Joint SOH-SOC Estimation Model for Lithium-Ion Batteries Based on GWO-BP Neural Network

Abstract

:1. Introduction

1.1. Preliminary Work

- (1)

- According to the main influencing factors of the SOH and its change law, combined with the operational characteristics and prediction accuracy of different neural networks, we selected the GWO-BP neural network for SOH prediction.

- (2)

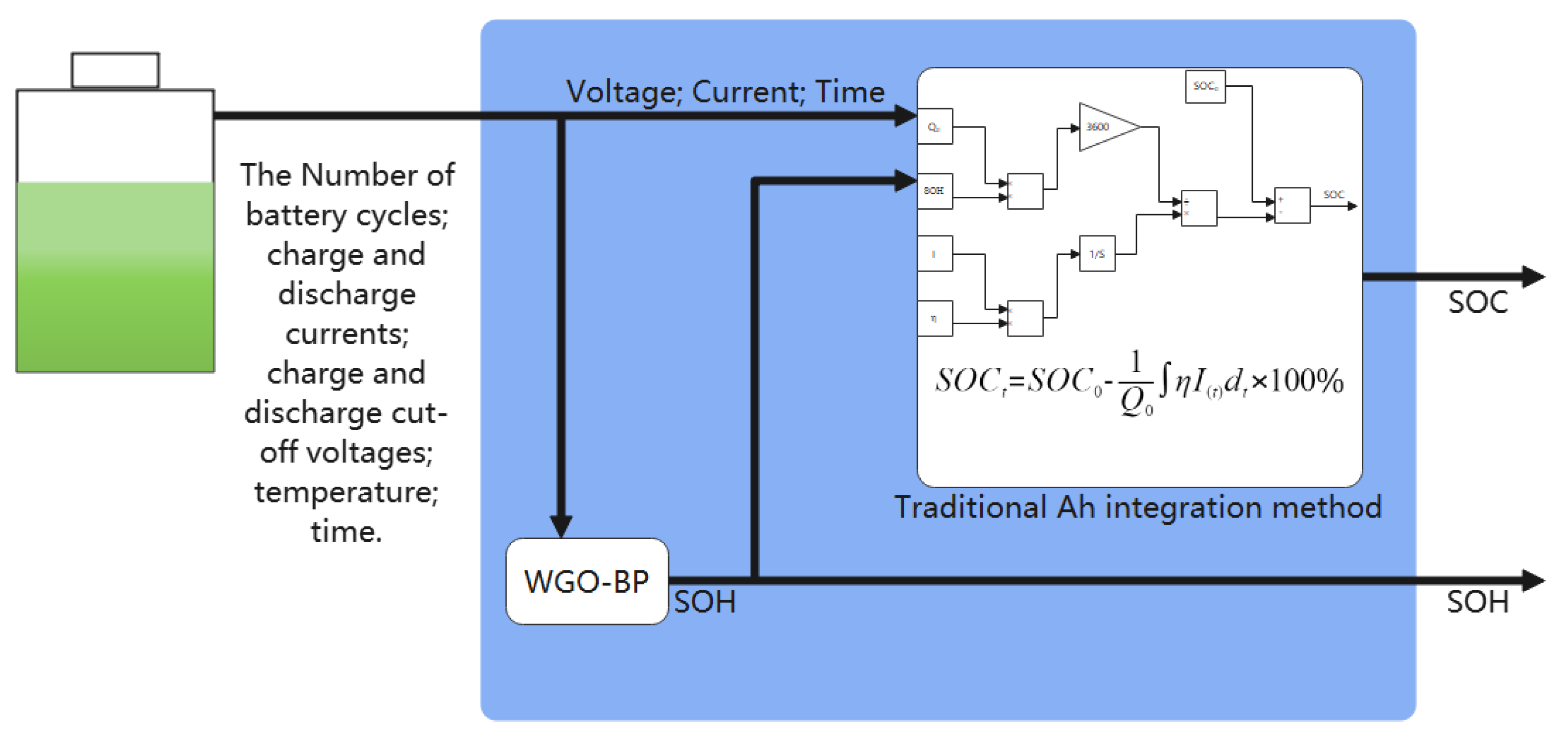

- We proposed a joint SOH-SOC estimation model based on neural networks and the traditional Ah integration method.

1.2. Contribution

- (1)

- We proposed a joint SOH-SOC estimation model based on neural networks and the Ah integration method to optimize the traditional Ah integration method and improve the accuracy of SOC estimation.

- (2)

- We used the ONLY-BP and GWO-BP neural networks to predict the SOH, and analyzed the resultant errors. We chose the more effective GWO-BP neural network for the SOH prediction part of the joint SOH-SOC estimation model.

- (3)

- A combination of neural networks and traditional SOC estimation methods were used, with a relatively simple model structure and fast computing speed. It avoided the complexity of SOC estimation caused by the combination of multiple neural networks. The more complex the structure, the greater the error probability, the longer the calculation time, and the lower the timeliness of SOC estimation.

- (4)

- The battery dataset we used in this paper was a hybrid dataset consisting of a mixture of the 1278 battery data samples collected, the NASA battery dataset, and data from the CALCE battery dataset [16]. The experimental results are all smaller than the specified errors, which further verifies the stability of our proposed joint estimation model.

2. SOH Estimation

2.1. Influencing Factors of SOH

2.2. BP Neural Networks

2.2.1. Principle of BP Neural Network

- (1)

- Input layer: This is the information input end to reading input data, and there are as many input nodes as there are types of input data.

- (2)

- Hidden layer: This is the information processing end, divided into one or more layers. The prediction accuracy of a neural network increases with the number of hidden layers, and the structure becomes complex, leading to increased training time and even overfitting. Typically, there is only one hidden layer, and the prediction accuracy is adjusted by changing the number of nodes in the hidden layer.

- (3)

- Output layer: This is the output of the information, the result we want, and therefore, has the same number of nodes as the number of data we predict.

2.2.2. Building BP Neural network

2.3. Grey Wolf Optimizer

2.4. Comparison of Errors

3. SOC Estimation

3.1. Ah Integration Method

3.2. Joint SOH-SOC Estimation Model

4. Testing and Analysis

- (1)

- A comparative analysis of the accuracy of the ONLY-BP and GWO-BP neural networks for predicting battery SOH was conducted to select one of the estimation methods with higher accuracy for the joint SOH-SOC estimation model.

- (2)

- The accuracy of predicting battery SOC was compared between the conventional Ah integration method and the joint SOH-SOC estimation model.

4.1. Acquisition of Test Data

4.2. Verification of Test

4.3. Analysis of Experimental Results

5. Summary

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chemali, E.; Preindl, M.; Malysz, P.; Emadi, A. Electrochemical and Electrostatic Energy Storage and Management Systems for Electric Drive Vehicles: State-of-the-Art Review and Future Trends. IEEE. Emerg. Sel. Top. Power Electron. 2016, 4, 1117–1134. [Google Scholar] [CrossRef]

- Zheng, Y.; Lu, Y.; Gao, W.; Han, X.; Feng, X.; Ouyang, M. Micro-Short-Circuit Cell Fault Identification Method for Lithium-Ion Battery Packs Based on Mutual Information. IEEE Trans. Ind. Electron. 2021, 68, 4373–4381. [Google Scholar] [CrossRef]

- Hannan, M.A.; Lipu, M.H.; Hussain, A.; Mohamed, A. A review of lithium-ion battery state of charge estimation and management system in electric vehicle applications: Challenges and recommendations. Renew. Sustain. Energy Rev. 2017, 78, 834–854. [Google Scholar] [CrossRef]

- Huang, S.C.; Tseng, K.H.; Liang, J.W.; Chang, C.L.; Pecht, M.G. An online SOC and SOH estimation model for lithium-ion batteries. Energies 2017, 10, 512. [Google Scholar] [CrossRef]

- Yang, Q.; Ma, K.; Xu, L.; Song, L.; Li, X.; Li, Y. A Joint Estimation Method Based on Kalman Filter of Battery State of Charge and State of Health. Coatings 2022, 12, 1047. [Google Scholar] [CrossRef]

- Ahmed, M.S.; Balasingam, B. A scaling approach for improved open circuit voltage modeling in Li-ion batteries. In Proceedings of the 2019 IEEE Electrical Power and Energy Conference (EPEC), Montréal, QC, Canada, 16–18 October 2019; pp. 1–6. [Google Scholar]

- Wei, Z.; Zhao, D.; He, H.; Cao, W.; Dong, G. A noise-tolerant model parameterization method for lithium-ion battery management system. Appl. Energy 2020, 268, 114932. [Google Scholar] [CrossRef]

- Jin, G.; Li, L.; Xu, Y.; Hu, M.; Fu, C.; Qin, D. Comparison of SOC Estimation between the Integer-Order Model and Fractional-Order Model Under Different Operating Conditions. Energies 2020, 13, 1785. [Google Scholar] [CrossRef] [Green Version]

- Hou, E.; Xu, Y.; Qiao, X.; Liu, G.; Wang, Z. State of power estimation of echelon-use battery based on adaptive dual extended Kalman filter. Energies 2021, 14, 5579. [Google Scholar] [CrossRef]

- Qiao, X.; Wang, Z.; Hou, E.; Liu, G.; Cai, Y. Online Estimation of Open Circuit Voltage Based on Extended Kalman Filter with Self-Evaluation Criterion. Energies 2022, 15, 4373.n. [Google Scholar] [CrossRef]

- Lai, X.; Yuan, M.; Tang, X.; Yao, Y.; Weng, J.; Gao, F.; Ma, W.; Zheng, Y. Co-Estimation of State-of-Charge and State-of-Health for Lithium-Ion Batteries Considering Temperature and Ageing. Energies 2022, 15, 7416. [Google Scholar] [CrossRef]

- Tian, H.; Chen, J. Deep Learning with Spatial Attention-Based CONV-LSTM for SOC Estimation of Lithium-Ion Batteries. Processes 2022, 10, 2185. [Google Scholar] [CrossRef]

- Shahriar, S.M.; Bhuiyan, E.A.; Nahiduzzaman, M.; Ahsan, M.; Haider, J. State of Charge Estimation for Electric Vehicle Battery Management Systems Using the Hybrid Recurrent Learning Approach with Explainable Artificial Intelligence. Energies 2022, 15, 8003. [Google Scholar] [CrossRef]

- Yang, B.; Wang, Y.; Zhan, Y. Lithium Battery State-of-Charge Estimation Based on a Bayesian Optimization Bidirectional Long Short-Term Memory Neural Network. Energies 2022, 15, 4670. [Google Scholar] [CrossRef]

- Meng, J.; Boukhnifer, M.; Diallo, D. Lithium-Ion Battery Monitoring and Observability Analysis with Extended Equivalent Circuit Model. In Proceedings of the 2020 28th Mediterranean Conference on Control and Automation (MED), Saint-Raphaël, France, 5–18 September 2020; pp. 764–769. [Google Scholar]

- Dos Reis, G.; Strange, C.; Yadav, M.; Li, S. Lithium-ion battery data and where to find it. Energy AI 2021, 5, 100081. [Google Scholar] [CrossRef]

- Zheng, Y.; Lv, X.; Qian, L.; Liu, X. An Optimal BP Neural Network Track Prediction Method Based on a GA–ACO Hybrid Algorithm. J. Mar. Sci. Eng. 2022, 10, 1399. [Google Scholar] [CrossRef]

- Seyedali, M.; Seyed, M.M.; Andrew, L. Grey Wolf Optimizer. Adv. Eng. Softw. 2014, 69, 46–61. [Google Scholar]

- Jafari, S.; Shahbazi, Z.; Byun, Y.-C.; Lee, S.-J. Lithium-Ion Battery Estimation in Online Framework Using Extreme Gradient Boosting Machine Learning Approach. Mathematics 2022, 10, 888. [Google Scholar] [CrossRef]

- Ding, Z.T.; Deng, T.; Li, Z.F.; Yin, Y.L. Research on SOC estimation method for lithium-ion batteries based on Ah integral and traceless Kalman filter. China Mech. Eng. 2020, 31, 1823–1830. [Google Scholar]

| Battery Number | Charge Cut-Off Voltage | Discharge Cut-Off Voltage | Discharge Rate | Ambient Temperature |

|---|---|---|---|---|

| 46 | 4.2 V | 2.2 V | 0.5 C | 4 °C |

| 54 | 4.2 V | 2.2 V | 1 C | 4 °C |

| 5 | 4.2 V | 2.7 V | 1 C | 24 °C |

| 7 | 4.2 V | 2.2 V | 1 C | 24 °C |

| 18 | 4.2 V | 2.5 V | 1 C | 24 °C |

| 25 | 4.2 V | 2 V | 1 C | 24 °C |

| 29 | 4.2 V | 2 V | 2 C | 43 °C |

| Capacity/mAh | 2000 | Charge cut-off voltage/V | 4.2 |

| Discharge cut-off voltage/V | 2.75 | Nominal voltage/V | 3.7 |

| Anode materials | Ternary materials | Negative electrode materials | Amorphous carbon |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Hou, J.; Wang, Z.; Jiang, Y. Joint SOH-SOC Estimation Model for Lithium-Ion Batteries Based on GWO-BP Neural Network. Energies 2023, 16, 132. https://doi.org/10.3390/en16010132

Zhang X, Hou J, Wang Z, Jiang Y. Joint SOH-SOC Estimation Model for Lithium-Ion Batteries Based on GWO-BP Neural Network. Energies. 2023; 16(1):132. https://doi.org/10.3390/en16010132

Chicago/Turabian StyleZhang, Xin, Jiawei Hou, Zekun Wang, and Yueqiu Jiang. 2023. "Joint SOH-SOC Estimation Model for Lithium-Ion Batteries Based on GWO-BP Neural Network" Energies 16, no. 1: 132. https://doi.org/10.3390/en16010132