Evaluation of Water Inrush Hazard in Coal Seam Roof Based on the AHP-CRITIC Composite Weighted Method

Abstract

:1. Introduction

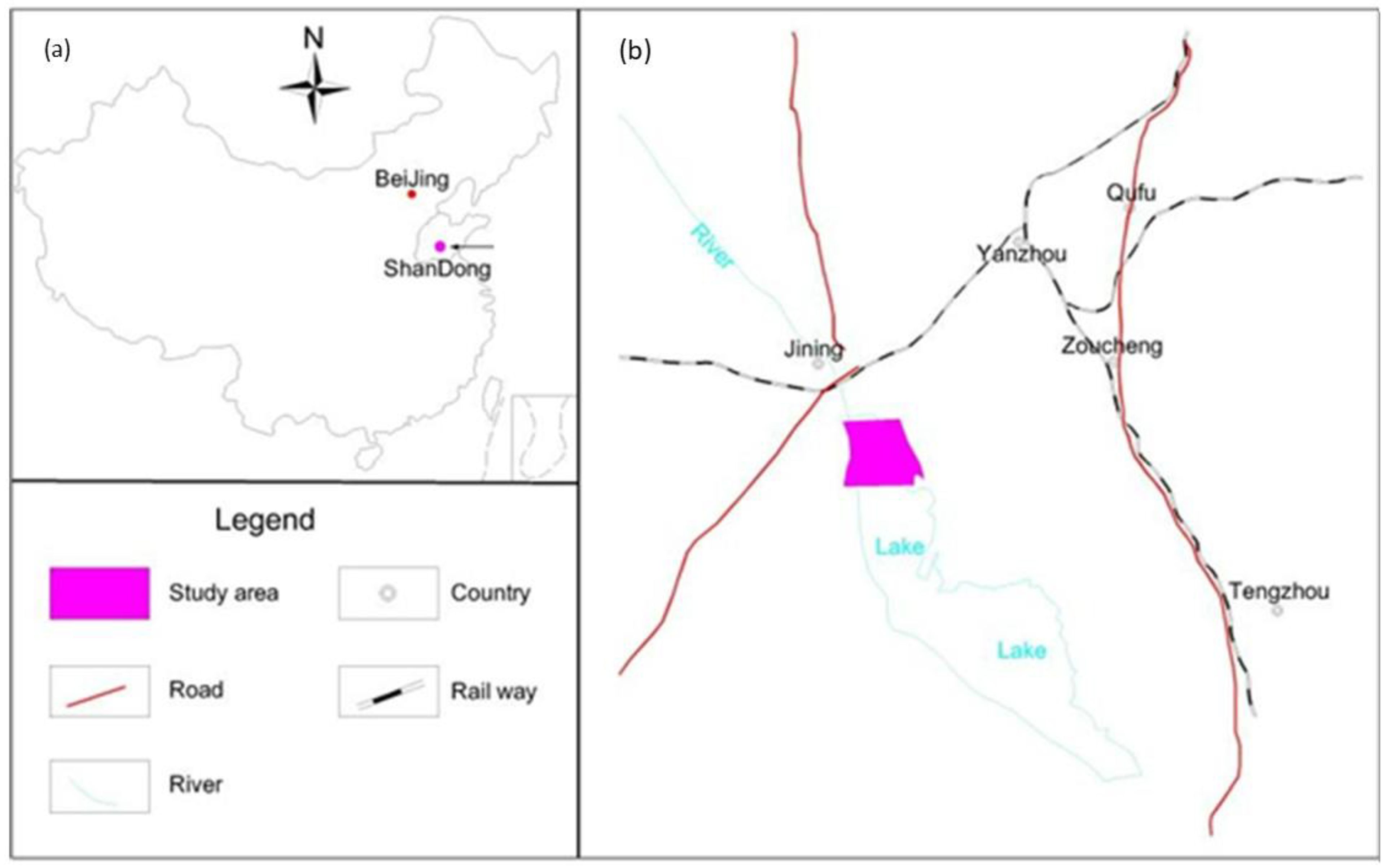

2. Analysis of Mining Conditions and Water Hazards in the Study Area

2.1. Mining Conditions

2.2. Water Hazard Analysis

3. Water Inrush Factor Selection

3.1. Nature of the Aquifer

- (1)

- Burial depth (Dp)

- (2)

- Aquifer thickness (Tk)

- (3)

- Core collection rate (Cr)

- (4)

- Brittle–plastic rock thickness ratio (Tkr)

- (5)

- Number of aquifers and barriers (Num)

3.2. Development Height of Water-Conducting Fracture Zone

3.3. Geological Structure

- (1)

- Fault density (Fd)

- (2)

- Fault frequency density (Ff)

- (3)

- Fault size index (Fs)

- (4)

- Coefficient of variation in the inclination angle of the coal floor (CDVAC)

4. Methodology

4.1. Assessment Steps

- (1)

- Collect data and comprehensively analyze geological and hydrogeological conditions based on existing geological data in the study area and select the influencing factors.

- (2)

- Establish an evaluation index system and standardize data processing.

- (3)

- Determine the weight of the relevant factors and establish a model to determine the water hazard area of the coal roof in the study area to obtain the evaluation results.

- (4)

- Describe and interpret the results.

4.2. Data Normalization

4.3. Evaluation Method

4.3.1. AHP Method

- (1)

- Building a hierarchical model

- (2)

- Constructing a judgment matrix and weight calculation

- (3)

- Hierarchical consistency test

4.3.2. CRITIC Method

- (1)

- Index variability

- (2)

- Index conflict

- (3)

- Amount of information

- (4)

- Objective weight

4.3.3. Determination of Comprehensive Weight

4.4. Model Establishment

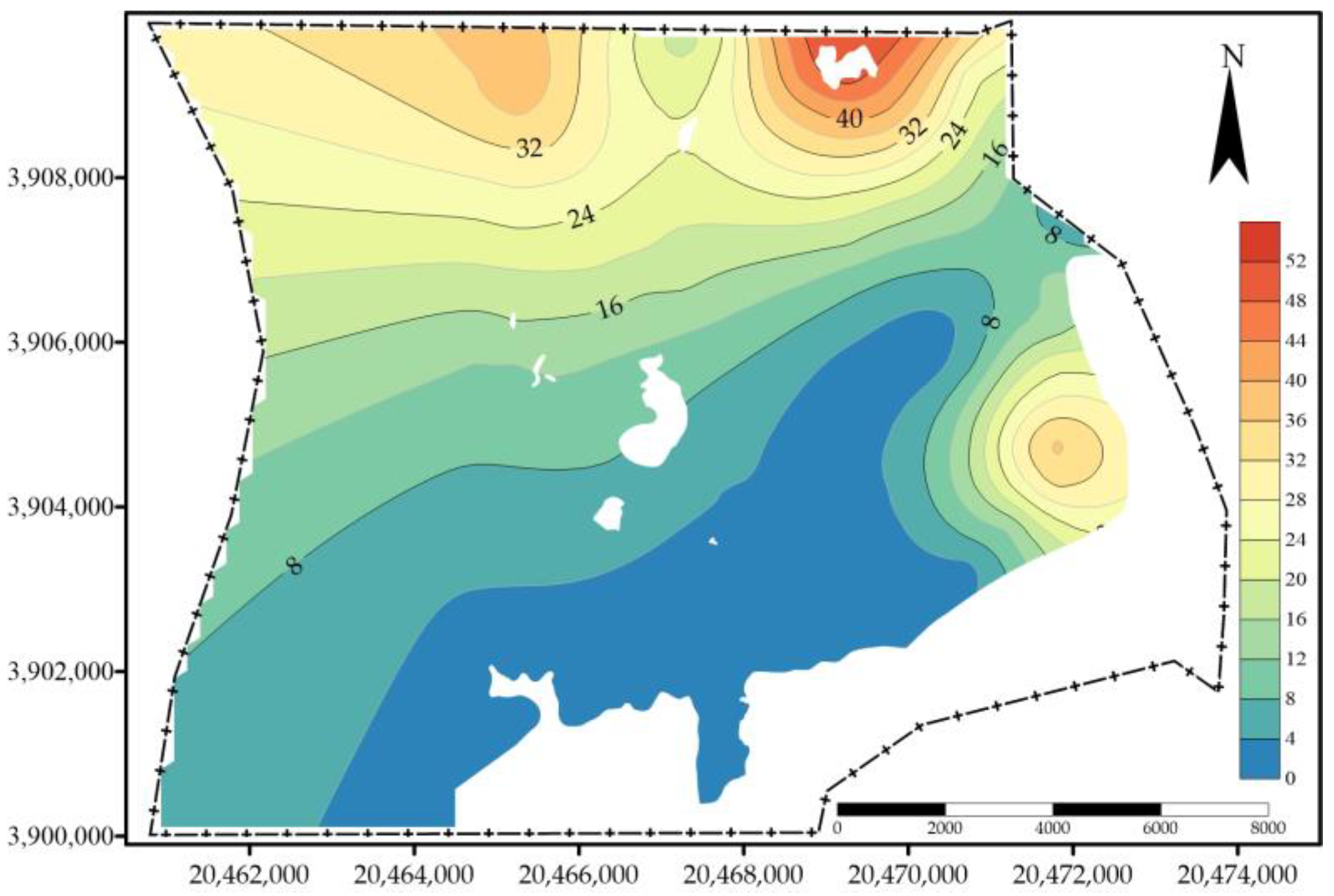

5. Results and Validation

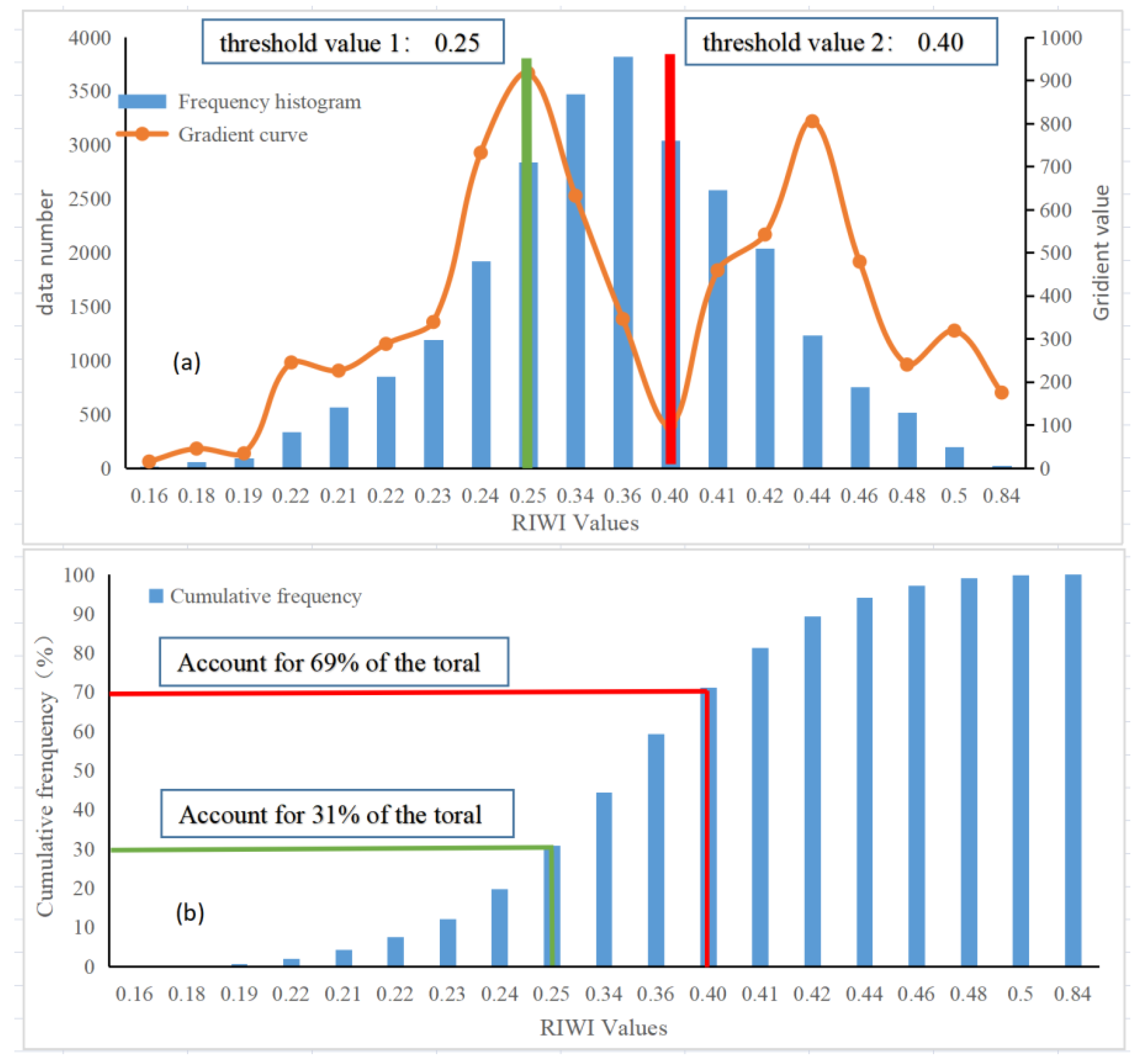

5.1. Results

5.2. Validation

6. Discussion

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Cui, F.P.; Wu, Q.; Lin, Y.H.; Zeng, Y.F.; Zhang, K.L. Damage features and formation mechanism of the strong water inrush disaster at the daxing co mine, Guangdong Province, China. Mine Water Environ. 2018, 37, 346–350. [Google Scholar] [CrossRef]

- Wang, P.P.; Jiang, Y.D.; Ren, Q.S. Roof hydraulic fracturing for preventing floor water inrush under multi aquifers and mining disturbance: A case study. Energies 2022, 15, 1187. [Google Scholar]

- Xie, D.L.; Han, J.; Zhang, H.D.; Wang, K.; Du, Z.W.; Miao, T.Y. Risk assessment of water inrush from coal seam roof based on combination weighting-set pair analysis. Sustainability 2022, 14, 11978. [Google Scholar] [CrossRef]

- Xiao, L.L.; Zhang, Q.Q.; Niu, C.; Wang, H.W. Spatiotemporal patterns in river water quality and pollution source apportionment in the arid Beichuan river basin of northwestern China using positive matrix factorization receptor modeling techniques. Int. J. Environ. Res. Public Health 2020, 17, 5015. [Google Scholar] [CrossRef]

- Niu, C.; Zhai, T.L.; Zhang, Q.Q.; Wang, H.W.; Xiao, L.L. Research advances in the analysis of nitrate pollution sources in a freshwater environment using δ15N-NO3− and δ18O-NO3−. Int. J. Environ. Res. Public Health 2021, 18, 11805. [Google Scholar] [CrossRef]

- Wei, M.J.; Wu, J.H.; Li, W.Q.; Zhang, Q.X.; Su, F.M.; Wang, Y.H. Groundwater geochemistry and its impacts on groundwater arsenic enrichment, variation, and health risks in Yongning County, Yinchuan Plain of northwest China. Expo. Health 2022, 14, 219–238. [Google Scholar] [CrossRef]

- Han, C.H.; Wei, J.C.; Zhang, W.J.; Yang, F.; Xie, D.L.; Xie, C. Quantitative permeation grouting in sand layer with consideration of grout properties and medium characteristics. Constr. Build. Mater. 2022, 327, 126947. [Google Scholar] [CrossRef]

- Niu, C.; Zhang, Q.Q.; Xiao, L.L.; Wang, H.W. Spatiotemporal variation in groundwater quality and source apportionment along the ye river of north China using the PMF model. Int. J. Environ. Res. Public Health 2022, 19, 1779. [Google Scholar] [CrossRef]

- Liu, T.Q. Laws of Surface Movement and Overburden Failure in Coal Mines and Their Application; Beijing Coal Industry Press: Beijing, China, 1981. [Google Scholar]

- Gao, Y.F. “Four-zone” model of rock mass movement and back analysis of dynamic displacement. J. China Coal Soc. 1996, 21, 51–56. [Google Scholar]

- Qu, Q.D.; Xu, J.L.; Qian, M.G. Study on influences of key strata movement on gas emissions of adjacent layers. J. Min. Saf. Eng. 2007, 26, 1478–1484. [Google Scholar]

- Wu, Q.; Xu, K.; Zhang, W. Further research on “three maps-two predictions” method for prediction on coal seam roof water bursting risk. J. China Coal Soc. 2016, 41, 1341–1347. [Google Scholar]

- Wu, Q.; Fan, S.K.; Zhou, W.F.; Liu, S.Q. Application of the analytic hierarchy process to assessment of water inrush: A case study for the No. 17 coal seam in the Sanhejian coal mine, China. Mine Water Environ. 2013, 32, 229–238. [Google Scholar] [CrossRef]

- Shi, S.; Miao, Y.C.; Wu, H.K.; Xu, Z.P.; Liu, C.W. The stress evolution of adjacent working faces passing through an abandoned roadway and the damage depth of the floor. Energies 2022, 15, 5824. [Google Scholar] [CrossRef]

- Zhou, X.X.; Ouyang, Z.H.; Sun, B.C. An approach to dynamic disaster prevention in strong rock burst coal seam under multi-aquifers: A case study of Tingnan coal mine. Energies 2021, 14, 7287. [Google Scholar] [CrossRef]

- Xu, D.J.; Peng, S.P.; Xiang, S.Y.; He, Y.L. A novel caving model of overburden strata movement induced by coal mining. Energies 2017, 10, 476. [Google Scholar] [CrossRef] [Green Version]

- Zeng, Y.F.; Wu, Q.; Liu, S.Q.; Zhai, Y.L.; Lian, H.Q.; Zhang, W. Evaluation of a coal seam roof water inrush: Case study in the Wangjialing coal mine, China. Mine Water Environ. 2018, 37, 174–184. [Google Scholar] [CrossRef]

- Zeng, Y.F.; Wu, Q.; Du, X.; Liu, S.Q.; Zan, J.C.; Dou, G.D.; Wu, Z.T. Further research on“water-richness index method”for evaluation of aquifer water abundance. J. China Coal Soc. 2020, 45, 2423–2431. [Google Scholar]

- Liu, Y.; Zhu, J.Z.; Liu, Q.M.; Yuan, A.Y.; He, S.F.; Bai, Y.S. Mechanism Analysis of Delayed Water Inrush from Karst Collapse Column during Roadway Excavation Based on Seepage Transition Theory: A Case Study in PanEr Coal Mine. Energies 2022, 15, 4987. [Google Scholar] [CrossRef]

- Liu, W.T.; Zheng, Q.S.; Pang, L.F.; Dou, W.M.; Meng, X.X. Study of roof water inrush forecasting based on EM-FAHP two-factor model. Math. Biosci. Eng. 2021, 18, 4987–5005. [Google Scholar] [CrossRef]

- Gao, C.Y.; Wang, D.L.; Liu, K.R.; Deng, G.W.; Li, J.F.; Jie, B.L. A multifactor quantitative assessment model for safe mining after roof drainage in the Liangshuijing coal mine. ACS Omega 2022, 7, 26437–26454. [Google Scholar] [CrossRef]

- Liu, S.L.; Li, W.P. Fuzzy comprehensive risk evaluation of roof water inrush based on catastrophe theory in the Jurassic coalfield of northwest China. J. Intell. Fuzzy Syst. 2019, 37, 2101–2111. [Google Scholar] [CrossRef]

- Wu, Q.; Liu, Y.Z.; Zhou, W.F.; Li, B.Y.; Zhao, B.; Liu, S.Q.; Sun, W.J.; Zeng, Y.F. Evaluation of water inrush vulnerability from aquifers overlying coal seams in the Menkeqing coal mine, China. Mine Water Environ. 2015, 34, 258–269. [Google Scholar] [CrossRef]

- Zhang, W.Q.; Li, B.; Yu, H.L. The correlation analysis of mine roof water inrush grade and influence factors based on Fuzzy Matter-Element. J. Intell. Fuzzy Syst. 2016, 31, 3163–3170. [Google Scholar] [CrossRef]

- Yin, H.Y.; Zhao, H.; Xie, D.L.; Sang, S.Z.; Shi, Y.L.; Tian, M.H. Mechanism of mine water inrush from overlying porous aquifer in quaternary: A case study in Xinhe coal mine of Shandong Province, China. Arab. J. Geosci. 2019, 12, 163. [Google Scholar] [CrossRef]

- Xiao, L.L.; Wu, Q.; Niu, C.; Dai, G.L.; Wang, S.Q.; Ren, D.J.; Luo, S.T. Application of a new evaluation method for floor water inrush risk from the Ordovician fissure confined aquifer in Xiayukou coal mine, Shanxi, China. Carbonates Evaporites 2020, 35, 97. [Google Scholar] [CrossRef]

- Zhang, W.; Li, w.; Huang, Y.L.; Ouyang, S.Y.; Ma, K.; Li, J.M.; Gao, H.D.; Zhang, P. A case study of the water abundance evaluation of roof aquifer based on the development height of water-conducting fracture zone. Energies 2020, 13, 4095. [Google Scholar]

- Wu, Q.; Zhao, D.K.; Wang, Y.; Shen, J.J.; Mu, W.P.; Liu, H.L. Method for assessing coal-floor water-inrush risk based on the variable-weight model and unascertained measure theory. Hydrogeol. J. 2017, 25, 2089–2103. [Google Scholar] [CrossRef]

- Wang, E.Y. Seueral problems of little faults study in coal mining. China Min. 2006, 8, 60–62. [Google Scholar]

- Cao, D.Y.; Zhou, Y.X.; Wet, Y.C. Development of the quantitative evaluation information system of mining geology structure. J. China Coal Soc. 2002, 4, 379–382. [Google Scholar]

- Yin, H.Y.; Shi, Y.L.; Niu, H.G.; Xie, D.L.; Wei, J.C.; Lefticariu, L.; Xu, S.X. A GIS-based model of potential groundwater yield zonation for a sandstone aquifer in the Juye Coalfield, Shangdong, China. J. Hydrol. 2018, 557, 434–447. [Google Scholar] [CrossRef]

- Park, I.; Kim, S.; Lee, S. Groundwater Productivity Potential Mapping Using Evidential Belief Function. Groundwater 2014, 52, 201–207. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Chen, S.J.; Gong, H.J.; Niu, P.K.; Zeng, Y.F. Risk Evaluation of Water Inrush in Poor Water Yield Capacity Aquifer of Coal Seam Direct Roof. Coal Mine Saf. 2018, 49, 181–184. [Google Scholar]

- Xiao, L.L.; Niu, C.; Dai, G.L.; Nie, W.J.; Zhang, H.T.; Gao, Y.F. Evaluation of water abundance in Zhiluo formation based watery structure index method. Coal Sci. Technol. 2018, 46, 207–213. [Google Scholar]

- Zhu, Z.K.; Xu, Z.M.; Sun, Y.J.; Huang, X.L. Research on the risk evaluation methods of water inrush from coal floor based on dimensionless multi-source information fusion technique. J. Min. Saf. Eng. 2013, 30, 911–916. [Google Scholar]

- Paradowski, B.; Shekhovtsov, A.; Baczkiewicz, A.; Kizielewicz, B.; Salabun, W. Similarity analysis of methods for objective determination of weights in multi-criteria decision support systems. Symmetry 2021, 13, 1874. [Google Scholar] [CrossRef]

- Zeng, Y.F.; Wu, Q.; Liu, S.Q.; Zhai, Y.L.; Zhang, W.; Liu, Y.Z. Vulnerability assessment of water bursting from Ordovician limestone into coal mines of China. Environ. Earth Sci. 2016, 75, 1431. [Google Scholar] [CrossRef]

- Barbara, W.; Zbigniew, F. Priorities for Research on Sustainable Agriculture: The Case of Poland. Energies 2022, 15, 257. [Google Scholar]

- Razandi, Y.; Pourghasemi, H.R.; Neisani, N.S.; Rahmati, O. Application of analytical hierarchy process, frequency ratio, and certainty factor models for groundwater potential mapping using GIS. Earth Sci. Inform. 2015, 8, 867–883. [Google Scholar] [CrossRef]

- Malczewski, J. GIS and Multicriteria Decision Analysis; Wiley: New York, NY, USA, 1999; pp. 177–192. [Google Scholar]

- Adiat, K.A.N.; Nawawi, M.N.M.; Abdullah, K. Assessing the accuracy of GIS-based elementary multi criteria decision analysis as a spatial prediction tool—A case of predicting potential zones of sustainable groundwater resources. J. Hydrol. 2012, 440–441, 75–89. [Google Scholar] [CrossRef]

- Abdel-Basset, M.; Mohamed, R. A novel plithogenic TOPSIS- CRITIC model for sustainable supply chain risk management. J. Clean. Prod. 2020, 247, 119586. [Google Scholar] [CrossRef]

| n | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| RI | 0 | 0 | 0.52 | 0.89 | 1.12 | 1.26 | 1.36 | 1.41 | 1.46 | 1.49 | 1.51 |

| Superior | Underlying Factors | Sibling Weight | Global Weight |

|---|---|---|---|

| Aquifer properties 0.5278 | Dp | 0.1111 | 0.0586 |

| Tk | 0.5556 | 0.2932 | |

| Cr | 0.1111 | 0.0586 | |

| Tkr | 0.1111 | 0.0586 | |

| Num | 0.1111 | 0.0586 | |

| Fracture zone development 0.3325 | H | 1 | 0.3325 |

| Geological structure 0.1396 | Fd | 0.5 | 0.0698 |

| Ff | 0.1667 | 0.0233 | |

| Fs | 0.1667 | 0.0233 | |

| CDVAC | 0.1667 | 0.0233 |

| Evaluation Index | Index Variability | Index Conflict | Amount of Information | Weight |

|---|---|---|---|---|

| Dp | 0.251 | 7.736 | 1.942 | 10% |

| Tk | 0.281 | 8.108 | 2.278 | 12% |

| Cr | 0.231 | 11.823 | 2.727 | 14% |

| Tkr | 0.247 | 7.89 | 1.948 | 10% |

| Num | 0.204 | 9.491 | 1.936 | 10% |

| H | 0.253 | 7.186 | 1.817 | 10% |

| Fd | 0.145 | 7.695 | 1.115 | 6% |

| Ff | 0.158 | 7.966 | 1.257 | 7% |

| Fs | 0.261 | 8.199 | 2.137 | 11% |

| CDVAC | 0.214 | 8.616 | 1.844 | 10% |

| Evaluation Index | Dp | Tk | Cr | Tkr | Num | H | Fd | Ff | Fs | CDVAC |

|---|---|---|---|---|---|---|---|---|---|---|

| Weight | 0.058 | 0.339 | 0.081 | 0.058 | 0.058 | 0.306 | 0.039 | 0.015 | 0.025 | 0.022 |

| Natural Break Point Distribution | Range of Threshold | Risk Level | ||

|---|---|---|---|---|

| Break Point | Frequency Distribution (Percentage of the Total Data) | Gradient Change | ||

| 0.25 | 30% | +665 | F < 0.25 | low |

| 0.40 | 69% | −84 | 0.25 < F < 0.40 | medium |

| 0.84 | 100% | 31,230 (total data) | 0.40 < F | high |

| NO. | Risk Area | Location | Water Quantity (m3/h) | Water Source | NO. | Risk Area | Location | Water Quantity (m3/h) | Water Source |

|---|---|---|---|---|---|---|---|---|---|

| 1 | High | No. 16 | 60 | Roof of CB3 | 33 | Medium | No. 6 | 120 | Roof of CB3 |

| 2 | 35 | 34 | 368 | ||||||

| 3 | 30 | 35 | 180 | ||||||

| 4 | No. 6 | 300 | 36 | 236.7 | |||||

| 5 | 64 | 37 | 527.13 | ||||||

| 6 | 175.6 | 38 | 296 | ||||||

| 7 | 194.66 | 39 | 112 | ||||||

| 8 | 430 | 40 | No. 7 | 70 | |||||

| 9 | 274.8 | 41 | 105 | ||||||

| 10 | 75 | 42 | No. 1 | 65 | |||||

| 11 | 97 | 43 | 96 | Lower Jurassic conglomerate and roof of CB3 | |||||

| 12 | 150 | 44 | 533.84 | ||||||

| 13 | 46 | 45 | 497 | ||||||

| 14 | 460 | 46 | 232 | ||||||

| 15 | 260 | 47 | No. 5 | 259 | |||||

| 16 | 350 | 48 | 268 | ||||||

| 17 | 187 | 49 | Low | No. 1 | 140 | ||||

| 18 | 38 | 50 | 84.6 | ||||||

| 19 | No. 4 | 48.4 | 51 | 40.3 | |||||

| 20 | 126.4 | 52 | West return airway | 49.8 | Roof of CB3 | ||||

| 21 | No. 1 | 170 | Lower Jurassic conglomerate and roof of CB3 | 53 | West auxiliary transportation roadway | 116 | |||

| 22 | 140 | 54 | No. 6 | 251.6 | |||||

| 23 | 137.5 | 55 | 402.2 | ||||||

| 24 | 72 | 56 | No. 5 | 45 | |||||

| 25 | 90 | 57 | 75 | ||||||

| 26 | 133 | 58 | 48 | ||||||

| 27 | 140 | 59 | 45 | ||||||

| 28 | 120 | ||||||||

| 29 | 110 | ||||||||

| 30 | 105 | ||||||||

| 31 | No. 5 | 137 | |||||||

| 32 | No. 1 | 81 | Floor of CB3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, L.; Li, F.; Niu, C.; Dai, G.; Qiao, Q.; Lin, C. Evaluation of Water Inrush Hazard in Coal Seam Roof Based on the AHP-CRITIC Composite Weighted Method. Energies 2023, 16, 114. https://doi.org/10.3390/en16010114

Xiao L, Li F, Niu C, Dai G, Qiao Q, Lin C. Evaluation of Water Inrush Hazard in Coal Seam Roof Based on the AHP-CRITIC Composite Weighted Method. Energies. 2023; 16(1):114. https://doi.org/10.3390/en16010114

Chicago/Turabian StyleXiao, Lele, Fan Li, Chao Niu, Gelian Dai, Qian Qiao, and Chengsen Lin. 2023. "Evaluation of Water Inrush Hazard in Coal Seam Roof Based on the AHP-CRITIC Composite Weighted Method" Energies 16, no. 1: 114. https://doi.org/10.3390/en16010114