1. Introduction

Due to the severe problems, such as global warming and harm to human health, caused by internal combustion engine-powered vehicles, electric vehicles have been attracting increasing attention [

1,

2,

3]. They enable higher energy efficiency without exhaust emissions, and the use of electricity incorporating higher percentages of renewable energy resources plays a significant role in enabling improved life-cycle impacts compared to conventional technologies [

4,

5]. The inventory of electric vehicles continues to increase significantly, with over 7 million vehicles worldwide in 2019 [

6]. Furthermore, their purchase cost barriers are expected to be alleviated by the anticipated evolution in battery technology [

6,

7]. Consequently, electric vehicles are expected to be the main mode of personal passenger transport in the future.

Furthermore, urban mobility brings additional challenges in terms of use of space, parking requirements, and the associated drive cycle, bringing opportunities for small electric vehicles, which have the particular benefits of small size, low cost, and low energy consumption for short-distance travelling [

8]. While many different names and classifications exist for such vehicles around the world, we refer to them as

L-category electric vehicles, following the terminology used in Europe and based on the class of vehicles that is specifically used in our case study [

9]. This class of vehicles is framed within the L7 category for quadricycles, whose unladen mass is not more than 400 kg (not including the mass of batteries in the case of electric vehicles) and whose maximum net engine power does not exceed 15 kW [

10]. These small vehicles are generally within the M1 category according to the UNECE global technical regulations [

11,

12]. However, this classification changes over the geographical area. In India, quadricycles must comply with the maximum permissible kerb weight of 450 kg in case of a passenger vehicle, up to 15 kW maximum power and a maximum speed of 70 km/h [

13]. In Korea, these vehicles are included within the concept of micro-mobility, defining maximum allowable dimensions (length up to 3.6 m, width up to 1.5 m, height up to 2.0 m), as well as a maximum power of 15 kW and a maximum mass of 600 kg [

14]. In the U.S., quadricycles fall within the class of Low-Speed Vehicles, whose speed attainable in 1.6 km (1 mile) is more than 32 km/h and lower than 40 km/h, also limiting Gross Vehicle Weight Rating up to 1134 kg due to safety purposes [

15,

16]. Elsewhere, other regional rules can apply, however it can be stated that, generally, quadricycles represent a mobility opportunity due to their small size, low power and weight, energy efficiency, and suitability for all types of drivers.

With their more efficient use of space due to their small size, the increased use of L-category electric vehicles has the potential to reshape urban mobility. One of the main applications is as the first-mile or last-mile access mode for a longer journey [

17]. Especially under epidemic situations, L-category electric vehicles could be a good option to decrease infection spread by reducing public transport use for those who cannot afford conventional electric vehicles. The relatively low purchase and operating costs of such vehicles also provide them with the potential to better address concerns over social inequalities concerning energy poverty [

18].

Thus, although the current market for L-category vehicles is relatively small (Santucci et al., 2016, estimated around 10,000 had been sold within EU countries by that date), their great potential in benefiting our lives suggests they deserve greater attention. Indeed, as the market analysis model forecasts have shown [

19], their sales volume is likely to continue to grow for the foreseeable future. One of the first examples of these L-category electric vehicles was the Renault Twizy [

20], launched in 2012, with a more recent (2020) example the Citröen Ami [

21], suggesting that this type of vehicle is seen as an opportunity by major vehicle manufacturers. According to the plan approved by the European Commission for achieving clean urban transport, the goal is that “by 2050 nearly all cars, vans, buses as well as new heavy-duty vehicles will be zero-emission” [

22], while at the same time encouraging the use of smaller, lighter and more specialized road passenger vehicles [

8], namely focused on micro-mobility.

The popularization of L-category electric vehicles will most probably be fostered by the increasingly accepted concept of micro-mobility and mobility as a service, but its adoption relies on the existence of a correlated test procedure necessary to ensure their production consistency and to meet the requirements of consumers, namely regarding energy consumption. For M-category (light-duty vehicles, passenger cars and vans, carrying passengers) electric vehicles, certification driving cycles and procedures are well established. However, their representativeness can be discussed, since differences have been found between energy use within certification cycles and real-world conditions [

23,

24,

25,

26]. Consequently, even for M-category vehicles, the pursuit of representative drive cycles for alternative vehicle technologies based on real-world use has also started to be explored. For example, Zhang et al. developed tailored driving cycles for electric vehicles based on a sample of 40 electric taxis, by developing a Markov Monte Carlo method considering the driving features of different roads [

27]. Defining a driving cycle for a test procedure is the main basis for assessing vehicle performance [

28,

29], particularly for electric vehicles where regeneration plays an important role in the gross energy consumption.

A detailed test procedure is available for a different type of L-category vehicle to that considered in the present paper, namely those powered by an internal combustion engine [

30]. However, since L-category vehicles have power and weight limits (without a battery), additional mass associated with energy storage could limit the power-to-weight ratio, possibly leading to differences in their driving capabilities, as has been observed from comparisons of conventional L-category vehicles and electric ones [

31,

32]. Problems may therefore arise if the driving cycle of a conventional L-category vehicle is applied to the performance assessment of electric modes, such as the electric ones being unable to follow the driving cycle due to their small-rated power-to-weight output.

Due to the short running distance of L-category electric vehicles, they are more suitable for urban utilization. In real-world driving, traffic conditions are much more complex than the ones considered in driving cycles [

33]. One study quantified that traffic conditions and driving behaviour may increase energy consumption by up to 40% and 16%, respectively, compared to the worst performance condition [

34]. Regarding road grade, ascending roads (with 3% grade) increased energy consumption by 50% while descending roads (−3% grade) decreased energy consumption by 80%, due to the presence of regenerative braking systems. These facts may lead to more difficulty for L-category electric vehicles in real driving, such as on hilly terrain where acceleration is limited due to their power output.

Additionally, in urban driving, vehicles are periodically under stop-and-go situations [

35] (e.g., resulting from many traffic lights), which will cause much energy loss if the energy regeneration technology is missing [

25]. With regards to the L-category electric vehicles on the market, most of them do not include energy recovery devices leading to lower energy efficiency performance. Energy loss will be significant if the vehicle is travelling downhill where brake actions are necessary to ensure safety and to be within the speed limit. Furthermore, a better understanding of real-world performance in specific routes, acknowledging the influence of road grade and traffic, may also contribute to better route optimization and charging optimization systems [

36,

37].

Therefore, it has been shown that M-category vehicles have well-established certification procedures but do not incorporate real driving energy consumption in a generalized way. For L-category vehicles, the certification procedures are mostly suited to conventional propulsion technologies and do not consider real driving energy use, which gains importance due to their limited power-to-weight ratio or the possibility of regeneration. Taking into consideration the emergence of L-category electric vehicles in an urban context and their power-to-weight limitations, this paper proposes an innovative approach for evaluating current certification drive cycles available for this vehicle class and compares them with real-world driving cycles. The impacts of regenerative capabilities and road grade on the L-category vehicles’ energy performance are also assessed, paving the way for improved future energy characterization of a growing vehicle market.

The structure of the paper is as follows. Firstly, in

Section 2 we describe the previously-reported experimental data that we will re-purpose for the study, and begin to explain the specific motivation for our work. In

Section 3 we present the details of a generic methodology for modifying a given reference speed profile to apply to a vehicle with generally lower power capabilities. This methodology is applied in

Section 4 to a particular case of electric L-category vehicles, where the sensitivity of the method is explored in tests on fictitious gradient profiles. In

Section 5, it is applied to a realistic case of road profiles from the city of Lisbon. Finally, conclusions and directions for further research are described in

Section 6.

3. Methodology for Creating Adjusted Speed Profiles

3.1. Goals of Methodology

An overview of the methodology to be applied is presented in

Figure 4. It assumes as inputs (a) a given reference speed profile, and (b) a relationship between VSP and (speed, acceleration, gradient) for a given vehicle type, along with a maximum VSP. Equivalently to working with the reference speed profile in (a) we may derive from it a reference acceleration profile and initial speed at the entry to the road stretch; in addition, a reference distance-time profile may be deduced. The goal of the adjustment process is to derive an adjusted acceleration profile that does not violate the given maximum VSP.

At first sight, since high VSP values are typically associated with high acceleration events, this might seem to be a quite trivial task of simply bounding the acceleration profile at some given maximum. However, on closer inspection, there are several complications to this process, and it is these considerations that motivate our method (to be subsequently described):

From Equation (1), it can be seen that high VSP values arise from a combination of speed, acceleration, and gradient; it is not simply that there is a maximum acceleration, regardless of speed or gradient.

Given speed and gradient, Equation (1) is easily rearranged to make acceleration a function of VSP, and a maximum acceleration is then deduced given the maximum VSP. If done in continuous time, then this would indeed impose the maximum VSP constraint. However, the reference profiles are specified at a given time discretization. If we compute the maximum acceleration, given the speed at the start of a time increment, so as to be bounded by the maximum VSP, then by the end of the time increment the vehicle (since accelerating) will be going faster, and so may violate the maximum VSP by the end of the time increment.

In general, the adjustment process will result in lower acceleration and lower speeds. As a result, downstream from any adjustment made during an acceleration event, we may have a deceleration event with physically impossible consequences, i.e., a negative speed.

As noted, the adjustment process will generally result in lower speeds. The reference speed profiles are intended to represent travel over a road stretch of a given length, but are specified by a speed profile over a given time period. If the adjusted speed profile is applied for the same time period, then it will not represent the same length of road, since by the end of the time period, the vehicle (travelling at lower speeds) will not have reached the end of the road stretch. Thus, in tandem with adjusting speeds, a logical method is needed for extending the time period over which the driving cycle applies, so that it applies to the same road length.

In brief, points 1 and 2 are addressed by a numerical search (Newton) method at each time increment, which deduces the maximum acceleration possible at the current location, given the current gradient, and given the consequential effect of that acceleration on the speed at the end of the time increment. Point 3 is handled by bounding acceleration so that the consequential speed at the end of the increment is at least zero. Point 4 is dealt with essentially by assuming that speed reduction will mean that vehicles will tend to cruise for longer; it is as if there is a vehicle following the unadjusted speed profile, with which our adjusted vehicle tries wherever possible to ‘catch up’ in terms of the distance traversed. Taken together, these three adjustment processes are thus concerned with acceleration, deceleration, and cruising respectively. The three processes are first described in more detail in

Section 3.2,

Section 3.3, and

Section 3.4 respectively, before presenting the overall algorithm in

Section 3.5.

3.2. Acceleration Steps: Bounding of Acceleration

Consider a particular increment of time of length

seconds, and suppose that we are given the speed

m/s and location from some origin

metres of a vehicle at the start of the time increment. The aim will be to determine the constant acceleration

m/s

2 during that increment, and thereby the resulting speed

m/s at the end of the time increment. Clearly by standard equations of motion:

and the location

of the vehicle at the end of the time increment is given by:

Then, according to Equation (1), we may associate a VSP with any (location, speed, acceleration) triple

. Since we are imagining time increments in the order of seconds, then the road gradient will hardly change between location

and

, so we approximate

for some simplification. Then the VSP at the end of the time increment

is obtained by combining Equations (1), (4) and (5) to give:

Thus, given the (location, speed)

at the start of the time increment, the VSP at the end of the time increment may be thought of as a function only of the acceleration

, parameterized by

:

By inspection, is monotonically increasing in , and so its inverse function exists. Let denote this inverse function for a VSP given , i.e., such that:.

Now let denote the assumed maximum VSP of a vehicle under consideration. We may then, by the reasoning above, calculate a maximum acceleration corresponding to the maximum VSP according to . Note that this maximum acceleration is not constant, depending through on the current speed and local conditions in terms of gradient through ; this is implicitly handled through the method described (so we could write to denote this dependence).

Since the inverse function is not available in analytic form, the procedure is to instead numerically estimate the acceleration

that satisfies

or equivalently

. This is done via a Newton scheme whereby the

iteration is given by:

where

is given by (7) and:

3.3. Deceleration Steps: Bounding of Deceleration

The adjustments described in

Section 3.2 will in general decrease (or leave unaltered) accelerations and speeds, relative to the reference values. Suppose that we are considering a particular time-step, and that in a

previous time-step the bounding of acceleration has indeed resulted in a speed reduction relative to the reference speed. Thus, even before we consider what might happen in the current time-step, the vehicle may be travelling at a lower initial speed than the reference speed at the start of the time-step. Now consider the current reference acceleration; if it is negative, then there is no guarantee that such a deceleration will be feasible from the initial speed, as it may result in a negative speed by the end of the time increment. In practice, this is quite a rare occurrence, but it can occur and lead to physically impossible profiles. Therefore, a simple adjustment is made for deceleration events, namely that given any time-period (length

) and an initial speed at the start of that time period

, then the acceleration

is bounded below so as the speed at the end of the time-interval

is no less than zero:

implying:

3.4. Cruising Steps: “Catching Up” Distance

The third and final type of step is the cruising one. This arises as we aim to specify a speed profile for a road segment of a given

length. The main speed adjustment steps (as described in

Section 3.2) will mean that in the adjusted profile the speeds will generally be lower than in the reference profile. If we specify the adjusted profile for only the same number of time steps as the reference profile, a vehicle following that trajectory will then clearly only traverse part of the road segment by the end of the time period. For a slower vehicle to traverse the same length as a vehicle following the reference profile, it must travel for longer in time. The question is: what logic might we use to add additional time periods?

The approach is based on the premise that the variations in speed/acceleration in the reference profile are associated with spatial (as opposed to temporal) locations on the route, e.g., intersections, locations where queuing occurs. Therefore, the adjusted speed profile should, where possible, aim to track the spatial variations in the reference speed profile. It can be imagined that a vehicle following the (slower) adjusted profile is trying to ‘catch up’ the distance travelled by a vehicle following the reference profile, and so each time it falls behind it will cruise at the current speed for several time steps. The effect of this, as seen in

Section 4, is that the peaks of the adjusted profile both lag behind those of the reference profile in time, as well as being somewhat extended; this seems logical behaviorally, that someone travelling at a slower speed than another vehicle will just maintain that slower speed for longer to reach the same point.

Suppose then, having applied a step from

Section 3.2 or

Section 3.3 as appropriate, to a given reference time increment, the total distance travelled on the adjusted profile so far is

metres, and the distance travelled using the reference speeds by the end of this reference time interval is

. Then the cumulative lost distance relative to the reference profile is

. Suppose that when applying the methods of

Section 3.2 or

Section 3.3 an adjusted speed of

m/s was determined for the end of the last time increment. If

then skip this step; so let us assume now that

. Firstly, we determine whether the vehicle is in a ‘cruising mode’, and if it has reached some desired speed. This is indicated either by the reference acceleration for the previous period

being equal to zero, or by the fact that the reference acceleration is about to “pass through” zero if it were not for discretization. This latter state is indicated by a positive reference acceleration

for the previous period and a negative reference acceleration

for the following period.

Hence overall our test is:

We now check whether additional time increments can be inserted with the vehicle cruising at a speed of

, without the distance for these increments exceeding

. Due to the discretization, we are unlikely to be able to catch up all the distance in

(though that is the goal), so instead, we insert as many time increments as possible in order to travel as close as possible to

metres. Since by cruising at a speed of

m/s we will travel

metres in one time increment of

seconds, the number of time increments we will be able to insert is:

where for any real number

the notation

denotes the largest integer

. These time increments are then inserted, before moving on to consider the next time increment from the reference speed profile.

Having applied this process to the full time period of the reference speed profile, it is likely that there will be a small amount of cumulative lost distance remaining at the end. This is accounted for by rewinding to the last time at which cruising increments were inserted, and inserting additional increments at that time to account for as much of the remaining cumulative lost distance as is possible within the error of discretization.

3.5. Overall Solution Process

The solution process makes use of three

methods corresponding to the techniques described in

Section 3.2,

Section 3.3 and

Section 3.4. A method in this sense is a computational process with given inputs and outputs as follows:

The method

, applied only when

, first estimates an upper bound on acceleration over a time interval of length

seconds given an initial speed of

m/s and given a bound on vehicle specific power of

W/kg. The acceleration bound will vary with both speed

and location

(the latter dependence due to variations in gradient). The upper bound is estimated by the iterative process (8) based on (7) and (9), with the converged solution denoted

(m/s

2). The method then provides as output the bounded acceleration

(in relation to the input reference/default acceleration

) and the corresponding speed

according to:

The method

, applied only when

, bounds acceleration from below to avoid physically impossible (negative) speed on exit from the time increment. It provides as output the bounded acceleration

(in relation to

) and corresponding speed

according to:

The method is applied after either of the two methods above, and only when three conditions are all met: (i) the adjusted speed , (ii) the reference acceleration is indicative of cruising ( or { and }), and (iii) the cumulative lost distance . It provides as output the maximum number of time intervals of length seconds at which a vehicle may cruise at m/s in order to recover the most lost distance, according to (13). An implementation issue to note is that since is stored as a real number, the practical test of “zero acceleration” applied is for some small .

With these three methods as the building blocks, it is then possible to describe the overall adjustment process. Suppose that a vehicle is moving in time and space along a stretch of road of given length L metres, and that time is discretized into increments of length seconds. Let denote the speeds over time increments in a given reference driving cycle, with m/s the reference speed at the end of the time increment (i.e., so at continuous time ). Assuming uniform acceleration within a time increment (between the exit speed of the last time increment and the exit speed of the present one), Equation (4) may be applied to additionally infer a reference acceleration profile . In addition, Equation (5) may be used to deduce a reference distance-time profile . The basic logic of the adjustment method is that a vehicle will attempt to follow the acceleration/deceleration patterns in the reference acceleration profile, as far as possible; and that at the same time the distance lag relative to the reference speed profile will be used to indicate when additional cruising time steps should be inserted.

- -

The solution process to deduce the adjusted speed profile and acceleration profile is defined in Algorithm 1.

| Algorithm 1. Overall solution process. |

Initialise the vector with the single element , and initialise as an empty vector. Set . Set . For do the following steps in sequence of increasing :

If , apply: If , apply: If , set and Set . Append with and with . If and ( or ( and )) and apply: Otherwise set . Append with n additional elements of , and with n additional elements of . Set . Set

|

5. Case Study Application

Finally, we apply the method to a real-life road gradient profile, as measured in the city of Lisbon. This is an interesting case due to the undulating terrain, and because the data used were part of the study that calibrated the power and energy relationships, as described in

Section 2.1. A stretch of road was considered of a similar length to that considered in WMTC Reference Cycle 2 (see

Section 2.2), for which the road profile is illustrated in

Figure 13. If the WMTC Reference Cycle 2 speeds are exactly followed, then the portion of the gradient up to the red line is used. Again considering Vehicle Type 2 (as defined in

Table 7) and the WMTC reference speeds (

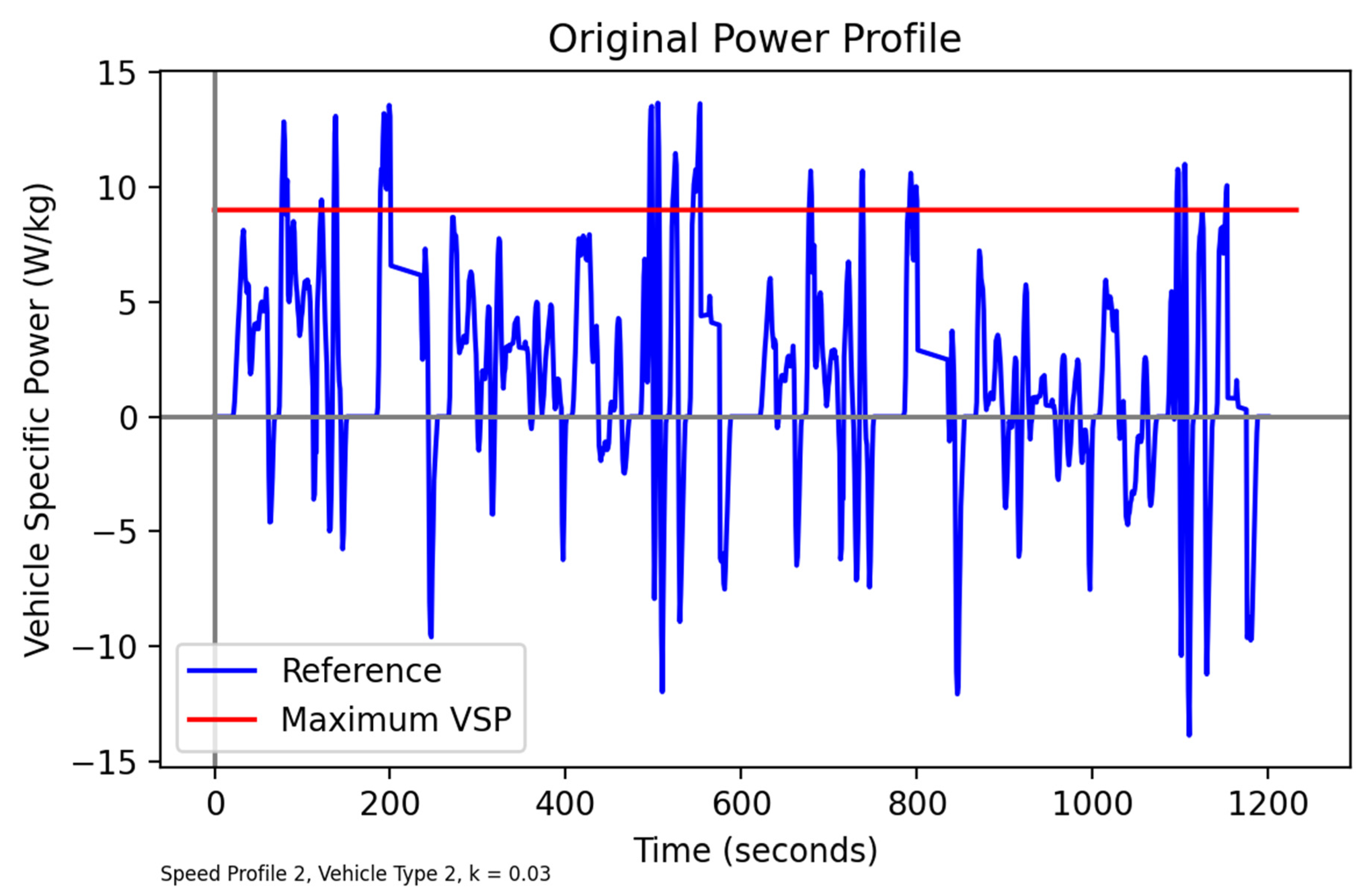

Figure 1), the resulting VSP profile (

Figure 14) again shows violations of the maximum VSP, suggesting that the reference speed profile is not suited to this vehicle type and terrain. Applying the methodology described in

Section 3, a modified speed profile is produced (

Figure 15). It is noticeable that, as would be anticipated, many of the speed modifications are associated with steeper uphill sections of the profile; for example, significant modifications are apparent towards the end of the cycle, corresponding to the final uphill section of

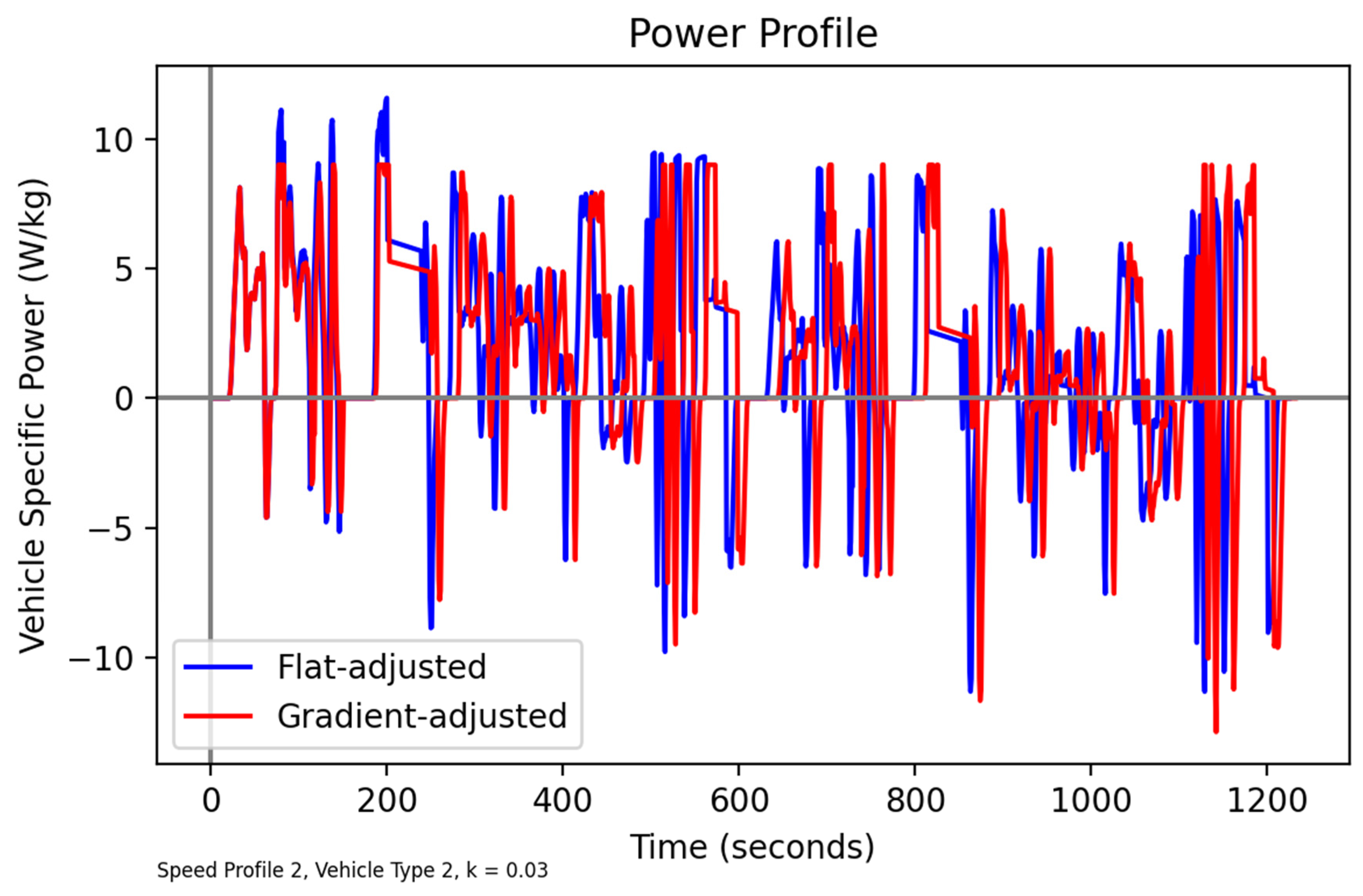

Figure 13. A comparison of the VSP profiles corresponding to the reference and modified speeds is given in

Figure 16, and confirms that the method is successful in constraining VSP to a feasible range, with the impacts on energy consumption depicted in

Figure 17.

As a final experiment, we performed an analysis of the road slope in a forward and reversed direction, with the summary statistics for the original direction in

Table 11 and

Table 12, and for the reverse direction in

Table 13 and

Table 14. The adjusted results indicate a small difference of −0.8% in total travel time under the reverse topography compared with the original. However, at the same time, the total energy is reduced by 4.9%, regenerated energy decreases by 4.6%, while the percentage of time in a negative energy state increases by 6.5% for the reversed slope compared with the original topography. This suggests that the original road slope combined with the real-world cycle, after adjustment, is more energy demanding, but also produces higher energy from regeneration, although there are fewer opportunities to regenerate. Such a comparison demonstrates the complexity of real-world driving energy consumption on an L-category EV.

6. Conclusions

In the context of an expected emergence of L-category electric vehicles in the urban context, a generic methodology has been developed to adjust reference speed profiles to be applicable to the performance characteristics of these specific vehicles, while also accounting for different terrains. The methodology comprises three main elements: bounding maximum instantaneous power by dynamically limiting acceleration, given the current speed and gradient; bounding decelerations to avoid physically impossible speeds that may otherwise arise due to previous adjustments to speeds; and inserting cruising periods to ensure that the modified profile covers the same route length, albeit over a longer period of time.

The methodology has been applied, firstly, to derive speed profiles for electric quadricycles on flat terrain, given reference speed profiles for motorcycles. The results show that adjustments made to cope with the power limitations of L-EV do not introduce significant differences in energy consumption, suggesting that the certification does not require an extensive modification. Secondly, it was explored to what extent bespoke speed profiles are necessary for undulating terrain, as opposed to adopting the speed profiles developed for flat terrain in all cases. The first set of tests considered a fictitious road profile that was easily adjustable, namely a symmetric hill versus a symmetric valley. In this case, it was found that the power limitations, as well as the combination of a fixed driving profile and different magnitudes of slope and shapes of slope, lead to differences of up to 5% in energy use and of up to 10% in regenerated energy. The second set of tests analyzed the impact of topography on real-world driving cycles and slope (by considering a real-world profile driven in both directions), and qualitatively confirmed the results obtained for the fictitious profile tests.

The developed speed profiles are useful in their own right for studies that wish to assess the impacts of different measures and policies on electric quadricycles, with the advantage of considering regenerative capabilities and road grade, which are crucial in the characterization of energy performance in real-world conditions. The developed method may be readily extended to other L-category electric vehicles, given the relevant input information on vehicle specific power relations and maximum VSP.