Condensation Flow and Heat Transfer Characteristics of R410A in Micro-Fin Tubes and Three-Dimensional Surface Enhanced Tubes

Abstract

:1. Introduction

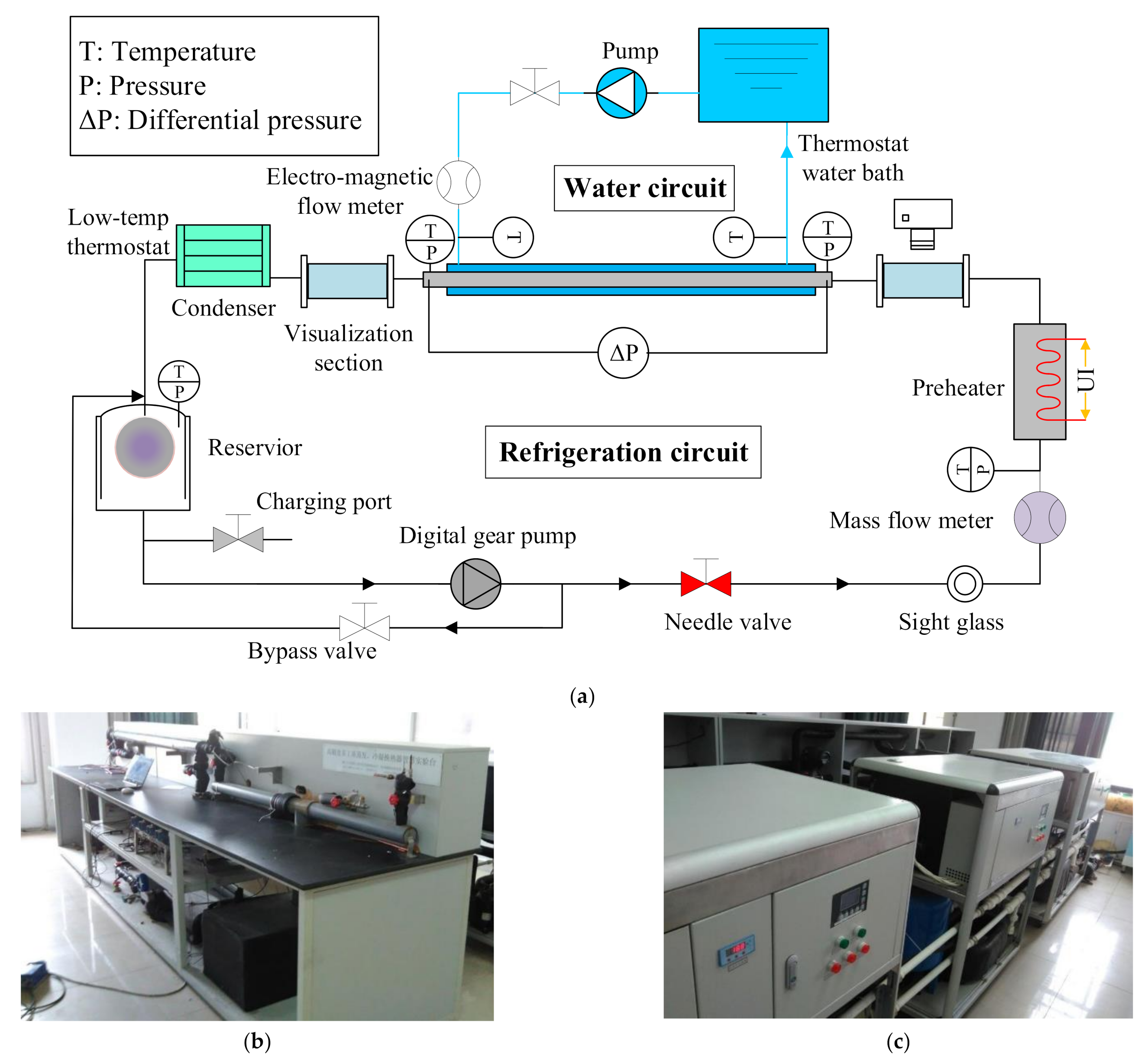

2. Experimental Details

3. Theory

4. Results

4.1. Verification of Experimental Reliability

4.2. Heat Transfer Performance

4.3. Pressure Drop Characteristics

4.4. Flow Pattern Analysis

5. Conclusions

- It can also be concluded that tubes produced from higher thermal conductivity material or tubes of a smaller diameter will lead to better heat transfer performance. The improvement of heat transfer performance of smooth tubes by thermal conductivity is limited, and the influence of enhanced tubes is more significant.

- Frictional pressure drop increases with the mass flow rate of the refrigerant. This is attributed to the higher mass flow rate producing more intense fluid turbulence. Three-dimensional 1EHT-enhanced tubes showed the highest frictional pressure drop during flow condensation at the same conditions; this is related to the dimples that make up the surface structure.

- In the investigation of flow patterns, as the vapor quality increases, the flow patterns that are observed in turn include: stratified wavy flow, intermittent flow, semi-annular flow, and annular flow. In addition, the transition from stratified wavy flow to intermittent flow and intermittent flow to annular flow in enhanced tubes occurs at lower vapor qualities. This is mainly influenced by the surface enhancing structure that promotes the liquid to extend to the upper part of the tube.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| A | test tube surface area, m2 | Greek symbols | |

| Al | liquid cross-sectional area, m2 | ε | void fraction |

| Ald | liquid cross-sectional area, dimensionless | θstrat | stratified angle, rad |

| Av | vapor cross-sectional area, m2 | λ | thermal conductivity, W/(m·K) |

| Avd | dimensionless vapor cross-sectional area | μ | dynamic viscosity, Pa·s |

| cp | specific heat, J/(kg·K) | ρ | density, kg/m3 |

| d | test tube diameter, m | σ | surface tension, N/m |

| dh | hydraulic diameter, m | Subscripts | |

| f | Fanning friction factor | a | acceleration |

| Fr | Froude number | bulk | Bulk temperature |

| g | gravitational acceleration, m/s2 | exp | experimental |

| G | mass flux, kg/(m2 s) | f | frictional |

| Gstrat | Stratified flow transition mass velocity, kg/(m2 s) | i | inner |

| Gwavy | Wavy flow transition mass velocity, kg/(m2 s) | in | inlet |

| h | heat transfer coefficient, W/(m2·K) | l | liquid phase |

| hl | liquid height, m | o | outer |

| hld | dimensionless liquid height | out | outlet |

| hlv | latent heat of vaporization, J/kg | ph | preheating section |

| k | thermal conductivity, W/(m·K) | ref | refrigerant |

| L | tube length, m | sat | saturated |

| LMTD | logarithmic mean temperature, K | sc | sudden expansion |

| m | mass flux, kg/s | sl | sudden contraction |

| p | Perimeter, m | t | total |

| P | Pressure, kpa | te | test section |

| Pr | Prandtl number | tp | two-phase |

| Q | heat transfer amount, W | ts | test section |

| q | heat flux, W/m2 | v | vapor phase |

| Re | Reynolds number | w | water |

| T/t | temperature, K/°C | ||

| We | Weber number | ||

| x | vapor quality | ||

| xIA | intermittent to annular flow transition quality | ||

References

- Li, W.; Tang, W.; Chen, J.; Zhu, H.; Kukulka, D.J.; He, Y.; Sun, Z.; Du, J.; Zhang, B. Convective condensation in three enhanced tubes with different surface modifications. Exp. Therm. Fluid Sci. 2018, 97, 79–88. [Google Scholar] [CrossRef] [Green Version]

- Guo, S.P.; Wu, Z.; Li, W.; Kukulka, D.J.; Sunden, B.; Zhou, X.P.; Wei, J.J.; Simon, T. Condensation and evaporation heat transfer characteristics in horizontal smooth, herringbone and enhanced surface EHT tubes. Int. J. Heat Mass Tran. 2015, 85, 281–291. [Google Scholar] [CrossRef]

- Sun, Z.C.; Li, W.; Ma, X.; Ma, L.X.; Yan, H. Two-phase heat transfer in horizontal dimpled/protruded surface tubes with petal-shaped background patterns. Int. J. Heat Mass Transf. 2019, 140, 837–851. [Google Scholar] [CrossRef]

- Kukulka, D.J.; Smith, R.; Li, W. Comparison of tubeside condensation and evaporation characteristics of smooth and enhanced heat transfer 1EHT tubes. Appl. Eng. 2015, 89, 1079–1086. [Google Scholar] [CrossRef]

- Kukulka, D.J.; Smith, R. Thermale-hydraulic performance of Vipertex 1EHT enhanced heat transfer tubes. Appl. Therm. Eng. 2013, 61, 60–66. [Google Scholar] [CrossRef]

- Sun, Z.C.; Li, W.; Guo, R.H.; He, Y.; Kukulka, D.J. Condensation heat transfer in horizontal three dimensional two-layer two-side enhanced tubes. Int. J. Heat Mass Transf. 2018, 127, 141–145. [Google Scholar] [CrossRef]

- Zheng, B.; Wang, J.; Guo, Y.; Kukulka, D.J.; Tang, W.Y.; Smith, R.; Sun, Z.C.; Li, W. An Experimental Study of In-Tube Condensation and Evaporation Using Enhanced Heat Transfer (EHT) Tubes. Energies 2021, 14, 867. [Google Scholar] [CrossRef]

- Chen, J.; Li, W. Local flow boiling heat transfer characteristics in three-dimensional enhanced tubes. Int. J. Heat Mass Transf. 2018, 121, 1021–1032. [Google Scholar] [CrossRef]

- Chen, J.; Li, W. Local convective condensation heat transfer in horizontal double-layer three-dimensional dimple-grooved tubes. Int. J. Heat Mass Transf. 2018, 127, 810–820. [Google Scholar] [CrossRef]

- Li, W.; Tang, W.Y.; Gu, Z.; Guo, Y.; Ma, X.; Minkowycz, W.J.; He, Y.; Kukulka, D.J. Analysis of condensation and evaporation heat transfer inside 3-D enhanced tubes. Numer. Heat Transf. Appl. 2020, 78, 525–540. [Google Scholar] [CrossRef]

- Gu, Y.; Ding, Y.; Liao, Q.; Fu, Q.; Zhu, X.; Wang, H. Condensation heat transfer characteristics of moist air outside 3-D finned tubes with different wettability. Energy 2020, 207, 118202. [Google Scholar] [CrossRef]

- Zhang, J.; Zhou, N.; Li, W.; Luo, Y.; Li, S. An experimental study of R410A condensation heat transfer and pressure drops characteristics in microfin and smooth tubes with 5mm OD. Int. J. Heat Mass Transf. 2018, 125, 1284–1295. [Google Scholar] [CrossRef]

- Zhao, C.; Ji, W.; Jin, P.; Zhong, Y.; Tao, W. The influence of surface structure and thermal conductivity of the tube on the condensation heat transfer of R134a and R404A over single horizontal enhanced tubes. Appl. Therm. Eng. 2017, 125, 1114–1122. [Google Scholar] [CrossRef]

- Ji, W.; Zhao, C.; Zhang, D.; Li, Z.; He, Y.; Tao, W. Condensation of R134a outside single horizontal titanium, cupronickel (B10 and B30), stainless steel and copper tubes. Int. J. Heat Mass Transf. 2014, 77, 194–201. [Google Scholar] [CrossRef]

- Ali, H.M.; Briggs, A. Condensation heat transfer on pin-fin tubes: Effect of thermal conductivity and pin height. Appl. Therm. Eng. 2013, 60, 465–471. [Google Scholar] [CrossRef]

- Tang, W.; Sun, Z.; Li, W. Visualization of flow patterns during condensation in dimpled surface tubes of different materials. Int. J. Heat Mass Transf. 2020, 161, 120251. [Google Scholar] [CrossRef]

- Li, G.; Huang, L.; Tao, L. Experimental investigation of refrigerant condensation heat transfer characteristics in the horizontal microfin tubes. Appl. Therm. Eng. 2017, 123, 1484–1493. [Google Scholar] [CrossRef]

- Kukulka, D.J.; Smith, R.; Li, W. Condensation and Evaporation Characteristics of Vipertex 1EHT Enhanced Heat Transfer Tubes. Chem. Eng. Tran. 2014, 39, 727–732. [Google Scholar]

- Kukulka, D.J.; Smith, R.; Li, W. Experimental Comparison of the Evaporation and Condensation Heat Transfer Coefficients on the Outside of Enhanced Surface Tubes with Different Outer Diameters. Chem. Eng. Tran. 2019, 76, 31–36. [Google Scholar]

- Li, W.; Wang, J.; Guo, Y.; Shi, Q.; He, Y.; Kukulka, D.J.; Luo, X.; Kabelac, S. R410Aflow condensation inside two dimensional micro-fin tubes and three dimensional dimple tubes. Int. J. Heat Mass Transf. 2022, 182, 121910. [Google Scholar] [CrossRef]

- Alves, G.E. Co-current liquid-gas flow in a pipeline contactor. Chem. Eng. Prog. 1954, 50, 449–456. [Google Scholar]

- Collier, J.G.; Thome, J.R. Convective Boiling and Condensation; Clarendon Press: Oxford, UK, 1994; p. 28. [Google Scholar]

- Taitel, Y.; Dukler, A.E. A model for predicting flow regime transitions in horizontal and near horizontal gas-liquid flow. AIChE J. 1976, 22, 47–55. [Google Scholar] [CrossRef]

- Steniner, D. Heat transfer to boiling saturated liquids. In VDI-War Meatlas (VDI Heat Atlas); Fullarton, J.W., Translator; VDI-Gessellschaft Verfahrenstechnik and Chemieingenicurwesen (GCV): Dusseldorf, Germany, 1993. [Google Scholar]

- Kattan, N.; Thome, J.R.; Favrat, D. Flow boiling in horizontal tubes: Part 1––Development of a diabatic two-phase flow pattern map. Heat Transf. 1998, 120, 140–147. [Google Scholar] [CrossRef]

- Kattan, N.; Thome, J.R.; Favrat, D. Flow boiling in horizontal tubes: Part 2––New heat transfer data for five refrigerants. Heat Transfer 1998, 120, 148–155. [Google Scholar] [CrossRef]

- Kattan, N.; Thome, J.R.; Favrat, D. Flow boiling in horizontal tubes: Part 3––Development of a new heat transfer model based on flow pattern. Heat Transf. 1998, 120, 156–165. [Google Scholar] [CrossRef]

- Wojtan, L.; Ursenbacher, T.; Thome, J.R. Investigation of flow boiling in horizontal tubes: Part I—A new diabatic two-phase flow pattern map. Int. J. Heat Mass Transf. 2005, 48, 2955–2969. [Google Scholar] [CrossRef]

- Hajal, J.E.; Thome, J.R.; Cavallini, A. Condensation in horizontal tubes, part 1: Two-phase flow pattern map. Int. J. Heat Mass Transf. 2003, 46, 3349–3363. [Google Scholar] [CrossRef]

- Cavallini, A.; Del Col, D.; Doretti, L.; Matkovic, M.; Rossetto, L.; Zilio, C.; Censi, G. Condensation in Horizontal Smooth Tubes: A New Heat Transfer Model for Heat Exchanger Design. Heat Transf. Eng. 2006, 27, 31–38. [Google Scholar] [CrossRef]

- Lemmon, E.W.; Huber, M.L.; Mclinden, M.O. NIST Standard Reference Database 23: Reference Fluid Thermodynamic and Transport Properties-REFPROP. 9.0; Standard Reference Data Program; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2010.

- Gnielinski, V. New Equations for Heat and Mass Transfer in Turbulent Pipe and Channel Flow. Int. J. Chem. Eng. 1976, 16, 8–16. [Google Scholar]

- Petukhov, B.S. Heat Transfer and Friction in Turbulent Pipe Flow with Variable Physical Properties. Adv. Heat Transf. 1970, 6, 503–564. [Google Scholar]

- Rouhani, S.Z.; Axelsson, E. Calculation of void volume fraction in the subcooled and quality boiling regions. Int. J. Heat Mass Transf. 1970, 13, 383–393. [Google Scholar] [CrossRef]

- Richardson, B.E. Some Problems in Horizontal Two-phase Two-component Flow. Ph.D. Thesis, Purdue University, West Lafayette, IN, USA, 1959. [Google Scholar]

- Moffat, R.J. Describing the uncertainties in experimental results. Exp. Therm. Fluid Sci. 1988, 1, 3–17. [Google Scholar] [CrossRef] [Green Version]

- Dittus, F.W.; Boelter, L.M.K. Heat transfer in automobile radiator of the tubular type. Int. Commun. Heat Mass 1985, 12, 3–22. [Google Scholar] [CrossRef]

- Petukhov, B.S.; Popov, V.N. Theoretical calculation of heat exchange in turbulent flow in tubes of an incompressible fluid with variable physical properties. High. Temp. 1963, 1, 69–83. [Google Scholar]

- Biberg, D. An explicit approximation for the wetted angle in two-Phase stratified pipe flow. Can. J. Chem. Eng. 1999, 77, 1221–1224. [Google Scholar] [CrossRef]

- Zürcher, O.; Favrat, D.; Thome, J.R. Evaporation of Ammonia in a Smooth Horizontal Tube: Heat Transfer Measurements and Predictions. J. Heat Transf. ASME 1999, 121, 89–101. [Google Scholar] [CrossRef]

- Mashouf, H.; Shafaee, M.; Sarmadian, A.; Mohseni, S.G. Visual study of flow patterns during evaporation and condensation of R-600a inside horizontal smooth and helically dimpled tubes. Appl. Eng. 2017, 124, 1392–1400. [Google Scholar] [CrossRef] [Green Version]

| Parameter | Smooth Tube | 1EHT Tube | HX Tube |

|---|---|---|---|

| Material | Cu/SS | Cu/SS | Cu/SS |

| Outer diameter (mm) | 9.52/12.7 | 9.52/12.7 | 9.52/12.7 |

| Thickness (mm) | 0.61 | 0.61 | 0.61 |

| Length (m) | 2 | 2 | 2 |

| Dimple (ridges)/fin height (mm) | - | 0.19/1.71 | 0.25 |

| Dimple (ridges)/fin width (mm) | - | 0.35/1.34 | 0.31 |

| Dimple (ridges)/fin pitch (mm) | - | 4 | 0.8 |

| Helix angle (°) | - | 60 | 21 |

| Surface Area enhancement ratio | 1 | 1.34 | 1.44 |

| Measurement Parameters | Accuracy |

|---|---|

| Di (mm) | ± 0.05 |

| L (mm) | ± 0.2 |

| T (K) | ± 0.05 |

| P (range: 0–40 bar) | ± 0.08 |

| ΔP (range: 0–100 kPa) | ± 0.05 |

| mw (range: 0–12 L min−1) | ± 0.042 |

| mref (range: 0–90 kg h−1) | ± 0.18 |

| Calculation Parameters | Accuracy |

|---|---|

| m (kg m−2 s−1) | ± 3.25% |

| Q (W m−2) | ± 4.71% |

| x | ± 6.30% |

| h (W m−2 k−1) | ± 11.32% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, Y.; Cheng, H.; Li, W.; Kukulka, D.J.; Smith, R. Condensation Flow and Heat Transfer Characteristics of R410A in Micro-Fin Tubes and Three-Dimensional Surface Enhanced Tubes. Energies 2022, 15, 2951. https://doi.org/10.3390/en15082951

Gao Y, Cheng H, Li W, Kukulka DJ, Smith R. Condensation Flow and Heat Transfer Characteristics of R410A in Micro-Fin Tubes and Three-Dimensional Surface Enhanced Tubes. Energies. 2022; 15(8):2951. https://doi.org/10.3390/en15082951

Chicago/Turabian StyleGao, Yu, Hong Cheng, Wei Li, David John Kukulka, and Rick Smith. 2022. "Condensation Flow and Heat Transfer Characteristics of R410A in Micro-Fin Tubes and Three-Dimensional Surface Enhanced Tubes" Energies 15, no. 8: 2951. https://doi.org/10.3390/en15082951

APA StyleGao, Y., Cheng, H., Li, W., Kukulka, D. J., & Smith, R. (2022). Condensation Flow and Heat Transfer Characteristics of R410A in Micro-Fin Tubes and Three-Dimensional Surface Enhanced Tubes. Energies, 15(8), 2951. https://doi.org/10.3390/en15082951