

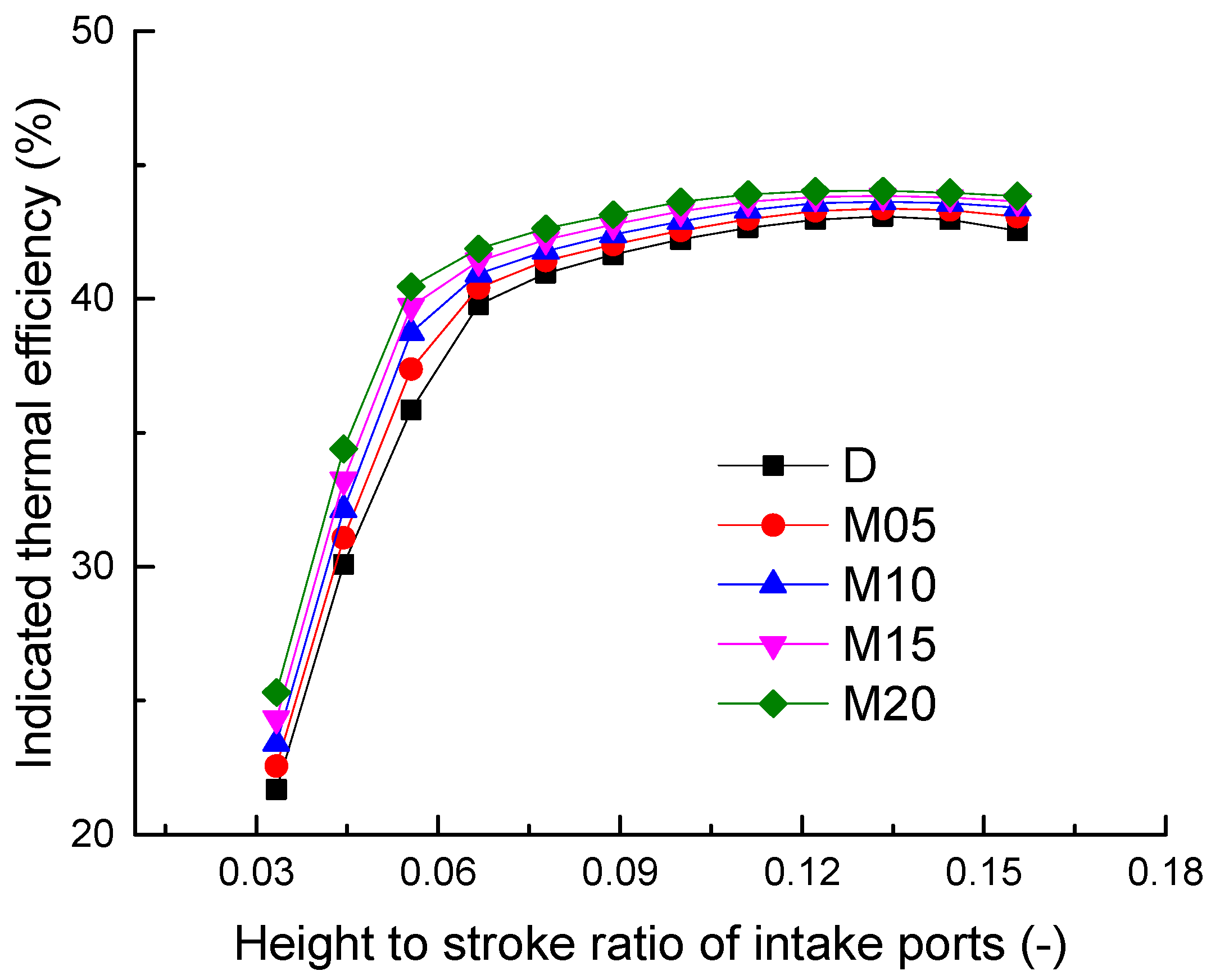

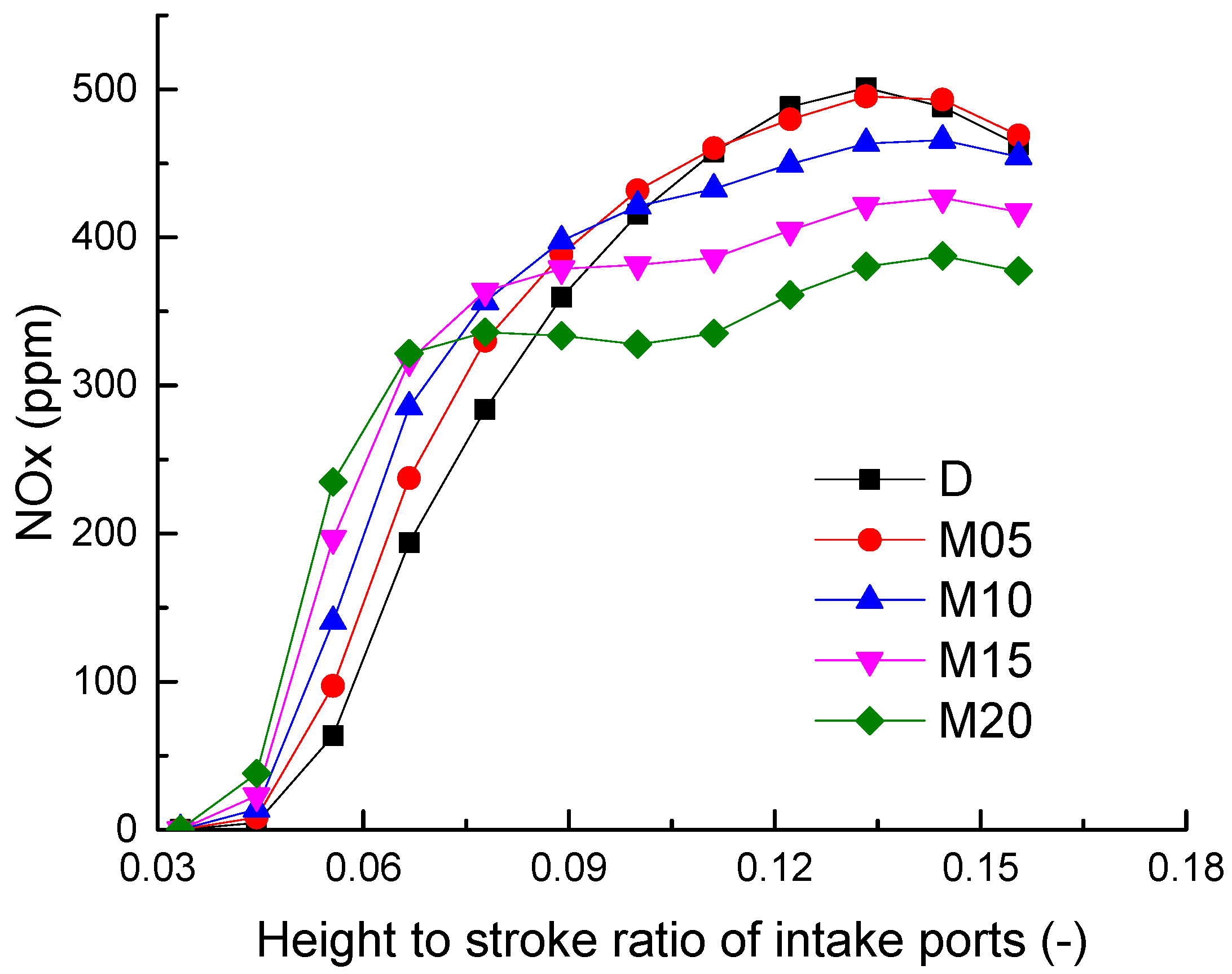

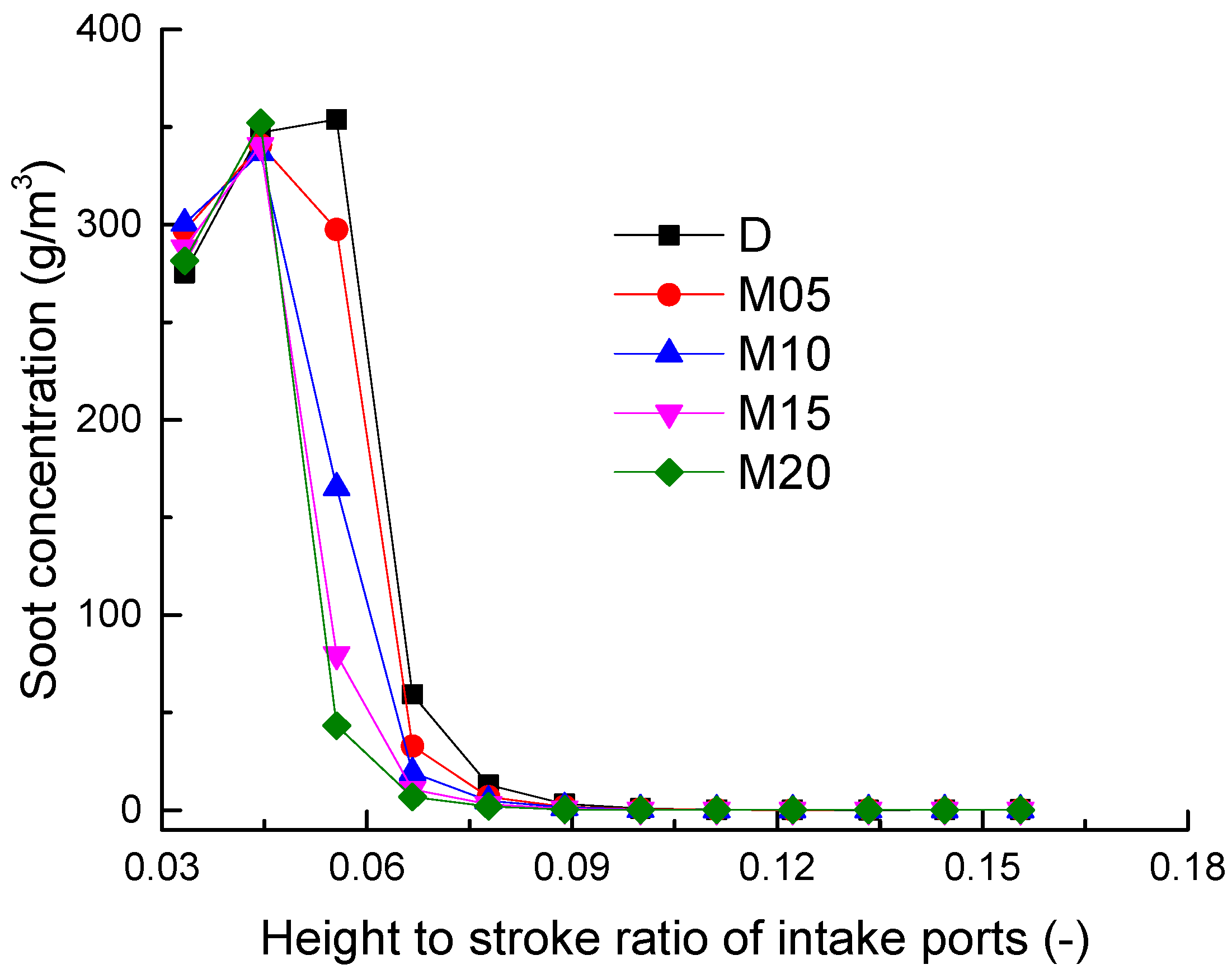

3.1. The Influence of Intake Port

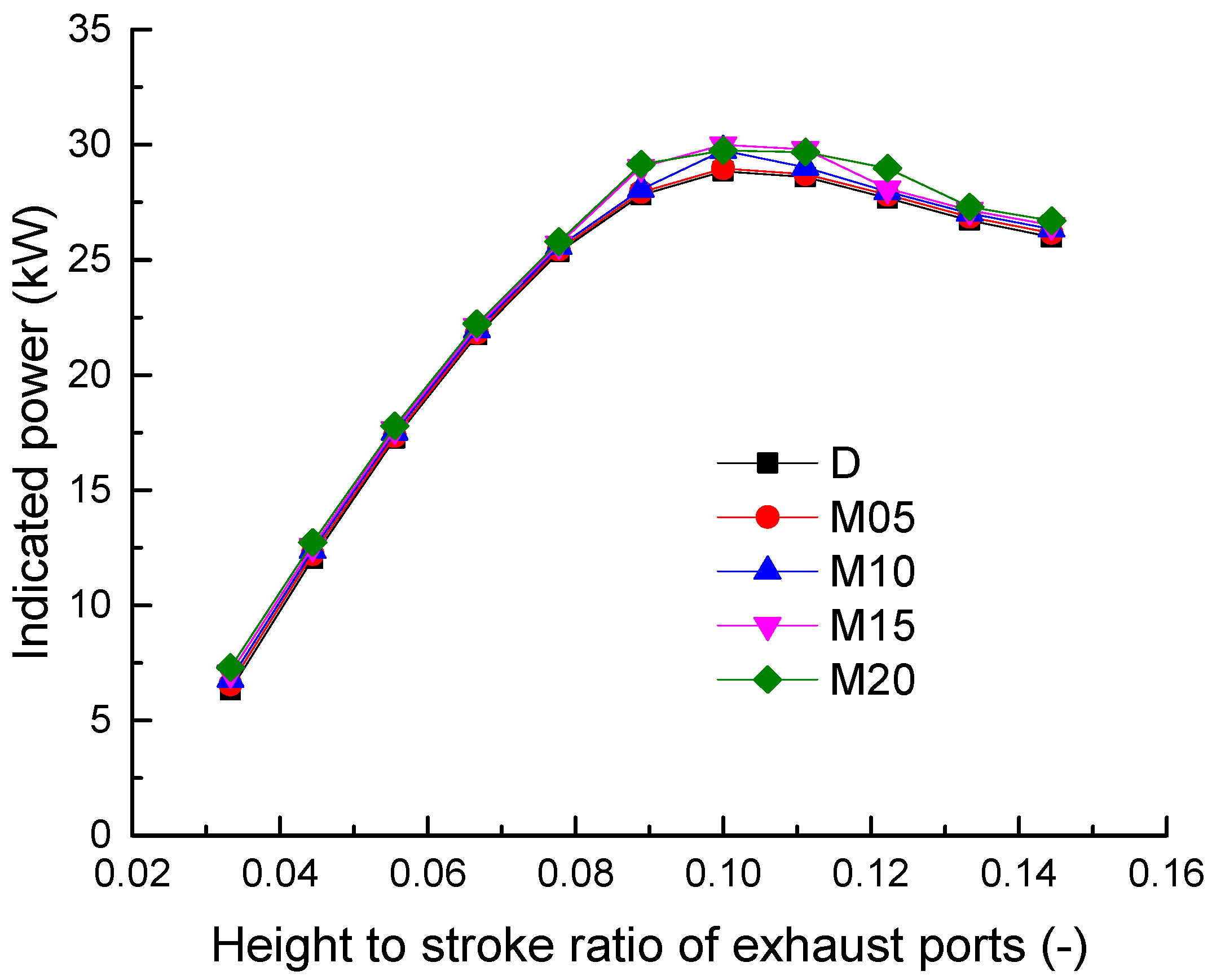

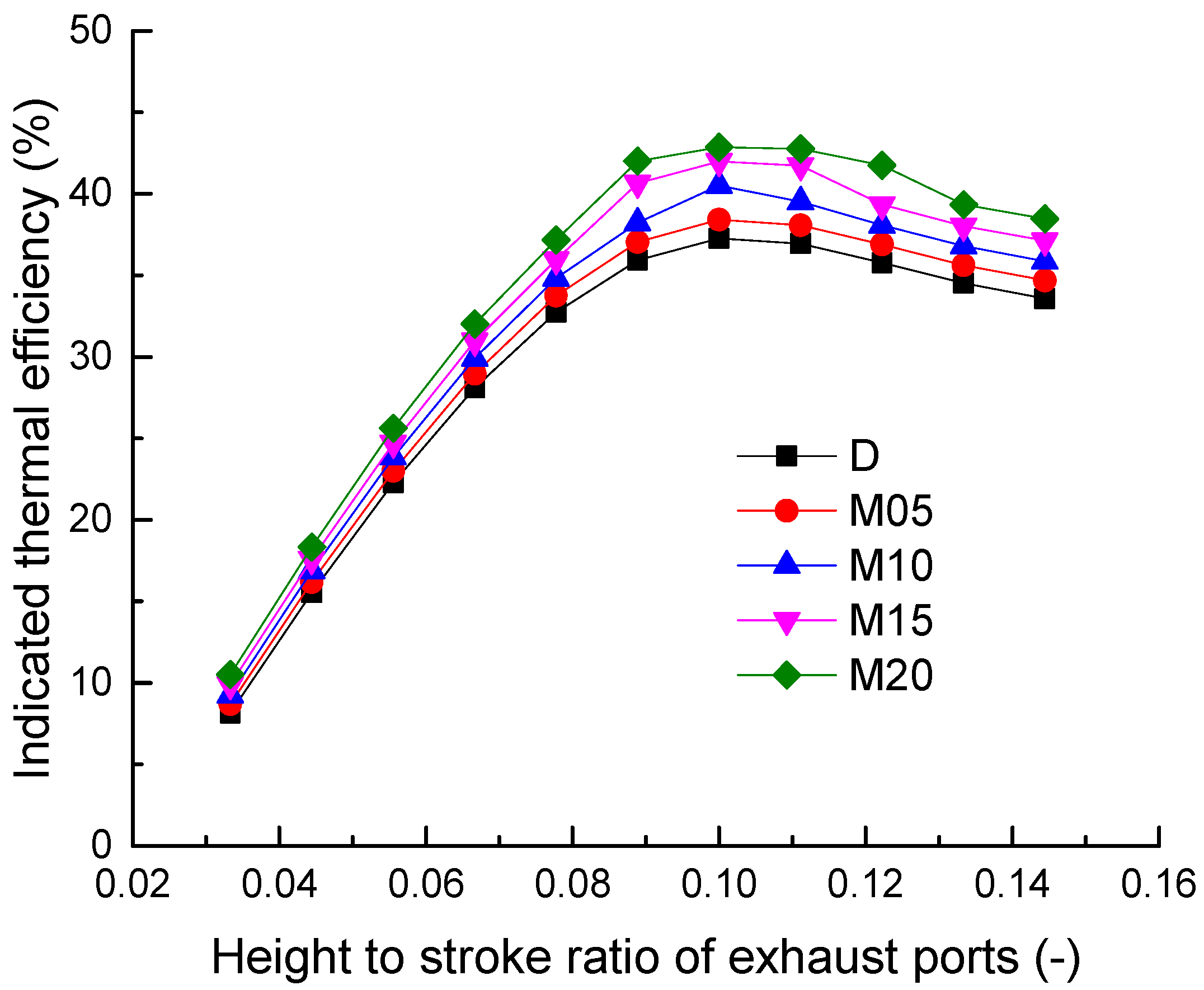

3.2. The Influence of Exhaust Port

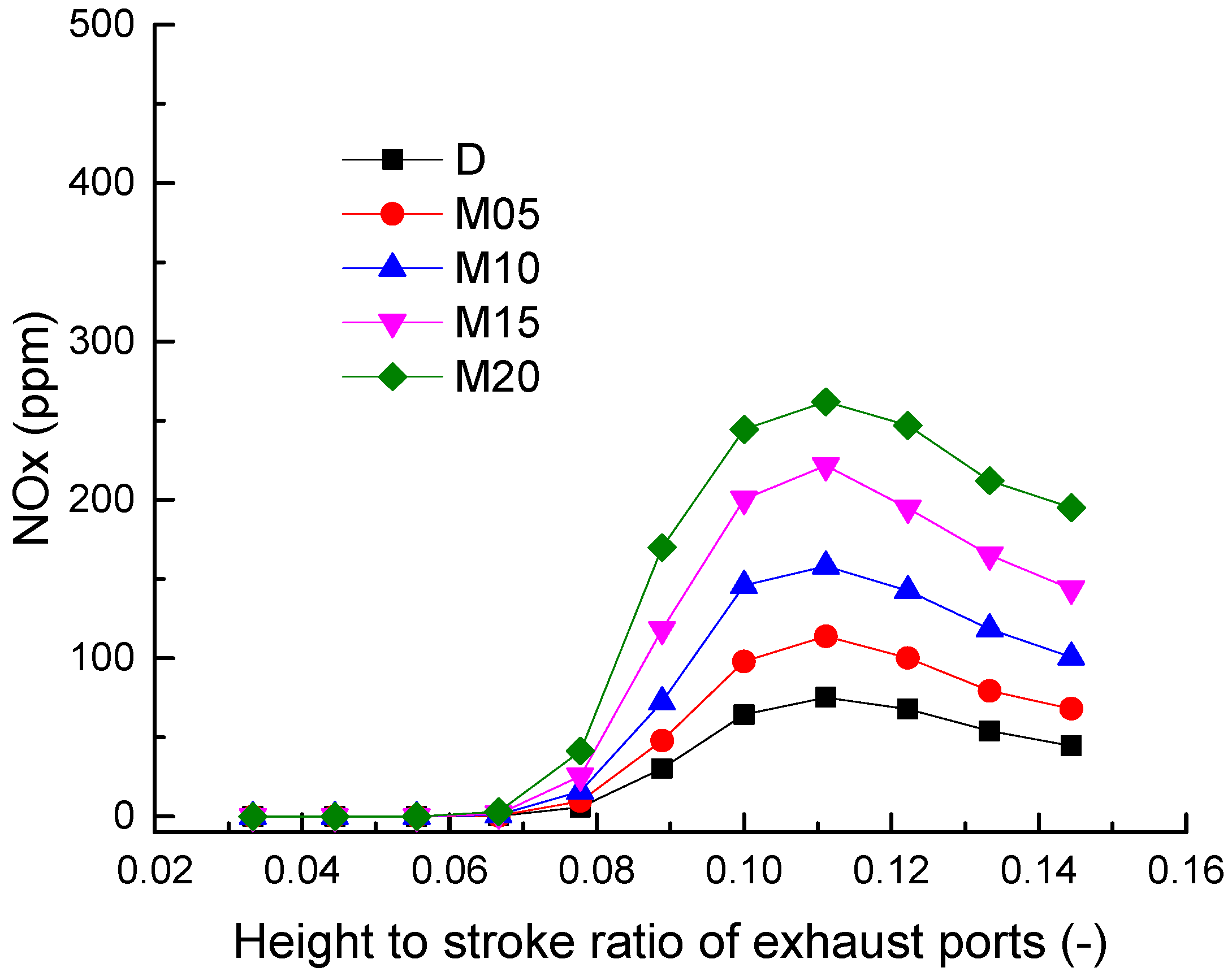

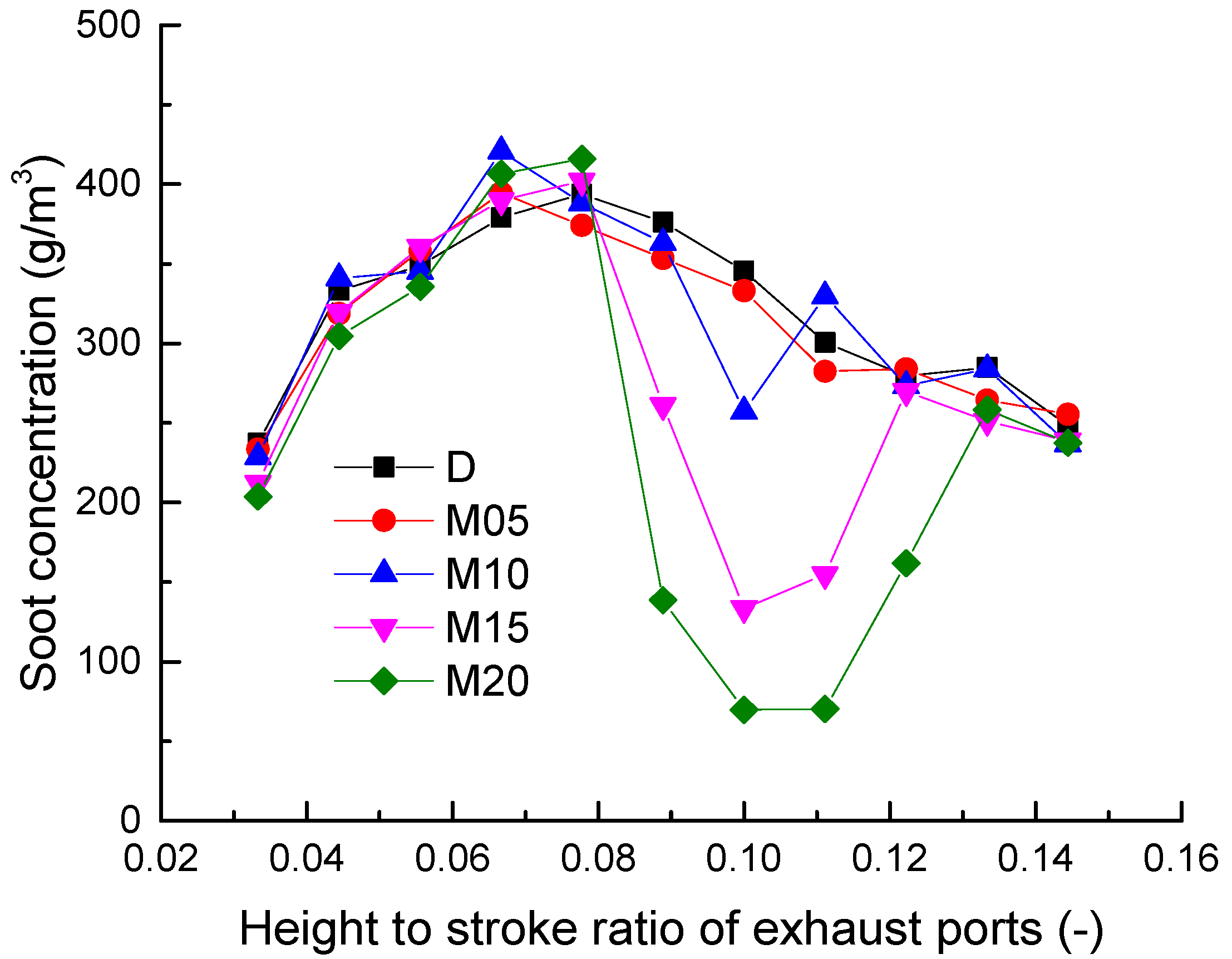

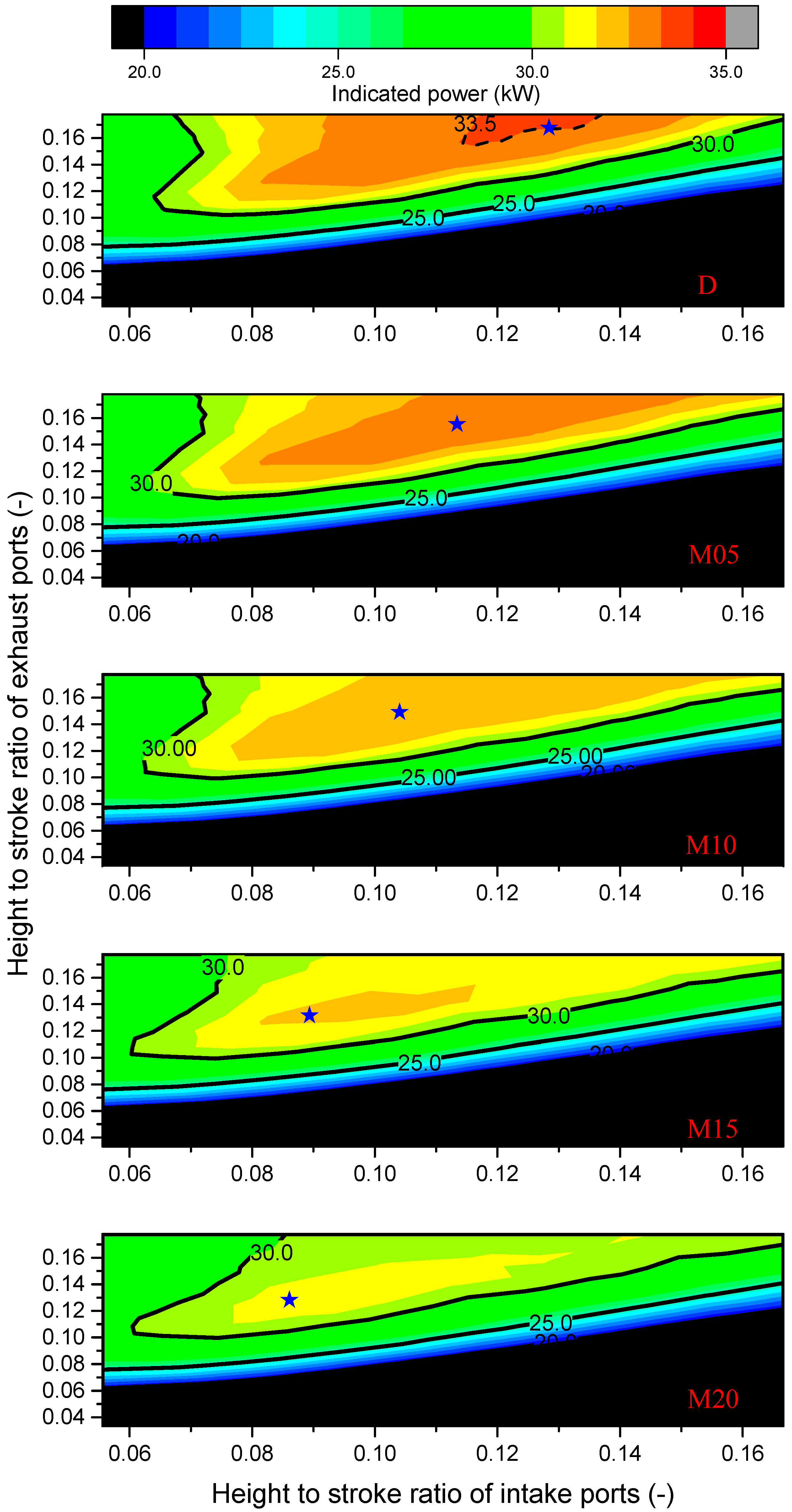

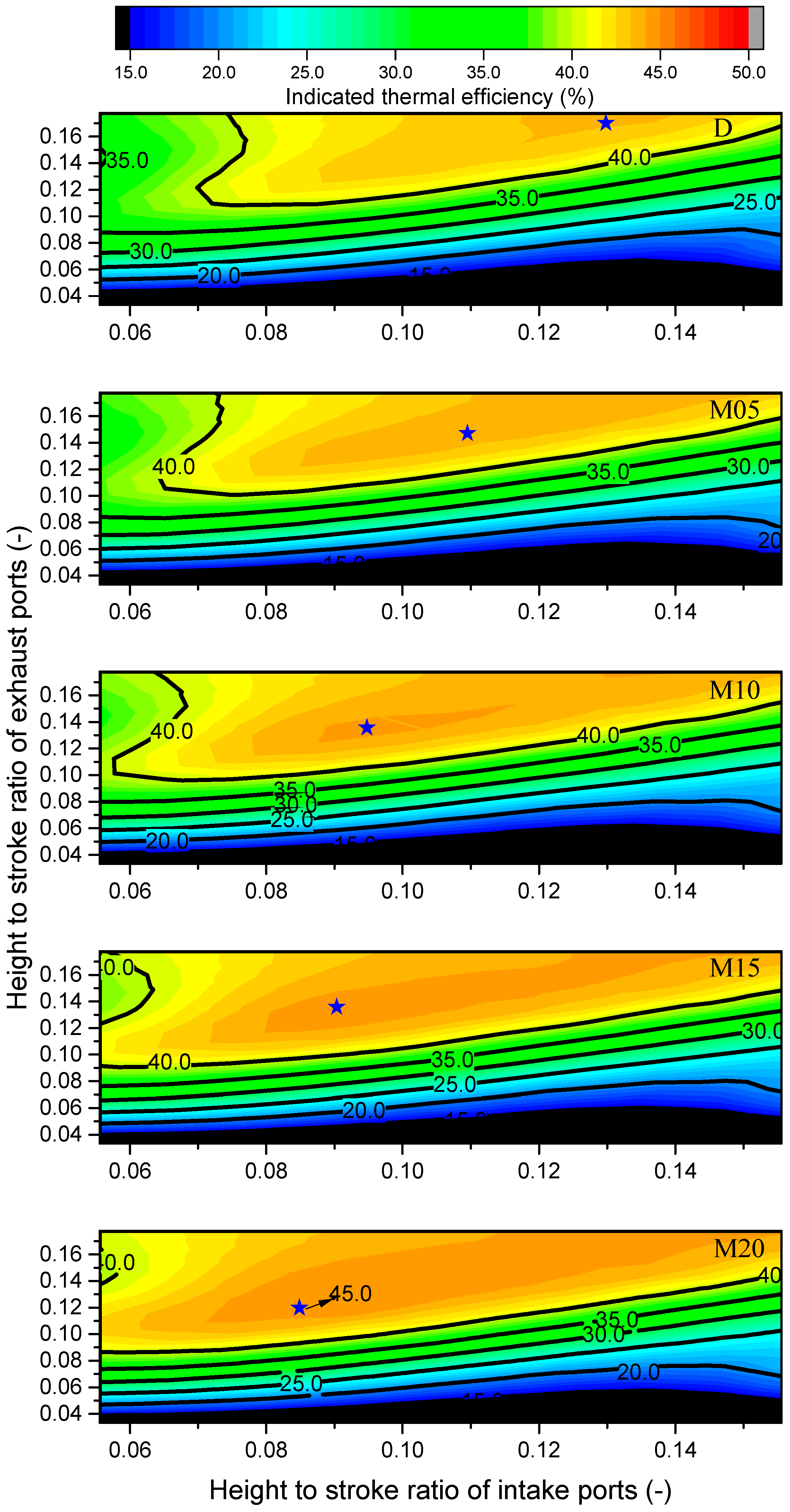

3.3. The Interaction of Intake and Exhaust Ports

4. Conclusions

- (1)

- By increasing the intake air, the larger intake port height promotes complete combustion of fuel, enhancing the influence of the methanol blending ratio on the indicated power. By reducing the residual gas, the larger exhaust port height promotes no significant drop in IP with increasing methanol ratio, enhancing the influence of the methanol blending ratio on the ITE.

- (2)

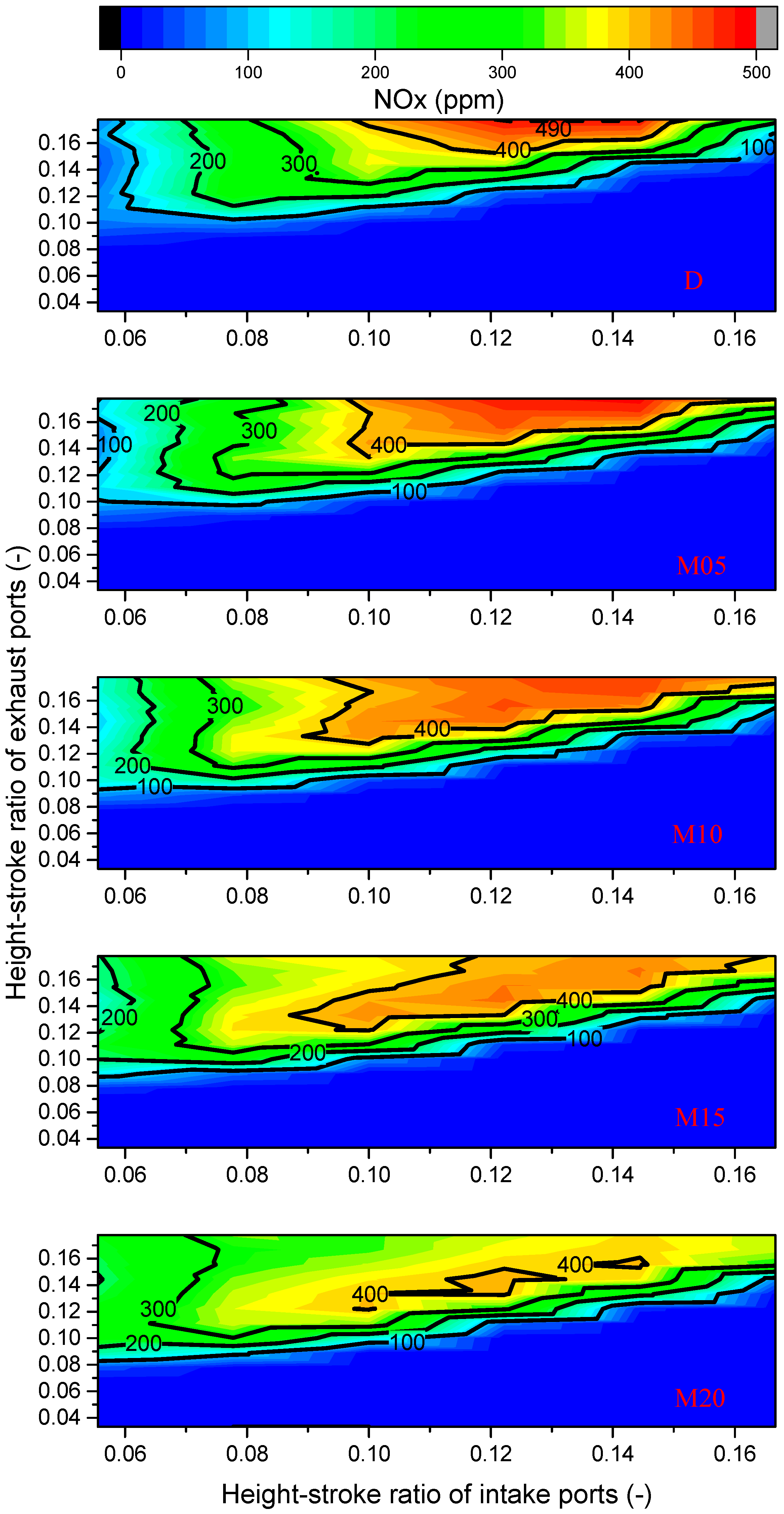

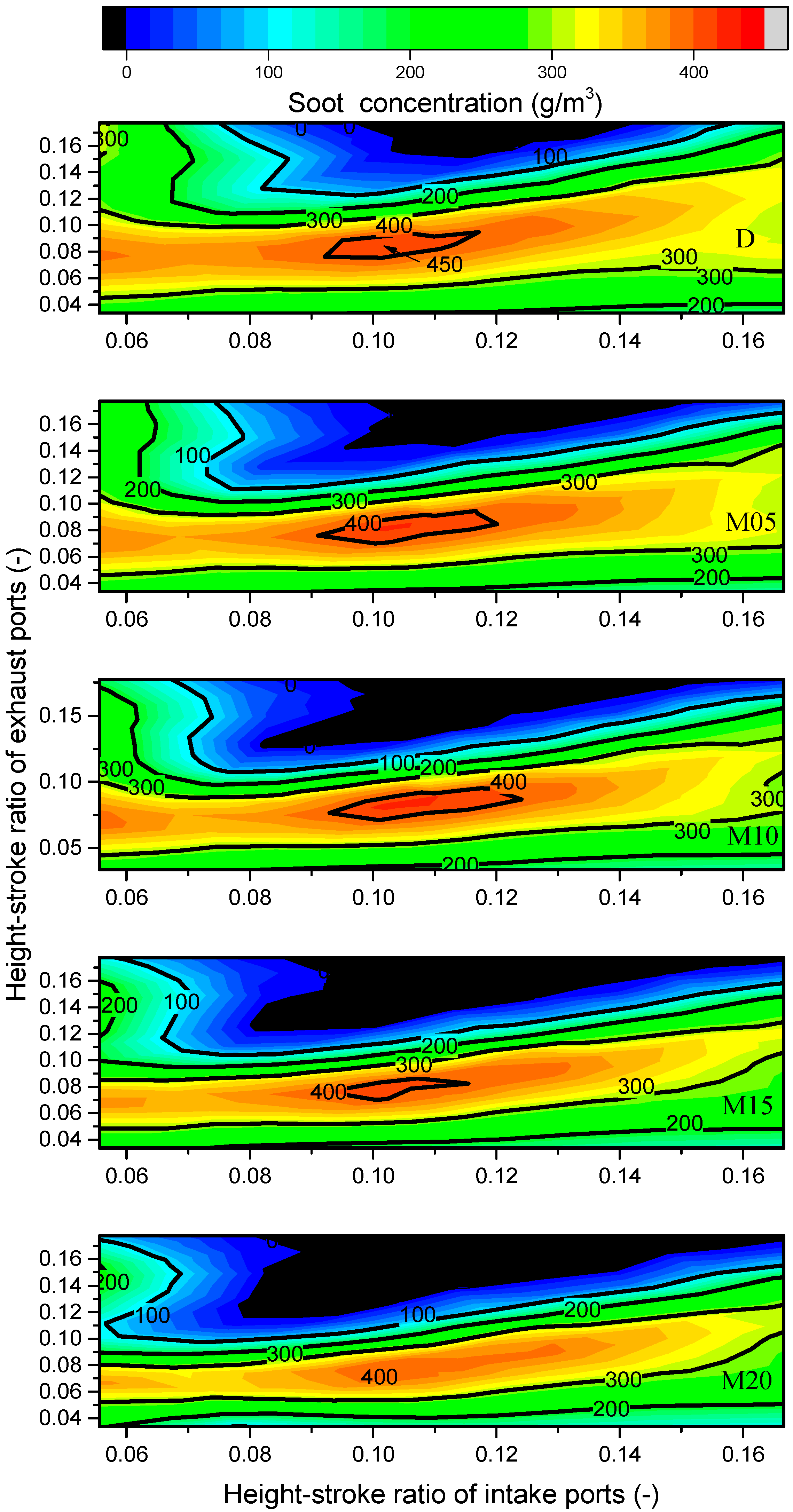

- The increasing methanol ratio uniformly raises NOx under the HSR of the exhaust ports. However, it indicates a significant difference in NOx emissions under different HSRs of the intake ports. Before the HSR of the intake ports increases to 0.08, the increasing methanol ratio uniformly raises NOx. After the HSR of the intake ports exceeds 0.1, the increasing methanol blending ratio decreases NOx. The methanol increases oxygen to promote combustion but also reduce the total energy of fuel. In addition, the soot concentration indicates an opposite phenomenon compared with the NOx emissions.

- (3)

- Under the interaction of the intake and exhaust ports, when the HSR of the intake and exhaust ports are both large, the IP and the ITE are both the largest. The HSR of ports for the optimal IP and ITE is decreased by the increasing methanol ratio. The NOx emission shows the same phenomenon as IP and ITE, while the soot concentration indicates an opposite result. The methanol in diesel weakens power performance but improves fuel economy and emission performance in OP2S diesel engines. The methanol ratio should be kept to 10–15% to balance power and emission performances.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| HCCI | Homogeneous charge compression ignition |

| HSR | Height-to-stroke ratio |

| ICEs | Internal combustion engines |

| IP | Indicated power |

| ITE | Indicated thermal efficiency |

| LTC | Low-temperature combustion |

| OP2S | Opposed-piston two-stroke |

| RCCI | Reactivity-controlled compression ignition |

| WCR | Width-to-circumference ratio |

References

- Kalghatgi, G. Development of Fuel/Engine Systems—The Way Forward to Sustainable Transport. Engineering 2019, 5, 510–518. [Google Scholar] [CrossRef]

- Su, W.; Zhang, Z.; Liu, R.; Qiao, Y. Development Trend for Technology of Vehicle Internal Combustion Engine. Chin. J. Eng. Sci. 2018, 20, 97–103. [Google Scholar] [CrossRef]

- Johnson, T.; Joshi, A. Review of Vehicle Engine Efficiency and Emissions; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2018. [Google Scholar] [CrossRef]

- Falkner, R. The Paris Agreement and the new logic of international climate politics. Int. Aff. 2016, 92, 1107–1125. [Google Scholar] [CrossRef]

- Panda, K.; Ramesh, A. Parametric investigations to establish the potential of methanol based RCCI engine and comparison with the conventional dual fuel mode. Fuel 2022, 308, 122025. [Google Scholar] [CrossRef]

- Xu, C.; Zhuang, Y.; Qian, Y.; Cho, H. Effect on the performance and emissions of methanol/diesel dual-fuel engine with different methanol injection positions. Fuel 2022, 307, 121868. [Google Scholar] [CrossRef]

- Su, L.-W.; Li, X.-R.; Sun, Z.-Y. The consumption, production and transportation of methanol in China: A review. Energy Policy 2013, 63, 130–138. [Google Scholar] [CrossRef]

- Sayin, C.; Ilhan, M.; Canakci, M.; Gumus, M. Effect of injection timing on the exhaust emissions of a diesel engine using diesel–Methanol blends. Renew. Energy 2009, 34, 1261–1269. [Google Scholar] [CrossRef]

- Panda, K.; Ramesh, A. Diesel injection strategies for reducing emissions and enhancing the performance of a methanol based dual fuel stationary engine. Fuel 2021, 289, 119809. [Google Scholar] [CrossRef]

- Wei, L.; Yao, C.; Wang, Q.; Pan, W.; Han, G. Combustion and emission characteristics of a turbocharged diesel engine using high premixed ratio of methanol and diesel fuel. Fuel 2015, 140, 156–163. [Google Scholar] [CrossRef]

- Ma, B.; Yao, A.; Yao, C.; Chen, C.; Qu, G.; Wang, W.; Ai, Y. Multiple combustion modes existing in the engine operating in diesel methanol dual fuel. Energy 2021, 234, 121285. [Google Scholar] [CrossRef]

- Abani, N.; Chiang, M.; Thomas, I.; Nagar, N.; Zermeno, R.; Regner, G. Developing a 55% BTE Commercial Heavy-Duty Opposed-Piston Engine without a Waste Heat Recovery System. In Heavy-Duty-, On-und Off-Highway-Motoren 2016; Springer: Wiesbaden, Germany, 2017; pp. 292–310. [Google Scholar]

- Huo, M.; Huang, Y.; Hofbauer, P. Piston Design Impact on the Scavenging and Combustion in an Opposed-Piston, Opposed-Cylinder (OPOC) Two-Stroke Engine. SAE Paper 2015-01-1269. In Proceedings of the SAE 2015 World Congress & Exhibition, Detroit, IL, USA, 23 April 2015. [Google Scholar]

- Pirault, J.-P.; Flint, M. Opposed-Piston Engine Renaissance Power for the Future; Achates Power Inc.: San Diego, CA, USA, 2010. [Google Scholar]

- Ma, F.; Zhang, S.; Zhao, Z.; Wang, Y. Research on the Operating Characteristics of Hydraulic Free-Piston Engines: A Systematic Review and Meta-Analysis. Energies 2021, 14, 3530. [Google Scholar] [CrossRef]

- Ma, F.; Yang, W.; Xu, J.; Li, Y.; Zhao, Z.; Zhang, Z.; Wang, Y. Experimental Investigation of Combustion Characteristics on Opposed Piston Two-Stroke Gasoline Direct Injection Engine. Energies 2021, 14, 2105. [Google Scholar] [CrossRef]

- Patil, S.; Ghazi, A.; Redon, F.; Sharp, C.; Schum, D.; Headley, J. Cold Start HD FTP Test Results on Multi-Cylinder Opposed-Piston Engine Demonstrating Rapid Exhaust Enthalpy Rise to Achieve Ultra Low NOx (No. 2018-01-1378); SAE Technical Paper; SAE International: Warrendale, PA, USA, 2018. [Google Scholar]

- Yang, W.; Li, X.R.; Zhao, W.H.; Kang, Y.N.; Liu, F.S. Effect of Layered-Port VVT on Performance of Opposed-Piston Two-Stroke Diesel Engine. J. Energy Eng. 2019, 145, 04019027. [Google Scholar] [CrossRef]

- Ma, F.K.; Wang, J.; Feng, Y.N.; Zhang, Y.G.; Su, T.X.; Zhang, Y.; Liu, Y.H. Parameter Optimization on the Uniflow Scavenging System of an OP2S-GDI Engine Based on Indicated Mean Effective Pressure (IMEP). Energies 2017, 10, 368. [Google Scholar] [CrossRef] [Green Version]

- Asad, U.; Divekar, P.S.; Zheng, M. High efficiency ethanol–diesel dual-fuel combustion: Analyses of performance, emissions and thermal efficiency over the engine load range. Fuel 2022, 310, 122397. [Google Scholar] [CrossRef]

| Engine Parameter | Value |

|---|---|

| Bore [mm] | 85 |

| Stroke [mm] | 2 × 90 |

| Compression ratio [-] | 22 |

| Intake temperature [K] | 320 |

| Intake pressure [MPa] | 0.13 |

| Back pressure [MPa] | 0.1 |

| Rated speed [r/min] | 3000 |

| Cycle fuel injection [mg/cycle] | 36 |

| Intake port height [mm] | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 | 26 | 28 |

| HSR of intake ports | 0.033 | 0.044 | 0.056 | 0.067 | 0.078 | 0.089 | 0.100 | 0.111 | 0.122 | 0.133 | 0.144 | 0.156 |

| Exhaust port height [mm] | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 | 26 | |

| HSR of exhaust ports | 0.033 | 0.044 | 0.056 | 0.067 | 0.078 | 0.089 | 0.100 | 0.111 | 0.122 | 0.133 | 0.144 |

| Type | 100% Diesel | 5% Methanol + 95% Diesel | 10% Methanol + 90% Diesel | 15% Methanol + 85% Diesel | 20% Methanol + 80% Diesel |

|---|---|---|---|---|---|

| Mark | D | M05 | M10 | M15 | M20 |

| Properties | Diesel | Methanol |

|---|---|---|

| Lower heating value [MJ/kg] | 42.5 | 19.7 |

| Cetane number [-] | 48 | <5 |

| Density [25 °C, kg/m3] | 840 | 790 |

| Boiling point [°C] | 287 | 64.7 |

| H/C ratio [-] | 0.16 | 0.33 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, W.; Zhang, L.; Ma, F.; Xu, D.; Ji, W.; Zhao, Y.; Zhang, J. Simulation about the Effect of the Height-to-Stroke Ratios of Ports on Power and Emissions in an OP2S Engine Using Diesel/Methanol Blends. Energies 2022, 15, 2942. https://doi.org/10.3390/en15082942

Yang W, Zhang L, Ma F, Xu D, Ji W, Zhao Y, Zhang J. Simulation about the Effect of the Height-to-Stroke Ratios of Ports on Power and Emissions in an OP2S Engine Using Diesel/Methanol Blends. Energies. 2022; 15(8):2942. https://doi.org/10.3390/en15082942

Chicago/Turabian StyleYang, Wei, Lei Zhang, Fukang Ma, Dan Xu, Wenjing Ji, Yangyang Zhao, and Jianing Zhang. 2022. "Simulation about the Effect of the Height-to-Stroke Ratios of Ports on Power and Emissions in an OP2S Engine Using Diesel/Methanol Blends" Energies 15, no. 8: 2942. https://doi.org/10.3390/en15082942

APA StyleYang, W., Zhang, L., Ma, F., Xu, D., Ji, W., Zhao, Y., & Zhang, J. (2022). Simulation about the Effect of the Height-to-Stroke Ratios of Ports on Power and Emissions in an OP2S Engine Using Diesel/Methanol Blends. Energies, 15(8), 2942. https://doi.org/10.3390/en15082942