1. Introduction

The complexity of aspects related to the generation, transmission, distribution, and the use of energy has considerably increased recently, with the worsening of environmental problems worldwide, climate changes, and the depletion of natural reserves, but also in the current context of the energy crisis. Therefore, current concerns in the field of energy generation are oriented towards the application of technologies with the least impact on the environment. Moreover, energy consumption must be controlled and managed, especially through careful monitoring of energy efficiency and diversification of primary energy sources. In this context, the combined generation of electricity and heat or cogeneration (CHP—combined heat and power) is significantly more efficient than separate production [

1]. Cogeneration considerably reduces the consumption of primary energy and consequently leads to a reduction in greenhouse gas emissions. Cogeneration technologies can be connected to different primary energy sources. The carbon dioxide emission factors are presented in

Table 1 [

2,

3].

Distributed generation is a suitable option for future energy systems in terms of sustainable development and expanding the use of renewable energy sources. The main reason for using low-power cogeneration in distributed generation applications is the efficient utilization of heat and electricity as close as possible to the place of consumption.

In recent years, there have been major changes in the energy markets, with new challenges for the market participants, but also with an intense promotion of renewable energy sources. Compared to solar and wind energy sources, cogeneration plants have the advantage of a stable and continuous source of heat and electricity for consumers. In this context, operators of cogeneration plants cannot remain indifferent to the changes in the energy markets and are looking for solutions to maximize profitability and maintain competitiveness with other energy sources [

4,

5,

6].

Knowing the specific conditions of the energy markets and adapting the mathematical calculation models to the technical features of the cogeneration plant can guarantee success on the market. Thus, paper [

7] proposes an algorithm for economic dispatching of high-power cogeneration units and paper [

8] proposes an algorithm for optimal operation based on real-time forecasting of prices on deregulated energy markets.

There is currently a tendency to produce energy as close as possible to the place of consumption with the help of medium- and low-power energy sources [

9]. To achieve the balance between production and consumption, these small generation units can be integrated and managed collectively as a single source (virtual power plant) through a flexible collaboration between the independent entities [

10]. The high volatility of energy prices caused by geopolitical developments causes CHP profitability to fluctuate [

11].

A specific problem for cogeneration sources is the need to distribute the total operating costs between the two forms of useful energy generated: heat and electricity. Knowing the elements related to the production structure of the two forms of energy and their related fuel consumption, we can move on to establishing the costs of heat and electricity generation.

Conventionally, the total operating costs of a cogeneration plant can fall into two large categories: variable costs (which depend on the heat and electricity production of the cogeneration plant) and fixed costs (the rest of the costs that do not depend on production). The allocation of the two categories of costs can be realized according to various methods [

12,

13,

14]. Allocation methods produce different results. An example in this sense is presented in paper [

15] in the case of a combined cycle cogeneration plant.

The impact of the adjustment of energy demand (electricity and hot water) on the cost and environmental performance of cogeneration systems according to the priorities of the interested parties is presented in [

16]. Trigeneration is widespread in the case of buildings, and the cost allocation methods can be extended in such cases [

17,

18,

19].

Depending on the cogeneration technology adopted (steam turbines, gas turbines, gas and steam combined cycles, reciprocating engines, Organic Rankine Cycle), cogeneration systems can have different operating regimes, from pure cogeneration modes (in which all the electricity is generated in cogeneration mode based on heat demand) to non-cogeneration modes (in which the system only produces electricity).

A comparison between different cogeneration technologies can be made according to different criteria (energy, environmental, and economic) [

20]. Due to its modular construction, Organic Rankine Cycle (ORC) technology can be coupled to different primary energy resources: solar, geothermal, biomass, and waste heat recovery. In addition, unlike the conventional Rankine Cycle, local production of medium- and low-power electrical and thermal energy is possible. The long-term uncertainty of energy demand has an influence on the dimensioning of the cogeneration unit in the design phase, but also for the estimation of the annual operating costs [

21]. Thermal energy storage is necessary to be used in case of variations in heat demand [

22,

23,

24].

Different approaches can be found in specialized literature regarding the allocation of products generated in cogeneration and trigeneration. The paper [

25] presents the allocation of primary energy consumption in cogeneration in a local (regional) production scenario. Approaches to thermoecological and exergoeconomic costs of multiproduct systems are presented in papers [

26,

27,

28,

29,

30]. The quantity and quality of energy are considered in [

31,

32]. Marginal costs are considered in the allocation of resources in the case of district heating [

33,

34]. The allocation of carbon dioxide emissions for products generated in cogeneration are presented in [

35,

36]. Depending on the methodology used, the allocation of joint costs can lead to different outputs that reflect the link between the joint costs and the objectives pursued.

The generation of electricity in cogeneration and from renewable energy sources is encouraged through various support schemes [

37,

38]. The participation of cogeneration plants (without support schemes) in competitive energy markets is the objective of this study.

Setting prices for electricity and heat generated in cogeneration in a market economy depends on the type of market: competitive markets where prices are a consequence only of the supply–demand ratio; regulated markets in which prices are a consequence of both the supply–demand ratio and the action of specific regulations. The type of energy market in which the cogeneration producer operates has a major impact on the choice of the allocation methodology. From an economic point of view, there is a considerable margin to allocate the costs of one of the products according to the interests of the cogeneration producer on the respective energy markets.

Usually, a cogeneration plant that delivers heat in a district heating system is often viewed as a monopoly or in a dominant market position. Therefore, the cogeneration producers may face competition from other heating alternatives, such as individual gas boilers. In these cases, the heat price must be set at competitive levels with alternative heating sources.

The economic viability of a cogeneration plant will depend on the demand for heat and electricity. These two factors must be accurately evaluated when analyzing the feasibility or operating strategies of a cogeneration plant to ensure the correct calibration of the plant and thus to ensure long-term viability.

If the installation is incorrectly calibrated, for example, if the entire available heat is not used, the economic viability of the cogeneration system will be negatively affected. To maximize the savings of the CHP plant in relation to the initial capital investment, com-pared to the separate production of electricity and heat, the annual operating time should be sufficiently high.

The main contributions and novelty elements of this paper can be summarized as follows:

The use of allocation methods in determining heat and electricity prices in the case of a cogeneration plant based on Organic Rankine Cycle (ORC) and biomass fuel.

The economic market method was extended with an algorithm based on the theory of duality, useful in the operation of the cogeneration plant and for the performance of management strategies on the energy markets.

The example provided demonstrates how cogeneration benefits can be shared between heat and electricity to increase the competitiveness of the CHP plant i the energy markets.

The paper is organized as follows.

Section 2 presents the methodology used.

Section 3 presents a case study for a CHP plant based on ORC and biomass fuel. The findings and their implications are summarized in

Section 4. Finally, the conclusions of this paper are summarized in

Section 5.

2. Materials and Methods

2.1. Modeling Costs and Fuel Consumption in Cogeneration Plants

The annual operation costs of a cogeneration plant can be expressed with the following equation [

39]:

The variable costs (V) consist of the annual expenses for the fuel consumed, those for the energy consumed, for the water consumed, and the electricity of the cogeneration plant. If the volume of production is equal to zero, then the variable costs are also zero.

The fixed costs (F) consist of the annual expenses for the amortization of the investments, those with the operating personnel, and with the plant maintenance. In general, they include expenses independent of the energy production of the cogeneration plant.

Annual fees and taxes (T) and also ecotaxes (E) are included in the total costs. The ecotaxes are generally environmental, dependent on the size of the potential emissions (especially CO2 emissions). As the emissions are dependent on the amount of energy produced and on the fuel consumption, they can be considered dependent on the annual fuel consumption.

The rates (R) are dependent on the loans to be repaid correlated with the repayment period and the annual interest rate. They are independent of the values of the plant’s annual energy production.

Bonuses (B) are dependent on the amount of electricity produced in cogeneration based on conventional fuels and/or based on renewable energies. They represent a source related to each kWh produced in cogeneration, fixed or variable, depending on the annual amount of electricity demonstrated (certified/qualified) to be produced in cogeneration, according to the methodology established by the regulator.

The profit/benefit (b) desired by the producer is also included in the total costs.

A correct delimitation of costs in fixed or variable costs is useful in making forecasts and implicitly in making decisions at the management level. The total costs TC of the cogeneration plant can be expressed with the equation:

where

FC represents the fixed costs that include all expenses that do not depend on production, but indirectly depend on it through the nominal capacity installed in the CHP plant, and

VC (

H,

E) are the variable costs and whose value depends on the size of the annual production of electricity and heat of the cogeneration plant.

The total fuel consumption of a cogeneration plant can be expressed according to the quantities of energy produced with the relation [

40]:

where:

EG is the electricity generated (kWh);

HG is the heat generated (kWh);

a, b, c, d, e, and f are the coefficients of the polynomial.

The determination of the coefficients a–f can be realized by applying the least squares method on as many characteristic regimes as possible to cover the range of possibilities for the operation of the cogeneration unit.

Using the function:

the coefficients

a–f result by solving the system of equations:

An algorithm for solving the system of Equation (5) implemented in the MATLAB computing environment is presented in

Appendix A.

In a competitive economy, prices are directly related to the ratio between supply and demand. For a certain product, it is considered that the market stabilizes for that price value for which the amount of energy demanded by consumers is equal to that offered by the producer. The price that establishes this state is an equilibrium price called the market price

p0 [

39].

On the other hand, the price proposed by the producer (

pp) for negotiation with buyers is given:

where

c is the unit cost of production and

b is the desired profit.

Comparing the market price p0 with the producer’s proposed price pp allows an initial estimate of the producer’s efficiency:

- (a)

p0 ≥ pp, the producer covers his/her production costs and achieves a higher profit, or at least equal to the initially estimated one;

- (b)

c ≤ p0 ≤ pp, the producer covers his/her production costs and achieves a lower profit than initially estimated;

- (c)

p0 < c, the producer does not cover his/her production costs. In this case, a reduction in production costs is necessary.

Therefore, knowing the costs is an essential condition in analyzing the profitability of the cogeneration process.

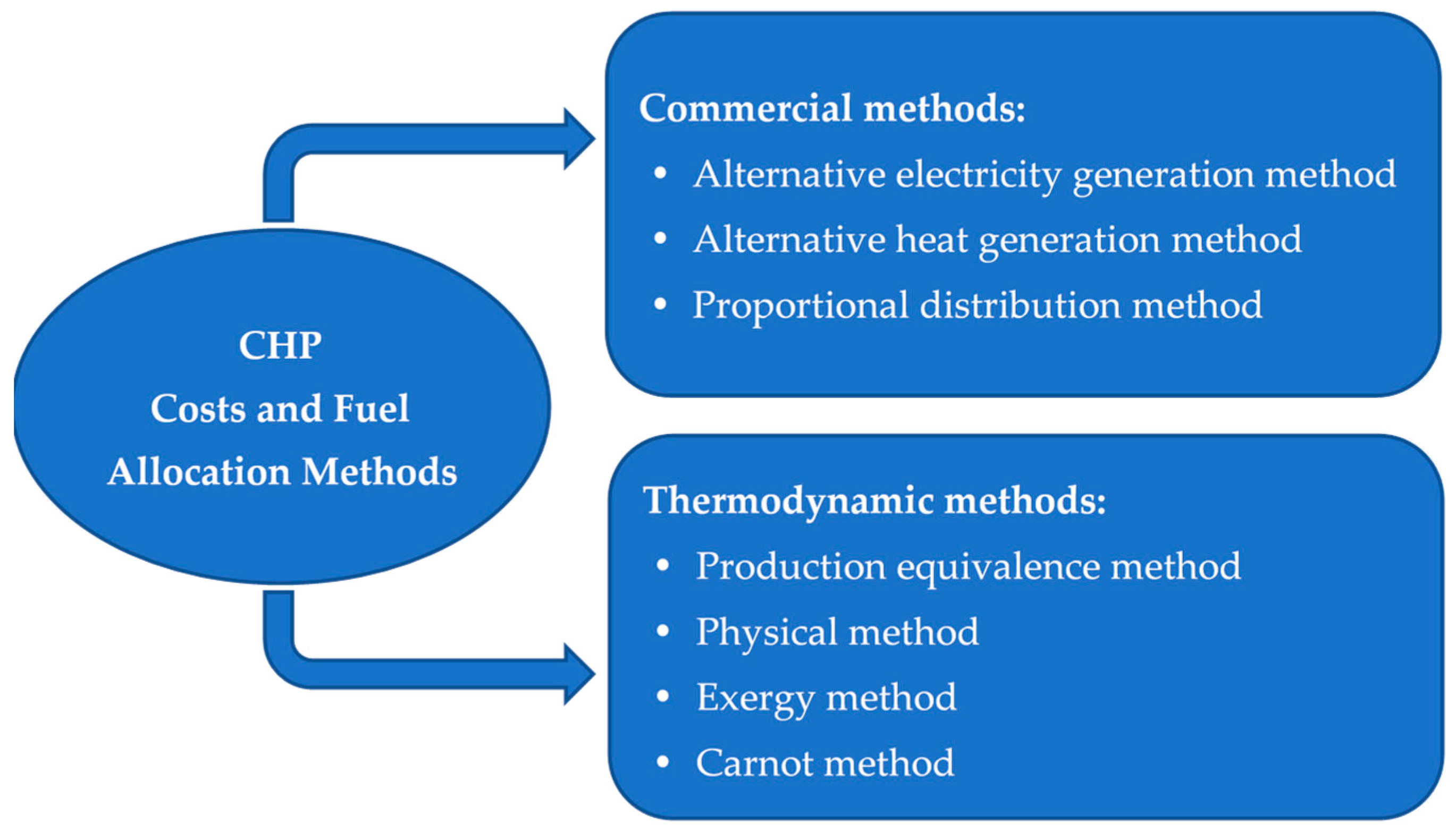

2.2. Methods of Allocating Costs and Fuel in Cogeneration

Over time, several methods of allocating fuel and costs have been developed. The most used ones are shown in

Figure 1 [

39,

41,

42,

43].

The main difference between the two categories is that commercial methods do not distinguish between production cost differences, for example, for different steam extraction pressures or between cogeneration and condensation electricity. In contrast, thermodynamic methods consider this type of cost differences. In addition to costs, the methods can also be applied for the allocation of fuel or emissions related to the products (useful energies) resulting from the cogeneration process.

2.2.1. Alternative Electricity Generation Method

The annual fuel consumption allocated for the electricity is considering the alternative option of separate electricity production, with performant technologies, using the same primary energy source (fuel):

where:

ECHP is the electricity generated annually in the cogeneration plant (kWh/year);

ηe,sep is the reference efficiency of a power plant that produces only electricity with the same type of primary fuel (for example, a thermoelectric power plant with a condensing turbine).

Therefore, the fuel consumption is assumed to be equal to that which would result if the respective electricity was produced in a thermal power plant with a condensation turbine.

The annual fuel consumption for heat generation in the CHP plant results from the fuel difference:

where

BCHP is the total annual fuel consumption of the cogeneration plant (kWh/year).

The variable costs of electricity production (

VCe) in cogeneration are equated to the variable production costs in the case of separate electricity production:

and the variable costs for heat production in cogeneration (

VCh):

where

VC represents the total variable costs of the CHP plant.

Accordingly, the fixed costs can be allocated according to the fixed costs of the alternative electricity generation technology.

2.2.2. Alternative Heat Generation Method

Similarly, this method represents the opposite trend in which the annual fuel consumption allocated for heat production is considered in the alternative option of separate heat production, with efficient technologies, using the same primary energy source:

where:

HCHP is the useful heat generated annually in the CHP plant (kWh/year);

ηh,sep is the reference efficiency of a plant that only produces thermal energy with the same type of primary fuel (for example, a steam or hot water boiler).

Therefore, the fuel consumption is assumed to be equal to that which would result if the respective electricity was generated in a thermal power plant with a condensing turbine.

The annual fuel consumption for thermal energy generation results from the fuel difference:

The variable costs of thermal energy generation in

VCh cogeneration are equated to the variable production costs in the case of separate generation:

and the variable costs for the electricity generation in cogeneration

VCe:

2.2.3. Proportional Distribution Method

The specific fuel consumption for heat production in cogeneration is considered to be equal to that of separate generation, i.e., the inverse of the heat efficiency:

The specific fuel consumption for cogeneration electricity generation can be calculated with the equation:

where:

BCHP is the total fuel consumption of the CHP plant (kWh/year);

E is the annual electricity production of the CHP plant (kWh/year);

H is the annual heat production of the CHP plant (kWh/year);

ηh,sep is the reference efficiency in the case of the alternative heat production option.

The variable costs allocated to the production of electricity in cogeneration (

VCe) can be calculated as follows:

Similarly, the variable costs allocated to the production of heat in cogeneration (

CVh) can be calculated as follows:

2.2.4. Proportional Distribution Method

The proportional distribution method (benefit distribution) distributes the total fuel consumption between the two forms of energy, proportional to their energy equivalent in the common production process:

respectively:

where

xe and

xq represent the total consumption breakdown keys:

2.2.5. Physical Method

This method considers that the annual fuel savings achieved in cogeneration compared to separate production have two components:

Thus, the annual fuel savings are allocated to both products resulting from the cogeneration process and calculated with the following equations:

respectively:

From Equations (24) and (25), it is observed that the fuel saving in cogeneration is due to the superiority of the overall efficiency of the CHP plant (ηCHP) compared to the separate generation of heat and electricity.

2.2.6. Exergy Method

In the case of the exergetic method, the cost allocation is based on the exergetic flows (useful energy flows) of the energy products resulting from the cogeneration process: electricity and useful heat. Exergy is a thermodynamic term that defines the quality of energy. As energy is used in a process, it loses quality, and its exergy decreases. Exergy flows of thermodynamic processes can be calculated with enthalpies (the degree of energy content as a function of pressure, temperature, and humidity) and entropies (the degree of disorder or uncertainty in a closed thermodynamic system as a function of absolute temperature).

The application of this method requires deep knowledge of the thermodynamic processes and operating peculiarities of the cogeneration plant, and therefore, it is quite complicated to use. However, the method is considered the most thermodynamically correct method to share the benefits of the simultaneous production of electricity and heat generated in cogeneration.

2.2.7. Carnot Method

The Carnot method uses, as an allocation procedure, the maximum potential to provide useful energy (exergy). This maximum potential is evidenced by the efficiency of the Carnot cycle, applied only to heat production, Equation (29). For electricity generation, ηC = 1. Therefore, the Carnot method is a form of exergetic allocation.

The allocation of fuel consumption to generate electricity

E and useful heat

H in cogeneration can be carried out in accordance with the first and second laws of thermodynamics, respectively, as follows:

with:

where:

ae is the fuel allocation factor related to electricity production;

ah is the fuel allocation factor related to heat production;

ηC is the efficiency of the Carnot cycle.

The efficiency of the Carnot cycle is applied only to heat production (the exergetic fraction within the useful thermal energy):

where:

Th is the useful heat delivery temperature (K);

T0 is the ambient temperature, set at 273.15 degrees Kelvin (equivalent to 0 °C).

2.3. Setting Prices for Electricity and Heat Generated in Cogeneration

The cost allocation methods in cogeneration allow an elastic setting of tariffs for the two forms of energy depending on the producer’s management strategies on the energy markets. Thus, between the possible annual receipts and the total operating costs of the cogeneration plant, a balance equation can be established, with the graphical representation in

Figure 2:

The line AB in

Figure 2 indicates the pairs of

pE and

pH values which, for the quantities of energy E and heat H, balance the total operating costs of the cogeneration plant. The electricity price will be the maximum (

pEMax) when the heat is sold for free (

pH = 0), and implicitly, the heat price will be the maximum (

pHMax) when electricity is sold for free (

pE = 0).

The equilibrium Equation (30) must also be corrected with other possible receipts, for example, revenues from different support schemes (

B), but also with the desired profit (

b in %) by the cogeneration energy producer:

If pE0 and pH0 are the average electricity and heat prices existing in the energy markets, it is easy to find the area where the pairs of pE and pH values can be positioned, respectively, above the balance line in the area delimited by points A, B, and C.

2.4. The Use of Dual and Primal Problems in Cogeneration Applications

The dual of a canonical form of maximization is a canonical form of minimization and vice versa:

The system of Equation (32) can be customized to maximize the possible revenues and thus minimize the total operating costs in cogeneration applications.

3. Case Study

A power cogeneration plant (1.287 MWe; 5.386 MWth) based on ORC technology and biomass fuel is used in the case study (

Figure 3). In the case of cogeneration, the abbreviation MWe refers to electrical power and the abbreviation MWth refers to thermal power. The nominal technical characteristics of the CHP plant are presented in

Table 2.

The heat demand of the cogeneration plant is continuous for approximately 8200 h per year, being used for technological purposes for drying wood. The CHP plant entered commercial operation in 2015. The biomass used in the plant is made up of waste resulting from the primary industrialization of wood and from agriculture (wood chips, bark, sawdust straw).

Figure 4 shows the distribution of fuel consumption between the two forms of useful energy generated (heat and electricity) using the allocation methods.

As alternative options for electricity and heat generation, the reference values presented in the EU Regulation [

44] for the same type of fuel were considered (

ηEref = 32% and

ηHref = 86%).

It can be seen in

Figure 4 that the power to heat ratio C (C = E/H) considerably influences the allocation of fuel consumption in the case of the analyzed cogeneration plant. Thus, three allocation methods (alternative electricity generation method, the physical method, and Carnot method) allocate fuel consumption in proportion of approx. 40–50% of the heat generation, and the other three methods (alternative heat generation method, proportional distribution method, and production equivalence method) distribute the fuel consumption in a proportion of approx. 80% of heat generation and only 20% of electricity generation.

The application of allocation methods in the case of the analyzed CHP plant highlights the following extreme cases:

Alternative electricity generation method: 50.10% of the fuel is allocated to electricity generation, the scenario in which all the economy achieved in cogeneration is attributed to heat production with a minimum heat sale price of 20.58 EUR/MWh;

Production equivalence method: 19.18% of the fuel is allocated to the generation of electricity, the scenario that significantly benefits electricity, contributing to the cheapening of its production, with a minimum selling price of electricity of 33.34 EUR/MWh.

Figure 5 shows the heat and electricity prices resulting from the application of fuel allocation methods and fixed and variable costs, respectively.

In

Figure 5, points 1–6 represent the heat and electricity prices resulting from the application of the allocation methods:

Point 1: Alternative electricity generation method;

Point 2: Alternative heat generation method;

Point 3: Proportional distribution method;

Point 4: Production equivalence method;

Point 5: Physical method;

Point 6: Carnot method.

Regardless of the cogeneration technology and the allocation method used, the resulting heat and electricity prices must balance the total costs and the proposed profit.

The variation in the total costs (including the desired profit) or the reduction in heat production will change the shape of the economic characteristic of the cogeneration plant (

Figure 6).

In

Figure 5 and

Figure 6, the line AB represents the economic operation characteristic of the CHP plant on the electricity and heat markets. Point A corresponds to the situation

pE = 0 when the electricity would be delivered for free, all costs being allocated to heat generation; similarly, point B corresponds to the situation

pH = 0 when the heat would be delivered for free, all costs being allocated to electricity generation. Therefore, any distribution of total costs that leads to pairs of

pH and

pE values located on the AB line is mathematically correct. Thus, the multiple possibilities of allocating the operating costs of the cogeneration plant according to different methods are explained, but at the same time, a simple means is available to check the price of heat or electricity if one of them is artificially increased or cheapened.

The cogeneration plant remains competitive on the market only if the prices of heat and electricity are located on the AB line or above it in the area delimited by points A, C, D, and E (

Figure 5). This area decreases accordingly in the case of an increase in total costs (especially due to the purchase of fuel) but also in the case of a reduction in the production of heat and electricity or the duration of operation of the CHP plant (

Figure 6).

A change in the purchase price of the fuel but also in the quantities of heat and electricity delivered from the CHP plant will damage this balance. Thus, the economic market method was extended with a price verification algorithm useful also for making forecast calculations to maintain the profitability of the cogeneration plant in response to changes in production and market conditions.

The objective of the primary problem is to determine the minimum quantities of heat (H) and electricity (E) required to be generated by the cogeneration plant that will balance the production costs and the proposed profit (TCCHP) and the respective maximization of revenues (RCHP).

The primal problem is given in the form:

with the constraints:

and:

where

bE is the fuel consumption for the electricity generation (kWh/kg);

bH is the fuel consumption for the heat generation (kWh/kg);

BCHP is the fuel consumption of the CHP plant (kWh);

vcNFE represents the variable costs (excluding fuel) allocated to electricity (EUR);

vcNFH represents the variable costs (excluding fuel) allocated to heat (EUR);

VCNF represents total variable costs without fuel costs (EUR);

fcE represents the fixed costs allocated to electricity (EUR);

fcH represents the fixed costs allocated to heat (EUR); FC represents total fixed costs (EUR);

NH is the thermal power of the CHP;

NE is the electrical power of the CHP.

With the help of the dual problem, the maximum specific cost of the purchased fuel can be estimated to minimize the total costs and maintain the profitability of the CHP plant on the market:

with the constraints (the dual problem has as many restrictions as the primal problem has variables):

The application of the duality theory assumes that the two functions of revenue maximization and operating cost minimization are equal [

45]:

In this way, additional useful information is obtained in the economic analysis and the substantiation of the decisions regarding the operation of the cogeneration plant. The Excel Solver program was used to solve the optimization problem.

4. Summary Results and Discussion

Depending on the allocation method used, different outputs are obtained for heat and electricity prices.

Table 3 summarizes the results obtained in the reference scenario for a specific fuel cost

pb = 18.95 EUR/MWh.

The analysis of the structure of the annual operating costs of the cogeneration plant shows a major influence of the annual costs with the primary energy source (fuel). Their share of the total costs is all the greater, as the unit cost of fuel increases and as the basic installations of the plant are more modern and with a more advanced degree of automation. A fuel price sensitivity analysis is presented in

Table 4 and

Figure 7. The sensitivity analysis allows the identification of those critical variables of the total operating costs, and it is a useful tool for measuring how their variation (in the sense of decrease or increase) has an impact on the economic performance of the CHP. A fuel price increase of 10% influences the total operating costs of the cogeneration plant by approximately 7%.

The algorithm proposed in this study aims to find the answer to the following question: Can the CHP still be competitive on the energy markets with a significant increase in the price of fuel?

Therefore, a 60% increase in the price of fuel is simulated in the following scenarios (

Table 5 and

Figure 8). In this way, new values of heat and electricity prices are obtained that balance the total costs and allow the CHP to remain profitable in the absence of a support scheme.

Scenarios 1–6 from

Figure 8 correspond to the allocation methods analyzed in this study with the following calculation assumptions:

The value of the electricity price was established as a result of the application of the allocation methods in the new conditions of increasing fuel costs.

The price of heat was considered the same in all scenarios because, as a rule, cogeneration plants supply heat to captive consumers. Therefore, the producer has a monopoly character. However, the producer must propose a lower price or at most equal to the price expected on the thermal energy market if the heat consumer were to opt for an alternative option of separate heat generation. Thus, the producer will remain attractive on the thermal energy market.

Unlike the price of heat, which can be forecasted and kept constant for a longer time, the situation is different in the case of the price of electricity, which is much more volatile, being influenced by the specific conditions of the power markets in which the producer operates: centralized market for bilateral contracts, intraday market, and day ahead market.

The strict application of the allocation methods without being collated with the specific conditions of the power markets can lead to price values located outside the range in which the CHP plant would remain competitive on the market. Such an example can be seen in Scenarios 1 and 6 from

Table 3 where the price of electricity would have exceeded the maximum value expected at a given moment on the market. Therefore, in the simulation, the maximum value expected on the power market was considered for the price of electricity.

Figure 8 shows the minimum quantities of heat and electricity that balance the operating costs (including the desired profit) under the new conditions of increasing the price of the purchased fuel. It can be easily seen that the CHP plant has a reserve of production growth between 7% and 27% (7% in Scenario 4; 27% in Scenario 1 and Scenario 6) which can maximize annual receipts and implicitly increase profit.

The proposed algorithm can be used to obtain additional information useful for establishing the operation strategies of the cogeneration plant on the energy markets, such as fuel price variation, increase in variable costs, increase in fixed costs, the variation in heat and electricity prices on the energy markets, reducing the operating time of the CHP plant, and reducing heat demand.

5. Conclusions

Whatever the cogeneration technology used and the type of energy market in which the cogeneration producer operates, the establishment of electricity and heat prices is based on knowing the costs. The joint generation of electricity and heat from the same primary energy source allows a flexible setting of prices for the two forms of useful energy but conditioned by the particularities of the energy markets and the management strategy of the cogeneration producer.

The prices applied for the sale of heat and electricity are the basis of the economic success of a cogeneration plant in attracting, maintaining, or rejecting consumers of heat and/or electricity.

In this paper, the economic market method was extended with an algorithm based on the duality theory. Thus, the decision makers can have a useful and fast tool for carrying out management strategies and keeping the CHP plant competitive in the energy markets.

An example of a cogeneration plant (1.287 MWe; 5.386 MWth) based on ORC technology is provided in this study. The fuel has the greatest influence on the variable costs and implicitly on the total operating costs of the CHP plant. A 60% increase in fuel prices was simulated in all scenarios, resulting in a 41% increase in total operating costs. Under the conditions of keeping the price of heat at a constant value (48.60 EUR/MWh), the price of electricity has the most competitive values in scenarios 3–5 (58.67–71.02 EUR/MWh) with a production reserve between 7% and 11%, sufficient for maximizing the profit. In scenarios 1, 2, and 6, the price of electricity has less attractive values, being located towards the maximum limit expected on the market (104.83–130 EUR/MWh) but with a larger production reserve (21–27%) that can maximize the producer’s profit of energy in cogeneration.

Therefore, depending on the type of energy markets it operates on (regulated or competitive), the cogeneration producer has a useful tool for performing economic market analyses and establishing operating strategies for the CHP plant.