Interactions between Seismic Safety and Energy Efficiency for Masonry Infill Walls: A Shift of the Paradigm

Abstract

:1. Introduction

2. Review of Retrofitting Techniques for Masonry Infill Walls

2.1. Structural Retrofitting Techniques

2.2. Energy Retrofitting Techniques

2.3. Structural Plus Energy Retrofitting Techniques

3. Methodology and Specimen Description

3.1. Specimen Description

- Type 1: masonry infill walls made of hollow clay horizontal brick units (length, height, and thickness of 300 × 200 × 150 mm3, respectively), 1 cm of plaster; no mechanical connection to the envelope RC elements, and no gaps between the wall and the frame, with no seismic strengthening and no energy strengthening. A detailed schematic of this typology is shown in Figure 4a;

- Type 2: masonry infill walls made of hollow clay horizontal brick units (the same as type 1), 2 cm of plaster, no gaps between the wall and the frame, and no mechanical connection to the envelope RC elements, with seismic strengthening (i.e., textile-reinforced mortar solution) but no energy strengthening. Figure 4b presents a detailed schematic of this infill wall typology;

- Type 3: masonry infill walls made of hollow clay horizontal brick units (the same as type 1), 1 cm of plaster, no gaps between the wall and the frame, no mechanical connection to the envelope RC elements, and no seismic strengthening, but with energy strengthening (i.e., external thermal energy insulation). A detailed schematic of this typology is shown in Figure 4c;

- Type 4: masonry infill walls made of vertical hollow lightweight concrete brick units with a geometry of 400 × 190 × 315 mm3 (length, height, and thickness, respectively), no plaster, no gaps between the wall and the frame, no mechanical connection to the envelope RC elements, no seismic strengthening, and no energy strengthening, but masonry units with improved energy properties. A detailed schematic of this wall typology is shown in Figure 4d;

- Type 5: masonry infill walls made of vertical hollow lightweight concrete brick units (the same as type 4), 2 cm of plaster, no gaps between the wall and the frame, and no mechanical connection to the envelope RC elements, with seismic strengthening (i.e., textile-reinforced mortar) but no energy strengthening, and masonry units with improved energy properties (i.e., lower heat transfer coefficient (Uvalue)). A detailed schematic of this masonry infill wall typology is shown in Figure 4e.

3.2. Construction Procedure

3.3. Material Properties

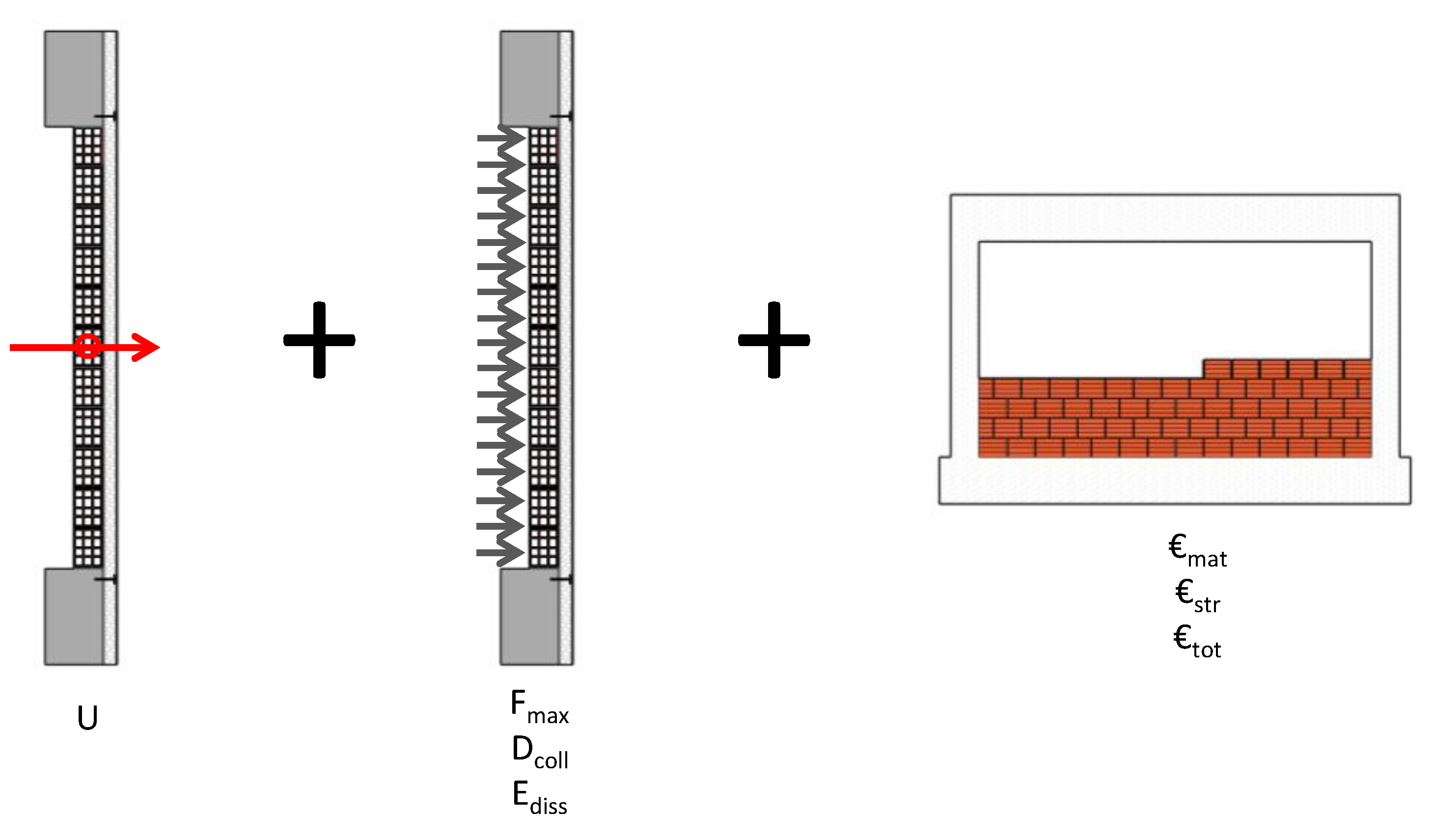

4. Combined Performance Assessment Analysis of Masonry Infill Walls

4.1. Energy Performance Assessment

4.2. Structural Performance Assessment

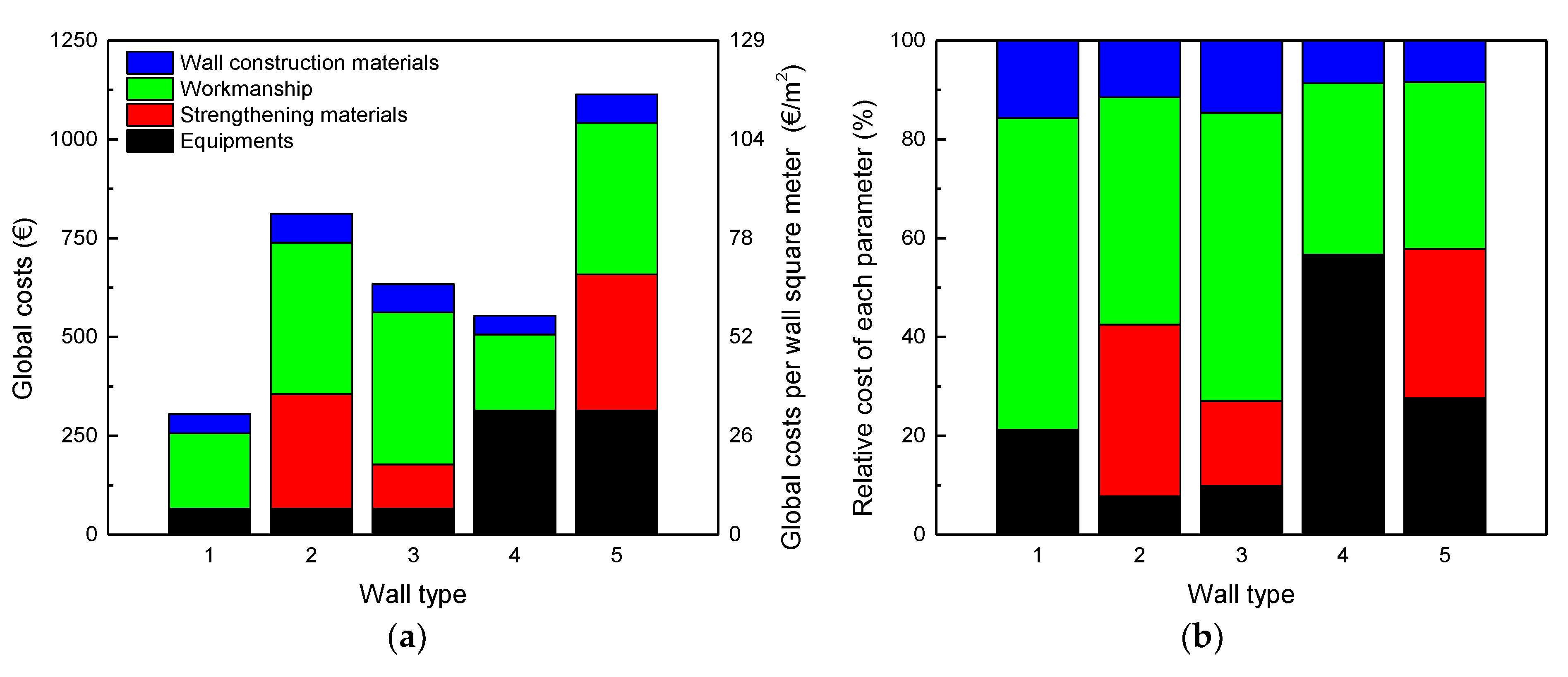

4.3. Cost Analysis

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- European Parliament. Boosting Building Renovation: What Potential and Value for Europe? Technical Report; European Parliament: Strasbourg, France, 2016. [Google Scholar]

- Bournas, D.A. Concurrent seismic and energy retrofitting of RC and masonry building envelopes using inorganic textile-based composites combined with insulation materials: A new concept. Compos. Part B Eng. 2018, 148, 166–179. [Google Scholar] [CrossRef]

- European Comission. Directive of the European Parliament and of the Council on the Energy Performance of Buildings (Recast); European Comission: Brussels, Belgium, 2021. [Google Scholar]

- European Council. Communication from the Comission to the European Parliament: The European Economic and Social Committee and the Committee of the Regions; European Council: Brussels, Belgium, 2019. [Google Scholar]

- European Comission. A Renovation Wave for Europe—Greening Our Buildings, Creating Jobs, Improving Lives; European Comission: Brussels, Belgium, 2020. [Google Scholar]

- Masi, A.; Chiauzzi, L.; Santarsiero, G.; Manfredi, V.; Biondi, S.; Spacone, E.; Del Gaudio, C.; Ricci, P.; Manfredi, G.; Verderame, G.M. Seismic response of RC buildings during the Mw 6.0 August 24, 2016 Central Italy earthquake: The Amatrice case study. Bull. Earthq. Eng. 2019, 17, 5631–5654. [Google Scholar] [CrossRef]

- Luca, F.; Verderame, G.M.; Gómez-Martínez, F.; Pérez-García, A. The structural role played by masonry infills on RC building performances after the 2011 Lorca, Spain, earthquake. Bull. Earthq. Eng. 2014, 12, 1999–2026. [Google Scholar] [CrossRef] [Green Version]

- Hermanns, L.; Fraile, A.; Alarcón, E.; Álvarez, R. Performance of buildings with masonry infill walls during the 2011 Lorca earthquake. Bull. Earthq. Eng. 2014, 12, 1977–1997. [Google Scholar] [CrossRef] [Green Version]

- Gautam, D.; Rodrigues, H.; Bhetwal, K.K.; Neupane, P.; Sanada, Y. Common structural and construction deficiencies of Nepalese buildings. Innov. Infrastruct. Solut. 2016, 1, 1. [Google Scholar] [CrossRef] [Green Version]

- Roeslin, S.; Ma, Q.T.M.; García, H.J. Damage Assessment on Buildings Following the 19th September 2017 Puebla, Mexico Earthquake. Front. Built Environ. 2018, 4, 72. (In English) [Google Scholar] [CrossRef]

- Del Gaudio, C.; de Risi, M.T.; Scala, S.A.; Verderame, G.M. Seismic Loss Estimation in Pre-1970 Residential RC Buildings: The Role of Infills and Services in Low–Mid-Rise Case Studies. Front. Built Environ. 2020, 6, 589230. (In English) [Google Scholar] [CrossRef]

- De Risi, M.T.; del Gaudio, C.; Verderame, G.M. Evaluation of repair costs for masonry infills in RC buildings from observed damage data: The case-study of the 2009 L’Aquila earthquake. Buildings 2019, 9, 122. [Google Scholar] [CrossRef] [Green Version]

- Furtado, A.; Rodrigues, H.; Arêde, A.; Varum, H. Experimental tests on strengthening strategies for masonry infill walls: A literature review. Constr. Build. Mater. 2020, 263, 120520. [Google Scholar] [CrossRef]

- Jelle, B. Traditional, state-of-the-art and future thermal building insultation materials and solutions-properties, requirements and possibilities. Energy Build. 2011, 43, 2549–2563. [Google Scholar] [CrossRef] [Green Version]

- Xian, S.; Lin, N.; Hatzikyriakou, A. Storm surge damage to residential areas: A quantitative analysis for Hurricane Sandy in comparison with FEMA flood map. Nat. Hazards 2015, 79, 1867–1888. [Google Scholar] [CrossRef]

- Unnikrishnan, V.U.; Barbato, M. Performance-Based Comparison of Different Storm Mitigation Techniques for Residential Buildings. J. Struct. Eng. 2016, 142, 04016011. [Google Scholar] [CrossRef]

- Ścisło, Ł.; Łacny, Ł.; Guinchard, M. COVID-19 lockdown impact on CERN seismic station ambient noise levels. Open Eng. 2022, 12, 62–69. [Google Scholar] [CrossRef]

- Łacny, L.; Scisło, L.; Guinchard, M. Application of Probabilistic Power Spectral Density Technique to Monitoring the Long-Term Vibrational Behaviour of CERN Seismic Network Stations. Vib. Phys. Syst. 2020, 31, 2020311. [Google Scholar]

- Scislo, L.; Guinchard, M. Source based measurements and monitoring of ground motion conditions during civil engineering works for high luminosity upgrade of the LHC. In Proceedings of the 26th International Congress on Sound and Vibration, ICSV 2019, Montreal, QC, Canada, 7–11 July 2019. [Google Scholar]

- Varum, H.; Furtado, A.; Rodrigues, H.; Dias-Oliveira, J.; Vila-Pouca, N.; Arêde, A. Seismic performance of the infill masonry walls and ambient vibration tests after the Ghorka 2015, Nepal earthquake. Bull. Earthq. Eng. 2017, 15, 1185–1212. [Google Scholar] [CrossRef]

- Anić, F.; Penava, D.; Abrahamczyk, L.; Sarhosis, V. A review of experimental and analytical studies on the out-of-plane behaviour of masonry infilled frames. Bull. Earthq. Eng. 2020, 18, 2191–2246. [Google Scholar] [CrossRef]

- Di Domenico, M.; de Risi, M.T.; Ricci, P.; Verderame, G.M.; Manfredi, G. Empirical prediction of the in-plane/out-of-plane interaction effects in clay brick unreinforced masonry infill walls. Eng. Struct. 2021, 227, 111438. [Google Scholar] [CrossRef]

- Di Domenico, M.; Ricci, P.; Verderame, G.M. Experimental Assessment of the Influence of Boundary Conditions on the Out-of-Plane Response of Unreinforced Masonry Infill Walls. J. Earthq. Eng. 2020, 24, 881–919. [Google Scholar] [CrossRef]

- Wang, X.; Zhao, W.; Kong, J.; Zhao, T. Numerical Investigation on the Influence of In-Plane Damage on the Out-of-Plane Behavior of Masonry Infill Walls. Adv. Civ. Eng. 2020, 2020, 6276803. [Google Scholar] [CrossRef] [Green Version]

- Akhoundi, F.; Vasconcelos, G.; Lourenço, P. Experimental Out-Of-Plane Behavior of Brick Masonry Infilled Frames. Int. J. Archit. Herit. 2020, 14, 221–237. [Google Scholar] [CrossRef]

- Ricci, P.; di Domenico, M.; Verderame, G.M. Experimental investigation of the influence of slenderness ratio and of the in-plane/out-of-plane interaction on the out-of-plane strength of URM infill walls. Constr. Build. Mater. 2018, 191, 507–522. [Google Scholar] [CrossRef]

- Calvi, G.M.; Bolognini, D. Seismic response of reinforced concrete frames infilled with weakly reinforced masonry panels. J. Earthq. Eng. 2001, 5, 153–185. [Google Scholar] [CrossRef]

- Stathas, N.; Karakasis, I.; Strepelias, E.; Palios, X.; Bousias, S.; Fardis, M.N. Tests and analysis of RC building, with or without masonry infills, for instant column loss. Eng. Struct. 2019, 193, 57–67. [Google Scholar] [CrossRef]

- Verderame, G.M.; de Luca, F.; Ricci, P.; Manfredi, G. Preliminary analysis of a soft-storey mechanism after the 2009 L’Aquila earthquake. Earthq. Eng. Struct. Dyn. 2011, 40, 925–944. [Google Scholar] [CrossRef] [Green Version]

- Mohammadi, M.; Akrami, V.; Mohammadi-Ghazi, R. Methods to Improve Infilled Frame Ductility. J. Struct. Eng. 2011, 137, 646–653. [Google Scholar] [CrossRef]

- Vailati, M.; Monti, G.; di Gangi, G. Earthquake-Safe and Energy-Efficient Infill Panels for Modern Buildings. In Earthquake Engineering and Structural Dynamics in Memory of Ragnar Sigbjörnsson: Selected Topics; Rupakhety, R., Ólafsson, S., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 233–261. [Google Scholar]

- Aliaari, M.; Memari, A.M. Analysis of masonry infilled steel frames with seismic isolator subframes. Eng. Struct. 2005, 27, 487–500. [Google Scholar] [CrossRef]

- Goodno, B.; Pinelli, J.; Craig, J. An optimal design approach for passive damping of building structures using architectural cladding. In Proceedings of the World Conference on Earthquake Engineering—11WCEE, Acapulco, Mexico, 23–28 June 1996. [Google Scholar]

- Lunn, D.S.; Rizkalla, S.H. Design of FRP-strengthened infill-masonry walls subjected to out-of-plane Loading. J. Compos. Constr. 2014, 18, A4013002. [Google Scholar] [CrossRef]

- Kakaletsis, D. Comparison of CFRP and alternative seismic retrofitting techniques for bare and infilled RC frames. J. Compos. Constr. 2011, 15, 565–577. [Google Scholar] [CrossRef]

- Yuksel, E.; Ozkaynak, H.; Buyukozturk, O.; Yalcin, C.; Dindar, A.A.; Surmeli, M.; Tastan, D. Performance of alternative CFRP retrofitting schemes used in infilled RC frames. Constr. Build. Mater. 2010, 24, 596–609. [Google Scholar] [CrossRef]

- Dehghani, A.; Nateghi, F.; Fischer, G. Engineered cementitious composites for strengthening masonry infilled reinforced concrete frames. Eng. Struct. 2015, 105, 197–208. [Google Scholar] [CrossRef] [Green Version]

- Kesner, K.; Billington, S.L. Investigation of infill panels made from engineered cementitious composites for seismic strengthening and retrofit. J. Struct. Eng. 2005, 131, 1712–1720. [Google Scholar] [CrossRef]

- Furtado, A.; Rodrigues, H.; Arêde, A.; Melo, J.; Varum, H. The use of textile-reinforced mortar as a strengthening technique for the infill walls out-of-plane behaviour. Compos. Struct. 2021, 255, 113029. [Google Scholar] [CrossRef]

- De Risi, M.T.; Furtado, A.; Rodrigues, H.; Melo, J.; Verderame, G.M.; António, A.; Varum, H.; Manfredi, G. Experimental analysis of strengthening solutions for the out-of-plane collapse of masonry infills in RC structures through textile reinforced mortars. Eng. Struct. 2020, 207, 110203. [Google Scholar] [CrossRef]

- Koutas, L.N.; Bournas, D.A. Out-of-Plane Strengthening of Masonry-Infilled RC Frames with Textile-Reinforced Mortar Jackets. J. Compos. Constr. 2019, 23, 04018079. [Google Scholar] [CrossRef]

- Bournas, D. 17—Strengthening of Existing Structures: Selected Case Studies. In Textile Fibre Composites in Civil Engineering; Triantafillou, T., Ed.; Woodhead Publishing: Sawston, UK, 2016; pp. 389–411. [Google Scholar]

- Acun, B.; Sucuoglu, H. Strengthening of masonry infill walls in reinforced concrete frames with wire mesh reinforcement. In Proceedings of the 8th US National Conference on Earthquake Engineering, San Francisco, CA, USA, 18–22 April 2006; Volume 10, pp. 6022–6031. [Google Scholar]

- Altin, S.; Anil, O.; Kopraman, Y.; Belgin, C. Strengthening masonry infill walls with reinforced plaster. Proc. Inst. Civ. Eng. Struct. Build. 2010, 163, 331–342. [Google Scholar] [CrossRef]

- Barkhordari, M.A.; Foroughi, M. The effect of shotcrete and steel mesh on masonry infill in steel structures. In Proceedings of the 13th International Conference on Civil, Structural and Environmental Engineering Computing, Crete, Greece, 6–9 September 2011. [Google Scholar]

- Abdel-Mooty, M.A.N. Experimental evaluation of the response of ferrocement strengthened lightweight masonry walls to impact loads. In Research and Applications in Structural Engineering, Mechanics and Computation; CRC Press: Boca Raton, FL, USA, 2013. [Google Scholar]

- Aykac, S.; Ozbek, E.; Kalkan, I.; Aykac, B. Discussion on Seismic capacity of masonry infilled RC frame strengthening with expanded metal ferrocement by A. Leeanansaksiri, P. Panyakapo, A. Ruangrassamee [Eng. Struct. 159 (2018) 110–127]. Eng. Struct. 2018, 171, 928–932. [Google Scholar] [CrossRef]

- Leeanansaksiri, A.; Panyakapo, P.; Ruangrassamee, A. Seismic capacity of masonry infilled RC frame strengthening with expanded metal ferrocement. Eng. Struct. 2018, 159, 110–127. [Google Scholar] [CrossRef]

- Barreira, E.; de Freitas, V.P. External Thermal Insulation Composite Systems: Critical Parameters for Surface Hygrothermal Behaviour. Adv. Mater. Sci. Eng. 2014, 2014, 650752. [Google Scholar] [CrossRef] [Green Version]

- Michalak, J. External Thermal Insulation Composite Systems (ETICS) from Industry and Academia Perspective. Sustainability 2021, 13, 13705. [Google Scholar] [CrossRef]

- Lowe, R.J.; Wingfield, J.; Bell, M.; Bell, J.M. Evidence for heat losses via party wall cavities in masonry construction. Build. Serv. Eng. Res. Technol. 2007, 28, 161–181. [Google Scholar] [CrossRef]

- Agurto, L.; Allacker, K.; Fissore, A.; Agurto, C.; de Troyer, F. Design and experimental study of a low-cost prefab Trombe wall to improve indoor temperatures in social housing in the Biobío region in Chile. Sol. Energy 2020, 198, 704–721. [Google Scholar] [CrossRef]

- Kisilewicz, T. On the Role of External Walls in the Reduction of Energy Demand and the Mitigation of Human Thermal Discomfort. Sustainability 2019, 11, 1061. [Google Scholar] [CrossRef] [Green Version]

- Barbosa, S.; Ip, K. Perspectives of double skin façades for naturally ventilated buildings: A review. Renew. Sustain. Energy Rev. 2014, 40, 1019–1029. [Google Scholar] [CrossRef]

- Liping, W.; Hien, W.N. The impacts of ventilation strategies and facade on indoor thermal environment for naturally ventilated residential buildings in Singapore. Build. Environ. 2007, 42, 4006–4015. [Google Scholar] [CrossRef]

- Sadineni, S.B.; Madala, S.; Boehm, R.F. Passive building energy savings: A review of building envelope components. Renew. Sustain. Energy Rev. 2011, 15, 3617–3631. [Google Scholar] [CrossRef]

- Perini, K.; Ottelé, M.; Fraaij, A.L.A.; Haas, E.M.; Raiteri, R. Vertical greening systems and the effect on air flow and temperature on the building envelope. Build. Environ. 2011, 46, 2287–2294. [Google Scholar] [CrossRef]

- Ascione, F. Energy conservation and renewable technologies for buildings to face the impact of the climate change and minimize the use of cooling. Sol. Energy 2017, 154, 34–100. [Google Scholar] [CrossRef]

- Manos, G.C.; Melidis, L.; Katakalos, K.; Kotoulas, L.; Anastasiadis, A.; Chatziastrou, C. Out-of-Plane Flexure of Masonry Panels with External Thermal Insulation. Buildings 2021, 11, 335. [Google Scholar] [CrossRef]

- Manos, G.C.; Melidis, L.; Katakalos, K.; Kotoulas, L.; Anastasiadis, A.; Chatziastrou, C. Masonry panels with external thermal insulation subjected to in-plane diagonal compression. Case Stud. Constr. Mater. 2021, 14, e00538. [Google Scholar] [CrossRef]

- Karlos, K.; Tsantilis, A.; Triantafillou, T. Integrated Seismic and Energy Retrofitting System for Masonry Walls Using Textile-Reinforced Mortars Combined with Thermal Insulation: Experimental, Analytical, Numerical Study. J. Compos. Sci. 2020, 4, 189. [Google Scholar] [CrossRef]

- Gkournelos, P.D.; Triantafillou, T.C.; Bournas, D.A. Integrated Structural and Energy Retrofitting of Masonry Walls: Effect of In-Plane Damage on the Out-of-Plane Response. J. Compos. Constr. 2020, 24, 04020049. [Google Scholar] [CrossRef]

- Artino, A.; Evola, G.; Margani, G.; Marino, E.M. Seismic and Energy Retrofit of Apartment Buildings through Autoclaved Aerated Concrete (AAC) Blocks Infill Walls. Sustainability 2019, 11, 3939. [Google Scholar] [CrossRef] [Green Version]

- Furtado, A.; Costa, C.; Arêde, A.; Rodrigues, H. Geometric characterisation of Portuguese RC buildings with masonry infill walls. Eur. J. Environ. Civ. Eng. 2016, 20, 396–411. [Google Scholar] [CrossRef]

- Agante, M.; Furtado, A.; Rodrigues, H.; Arêde, A.; Fernandes, P.; Varum, H. Experimental characterization of the out-of-plane behaviour of masonry infill walls made of lightweight concrete blocks. Eng. Struct. 2021, 244, 112755. [Google Scholar] [CrossRef]

- CEN. NP EN 771-1. Especificações Para Unidades de Alvenaria Parte 1: Unidades Cerâmicas (Tijolos Cerâmicos); CEN: Brussels, Belgium, 2016. [Google Scholar]

- CEN. EN 196-2006. Methods of Testing Cement; CEN: Brussels, Belgium, 2006. [Google Scholar]

- ISO. ISO 6946:2017. Building Components and Building Elements—Thermal Resistance and Thermal Transmittance—Calculation Methods; ISO: Geneva, Switzerland, 2017. [Google Scholar]

- Diário da República. Portaria n.º 138-I/2021. Regulamenta os Requisitos Mínimos de Desempenho Energético Relativos à Envolvente dos Edifícios e Aos Sistemas Técnicos e a Respetiva Aplicação em Função do Tipo de Utilização e Específicas Características Técnicas. 2021. Available online: https://dre.pt/dre/detalhe/portaria/138-i-2021-166296492 (accessed on 3 April 2022).

| Retrofitting Technique | Retrofitting of Existing Buildings or New Buildings | Cost of Implementation | Return Period | Compatibility with Energy Retrofitting |

|---|---|---|---|---|

| Fiber-reinforced polymers | Both | ⬤⬤⬤⬤ | ⬤⬤⬤ | ⬤⬤⬤ |

| Engineering cementitious composites | Both | ⬤⬤⬤⬤ | ⬤⬤⬤ | ⬤⬤⬤ |

| Inclusion of sliding devices | New buildings | ⬤⬤⬤⬤⬤ | ⬤⬤⬤⬤ | ⬤ |

| Inclusion energy dissipation devices | New buildings | ⬤⬤⬤⬤⬤ | ⬤⬤⬤⬤ | ⬤ |

| Textile-reinforced mortars | Both | ⬤⬤ | ⬤⬤⬤ | ⬤⬤⬤⬤⬤ |

| Retrofitting Technique | Retrofitting of Existing Buildings or New Buildings | Cost of Implementation | Return Period | Compatibility with Structural Retrofitting |

|---|---|---|---|---|

| External thermal insulation composite systems | Both | ⬤⬤⬤ | ⬤⬤⬤ | ⬤⬤⬤⬤⬤ |

| External insulation of party wall | Both | ⬤⬤ | ⬤⬤⬤ | ⬤⬤⬤ |

| Prefabricated units for external wall insulation | New buildings | ⬤⬤⬤ | ⬤⬤⬤ | ⬤ |

| Cement panels for façade refurbishment | Both | ⬤⬤⬤⬤ | ⬤⬤⬤⬤ | ⬤ |

| Internal thermal insulation | Both | ⬤⬤⬤ | ⬤⬤⬤ | ⬤⬤⬤⬤⬤ |

| Thermal insulation of external walls by injecting insulation material | Existing buildings | ⬤ | ⬤⬤⬤⬤ | ⬤ |

| Naturally ventilated façades | New buildings | ⬤⬤⬤ | ⬤⬤⬤⬤ | ⬤ |

| Green walls | New buildings | ⬤⬤ | ⬤⬤⬤⬤ | ⬤ |

| Wall | Masonry Unit Compressive Strength 1 (Mpa) | Masonry Thermal Resistance (m²·K·W−1)/Uvalues (W·m−²·K−1) | Mortar Compressive Strength (MPa) | Mortar Flexural Strength (MPa) | Masonry Wall Compressive Strength 1,2 (MPa) | Elastic Modulus 1,2 (MPa) | Masonry Wall Diagonal Tensile Strength 1 (MPa) | Shear Modulus 1 (MPa) | Masonry Wall Parallel Flexural Strength 1,3 (MPa) | Masonry Wall Perpendicular Flexural Strength 1,4 (MPa) |

|---|---|---|---|---|---|---|---|---|---|---|

| Type 1 | 1.04 CoV = 23.6% | 0.57/1.75 | 5.24 5 C.o.V. = 7.8% 4.01 6 C.o.V. = 8.2% | 1.90 5 C.o.V. = 6.6% 1.81 6 C.o.V. = 7.3% | 1.09 CoV = 12.8% | 1975 CoV = 36.7% | 0.65 CoV = 22.2% | 996 CoV = 8.9% | 0.22 CoV = 17.6% | 0.30 CoV = 7.9% |

| Type 2 | 0.58/1.72 | 3.52 5 C.o.V. = 6.6% 6.52 6 C.o.V. = 8.6% | 1.53 5 C.o.V. = 4.9% 2.56 6 C.o.V. = 11.9% | |||||||

| Type 3 | 2.52/0.40 | 6.11 5 C.o.V. = 1.1% 6.20 6 C.o.V. = 2.7% | 2.11 5 C.o.V. = 6.6% 2.17 6 C.o.V. = 5.4% | |||||||

| Type 4 | 2.60 CoV = 23.9% | 2.13/0.47 | 6.58 5 C.o.V. = 34.9% | 2.43 5 C.o.V. = 26.4% | 1.82 CoV = 5.1% | 2424 CoV = 24.3% | 1.09 CoV = 12.8% | 0.204 CoV = 5.7% | 0.08 CoV = 14.2% | 0.17 CoV = 25.2% |

| Type 5 | 2.15/0.47 | 6.20 5 C.o.V. = 4.9% 7.30 6 C.o.V. = 7% | 1.81 5 C.o.V. = 4.9% 2.32 6 C.o.V. = 8.5% |

| Winter Climate Zones | I1 | I2 | I3 |

|---|---|---|---|

| Umáx | 0.50 | 0.40 | 0.35 |

| Wall Type | Material Costs (EUR) | Workmanship Costs (EUR) | Equipment Costs (EUR) | Global Costs (EUR) | Unit Cost (EUR/m2) |

|---|---|---|---|---|---|

| Type 1 | Total wall construction materials: Masonry units: 23 EUR Mortar: 42 EUR Total: 65 EUR | 12 EUR/h (8 h—2 persons) Total: 192 EUR | Total: 48 EUR | 305 EUR | 32 EUR/m2 |

| Type 2 | Total wall construction materials: Masonry units: 23 EUR Mortar: 42 EUR Total strengthening materials: Textile mesh: 169 EUR Mortar: 46 EUR Steel connectors plus steel plate (mesh–frame): 65 EUR Plastic connectors (mesh–panel): 10 EUR Total: 355 EUR | 12 EUR/h (16 h—2 persons) Total: 384 EUR | Total: 72 EUR | 811 EUR | 84 EUR/m2 |

| Type 3 | Total wall construction materials: Masonry units: 23 EUR Mortar: 42 EUR Total strengthening materials: Traditional Mortar: 33 EUR Glue Cement Mortar: 14 EUR EPS plates: 25 EUR Textile mesh: 22 EUR Plastic connectors: 19 EUR Total: 178 EUR | 12 EUR/h (16 h—2 persons) Total: 384 EUR | Total: 72 EUR | 634 EUR | 66 EUR/m2 |

| Type 4 | Total wall construction materials: Masonry units: 264 EUR Mortar: 50 EUR Total: 314 EUR | 12 EUR/h (8 h—2 persons) Total: 192 EUR | Total: 48 EUR | 554 EUR | 57 EUR/m2 |

| Type 5 | Total wall construction materials: Masonry units: 264 EUR Mortar: 50 EUR Total strengthening materials: Textile mesh: 225 EUR Mortar: 46 EUR Steel connectors (mesh–frame): 49 EUR Steel connectors (mesh–panel): 24 EUR Total: 652 EUR | 12 EUR/h (16 h—2 persons) Total: 384 EUR | Total: 72 EUR | 1108 EUR | 115 EUR/m2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Furtado, A.; Rodrigues, H.; Arêde, A.; Rodrigues, F.; Varum, H. Interactions between Seismic Safety and Energy Efficiency for Masonry Infill Walls: A Shift of the Paradigm. Energies 2022, 15, 3269. https://doi.org/10.3390/en15093269

Furtado A, Rodrigues H, Arêde A, Rodrigues F, Varum H. Interactions between Seismic Safety and Energy Efficiency for Masonry Infill Walls: A Shift of the Paradigm. Energies. 2022; 15(9):3269. https://doi.org/10.3390/en15093269

Chicago/Turabian StyleFurtado, André, Hugo Rodrigues, António Arêde, Fernanda Rodrigues, and Humberto Varum. 2022. "Interactions between Seismic Safety and Energy Efficiency for Masonry Infill Walls: A Shift of the Paradigm" Energies 15, no. 9: 3269. https://doi.org/10.3390/en15093269