Techno-Economic and Environmental Analysis of Renewable Mix Hybrid Energy System for Sustainable Electrification of Al-Dhafrat Rural Area in Oman

Abstract

:1. Introduction

- Spotlight on technical, economic, and environmental aspects of installing a renewable–mix hybrid energy system for a diesel-based rural area community in the Sultanate of Oman.

- Establish an optimal renewable–mix hybrid microgrid system for the Al-Dhafrat rural community for sustainable development and well-being of the people.

- Testing system operational performance, such as bus voltage profile and system losses, while optimally designing a hybrid power system supplying power to the rural community loads.

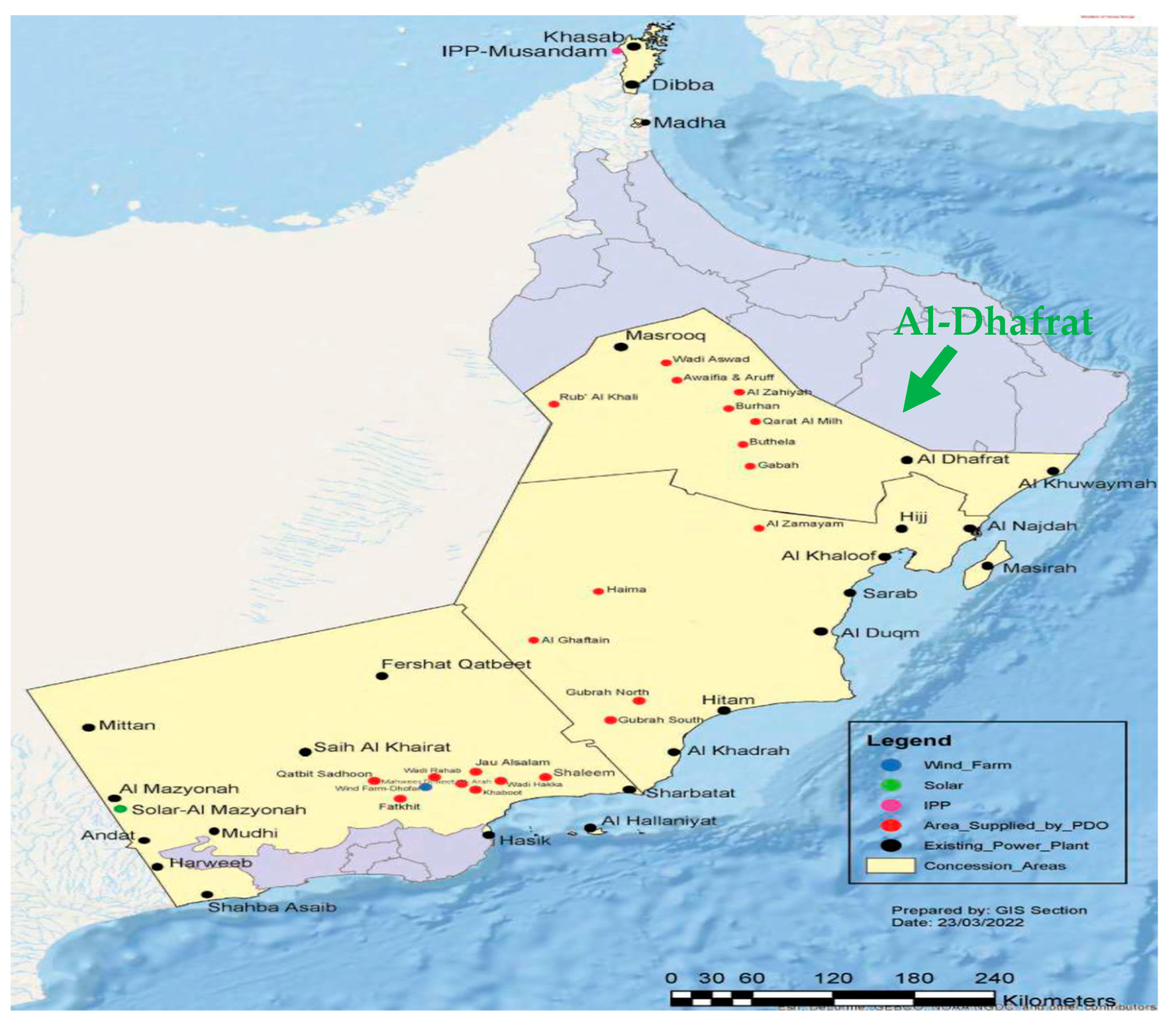

2. Study Area

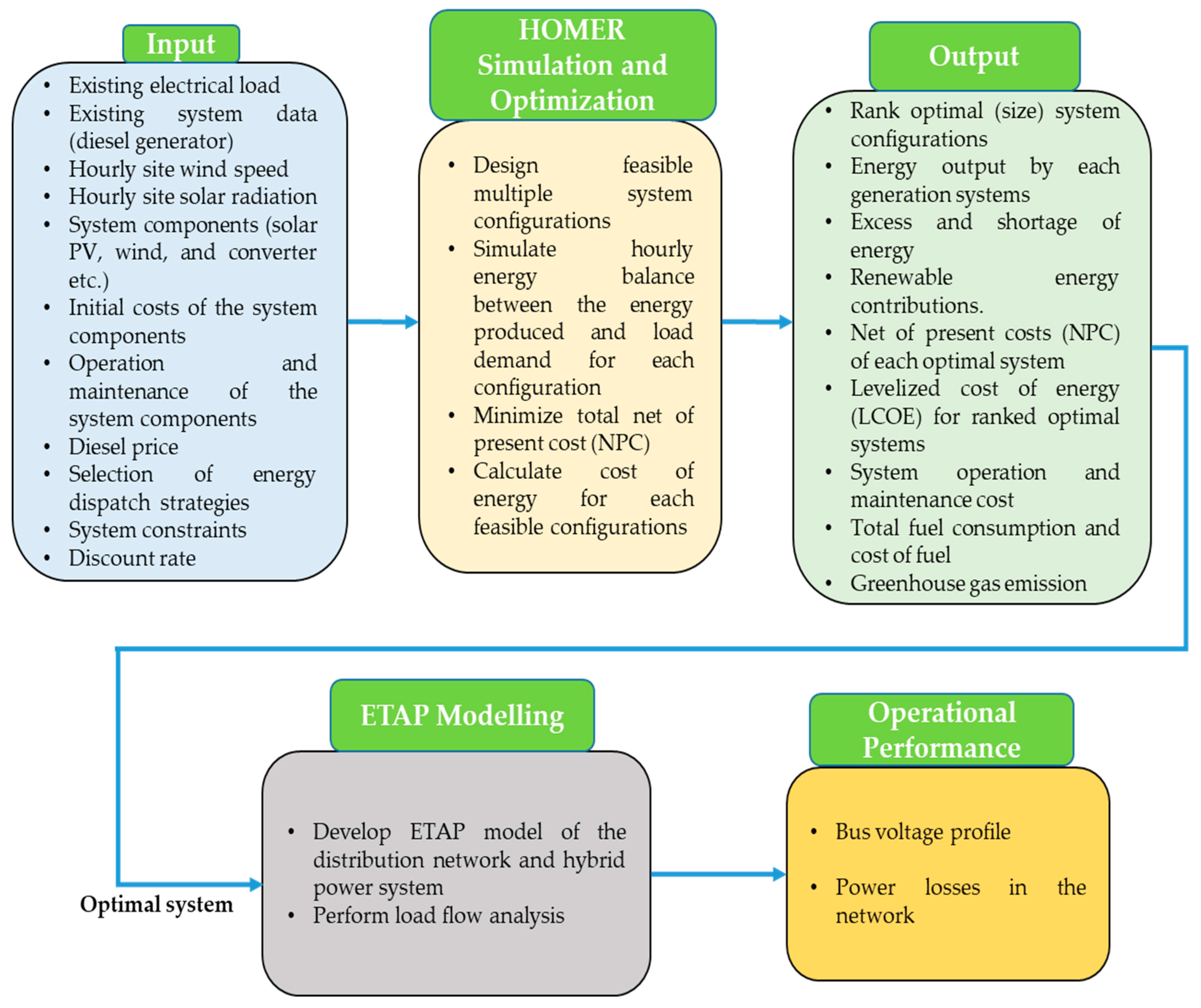

3. Research Methodology

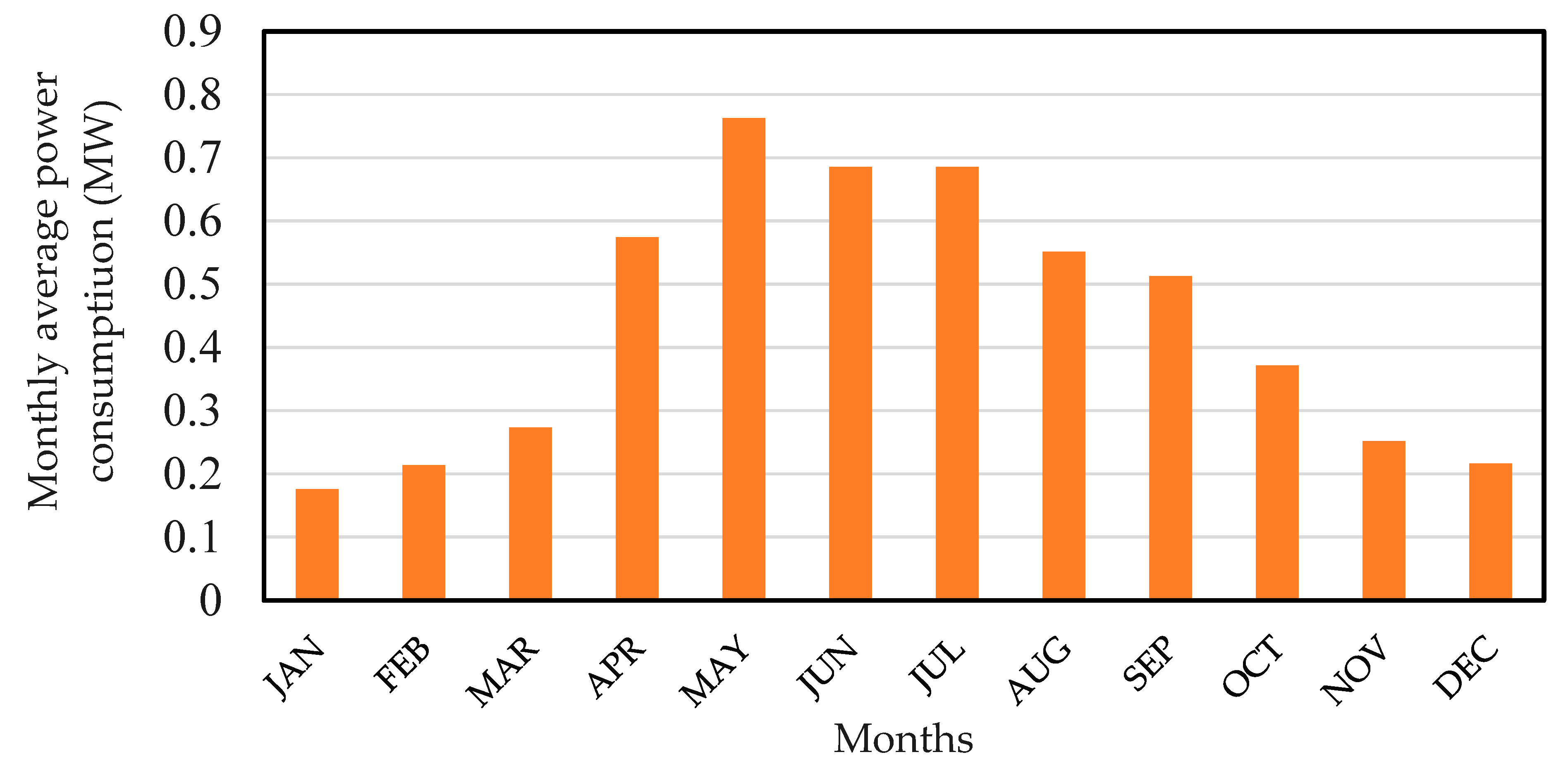

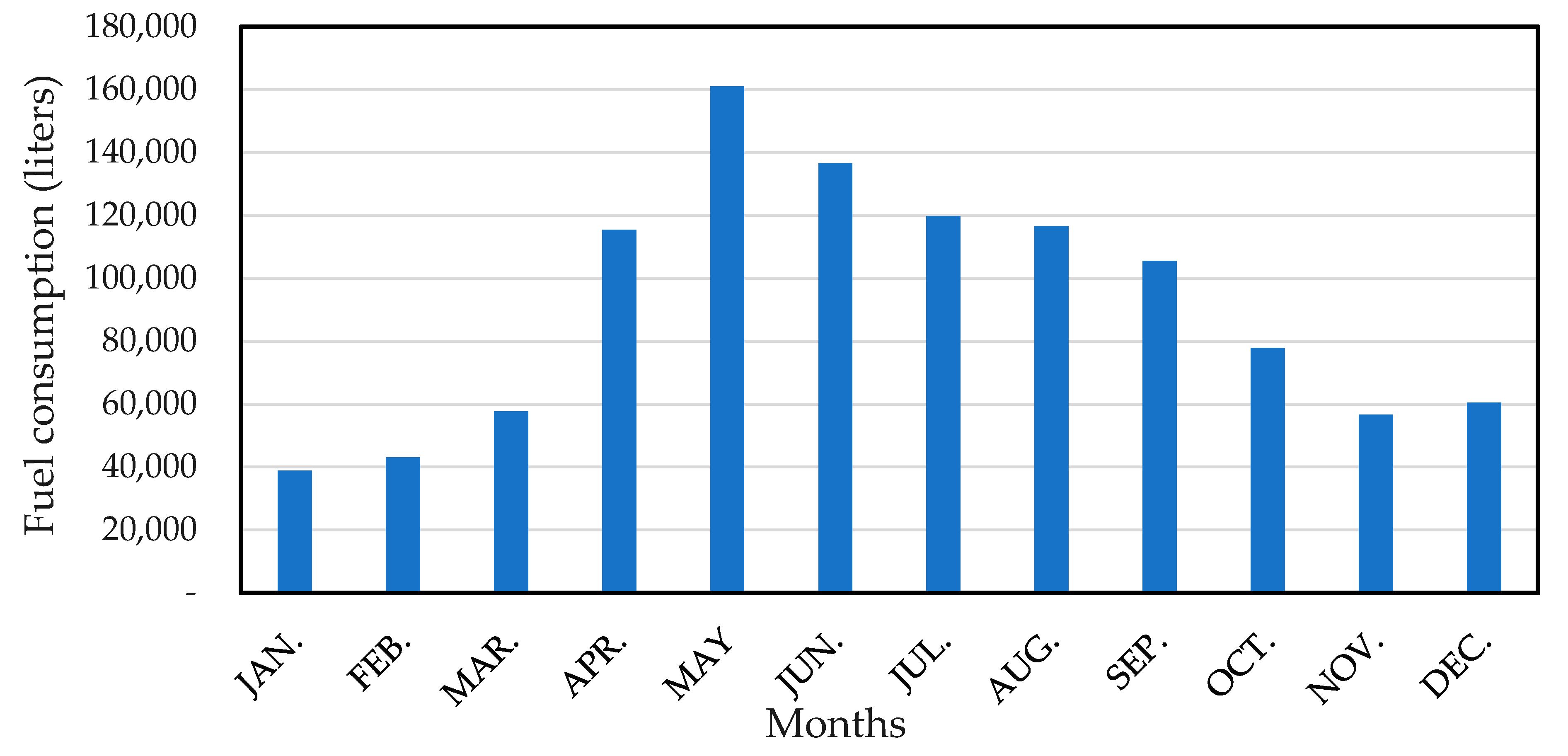

3.1. Electrical Load

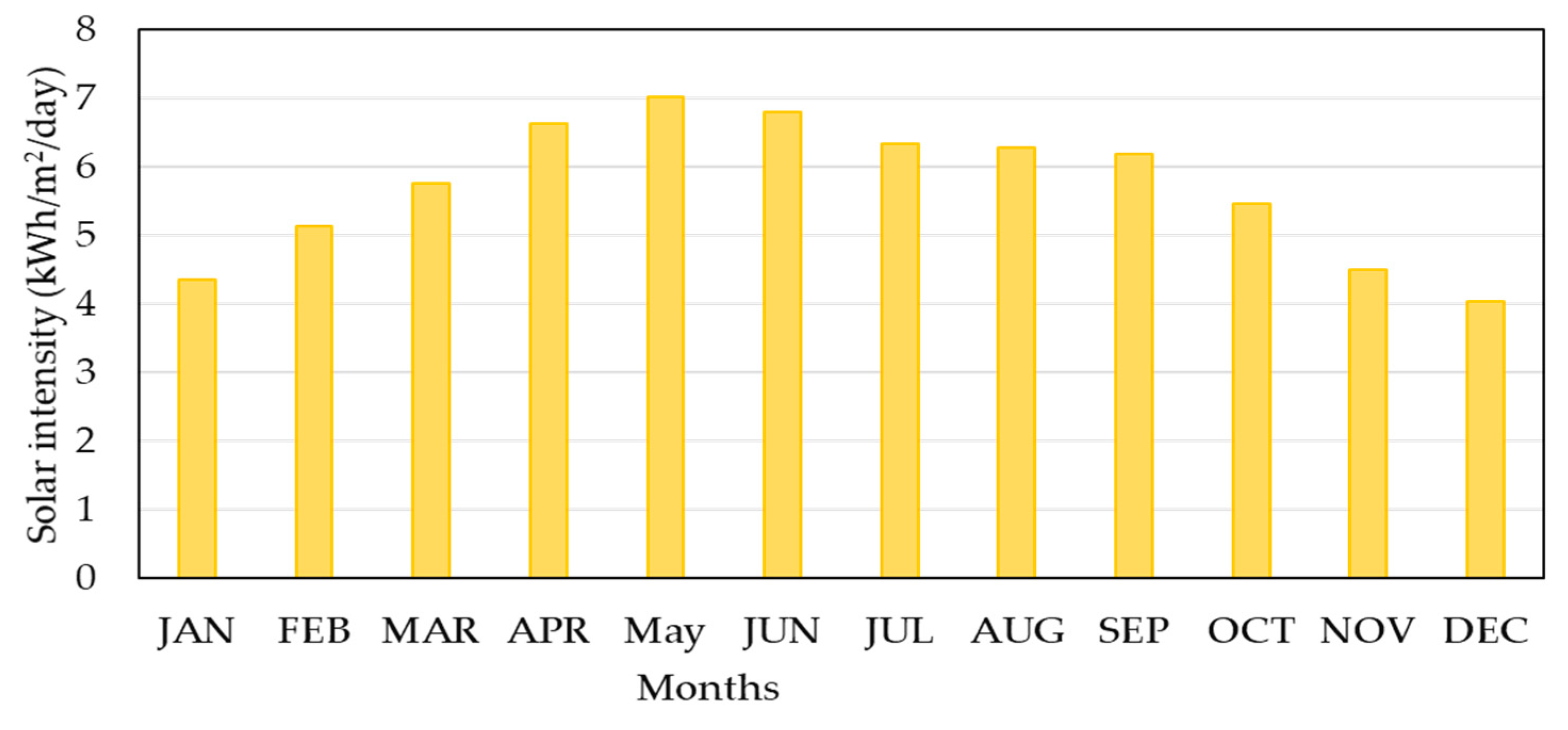

3.2. Site Solar Irradiation

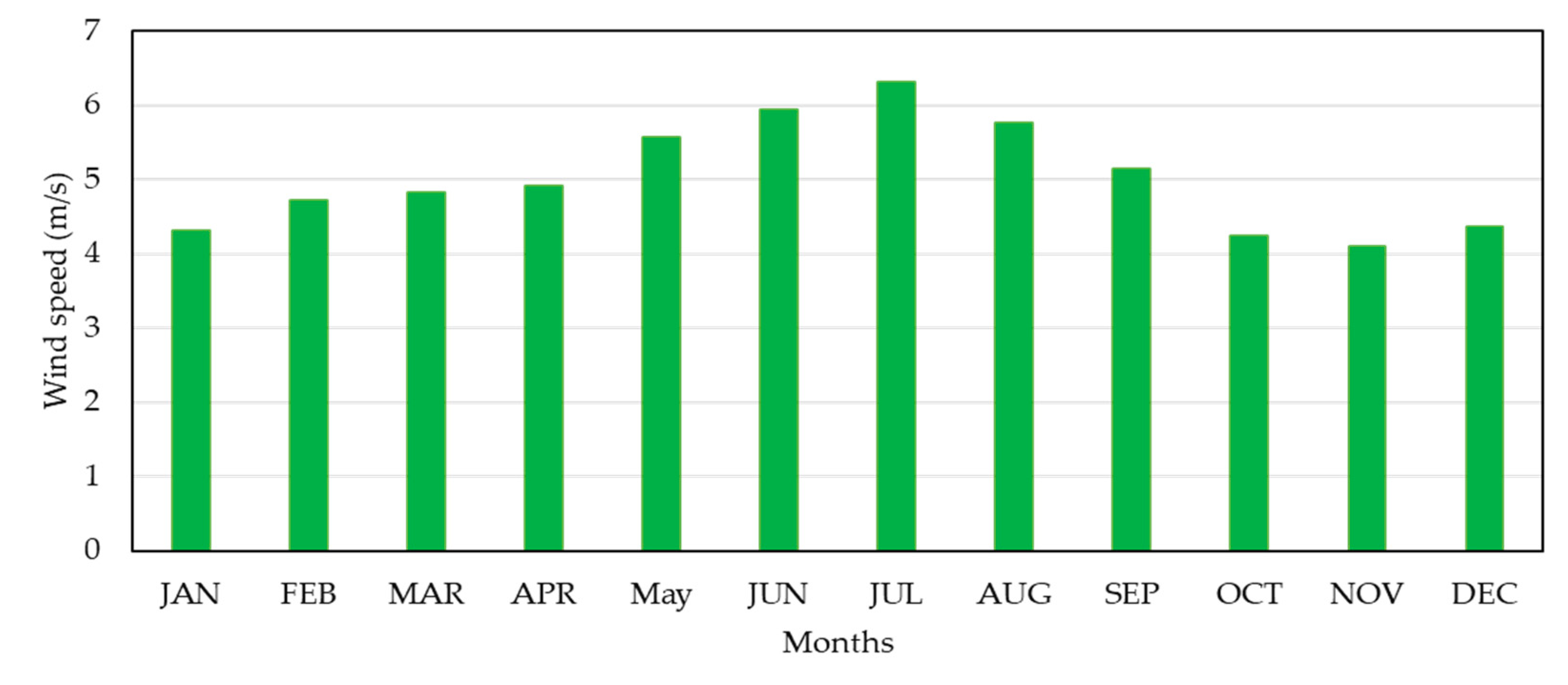

3.3. Site Wind Speed

3.4. Diesel Generator

3.5. Solar Photovoltaic Array

3.6. Wind Generator

3.7. Inverter

3.8. System Economic

3.9. Dispatch Strategy and System Constraints

3.10. Environmental Factors

3.11. Load Flow Analysis

4. Results and Discussion

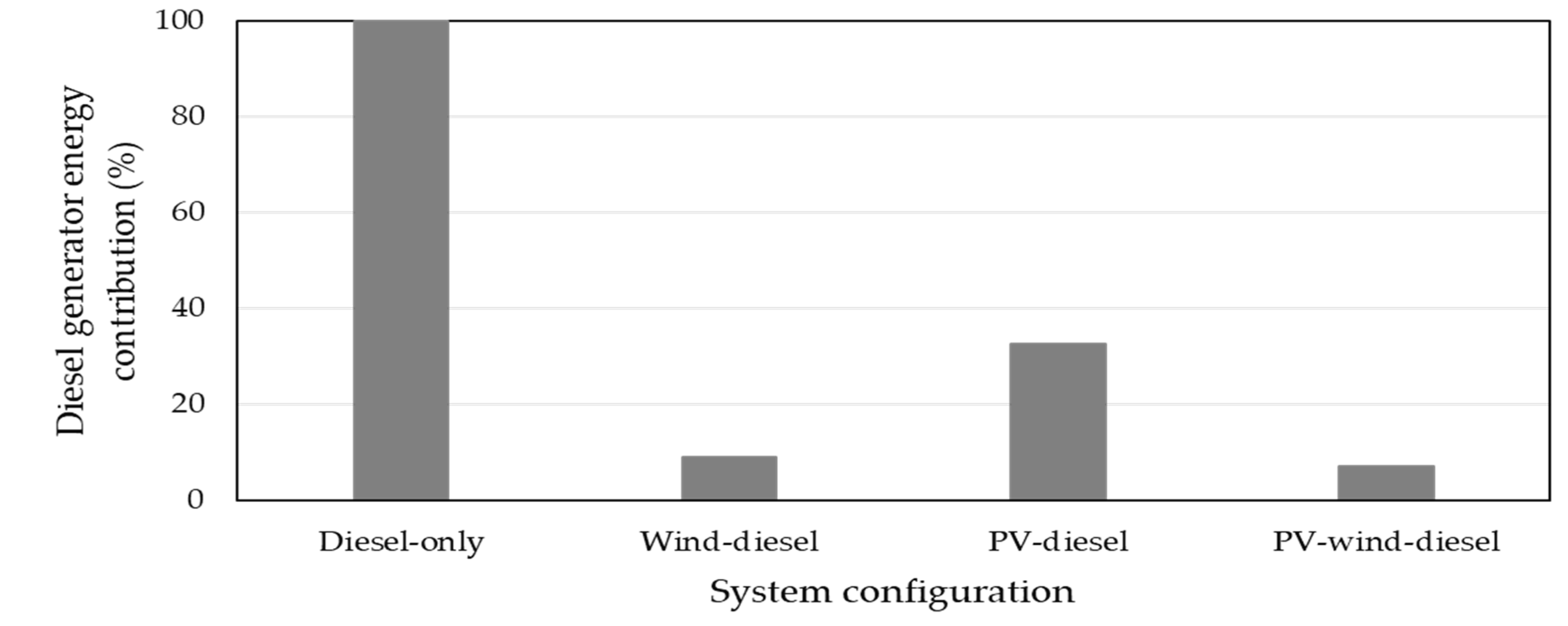

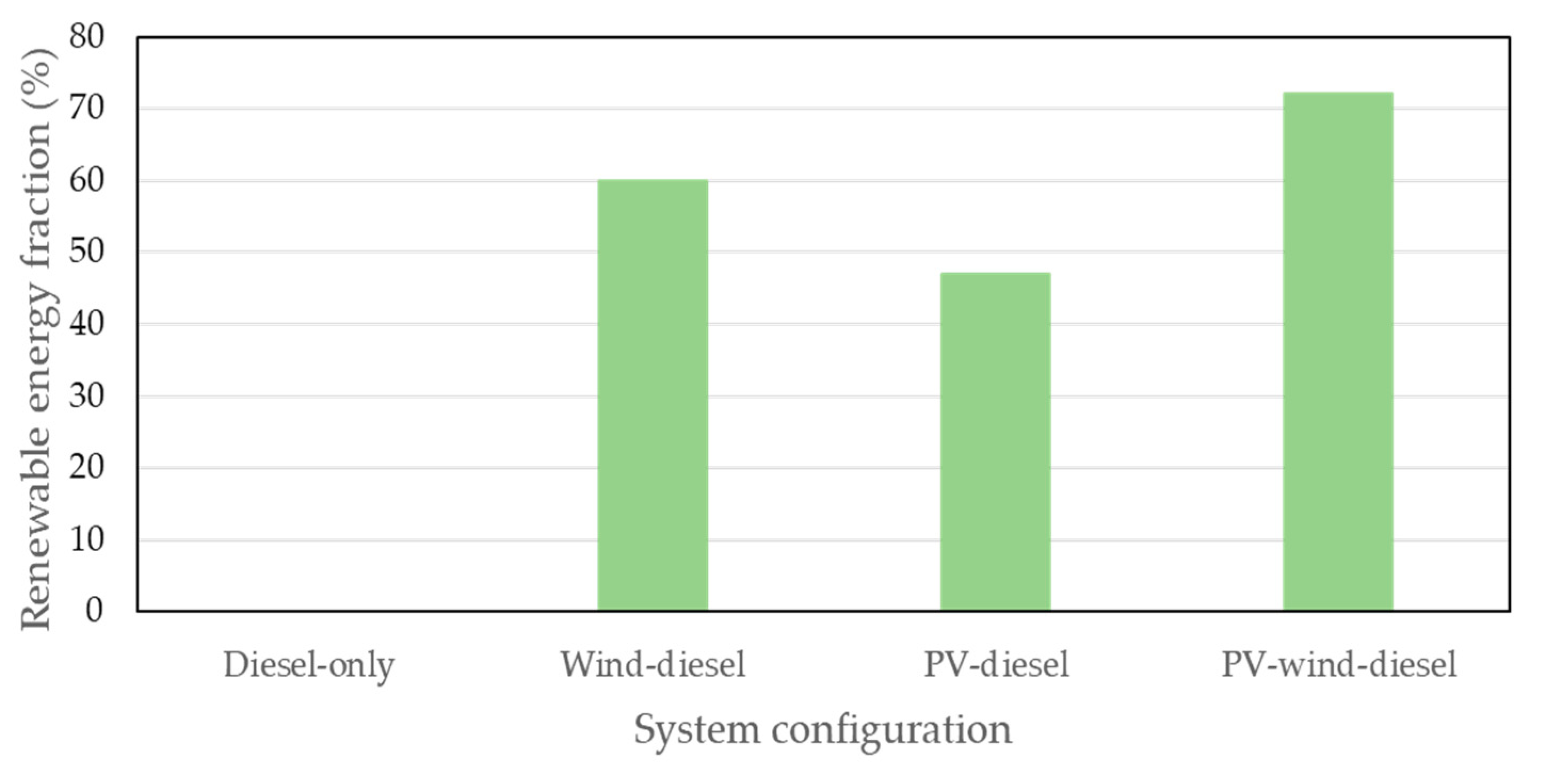

4.1. Optimal System Configurations

4.2. Economic Assessment

4.3. Environmental Assessment

4.4. Comparison between the Base System (System-I) and the Best Optimal Hybrid Configuration (System-IV)

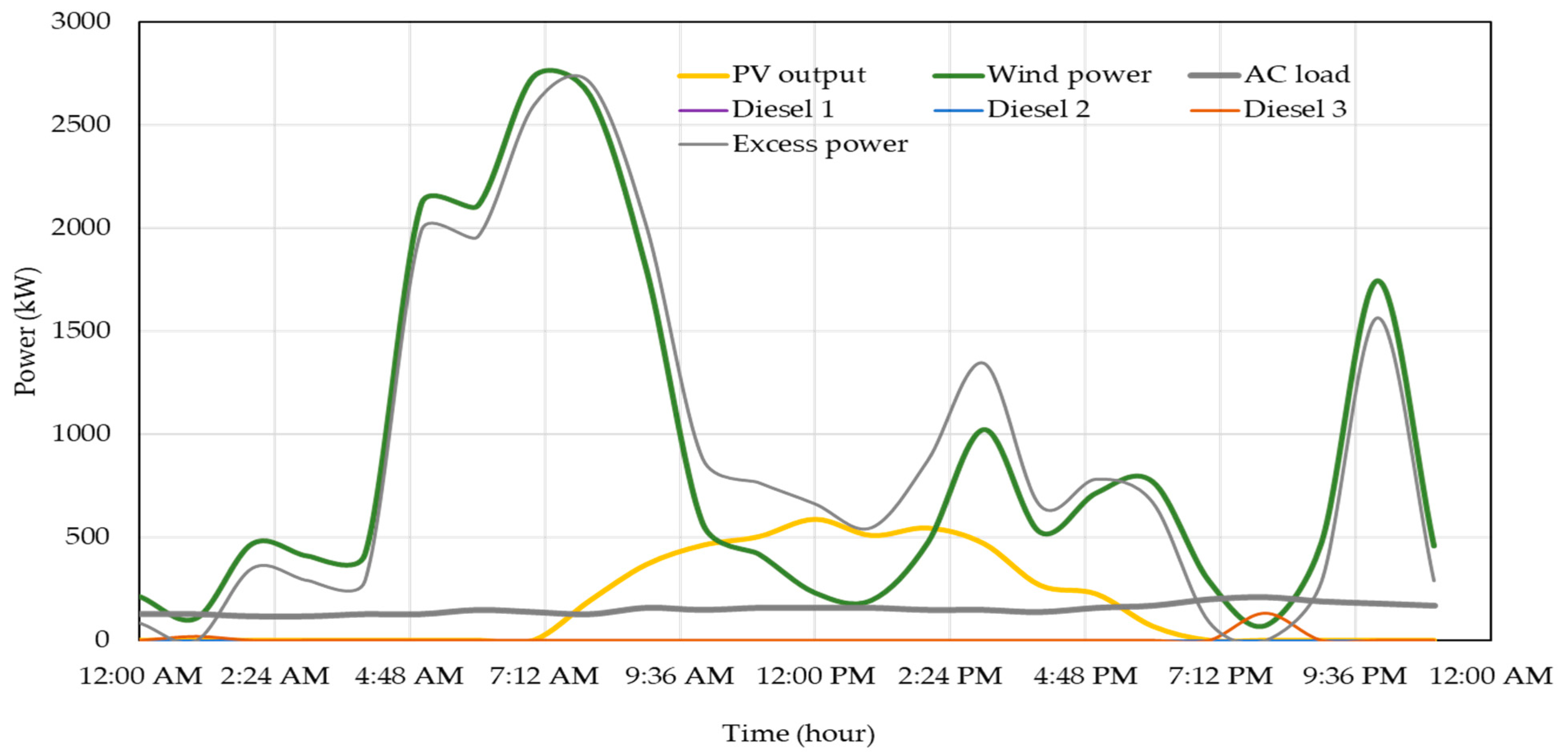

4.5. Power Balance Analysis in the Best Optimal Hybrid Configuration

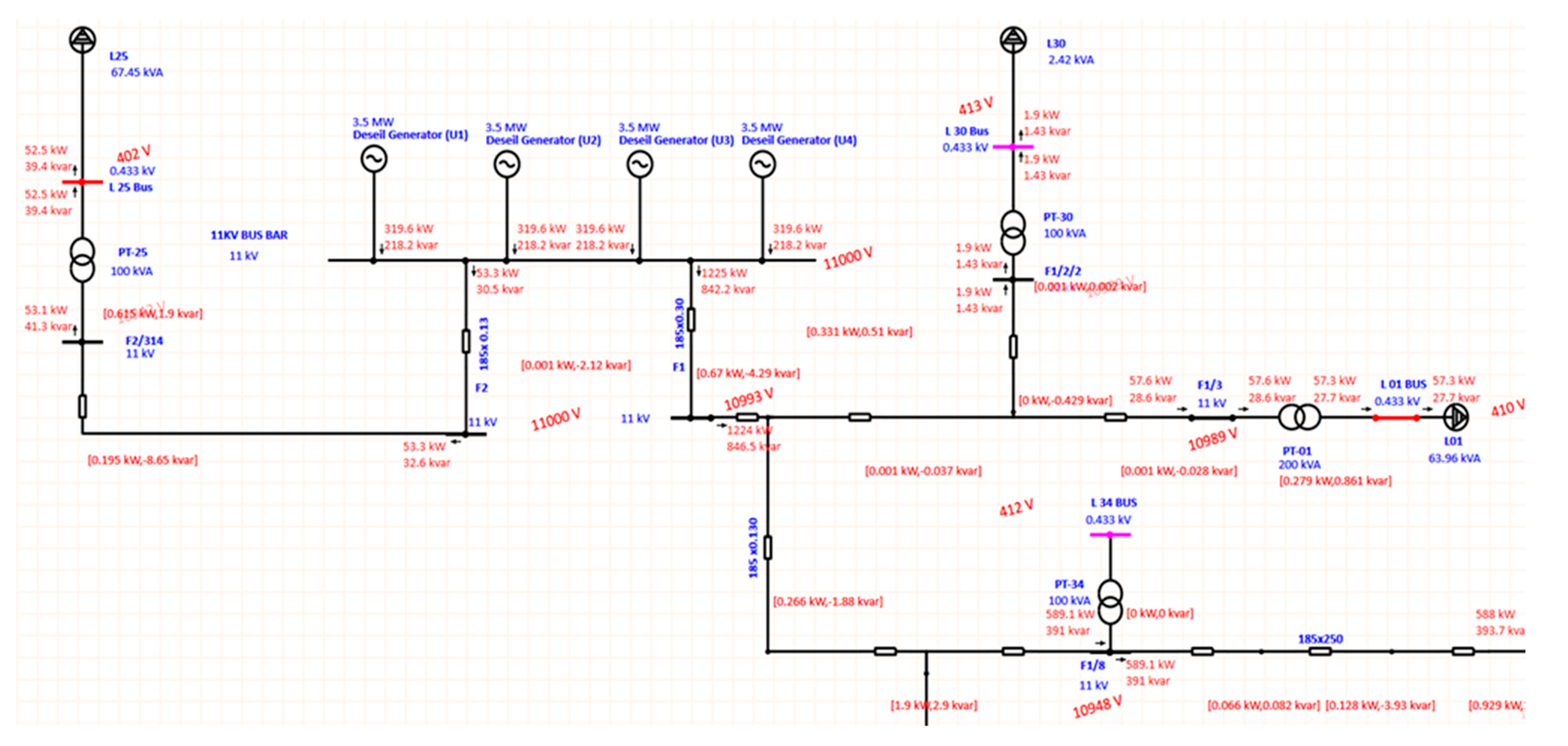

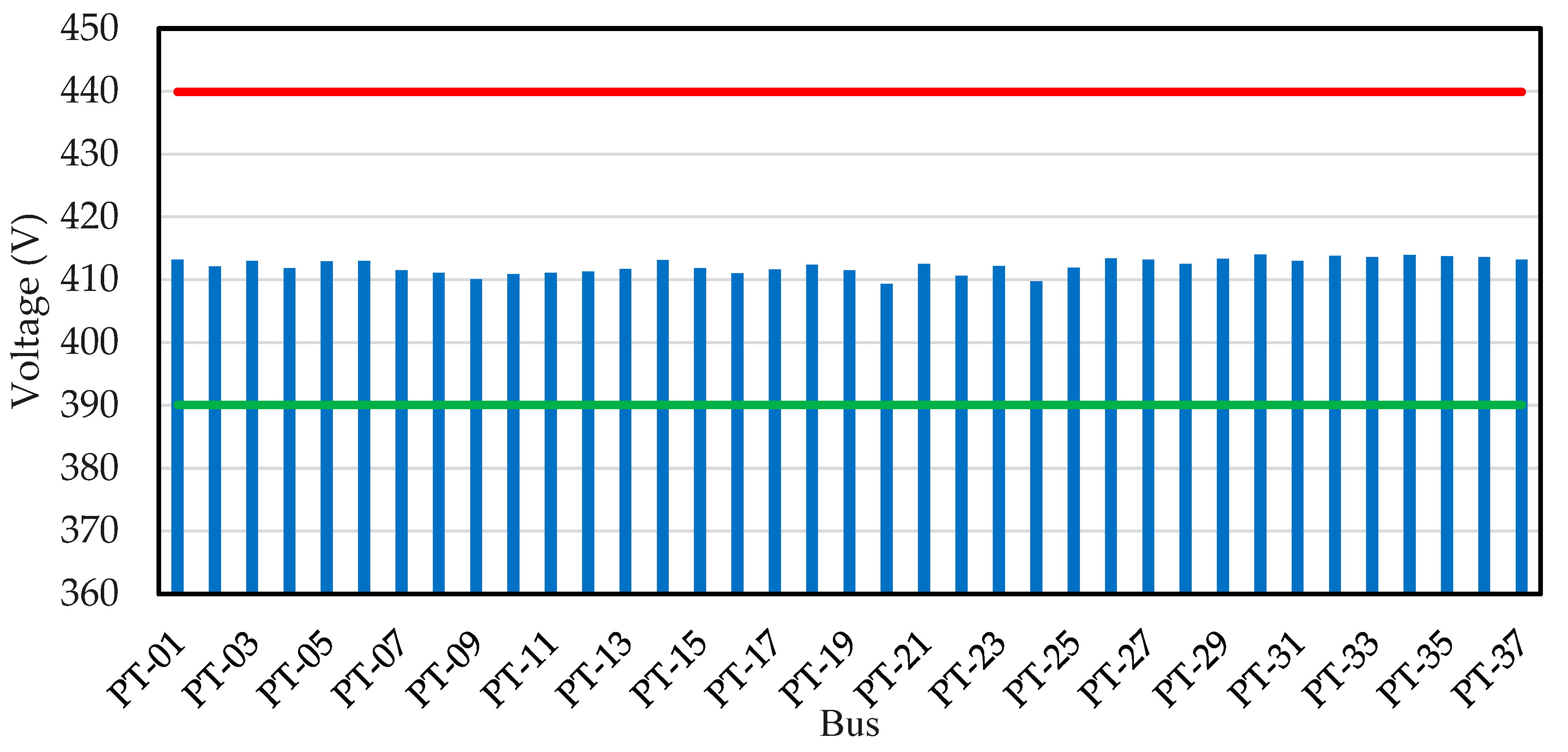

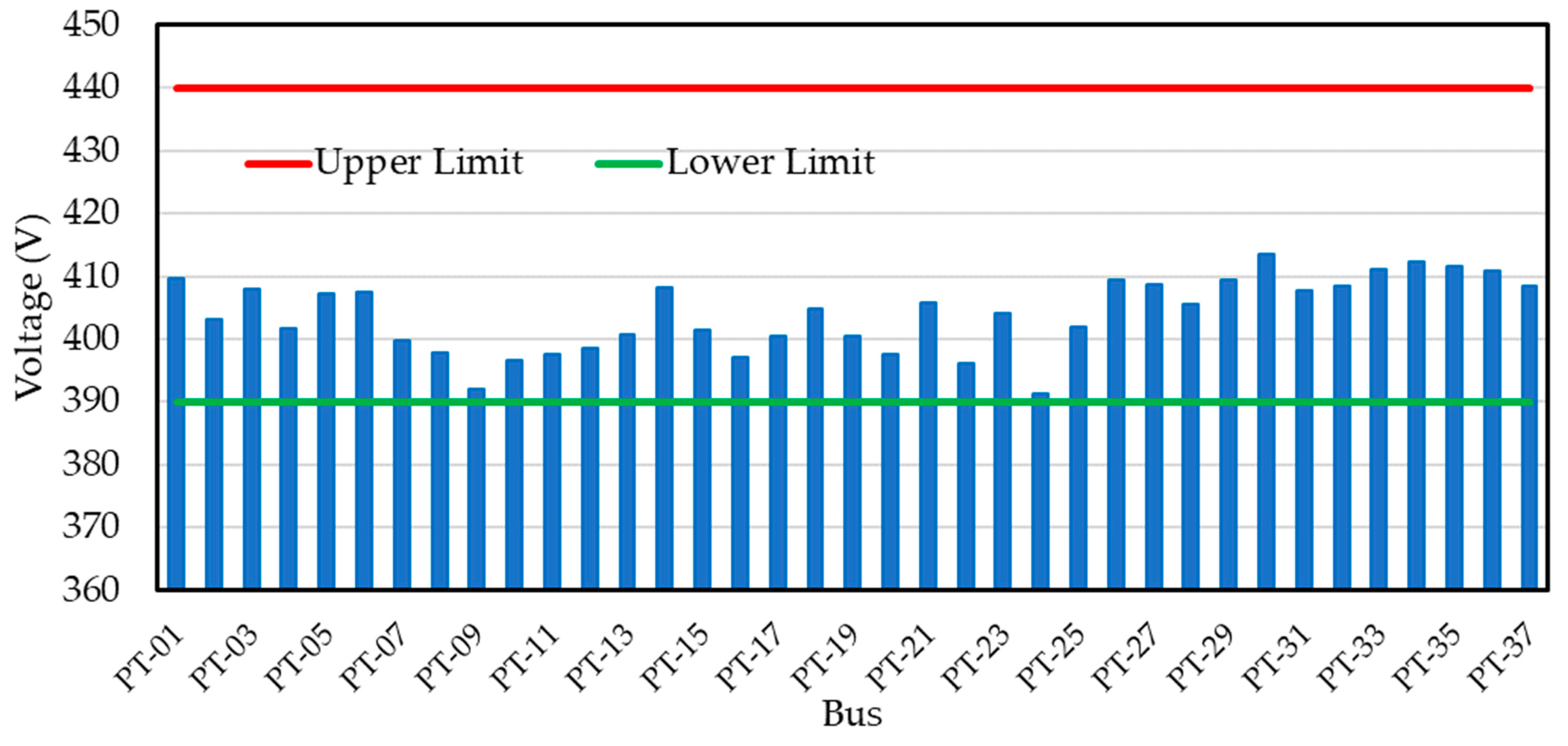

4.6. Operational Performance Assessment of the Best Optimal Hybrid Configuration (System-IV)

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| HOMER | Hybrid Optimization of Multiple Energy Resources |

| MIS | main interconnected system |

| ETAP | Electrical Transient Analyzer Program |

| PV | solar photovoltaic |

| GHG | greenhouse gas emission |

| NPC | net present cost |

| LCOE | levelized cost of energy |

| MZEC | Mazoon Electricity Company |

| NASA | National Aeronautics and Space Administration |

| STC | standard testing condition |

| CRF | capital recovery factor |

| LF | load following |

| CC | cycle charging |

References

- International Renewable Energy Agency (IRENA). Renewable Capacity Statistics 2022. Available online: https://reglobal.co/irenas-renewable-capacity-statistics-2022/ (accessed on 9 October 2022).

- Alharthi, M.; Dogan, E.; Taskin, D. Analysis of CO2 emissions and energy consumption by sources in MENA countries: Evidence from quantile regressions. Environ. Sci. Pollut. Res. 2021, 28, 38901–38908. [Google Scholar] [CrossRef] [PubMed]

- Al-Badi, A.H.; Al Wahaibi, A.; Ahshan, R.; Malik, A. Techno-Economic Feasibility of a Solar-Wind-Fuel Cell Energy System in Duqm, Oman. Energies 2022, 15, 5379. [Google Scholar] [CrossRef]

- Tanweer. Annual Report 2021. Available online: https://tanweer.om/uploadsall/Pdfs/236dd4bc-1d9d-488c-b895-5ea328fc2e3a.pdf/ (accessed on 11 October 2022).

- Ahshan, R.; Saleh, S.A.; Al-Badi, A.H. Performance Analysis of a Dq Power Flow Based Energy Storage Control System for Microgrid Applications. IEEE Access 2020, 8, 178706–178721. [Google Scholar] [CrossRef]

- Ahshan, R.; Hosseinzadeh, N.; Al-Badi, A.H. Economic Evaluation of a Remote Microgrid System for an Omani Island. Int. J. Smart Grid Clean Energy 2020, 9, 495–510. [Google Scholar] [CrossRef]

- Masrur, H.; Howlader, H.O.R.; Elsayed Lotfy, M.; Khan, K.R.; Guerrero, J.M.; Senjyu, T. Analysis of Techno-Economic-Environmental Suitability of an Isolated Microgrid System Located in a Remote Island of Bangladesh. Sustainability 2020, 12, 2880. [Google Scholar] [CrossRef] [Green Version]

- Seedahmed, M.M.A.; Ramli, M.A.M.; Bouchekara, H.R.E.H.; Shahriar, M.S.; Milyani, A.H.; Rawa, M. A techno-economic analysis of a hybrid energy system for the electrification of a remote cluster in western Saudi Arabia. Alex. Eng. J. 2022, 61, 5183–5202. [Google Scholar] [CrossRef]

- Rad, M.A.V.; Ghasempour, R.; Rahdan, P.; Mousavi, S.; Arastounia, M. Techno-economic analysis of a hybrid power system based on the cost-effective hydrogen production method for rural electrification, a case study in Iran. Energy 2020, 190, 116421. [Google Scholar] [CrossRef]

- Kolhe, M.L.; Ranaweera, K.M.I.U.; Sisara Gunawardana, A.G.B. Techno-economic sizing of off-grid hybrid renewable energy system for rural electrification in Sri Lanka. Sustain. Energy Technol. Assess. 2015, 11, 53–64. [Google Scholar] [CrossRef]

- Chowdhury, T.; Hasan, S.; Chowdhury, H.; Hasnat, A.; Rashedi, A.; Asyraf, M.R.M.; Hassan, M.Z.; Sait, S.M. Sizing of an Island Standalone Hybrid System Considering Economic and Environmental Parameters: A Case Study. Energies 2022, 15, 5940. [Google Scholar] [CrossRef]

- Giallanza, A.; Porretto, M.; Li Puma, G.; Marannano, G. A sizing approach for stand-alone hybrid photovoltaic-wind-battery systems: A Sicilian case study. J. Clean. Prod. 2018, 199, 817–830. [Google Scholar] [CrossRef]

- Roy, D.; Hassan, R.; Das, B.K. A hybrid renewable-based solution to electricity and freshwater problems in the off-grid Sundarbans region of India: Optimum sizing and socio-enviro-economic evaluation. J. Clean. Prod. 2022, 372, 133761. [Google Scholar] [CrossRef]

- Amupolo, A.; Nambundunga, S.; Chowdhury, D.S.P.; Grün, G. Techno-Economic Feasibility of Off-Grid Renewable Energy Electrification Schemes: A Case Study of an Informal Settlement in Namibia. Energies 2022, 15, 4235. [Google Scholar] [CrossRef]

- Uddin, M.N.; Biswas, M.M.; Nuruddin, S. Techno-economic impacts of floating PV power generation for remote coastal regions. Sustain. Energy Technol. Assess. 2022, 51, 101930. [Google Scholar] [CrossRef]

- Ali, F.; Ahmar, M.; Jiang, Y.; AlAhmad, M. A techno-economic assessment of hybrid energy systems in rural Pakistan. Energy 2021, 215, 119103. [Google Scholar] [CrossRef]

- Zebra, E.I.C.; van der Windt, H.J.; Nhumaio, G.; Faaij, A.P.C. A review of hybrid renewable energy systems in mini-grids for off-grid electrification in developing countries. Renew. Sustain. Energy Rev. 2021, 144, 111036. [Google Scholar] [CrossRef]

- Odou, O.D.T.; Bhandari, R.; Adamou, R. Hybrid off-grid renewable power system for sustainable rural electrification in Benin. Renew. Energy 2020, 145, 1266–1279. [Google Scholar] [CrossRef]

- Javed, M.S.; Song, A.; Ma, T. Techno-economic assessment of a stand-alone hybrid solar-wind-battery system for a remote island using genetic algorithm. Energy 2019, 176, 704–717. [Google Scholar] [CrossRef]

- Krishan, O.; Suhag, S. Techno-economic analysis of a hybrid renewable energy system for an energy poor rural community. J. Energy Storage 2019, 23, 305–319. [Google Scholar] [CrossRef]

- Faridah, L.; Purwadi, A.; Ibrahim, M.H.; Rizqiawan, A. Study and design of hybrid off-grid power system for communal and administrative load at 3 regions in Maluku, Indonesia. In Proceedings of the 2018 Conference on Power Engineering and Renewable Energy (ICPERE), Solo, Indonesia, 29–31 October 2018. [Google Scholar]

- Manama, S.M.; Scipioni, A.; Davat, B.; el Ganaoui, M. The idea of feeding a rural area in Comoros zith a micro-grid system with renewable energy source with hydrogen storages. In Proceedings of the 6th International Renewable and Sustainable Energy Conference, IRSEC 2018, Rabat, Morocco, 5–8 December 2018. [Google Scholar]

- Li, C.; Ge, X.; Zheng, Y.; Xu, C.; Ren, Y.; Song, C.; Yang, C. Techno-economic feasibility study of autonomous hybrid wind/PV/battery power system for a household in Urumqi, China. Energy 2013, 55, 263–272. [Google Scholar] [CrossRef]

- Abdilahi, A.M.; Yatim, A.H.M.; Mustafa, M.W.; Khalaf, O.T.; Shumran, A.F.; Nor, F.M. Feasibility study of renewable energy-based microgrid system in Somaliland’s urban centers. Renew. Sustain. Energy Rev. 2014, 40, 1048–1059. [Google Scholar] [CrossRef]

- Olatomiwa, L. Optimal configuration assessments of hybrid renewable power supply for rural healthcare facilities. Energy Rep. 2016, 2, 141–146. [Google Scholar] [CrossRef] [Green Version]

- Tayyab, M.; Zubair, M. PV-solar/Wind Hybrid Energy System for GSM/CDMA Type Mobile Telephony Base Station. Int. J. Eng. Res. Appl. 2015, 5, 74–79. [Google Scholar]

- Maouedj, R.; Mammeri, A.; Draou, M.; Benyoucef, B. Performance evaluation of hybrid photovoltaic-wind power systems. Energy Procedia 2014, 50, 797–807. [Google Scholar] [CrossRef] [Green Version]

- Nkuriyingoma, O.; Özdemir, E.; Sezen, S. Techno-economic analysis of a PV system with a battery energy storage system for small households: A case study in Rwanda. Front. Energy Res. 2022, 10, 957564. [Google Scholar] [CrossRef]

- Dahiru, A.T.; Tan, C.W. Optimal sizing and techno-economic analysis of grid-connected nanogrid for tropical climates of the Savannah. Sustain. Cities Soc. 2020, 52, 101824. [Google Scholar] [CrossRef]

- Kumar, J.; Suryakiran, B.V.; Verma, A.; Bhatti, T.S. Analysis of techno-economic viability with demand response strategy of a grid-connected microgrid model for enhanced rural electrification in Uttar Pradesh state, India. Energy 2019, 178, 176–185. [Google Scholar] [CrossRef]

- Kasaeian, A.; Rahdan, P.; Rad, M.A.V.; Yan, W.M. Optimal design and technical analysis of a grid-connected hybrid photovoltaic/diesel/biogas under different economic conditions: A case study. Energy Convers. Manag. 2019, 198, 111810. [Google Scholar] [CrossRef]

- Li, C.; Zhou, D.; Zheng, Y. Techno-economic comparative study of grid-connected PV power systems in five climate zones, China. Energy 2018, 165, 1352–1369. [Google Scholar] [CrossRef]

- Islam, M.S. A techno-economic feasibility analysis of hybrid renewable energy supply options for a grid-connected large office building in southeastern part of France. Sustain. Cities Soc. 2018, 38, 492–508. [Google Scholar] [CrossRef]

- Alharthi, Y.Z.; Siddiki, M.K.; Chaudhry, G.M. Resource Assessment and Techno-Economic Analysis of a Grid-Connected Solar PV-Wind Hybrid System for Different Locations in Saudi Arabia. Sustainability 2018, 10, 3690. [Google Scholar] [CrossRef] [Green Version]

- Maleki, A.; Rosen, M.A.; Pourfayaz, F. Optimal Operation of a Grid-Connected Hybrid Renewable Energy System for Residential Applications. Sustainability 2017, 9, 1314. [Google Scholar] [CrossRef]

- Nacer, T.; Hamidat, A.; Nadjemi, O. Techno-economic Impacts Analysis of a Hybrid Grid Connected Energy System Applied for a Cattle Farm. Energy Procedia 2015, 75, 963–968. [Google Scholar] [CrossRef] [Green Version]

- Zahedi, R.; Seraji, M.A.N.; Borzuei, D.; Moosavian, S.F.; Ahmadi, A. Feasibility study for designing and building a zero-energy house in new cities. Sol. Energy 2022, 240, 168–175. [Google Scholar] [CrossRef]

- Nasa.gov. ArcGIS Web Application. 2018. Available online: https://power.larc.nasa.gov/data-access-viewer/ (accessed on 5 October 2022).

- HOMER Pro 3.14 Manual. Available online: https://www.homerenergy.com/products/pro/docs/latest/index.html (accessed on 27 October 2022).

- Ahshan, R. Potential and Economic Analysis of Solar-to-Hydrogen Production in the Sultanate of Oman. Sustainability 2021, 13, 9516. [Google Scholar] [CrossRef]

- Solaris Shop. Canadian Solar CS6U-340m. 2016. Available online: https://www.solaris-shop.com/content/CS6U-340M%20Specs.pdf (accessed on 21 April 2022).

- Ahshan, R.; Al-Abri, R.; Al-Zakwani, H.; Ambu-saidi, N.; Hossain, E. Design and Economic Analysis of a Solar PV System for a Campus Sports Complex. Int. J. Renew. Energy Res. 2020, 10, 67–68. [Google Scholar]

- Ahshan, R.; Onen, A.; Al-Badi, A.H. Assessment of Wind-to-Hydrogen (Wind-H2) Generation Prospects in the Sultanate of Oman. Renew. Energy 2022, 200, 271–282. [Google Scholar] [CrossRef]

- Norvento nED 100-24. Available online: https://en.wind-turbine-models.com/turbines/1804-norvento-ned-100-24 (accessed on 25 October 2022).

- Ramli, M.A.M.; Hiendro, A.; Twaha, S. Economic analysis of PV/diesel hybrid system with flywheel energy storage. Renew. Energy 2015, 78, 398–405. [Google Scholar] [CrossRef]

- Saadat, H. Power System Analysis, 3rd ed.; PSA Publishing: North York, NY, USA, 2010. [Google Scholar]

| Diesel Generator | |

|---|---|

| Lifetime | 219,000 h |

| Minimum load ratio | 30% |

| Intercept coefficient | 0.0226 L/kWh |

| Fuel slope | 0.2293 L/kWh |

| Operation and maintenance cost | USD 10.27/operational h |

| Diesel fuel cost | USD 1.49/L |

| PV Module | |

|---|---|

| Cell type | Monocrystalline |

| Lifetime | 25 years |

| Derating factor | 78% |

| Initial cost | USD 882/kW |

| Replacement cost | USD 882/kW |

| Operation and maintenance cost | USD 14/kW/year |

| Temperature coefficient of power | −0.41%/°C |

| Wind Turbine | |

|---|---|

| Rated power | 100 kW |

| Lifetime | 25 years |

| Cut-in and cut-out wind speeds | 3 m/s and 20 m/s |

| Hub height | 36 m |

| Initial cost | USD 1255/kW |

| Replacement cost | USD 700/kW |

| Operation and maintenance cost | USD 10/kW/year |

| Temperature coefficient of power | −0.41%/°C |

| Inverter | |

|---|---|

| Lifetime | 10 years |

| Efficiency | 95% |

| Initial cost | USD 750/kW |

| Replacement cost | USD 700/kW |

| Operation and maintenance cost | USD 15/year |

| GHG | Factor (g/L fuel) |

|---|---|

| Carbon dioxide, CO2 | 2640 |

| Carbon monoxide, CO | 0.38 |

| Particulate matter | 0.03 |

| Sulphur dioxide, SO2 | 6.55 |

| Nitrogen Oxides, NO | 23.15 |

| System Type | Description |

|---|---|

| System-I | Diesel-only (Base system) |

| System-II | Diesel and renewable source (Wind–diesel) |

| System-III | Diesel and renewable source (PV–diesel) |

| System-IV | Diesel and mixed renewable source (PV–wind–diesel) |

| Component, Capacity | System-I (Diesel-Only) | System-II (Wind–Diesel) | System-III (PV–Diesel) | System-IV (PV–Wind–Diesel) |

|---|---|---|---|---|

| Diesel generator, kW | 10,500 | 5600 | 8400 | 5600 |

| Photovoltaic, kW | 0 | 0 | 2469 | 718 |

| Wind turbine, kW | 0 | 3900 | 0 | 3200 |

| Inverter, kW | 0 | 0 | 1208 | 401 |

| Economic Output | System-I (Diesel-Only) | System-II (Wind–Diesel) | System-III (PV–Diesel) | System-IV (PV–Wind–Diesel) |

|---|---|---|---|---|

| NPC (millions of USD) | 31.02 | 14.59 | 22.87 | 14.09 |

| LCOE, USD/kWh | 0.5663 | 0.2663 | 0.4175 | 0.2573 |

| Diesel cost (millions of USD) | 30.70 | 10.25 | 17.78 | 9.08 |

| Diesel consumption (L/year) | 1,414,360 | 471,999 | 819,193 | 418,204 |

| Operation and maintenance cost (millions of USD) | 1.31 | 0.57 | 2.33 | 0.95 |

| Pollutant (kg/year) | System-I (Diesel-Only) | System-II (Wind–Diesel) | System-III (PV–Diesel) | System-IV (PV–Wind–Diesel) |

|---|---|---|---|---|

| Carbon dioxide | 3,740,680 | 1,248,335 | 2,166,590 | 1,106,061 |

| Carbon monoxide | 537 | 179 | 311 | 159 |

| Unburned hydrocarbons | 212 | 71 | 123 | 63 |

| Particulate matter | 42.2 | 14.2 | 24.6 | 13 |

| Sulphur dioxide | 9277 | 3096 | 5373 | 2743 |

| Nitrogen oxides | 32,742 | 10,927 | 18,964 | 9681 |

| Total emissions (kg/year) | 3,783,490.2 | 1,262,622.2 | 2,191,385.6 | 1,118,720 |

| Components | Capital Cost | Replacement Cost | Operation and Maintenance Cost | Fuel Cost | Salvage | Total Expenditure |

|---|---|---|---|---|---|---|

| Diesel generator | 0 | 0 | 1,306,139.21 | 30,697,386.56 | 983,305.95 | 31,020,219.81 |

| Wind generator | 0 | 0 | 0 | 0 | 0 | 0 |

| PV | 0 | 0 | 0 | 0 | 0 | 0 |

| Converter | 0 | 0 | 0 | 0 | 0 | 0 |

| System | 0 | 0 | 1,306,139.21 | 30,697,386.56 | 983,305.95 | 31,020,219.81 |

| Components | Capital Cost | Replacement Cost | Operation and Maintenance Cost | Fuel Cost | Salvage | Total Expenditure |

|---|---|---|---|---|---|---|

| Diesel generator | 0 | 0 | 518,207.11 | 9,076,741.14 | 1,132,856.14 | 9,432,138.15 |

| Wind generator | 4,016,000.00 | 0 | 4661.28 | 0 | 0 | 4,020,661.28 |

| PV | 634,160.89 | 0 | 430,767.48 | 0 | 0 | 1,064,928.37 |

| Converter | 301,016.52 | 290,614.21 | 0 | 0 | 44,838.04 | 546,792.69 |

| System | 49,511,774.41 | 290,614.21 | 953,635.86 | 9,076,741.14 | 1,177,694.18 | 14,094,474.45 |

| Summer Load | Winter Load | |

|---|---|---|

| Generated power | (1278 + j873) kVA | (252 + j101) kVA |

| Power losses | (28.8 − j18.9) kVA | (0.001 − j0.0813) kVA |

| Summer Load | |

|---|---|

| Generated power | (1278 + j873) kVA |

| Power losses | (23.8 − j19.9) kVA |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al Abri, A.; Al Kaaf, A.; Allouyahi, M.; Al Wahaibi, A.; Ahshan, R.; Al Abri, R.S.; Al Abri, A. Techno-Economic and Environmental Analysis of Renewable Mix Hybrid Energy System for Sustainable Electrification of Al-Dhafrat Rural Area in Oman. Energies 2023, 16, 288. https://doi.org/10.3390/en16010288

Al Abri A, Al Kaaf A, Allouyahi M, Al Wahaibi A, Ahshan R, Al Abri RS, Al Abri A. Techno-Economic and Environmental Analysis of Renewable Mix Hybrid Energy System for Sustainable Electrification of Al-Dhafrat Rural Area in Oman. Energies. 2023; 16(1):288. https://doi.org/10.3390/en16010288

Chicago/Turabian StyleAl Abri, Abdullah, Abdullah Al Kaaf, Musaab Allouyahi, Ali Al Wahaibi, Razzaqul Ahshan, Rashid S. Al Abri, and Ahmed Al Abri. 2023. "Techno-Economic and Environmental Analysis of Renewable Mix Hybrid Energy System for Sustainable Electrification of Al-Dhafrat Rural Area in Oman" Energies 16, no. 1: 288. https://doi.org/10.3390/en16010288