Theoretical Study on the Micro-Flow Mechanism of Polymer Flooding in a Double Heterogeneous Oil Layer

Abstract

:1. Introduction

2. Modeling

2.1. Micro-Model

2.2. Mathematical Model

2.3. Boundary Conditions

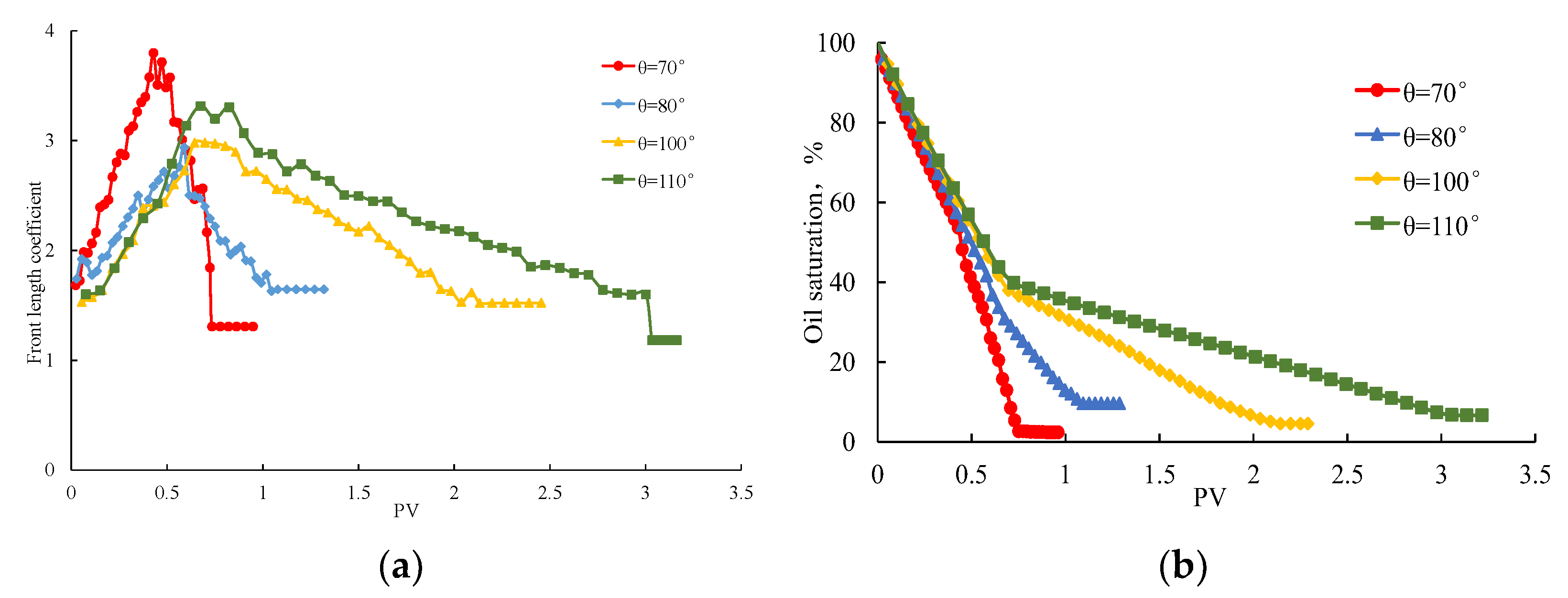

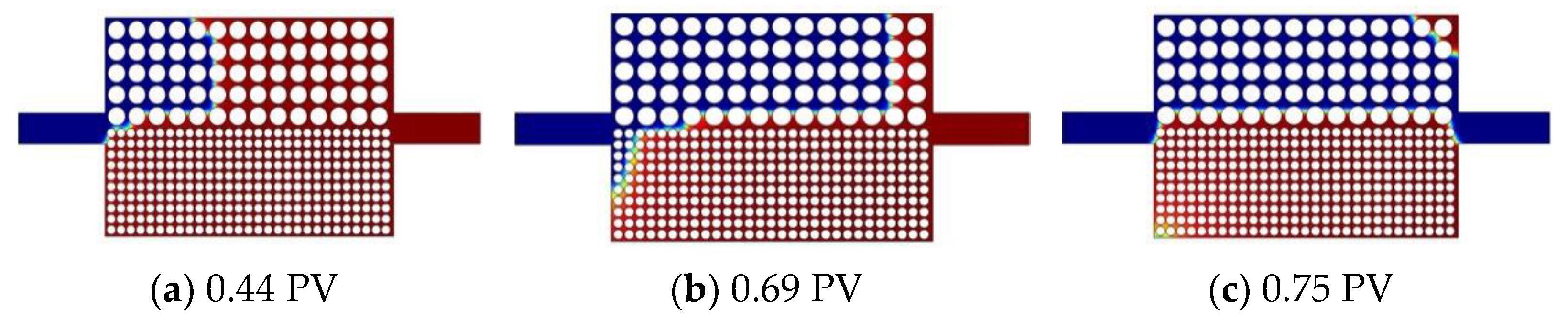

3. Influence of Wettability on Micro-Flow Characteristics

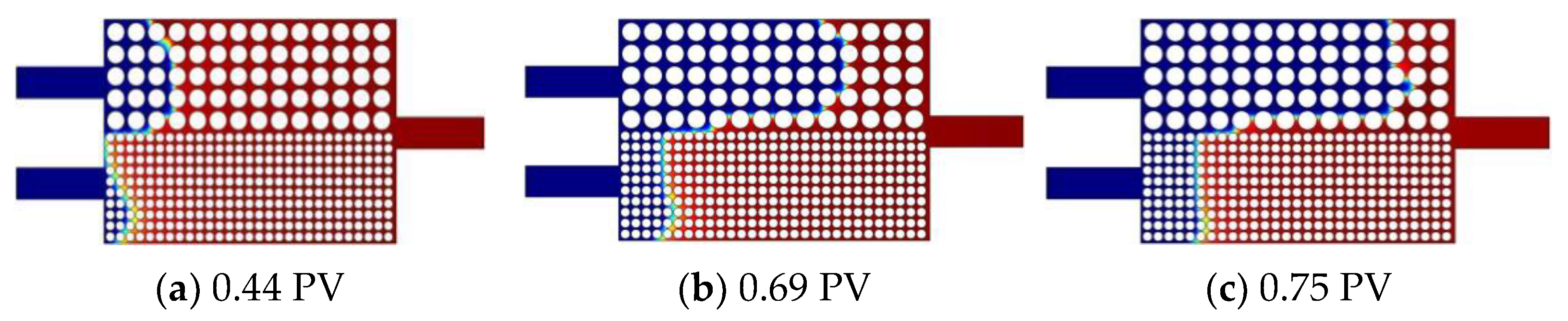

4. Influence of Injection Method on Micro-Flow Characteristics

5. Influence of Permeability Contrast on Micro-Flow Characteristics

6. Conclusions

- (i)

- Based on the N-S equation, a mathematical model of a two-phase micro-flow was established, and the micro-models of full perforation and commingling production, partial perforation and commingling production-injection, and separate-layer injection, and commingling production with different perforation degrees were established. The front length coefficient was defined to quantitatively describe the non-piston-like displacement phenomenon of the front propulsion;

- (ii)

- When the rock surface was oil-wet, the polymer solution preferentially displaced the crude oil in the high-permeability layer; in contrast, it preferentially displaced the crude oil in the low-permeability layer under water-wet conditions, and the interlayer breakthroughs were obvious in the early stages of displacement. When the displacement front broke through, the water-wet (oil-wet) began to displace the high (low) permeability layer, and the front length coefficient decreased while the interlayer breakthrough slowed;

- (iii)

- The decreased rate of oil saturation under the water-wet condition was higher than that under the oil-wet condition. After the breakthrough of the polymer flooding front, a preferential flow pathway was formed, which slowed the subsequent polymer flooding of crude oil, especially under oil-wet conditions;

- (iv)

- When the rock surface was oil-wet, the perforation degree of the inlet had a significant influence on the micro-oil displacement efficiency, and the micro-oil displacement efficiency of the full perforation and commingling production models was 26.21% and 37.75%, respectively, higher than that of the separate-layer injection and commingling production and partial perforation and commingling production-injection models, respectively;

- (v)

- The larger the permeability contrast was, the more obvious the interlayer breakthrough would be. The displacement efficiency of the model with a permeability contrast of 6.71 was 6.7% higher than that of the model with a permeability contrast of 11.11.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, S.L.; Wang, X.Y.; Huang, C.; Cai, Q.L.; Xing, J.C.; Jiang, W.X.; Wang, Y.F. Research progress of EOR with alteration of rock wettability in low-permeability reservoir. Fault-Block Oil Gas Field 2012, 19, 472–476. [Google Scholar]

- Zhu, D.Y.; Dai, P.Q.; Luo, X.B.; Zhang, Y.C. Novel Characterization of Wetting Properties and the Calculation of Liquid-Solid Interface Tension (I). Sci. Technol. Eng. 2007, 7, 3057–3062. [Google Scholar]

- Li, X.B.; Liu, Y. Contact angle model and wettability on the surfaces with microstructures. Mater. Rep. 2009, 23, 101–103. [Google Scholar]

- Jia, Z.W.; Yang, Q.Y.; Lan, Y.B.; Zhang, H.X. Experimental study on the process of water-oil displacement with the micro-model. Pet. Geol. Oilfield Dev. Daqing 2002, 21, 46–49. [Google Scholar]

- Zhu, W.Y.; Ju, Y.; Zhao, M.; Chen, Q.; Yang, Z.M. Spontaneous imbibition mechanism of flow through porous media and waterflooding in low-permeability fractured sandstone reservoir. Acta Pet. Sin. 2002, 23, 56–59. [Google Scholar]

- Liu, Z.Y.; Zeng, Q.H.; Tang, Z.H.; Zhang, G.S. Effect of wettability on recovery and relative permeability. Oil Gas Geol. 2000, 21, 148–150. [Google Scholar]

- Zhang, J.C.; Jin, H.L.; Liang, W.Q.; Yu, X.J. Research and practice of multiple water injection technology for fractured buried hill reservoirs. Spec. Oil Gas Reserv. 2012, 19, 86–89. [Google Scholar]

- Zhang, H.M.; Wang, S.B.; Wang, Y.M. Application of interval subdivision in water injectors in “stabilizing oil production and controlling water cut”. Pet. Geol. Oilfield Dev. Daqing 1997, 16, 64–66. [Google Scholar]

- Huang, F.S.; Zhao, Y.S. Research on optimal hierarchical modeling of subdivisional separate layer injection in high water cut sandstone oil field. Pet. Geol. Oilfield Dev. Daqing 1998, 17, 33–34. [Google Scholar]

- Gang, Z.B.; Wei, X.F. Review and outlook of separate layer water injection technology in Daqing Oilfield. Spec. Oil Gas Reserv. 2006, 13, 4–9. [Google Scholar]

- Chen, T. Experimental study of water-oil displacement with microscopic models of heterogeneous reservoirs. Pet. Geol. Recovery Effic. 2007, 14, 72–75. [Google Scholar]

- Gu, Q.Q.; Liu, H.H.; Wu, L. Preferential imbibition in a dual-permeability pore network. J. Fluid Mech. 2020, 915, A138. [Google Scholar] [CrossRef]

- Guo, W.K. Progress and prospect of geology and development technology in Daqing oilfield. Pet. Geol. Oilfield Dev. Daqing 2004, 23, 54–59. [Google Scholar]

- Quezada, G.R.; Toro, N.; Saavedra, J.H.; Robles, P.; Salazar, I.; Navarra, A.; Jeldres, R.I. Molecular Dynamics Study of the Conformation, Ion Adsorption, Diffusion and Water Structure of Soluble Polymers in Saline Solutions. Polymers 2021, 13, 3550. [Google Scholar] [CrossRef] [PubMed]

- Jeldres, R.I.; Concha, F.; Toledo, P.G. Population balance modelling of particle flocculation with attention to aggregate restructuring and permeability. Polymers 2015, 224, 62–71. [Google Scholar] [CrossRef] [PubMed]

- Bogdanov, I.; Kpahou, J.; Kamp, A. Direct Pore-scale Modeling of Two-phase Flow Through Natural Media. In Proceedings of the European COMSOL Conference, Stuttgart, Germany, 26–28 October 2011. [Google Scholar]

- Afrapoli, M.S.; Crescente, C.; Li, S.D.; Alipour, S.; Torsaeter, O. Simulation Study of Displacement Mechanisms in Microbial Improved Oil Recovery Experiments. In Proceedings of the SPE EOR Conference at Oil and Gas West Asia, Muscat, Oman, 16–18 April 2012. [Google Scholar]

- Rabbani, S.; Abderrahmane, H.; Sassi, M. Investigation of Enhanced Oil Recovery with the Upscaled Three Phase Flow Model in an Oil Reservoir. In Proceedings of the SPE Gas & Oil Technology Showcase and Conference, Dubai, United Arab Emirates, 21–23 October 2019; p. 198575. [Google Scholar]

- Yue, P.T.; Feng, J.J.; Liu, C.; Shen, J. A diffuse-interface method for simulating two-phase flows of complex fluids. Fluid Mech. 2004, 515, 293–317. [Google Scholar] [CrossRef] [Green Version]

- Zhu, G.P.; Yao, J.; Zhang, L.; Sun, H.; Li, A.F.; Zhang, K. Pore-scale investigation of residual oil distributions and formation mechanisms at the extra-high water-cut stage. Chin. Sci. Bull. 2017, 62, 2553–2563. [Google Scholar]

- Tryggvason, G.; Bunner, B.; Esmaeeli, A.; Juric, D.; Rawahi, A.; Tauber, W.; Han, J.; Nas, S.; Jan, Y.J. A front-tracking method for the computations of multiphase flow. J. Comput. Phys. 2001, 169, 708–759. [Google Scholar] [CrossRef] [Green Version]

- Yue, P.T.; Zhou, C.F.; Feng, J.J.; Ollivier-Gooch, C.F.; Hu, H.H. Phase-field simulations of interfacial dynamics in viscoelastic fluids using finite elements with adaptive meshing. J. Comput. Phys. 2006, 219, 147–167. [Google Scholar] [CrossRef]

- Zhou, S.W.; Zhuang, X.Y.; Rabczuk, T. A phase-field modeling approach of fracture propagation in poroelastic media. Eng. Geol. 2018, 240, 189–203. [Google Scholar] [CrossRef] [Green Version]

- Boyer, F.; Lapuerta, C.; Minjeaud, S.; Piar, B.; Quintard, M. Cahn–Hilliard/Navier-Stokes Model for the Simulation of Three-Phase Flows. Transp. Porous Media 2010, 82, 463–483. [Google Scholar] [CrossRef]

- Magaletti, F.; Picano, F.; Chinappi, M.; Marino, L.; Casciola, C.M. The sharp-interface limit of the Cahn-Hilliard/Navier-Stokes model for binary fluids. J. Fluid Mech. 2013, 714, 95–126. [Google Scholar] [CrossRef]

- Shardt, O.; Derksen, J.J.; Mitra, S.K. Simulations of droplet coalescence in simple shear flow. Langmuir 2013, 29, 6201–6212. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.G.; Kim, K.; Kim, J. On the long time simulation of the Rayleigh-Taylor instability. Int. J. Numer. Methods Eng. 2010, 85, 1633–1647. [Google Scholar] [CrossRef]

- Zhong, H.; He, Y.; Yang, E.; Bi, Y.; Yang, T. Modeling of microflow during viscoelastic polymer flooding in heterogenous reservoirs of Daqing Oilfield. J. Pet. Sci. Eng. 2022, 210, 110091. [Google Scholar] [CrossRef]

- Luo, H.; Wen, J.; Lv, C.; Wang, Z. Modeling of viscosity of unstable crude oil–water mixture by characterization of energy consumption and crude oil physical properties. J. Pet. Sci. Eng. 2022, 212, 110222. [Google Scholar] [CrossRef]

- Shen, J. Modeling and numerical approximation of two-phase incompressible flows by a phase-field approach. Multisc. Model Anal. Mater. Simul. 2011, 22, 147–195. [Google Scholar]

- Hizir, F.E.; Hardt, D.E. Phase-field modeling of liquids splitting between separating surfaces and its application to high-resolution roll-based printing technologies. Phys. Fluids 2017, 29, 052007. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.; Long, J.; Zhao, Y.; Duan, Q.; Dai, Z.; Su, S. Molecular simulation on friction reducing performance of friction modifiers. Acta Pet. Sin. 2018, 34, 136–143. [Google Scholar]

- Wylie, P.; Mohanty, K.K. Effect of Wettability on Oil Recovery by Near-miscible Gas Injection. SPE Reserv. Eng. 1998, 21, 264–268. [Google Scholar]

- Cinar, Y.; Jessen, K.; Berenblyum, R.; Juanes, R.; Orr, F.M. An Experimental and Numerical Investigation of Crossflow Effects in Two-Phase Displacements. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 24–27 September 2006; Volume 11, pp. 216–226. [Google Scholar]

- Pande, K.K.; Orr, F.M. Effect of Viscous Crossflow on Miscibility Development in a Two-Layer Flow System: Part I—Ternary Vaporizing Gas Drives. SPE Adv. Technol. Ser. 1994, 2, 7–16. [Google Scholar] [CrossRef]

- Pande, K.K.; Orr, F.M. Effect of Viscous Crossflow on Miscibility Development in a Two-Layer Flow System: Part II—Ternary Condensing Gas Drives. SPE Adv. Technol. Ser. 1994, 2, 17–25. [Google Scholar] [CrossRef]

- Zhang, B.; Okuno, R. Modeling of capacitance flow behavior in EOS compositional simulation. J. Pet. Sci. Eng. 2015, 131, 96–113. [Google Scholar] [CrossRef]

- Herminghaus, S. Wettability controls slow immiscible displacement through local interfacial instabilities. Phys. Rev. Fluids 2016, 1, 074202. [Google Scholar]

- Yang, W.; Fu, C.; Du, Y.; Xu, K.; Balhoff, M.T.; Weston, J.; Lu, J. Dynamic contact angle reformulates pore-scale fluid-fluid displacement at ultralow interfacial tension. SPE J. 2021, 26, 1278–1289. [Google Scholar] [CrossRef]

- Wang, Z.; Xu, Y.; Gan, Y.; Han, X.; Liu, W.; Xin, H. Micromechanism of partially hydrolyzed polyacrylamide molecule agglomeration morphology and its impact on the stability of crude oil−water interfacial film. J. Pet. Sci. Eng. 2022, 214, 110492. [Google Scholar] [CrossRef]

- Wang, Y.; Li, X.; Lu, J. Experimental study and numerical modeling of boron transport in reservoir and its influence on seawater-breakthrough calculation. SPE Reserv. Eval. Eng. 2021, 24, 292–309. [Google Scholar] [CrossRef]

- Yang, E.; Fang, Y.; Liu, Y.; Li, Z.; Wu, J. Research and application of microfoam selective water plugging agent in shallow low-temperature reservoirs. J. Pet. Sci. Eng. 2020, 193, 107354. [Google Scholar] [CrossRef]

- Liu, Y.; Rui, Z. A storage-driven CO2 EOR for a net-zero emission target. Engineering 2022, in press. [Google Scholar] [CrossRef]

- Wang, Z.; Le, X.; Feng, Y.; Zhang, C. The role of matching relationship between polymer injection parameters and reservoirs in enhanced oil recovery. J. Pet. Sci. Eng. 2013, 111, 139–143. [Google Scholar] [CrossRef]

- Ren, Y.; Zhang, X.; Luo, P.; Liu, Y.; Chen, X. An experimental study of hot water flood for enhancing oil recovery in ultra-low permeability reservoir. Unconv. Oil Gas 2019, 6, 69–74. [Google Scholar]

| Fluid | Rheology | Density (kg/m3) | Dynamic Viscosity (Pa·s) | Interfacial Tension (N/m) |

|---|---|---|---|---|

| Crude oil | Newtonian fluid | 860 | 0.01 | 4.8 × 10−3 |

| Polymer solution | Power-law fluid | 960 | 0.01 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhong, H.; He, Y.; Zhao, X.; Peng, X. Theoretical Study on the Micro-Flow Mechanism of Polymer Flooding in a Double Heterogeneous Oil Layer. Energies 2022, 15, 3236. https://doi.org/10.3390/en15093236

Zhong H, He Y, Zhao X, Peng X. Theoretical Study on the Micro-Flow Mechanism of Polymer Flooding in a Double Heterogeneous Oil Layer. Energies. 2022; 15(9):3236. https://doi.org/10.3390/en15093236

Chicago/Turabian StyleZhong, Huiying, Yuanyuan He, Xin Zhao, and Xiaojuan Peng. 2022. "Theoretical Study on the Micro-Flow Mechanism of Polymer Flooding in a Double Heterogeneous Oil Layer" Energies 15, no. 9: 3236. https://doi.org/10.3390/en15093236