Comprehensive Analysis of the State of Technology in the Field of Waste Heat Recovery from Grey Water

Abstract

:1. Introduction

2. Materials and Methods

3. Theoretical Background

4. DWHR Applications in Domestic Conditions

4.1. General Classification of DWHR Units

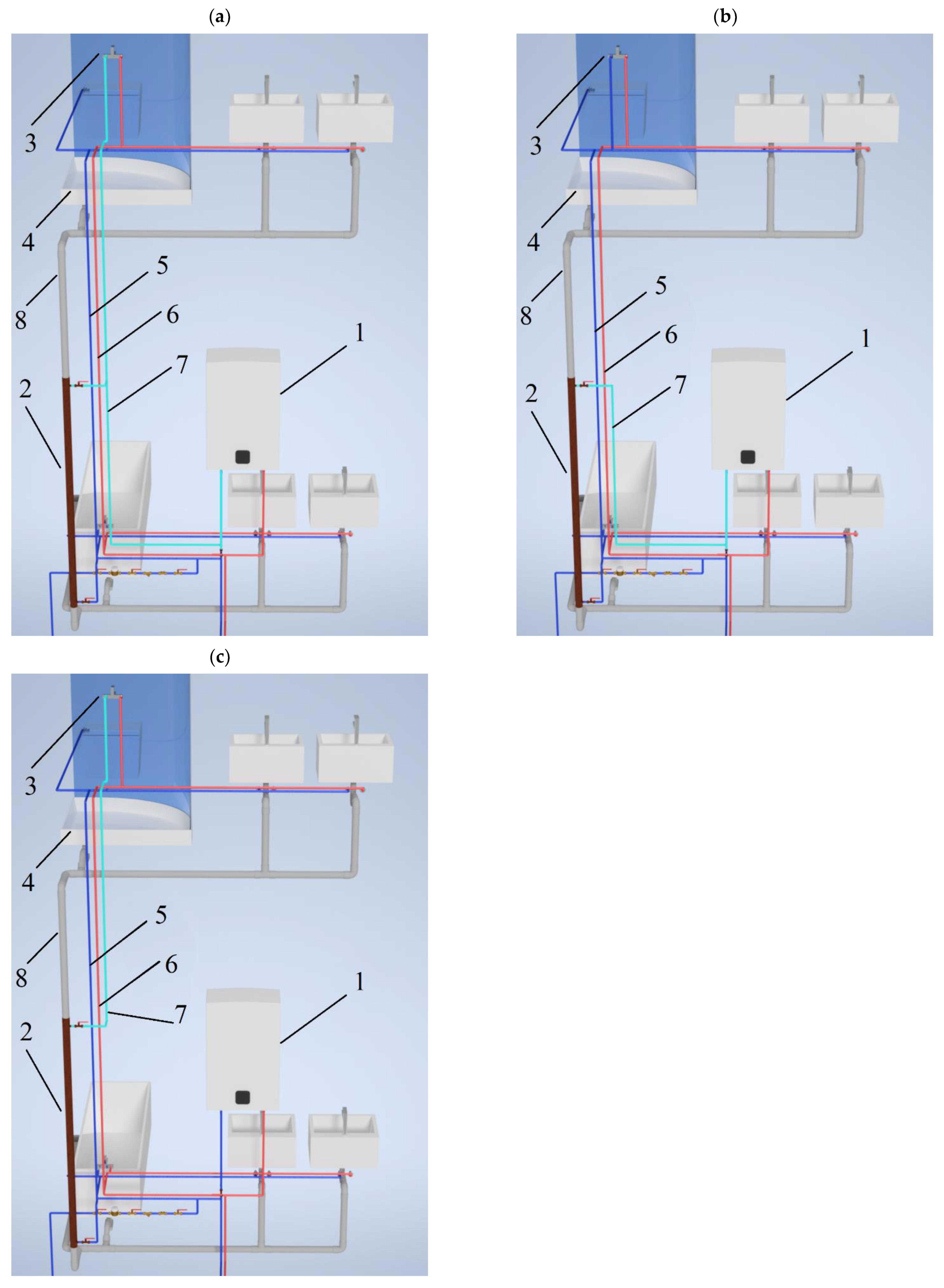

4.2. Variants of Heat Exchanger Installation

4.3. DWHR Standards

4.4. A Short Review of Published Studies

5. Results and Discussion

5.1. Horizontal Heat Exchangers

5.2. Vertical Heat Exchangers

5.3. Financial Legitimacy of the Use of Heat Exchangers

5.4. The Concept of the Circular Economy in the Energy Sector

6. Conclusions

7. Future Directions

- Scientific and industrial research aimed at developing solutions and technologies for low-cost production of heat exchangers and improving their energy efficiency. Activities in this area may be of significant importance for the profitability of industrial production and the financial viability of using these types of solutions.

- Undertaking educational activities aimed at increasing environmental awareness related to the use of waste heat as the most ecological and cheapest way of obtaining energy.

- Implementation of a financial support system for investments in waste heat recovery by individual and institutional recipients for existing and newly built facilities, for various purposes.

- Development of publicly available, reliable tools to calculate the profitability of investments related to the use of heat recovery systems.

- Development of design tools, including building information modeling (BIM) technology, to facilitate the design, selection and management of investment projects.

- Action by public administration bodies, in consultation with research institutes, to develop a common strategy for promoting the CE in the energy sector and in construction.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- AR6 Synthesis Report: Climate Change. Available online: https://www.ipcc.ch/report/ar6/wg1/downloads/report/IPCC_AR6_WGI_Full_Report.pdf (accessed on 3 September 2022).

- Mrazek, M.; Honc, D.; Sanseverino, E.R.; Zizzo, G. Simplified Energy Model and Multi-Objective Energy Consumption Optimization of a Residential House. Appl. Sci. 2022, 12, 10212. [Google Scholar] [CrossRef]

- Mukhtarov, S.; Aliyev, F.; Aliyev, J.; Ajayi, R. Renewable Energy Consumption and Carbon Emissions: Evidence from an Oil-Rich Economy. Sustainability 2023, 15, 134. [Google Scholar] [CrossRef]

- EIA. International Energy Outlook 2019. U.S. Energy Information Administration. Available online: https://www.eia.gov/outlooks/ieo/pdf/ieo2019.pdf (accessed on 1 August 2022).

- Adoption of the Paris Agreement. Available online: http://unfccc.int/resource/docs/2015/cop21/eng/l09r01.pdf (accessed on 1 September 2022).

- International Energy Agency. World Energy Outlook 2019. Flagship Report-November 2019. Available online: https://www.iea.org/topics/world-energy-outlook (accessed on 3 April 2020).

- EIA. International Energy Renewables 2019. U.S. Energy Information Administration. Available online: https://www.iea.org/reports/renewables-2019 (accessed on 2 April 2020).

- Hernandez-Morales, A.; Hernandez, A. Europe’s Energy Freakout, Politico, 19. Available online: https://www.politico.eu/article/europe-energy-crisis-pipeline-natural-gas-eu (accessed on 1 September 2022).

- European Commission. Communication. Tackling Rising Energy Prices: A Toolbox for Action and Support. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:52021DC0660&from=EN (accessed on 1 September 2022).

- IEA. Net Zero by 2050: A Roadmap for the Global Energy Sector, 4th Revision, October 2021. Available online: https://www.iea.org/reports/net-zero-by-2050 (accessed on 1 September 2022).

- European Green Deal. Available online: https://ec.europa.eu/info/sites/default/files/european-green-deal-communication_en.pdf (accessed on 1 September 2022).

- Energy Policy of Poland until 2040. Available online: https://www.gov.pl/web/climate/energy-policy-of-poland-until-2040-epp2040 (accessed on 1 September 2022).

- Popkostova, Y. Europe’s Energy Crisis Conundrum—Publications Office of the EU, 2022. European Union Institute for Security Studies. Available online: https://www.iss.europa.eu/sites/default/files/EUISSFiles/Brief_2_Energy%20Crisis.pdf (accessed on 1 September 2022).

- Soboń, A.; Słyś, D.; Ruszel, M.; Wiącek, A. Prospects for the Use of Hydrogen in the Armed Forces. Energies 2021, 14, 7089. [Google Scholar] [CrossRef]

- Ruszel, M.; Maslon, A.; Ogarek, P. Analysis of biogas from sewage sludge digestion in terms of diversification in the natural gas production structure in Poland. Desalination Water Treat. 2021, 232, 298–307. [Google Scholar] [CrossRef]

- Hernández-Chover, V.; Castellet-Viciano, L.; Hernández-Sancho, F. A Tariff Model for Reclaimed Water in Industrial Sectors: An Opportunity from the Circular Economy. Water 2022, 14, 3912. [Google Scholar] [CrossRef]

- Siuta-Tokarska, B.; Thier, A.; Hornicki, K. The Concept of Extended Producer Responsibility in the Field of Packaging Industry and the Energy Sector in the Light of the Circular Economy—The Example of Poland. Energies 2022, 15, 9060. [Google Scholar] [CrossRef]

- Zhang, Y.; Grant, A.; Sharma, A.; Chen, D.; Chen, L. Alternative water resources for rural residential development in Western Australia. Water Resour. Manag. 2010, 24, 25–36. [Google Scholar] [CrossRef]

- Christoff, P. The promissory note: COP 21 and the Paris Climate Agreement. Environ. Politics 2016, 25, 765–787. [Google Scholar] [CrossRef]

- Meggers, F.; Leibundgut, H. The potential of wastewater heat and exergy: Decentralized high-temperature recovery with a heat pump. Energy Build. 2011, 43, 879–886. [Google Scholar] [CrossRef]

- Vatansever, D.; Siores, E.; Shah, T. Alternative Resources for Renewable Energy: Piezoelectric and Photovoltaic Smart Structures. Glob. Warm. Impacts Future Perspect. 2012, 263–290. [Google Scholar] [CrossRef]

- Semkov, K.; Mooney, E.; Connolly, E.; Adley, C. Efficiency improvement through waste heat reduction. Appl. Therm. Eng. 2014, 70, 716–722. [Google Scholar] [CrossRef]

- Ravichandran, A.; Diaz-Elsayed, N.; Thomas, S.; Zhang, Q. An assessment of the influence of local conditions on the economic and environmental sustainability of drain water heat recovery systems. J. Clean. Prod. 2021, 279, 123589. [Google Scholar] [CrossRef]

- Manouchehri, R.; Collins, M.R. Investigating the Impact of Plumbing Configuration on Energy Savings for Falling-Film Drain Water Heat Recovery Systems. Energies 2022, 15, 1141. [Google Scholar] [CrossRef]

- Paska, J.; Surma, T.; Terlikowski, P.; Zagrajek, K. Electricity Generation from Renewable Energy Sources in Poland as a Part of Commitment to the Polish and EU Energy Policy. Energies 2020, 13, 4261. [Google Scholar] [CrossRef]

- Efficiency of Energy Use in 2010–2020 in Poland. Available online: https://stat.gov.pl/files/gfx/portalinformacyjny/pl/defaultaktualnosci/5485/1/9/1/energia_2021.pdf (accessed on 1 September 2022).

- Natural Resources Canada. Available online: https://oee.nrcan.gc.ca/corporate/statistics/neud/dpa/showTable.cfm?type=CP§or=res&juris=ca&rn=2&page=0 (accessed on 1 September 2022).

- Schmid, F. Sewage water: Interesting heat source for heat pumps and chillers. In Proceedings of the 9th International IEA Heat Pump Conference, Zürich, Switzerland, 22 May 2008; pp. 1–12. [Google Scholar]

- Wehbi, Z.; Taher, R.; Faraj, J.; Ramadan, M.; Castelain, C.; Khaled, M. A short review of recent studies on wastewater heat recovery systems: Types and applications. Energy Rep. 2022, 8, 896–907. [Google Scholar] [CrossRef]

- Ritchie, H.; Max Roser, M.; Rosado, P. Energy Production and Consumption. Available online: https://ourworldindata.org/energy (accessed on 1 September 2022).

- Wanjiru, E.; Xia, X. Optimal energy-water management in urban residential buildings through grey water recycling. Sustain. Cities Soc. 2017, 32, 654–668. [Google Scholar] [CrossRef] [Green Version]

- Stec, A.; Kordana, S. Analysis of profitability of rainwater harvesting, gray water recycling and drain water heat recovery systems. Resour. Conserv. Recycl. 2015, 105, 84–94. [Google Scholar] [CrossRef]

- Larrinaga, P.; Campos-Celador, A.; Legarreta, J.; Diarce, G. Evaluation of the theoretical, technical and economic potential of industrial waste heat recovery in the Basque Country. J. Clean. Prod. 2021, 312, 127494. [Google Scholar] [CrossRef]

- Vavrin, J.L. A Quantitative Study of the Viability of Greywater Heat Recovery (GWHR); Defense Technical Information Center: Belvoir Fort, VA, USA, 2011.

- Boyjoo, Y.; Pareek, V.K.; Ang, M. A review of greywater characteristics and treatment processes. Water Sci. Technol. 2013, 67, 1403–1424. [Google Scholar] [CrossRef]

- Pomianowski, M.Z.; Johra, H.; Marszal-Pomianowska, A.; Zhang, C. Sustainable and energy-efficient domestic hot water systems: A review. Renew. Sustain. Energy Rev. 2020, 128, 109900. [Google Scholar] [CrossRef]

- Oteng-Peprah, M.; Acheampong, M.A.; de Vries, N.K. Greywater Characteristics, Treatment Systems, Reuse Strategies and User Perception—A Review. Water Air Soil Pollut. 2018, 229, 255. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Muneer, T.; Jorge, K.; Thomas, G. Heat Transfer: A Problem Solving Approach, 1st ed.; Taylor & Francis Group: Abingdon, UK, 2013. [Google Scholar]

- Zarzycki, R. Wymiana Ciepła i Ruch Masy w Inżynierii Środowiska; Wydawnictwo Naukowo-Techniczne: Warszawa, Poland, 2005. [Google Scholar]

- Zhang, P.; Ye, J.; Zeng, G. Thermal Effects. Water Environ. Res. 2015, 87, 1901–1913. [Google Scholar] [CrossRef] [PubMed]

- Zagórski, J. Zarys Techniki Cieplnej; Wydawnictwo Naukowo-Techniczne: Warszawa, Poland, 1993. [Google Scholar]

- Cipolla, S.S.; Maglionico, M. Heat recovery from urban wastewater: Analysis of the variability of flow rate and temperature in the sewer of Bologna, Italy. Energy Procedia 2014, 45, 288–297. [Google Scholar] [CrossRef] [Green Version]

- Chudzicki, J.; Sosnowski, S. Instalacje Kanalizacyjne. Projektowanie, Wykonanie, Eksploatacja. Wydanie Trzecie; Wydawnictwo Seidel-Przywecki: Warszawa, Poland, 2011. [Google Scholar]

- Juan, Y.K.; Chen, Y.; Lin, J.M. Greywater reuse system design and economic analysis for residential buildings in Taiwan. Water 2016, 8, 546. [Google Scholar] [CrossRef]

- DIN-EN 12056-2; Gravity Drainage Systems Inside Buildings—Part 2: Sanitary Pipework, Layout and Calculation. British Standards Institution: London, UK, 2001.

- Vavricka, R.; Bohac, J.; Matuska, T. Experimental development of the plate shower heat exchanger to reduce the domestic hot water energy demand. Energy Build. 2022, 254, 111536. [Google Scholar] [CrossRef]

- Kordana, S. SWOT analysis of wastewater heat recovery systems application. In Proceedings of the 9th Conference on Interdisciplinary Problems in Environmental Protection and Engineering EKO-DOK, Boguszow-Gorce, Poland, 23–25 April 2017. [Google Scholar]

- Kimmels, A. Shower Heat Recovery Systems. Meander Heat Recovery. Available online: http://www.meanderhr.com/report/meanderhr_com_shower_dwhr_overview.pdf (accessed on 1 September 2022).

- Marszal-Pomianowska, A.; Jensen, R.L.; Pomianowski, M.; Larsen, O.K.; Jørgensen, J.S.; Knudsen, S.S. Comfort of Domestic Water in Residential Buildings: Flow, Temperature and Energy in Draw-Off Points: Field Study in Two Danish Detached Houses. Energies 2021, 14, 3314. [Google Scholar] [CrossRef]

- Nagpal, H.; Spriet, J.; Murali, M.; McNabola, A. Heat Recovery from Wastewater—A Review of Available Resource. Water 2021, 13, 1274. [Google Scholar] [CrossRef]

- Kordana-Obuch, S.; Starzec, M.; Słyś, D. Assessment of the Feasibility of Implementing Shower Heat Exchangers in Residential Buildings Based on Users’ Energy Saving Preferences. Energies 2021, 14, 5547. [Google Scholar] [CrossRef]

- Mazhar, A.; Liu, S.; Shukla, A. A key review of non-industrial greywater heat harnessing. Energies 2018, 11, 386. [Google Scholar] [CrossRef] [Green Version]

- Piotrowska, B.; Słyś, D.; Kordana-Obuch, S.; Pochwat, K. Critical Analysis of the Current State of Knowledge in the Field of Waste Heat Recovery in Sewage Systems. Resources 2020, 9, 72. [Google Scholar] [CrossRef]

- Collins, M.R.; van Decker, G.W.E.; Murray, J. Characteristic effectiveness curves for falling-film drain water heat recovery systems. HVACR Res. 2013, 19, 649–662. [Google Scholar]

- Tomlinson, J. Heat Recovery from Wastewater Using a Gravity-Film Heat Exchanger. Federal Energy Management Program, Department of Energy, Washington, DC, USA, 2005. Available online: http://gfxtechnology.com/Femp-ORNL.pdf (accessed on 29 November 2022).

- Directive (EU) 2018/2001 on the Promotion of the Use of Energy from Renewable Sources. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/HTML/?uri=LEGISSUM:4372645 (accessed on 25 November 2022).

- Ratajczak, K.; Michalak, K.; Narojczyk, M.; Amanowicz, Ł. Real Domestic Hot Water Consumption in Residential Buildings and Its Impact on Buildings’ Energy Performance—Case Study in Poland. Energies 2021, 14, 5010. [Google Scholar] [CrossRef]

- Niewitecka, K. Possibilities of heat energy recovery from greywater systems. The First Conference of the International Water Association IWA for Young Scientist in Poland “Water, Wastewater and Energy in Smart Cities”. ES3 Web Conf. 2018, 30, 03003. [Google Scholar] [CrossRef] [Green Version]

- 2019-RES-DHW2-F; Codes and Standards Enhancement (CASE) Initiative, California Building Energy Efficiency Standards Drain Water Heat Recovery—Final Report; Residential Plumbing. 2017. Available online: https://title24stakeholders.com/wp-content/uploads/2017/09/2019-T24-CASE-Report_DWHR_Final_September-2017.pdf (accessed on 15 December 2022).

- CSA. B55.1-15; Test Method for Measuring Efficiency and Pressure Loss of Drain Water Heat Recovery Units. Canadian Standards Association: Mississauga, ON, Canada, 2015.

- IAPMO IGC 346-2017; Test Method for Measuring the Performance of Drain Water Heat Recovery Units. IAPMO: Ontario, CA, USA, 2017.

- BS EN 1717:2000; Protection Against Pollution of Potable Water in Water Installations and General Requirements of Devices to Prevent Pollution by Backflow. BSI Standards Publication: London, UK, 2000.

- Ip, K.; She, K. Waste heat recovery from showers: Case study of a university sport facility in the UK. Water Effic. Conf. 2016, 114–121. Available online: http://www.watefnetwork.co.uk/files/default/resources/Conference2016/WatefCon2016_Proceedings.pdf (accessed on 4 December 2022).

- Danish Energy Agency. Regulation and Planning of District Heating in Denmark; Danish Energy Agency: København, Denmark, 2016; p. 27.

- Bøhm, B.; Schrøder, F.; Bergsøe, N.C. Varmt Brugsvand—Måling af Forbrug og Varmetab fra Cirkulationsledninger; SBI Forlag: Hoersholm, Denmark, 2009. [Google Scholar]

- Prado, R.T.A.; Gonçalves, M. Water heating through electric shower and energy demand. Energy Build. 1998, 29, 77–82. [Google Scholar] [CrossRef]

- Peereboo, P.W.E.; Visser, J.C. Recovering heat from shower water in dwellings. In Proceedings of the CIBW062 Symposium on Water Supply and Drainage for Buildings, Sydney, Australia, 8-10 November 1998. [Google Scholar]

- de Paepe, M.; Theuns, E.; Lenaers, S.; van Loon, J. Heat recovery system for dishwashers. Appl. Therm. Eng. 2003, 23, 743–756. [Google Scholar] [CrossRef]

- Bartkowiak, S.; Fisk, R.; Funk, A.; Hair, J.; Skerlos, S.J. Residential drain water heat recovery systems: Modeling, analysis, and implementation. J. Green Build. 2010, 5, 85–94. [Google Scholar] [CrossRef] [Green Version]

- McNabola, A.; Shields, K. Efficient drain water heat recovery in horizontal domestic shower drains. Energy Build. 2013, 59, 44–49. [Google Scholar] [CrossRef]

- Torras, S.; Oliet, C.; Rigola, J.; Oliva, A. Drain water heat recovery storage-type unit for residential housing. Appl. Therm. Eng. 2016, 103, 670–683. [Google Scholar] [CrossRef] [Green Version]

- Kordana, S. An assessment of the potential for shower water heat recovery. E3S Web Conf. 2018, 45, 00034. [Google Scholar] [CrossRef]

- Kordana, S.; Słyś, D. Analysis of profitability of using a heat recovery system from grey water discharged from the shower (case study of Poland). E3S Web Conf. 2017, 22, 00085. [Google Scholar] [CrossRef] [Green Version]

- Manouchehri, R.; Collins, M.R. An experimental analysis of the impact of temperature on falling film drain water heat recovery system effectiveness. Energy Build. 2016, 130, 1–7. [Google Scholar] [CrossRef]

- Słyś, D.; Kordana, S. Financial analysis of the implementation of a Drain Water Heat Recovery unit in residential housing. Energy Build. 2014, 71, 1–11. [Google Scholar] [CrossRef]

- Zaloum, C.; Gusdorf, J.; Parekh, A. Drainwater Heat Recovery Performance Testing at Canadian Centre for Housing Technology; Technical Series, CCHT, 07-116; Canada Mortgage and Housing Corporation: Ottawa, ON, Canada, 2007. [Google Scholar]

- Shields, K. Drain Water Heat Recovery. Master’s Thesis, Trinity College Dublin, Dublin, Ireland, 2011. [Google Scholar]

- Wong, L.T.; Mui, K.W.; Guan, Y. Shower water heat recovery in high rise residential buildings of Hong Kong. Appl. Energy 2010, 87, 703–709. [Google Scholar] [CrossRef]

- MacKelvie, W. Composite Pipe Heat Exchanger for Drainwater Heat Recovery. U.S. Patent Application No. 20130306289, 20 September 2016. [Google Scholar]

- Schmid, R.; Svaton, R.; Rusch, C. Heat Exchanger for a Shower or Bathtub. U.S. Patent Application No. US 10072897 B2, 10 September 2018. [Google Scholar]

- Żakowski, P. Shower Heat Exchanger Made of Typical Sewer Components. The Patent Office of the Republic of Poland Number W.129137, 27 April 2020. Available online: https://ewyszukiwarka.pue.uprp.gov.pl/search/pwp-details/W.129137?lng=pl (accessed on 1 September 2022).

- Kramarz, J. Sewr-Type Heat Absorber. The Patent Office of the Republic of Poland Number Pat.196379, 25 July 2000. [Google Scholar]

- MacKelvie, W. Drainwater Heat Recovery System. U.S. Patent Application No. US 2001/0004009 A1, 21 June 2001. [Google Scholar]

- Shower Heat Exchanger IZi30/IZi40 (ZYPHO) (PCT054506). Available online: https://www.zypho.pt/?it=base_home&nlg=16 (accessed on 1 September 2022).

- Mazur, A.; Stec, A.; Słyś, D. Horizontal Shower-Type Heat Exchanger. The Patent Office of the Republic of Poland Number Patent 234930, 2 January 2020. [Google Scholar]

- Mazur, A.; Słyś, D.; Dziopak, J. Horizontal Heat Exchanger. The Patent Office of the Republic of Poland Number Patent 230906, 3 September 2018. [Google Scholar]

- Mazur, A.; Stec, A.; Słyś, D. Linear Drainage with Heat Recovery. The Patent Office of the Republic of Poland Number Patent 230648, 11 October 2017. [Google Scholar]

- Kordana-Obuch, S.; Starzec, M. Horizontal Shower Heat Exchanger as an Effective Domestic Hot Water Heating Alternative. Energies 2022, 15, 4829. [Google Scholar] [CrossRef]

- Cardone, J. Shower Heat Exchanger with Clog-Removable Drain. U.S. Patent Application No. US8104532B2, 28 April 2011. [Google Scholar]

- Gilbert, G. Heat Exchange Devices. United. United States Patent No. US8893319 B2, 25 November 2014. [Google Scholar]

- Nobile, J.R. Heat Exchanger and Use Thereof in Showers. U.S. Patent Application No. 20080000616A1, 3 January 2008. [Google Scholar]

- Zaloum, C.; Lafrance, M.; Gusdorf, J. Drain Water Heat Recovery: Characterisation and Modelling; Final Report; Sustainable Buildings & Communities, Natural Resources Canada: Ottawa, ON, Canada, 2007. [Google Scholar]

- Wallin, J.; Claesson, J. Investigating the efficiency of a vertical inline drain water heat recovery heat exchanger in a system boosted with a heat pump. Energy Build. 2014, 80, 7–16. [Google Scholar] [CrossRef]

- Kramarz, J. Cascade Spiral Heat Exchanger. The Patent Office of the Republic of Poland Number Rp. 25423, 23 May 2019. [Google Scholar]

- Van Decker, G.W.E.; Watts, C.M. Helical Coil on Tube Heat Exchanger. U.S. Patent Application No. US20130025836A1, 31 January 2013. [Google Scholar]

- Mazur, A.; Stec, A.; Słyś, D. Vertical Spiral Heat Exchanger. The Patent Office of the Republic of Poland Number Patent 230910, 17 January 2018. [Google Scholar]

- Shower Heat Exchanger PiPe DW/PiPe (ZYPHO). Available online: https://www.zypho.pt/?it=base_home&nlg=16 (accessed on 1 September 2022).

- Stec, A.; Mazur, A.; Słyś, D. Vertical Heat Exchanger. The Patent Office of the Republic of Poland Number Patent 230590, 2 July 2018. [Google Scholar]

- Kramarz, J. Method of and Apparatus for Recuperating Waste Heat from Waste Water. The Patent Office of the Republic of Poland Number Patent 198134, 24 January 2001. [Google Scholar]

- Brunn, J. Grey Water Heat Recovery System. U.S. Patent Application No. US 2011/0155366 A1, 30 June 2011. [Google Scholar]

- Vaillancourt Mario, M.V. Heat Recovery Unit for Gray Water Equipped with a Protection Method and Device Preventing Contamination of Potable Water. Innovation, Science and Economic Development Canada Patent Publication Number CA2991210A1, 24 July 2018. [Google Scholar]

- Nolde, E. Water and energy recycling at a residential passive house. In Proceedings of the Poster Sustainable Building Conference, Graz, Austria, 25–28 September 2013; pp. 1353–1360. [Google Scholar]

- D’Adamo, I. Adopting a Circular Economy: Current Practices and Future Perspectives. Soc. Sci. 2019, 8, 328. [Google Scholar] [CrossRef] [Green Version]

- Mignacca, B.; Locatelli, G.; Velenturf, A. Modularisation as enabler of circular economy in energy infrastructure. Energy Policy 2020, 139, 111371. [Google Scholar] [CrossRef]

- Azevedo, S.G.; Godina, R.; de Oliveira Matias, J.C. Proposal of a Sustainable Circular Index for Manufacturing Companies. Resources 2017, 6, 63. [Google Scholar] [CrossRef] [Green Version]

- Rokicki, T.; Perkowska, A.; Klepacki, B.; Szczepaniuk, H.; Szczepaniuk, E.K.; Bereziński, S.; Ziółkowska, P. The Importance of Higher Education in the EU Countries in Achieving the Objectives of the Circular Economy in the Energy Sector. Energies 2020, 13, 4407. [Google Scholar] [CrossRef]

- Zorpas, A.A.; Doula, M.K.; Jeguirim, M. Waste Strategies Development in the Framework of Circular Economy. Sustainability 2021, 13, 13467. [Google Scholar] [CrossRef]

- de Medeiros, A.D.M.; da Silva Junior, C.J.G.; de Amorim, J.D.P.; do Nascimento, H.A.; Converti, A.; Costa, A.F.d.S.; Sarubbo, L.A. Biocellulose for Treatment of Wastewaters Generated by Energy Consuming Industries: A Review. Energies 2021, 14, 5066. [Google Scholar] [CrossRef]

- Circular Economy Report—Opportunities and Challenges. Available online: https://www.fortum.pl/media/5240/download (accessed on 12 December 2022).

- Sáez-de-Guinoa, A.; Zambrana-Vasquez, D.; Fernández, V.; Bartolomé, C. Circular Economy in the European Construction Sector: A Review of Strategies for Implementation in Building Renovation. Energies 2022, 15, 4747. [Google Scholar] [CrossRef]

- Andreou, A.; Fragkos, P.; Fotiou, T.; Filippidou, F. Assessing Lifestyle Transformations and Their Systemic Effects in Energy-System and Integrated Assessment Models: A Review of Current Methods and Data. Energies 2022, 15, 4948. [Google Scholar] [CrossRef]

- Neczaj, E.; Grosser, A. Circular Economy in Wastewater Treatment Plant—Challenges and Barriers. Proceedings 2018, 2, 614. [Google Scholar]

- Janik, A.; Ryszko, M. Szafraniec, Greenhouse Gases and Circular Economy Issues in Sustainability Reports from the Energy Sector in the European Union. Energies 2020, 13, 5993. [Google Scholar] [CrossRef]

- Clean Energy for All Europeans—Unlocking Europe’s Growth Potential. Available online: https://ec.europa.eu/commission/presscorner/detail/en/IP_16_4009 (accessed on 1 September 2022).

- Photovoltaics Micro- Installations in Poland. Available online: http://www.ptpiree.pl/energetyka-w-polsce/energetyka-w-liczbach/mikroinstalacje-w-polsce (accessed on 17 October 2022).

- PV Market in Poland 202. Available online: https://ieo.pl/en/pv-report (accessed on 17 October 2022).

- Clean Air Program. Available online: https://czystepowietrze.gov.pl (accessed on 24 October 2022).

- My Power. Available online: https://mojprad.gov.pl (accessed on 24 October 2022).

- RES Index in Poland. Available online: https://alians-oze.pl/?aktualnosci=oze-index-62-polakow-decyduje-sie-na-fotowoltaike-ze-wzgledu-na-oszczednosci (accessed on 16 October 2022).

| Studies | Title of the Invention/Device Type | General Features/Research Conclusions |

|---|---|---|

| [79] | composite pipe heat exchanger for drainwater heat recovery | a heat exchanger in the form of a horizontal drain containing the upper and lower composite pipes sealed together along respective longitudinal edges; the exchanger is made of copper and plastic in order to reduce production costs; (US 20130306289) |

| [80] | heat exchanger for a shower or bathtub | counterflow heat exchanger for installation under the shower trays and bathtubs; equipped with grey water drain; the cold water duct consists of a long pipe coiled in the grey water drain; the cold water pipe is coiled into several pipes arranged horizontally with respect to the orientation of the exchanger; the invention is made of plastic elements (tubes, partitions) to minimize production costs; (US10072897B2) |

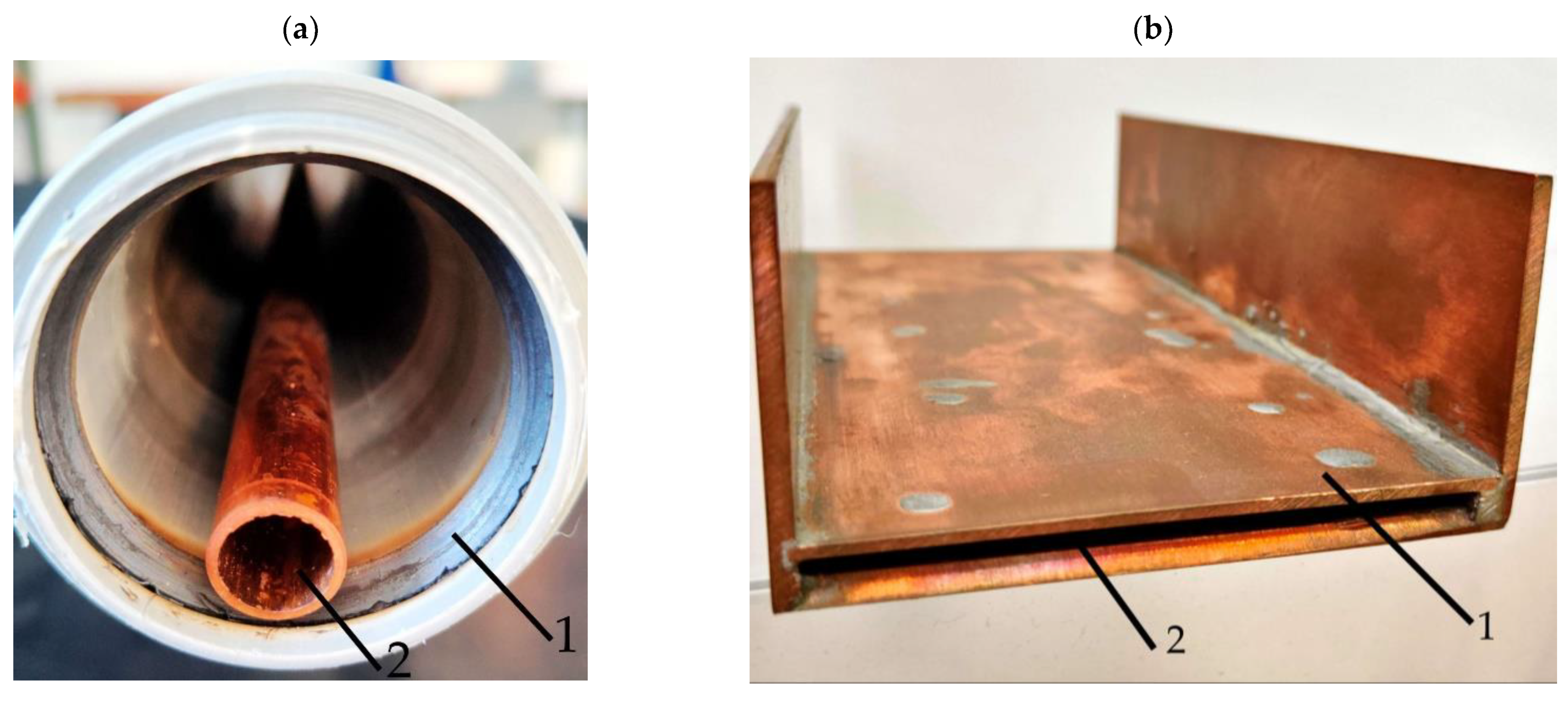

| [81] | shower heat exchanger made of typical sewer components | horizontal shower heat exchanger made of waste water fittings and a spiral copper coil placed in them; sewage inlet takes place at an angle of 45° to the axis of the device; (W.129137) |

| [82] | sewer-type heat absorber | the exchanger consists of a grey water drain; the drain is designed centrally and has two or more cold water supply pipes arranged on its circumference |

| [83] | drainwater heat recovery system | heat exchanger composed of a grey water drain, a cold water drain and a non-pressurized tank; horizontal and vertical installation of an exchanger is disclosed; (US 2001/0004009 A1) |

| [70] | horizontal DWHR | the heat exchanger is made of PVC drainage with a diameter of 40 mm, in which a copper water pipe with a diameter of 12.7 mm is placed; the possible efficiency of the device exceeds 50% |

| [84] | horizontal heat exchanger | device for heat recovery from grey water from shower drain; reduces energy consumption by up to 31%; the maximum amount of grey water supplied to the device is 25 dm3/min; (PCT054506) |

| [84] | horizontal heat exchanger | device for heat recovery from grey water from shower drain; reduces energy consumption by up to 39%; the maximum amount of grey water supplied to the device is 12.5 dm3/min; (PCT054506) |

| [85] | horizontal shower-type heat exchanger | horizontal shower heat exchanger with countercurrent grey and cold water flow; made of a waste water drain and a sealed internal drain through which water flows; the grey water drain is in the form of a rectangular chamber placed in the floor; a heat exchanger is to be installed in the shower tray or directly in the bathroom floor; (Pat.234930) |

| [86] | horizontal heat exchanger | horizontal heat exchanger with countercurrent grey and cold water flow; built with sealed grey water channel and internal cold water channel; inside the casing, there are at least two internal channel partitions; the horizontal heat exchanger is used in particular to recover waste heat from grey water; (Pat.230906) |

| [87] | linear drainage with heat recovery | linear shower drain with heat recovery comprises a casing with a top cover which is an inlet opening for grey waste water; the exchanger consists of a channel separated by a tight wall; grey water flows in the upper part of the channel of the device, and cold water is led in the lower part; linear shower drain with heat recovery is intended for installation both in showers with and without a shower tray; in the absence of a shower tray, the linear drainage is installed in the floor in the area of the shower stall; (Pat.230648) |

| [88] | horizontal shower heat exchanger | compact shower heat exchanger designed for installation under the shower tray, as well as a linear shower drain with heat recovery; research has shown that the compact shower heat exchanger has a higher efficiency (22.43% to 31.82%) than its linear counterpart (23.03%) |

| [89] | shower heat exchanger with clog-removable drain | heat exchanger for installation under the bathtub or shower tray or under the bathroom floor; built of upper and lower channels; the lower channel through which the water flows is wavy; (US8104532B2) |

| [90] | heat exchange devices | exchanger made of two outlets—one for cold water, and the other for grey water; the cold water drain forms sections of the pipes in the serpentine system passing through the grey water drain, the exchanger uses countercurrent media flow; (US 8893319 B2) |

| [91] | heat exchanger and use thereof in showers | heat exchanger made out of two systems of drains; the first set of drains comprises horizontal pipes through which grey water is discharged; the second drain set comprises vertical and horizontal pipes for supplying cold water to the installation; horizontal cold water drains are placed inside the horizontal grey water drains; the pipes in the horizontal plane additionally form a loop in order to increase the heat exchange surface while maintaining the compactness of the exchanger; (20080000616A1) |

| Studies | Title of the Invention/Device Type | General Features/Research Conclusions |

|---|---|---|

| [93] | vertical spiral heat exchanger | heat exchanger consists of a vertical copper drain for grey water around which a copper drain for cold water is wrapped; available heat exchange surface for grey water drain at 0.20 m2; available heat exchange surface for a cold water drain of 0.57 m2; the possibility of heat recovery from waste water at the level of 25% |

| [94] | cascade spiral heat exchanger | cascade spiral heat exchanger in the form of connected drains of different diameters, one of which is wrapped in a spiral on a drain of larger diameter; intended to recover heat lost in the process of discharging domestic grey water from buildings and industrial grey water from facilities; (Rp.25423) |

| [95] | helical coil on tube heat exchanger | heat exchanger with a spiral pipe for cold water; the spiral drain is wrapped around the main grey water drain; the unit has fixed tube assemblies for both heat transfer media; (US20130025836A1) |

| [81] | shower heat exchanger made of typical sewer components | horizontal shower heat exchanger made of waste water fittings and a spiral copper coil placed in them; grey water inlet is arranged at an angle of 45° to the axis of the device; (W.129137) |

| [96] | vertical spiral heat exchanger | vertical spiral heat exchanger with countercurrent grey and cold water flow; built of a grey water pipe inside, with a tight spiral pipe for cold water, around it. The inner channel is equipped with the so-called helically arranged plates around the vertical axis of the heat exchanger; placed along the entire height of the sewage pipe; (Pat.230910) |

| [97] | vertical heat exchanger | vertical tube-in-tube exchanger with heat recovery for shower trays, shower drains or bathtubs, with a recommended flow of up to 12.5 dm3/min; energy savings of up to 64% possible |

| [97] | vertical heat exchanger | vertical tube-in-tube exchanger with heat recovery for shower trays, shower drains or bathtubs, with a recommended flow of up to 25 dm3/min; energy savings of up to 75% possible |

| [98] | vertical heat exchanger | vertical heat exchanger with an outer drain with grey water inside; grey water flows through the main vertical pipe, with space between the outer pipe and the main grey water pipe through which cold water is routed counter- currently and fed to the heat exchanger; (Pat.230590) |

| [99] | method of and apparatus for recuperating waste heat from waste water | heat exchanger for recovering grey water heat, in particular domestic sewage discharged into the sewage system, taking into account the separation of cold and warm waste water by means of a pressure-temperature valve; the heat is collected by the water to be heated in the domestic hot water preparation installation; the device allows for a minimum 50% savings in energy consumption needed to heat domestic water; (Pat.198134) |

| [100] | grey water heat recovery system | exchanger with a copper coil for cold water supply; the coil is placed inside the vertical grey water drain; the device may use a countercurrent geometry and is equipped with a controller that directs grey water through the bypass pipe; the device includes a dirt filter; the controller informs about the need to clean the filter; (US 2011/0155366 A1) |

| [101] | heat recovery unit for grey water equipped with a protection method and device preventing contamination of potable water | heat recovery installation consisting of grey water drain, heat exchanger, check valve, anode; the device is a recuperator with the function of removing heat contained in waste water in order to heat the water supplied to the bathtub or shower or water heater; the heat exchanger is an external vessel made of high-quality stainless steel; (CA2991210A1) |

| Location of Heat Exchanger Units | DWHR Unit Type | Heat Source Temperature Range | Wastewater Flow Rate | Efficiency | Purchase Cost of the Heat Exchanger Unit (EUR) |

|---|---|---|---|---|---|

| Heat exchangers installed directly under the sanitary utensil | Vertical heat exchangers | 30–50 °C | 7–14 dm3/min | 40–75% | 400–2000 |

| Horizontal heat exchangers | 30–50 °C | 7–14 dm3/min | 18–50% | ≅1000 | |

| Heat exchangers installed before the discharge to the sewage system | Vertical heat exchangers | 10–25 °C | ≅130 dm3/day | >40% | ≅1000 |

| Heat recovery system integrated with heat pump | 10–25 °C | ≅130 dm3/day | 40–70% | >1000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Piotrowska, B.; Słyś, D. Comprehensive Analysis of the State of Technology in the Field of Waste Heat Recovery from Grey Water. Energies 2023, 16, 137. https://doi.org/10.3390/en16010137

Piotrowska B, Słyś D. Comprehensive Analysis of the State of Technology in the Field of Waste Heat Recovery from Grey Water. Energies. 2023; 16(1):137. https://doi.org/10.3390/en16010137

Chicago/Turabian StylePiotrowska, Beata, and Daniel Słyś. 2023. "Comprehensive Analysis of the State of Technology in the Field of Waste Heat Recovery from Grey Water" Energies 16, no. 1: 137. https://doi.org/10.3390/en16010137