Simulation Research on Deadbeat Direct Torque and Flux Control of Permanent Magnet Synchronous Motor

Abstract

:1. Introduction

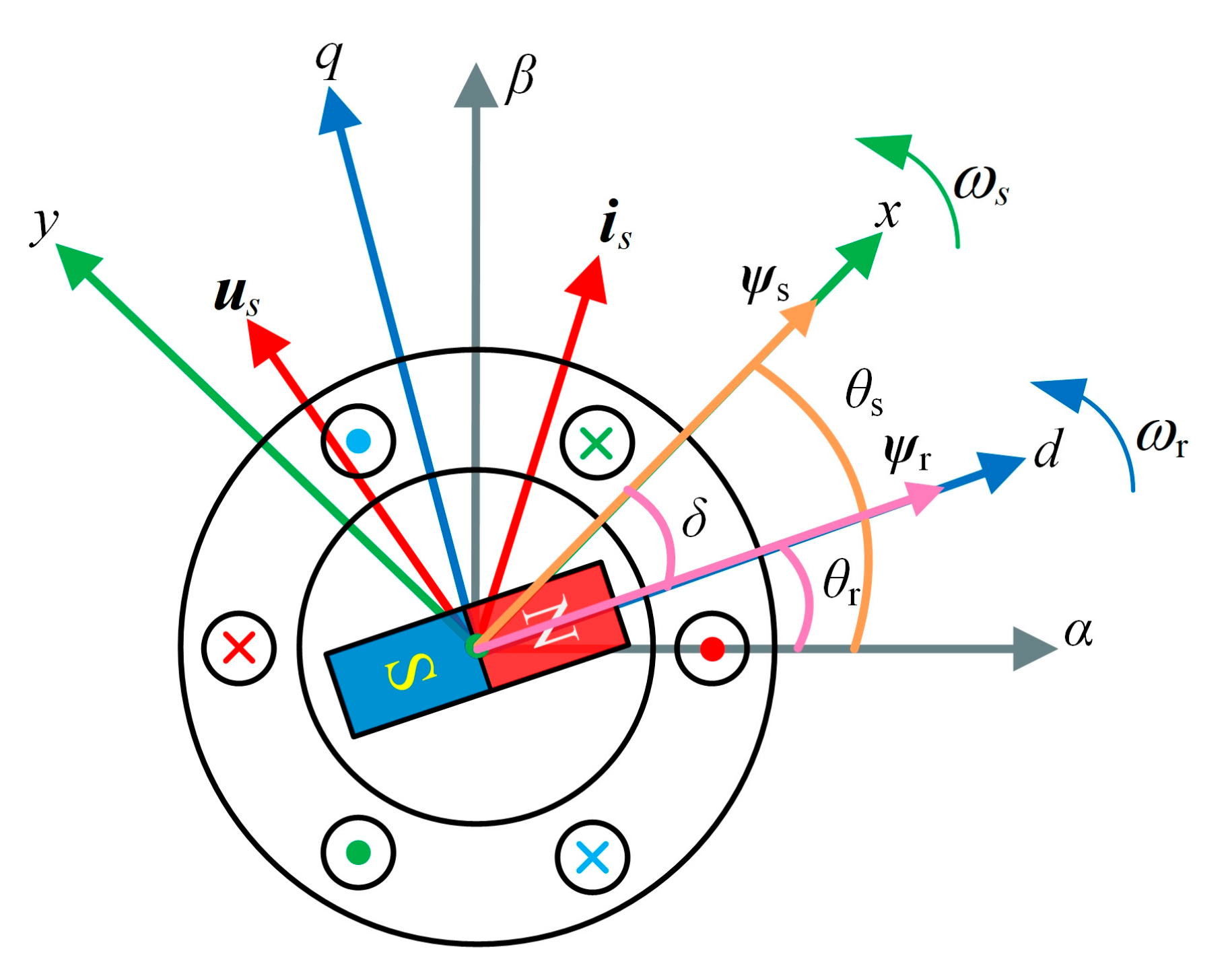

2. The Principles of the DB-DTFC

2.1. Definition and Relationship of Each Coordinate System

2.2. The Basic Principle of the Traditional DB-DTFC Algorithm

2.3. The New DB-DTFC Algorithm

3. System Design

4. Simulation and Results

4.1. Construction of System Simulation Platform

4.2. System Simulation and Results

5. Discussion

5.1. Comparison on Torque Control

5.2. Comparison of Torque Ripple Reduction

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Vafaie, M.H.; Mirzaeian Dehkordi, B.; Moallem, P.; Kiyoumarsi, A. A New Predictive Direct Torque Control Method for Improving Both Steady-State and Transient-State Operations of the PMSM. IEEE Trans. Power Electron. 2016, 31, 3738–3753. [Google Scholar] [CrossRef]

- Gao, C.; Nie, Y.; Si, J.; Fu, Z.; Feng, H. Mode Recognition and Fault Positioning of Permanent Magnet Demagnetization for PMSM. Energies 2019, 12, 1644. [Google Scholar] [CrossRef] [Green Version]

- Zhou, K.; Ai, M.; Sun, D.; Jin, N.; Wu, X. Field Weakening Operation Control Strategies of PMSM Based on Feedback Linearization. Energies 2019, 12, 4526. [Google Scholar] [CrossRef] [Green Version]

- Niewiara, Ł.J.; Szczepański, R.; Tarczewski, T.; Grzesiak, L.M. State Feedback Speed Control with Periodic Disturbances Attenuation for PMSM Drive. Energies 2022, 15, 587. [Google Scholar] [CrossRef]

- Hao, Z.; Yang, Y.; Gong, Y.; Hao, Z.; Zhang, Z.; Song, H.; Zhang, J. Linear/Nonlinear Active Disturbance Rejection Switching Control for Permanent Magnet Synchronous Motors. IEEE Trans. Power Electron. 2021, 36, 9334–9347. [Google Scholar] [CrossRef]

- Wang, W.; Tan, F.; Wu, J.; Ge, H.; Wei, H.; Zhang, Y. Adaptive Integral Backstepping Controller for PMSM with AWPSO Parameters Optimization. Energies 2019, 12, 2596. [Google Scholar] [CrossRef] [Green Version]

- Tang, Z.; Akin, B. A New LMS Algorithm Based Deadtime Compensation Method for PMSM FOC Drives. IEEE Trans. Ind. Appl. 2018, 54, 6472–6484. [Google Scholar] [CrossRef]

- Candelo-Zuluaga, C.; Riba, J.-R.; Garcia, A. PMSM Parameter Estimation for Sensorless FOC Based on Differential Power Factor. IEEE Trans. Instrum. Meas. 2021, 70, 1–12. [Google Scholar] [CrossRef]

- Zhang, X.; Cheng, Y.; Zhao, Z.; Yan, K. Optimized Model Predictive Control with Dead-Time Voltage Vector for PMSM Drives. IEEE Trans. Power Electron. 2021, 36, 3149–3158. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, X.; Guo, Y. Three-Vector Predictive Current Control for Interior Permanent Magnet Synchronous Motor. In Proceedings of the 2021 IEEE International Conference on Predictive Control of Electrical Drives and Power Electronics (PRECEDE), Jinan, China, 20–22 November 2021; pp. 443–448. [Google Scholar]

- Gong, Z.; Zhang, C.; Ba, X.; Guo, Y. Improved Deadbeat Predictive Current Control of Permanent Magnet Synchronous Motor Using a Novel Stator Current and Disturbance Observer. IEEE Access. 2021, 9, 142815–142826. [Google Scholar] [CrossRef]

- Zhang, X.; Hou, B. Double Vectors Model Predictive Torque Control Without Weighting Factor Based on Voltage Tracking Error. IEEE Trans. Power Electron. 2018, 33, 2368–2380. [Google Scholar] [CrossRef]

- Zhong, L.; Rahman, M.F.; Hu, W.Y.; Lim, K.W. Analysis of direct torque control in permanent magnet synchronous motor drives. IEEE Trans. Power Electron. 1997, 12, 528–536. [Google Scholar] [CrossRef]

- Bao, G.; Qi, W.; He, T. Direct Torque Control of PMSM with Modified Finite Set Model Predictive Control. Energies 2020, 13, 234. [Google Scholar] [CrossRef] [Green Version]

- Wang, D.; Yuan, T.; Wang, X.; Wang, X.; Li, W. A Composite Vectors Modulation Strategy for PMSM DTC Systems. Energies 2018, 11, 2729. [Google Scholar] [CrossRef] [Green Version]

- Abassi, M.; Khlaief, A.; Saadaoui, O.; Chaari, A.; Boussak, M. Performance analysis of FOC and DTC for PMSM drives using SVPWM technique. In Proceedings of the International Conference on Sciences and Techniques of Automatic Control and Computer Engineering (STA), Monastir, Tunisia, 21–23 December 2015; pp. 223–228. [Google Scholar]

- Ren, Y.; Zhu, Z.Q.; Green, J.E.; Li, Y.; Zhu, S.; Li, Z. Improved Duty-Ratio-Based Direct Torque Control for Dual Three-Phase Permanent Magnet Synchronous Machine Drives. IEEE Trans. Ind. Appl. 2019, 55, 5843–5853. [Google Scholar] [CrossRef]

- Tang, L.; Zhong, L.; Rahman, M.F.; Hu, Y. A novel direct torque controlled interior permanent magnet synchronous machine drive with low ripple in flux and torque and fixed switching frequency. IEEE Trans. Power Electron. 2004, 19, 346–354. [Google Scholar] [CrossRef]

- Basar, M.S.; Bech, M.M.; Andersen, T.O.; Scavenius, P.; Thomas-Basar, T. Comparison of sensorless FOC and SVM-DTFC of PMSM for low-speed applications. In Proceedings of the 4th International Conference on Power Engineering, Energy and Electrical Drives, Istanbul, Turkey, 13–17 May 2013; pp. 864–869. [Google Scholar]

- Lee, J.S.; Choi, C.H.; Seok, J.K.; Lorenz, R.D. Deadbeat-direct torque and flux control of interior permanent magnet synchronous machines with discrete time stator current and stator flux linkage observer. IEEE Trans. Ind. Appl. 2011, 47, 1749–1758. [Google Scholar] [CrossRef]

- Dastjerdi, R.S.; Abbasian, M.A.; Saghafi, H.; Vafaie, M.H. Performance Improvement of Permanent-Magnet Synchronous Motor Using a New Deadbeat-Direct Current Controller. IEEE Tran. Power Electron. 2019, 34, 3530–3543. [Google Scholar] [CrossRef]

- Lee, J.S.; Lorenz, R.D.; Valenzuela, M.A. Time-optimal and loss-minimizing deadbeat-direct torque and flux control for interior permanent-magnet synchronous machines. IEEE Trans. Ind. Appl. 2014, 50, 1880–1890. [Google Scholar] [CrossRef]

- Xie, W.; Wang, X.; Wang, F.; Xu, W.; Kennel, R.M.; Gerling, D.; Lorenz, R.D. Finite-control-set model predictive torque control with a deadbeat solution for PMSM drives. IEEE Trans. Ind. Electron. 2015, 62, 5402–5410. [Google Scholar] [CrossRef]

- Lee, J.S. Stability Analysis of Deadbeat-Direct Torque and Flux Control for Permanent Magnet Synchronous Motor Drives with Respect to Parameter Variations. Energies 2018, 11, 2027. [Google Scholar] [CrossRef] [Green Version]

- Scarcella, G.; Scelba, G.; Pulvirenti, M.; Lorenz, R.D. Fault-Tolerant Capability of Deadbeat-Direct Torque and Flux Control for Three-Phase PMSM Drives. IEEE Trans. Ind. Appl. 2017, 53, 5496–5508. [Google Scholar] [CrossRef]

- Vafaie, M.H.; Dehkordi, B.M.; Moallem, P.; Kiyoumarsi, A. Improving the Steady-State and Transient-State Performances of PMSM Through an Advanced Deadbeat Direct Torque and Flux Control System. IEEE Trans. Power Electron. 2017, 32, 2964–2975. [Google Scholar] [CrossRef]

- Saur, M.; Gaona Erazo, D.E.; Zdravkovic, J.; Lehner, B.; Gerling, D.; Lorenz, R.D. Minimizing Torque Ripple of Highly Saturated Salient Pole Synchronous Machines by Applying DB-DTFC. IEEE Trans. Ind. Appl. 2017, 53, 3643–3651. [Google Scholar] [CrossRef]

- Flieh, H.M.; Lorenz, R.D.; Totoki, E.; Yamaguchi, S.; Nakamura, Y. Dynamic Loss Minimizing Control of a Permanent Magnet Servomotor Operating Even at the Voltage Limit When Using Deadbeat-Direct Torque and Flux Control. IEEE Trans. Ind. Appl. 2019, 55, 2710–2720. [Google Scholar] [CrossRef]

- Koç, M.; Wang, J.; Sun, T. An inverter nonlinearity-independent flux observer for direct torque-controlled high-performance interior permanent magnet brushless AC drives. IEEE Trans. Power Electron. 2016, 32, 490–502. [Google Scholar] [CrossRef] [Green Version]

- Preindl, M.; Bolognani, S. Model Predictive Direct Speed Control with Finite Control Set of PMSM Drive Systems. IEEE Trans. Power Electron. 2013, 28, 1007–1015. [Google Scholar] [CrossRef]

| Parameters | Value |

|---|---|

| Number of stator pole pairs | 3 |

| Permanent-magnet flux | 0.483 Wb |

| Stator resistance | 3.3 Ω |

| d/q -axis stator inductance | 41.6/57.1 mH |

| Rated power | 2200 W |

| Rated speed | 1750 r/min |

| Rated torque | 12 N·m |

| Rated current/voltage | 4.1 A/380 V |

| DC-link voltage | 540 V |

| The moment of inertia | m2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, J.; Wang, J.; Yan, B. Simulation Research on Deadbeat Direct Torque and Flux Control of Permanent Magnet Synchronous Motor. Energies 2022, 15, 3009. https://doi.org/10.3390/en15093009

Chen J, Wang J, Yan B. Simulation Research on Deadbeat Direct Torque and Flux Control of Permanent Magnet Synchronous Motor. Energies. 2022; 15(9):3009. https://doi.org/10.3390/en15093009

Chicago/Turabian StyleChen, Jie, Jiajun Wang, and Bo Yan. 2022. "Simulation Research on Deadbeat Direct Torque and Flux Control of Permanent Magnet Synchronous Motor" Energies 15, no. 9: 3009. https://doi.org/10.3390/en15093009