Modelling, Analysis and Entropy Generation Minimization of Al2O3-Ethylene Glycol Nanofluid Convective Flow inside a Tube

Abstract

:1. Introduction

2. Methodology

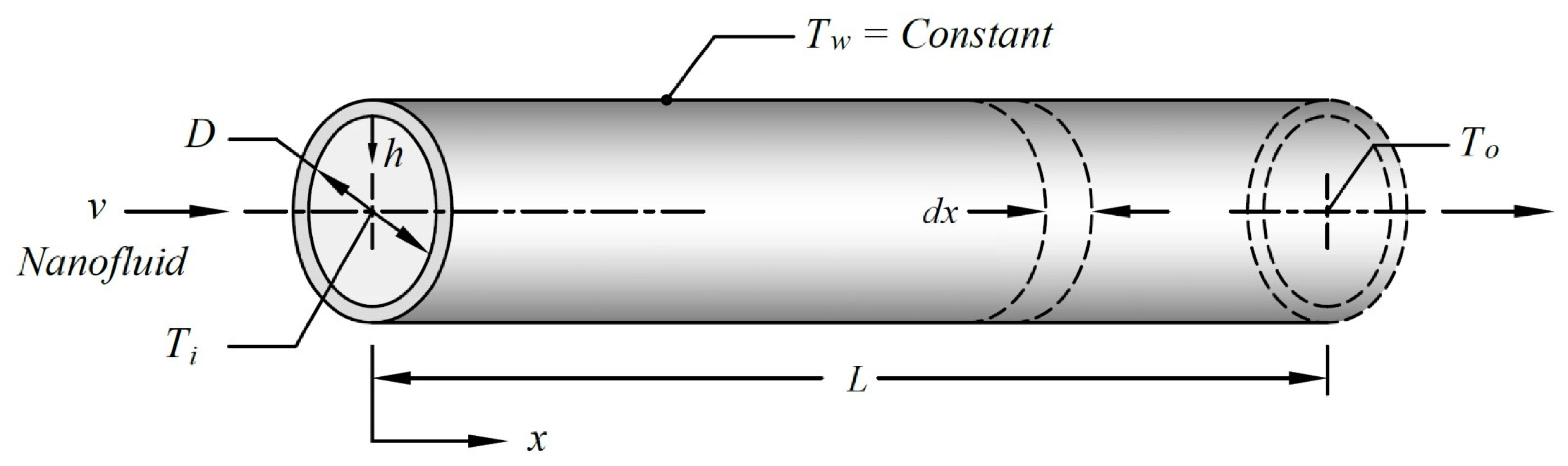

2.1. Problem Statement

2.2. Nanofluid Thermophysical Properties

2.3. Formulation for Heat Transfer

2.4. Formulation for Entropy Generation

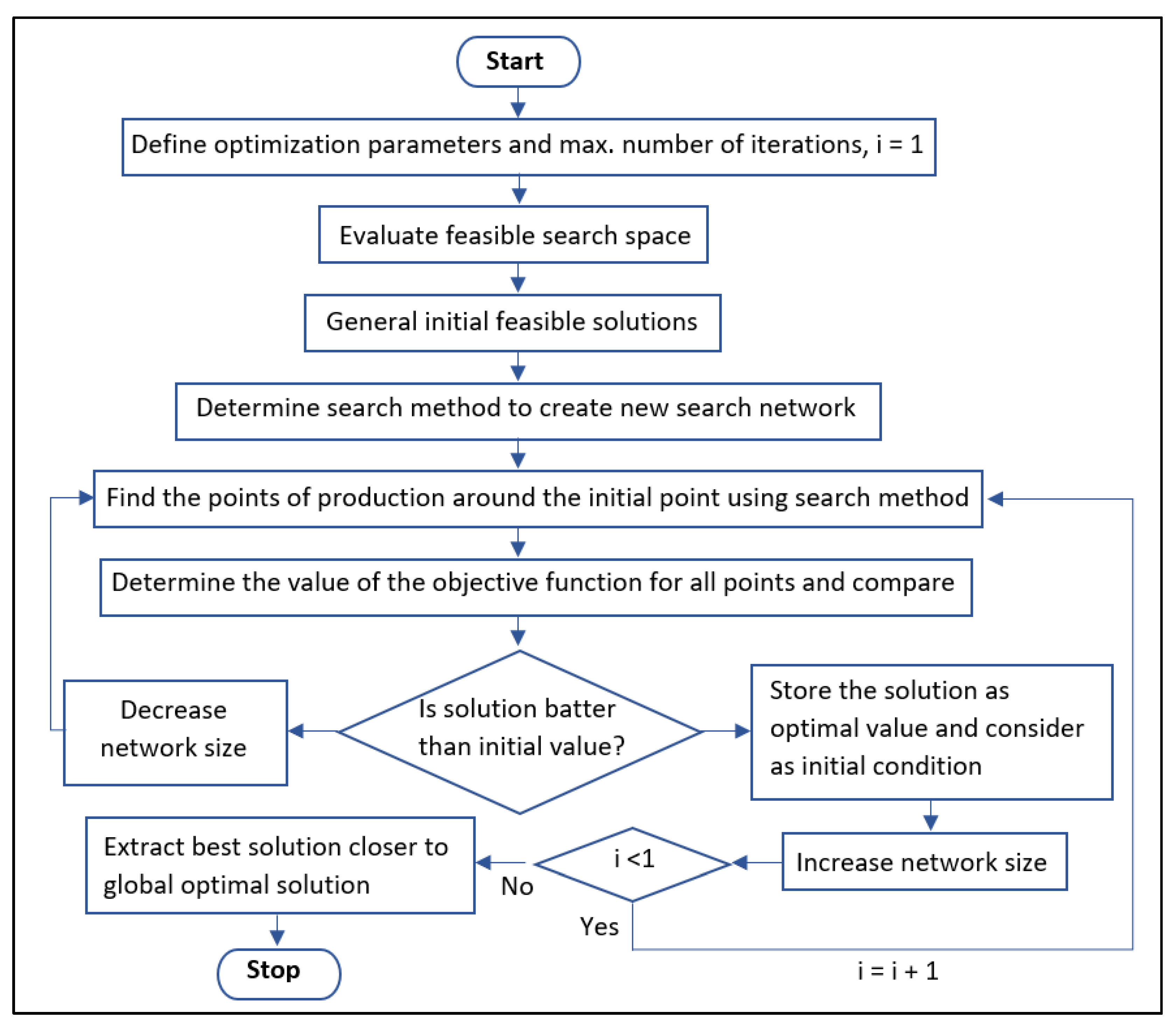

2.5. Genetic and DIRECT Algorithm

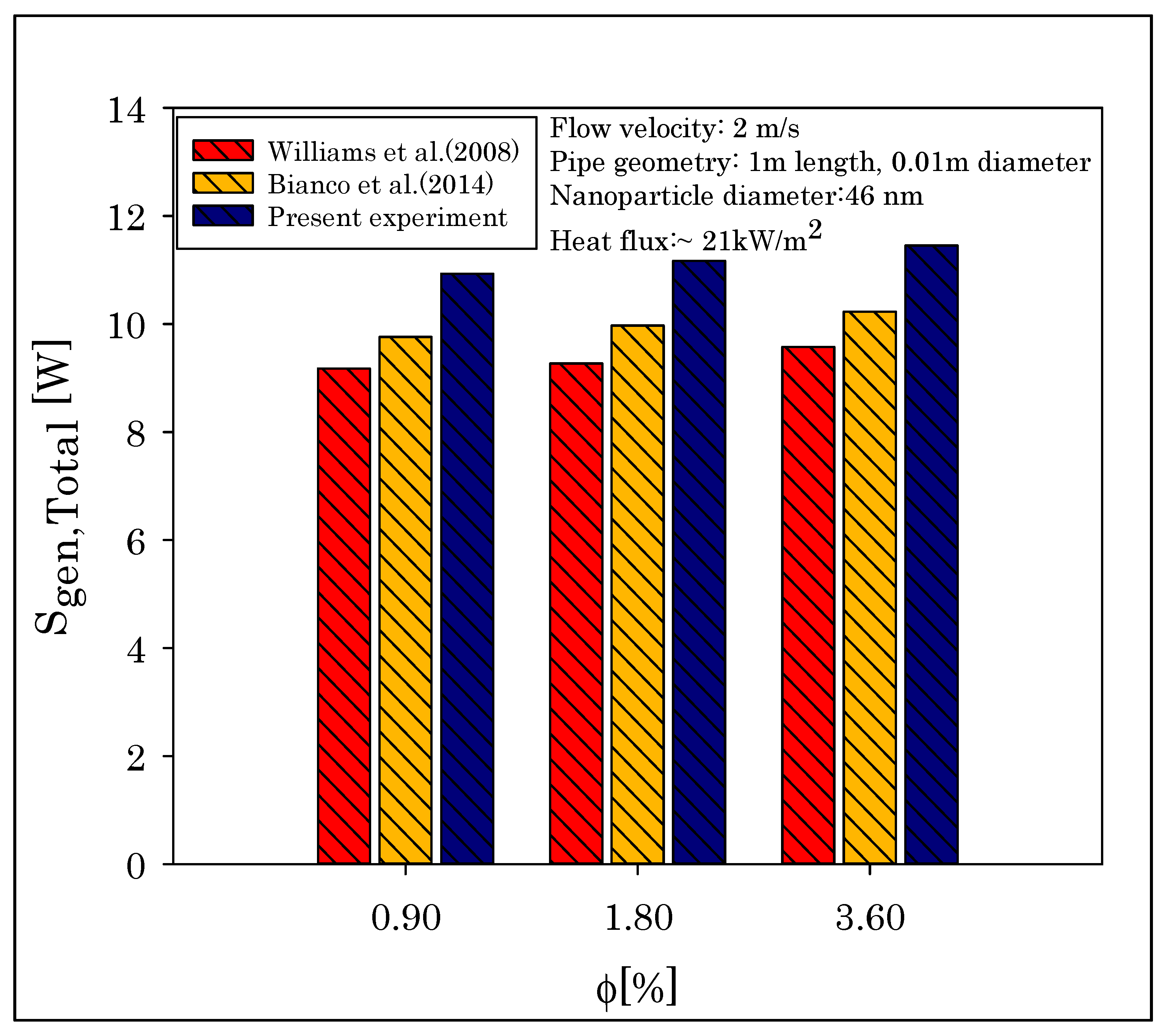

2.6. Validation

3. Results and Analysis

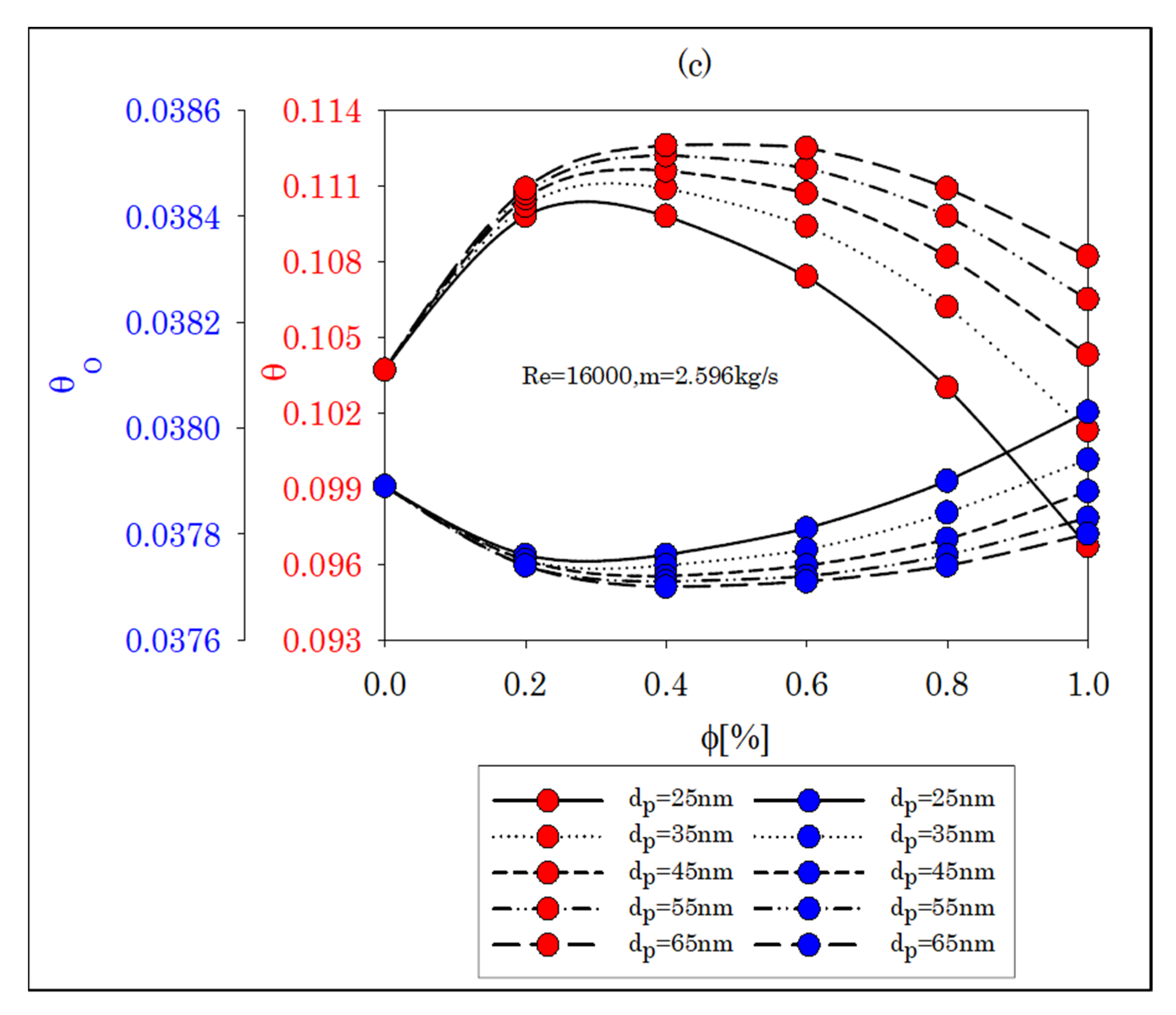

3.1. Temperature Profile of Flow

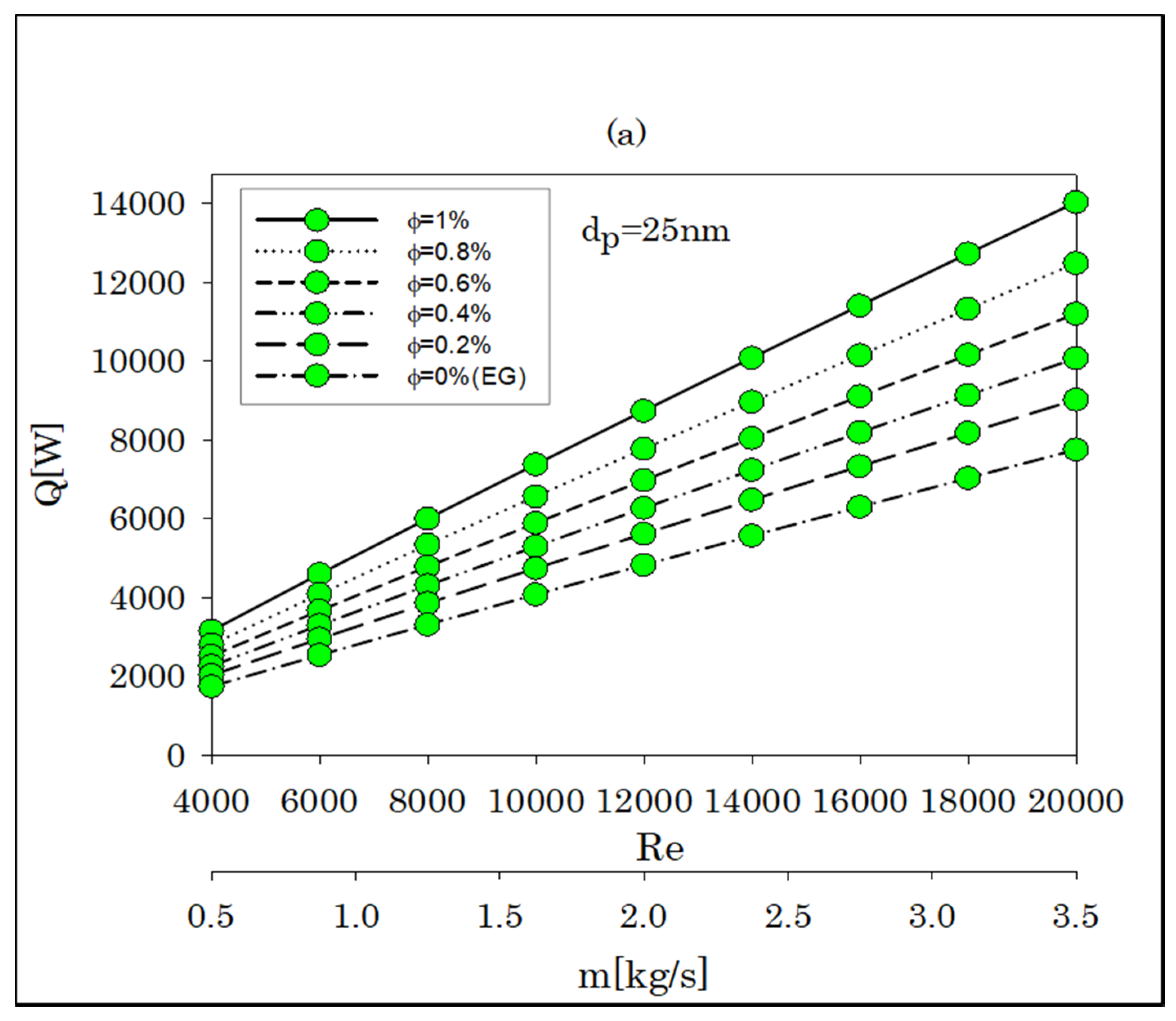

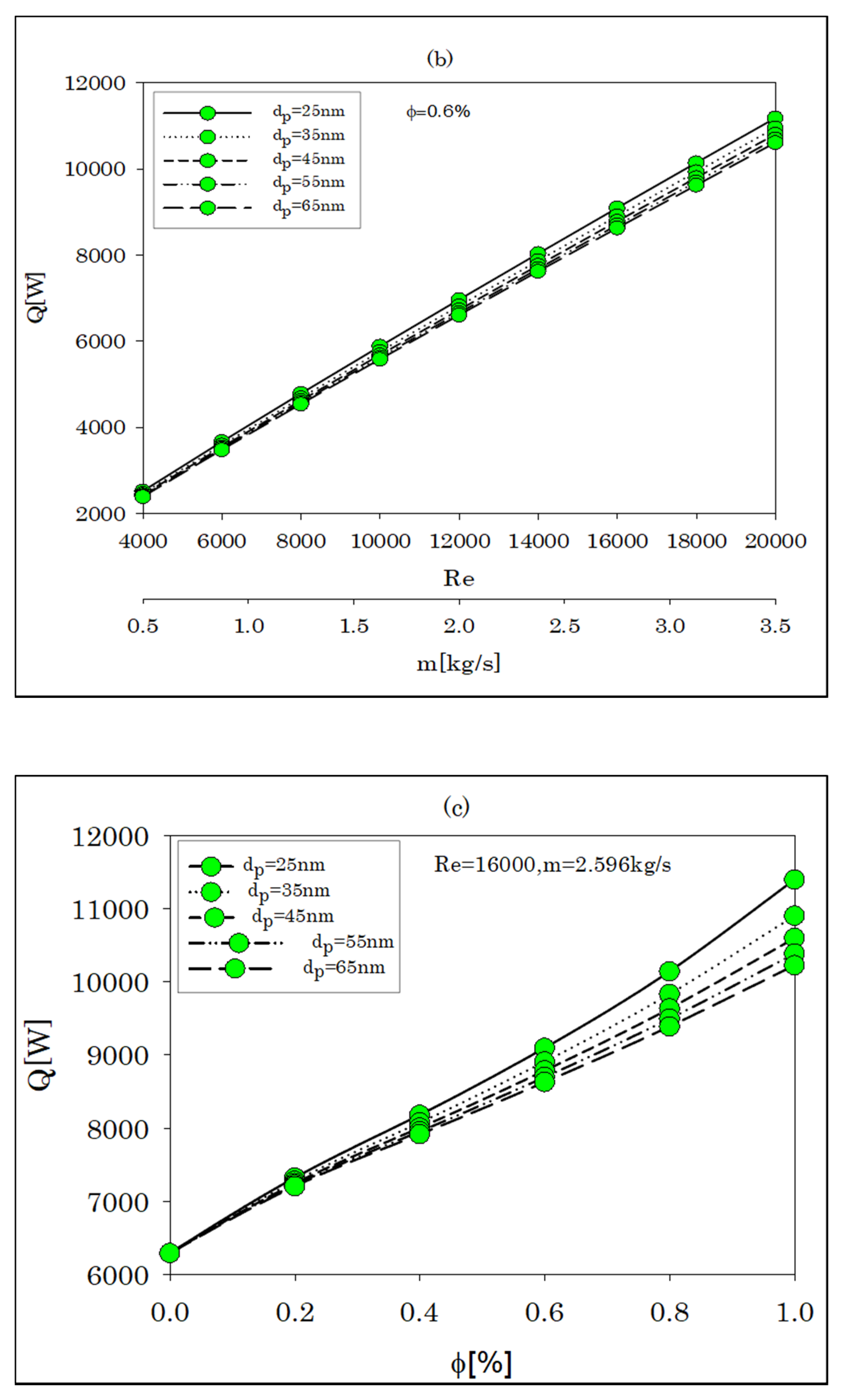

3.2. Convective Heat Transfer Rate

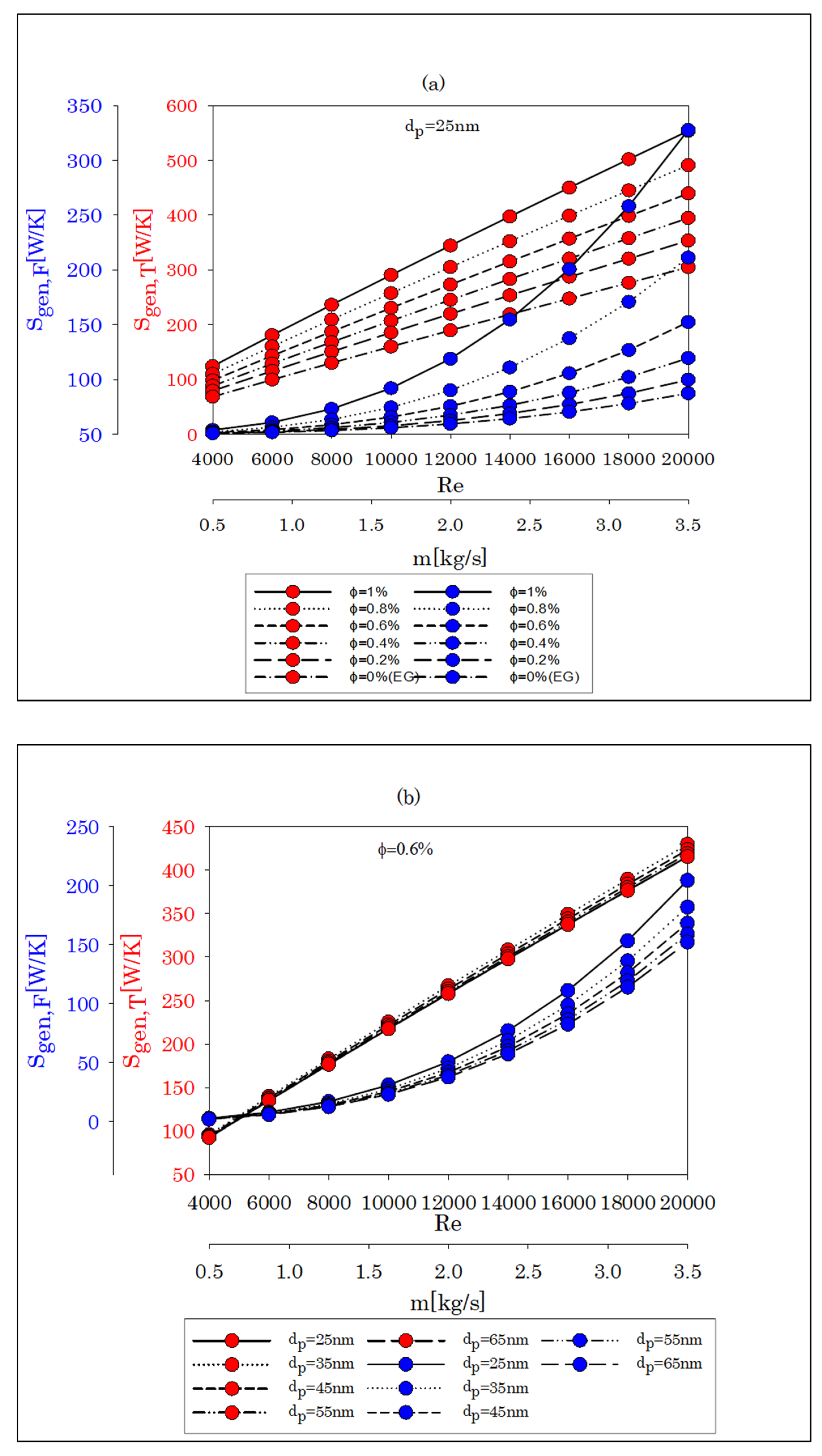

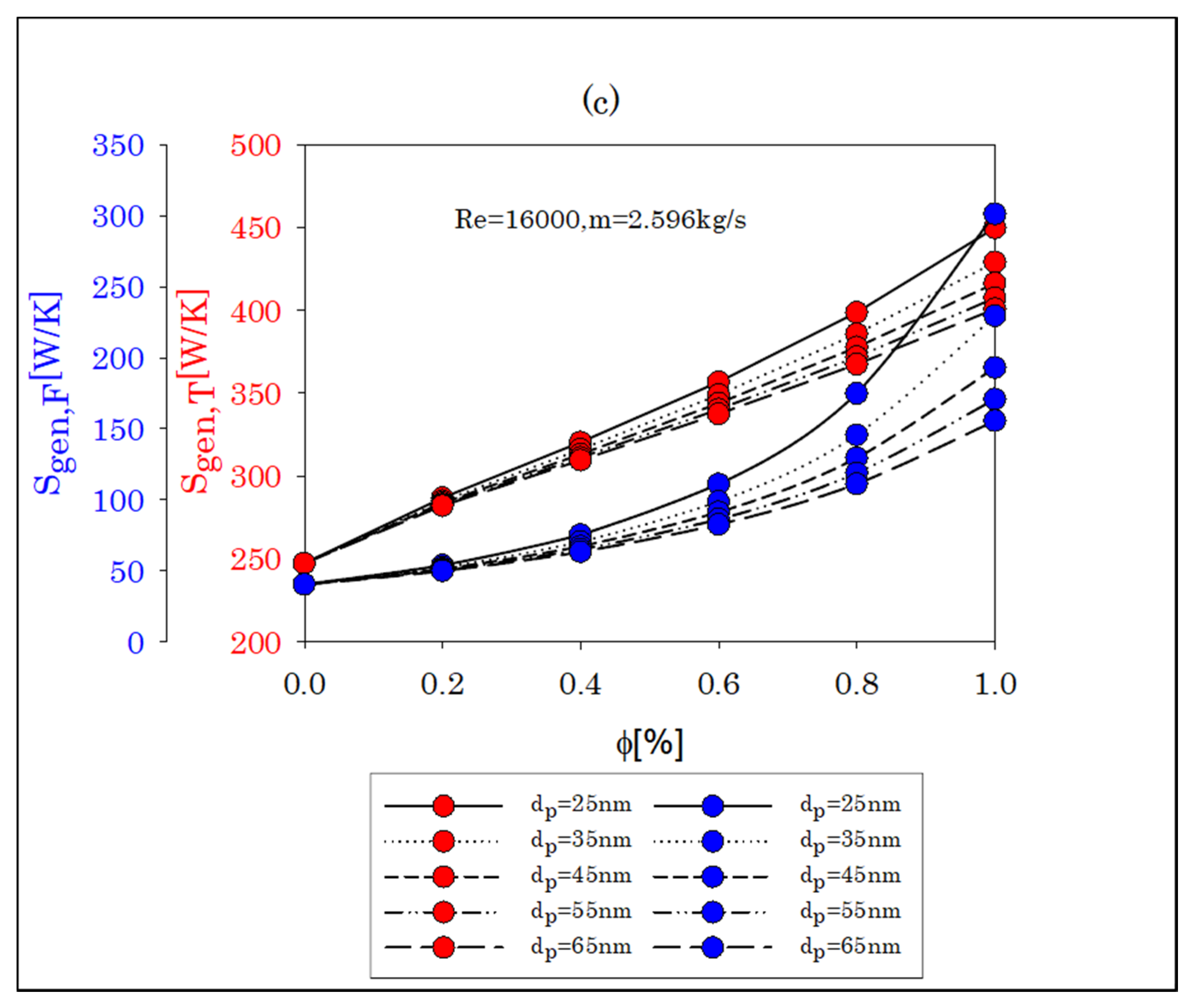

3.3. Thermal and Frictional Entropy Generation Rate

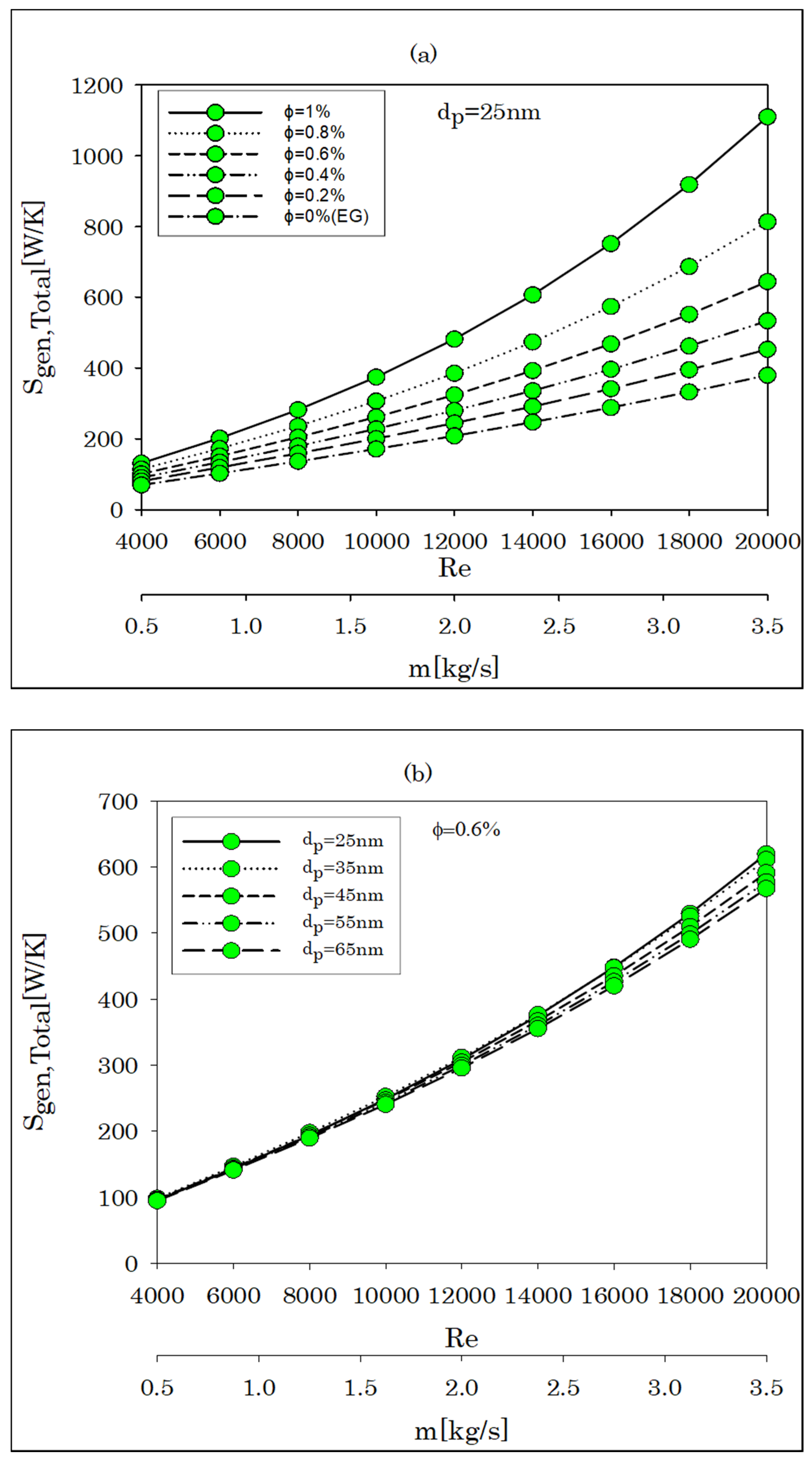

3.4. Total Entropy Generation Rate

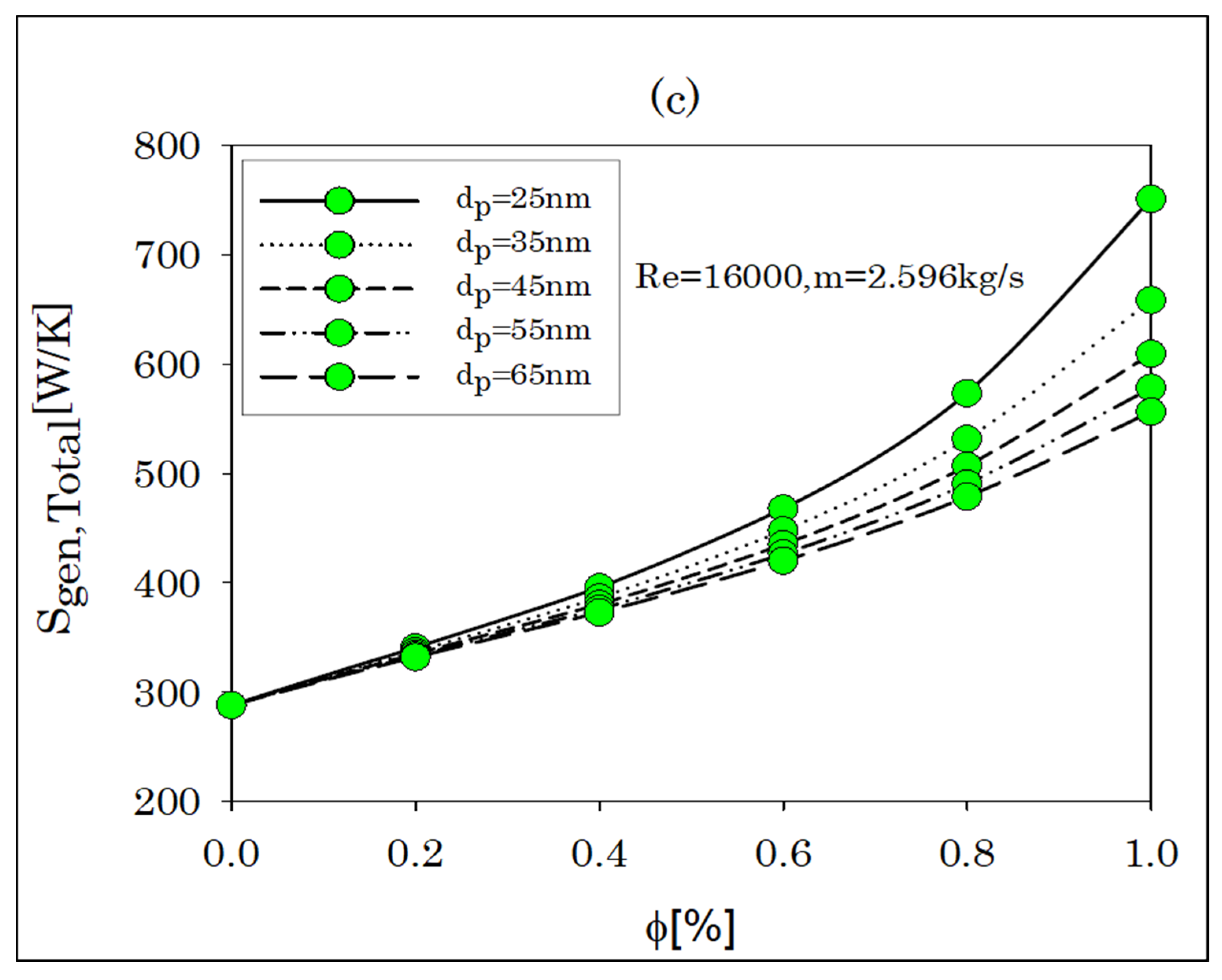

3.5. Irreversibility Distribution Ratio

3.6. Optimization Results

4. Conclusions

- (a)

- The heat transfer enhancement is achieved by increasing nanoparticle concentration, Re and mass flow rate. Moreover, a decrease in particle size aides in heat transfer enhancement.

- (b)

- By increasing Re, entropy generation increased. The optimal condition for minimum entropy generation is 4000. The corresponding m values are 0.54464 and 0.54453 kg/s with GA and DIRECT algorithms. As a result, Re should be kept as low as feasible in order to reduce entropy generation.

- (c)

- The increase in nanoparticle addition increases entropy generation. Therefore, a better thermodynamic system can be obtained by reducing particle volume fraction. The minimum value for entropy generation is obtained at ϕ = 0.2003% and 0.200% using the GA and DIRECT algorithms.

- (d)

- Entropy generation can be minimized by using bigger particles. Minimum entropy generation is possible with dp~65 nm according to the GA and DIRECT algorithms.

- (e)

- Sgen,T plays a dominating role over Sgen,F. However, at higher concentrations, i.e., at 0.8 and 1 vol.%, Sgen,F competes with Sgen,T.

- (f)

- The TEG values show a sharp increment from 0.8–1 vol.%. The enhancement indicates that the addition of nanoparticles increases the entropy generation in the flow.

- (g)

- increases with increasing Re or mass flowrate, dp and vol. concentration. This indicates enhancements in friction entropy generation with these parameters. remains < 1 as Sgen,T dominates Sgen,F throughout the analysis.

- (h)

- The nanofluid developed a maximum of 2.93-fold enhancement in TEG as compared to basefluid. Therefore, nanoparticles should be added to the basefluid carefully.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| EG | Ethylene glycol (-) |

| GA | Genetic algorithm (-) |

| Re | Reynold number (-) |

| TEG | Total entropy generation |

| Al2O3 | Aluminium oxide |

| TiO2 | Titanium oxide |

| EGM | Entropy generation minimization |

| D | Diameter (m) |

| DI | Deionized |

| d | Diameter of nanoparticle (nm) |

| f | Friction factor (-) |

| L | Length (m) |

| T | Average temperature (K) |

| v | Average velocity (m/s) |

| Prandlt number | |

| Boltzmann constant (J/K) | |

| MW | Molecular weight (g/mol) |

| NA | Avogadro number (particles/mol) |

| Cp | Specific heat capacity (J/KgK) |

| Mass flow rate (kg/s) | |

| h | Heat transfer coefficient(W/m2K) |

| Heat transfer rate (Watt) | |

| Heat transfer rate per unit length (Watt/m) | |

| Heat flux (W/m2) | |

| Ar | Aspect ratio of the tube |

| St | Stanton number (-) |

| Pr | Prandlt number (-) |

| Pe | Peclet number (-) |

| Entropy generation (W/K) | |

| Greek Symbols | |

| Thermal conductivity (W/mK) | |

| Volume concentration (%) | |

| Dynamic viscosity (Pa.s) | |

| α | Thermal diffusivity(m2/s) |

| Density (kg/m3) | |

| Ψ | Irreversibility distribution ratio (-) |

| Subscripts | |

| i | Inlet |

| o | outlet |

| np | Nanoparticles |

| bf | Basefluid |

| b | Brownian |

| w | Wall |

| avg | Average |

| T | Thermal |

| F | Frictional |

| Total | Gross |

References

- Haque, M.E.; Hossain, M.S.; Ali, H.M. Laminar forced convection heat transfer of nanofluids inside non-circular ducts: A review. Powder Technol. 2021, 378, 808–830. [Google Scholar] [CrossRef]

- Hafeez, M.B.; Amin, R.; Nisar, K.S.; Jamshed, W.; Abdel-Aty, A.-H.; Khashan, M.M. Heat transfer enhancement through nanofluids with applications in automobile radiator. Case Stud. Therm. Eng. 2021, 27, 101192. [Google Scholar] [CrossRef]

- Chabani, I.; Mebarek-Oudina, F.; Ismail, A.A.I. MHD Flow of a Hybrid Nano-Fluid in a Triangular Enclosure with Zigzags and an Elliptic Obstacle. Micromachines 2022, 13, 224. [Google Scholar] [CrossRef] [PubMed]

- Choi, T.J.; Park, M.S.; Kim, S.H.; Jang, S.P. Experimental Study on the Effect of Nanoparticle Migration on the Convective Heat Transfer Coefficient of EG/Water-based Al2O3 Nanofluids. Int. J. Heat Mass Transf. 2021, 169, 120903. [Google Scholar] [CrossRef]

- Mukherjee, S.; Panda, S.R.; Mishra, P.C.; Chaudhuri, P. Heat transfer enhancement with Tio2/water nanofluid in a horizontal circular tube subjected to varying heat flux: An experimental study. J. Enhanc. Heat Transf. 2021, 28, 21–48. [Google Scholar] [CrossRef]

- Ali, N.; Bahman, A.M.; Aljuwayhel, N.F.; Ebrahim, S.A.; Mukherjee, S.; Alsayegh, A. Carbon-Based Nanofluids and Their Advances towards Heat Transfer Applications—A Review. Nanomaterials 2021, 11, 1628. [Google Scholar] [CrossRef]

- Mukherjee, S.; Panda, S.R.; Mishra, P.C.; Chaudhuri, P. Convective Flow Boiling Heat Transfer Enhancement with Aqueous Al 2 O 3 and TiO 2 Nanofluids: Experimental Investigation. Int. J. Thermophys. 2021, 42, 1–26. [Google Scholar] [CrossRef]

- Saedodin, S.; Rostamian, S.H.; Zaboli, M. Hydrothermal analysis and optimization of heat transfer and pressure drop characteristics of different nanofluids in a circular tube with turbulator. Eur. Phys. J. Plus 2021, 136, 708. [Google Scholar] [CrossRef]

- Saleh, B.; Sundar, L.S. Entropy generation and exergy efficiency analysis of ethylene glycol-water based nanodiamond+ Fe3O4 hybrid nanofluids in a circular tube. Powder Technol. 2021, 380, 430–442. [Google Scholar] [CrossRef]

- Mukherjee, S.; Mishra, P.C.; Chaudhuri, P. Energy and Exergy Viability Analysis of Nanofluids As A Coolant for Microchannel Heat Sink. Int. J. Automot. Mech. Eng. 2019, 16, 6090–6107. [Google Scholar] [CrossRef]

- Awais, M.; Ullah, N.; Ahmad, J.; Sikandar, F.; Ehsan, M.M.; Salehin, S.; Bhuiyan, A.A. Heat transfer and pressure drop performance of Nanofluid: A state-of-the-art review. Int. J. Thermofluids 2021, 9, 100065. [Google Scholar] [CrossRef]

- Bejan, A. Entropy Generation Minimization: The Method of Thermodynamic Optimization of Finite-Size Systems and Finite-Time Processes; CRC Press: Boca Raton, FL, USA, 2013. [Google Scholar]

- Marzougui, S.; Bouabid, M.; Mebarek-Oudina, F.; Abu-Hamdeh, N.; Magherbi, M.; Ramesh, K. A Computational Analysis of Heat Transport Irreversibility Phenomenon in a Magnetized Porous Channel. Int. J. Numer. Methods Heat Fluid Flow 2020, 31, 2197–2222. [Google Scholar] [CrossRef]

- Şahin, A.Z. Entropy generation in turbulent liquid flow through a smooth duct subjected to constant wall temperature. Int. J. Heat Mass Transf. 2000, 43, 1469–1478. [Google Scholar] [CrossRef]

- Bianco, V.; Manca, O.; Nardini, S. Entropy generation analysis of turbulent convection flow of Al2O3–water nanofluid in a circular tube subjected to constant wall heat flux. Energy Convers. Manag. 2014, 77, 306–314. [Google Scholar] [CrossRef]

- Bianco, V.; Manca, O.; Nardini, S. Performance analysis of turbulent convection heat transfer of Al2O3 water-nanofluid in circular tubes at constant wall temperature. Energy 2014, 77, 403–413. [Google Scholar] [CrossRef]

- Bianco, V.; Nardini, S.; Manca, O. Enhancement of heat transfer and entropy generation analysis of nanofluids turbulent convection flow in square section tubes. Nanoscale Res. Lett. 2011, 6, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Leong, K.Y.; Saidur, R.; Mahlia, T.M.I.; Yau, Y.H. Entropy generation analysis of nanofluid flow in a circular tube subjected to constant wall temperature. Int. Commun. Heat Mass Transf. 2012, 39, 1169–1175. [Google Scholar] [CrossRef]

- Pati, S.; Roy, R.; Deka, N.; Boruah, M.P.; Nath, M.; Bhargav, R.; Randive, P.R.; Mukherjee, P.P. Optimal heating strategy for minimization of peak temperature and entropy generation for forced convective flow through a circular pipe. Int. J. Heat Mass Transf. 2020, 150, 119318. [Google Scholar] [CrossRef]

- Kadivar, M.; Sharifpur, M.; Meyer, J.P. Convection heat transfer, entropy generation analysis and thermodynamic optimization of nanofluid flow in spiral coil tube. Heat Transf. Eng. 2021, 42, 1573–1589. [Google Scholar] [CrossRef]

- Li, W.; Xie, Z.; Xi, K.; Xia, S.; Ge, Y. Constructal Optimization of Rectangular Microchannel Heat Sink with Porous Medium for Entropy Generation Minimization. Entropy 2021, 23, 1528. [Google Scholar] [CrossRef]

- Manay, E.; Akyürek, E.F.; Sahin, B. Entropy generation of nanofluid flow in a microchannel heat sink. Results Phys. 2018, 9, 615–624. [Google Scholar] [CrossRef]

- Han, Y.; Wang, X.-s.; Zhang, H.-n.; Chen, Q.-z.; Zhang, Z. Multi-objective optimization of helically coiled tube heat exchanger based on entropy generation theory. Int. J. Therm. Sci. 2020, 147, 106150. [Google Scholar] [CrossRef]

- Ebrahimi-Moghadam, A.; Mohseni-Gharyehsafa, B.; Farzaneh-Gord, M. Using artificial neural network and quadratic algorithm for minimizing entropy generation of Al2O3-EG/W nanofluid flow inside parabolic trough solar collector. Renew. Energy 2018, 129, 473–485. [Google Scholar] [CrossRef]

- Mohseni-Gharyehsafa, B.; Ebrahimi-Moghadam, A.; Okati, V.; Farzaneh-Gord, M.; Ahmadi, M.H.; Lorenzini, G. Optimizing flow properties of the different nanofluids inside a circular tube by using entropy generation minimization approach. J. Therm. Anal. Calorim. 2019, 135, 801–811. [Google Scholar] [CrossRef]

- Safarzadeh, S.; Niknam-Azodi, M.; Aldaghi, A.; Taheri, A.; Passandideh-Fard, M.; Mohammadi, M. Energy and entropy generation analyses of a nanofluid-based helically coiled pipe under a constant magnetic field using smooth and micro-fin pipes: Experimental study and prediction via ANFIS model. Int. Commun. Heat Mass Transf. 2021, 126, 105405. [Google Scholar] [CrossRef]

- Mohamadi, S.; Yazdi, M.H.; Solomin, E.; Fudholi, A.; Sopian, K.; Chong, P.L. Heat transfer and entropy generation analysis of internal flow of nanorefrigerant with slip condition at wall. Therm. Sci. Eng. Prog. 2021, 22, 100829. [Google Scholar] [CrossRef]

- Moghadasi, H.; Malekian, N.; Aminian, E.; Saffari, H. Thermodynamic analysis of entropy generation due to energy transfer through circular surfaces under pool boiling condition. J. Therm. Anal. Calorim. 2021, 147, 2495–2508. [Google Scholar] [CrossRef]

- Dong, Z.; Du, Q. The Local Distribution of Temperatures and Entropy Generation Rate in an Ideal Counterflow Heat Exchanger. Coatings 2021, 11, 970. [Google Scholar] [CrossRef]

- Liu, L.; Liu, D.; Huang, N. Entropy Generation for Negative Frictional Pressure Drop in Vertical Slug and Churn Flows. Entropy 2021, 23, 156. [Google Scholar] [CrossRef]

- Cao, Y.; Abdous, M.A.; Holagh, S.G.; Shafiee, M.; Hashemian, M. Entropy generation and sensitivity analysis of R134a flow condensation inside a helically coiled tube-in-tube heat exchanger. Int. J. Refrig. 2021, 130, 104–116. [Google Scholar] [CrossRef]

- Obidowski, D.; Stajuda, M.; Sobczak, K. Efficient Multi-Objective CFD-Based Optimization Method for a Scroll Distributor. Energies 2021, 14, 377. [Google Scholar] [CrossRef]

- Deymi-Dashtebayaz, M.; Akhoundi, M.; Ebrahimi-Moghadam, A.; Arabkoohsar, A.; Moghadam, A.J.; Farzaneh-Gord, M. Thermo-hydraulic analysis and optimization of CuO/water nanofluid inside helically dimpled heat exchangers. J. Therm. Anal. Calorim. 2021, 143, 4009–4024. [Google Scholar] [CrossRef]

- Han, B.; Chakraborty, A. Evaluation of energy flow, dissipation and performances for advanced adsorption assisted heat transformation systems: Temperature-entropy frameworks. Energy Convers. Manag. 2021, 240, 114264. [Google Scholar] [CrossRef]

- Corcione, M. Empirical correlating equations for predicting the effective thermal conductivity and dynamic viscosity of nanofluids. Energy Convers. Manag. 2011, 52, 789–793. [Google Scholar] [CrossRef]

- Corcione, M. A Semi-Empirical Model for Predicting the Effective Dynamic Viscosity of Nanoparticle Suspensions. Heat Transf. Eng. 2012, 33, 575–583. [Google Scholar] [CrossRef]

- Pak, B.C.; Cho, Y.I. Hydrodynamic and heat transfer study of dispersed fluids with submicron metallic oxide particles. Exp. Heat Transf. 1998, 11, 151–170. [Google Scholar] [CrossRef]

- Xuan, Y.; Li, Q. Investigation on Convective Heat Transfer and Flow Features of Nanofluids. J. Heat Transf. 2003, 125, 151–155. [Google Scholar] [CrossRef] [Green Version]

- Bergman, T.L.; Lavine, A.S.; Incropera, F.P.; DeWitt, D.P. Introduction to Heat Transfer; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Ratts, E.B.; Raut, A.G. Entropy generation minimization of fully developed internal flow with constant heat flux. J. Heat Transf. 2004, 126, 656–659. [Google Scholar] [CrossRef]

- Wei, R.; Shi, K.; Guo, X.; Wang, T.; Lv, X.; Li, Q.; Zhang, Y.; Zhao, J.; Yang, L. Evolving thermal conductivity upon formation and decomposition of hydrate in natural marine sediments. Fuel 2021, 302, 121141. [Google Scholar] [CrossRef]

- Jones, D.R.; Martins, J.R.R.A. The DIRECT algorithm: 25 years Later. J. Glob. Optim. 2021, 79, 521–566. [Google Scholar] [CrossRef]

- Jones, D.R. Direct global optimization algorithmDirect Global Optimization Algorithm. In Encyclopedia of Optimization; Floudas, C.A., Pardalos, P.M., Eds.; Springer: Boston, MA, USA, 2001; pp. 431–440. [Google Scholar]

- Williams, W.; Buongiorno, J.; Hu, L.-W. Experimental investigation of turbulent convective heat transfer and pressure loss of alumina/water and zirconia/water nanoparticle colloids (nanofluids) in horizontal tubes. J. Heat Transf. 2008, 130, 042412. [Google Scholar] [CrossRef]

- Rudyak, V.Y.; Krasnolutskii, S. Dependence of the viscosity of nanofluids on nanoparticle size and material. Phys. Lett. A 2014, 378, 1845–1849. [Google Scholar] [CrossRef]

| Properties | Al2O3 | Ethylene Glycol |

|---|---|---|

| Thermal conductivity | 40 W/mK | 0.252 W/mK |

| Density | 3970 kg/m3 | 1111.4 kg/m3 |

| Dynamic viscosity | - | 16.1 × 10−3 |

| Specific heat | 765 kgK | 2415 J/kgK |

| (a) | ||

| Input Parameters | Genetic Algorithm | DIRECT Algorithm |

| Re | 4000 | 4000 |

| M (kg/s) | 0.54464 | 0.54453 |

| ϕ (%) | 0.2003 | 0.200 |

| dp (nm) | 64.55924 | 65 |

| (b) | ||

| Output Parameters | Genetic Algorithm | DIRECT Algorithm |

| Q (W) | 1027.23858 | 1027.09394 |

| Sgen,T (W/K) | 41.32541 | 41.319501 |

| Sgen,F (W/K) | 0.582172 | 0.581821 |

| Sgen,Total (W/K) | 41.907589 | 41.901322 |

| 0.014088 | 0.014081 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mukherjee, S.; Aljuwayhel, N.F.; Bal, S.; Mishra, P.C.; Ali, N. Modelling, Analysis and Entropy Generation Minimization of Al2O3-Ethylene Glycol Nanofluid Convective Flow inside a Tube. Energies 2022, 15, 3073. https://doi.org/10.3390/en15093073

Mukherjee S, Aljuwayhel NF, Bal S, Mishra PC, Ali N. Modelling, Analysis and Entropy Generation Minimization of Al2O3-Ethylene Glycol Nanofluid Convective Flow inside a Tube. Energies. 2022; 15(9):3073. https://doi.org/10.3390/en15093073

Chicago/Turabian StyleMukherjee, Sayantan, Nawaf F. Aljuwayhel, Sasmita Bal, Purna Chandra Mishra, and Naser Ali. 2022. "Modelling, Analysis and Entropy Generation Minimization of Al2O3-Ethylene Glycol Nanofluid Convective Flow inside a Tube" Energies 15, no. 9: 3073. https://doi.org/10.3390/en15093073

APA StyleMukherjee, S., Aljuwayhel, N. F., Bal, S., Mishra, P. C., & Ali, N. (2022). Modelling, Analysis and Entropy Generation Minimization of Al2O3-Ethylene Glycol Nanofluid Convective Flow inside a Tube. Energies, 15(9), 3073. https://doi.org/10.3390/en15093073