Multi-Parameter Analysis of Gas Losses Occurring during the Determination of Methane-Bearing Capacity in Hard Coal Beds

Abstract

:1. Introduction

2. Materials and Methods

2.1. Study Area

2.2. Direct Drill Cuttings Method for Methane-Bearing Capacity Determination—Single-Phase Vacuum Degassing

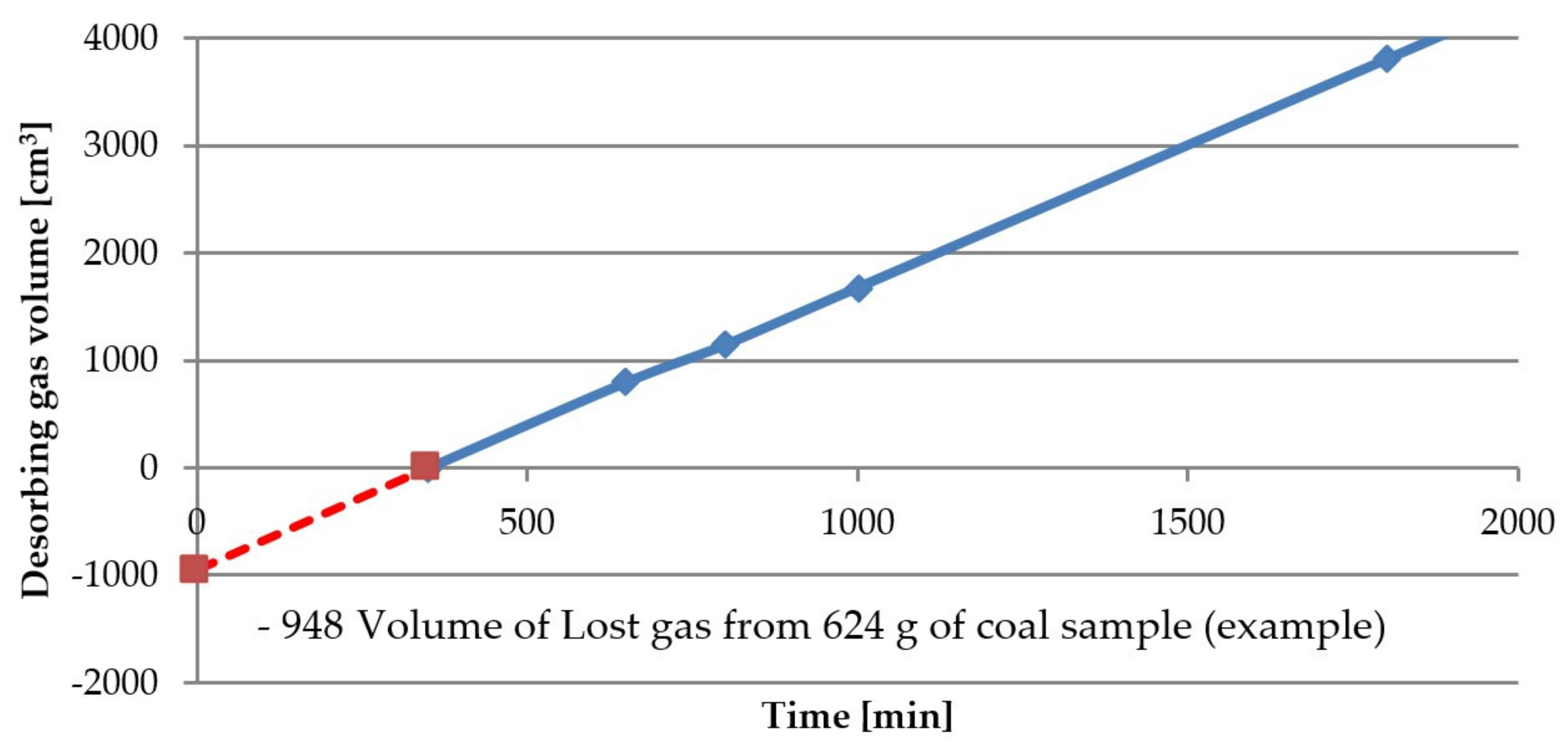

2.3. United States Bureau of Mines Direct Method for Methane-Bearing Capacity Determination

2.4. Investigation of Methane Sorption Kinetics and Isotherms

2.5. Coal Structure Investigation Based on Sorption Analyses

3. Results and Discussion

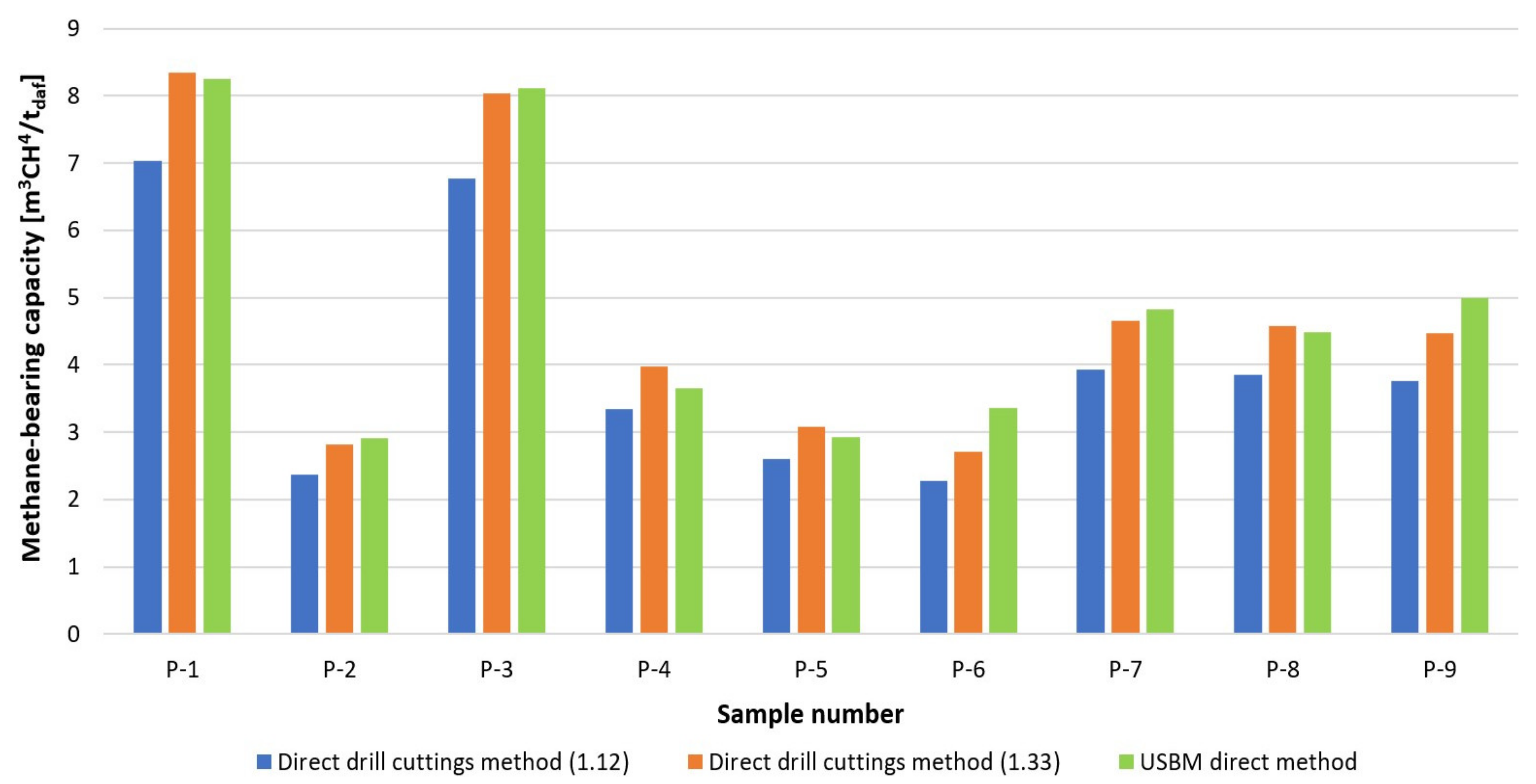

3.1. Results of the Methane-Bearing Capacity Test

3.2. Results of Methane Sorption Kinetics and Methane Sorption Isotherms

3.3. Results of Hard Coal Structure Analysis

3.4. Final Discussion

4. Conclusions

- For the coal samples analysed, the methane-bearing capacity results obtained by the United States Bureau of Mines method showed higher values than those obtained by the direct drill cuttings method, which used a loss factor of 1.12.

- The United States Bureau of Mines method was used as a reference method in which gas losses are determined accurately and individually for each coal sample analysed.

- A very important aspect to consider when determining gas losses at the coal sampling stage for methane-bearing capacity testing is its sorption kinetics. The parameters that best describe the kinetics of sorption processes are the effective diffusion coefficient and the half sorption time.

- The structural parameters associated with the hard coal pore system do not significantly affect the rate of gas desorption. Therefore, they do not affect the correct determination of gas losses during methane-bearing capacity tests.

- Based on the multi-parameter analysis performed, a gas loss compensation factor of 1.33 was determined, which is recommended for use when determining methane-bearing capacity using the direct drill cuttings method.

- The direct drill cuttings method, otherwise known as single-phase vacuum degassing, can be applied for routine control of the methane hazard in hard coal mines. The USBM method seems to be more appropriate for the estimation of methane resources in hard coal seams, possibilities of its exploitation, and for modelling the deposit or carrying out verification of methane-bearing capacity determination for longwalls.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Godyń, K.; Dutka, B. The influence of the content of maceral groups on selected sorption parameters in moderately carbonated coal samples from the southern part of the Upper Silesian Coal Basin. Pr. Inst. Mech. Górotworu PAN 2017, 19, 37–45. [Google Scholar]

- Karbownik, M.; Krawczyk, J.; Godyń, K.; Schlieter, T.; Ščučka, J. Analysis of the Influence of Coal Petrography on the Proper Application of the Unipore and Bidisperse Models of Methane Diffusion. Energies 2021, 14, 8495. [Google Scholar] [CrossRef]

- Gray, I. Reservoir Engineering in Coal Seams: Part 1—The physical process of gas storage and movement in coal seams. SPE Reserv. Eng. 1987, 2, 28–34. [Google Scholar] [CrossRef]

- Moore, T.A. Coalbed methane: A review. Int. J. Coal Geol. 2012, 101, 36–81. [Google Scholar] [CrossRef]

- Żyła, M. Układ Węgiel Kamienny—Metan w Aspekcie Desorpcji i Odzyskiwania Metanu z Gazów Kopalnianych; Uczelniane Wydawnictwa Naukowo-Dydaktyczne: Cracow, Australia, 2000. [Google Scholar]

- Wierzbiński, K.; Krause, E. Influence of working sections and ventilation-methane conditions in longwalls on methane hazard occurrence. Prz. Gór. 2009, 65, 52–60. [Google Scholar]

- Wasilewski, S. Monitoring of Gas Hazard in Polish Underground Hard Coal Mines. Mech. Autom. Gór. 2007, 45, 29–33. [Google Scholar]

- Krause, E.; Karbownik, M. Test of methane desorption and emission from samples of hard coal in the context of mine closures through flooding. J. Sustain. Min. 2019, 18, 127–133. [Google Scholar] [CrossRef]

- Patyńska, R. Methane emissions from ventilation and degasification systems of hard coal mines in Poland in the years 2001–2010. Miner. Resour. Menag. 2013, 29, 17–33. [Google Scholar] [CrossRef] [Green Version]

- Dziurzyński, W.; Krause, E. Influence of the field of aerodynamic potentials and surroundings of goaf on methane hazard in longwall N-12 in seam 329/1, 329/1-2 in “Krupiński” Coal Mine. Arch. Min. Sci. 2012, 57, 819–830. [Google Scholar] [CrossRef]

- Tutak, M.; Brodny, J. Forecasting Methane Emissions from Hard Coal Mines Including the Methane Drainage Process. Energies 2019, 12, 3840. [Google Scholar] [CrossRef] [Green Version]

- Słoczyński, T.; Drozd, A. Coalbed methane (CBM)—Global experience and the prospects of development in Poland. Nafta-Gaz 2017, 11, 851–856. [Google Scholar] [CrossRef]

- Bustin, A.M.M.; Bustin, R.M. Total gas-in-place, gas composition and reservoir properties of coal of the Mannville coal measures, Central Alberta. Int. J. Coal Geol. 2016, 153, 127–143. [Google Scholar] [CrossRef]

- Dang, W.; Zhang, J.; Tang, X.; Chen, Q.; Han, S.; Li, Z.; Du, X.; Wei, X.; Zhang, M.; Liu, J. Shale gas potential of Lower Permian marine-continental transitional black shales in the Southern North China Basin, central China: Characterization of organic geochemistry. J. Nat. Gas Sci. Eng. 2016, 28, 639–650. [Google Scholar] [CrossRef]

- Kędzior, S. The influence of tectonic factor on methane bearing capacity in chosen areas of the Upper Silesian Coal Basin. Pol. Geol. Inst. Spec. Pap. 2002, 7, 143–148. [Google Scholar]

- Gregg, S.J.; Sing, K.S.W. Adsorption, Surface Area and Porosity. Ber. Bunsenges. Phys. Chem. 1982, 86, 957. [Google Scholar] [CrossRef]

- Chaback, J.J.; Morgan, W.D.; Yee, D. Sorption of nitrogen, methane, carbon dioxide and their mixtures on bituminous coals at in-situ conditions. Fluid Phase Equilibria 1996, 117, 289–296. [Google Scholar] [CrossRef]

- Zarębska, K.; Baran, P.; Cygankiewicz, J.; Dudzińska, A. Sorption of carbon dioxide on Polish coals in low and elevated pressure. Fresenius Environ. Bull. 2012, 21, 4003–4008. [Google Scholar]

- Dudzińska, A. Investigation of adsorption and desorption of acetylene on hard coal samples from Polish mines. Int. J. Coal Geol. 2014, 128–129, 24–31. [Google Scholar] [CrossRef]

- Clarkson, C.R.; Bustin, R.M. The effect of pore structure and gas pressure upon the transport properties of coal: A laboratory and modeling study. 1. Isotherms and pore volume distributions. Fuel 1999, 78, 1333–1344. [Google Scholar] [CrossRef]

- Mastalerz, M.; Gluskoter, H.; Krupp, J. Carbon dioxide and methane sorption in high volatile bituminous coals from Indiana, USA. Int. J. Coal Geol. 2004, 60, 43–55. [Google Scholar] [CrossRef]

- Diamond, W.P.; Levine, J.R. Direct Method Determination of the Gas Content of Coal: Procedures and Results; Bureau of Mines Report of Investigations/l981; United States Department of the Interior: Washington, DC, USA, 1981; pp. 1–36.

- Diamond, W.P.; Schatzel, S.J. Measuring the gas content of coal: A review. Int. J. Coal Geol. 1998, 35, 311–331. [Google Scholar] [CrossRef]

- Mcculloch, C.M.; Levine, J.R.; Kissell, F.N.; Deul, M.; Mcculloch, C.M.; Levine, J.R.; Kissell, F.N.; Deul, M. Measuring the Methane Content of Bituminous Coalbeds; Report of Investigations 8043; US Bureau of Mines: Washington, DC, USA, 1975.

- Metcalfe, R.S.; Yee, D.; Seidle, J.P.; Puri, R. Review of research efforts in coalbed methane recovery. In Proceedings of the SPE Asia-Pacific Conference, Perth, Australia, 4–7 November 1991. SPE-23025-MS. [Google Scholar]

- Diamond, W.; Schatzel, S.; Garcia, F.; Ulery, J. The modified direct method: A solution for obtaining accurate coal desorption measurements. In Proceedings of the International Coalbed Methane Symposium, 128, Tuscaloosa, AL, USA, 14–18 May 2001; pp. 331–342. [Google Scholar]

- Shtepani, E.; Noll, L.A.; Elrod, L.W.; Jacobs, P.M. A new regression-based method for accurate measurement of coal and shale gas content. In Proceedings of the SPE Eastern Regional/AAPG Eastern Section Joint Meeting, SPE Reservoir Evaluation & Engineering 13, Pittsburgh, PA, USA, 11–15 October 2008. [Google Scholar]

- Kissell, F.N.; Mcculloch, C.M.; Elder, C.H. The Direct Method of Determining Methane Content of Coal Beds for Ventilation Design; U.S. Bureau of Mines Report of Investigations RI7767; US Department of Interior, Bureau of Mines: Washington, DC, USA, 1973.

- Bertard, C.; Bruyet, B.; Gunther, J. Determination of desorbable gas concentration of coal (direct method). Int. J. Rock Mech. Min. Sci. Geomech. 1970, 7, 43–65. [Google Scholar] [CrossRef]

- Chase, R. A Comparison of Methods Used for Determining the Natural Gas Content of Coalbeds from Exploratory Cores; Technical Report; MET/CR-79; US Department of Petroleum Engineering: Marietta, GA, USA, 1979.

- Smith, D.M.; Williams, F.L. Direct method of determining the methane content of coal—A modification. Fuel 1984, 63, 425–427. [Google Scholar] [CrossRef]

- Dang, W.; Zhang, J.C.; Tang, X.; Wei, X.L.; Li, Z.M.; Wang, C.H.; Chen, Q.; Liu, C. Investigation of gas content of organic-rich shale: A case study from Lower Permian shale in southern North China Basin, central China. Geosci. Front. 2018, 9, 559–575. [Google Scholar] [CrossRef]

- Szlązak, N.; Korzec, M.; Piergies, K. The Determination of the Methane Content of Coal Seams Based on Drill Cutting and Core Samples from Coal Mine Roadway. Energies 2022, 15, 178. [Google Scholar] [CrossRef]

- Szlązak, N.; Obracaj, D.; Korzec, M. Method for determining the coalbed methane content with determination the uncertainty of measurements. Arch. Min. Sci. 2016, 61, 443–456. [Google Scholar] [CrossRef] [Green Version]

- Polish Standard PN-G-44200:2013-10; Górnictwo—Oznaczanie Metanonośności w Pokładach Węgla Kamiennego—Metoda Zwiercinowa. The Polish Committee for Standardization: Warsaw, Poland, 2013.

- Ceglarska-Stefańska, G.; Zarębska, K.; Wolszczak, J. Sorption of pure components and mixtures CO2 and CH4 on hard coals. Miner. Resour. Manag. 2008, 24, 123–131. [Google Scholar]

- Majewska, Z.; Ziętek, J. Acoustic emission and sorptive deformation induced in coals of various rank by the sorption-desorption of gas. Acta Geophys. 2007, 55, 324–343. [Google Scholar] [CrossRef]

- Mohanty, M.M.; Pal, B.K. Sorption behavior of coal for implication in coal bed methane an overview. Int. J. Min. Sci. Technol. 2017, 27, 307–314. [Google Scholar] [CrossRef]

- Dulias, R. The Impact of Mining on the Landscape—A Study of the Upper Silesian Coal Basin in Poland; Springer: Cham, Switzerland, 2016. [Google Scholar]

- Kędzior, S.; Dreger, M. Methane occurrence, emissions and hazards in the Upper Silesian Coal Basin, Poland. Int. J. Coal Geol. 2019, 211, 103226. [Google Scholar] [CrossRef]

- Hard Coal. General Information and Occurrence. Available online: http://geoportal.pgi.gov.pl/surowce/energetyczne/wegiel_kamienny (accessed on 26 January 2022).

- Gabzdyl, W. Geology of Coal Deposits: Deposits of the World; Polish Agency for Ecological: Warsaw, Poland, 1994. [Google Scholar]

- Jureczka, J.; Ignatowicz, A.; Zdanowski, A. Polish hard coal basins—An overview of the history of the research of the National Geological Institute. Prz. Geol. 2019, 67, 578–583. [Google Scholar]

- Dreger, M. Changes in the methane emissions and hard coal output in the Brzeszcze mine (the Upper Silesian Coal Basin, Poland). Geol. Geophys. Environ. 2020, 46, 159–174. [Google Scholar] [CrossRef]

- Dreger, M. Methane emissions in selected hard-coal mines of the Upper Silesian Coal Basin in 1997–2016. Geol. Geophys. Environ. 2019, 45, 121–132. [Google Scholar] [CrossRef]

- Regulation of the Polish Minister of Energy of 23rd November 2016, on Detailed Requirements for Operating Underground Mining Plants. Available online: http://isap.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=WDU20170001118 (accessed on 27 January 2022).

- Mavor, M.J.; Pratt, T.J.; Britton, R.N. Improved methodology for determining total gas content. In Canister Gas Desorption Data Summary; Topical Report GRI-93/0410; Gas Research Institute: Chicago, IL, USA, 1994; Volume I. [Google Scholar]

- Mavor, M.J.; Pratt, T.J. Improved methodology for determining total gas content. In Comparative Evaluation of the Accuracy of Gas-in-Place Estimates and Review of Lost Gas Models; Topical Report GRI-94/0429; Gas Research Institute: Chicago, IL, USA, 1996; Volume II. [Google Scholar]

- ASTM International. ASTM D7569/D7569M—10 (Reapproved 2015) Determination of Gas Content of Coal—Direct Desorption Method; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- Skiba, M.; Młynarczuk, M. Estimation of Coal’s Sorption Parameters Using Artificial Neural Networks. Materials 2020, 13, 5422. [Google Scholar] [CrossRef]

- Wierzbiński, K. The course of methane adsorption kinetics as indicator of seam structural changes in the fault zone area. Prz. Gór. 2011, 6, 70–75. [Google Scholar]

- Chikatamarla, L.; Cui, X.; Bustin, R.M. Implications of volumetric swelling/shrinkage of coal in sequestration of acid gases. In Proceedings of the International Coalbed Methane Symposium, Tuscaloosa, AL, USA, 4–6 May 2004. [Google Scholar]

- Yang, X.; Wang, G.; Zhang, J.; Ren, T. The Influence of Sorption Pressure on Gas Diffusion in Coal Particles: An Experimental Study. Processes 2019, 7, 219. [Google Scholar] [CrossRef] [Green Version]

- Timofiejew, D.P. Adsprptionskinetik; VEB: Leipzig, Germany, 1967. [Google Scholar]

- Chalmers, G.R.L.; Bustin, R.M. On the effects of petrographic composition on coalbed methane sorption. Int. J. Coal Geol. 2006, 69, 288–304. [Google Scholar] [CrossRef]

- Ottiger, S.; Pini, R.; Storti, G.; Mazzotti, M. Competitive adsorption equilibria of CO2 and CH4 on dry coal. Adsorption 2008, 14, 539–556. [Google Scholar] [CrossRef]

- Cygankiewicz, J.; Dudzińska, A.; Żyła, M. The effect of particle size of comminuted bituminous coal on low-temperature sorption of nitrogen and room temperature sorption of carbon dioxide. Przem. Chem. 2006, 85, 1505–1509. [Google Scholar]

- Laxminarayana, C.; Crosdale, P.J. Role of coal type and rank on methane sorption characteristics of Bowen Basin, Australia coals. Int. J. Coal Geol. 1999, 40, 309–325. [Google Scholar] [CrossRef]

- Yang, Y.; Guo, C.; Chen, W.; Sun, H.; Yan, P.; Wu, X. A Method for Evaluating the Methane Content of the Nanoscale Pores in Deep Coalbeds. J. Nanosci. Nanotechnol. 2021, 21, 608–614. [Google Scholar] [CrossRef] [PubMed]

- Saghafi, A. Discussion on determination of gas content of coal and uncertainties of measurement. Int. J. Min. Sci. Technol. 2017, 27, 741–748. [Google Scholar] [CrossRef]

- Skoczylas, N. Fast evaluation of the coalbed methane content of coal viewed as an element leading to improvement in exploitation conditions. Miner. Resour. Manag. 2016, 32, 153–174. [Google Scholar] [CrossRef]

- Szlązak, N.; Borowski, M.; Korzec, M.; Obracaj, D.; Swolkień, J. Method for the determination of methane content of coal seams. Gór. Geoinż. 2011, 35, 101–117. [Google Scholar]

- Dutka, B.; Walaszczyk, W.; Wierzbicki, M. Estimation of the coal seam methane pressure on the base of the methane content and sorption properties of the coal from the “Krupiński” hard coal mine. Gór. Geoinż. 2009, 33, 145–152. [Google Scholar]

- Kudasik, M. Step sorption meter-novel apparatus for sorption measurements under the constant gas pressures. Pr. Inst. Mech. Górotworu PAN 2012, 14, 33–43. [Google Scholar]

- Dutka, B.; Godyń, K. Coalification as a process determining the methane adsorption ability of coal seams. Arch. Min. Sci. 2021, 66, 181–195. [Google Scholar] [CrossRef]

- Weishauptova, Z.; Sykorova, I. Dependence of carbon dioxide sorption on the petrographic composition of bituminous coals from the Czech part of the Upper Silesian Basin, Czech Republic. Fuel 2011, 90, 312–323. [Google Scholar] [CrossRef]

- Dudzińska, A.; Cygankiewicz, J.; Włodarek, M. Natural content of gases: Carbon monoxide, carbon dioxide, hydrogen and unsaturated hydrocarbons of ethylene, propylene and acetylene in selected bituminous coal seams. Int. J. Coal Geol. 2017, 178, 110–121. [Google Scholar] [CrossRef]

- Crosdale, P.J.; Beamish, B.B. Coalbed methane sorption related to coal composition. Int. J. Coal Geol. 1998, 35, 147–158. [Google Scholar] [CrossRef]

- Skoczylas, N.; Kudasik, M.; Wierzbicki, M.; Murzyn, T. New instruments and methods for analyzing the coal-methane system. Studia Geotech. Mech. 2015, 37, 85–91. [Google Scholar] [CrossRef] [Green Version]

| Abbreviation | Explanation | Abbreviation | Explanation |

|---|---|---|---|

| USBM | United States Bureau of Mines | D-R | Dubinin-Radushkevich model |

| CBM | Coal bed methane | BJH | Barrett-Joyner-Halenda model |

| CMM | Coal mine methane | USCB | Upper Silesian Coal Basin |

| AMM | Abandoned mine methane | A | Ash content |

| Mo | Methane-bearing capacity | Wh | Hygroscopic moisture |

| daf | Dry, ash-free | Wex | Transient moisture |

| De | Effective diffusion coefficient | Vdaf | Volatile matter content |

| adaf | Sorption capacity | QL | Lost gas |

| t1/2 | Half sorption time | QD | Desorbing gas |

| BET | Brunauer-Emmett-Teller model | QR | Residual gas |

| Sample Name | Methane-Bearing Capacity | Sorption Tests | |||

|---|---|---|---|---|---|

| Single-Phase Vacuum Degassing | USBM | Sorption Kinetics | Sorption Isotherms | Structure Analysis | |

| P-1 | Core samples Length~30 cm Sampling depth 2.0–2.5 m | Drill cuttings Weight~100 g Sampling depth 3.5–4.0 m | Drill cuttings Weight~1 kg Sampling depth 2.0–4.0 m | Drill cuttings Weight~1 kg Sampling depth 2.0–4.0 m | Drill cuttings Weight~1 kg Sampling depth 2.0–4.0 m |

| P-2 | |||||

| P-3 | |||||

| P-4 | |||||

| P-5 | |||||

| P-6 | |||||

| P-7 | |||||

| P-8 | |||||

| P-9 | |||||

| Sample Number | Methane-Bearing Capacity (m3 CH4/tdaf) | ||

|---|---|---|---|

| Direct Drill Cuttings Method Gas Loss Factor 1.12 | Direct Drill Cuttings Method Gas Loss Factor 1.33 | USBM Direct Method | |

| P-1 | 7.025 | 8.341 | 8.245 |

| P-2 | 2.370 | 2.814 | 2.909 |

| P-3 | 6.764 | 8.033 | 8.112 |

| P-4 | 3.341 | 3.968 | 3.653 |

| P-5 | 2.596 | 3.083 | 2.925 |

| P-6 | 2.277 | 2.705 | 3.350 |

| P-7 | 3.920 | 4.655 | 4.825 |

| P-8 | 3.855 | 4.578 | 4.481 |

| P-9 | 3.764 | 4.470 | 4.989 |

| Sample Name | Langmuir Isotherm Coefficients a(P) = (am*b*P)/(1 + b*P) | Sorption Points in Langmuir Isotherm | Sorption Kinetics | ||||

|---|---|---|---|---|---|---|---|

| am | b | P [bar] | a [cm3/gdaf] | adaf [cm3/gdaf] | De [cm2/s] | t1/2 [s] | |

| P-1 | 20.820 | 0.158 | 0 | 0 | 3.230 | 0.091 × 10−8 | 10,952 |

| 1 | 3.23 | ||||||

| 7 | 10.82 | ||||||

| 15 | 14.71 | ||||||

| P-2 | 18.451 | 0.158 | 0 | 0 | 2.730 | 0.117 × 10−8 | 8535 |

| 1 | 2.73 | ||||||

| 7 | 9.50 | ||||||

| 15 | 13.06 | ||||||

| P-3 | 16.884 | 0.184 | 0 | 0 | 2.750 | 0.092 × 10−8 | 10,859 |

| 1 | 2.75 | ||||||

| 7 | 9.38 | ||||||

| 15 | 12.46 | ||||||

| P-4 | 15.477 | 0.106 | 0 | 0 | 1.720 | 0.077 × 10−8 | 12,922 |

| 1 | 1.72 | ||||||

| 7 | 6.45 | ||||||

| 15 | 9.57 | ||||||

| P-5 | 21.265 | 0.151 | 0 | 0 | 3.100 | 0.084 × 10−8 | 11,797 |

| 1 | 3.10 | ||||||

| 7 | 10.67 | ||||||

| 15 | 14.88 | ||||||

| P-6 | 22.636 | 0.135 | 0 | 0 | 3.090 | 0.369 × 10−8 | 2695 |

| 1 | 3.09 | ||||||

| 7 | 10.67 | ||||||

| 15 | 15.28 | ||||||

| P-7 | 16.566 | 0.149 | 0 | 0 | 2.400 | 0.151 × 10−8 | 6610 |

| 1 | 2.40 | ||||||

| 7 | 8.24 | ||||||

| 15 | 11.54 | ||||||

| P-8 | 18.962 | 0.159 | 0 | 0 | 2.840 | 0.097 × 10−8 | 10,296 |

| 1 | 2.84 | ||||||

| 7 | 9.77 | ||||||

| 15 | 13.46 | ||||||

| P-9 | 17.851 | 0.182 | 0 | 0 | 3.08 | 0.569 × 10−8 | 1751 |

| 1 | 3.08 | ||||||

| 7 | 9.68 | ||||||

| 15 | 13.23 | ||||||

| Sample Name | Surface Area D-R [m2/g] | Micropore Volume D-R [cm3/g] | Average Pore Radius DA [nm] | Surface Area BET [m2/g] | Mezo and Macropore Volume BJH [cm3/g] | Porosity [%] |

|---|---|---|---|---|---|---|

| P-1 | 126.51 | 0.051 | 0.887 | 0.66 | 0.00060 | 3.66 |

| P-2 | 95.19 | 0.038 | 0.895 | 0.46 | 0.00057 | 2.07 |

| P-3 | 105.21 | 0.042 | 0.953 | 0.99 | 0.00140 | 2.71 |

| P-4 | 80.55 | 0.032 | 1.058 | 0.78 | 0.00092 | 1.91 |

| P-5 | 170.70 | 0.068 | 0.874 | 2.62 | 0.00202 | 4.71 |

| P-6 | 162.96 | 0.065 | 0.876 | 2.08 | 0.00299 | 5.08 |

| P-7 | 97.81 | 0.039 | 0.973 | 0.76 | 0.00088 | 2.18 |

| P-8 | 119.14 | 0.048 | 0.843 | 0.78 | 0.00081 | 2.80 |

| P-9 | 127.71 | 0.051 | 0.878 | 1.21 | 0.00192 | 2.65 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Karbownik, M.; Dudzińska, A.; Strzymczok, J. Multi-Parameter Analysis of Gas Losses Occurring during the Determination of Methane-Bearing Capacity in Hard Coal Beds. Energies 2022, 15, 3239. https://doi.org/10.3390/en15093239

Karbownik M, Dudzińska A, Strzymczok J. Multi-Parameter Analysis of Gas Losses Occurring during the Determination of Methane-Bearing Capacity in Hard Coal Beds. Energies. 2022; 15(9):3239. https://doi.org/10.3390/en15093239

Chicago/Turabian StyleKarbownik, Marcin, Agnieszka Dudzińska, and Jarosław Strzymczok. 2022. "Multi-Parameter Analysis of Gas Losses Occurring during the Determination of Methane-Bearing Capacity in Hard Coal Beds" Energies 15, no. 9: 3239. https://doi.org/10.3390/en15093239

APA StyleKarbownik, M., Dudzińska, A., & Strzymczok, J. (2022). Multi-Parameter Analysis of Gas Losses Occurring during the Determination of Methane-Bearing Capacity in Hard Coal Beds. Energies, 15(9), 3239. https://doi.org/10.3390/en15093239