Abstract

Transformer oil is conventionally used as an insulating liquid for the purpose of insulation and cooling in power transformers. The rise in the power demand has put stress on the existing insulation system used for power transmission. Nanotechnology provides an advanced approach to upgrade the conventional insulation system by producing nano-oil with enhanced dielectric characteristics. The aim of the study is to present the influence of area volume effect on the dielectric performance of mineral oil and its nanofluids. In this paper, nanofluids are prepared by dispersing two different concentrations of SiO2 nanoparticles in base transformer oil using a two-step method. The effect of area and volume is investigated on nanofluids in the laboratory using coaxial electrode configurations under different test conditions. The AC breakdown voltage and maximum electric stress is determined for the pure oil and nanofluids. The results show that the addition of SiO2 nanoparticles significantly improves the dielectric characteristics of transformer oil. Moreover, the breakdown phenomenon is also discussed to analyze the effect of nanoparticle, stressed area, and stressed volume on the dielectric strength of insulating oil. Nanofluids could be an alternative to mineral oil.

1. Introduction

Mineral oil is used as an insulation and coolant material that provides sufficient insulation between the windings and cooling facilities in power transformers [1,2]. Transformers undergo various kinds of stresses such as electrical, thermal, and mechanical stress during its entire operating life. The life of a transformer mainly depends upon the insulation and cooling capabilities of the insulation system used in it [3]. Transformer failure results in the interruption of power flow, economic losses, and high replacement costs. According to a study on transformer failure, insulation failure is one of the key reasons for transformer failures [4]. Therefore, it is important that mineral oil should possess upgraded insulating characteristics for the efficient and effective working of transformers in an electrical power system under overload conditions. Addressing this issue, researchers utilize nanoparticles as an additive in the oils to improve the insulating characteristics of mineral oil [5,6,7]. In view of the current scenario, nanofluids are produced by dispersing the optimum concentration of nanoparticles in base mineral oil [8].

For a high voltage power transmission, it is required to discover such an insulant that can provide an excellent insulation requirement and cooling. Upgraded insulants not only reduce the size of the insulation but also give better performance under extreme fault conditions [9]. In this era of transmitting extra-high and ultra-high voltage power, we require such insulation that not only provides the required dielectric properties, but also works as a superior smart insulant. Therefore, to develop such insulating materials, the dielectric strength of mineral oil-based nanofluids has been considered [10]. Considering these challenges, alumina-based materials are considered in various studies to improve the dielectric property of mineral oils [11,12]. The study shows that alumina-based nanofluids exhibit a higher AC breakdown strength and lightning impulse breakdown strength than pure mineral oil [11], and the effect of surface modification and the shape of Al2O3 nanoparticles on the dielectric strength of mineral oil was also investigated [12]. Moreover, it has been experimentally shown that alumina-based nanomaterials have a good corrosion resistance, which is beneficial in material corrosion studies and to predict the long-term stability of materials [13]. Transformer oil is extensively used in transformers as insulation because of its excellent dielectric strength and thermal property. The high dielectric strength and its better cooling capability make transformer oil suitable for use as insulation in power transformers. Tremendous performances shown in the past by transformer oil as an insulant in electrical equipment have made it perfect insulation. But in the recent past [14], there is a need to develop such an insulating fluid that can perform its functionalities effectively when it is exposed to unpleasant weather conditions because the performance of a power transformer is affected when it is exposed to different weather conditions [15,16]. The comparison of the existing literatures on the dielectric behaviour of transformer oil with the proposed work is discussed in Table 1.

Table 1.

Comparison table of the existing literature on dielectric behaviour of transformer oil with the proposed work.

This paper presents the effect of area and volume effects on the dielectric breakdown strength of a mineral oil-based SiO2 nanofluid. The silica insulating nanoparticle is chosen as an oil additive due to its excellent dielectric performance, and its hydrophilic nature. Additionally, the low cost of silica-based nanomaterials has made us to choose it as a dopant to improve the dielectric characteristics of mineral oil. The breakdown characteristics are not only affected by the maximum electric field strength but are also influenced by the area and volume effects [17]. Hence, the area and volume effect are the important factors that must be considered in the insulation design of power transformers. In this study, factors affecting the area and volume effect, nanoparticles and their uses, the determination of the stressed electrode area and the stressed liquid volume, experimental results, and the comparison of the performance of nanofluids are well explained. Furthermore, the area and volume effect for nano-modified transformer oil is also analyzed. The surface modification technique used to improve the long-term stability of nano-oils, and the phenomenon of the breakdown mechanism in nanofluids are also discussed in the paper. Two different concentrations of SiO2 nanoparticles (i.e., 0.05 wt% and 0.15 wt%) are used to modify pure mineral oil. The reason for choosing surface-modified silica nanoparticles is not that it forms a stable dispersion with mineral oil, but it also exhibits a better dielectric strength than mineral oil. The main contribution of this paper lies in investigating the experimental test results for the area and volume effects on the dielectric behavior of a nanofluid. The test results are very useful for electrical utilities in developing better condition monitoring systems for oil-filled transformers based on a property comparison. The oil and nanoparticles specifications are shown in Table 2 and Table 3.

Table 2.

Properties of Mineral oil.

Table 3.

Specification of Nanoparticle.

The rest of the paper is organized as follows: Section 2 discusses the experimental techniques and procedures followed to prepare the nanofluids, and the chemical method utilized to improve the dispersion stability of the nanofluids. The experimental set-up to determine the dielectric properties of the prepared nanofluids, along with the steps involved in the experimental procedure that includes the preparation of the electrode setup and the measurement at high voltage is described in Section 2. The experimental results for the AC breakdown voltage and the maximum electric stress along with the discussion is shown in Section 3. The conclusion is added in Section 4 of the paper.

2. Experimental Set-Up and Materials Preparation Techniques

2.1. Nanofluids Synthesis

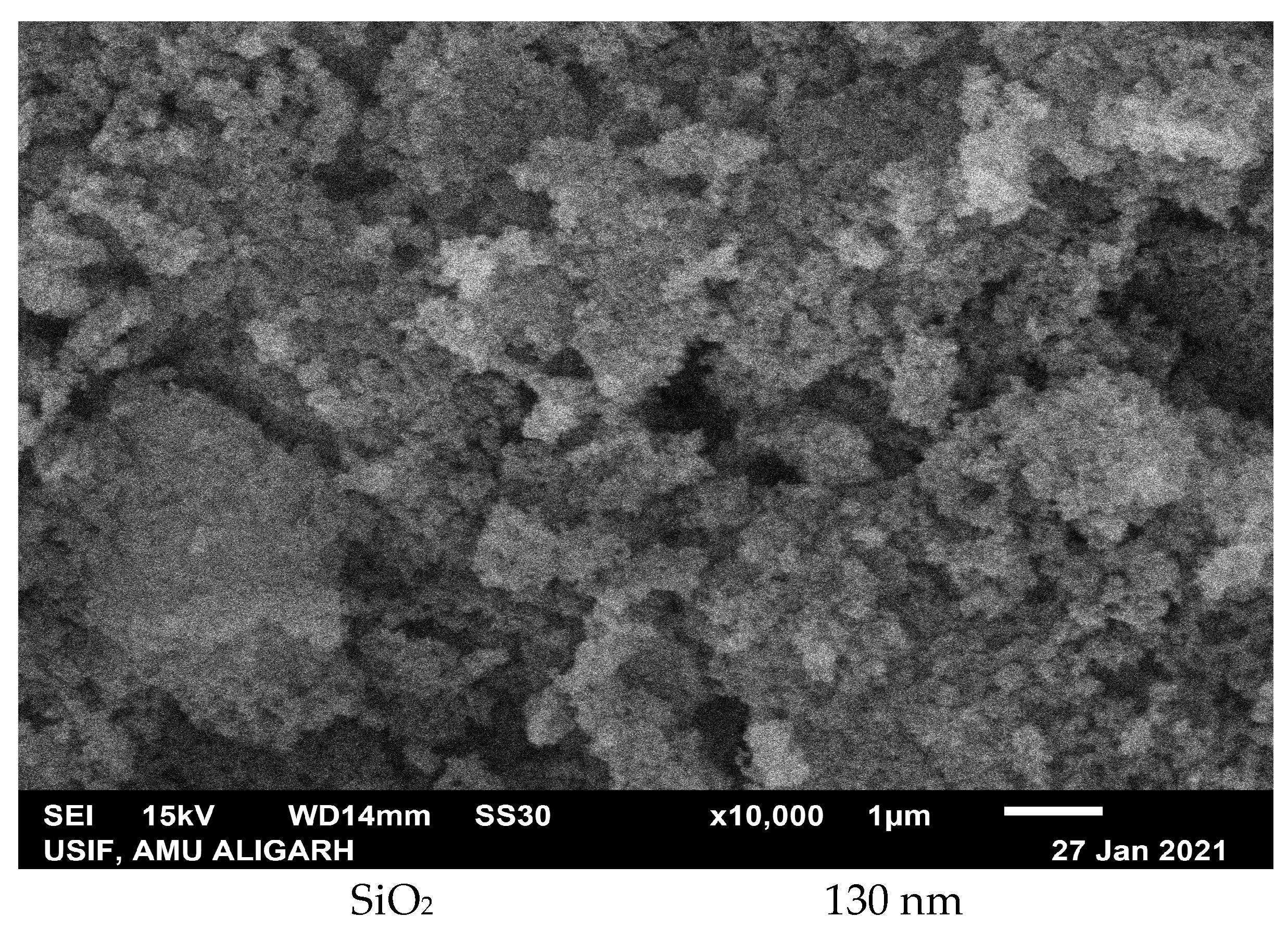

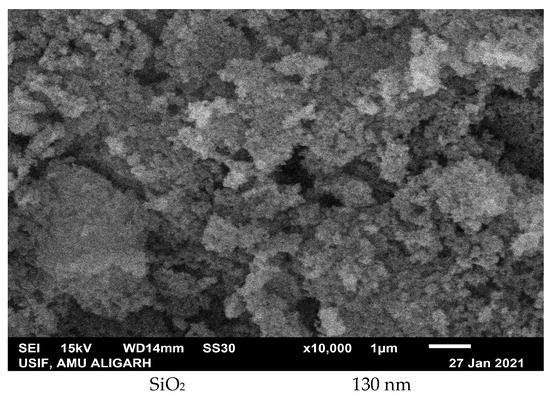

The SiO2 nanoparticles are used to improve the dielectric properties of the transformer oil. The nanoparticles were purchased from Sigma-Aldrich, which was additionally reduced in size using the top-down nanotechnology method. This technique gives more fine powder of nanoparticles. The transformer oil used in the present study for experimentation purpose was commercially obtained. The properties of oil and nanoparticles have been shown in Table 2 and Table 3, respectively. The nanoparticle size and its morphology were determined using the SEM (scanning electron microscopy) imaging, which is shown in Figure 1. The SEM imaging was carried out at different magnification ranges and for the different surface areas of the tested sample. The morphology was studied using SEM at a voltage of 15 kV in the scanning mode. The morphology of nanoparticles depends upon the synthesis conditions. The grain size was analyzed using software, and then statistical grain analysis was performed to determine the grain size. The standard method was applied to determine the size distribution of SiO2 nanoparticles [23]. The porosity of nano-samples can also be evaluated by processing the SEM images to obtain contrast images using custom software. The investigation of data obtained from SEM images shows that nanoparticle samples have close-packed microstructure.

Figure 1.

SEM image of SiO2 nanoparticles.

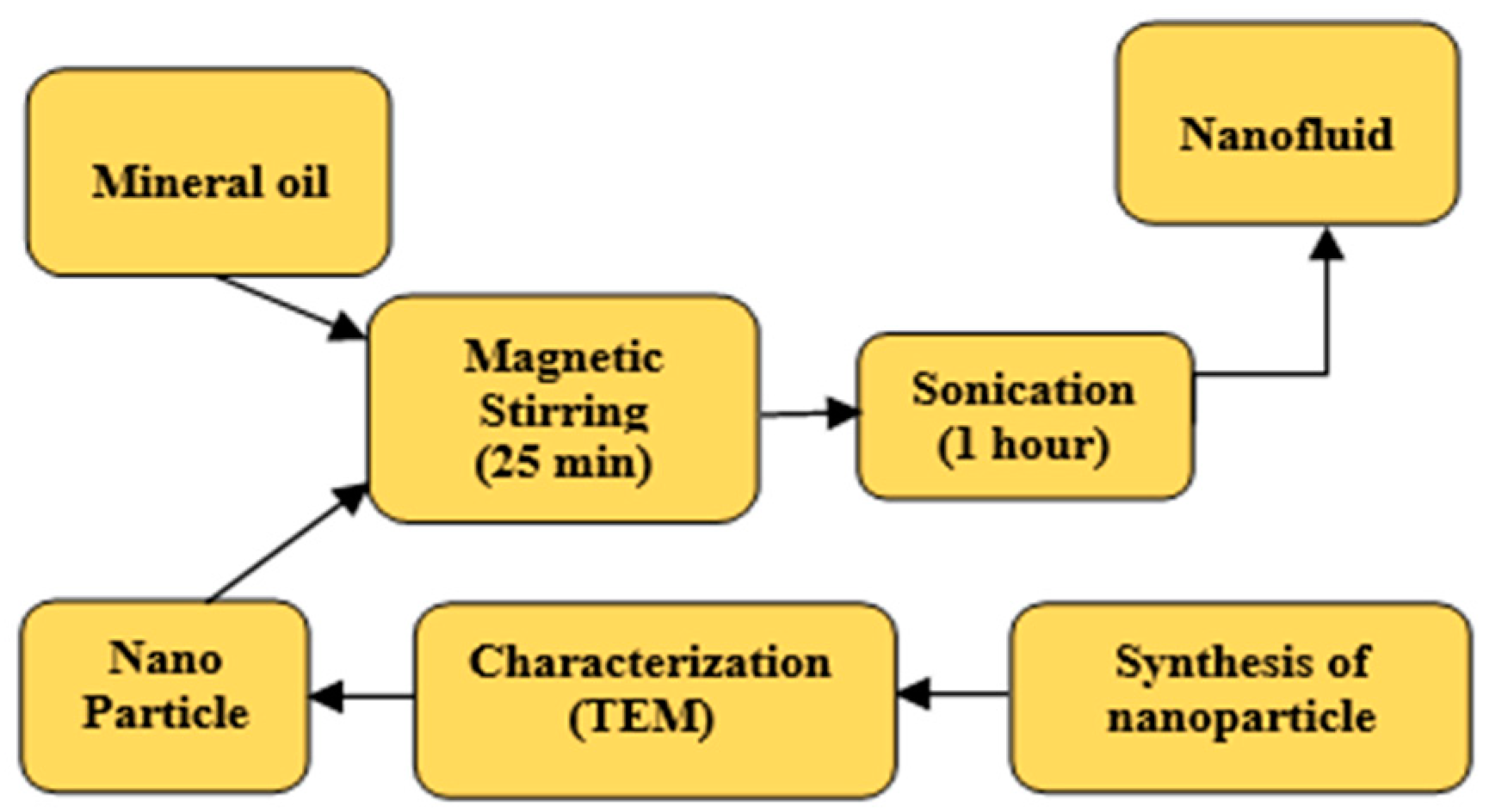

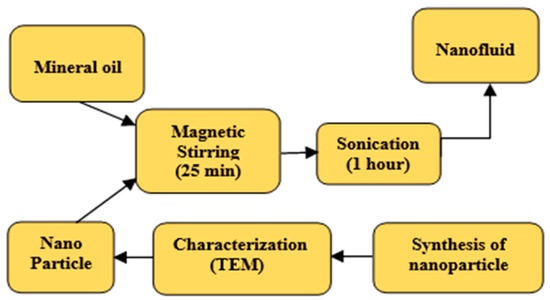

In this paper two individual samples of nanofluid are prepared by introducing different concentrations of SiO2 nanoparticles into the mineral oil via a two-step method [24,25]. This method is widely recognized and is extensively used by researchers to prepare nanofluids as it eliminates the process of drying and storing of nanoparticles, reduces cluster formation of nanoparticles, and gives more stable nanofluid dispersions even for longer durations of time. Oleic acid is added as a surfactant in the base mineral oil to reduce the clustering of nanoparticles in the oil up to a certain extent and enhancing the stability of nanofluids. The two-step method is a two-phase process, which includes synthesis of nanoparticles initially, then followed by the dispersion of nanoparticles in the base oil. The process of dispersing nanoparticles in the base oil includes magnetic stirring and ultra-sonication. The magnetic stirring involves the mixing of oleic acid in the pure oil using a magnetic bar that revolves at a constant speed to prepare the solution. Then, nanoparticles are added in the solution. Finally, the ultra-sonication process is followed; in which high-frequency waves (around 40 kHz) are generated that uniformly mix the nanoparticles in the pure mineral oil. This makes the sample ready for testing purpose. The method used for preparation of nanofluids is two-step method, as shown in Figure 2.

Figure 2.

Flow chart illustration for preparation of nanofluids.

2.2. Surface Modification for the Stability of Nanofluids

The dispersion stability of nanofluids is an essential parameter that needs to be analyzed to determine its application as insulating oil in electric transformers. Oleic acid is added as a surfactant in the base oil to improve the stability of nanofluids [26]. The nanoparticles are coated with a layer of oleic acid that provides an additional repulsive force between the nanoparticle surfaces. This concept is explained using a DVLO theory [27], according to which, nanoparticles are subjected to various electrical attractive and repulsive forces in a colloidal suspension such as the Van der Waals attractive forces and electrostatic repulsive forces. According to the theory, if the repulsive forces are higher than the attractive forces between the nanoparticles, then the colloidal suspension obtained will be stable. The nanofluids stability is tested using a simple bottle test in the present study, and it was ensured that prepared nanofluids samples are stable.

2.3. Measurement of Dielectric Properties

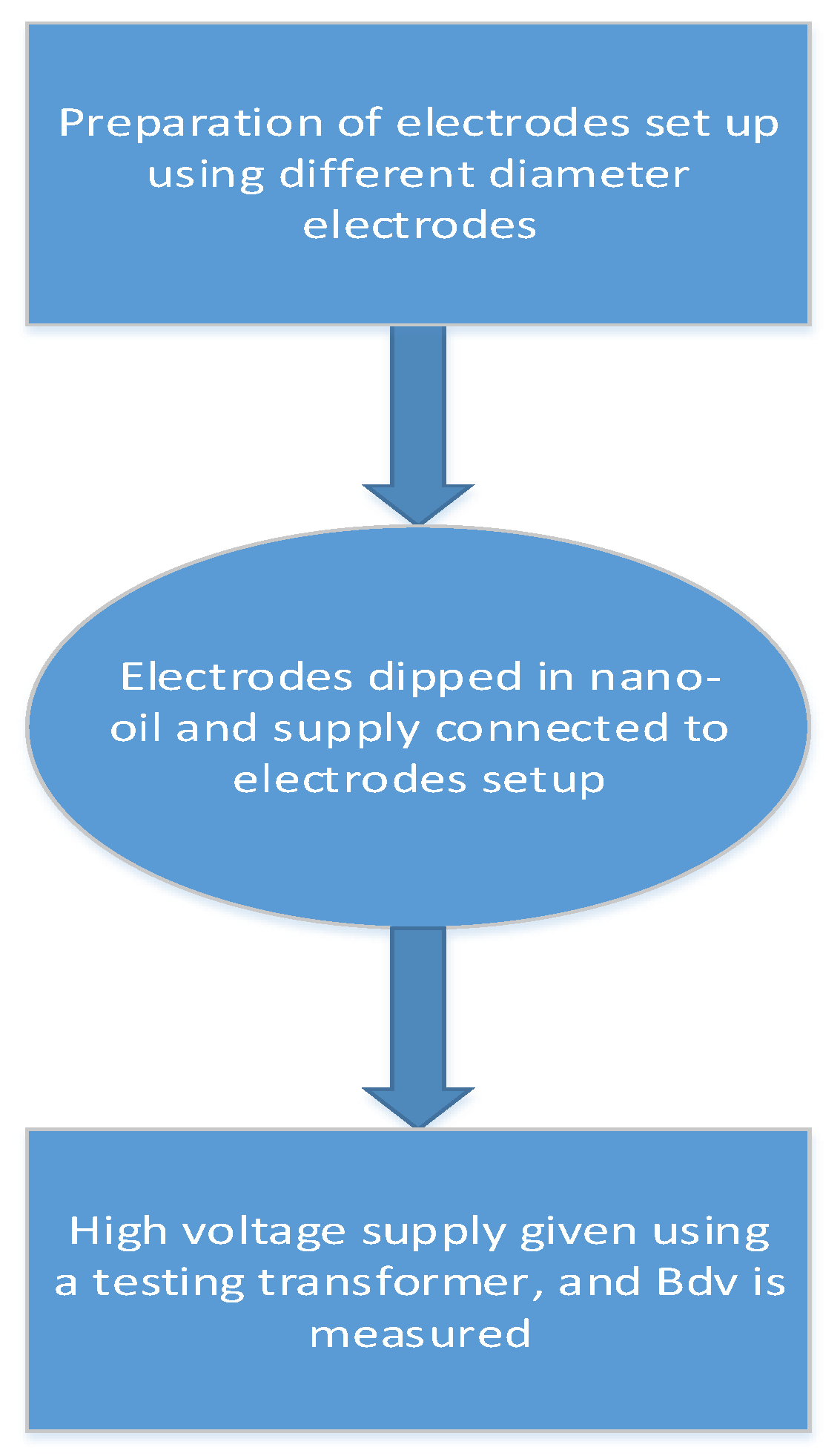

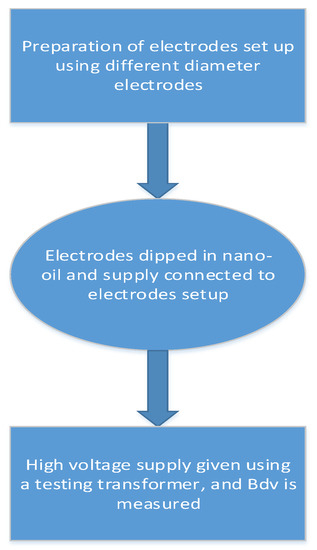

The AC breakdown test is essential to determine the dielectric capabilities of insulating liquids used in transformers. The area volume effect on AC breakdown voltage and maximum electric stress of mineral oil and its subsequent nanofluids is studied. The area and volume effect are investigated for co-axial electrode configurations. It is required to calculate (SEA)90 and (SLV)90 to analyze the effect of area and volume on the breakdown strength of mineral oil, where (SEA)90 is the stressed electrode area and (SLV)90 is the stressed liquid volume, which can be varied with gap length (g) and electrode length (L). To determine the area and volume effect, four cylindrical electrodes made up of brass having different diameters are used for the experiment. The diameter of outer electrodes is constant whereas diameter of inner electrodes is variable. For each set of electrode length, four inner electrodes with different diameters are used for co-axial cylindrical electrode configuration. The dimensions of the co-axial cylindrical electrodes used for breakdown measurement are shown in Table 4. The flowchart with the steps involved in the experimental procedure is shown in Figure 3.

Table 4.

Specifications of Electrodes.

Figure 3.

Steps involved in the experimental procedure.

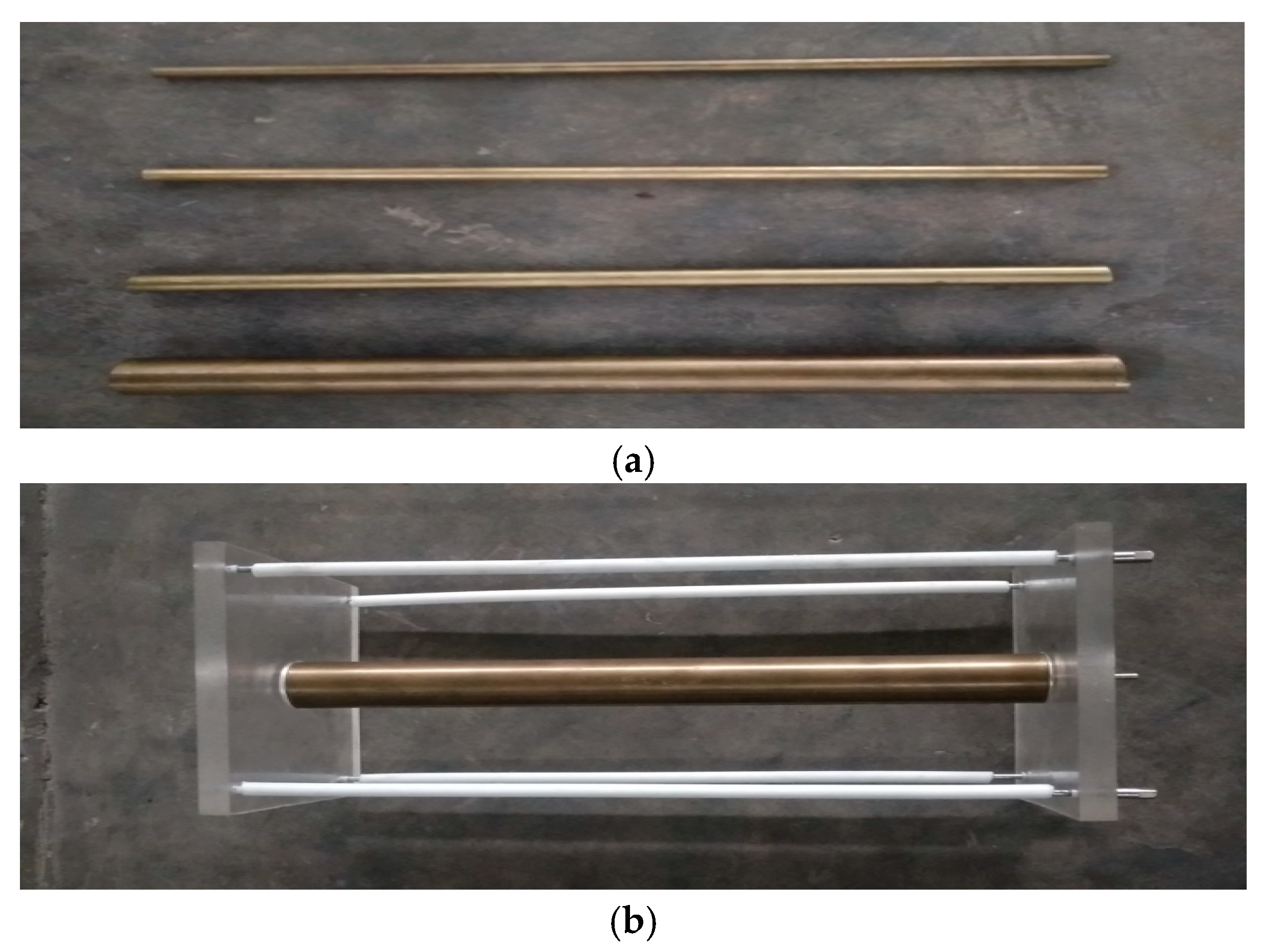

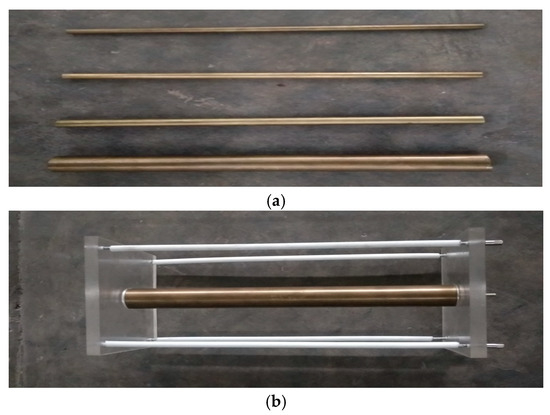

The gap length (g) is varied by using the inner electrodes having a different diameter, and the diameter of the outer electrode is kept fixed. Hence for each fixed length we will get four different gap lengths. Figure 4a shows the different electrodes used in the study. The inner and outer electrodes of the co-axial cylindrical configuration are insulated by a Perspex sheet. To achieve this, grooves are made to hold both cylindrical electrodes in a square piece of Perspex sheet. After holding the cylindrical electrodes in the grooves made in Perspex sheet the whole set up was supported by thin metal rods at the four corners of the Perspex sheet. These rods are covered by an insulation pipe and are screwed tightly by nuts. The whole set up arrangement is shown in Figure 4b. The thickness of the electrode is measured using a magnetic dial gauge having an accuracy of 1 µm.

Figure 4.

Experimental set-up with electrode configuration to determine the dielectric strength of oils at high voltage. (a) Electrodes of different diameter, (b) Electrode set-up.

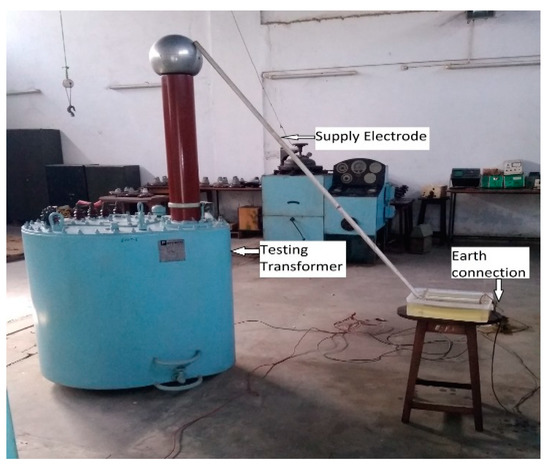

2.4. The Supply and Measurement of High Voltage

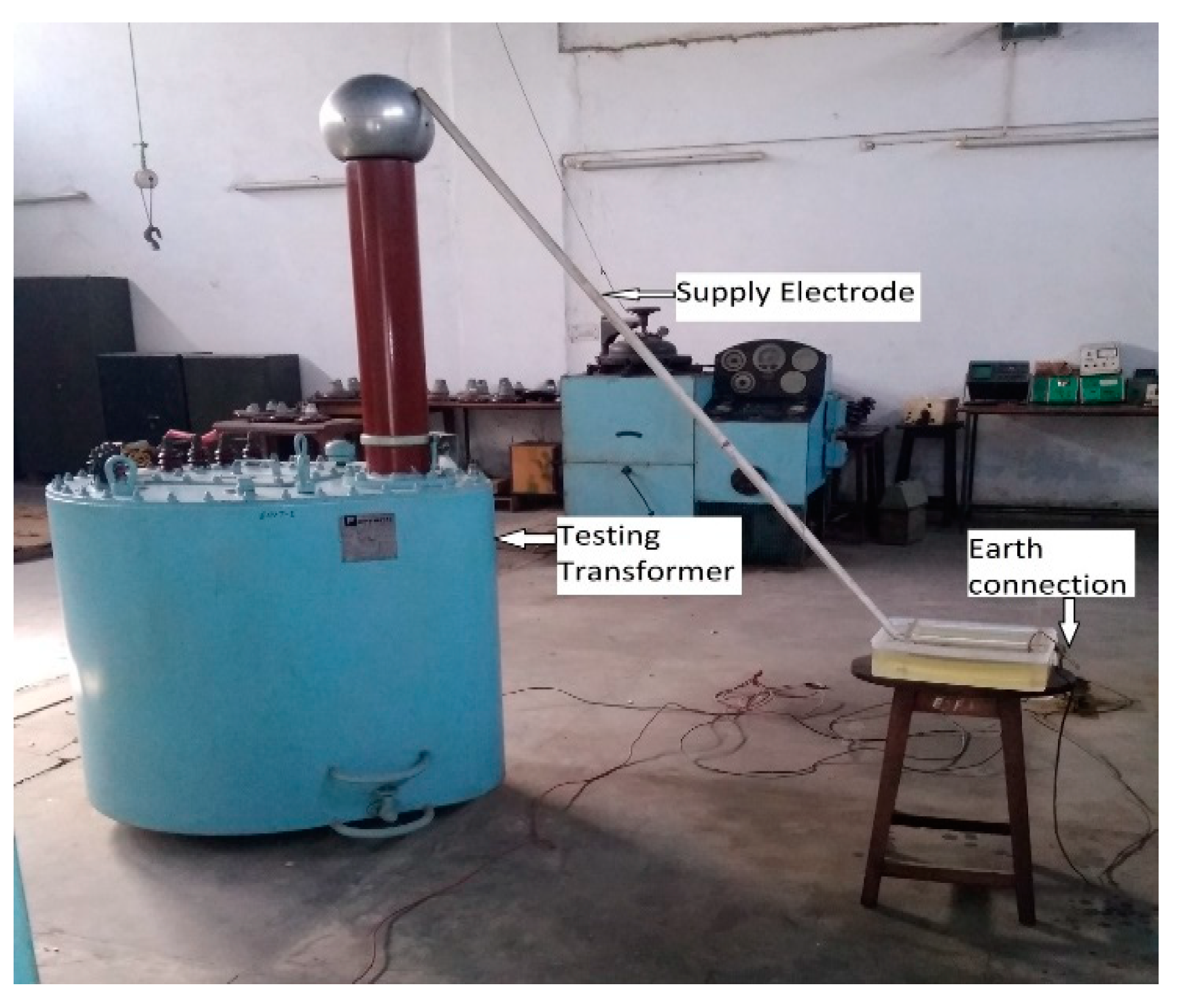

The high voltage measurement is completed using a testing transformer of 150 kV, 50 Hz, —phase, 30 kVA rating, as shown in Figure 5. These high voltages were measured with the help of an MI voltmeter (accuracy ± 1%) connected at the primary side of the testing transformer, which reads the low side voltages. The corresponding high voltages are obtained from a calibration curve drawn using a sphere–sphere electrode system having the diameter of 25 cm (IS-1876, 1961).

Figure 5.

High-voltage testing transformer and experimental set up.

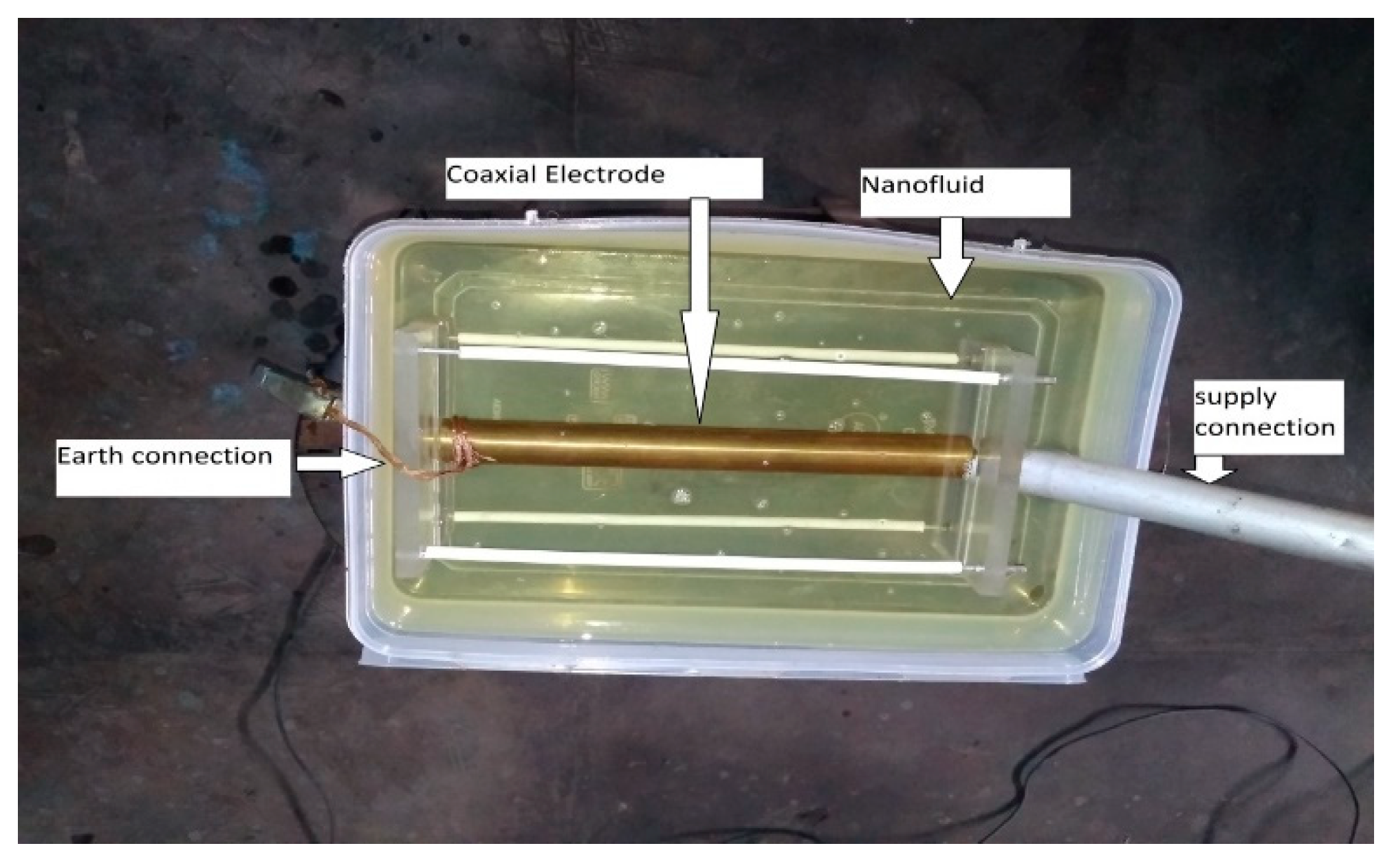

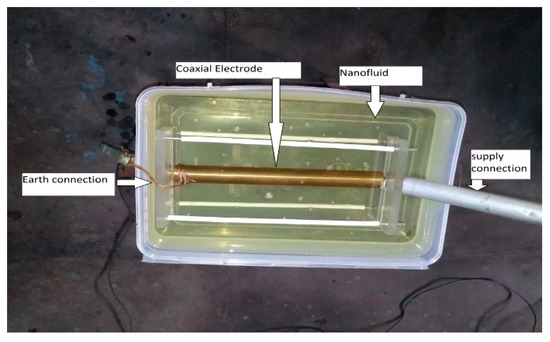

Before starting the experiment, the test vessel, which is made up of plastic, was cleaned using alcohol, and filled with the insulating oil as shown in Figure 6. The electrode assembly was completely dipped in the insulating oil. The cleaned and dried cylindrical electrode assembly is filled with the insulating oil in between the electrodes by an injection syringe through a minor hole. After injecting the insulation oil in between the electrodes, a screw was kept in to touch with the inner electrode. This is done to ensure power supply to the inner electrode as shown in the Figure 6. Now the whole electrode assembly is completely dipped in a vessel filled with insulating liquid, then wait for 5 min until the bubble formation stops. Now, the outer electrode is earthed through a wire and supply is given to inner electrode through a screw.

Figure 6.

Electrode dipped in the insulating oil and the supply connection to the electrode.

After connecting the electrodes properly, the supply voltage was given with help of a testing transformer, and the applied voltage was raised at a uniform rate of 5 kV/s. The breakdown voltage was measured with an accuracy of ±3%. Each sample is measured five times, and the average value of breakdown voltage is reported. The Emax, (SEA)90, and (SLV)90 is calculated by using the following equations:

Emax = V/(a.ln(b/a))

(SEA)90 = 2aπL; for a ≤ 0.9b

(SLV)90 = 19/81 × (πLa2); for a ≤ 0.9b

The units of Emax, (SEA)90, (SLV)90 are kV/mm, mm2, and mm3, respectively. V is the voltage applied, a and b represent inner cylindrical radius and outer cylindrical radius, respectively.

3. Experimental Results and Discussion

The graph between the average breakdown voltage and the maximum breakdown strength, with (SEA)90 and (SLV)90 for different concentrations of SiO2 nanoparticles, is plotted.

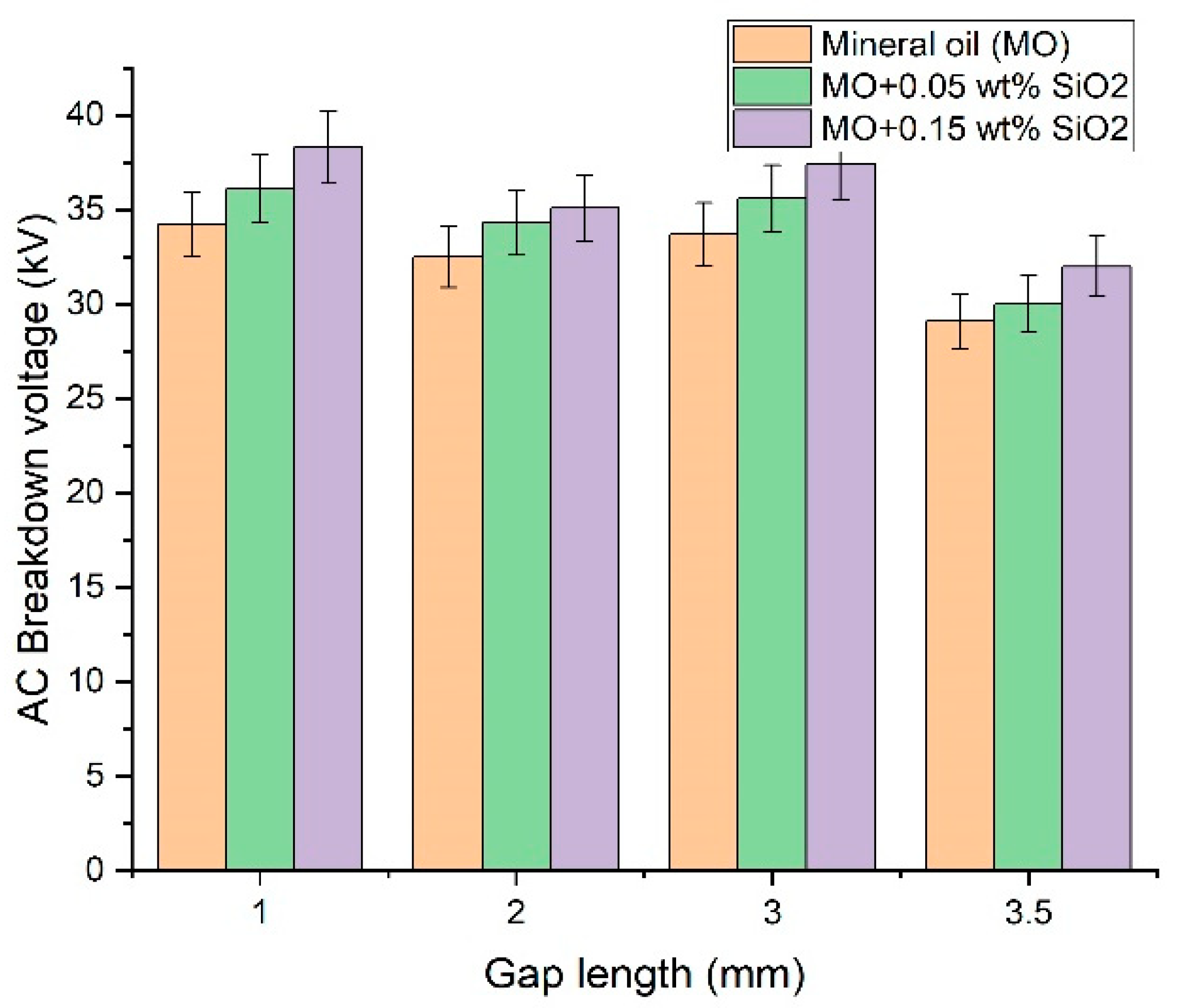

3.1. AC breakdown Voltage

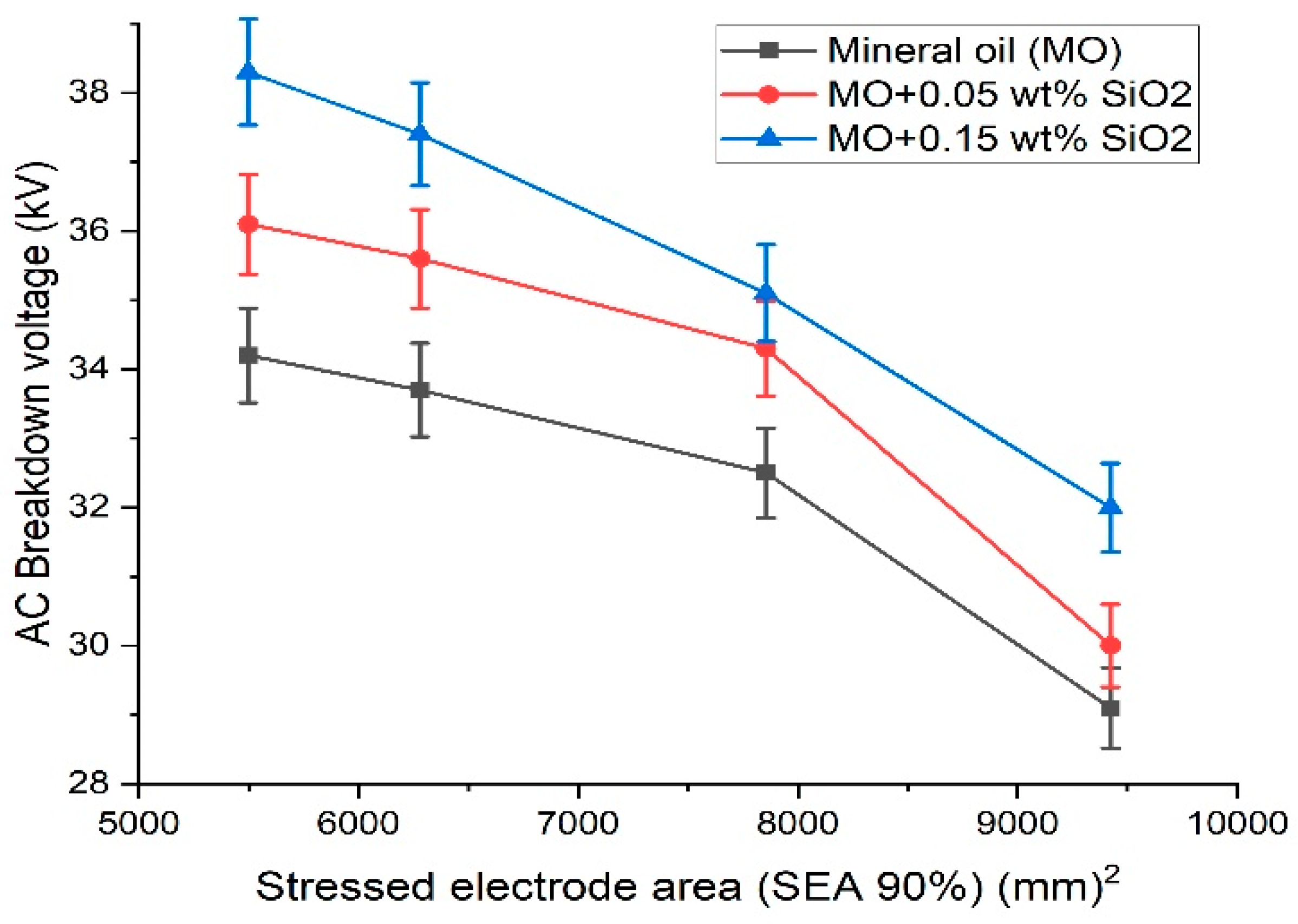

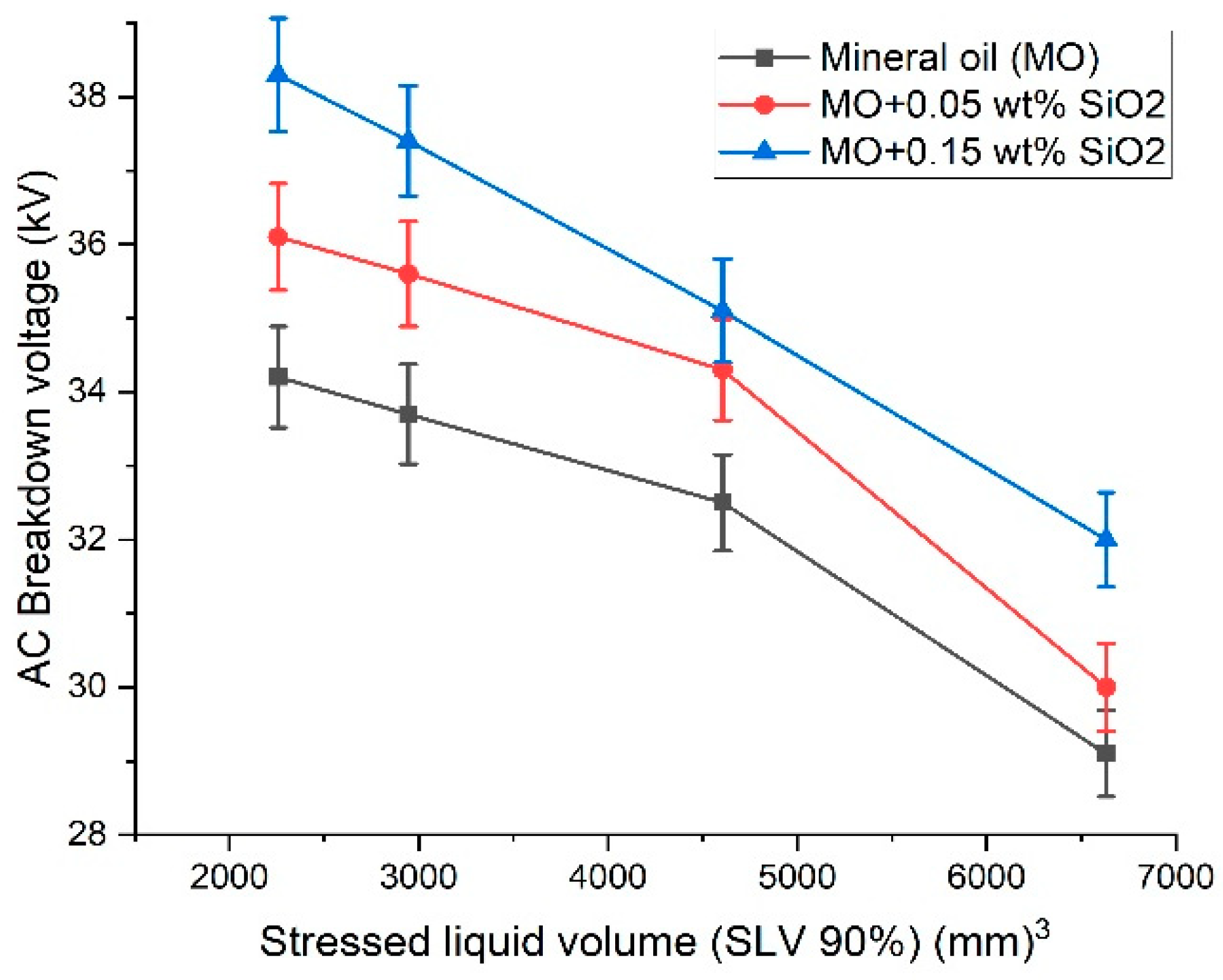

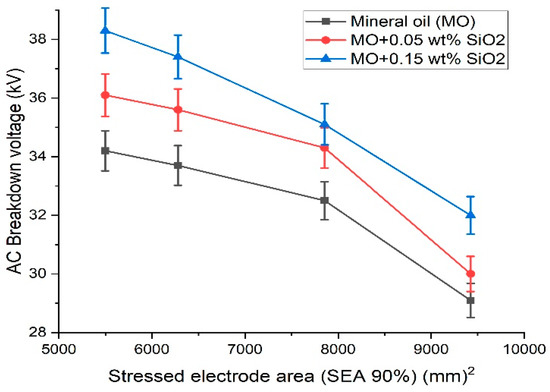

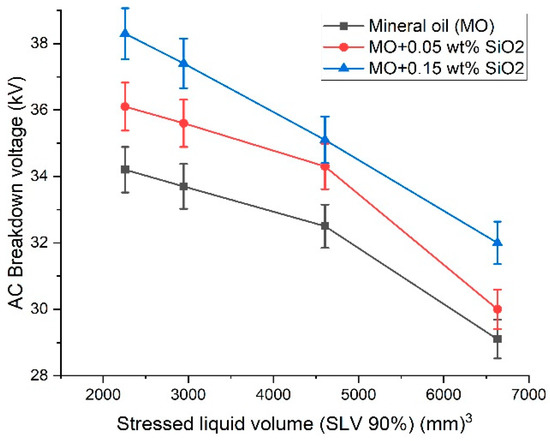

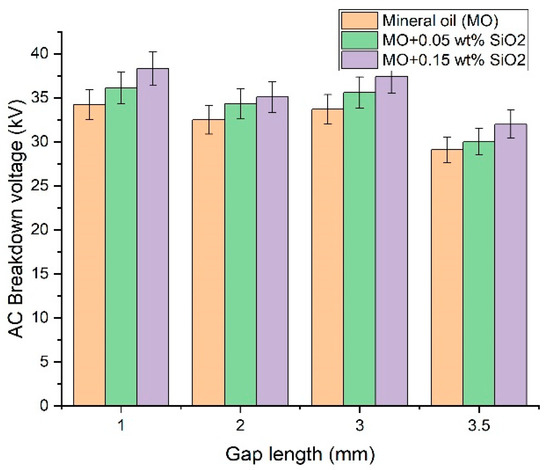

The AC breakdown voltage of pure mineral oil as well as nanofluids is measured with the variation in SEA90 (stressed electrode area) and SLV90 (stressed liquid volume), which are calculated using Equations (2) and (3), respectively. The results for the different concentrations of nanoparticles are tabulated as shown in Table 5 and Table 6, and the graphs plotted are shown in Figure 7 and Figure 8. The graph for breakdown voltage variation with electrode gap length is also plotted, as shown in Figure 9. The results show that the breakdown voltage decreases with the increase in SEA (90%) and SLV (90%) due to the greater probability of obtaining a high electric field on the electrode surface with the increase in its surface area. Moreover, the stressed oil volume theory explained the breakdown in liquids. The breakdown voltage is greatly influenced by the presence of impurities inside the oil, since these impurities being uniformly distributed in the oil would increase stressed oil volume, which results in the reduction of breakdown voltage [28,29,30]. However, the breakdown voltage increases with electrode separation as the electric stress will get reduced due to the increase of oil volume in the gap. The breakdown voltage is improved due to the addition of nanoparticles that can be attributed to the excellent dielectric property of solid particles.

Table 5.

Breakdown voltage of mineral oil with 0.05 wt% nanoparticle concentration.

Table 6.

Breakdown voltage of mineral oil with 0.15 wt% nanoparticle concentration.

Figure 7.

Graph showing the variation of breakdown voltage of mineral oil and its nanofluids with SEA (90%).

Figure 8.

Graph showing the variation of breakdown voltage of mineral oil and its nanofluids with SLV (90%).

Figure 9.

Graph showing the variation of breakdown voltage of mineral oil and its nanofluids with electrode gap length.

The nanoparticles act as a perfect dielectric when introduced into the oil and improves the dielectric strength of the oils [9]. However, the addition of nanoparticles with different sizes and concentrations may affect the AC breakdown characteristics of mineral oil. The interfacial layer between the oil and the nanoparticles plays a vital role in enhancing the breakdown strength of nano-oils. The charge is transferred through the interface between the oil and the nanoparticles. The increase in breakdown voltage can be attributed to the high shallow trap density introduced by the SiO2 nanoparticles. At lower concentrations, the interface between the oil and nanoparticle contains considerable traps that capture the electrons present in the oil and release them rapidly. This process of trapping and de-trapping would reduce the speed of electrons. Moreover, with a further increase in nanoparticle concentration the electron trap density would improve further as more nanoparticles would capture the fast electrons and reduce their mobility. Hence, this suppresses the streamer propagation and results in an improved breakdown strength of dielectric nanofluids [12]. However, the increase in nanoparticle concentration may result in nanoparticle aggregation and a reduction in the interfacial volume that leads to the reduced trap density, which may negatively affect the breakdown strength of nano-oils.

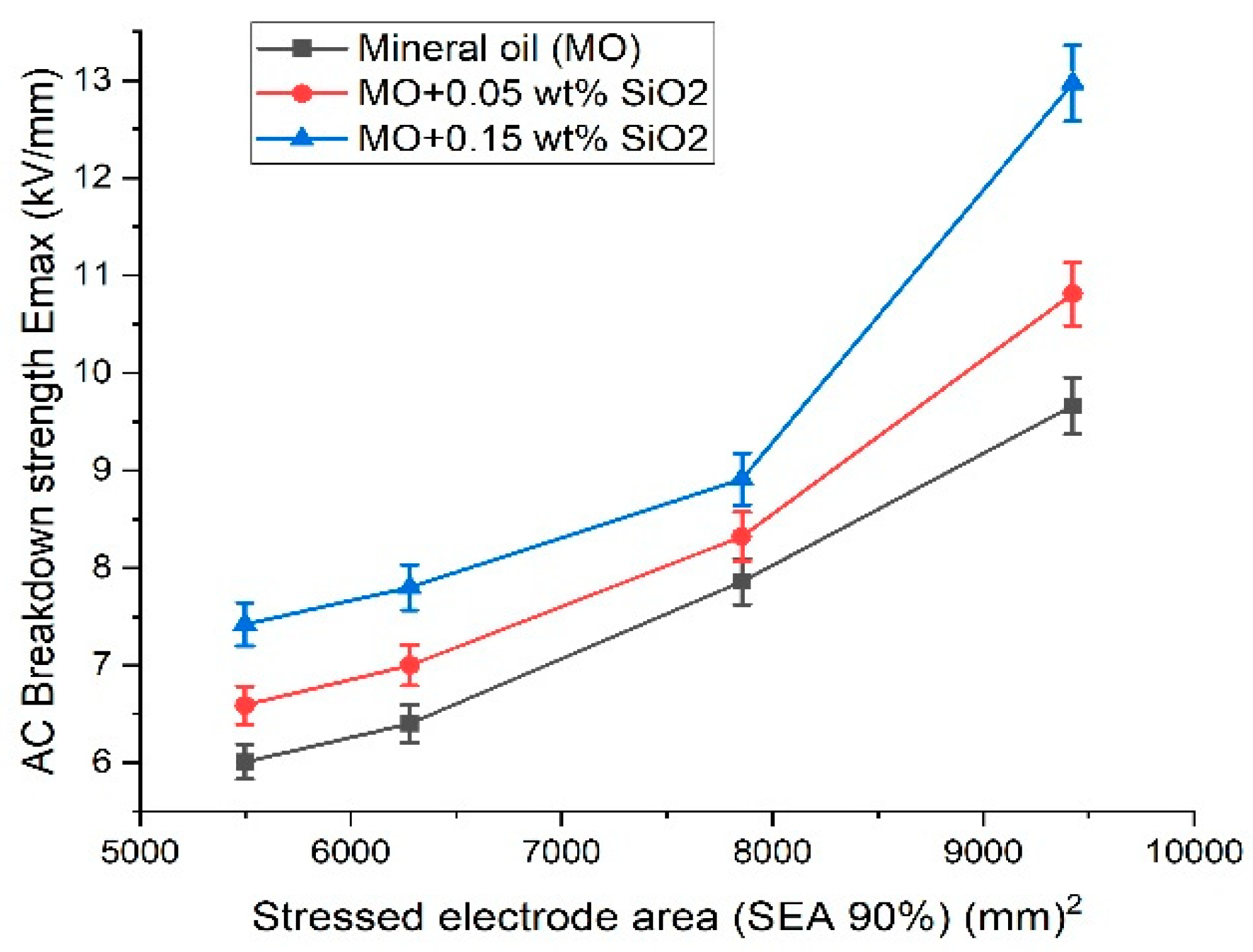

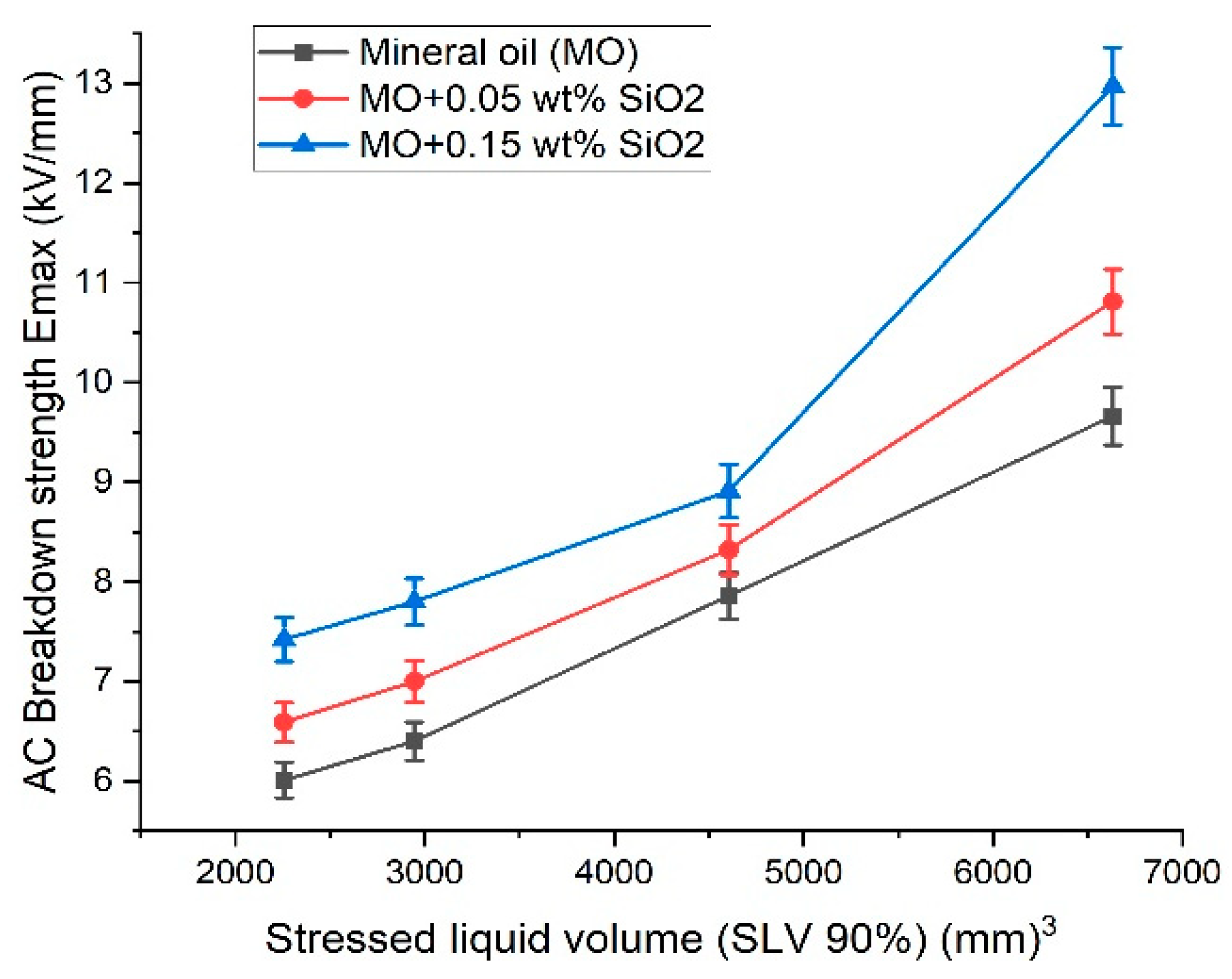

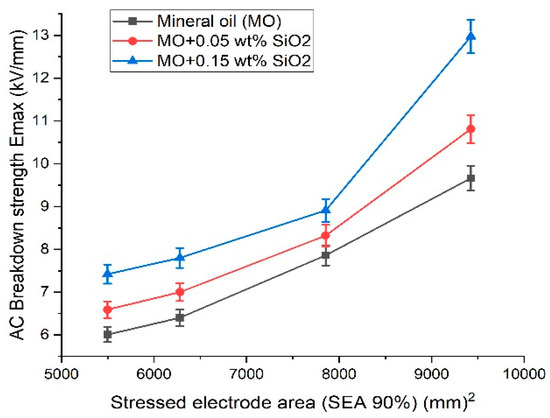

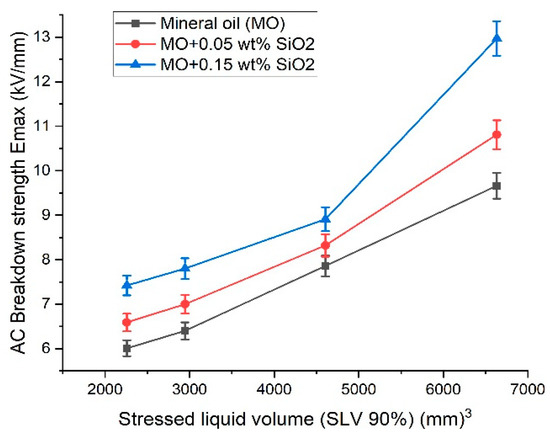

3.2. Maximum Electric Stress (Emax)

The results for the breakdown strength of mineral oil and its nanofluids are graphically represented, as shown in Figure 10 and Figure 11. The results indicate that the addition of nanoparticles enhances the breakdown strength of oils [30,31]. The maximum electric stress increases with the increase in stressed area and volume because a greater volume is stressed that will initiate the breakdown due to the presence of a weak link (particle).

Figure 10.

Graph showing the variation of maximum breakdown strength of mineral oil and its nanofluids with SEA (90%).

Figure 11.

Graph showing the variation of maximum breakdown strength of mineral oil and its nanofluids with SLV (90%).

In non-uniform fields, the stressed oil volume is considered as the volume, which is enclosed between the maximum stress (Emax) contour and 0.9 (Emax) contour. According to this theory, the breakdown strength is inversely proportional to the stressed oil volume, but the maximum electric stress varies in proportion to the stressed oil volume. The nanoparticle addition would greatly reduce the electrical stress in the insulation, which ultimately reduces the maximum electric field strength required for the insulation design [8].

4. Conclusions

The effect of area and volume, as well as the effect of nanoparticles on pure mineral oil and its nanofluids, was studied in this paper. The aim of the present study was to improve the dielectric strength of insulating oils, by considering certain effects such as area and volume that influence its dielectric performance. The phenomenon for an increase in the breakdown voltage of nanofluids is explained based on the electron trapping process. The change in nanoparticle concentration will change the shallow trap density and charge transport process, and therefore modify the streamer propagation, and hence the breakdown strength of nanofluids. The results have shown that the addition of nanoparticles could upgrade the dielectric strength of insulating liquids tested, and liquid volume and electrode surface area are the essential parameters that would influence the breakdown characteristics of oils. Nanofluids exhibit better results for breakdown voltage at higher concentrations of silica-based nanoparticles. Considerable improvement in the AC breakdown voltage of mineral oil is observed at a 0.15 wt% nanoparticle concentration compared to a 0.05 wt% nanoparticle concentration. An attempt has been made to upgrade the maximum electric field strength using nanoparticles required for electrical insulation design. In the future, nanofluids could be a better alternative for mineral oils to be used as an insulating oil in transformers as they possess a better dispersion stability and can be affordable in the longer run. The long-term stability of nanofluids is one of the major challenges for its application as an insulating oil in electric transformers. Therefore, there is a need to research for the addition of the optimum nanoparticle concentration in the oil, the dispersion stability, and the selection of nanoparticle that maximally enhances the dielectric strength of insulating oils.

Author Contributions

Conceptualization, S.A.K., M.T. and A.A.K.; Formal analysis, S.A.K., M.T., A.A.K., B.A. and L.M.-P.; Funding acquisition, M.T. and B.A.; Investigation, S.A.K., M.T. and A.A.K.; Methodology, S.A.K., M.T. and A.A.K.; Supervision, M.T. and A.A.K.; Validation, S.A.K. and M.T.; Writing—original draft, S.A.K. and M.T.; Writing—review and editing, A.A.K., B.A. and L.M.-P. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded in part by Taif University Researchers Supporting Project Number (TURSP-2020/278), Taif University, Taif, Saudi Arabia, in part by the Smart City Development Consultancy Project and Collaborative Research Grant Scheme [CRGS/MOHD TARIQ/01 and CRGS/MOHD TARIQ/02] projects, Department of Electrical Engineering, Aligarh Muslim University, India.

Acknowledgments

The authors also acknowledge the technical support provided by the Hardware-In-the-Loop (HIL) Lab and Dielectrics and Insulation Lab, Department of Electrical Engineering, Aligarh Muslim University, India.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Rajnak, M.; Timko, M.; Kopcansky, P.; Paulovicova, K.; Kuchta, J.; Franko, M.; Kurimsky, J.; Dolnik, B.; Cimbala, R. Transformer oil-based magnetic nanofluid with high dielectric losses tested for cooling of a model transformer. IEEE Trans. Dielectr. Electr. Insul. 2019, 26, 1343–1349. [Google Scholar] [CrossRef]

- Hessien, M.M.; Sabiha, N.A.; Ghoneim, S.S.; Alahmadi, A.A. Enhancement of Dielectric Characteristics of Transformer oils with Nanoparticles. Int. J. Appl. Eng. Res. 2017, 12, 15668–15673. [Google Scholar] [CrossRef]

- Rafiq, M.; Shafique, M.; Azam, A.; Ateeq, M. The impacts of nanotechnology on the improvement of liquid insulation of transformers: Emerging trends and challenges. J. Mol. Liq. 2020, 302, 112482. [Google Scholar] [CrossRef]

- Suhaimi, S.N.; Rahman, A.R.A.; Din, M.F.M.; Hassan, M.Z.; Ishak, M.T.; Bin Jusoh, M.T. A Review on Oil-Based Nanofluid as Next-Generation Insulation for Transformer Application. J. Nanomater. 2020, 2020, 2061343. [Google Scholar] [CrossRef]

- Jin, H.; Andritsch, T.; Tsekmes, I.A.; Kochetov, R.; Morshuis, P.; Smit, J.J. Properties of Mineral Oil based Silica Nanofluids. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 1100–1108. [Google Scholar] [CrossRef]

- Du, B.X.; Li, X.L.; Li, J. Thermal conductivity and dielectric characteristics of transformer oil filled with bn and Fe3O4 nanoparticles. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 2530–2536. [Google Scholar] [CrossRef]

- Maharana, M.; Bordeori, M.M.; Nayak, S.K.; Sahoo, N. Nanofluid based transformer oil: Effect of aging on thermal, electrical and physio-chemical. IET Sci. Meas. Technol. 2018, 12, 878–885. [Google Scholar] [CrossRef]

- Lv, Y.; Rafiq, M.; Li, C.; Shan, B. Study of dielectric breakdown performance of transformer oil based magnetic nanofluids. Energies 2017, 10, 1025. [Google Scholar] [CrossRef] [Green Version]

- Khan, S.A.; Tariq, M.; Khan, A.A.; Alamri, B. Effect of Iron/Titania-Based Nanomaterials on the Dielectric Properties of Mineral Oil, Natural and Synthetic Esters as Transformers Insulating Fluid. IEEE Access 2021, 9, 168971–168980. [Google Scholar] [CrossRef]

- Abd-Elhady, A.M.; Ibrahim, M.E.; Taha, T.; Izzularab, M.A. Effect of temperature on AC breakdown voltage of nanofilled transformer oil. IET Sci. Meas. Technol. 2018, 12, 138–144. [Google Scholar] [CrossRef]

- Rafiq, M.; Chengrong, L.; Lv, Y. Effect of Al2O3 nanorods on dielectric strength of aged transformer oil/paper insulation system. J. Mol. Liq. 2019, 284, 700–708. [Google Scholar] [CrossRef]

- Rafiq, M.; Lv, Y.; Li, C. Effect of Shape, Surface Modification and Concentration of Al2O3 Nanoparticles on Breakdown Performance of Transformer Oil. J. Electr. Eng. Technol. 2019, 15, 457–468. [Google Scholar] [CrossRef]

- Tishkevich, D.I.; Vorobjova, A.I.; Vinnik, D.A. Formation and Corrosion Behavior of Nickel/Alumina Nanocomposites. Solid State Phenom. 2020, 299, 100–106. [Google Scholar] [CrossRef]

- Fofana, I.; Wasserberg, V.; Borsi, H.; Gockenbach, E. Challenge of mixed insulating liquids for use in high-voltage trans-formers. 1. Investigation of mixed liquids. IEEE Electr. Insul. Mag. 2002, 18, 18–31. [Google Scholar] [CrossRef]

- Amin, D.; Walvekar, R.; Khalid, M.; Vaka, M.; Mubarak, N.M.; Gupta, T.C.S.M. Recent Progress and Challenges in Transformer Oil Nanofluid Development: A Review on Thermal and Electrical Properties. IEEE Access 2019, 7, 151422–151438. [Google Scholar] [CrossRef]

- Khan, S.A.; Khan, A.A.; Tariq, M. Measurement of Tan-delta and DC Resistivity of Synthetic Ester Based Oil Filled with Fe2O3, TiO2 and Al2O3 Nanoparticles. Smart Sci. 2021, 9, 216–225. [Google Scholar] [CrossRef]

- Siodla, K.; Ziomek, W.; Kuffel, E. The volume and area effect in transformer oil. In Proceedings of the Conference Record of the 2002 IEEE International Symposium on Electrical Insulation (Cat. No.02CH37316), Boston, MA, USA, 7–10 April 2002; IEEE: Piscataway, NJ, USA, 2003. [Google Scholar]

- Hill, L.R.; Schmidt, P.L. Insulation Breakdown as a Function of Area. Cond. Affect. Success Main Line Electrif. 1948, 67, 442–446. [Google Scholar] [CrossRef]

- Weber, K.S.; Endicott, H.S. Area effect and its external basis for the electric breakdown of transformer oil. Trans. AIEE 1956, 75, 371–381. [Google Scholar]

- Weber, K.S.; Endicott, H.S. External area effect for large area electrodes for the electric breakdown of transformer oil. Trans. AIEE 1957, 76, 1091–1098. [Google Scholar]

- Rozga, P.; Hantsz, D. Influence of volume effect on electrical discharge initiation in mineral oil in the setup of insulated electrodes. Electr. Eng. 2017, 99, 179–186. [Google Scholar] [CrossRef] [Green Version]

- MPatil, V.; Pote, R.S.; Kankale, R.S. Dielectric behavior of insulating material under transformer oil. Int. J. Emerg. Eng. Res. Technol. 2014, 2, 213–219. [Google Scholar]

- Tishkevich, D.; Grabchikov, S.; Zubar, T.; Vasin, D.; Trukhanov, S.; Vorobjova, A.; Yakimchuk, D.; Kozlovskiy, A.; Zdorovets, M.; Giniyatova, S.; et al. Early-Stage Growth Mechanism and Synthesis Conditions-Dependent Morphology of Nanocrystalline Bi Films Electrodeposited from Perchlorate Electrolyte. Nanomaterials 2020, 10, 1245. [Google Scholar] [CrossRef] [PubMed]

- Khan, S.A.; Khan, A.A.; Tariq, M. Experimental Analysis for the Effect of Fe/Ti Oxides and Fe-Cu Nanoparticles on the Dielectric Strength of Transformer Oil. In Proceedings of the 2019 International Conference on High Voltage Engineering and Technology (ICHVET), Hyderabad, India, 7–8 February 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 1–6. [Google Scholar]

- Ahmad, F.; Khan, A.A.; Khan, Q.; Hussain, R. State-of-Art in Nano-Based Dielectric Oil: A Review. IEEE Access 2019, 7, 13396–13410. [Google Scholar] [CrossRef]

- Khan, Q.; Singh, V.; Ahmad, F.; Khan, A.A. Dielectric performance of magnetic nanoparticles-based ester oil. IET Nanodielectr. 2021, 4, 45–52. [Google Scholar] [CrossRef]

- Huang, Z.; Li, J.; Yao, W.; Wang, F.; Wan, F.; Tan, Y.; Ali, M. Electrical and thermal properties of insulating oil-based nanofluids: A comprehensive overview. IET Nanodielectr. 2019, 2, 27–40. [Google Scholar] [CrossRef]

- Rafiq, M.; Khan, D.; Ali, M. Dielectric properties of transformer oil based silica nanofluids. In Proceedings of the 2015 Power Generation System and Renewable Energy Technologies (PGSRET), Islamabad, Pakistan, 10–11 June 2015; pp. 1–3. [Google Scholar] [CrossRef]

- Abid, M.A.; Khan, I.; Ullah, Z.; Ullah, K.; Haider, A.; Ali, S.M. Dielectric and Thermal Performance Up-Gradation of Transformer Oil Using Valuable Nano-Particles. IEEE Access 2019, 7, 153509–153518. [Google Scholar] [CrossRef]

- Du, Y.; Lv, Y.; Li, C.; Chen, M.; Zhong, Y.; Zhou, J.; Li, X.; Zhou, Y. Effect of Semiconductive Nanoparticles on Insulating Performances of Transformer Oil. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 770–776. [Google Scholar]

- Nadolny, Z.; Dombek, G. Electro-Insulating Nanofluids Based on Synthetic Ester and TiO2 or C60 Nanoparticles in Power Transformer. Energies 2018, 11, 1953. [Google Scholar] [CrossRef] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).