Experimental Study on Conformance Control Using Acidic Nanoparticles in a Heterogeneous Reservoir by Flue Gas Flooding

Abstract

:1. Introduction

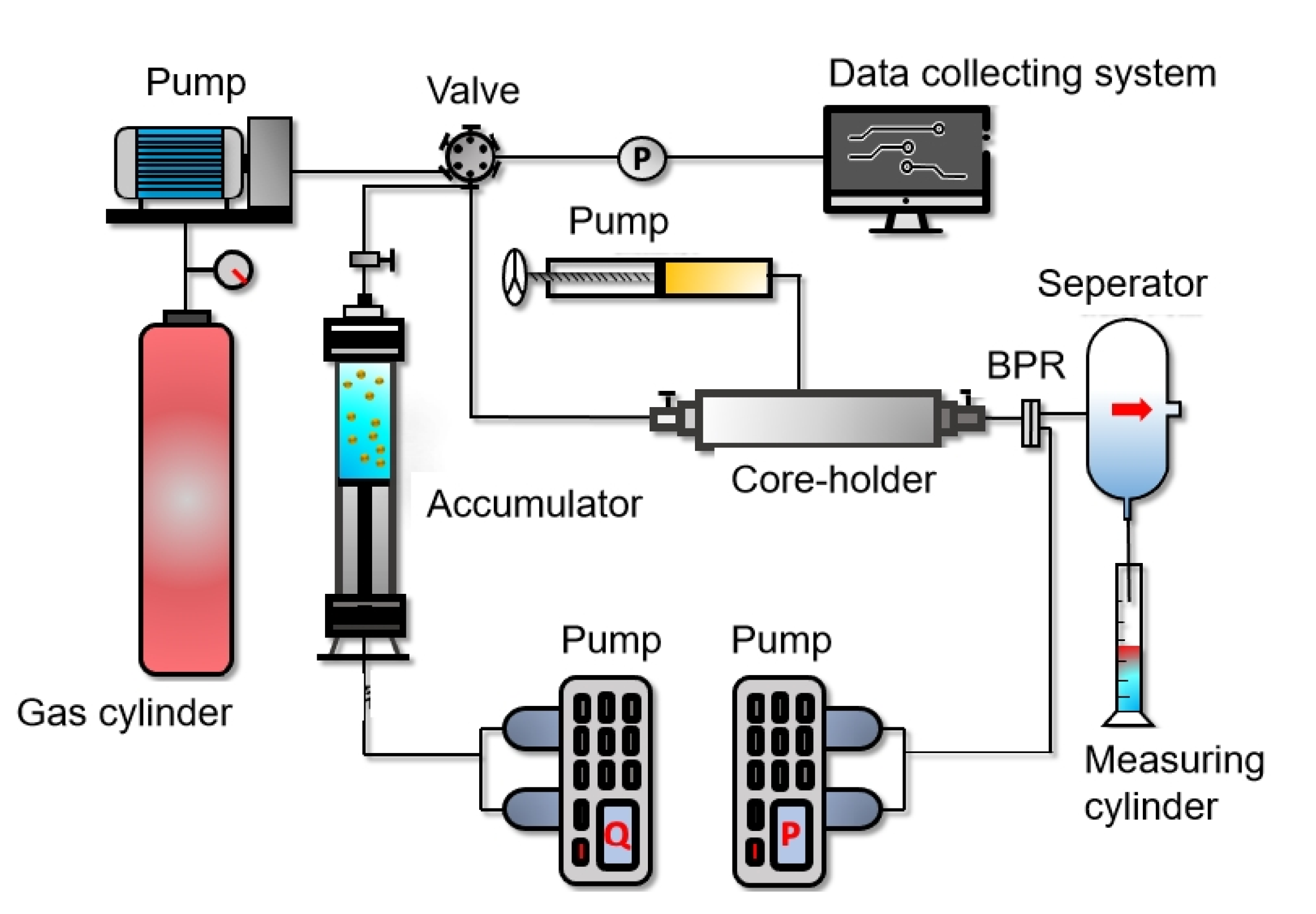

2. Experiments

2.1. Experimental Materials

2.2. Experimental Design

2.3. Experimental Procedure

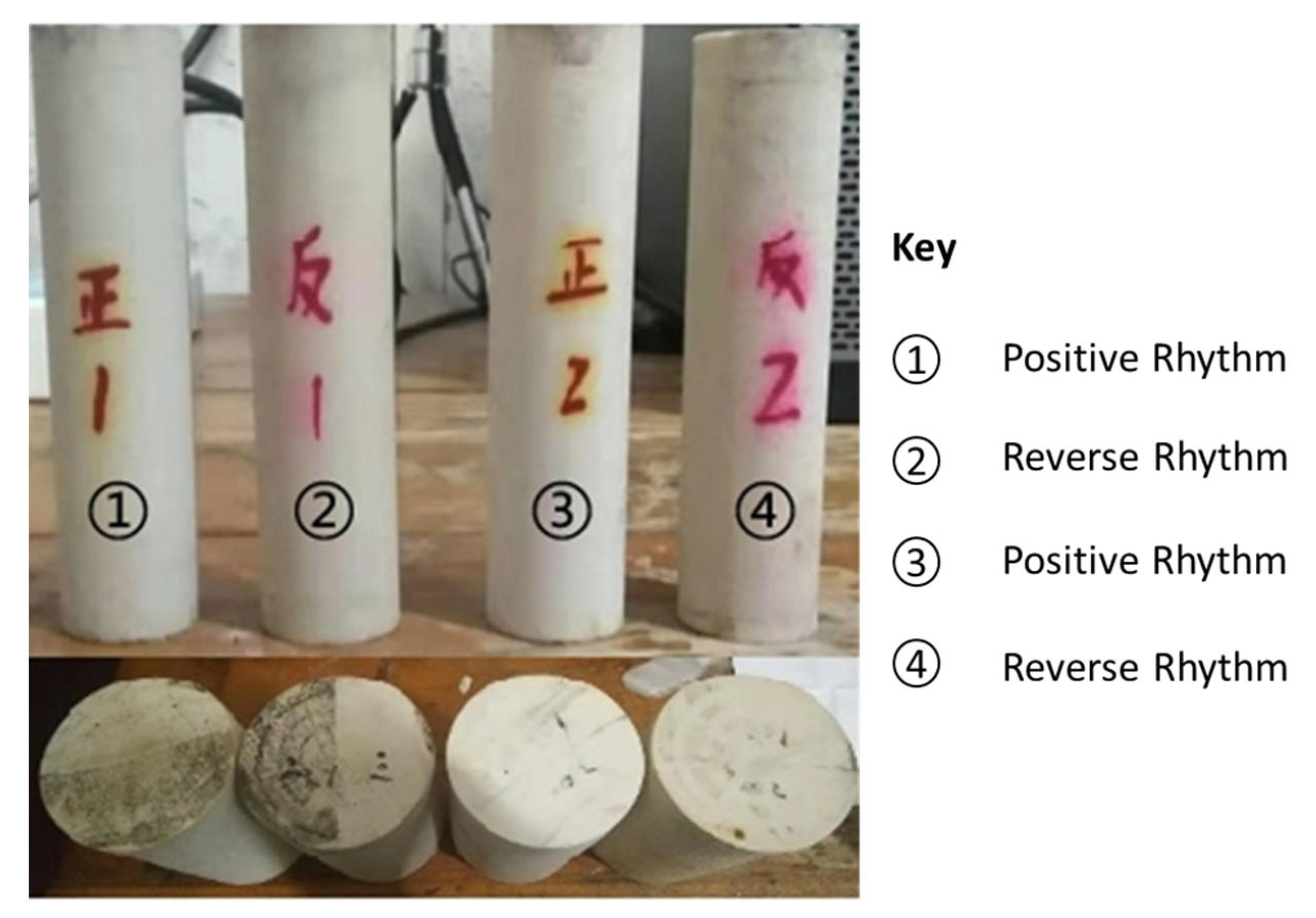

- Preparation of the core samples: the diameter and length of the core samples were measured, and the bulk volume of the core samples was calculated;

- Measurement of the porosity and permeability: the core samples were saturated with brine at an injection rate of 0.5 mL/min for 90 min, then 1 mL/min for 45 min. The injected brine volume was about ten pore volumes (10 PV) to ensure that the core samples were fully saturated with the brine;

- Oil saturation and measurement of initial oil saturation: crude oil was injected into the core at 0.5 mL/min until the water cut was zero, then the initial oil saturation was calculated. After that, the core was aged for 2–3 days at 42 °C;

- Flue gas flooding: the flue gas flooding was performed in an oven at 42 °C. The overburden pressure was 20 MPa, and the back pressure was 14 MPa. The gas injection rate was 0.5 mL/min. The amount of oil produced and the inlet pressure were measured every 2 min. The flue gas was injected into the core sample until there was no oil production;

- Injection of brine-slug or nanoparticle solution slug: the brine-slug or nanoparticle solution slug was injected into the core sample at 0.5 mL/min for 0.2 PV. The amount of oil produced and the inlet pressure were recorded;

- Flue gas flooding: the flue gas was injected into the core samples at 0.5 mL/min until there was no oil production. The amount of oil produced and the inlet pressure were recorded every 2 min. The oil recovery was then calculated.

3. Results and Discussion

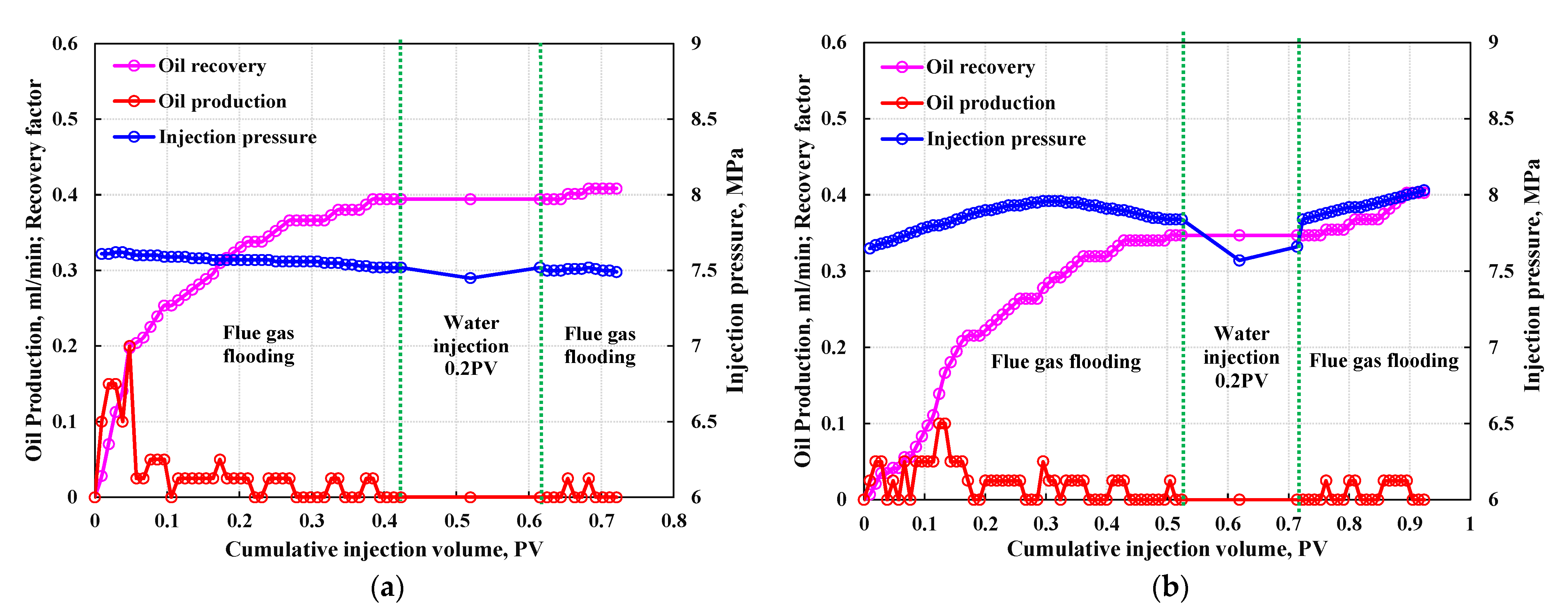

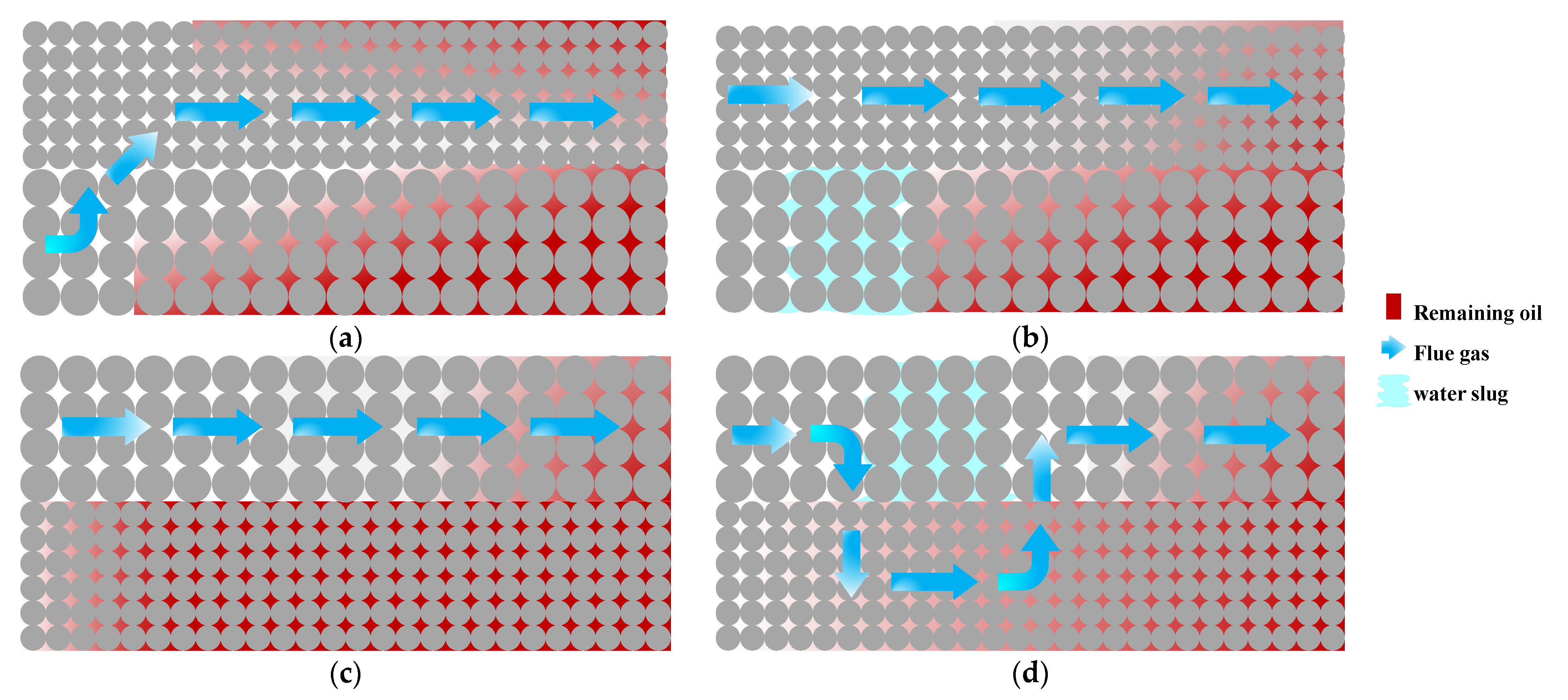

3.1. Effect of Heterogeneity on Flue Gas Flooding and Conformance Control

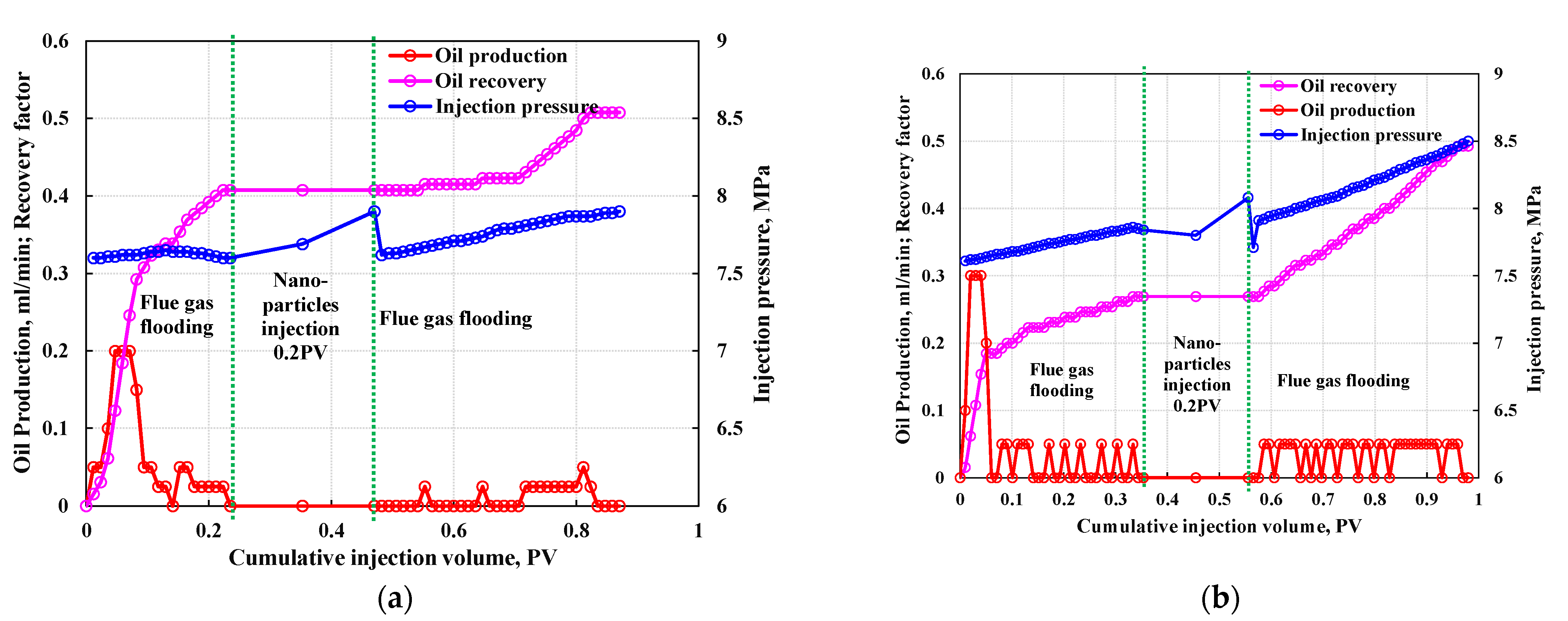

3.2. The Effect of Acidic Nanoparticles on Conformance Control during Flue Gas Flooding in Heterogeneous Reservoirs

4. Conclusions

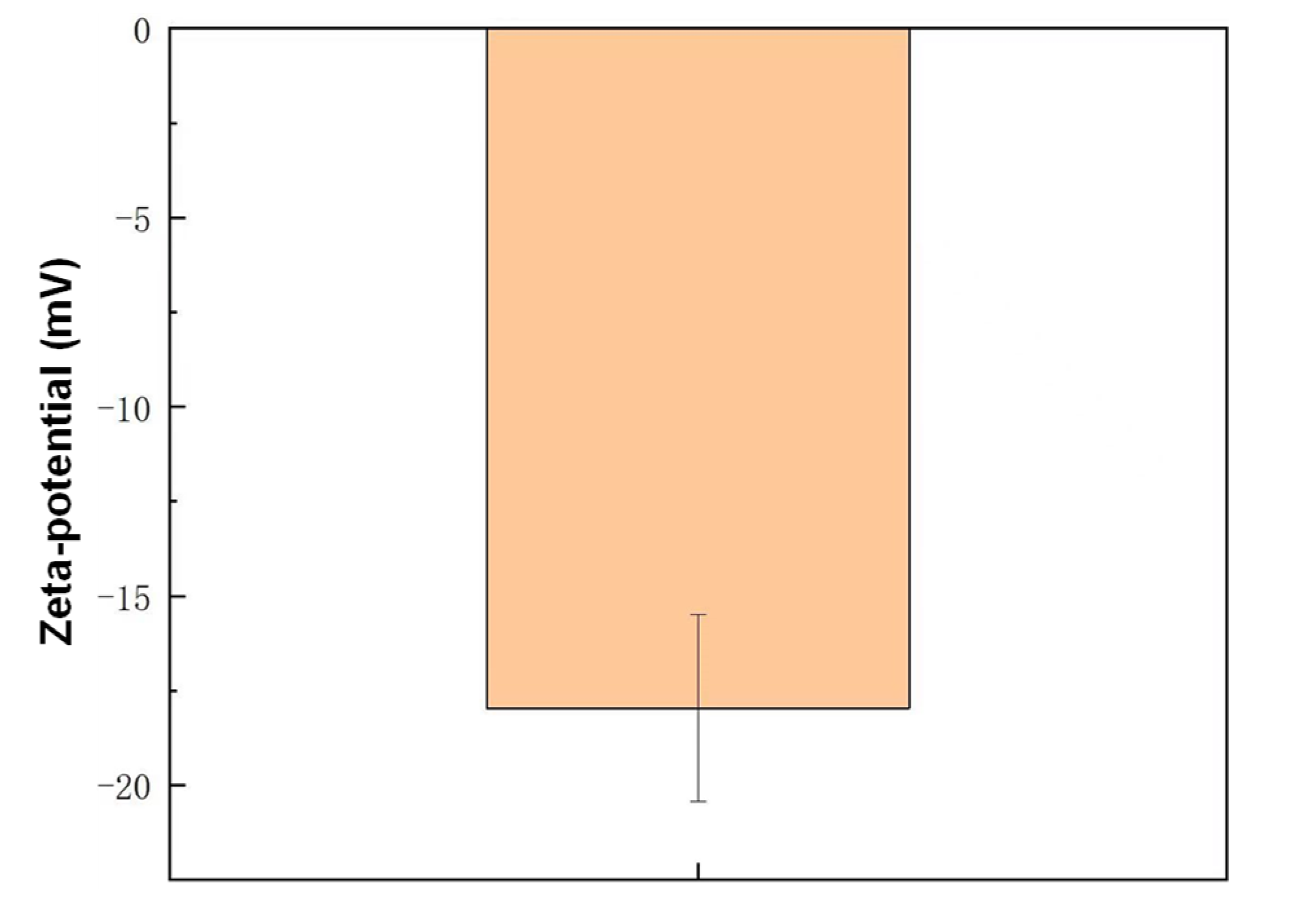

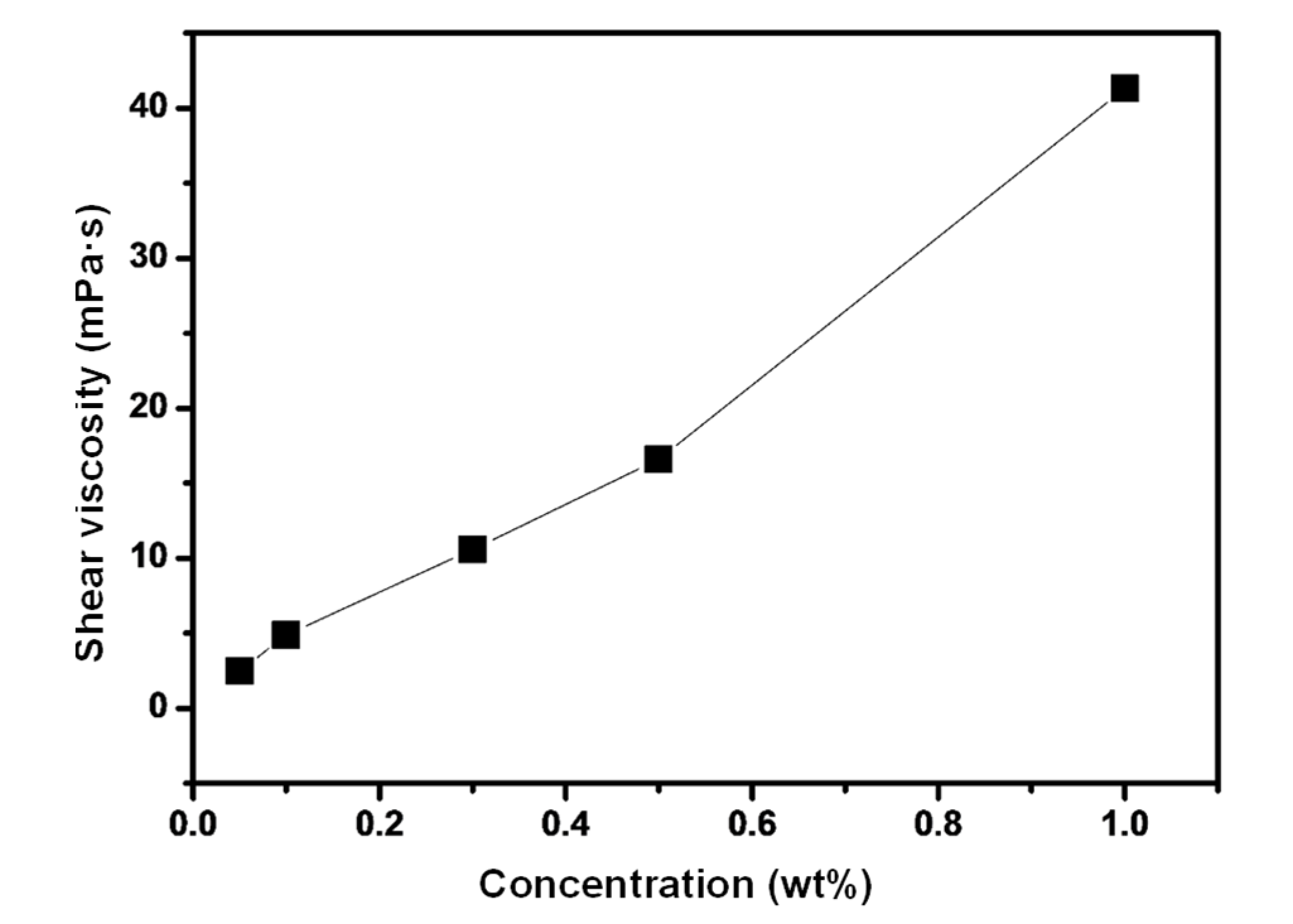

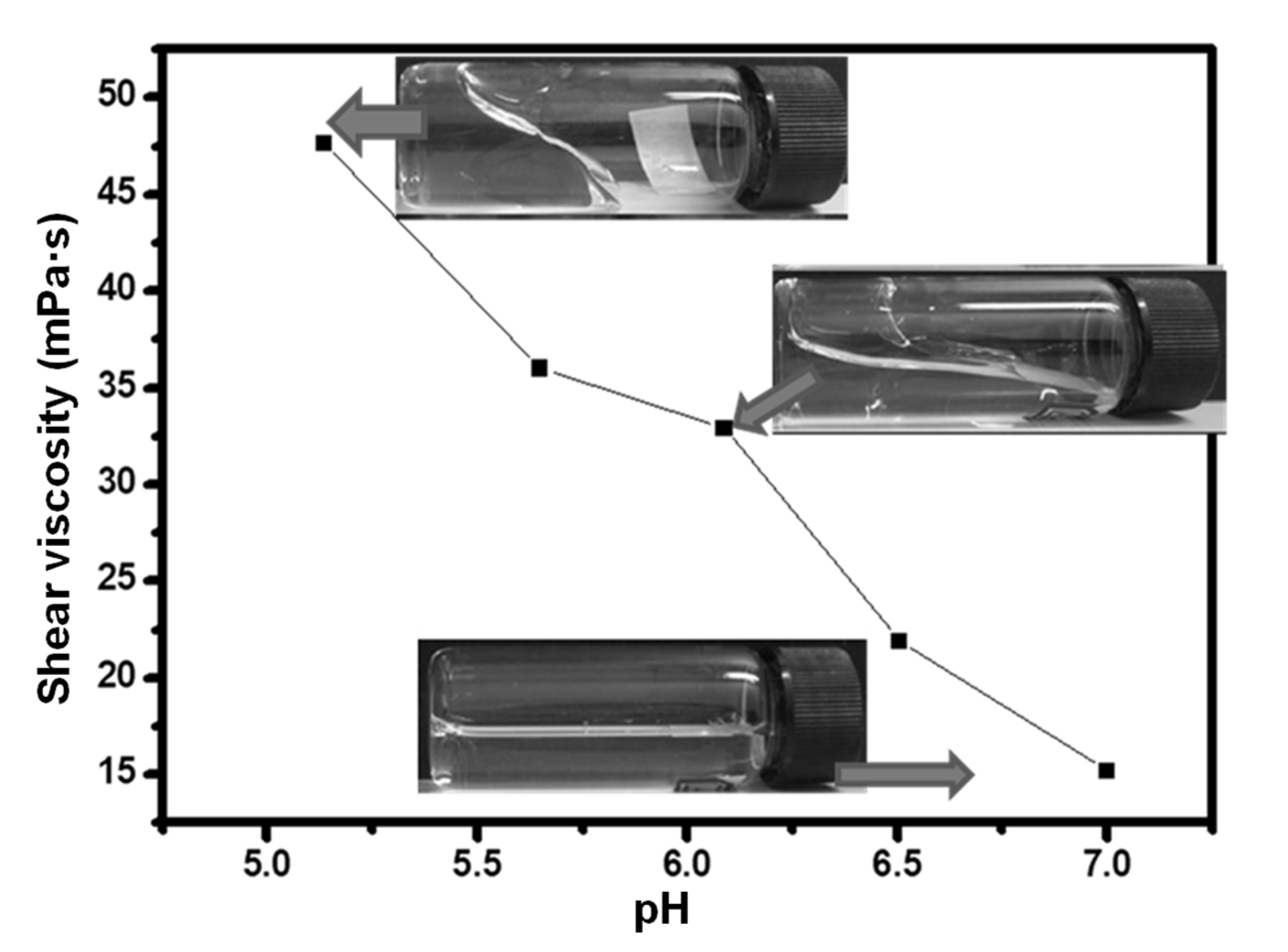

- A novel acidic nanoparticle with good dispersion and stability performance was developed. The zeta potential of the nanoparticle system is about −17.5, and the viscosity of the nanoparticle solution doubles as the pH decreases by 1;

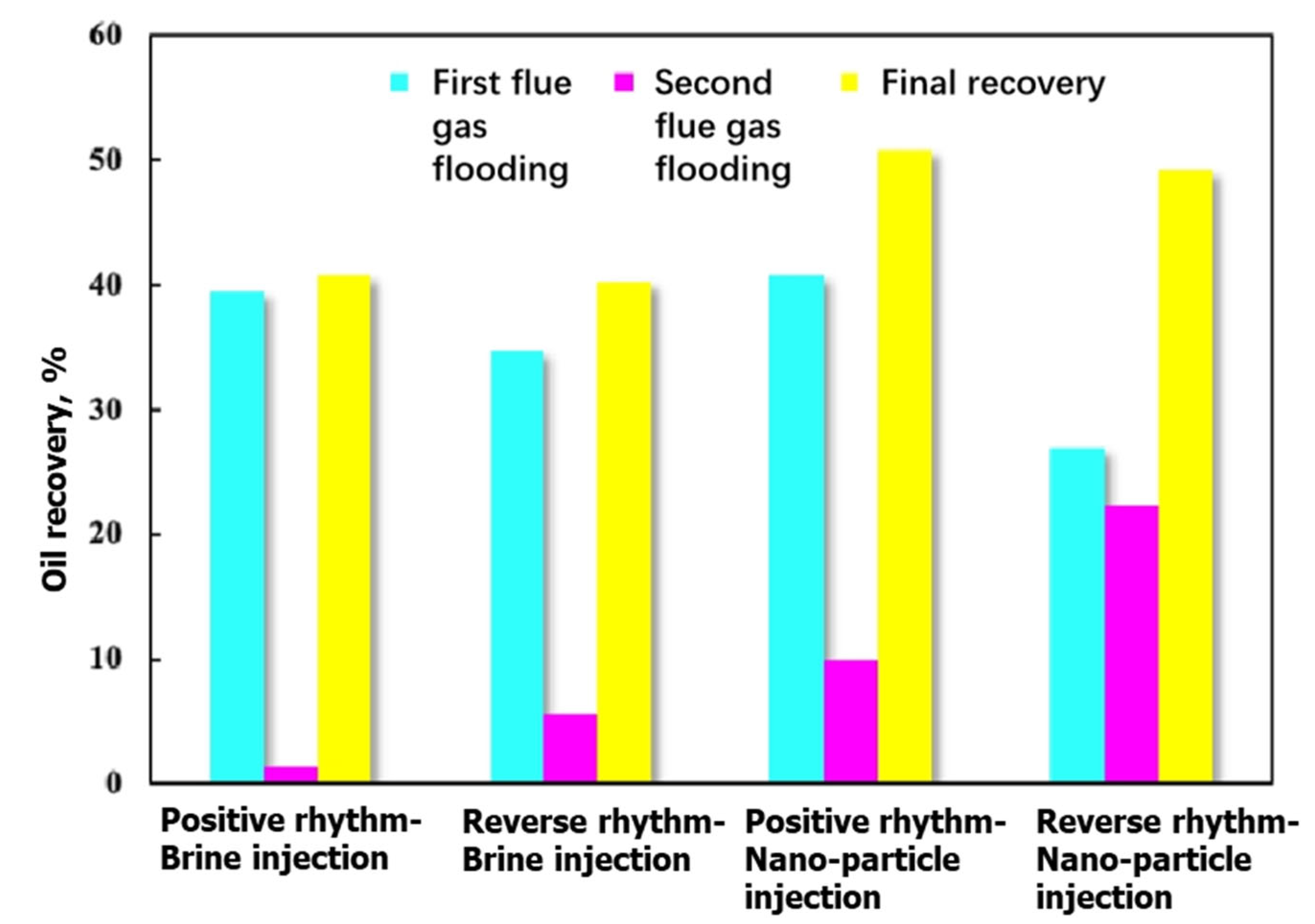

- The oil recovery of flue gas flooding from a positive rhythm core was 5–10% greater than that of a reverse rhythm core. The effect of water slug treatment on a reverse rhythm core is better than on a positive rhythm core;

- The oil recovery is enhanced by 10% for nanoparticle treatment in positive rhythm cores and by more than 20% in reverse rhythm cores. The ultimate oil recovery is around 50% by nanoparticle treatment of both positive and reverse rhythm cores, and it is 10% higher than that of water slug treatment. Therefore, the nanoparticle is more suitable than the aqueous solution for conformance control during flue gas flooding in heterogeneous reservoirs;

- The effect of flue gas flooding is better in a positive rhythm core under the action of gravity differentiation and least resistance. Water slugs can plug the upper high-permeability layer for least resistance to achieve a better effect for continued flue gas flooding in reverse rhythm cores. Nanoparticle treatment can achieve excellent effects due to its plugging ability, deformation characteristic, and viscosity increment in an acidic environment in reverse rhythm cores.

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| G | Gravity, N |

| MMP | Minimum miscible pressure, kPa |

| ΔF | Resistance, N |

| ΔP | Pressure difference, kPa |

References

- Tang, W.; Sheng, J.J. Huff-n-puff gas injection or gas flooding in tight oil reservoirs. J. Pet. Sci. Eng. 2022, 208, 109725. [Google Scholar] [CrossRef]

- Tang, Y.; Chen, Y.; He, Y.; Yu, G.; Guo, X.; Yang, Q.; Wang, Y. An improved system for evaluating the adaptability of natural gas flooding in enhancing oil recovery considering the miscible ability. Energy 2021, 236, 121441. [Google Scholar] [CrossRef]

- Yu, T.; Li, Q.; Hu, H.; Tan, Y.; Xu, L. Residual oil retention and stripping mechanism of hydrophilic pore surfaces during CO2 and N2 combined gas flooding. J. Pet. Sci. Eng. 2022, 218, 110989. [Google Scholar] [CrossRef]

- Tang, Y.; Zhang, H.; He, Y.; Guo, X.; Fan, K.; Wu, Z.; Zhou, D.; Tao, Z.; Li, J. A novel type curve for estimating oil recovery factor of gas flooding. Pet. Explor. Dev. 2022, 49, 605–613. [Google Scholar] [CrossRef]

- Ma, L.; Duan, X.; Wu, J.; Li, J.; Peng, L.; Wang, L.; Xiao, L. Simultaneous desulfurization and denitrification of flue gas enabled by hydrojet cyclone. J. Clean. Prod. 2022, 377, 134205. [Google Scholar] [CrossRef]

- Lu, S.; Fang, M.; Wang, Q.; Huang, L.; Sun, W.; Zhang, Y.; Li, Q.; Zhang, X. Public acceptance investigation for 2 million tons/year flue gas CO2 capture, transportation and oil displacement storage project. Int. J. Greenh. Gas Control. 2021, 111, 103442. [Google Scholar] [CrossRef]

- Wang, J.; Bai, H.; Wang, S.; Ji, Z.; Liu, H. Feasibility study on using CO2-rich industrial waste gas replacement for shale gas exploration based on adsorption characteristics. Chem. Eng. J. 2022, 443, 136386. [Google Scholar] [CrossRef]

- Yagihara, K.; Ohno, H.; Guzman-Urbina, A.; Ni, J.; Fukushima, Y. Analyzing flue gas properties emitted from power and industrial sectors toward heat-integrated carbon capture. Energy 2022, 250, 123775. [Google Scholar] [CrossRef]

- Chen, H.; Li, H.; Li, Z.; Li, S.; Wang, Y.; Wang, J.; Li, B. Effects of matrix permeability and fracture on production characteristics and residual oil distribution during flue gas flooding in low permeability/tight reservoirs. J. Pet. Sci. Eng. 2020, 195, 107813. [Google Scholar] [CrossRef]

- Jing, W.; Hao, B.; Shun, W.; Renjing, L.; Zemin, J.; Huiqing, L.; Omara, E.R. Feasibility study on CO2-rich industrial waste gas storage and replacement in carbonate gas reservoir based on adsorption characteristics. J. Pet. Sci. Eng. 2022, 217, 110938. [Google Scholar] [CrossRef]

- Wang, Z.; Li, S.; Li, Z. A novel strategy to reduce carbon emissions of heavy oil thermal recovery: Condensation heat transfer performance of flue gas-assisted steam flooding. Appl. Therm. Eng. 2022, 205, 118076. [Google Scholar] [CrossRef]

- Sun, H.; Wang, Z.; Sun, Y.; Wu, G.; Sun, B.; Sha, Y. Laboratory evaluation of an efficient low interfacial tension foaming agent for enhanced oil recovery in high temperature flue-gas foam flooding. J. Pet. Sci. Eng. 2020, 195, 107580. [Google Scholar] [CrossRef]

- Jiang, M.; Liu, Y.; Zhang, Y.; Cao, S.; Fang, H. Study on sedimentary facies and prediction of favorable reservoir areas in the Fuyu reservoir in the Bayanchagan area. J. Environ. Manag. 2022, 321, 115960. [Google Scholar] [CrossRef]

- Shang, X.; Hou, J.; Dong, Y. Genesis of reservoir heterogeneity and its impacts on petroleum exploitation in beach-bar sandstone reservoirs: A case study from the Bohai Bay Basin, China. Energy Geosci. 2022, 3, 35–48. [Google Scholar] [CrossRef]

- Jin, G.; Liu, J.; Liu, L.; Zhai, H.; Wu, D.; Su, J.; Xu, T. Effect of lithological rhythm of a confined hydrate reservoir on gas production performance using water flooding in five-spot vertical well system. J. Nat. Gas Sci. Eng. 2021, 92, 104019. [Google Scholar] [CrossRef]

- Jin, G.; Liu, J.; Liu, L.; Zhai, H.; Wu, D.; Xu, T. Effect of lithological rhythm on gas production performance via depressurization through a vertical well in a confined hydrate reservoir. Mar. Pet. Geol. 2020, 122, 104696. [Google Scholar] [CrossRef]

- Wu, Z.; Huiqing, L.; Cao, P.; Yang, R. Experimental investigation on improved vertical sweep efficiency by steam-air injection for heavy oil reservoirs. Fuel 2021, 285, 119138. [Google Scholar] [CrossRef]

- Liu, P.; Zhang, X. Enhanced oil recovery by CO2–CH4 flooding in low permeability and rhythmic hydrocarbon reservoir. Int. J. Hydrogen Energy 2015, 40, 12849–12853. [Google Scholar] [CrossRef]

- Yu, H.; Wang, Y.; Zhang, L.; Zhang, Q.; Guo, Z.; Wang, B.; Sun, T. Remaining oil distribution characteristics in an oil reservoir with ultra-high water-cut. Energy Geosci. 2022, 100116. [Google Scholar] [CrossRef]

- Cui, M.; Wang, R.; Lun, Z.; Lv, C. Characteristics of water alternating CO2 injection in low-permeability beach-bar sand reservoirs. Energy Geosci. 2022, 100119. [Google Scholar] [CrossRef]

- Zhao, Y.; Rui, Z.-H.; Zhang, Z.; Chen, S.-W.; Yang, R.-F.; Du, K.; Dindoruk, B.; Yang, T.; Stenby, E.H.; Wilson, M.A. Importance of conformance control in reinforcing synergy of CO2 EOR and sequestration. Pet. Sci. 2022; in press. [Google Scholar]

- Yang, H.B.; Zhou, B.B.; Zhu, T.Y.; Wang, P.X.; Zhang, X.F.; Wang, T.Y.; Wu, F.P.; Zhang, L.; Kang, W.L.; Ketova, Y.A.; et al. Conformance control mechanism of low elastic polymer microspheres in porous medium. J. Pet. Sci. Eng. 2021, 196, 107708. [Google Scholar] [CrossRef]

- Yang, J.; Hou, J.; Qu, M.; Liang, T.; Wen, Y. Experimental study the flow behaviors and mechanisms of nitrogen and foam assisted nitrogen gas flooding in 2-D visualized fractured-vuggy model. J. Pet. Sci. Eng. 2020, 194, 107501. [Google Scholar] [CrossRef]

- Das, A.; Mohanty, K.; Nguyen, Q. A pore-scale study of foam-microemulsion interaction during low tension gas flooding using microfluidics- secondary recovery. J. Pet. Sci. Eng. 2021, 201, 108444. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, J.; Li, X.; Xu, C.; Chen, X.; Zhang, B.; Zhao, G.; Zhang, H.; Li, Y. Conformance control by a microgel in a multi-layered heterogeneous reservoir during CO2 enhanced oil recovery process. Chin. J. Chem. Eng. 2022, 43, 324–334. [Google Scholar] [CrossRef]

- Di, Q.F.; Shuai HU, A.; Ding, W.P.; Wei, G.; Cheng, Y.C.; Feng, Y. Application of support vector machine in drag reduction effect prediction of nanoparticles adsorption method on oil reservoir’s micro-channels. J. Hydrodyn. 2015, 27, 99–104. [Google Scholar] [CrossRef]

- Hou, G.; Zhao, W.; Jia, Y.; Yuan, X.; Zhou, J.; Liu, T.; Hou, J. Field Application of Nanoscale Polymer Microspheres for In-Depth Profile Control in the Ultralow Permeability Oil Reservoir. Front. Chem. 2020, 8, 805. [Google Scholar] [CrossRef]

- Wang, J.; Zhou, F.J.; Li, J.J.; Yang, K.; Zhang, L.F.; Fan, F. Evaluation of the oil/water selective plugging performance of nano-polymer microspheres in fractured carbonate reservoirs. J. Zhejiang Univ. Sci. A 2019, 20, 714–726. [Google Scholar] [CrossRef]

| Number | Diameter, cm | Length, cm | Porosity, % | Soi | Kl, mD | Kh, mD |

|---|---|---|---|---|---|---|

| ① | 2.51 | 10.02 | 20.91 | 0.6827 | 9.56 | 53.82 |

| ② | 10.21 | 20.72 | 0.6857 | |||

| ③ | 9.74 | 19.23 | 0.6989 | |||

| ④ | 9.91 | 20.12 | 0.6566 |

| Components | Composition, mol% |

|---|---|

| N2 | 74.97 |

| CO2 | 15.25 |

| O2 | 3.38 |

| H2S | 0.06 |

| C3H8 | 0.14 |

| C2H6 | 0.29 |

| CH4 | 5.92 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ji, Z.; Zhang, Q.; Gao, Y.; Wang, J.; He, C.; Han, L.; Zhao, W. Experimental Study on Conformance Control Using Acidic Nanoparticles in a Heterogeneous Reservoir by Flue Gas Flooding. Energies 2023, 16, 315. https://doi.org/10.3390/en16010315

Ji Z, Zhang Q, Gao Y, Wang J, He C, Han L, Zhao W. Experimental Study on Conformance Control Using Acidic Nanoparticles in a Heterogeneous Reservoir by Flue Gas Flooding. Energies. 2023; 16(1):315. https://doi.org/10.3390/en16010315

Chicago/Turabian StyleJi, Zemin, Qun Zhang, Yang Gao, Jing Wang, Chang He, Lu Han, and Wenjing Zhao. 2023. "Experimental Study on Conformance Control Using Acidic Nanoparticles in a Heterogeneous Reservoir by Flue Gas Flooding" Energies 16, no. 1: 315. https://doi.org/10.3390/en16010315