Towards the Integration of Flexible Green Hydrogen Demand and Production in Ireland: Opportunities, Barriers, and Recommendations

Abstract

1. Introduction

- The EU’s strategic objective from 2020 up to 2024 is to install at least 6 GW of renewable hydrogen electrolyzers in the EU and the production of up to 1 million tons of renewable hydrogen (produced using mainly wind and solar energy).

- In the second stage, from 2025 to 2030, electrolysis with a capacity of 100 MW next to existing industrial demand centers such as larger refineries, steel plants, and chemical plants will be rolled out. They would ideally be powered directly by local renewable electricity sources. Furthermore, hydrogen refueling stations will be used to support hydrogen fuel-cell buses and, at a later stage, trucks. Electrolyzers will thus also be used to locally supply an increasing number of hydrogen refueling stations.

- Contribute to increasing the trust of the stakeholders by supporting the demonstration of hydrogen technologies to prove that they met the readiness level required for their deployment.

- Determine which production pathways for low-carbon (green) hydrogen should be prioritized.

- Support the development of the hydrogen infrastructure (production, storage, distribution and delivery, refueling stations, consumption, etc.) by direct or indirect incentivization mechanisms.

- Stimulate the demand of green hydrogen in case the selling price of green hydrogen is too high.

- Establish a certification mechanism for green hydrogen.

- Electricity: 62–81%

- Transport: 42–50%

- Buildings: 44–56%

- Industry/Enterprise: 29–41%

- Agriculture: 22–30% reduction

- Land Use, Land Use Change and Forestry (LULUCF): 37–58%

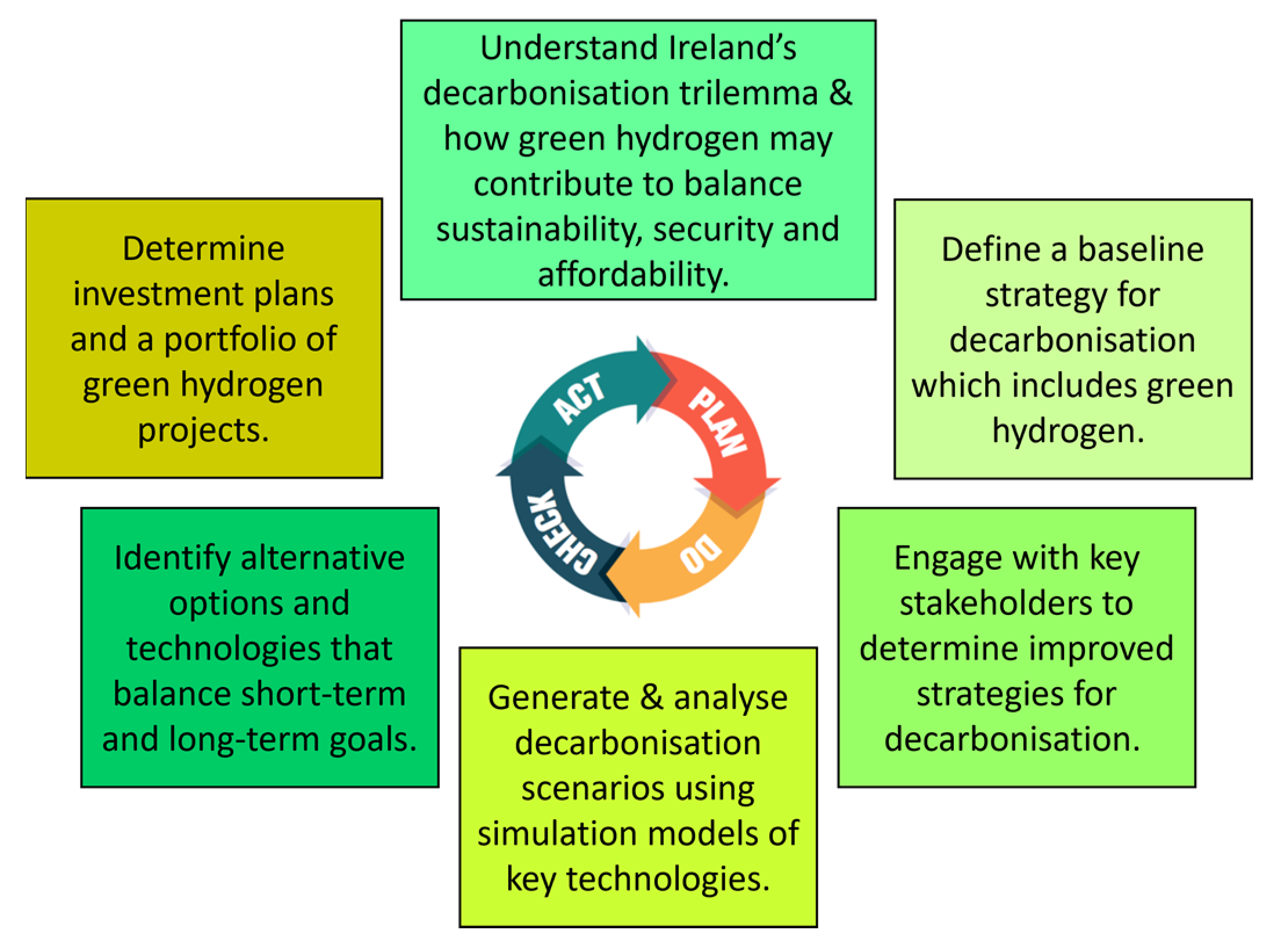

2. Methodology

- Support the development of a low-carbon hydrogen policy in Ireland;

- Collect evidence on the challenges and opportunities associated with the production of low-carbon hydrogen in Ireland;

- Collect evidence on the challenges and opportunities associated with the distribution and delivery of low-carbon hydrogen in Ireland;

- Collect evidence on the challenges and opportunities associated with the consumption of low-carbon hydrogen in Ireland;

- Revise the recommendations to the policymaker previously formulated.

3. A Hydrogen Policy in Ireland

4. Hydrogen Production

5. Hydrogen Distribution and Delivery

6. Hydrogen Consumption

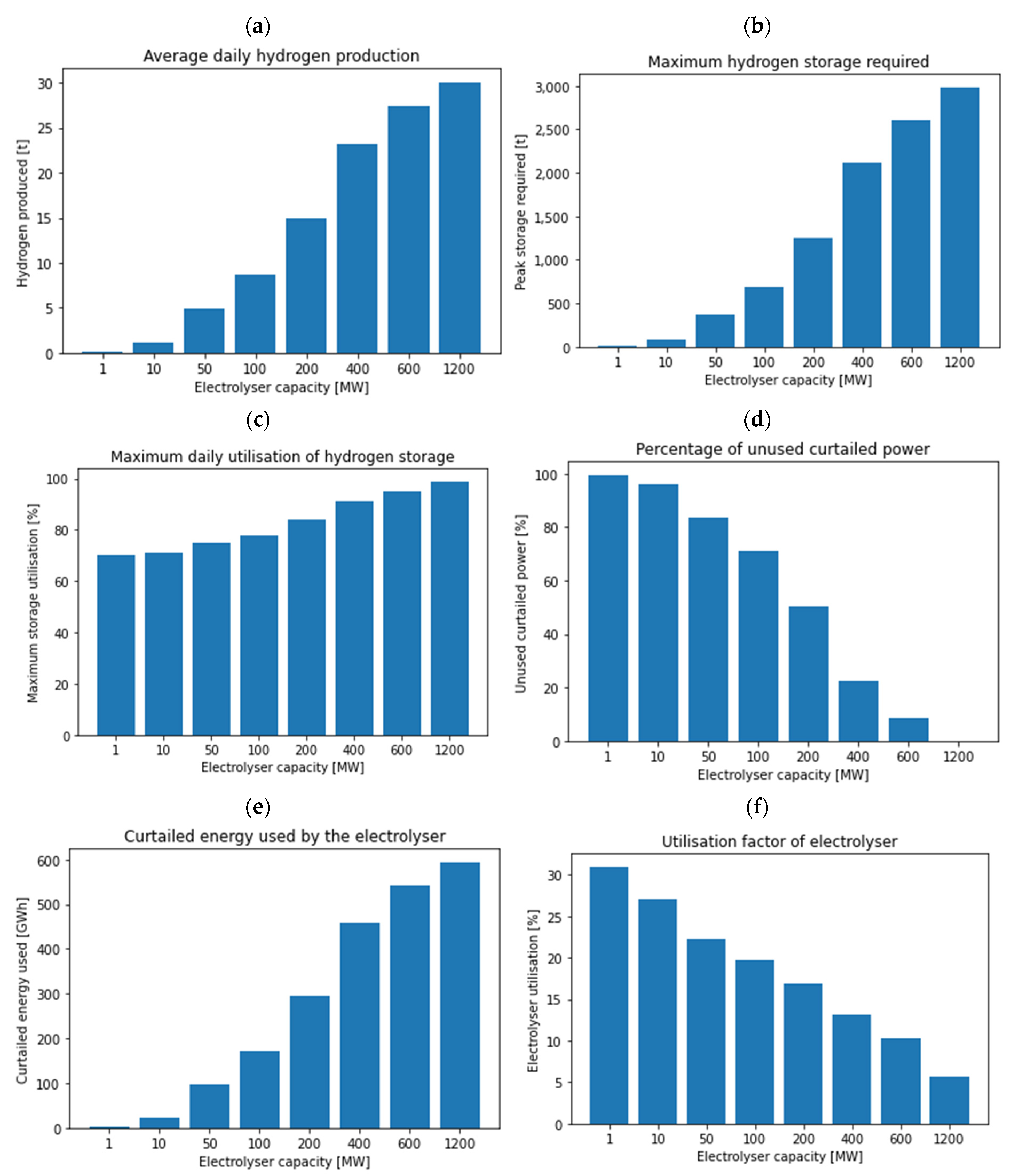

7. Integration of Hydrogen in the Power System

8. Recommendations

8.1. Recommendation 1: Demonstrate the Use of Green Hydrogen in Road Transportation

8.2. Recommendation 2: Build-Up Additional Renewable Energy Sources for Green Hydrogen Production and Provide Support for Green Hydrogen Production Using Curtailed Renewable Power When Applicable

8.3. Recommendation 3: Incentivize the Production of Green Hydrogen by Introducing Quotas for Green Hydrogen to Drive Demand in Case Its Selling Price Is Too High and Allow Auctions for Hydrogen Production Using Electricity from Renewables

8.4. Recommendation 4: Demonstrate the Use of Hydrogen as a Flexibility Provider to Perform Power System Balancing

8.5. Recommendation 5: Investigate and Demonstrate the Blending of Hydrogen into the Existing Gas Network

8.6. Recommendation 6: Investigate the Feasibility of Low-Carbon Hydrogen Using Carbon Capture and Storage Technologies Applicable to Geological Basins and Structures in Ireland

8.7. Recommendation 7: Robustly Evaluate the Feasibility of Large-Scale Hydrogen Storage in Salt Caverns

8.8. Recommendation 8: Establish a Greenhouse Gas Emissions Standard for Low-Carbon Hydrogen That Meets Multiple Relevant Criteria

8.9. Recommendation 9: Demonstrate Storage and Conversion Technologies Such as Power-to-Gas and Gas-to-Power Conversion in Microgrids

9. Discussion

10. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bleischwitz, R.; Bader, N. Policies for the transition towards a hydrogen ecoomy: The EU case. Energy Policy 2010, 38, 5388–5398. [Google Scholar] [CrossRef]

- Trans-European Networks for Energy, The European Commission. Available online: https://ec.europa.eu/energy/topics/infrastructure/trans-european-networks-energy_en (accessed on 14 October 2021).

- Available online: https://www.catf.us/2021/05/european-parliament-hydrogen-strategy/ (accessed on 16 August 2021).

- European Commission. A Hydrogen Strategy for a Climate-Neutral Europe. 2022. Available online: https://ec.europa.eu/commission/presscorner/api/files/attachment/865942/EU_Hydrogen_Strategy.pdf (accessed on 22 December 2022).

- Dodds, P.E.; Staffell, I.; Hawkes, A.D.; Li, F.; Grünewald, P.; McDowall, W.; Ekins, P. Hydrogen and fuel cell technologies for heating: A review. Int. J. Hydrog. Energy 2015, 40, 2065–2083. [Google Scholar] [CrossRef]

- Schiro, F.; Stoppato, A.; Benato, A. Modelling and analyzing the impact of hydrogen enriched natural gas on domestic gas boilers in a decarbonisation perspective. Carbon Resour. Convers. 2020, 3, 122–129. [Google Scholar] [CrossRef]

- The Government of Ireland. Ireland’s National Energy and Climate Plan 2021–2030. 2021. Available online: https://www.gov.ie/en/publication/0015c-irelands-national-energy-climate-plan-2021-2030/ (accessed on 4 June 2022).

- Machado, J.T.M.; Flynn, B.M.; Williamson, I. The national shaping of Europe’s Emerging Hydrogen Strategies: Coop-erative or Competitive Hydrogen politics? In Proceedings of the 10th FSR Annual Conference, Infrastructure investment challenges: Reconciling competition, decarbonisation and digitalisation, Online, 10–11 June 2021.

- Sasanpour, S.; Cao, K.-K.; Gils, H.C.; Jochem, P. Strategic policy targets and the contribution of hydrogen in a 100% renewable European power system. Energy Rep. 2021, 7, 4595–4608. [Google Scholar] [CrossRef]

- Ministry for the Ecological Transition and the Demographic Challenge. Hydrogen Roadmap European Gas Regulatory Forum. 2020. Available online: https://commission.europa.eu/system/files/2020-10/02.03.02_mf34_presentation-spain-hydrogen_roadmap-cabo.pdf (accessed on 22 December 2022).

- Fernandes, L.; Ferreira, P. Renewable energy scenarios in the Portuguese electricity system. Energy 2014, 69, 51–57. [Google Scholar] [CrossRef]

- Khatiwada, D.; Vasudevan, R.A.; Santos, B.H. Decarbonization of natural gas systems in the EU—Costs, barriers, and constraints of hydrogen production with a case study in Portugal. Renew. Sustain. Energy Rev. 2022, 168, 112775. [Google Scholar] [CrossRef]

- Maïzi, N.; Assoumou, E. Future prospects for nuclear power in France. Appl. Energy 2014, 136, 849–859. [Google Scholar] [CrossRef]

- Shirizadeh, B.; Quirion, P. Long-Term Optimization of the Hydrogen-Electricity Nexus in France: Green, Blue, or Pink Hydro-gen? Available online: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=4169441 (accessed on 22 December 2022).

- Pastore, L.M.; Basso, G.L.; Sforzini, M.; de Santoli, L. Technical, economic and environmental issues related to electrolysers capacity targets according to the Italian Hydrogen Strategy: A critical analysis. Renew. Sustain. Energy Rev. 2022, 166, 112685. [Google Scholar] [CrossRef]

- The Italian Hydrogen Strategy. Available online: https://www.wfw.com/articles/the-italian-hydrogen-strategy/ (accessed on 20 August 2021).

- UK Hydrogen Strategy Published, with Government Targeting £4bn of Private Investment by 2030. Available online: https://www.edie.net/uk-hydrogen-strategy-published-with-government-targeting-4bn-of-private-investment-by-2030 (accessed on 22 December 2022).

- Ofgem Gives Green Light to £12.7m Hydrogen Trial Project. Available online: https://www.nationalgrid.com/30-november-ofgem-gives-green-light-ps127m-hydrogen-trial-project (accessed on 4 June 2022).

- HyDeploy: UK Gas Grid Injection of Hydrogen in Full Operation. Available online: https://itm-power.com/news/hydeploy-uk-gas-grid-injection-of-hydrogen-in-full-operation (accessed on 22 December 2022).

- Laguipo, J.; Forde, C.; Carton, J.G. Enabling the scale up of green hydrogen in Ireland by decarbonising the haulage sector. Int. J. Hydrogen Energy 2022, 47, 26812–26826. [Google Scholar] [CrossRef]

- dos Santos, R.M.; Szklo, A.; Lucena, A.F.; de Miranda, P.E.V. Blue sky mining: Strategy for a feasible transition in emerging countries from natural gas to hydrogen. Int. J. Hydrog. Energy 2021, 46, 25843–25859. [Google Scholar] [CrossRef]

- Moradi, R.; Groth, K.M. Hydrogen storage and delivery: Review of the state of the art technologies and risk and reliability analysis. Int. J. Hydrogen Energy 2019, 44, 12254–12269. [Google Scholar] [CrossRef]

- Gaur, A.S.; Fitiwi, D.Z.; Lynch, M.; Longoria, G. Implications of heating sector electrification on the Irish power system in view of the Climate Action Plan. Energy Policy 2022, 168, 113136. [Google Scholar] [CrossRef]

- Longoria, G.; Lynch, M.; Curtis, J. Green hydrogen for heating and its impact on the power system. Int. J. Hydrogen Energy 2021, 46, 26725–26740. [Google Scholar] [CrossRef]

- Cheng, W.; Lee, S. How Green Are the National Hydrogen Strategies? Sustainability 2022, 14, 1930. [Google Scholar] [CrossRef]

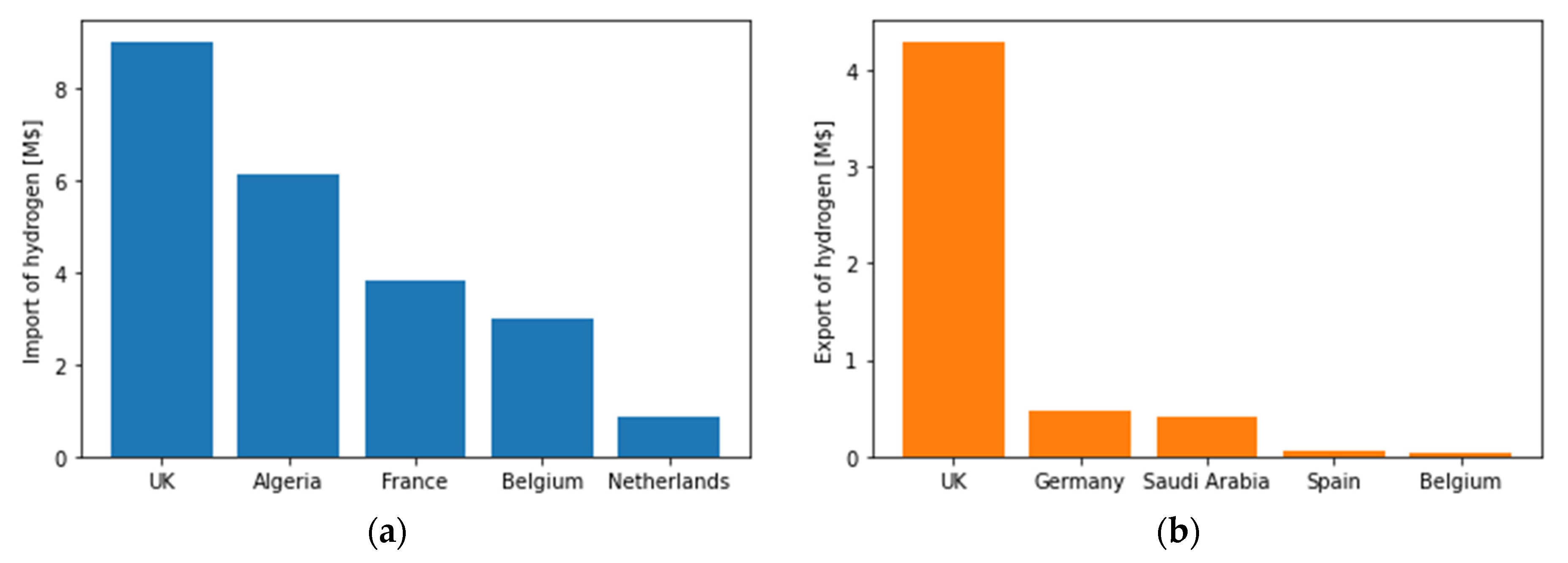

- Hydrogen in Ireland. Available online: https://oec.world/en/profile/bilateral-product/hydrogen/reporter/irl (accessed on 19 September 2021).

- Okolie, J.A.; Patra, B.R.; Mukherjee, A.; Nanda, S.; Dalai, A.K.; Kozinski, J.A. Futuristic applications of hydrogen in energy, biorefining, aerospace, pharmaceuticals and metallurgy. Int. J. Hydrogen Energy 2021, 46, 8885–8905. [Google Scholar] [CrossRef]

- Burkin, A.R. PRODUCTION OF SOME METAL POWDERS BY HYDROMETALLURGICAL PROCESSES*. Powder Met. 1969, 12, 243–250. [Google Scholar] [CrossRef]

- Bhaskar, A.; Assadi, M.; Somehsaraei, H.N. Decarbonization of the Iron and Steel Industry with Direct Reduction of Iron Ore with Green Hydrogen. Energies 2020, 13, 758. [Google Scholar] [CrossRef]

- Modak, J.M. Haber process for ammonia synthesis. Resonance 2011, 16, 1159–1167. [Google Scholar] [CrossRef]

- Khademi, M.; Rahimpour, M.; Jahanmiri, A. Differential evolution (DE) strategy for optimization of hydrogen production, cyclohexane dehydrogenation and methanol synthesis in a hydrogen-permselective membrane thermally coupled reactor. Int. J. Hydrogen Energy 2010, 35, 1936–1950. [Google Scholar] [CrossRef]

- Ramachandran, R.; Menon, R.K. An overview of industrial uses of hydrogen. Int. J. Hydrog. Energy 1998, 23, 593–598. [Google Scholar] [CrossRef]

- Reddy, S.Y.; Nalinakshi, M.; Chetana, R. Fully hydrogenated vegetable oil as a stabilizer for low fat butter spreads. J. Food Lipids 1999, 6, 245–259. [Google Scholar] [CrossRef]

- Zier, M.; Stenzel, P.; Kotzur, L.; Stolten, D. A review of decarbonization options for the glass industry. Energy Convers. Manag. X 2021, 10, 100083. [Google Scholar] [CrossRef]

- Prieto, M.; Díaz, J.; Egusquiza, E. Analysis of the fluid-dynamic and thermal behaviour of a tin bath in float glass manufacturing. Int. J. Therm. Sci. 2002, 41, 348–359. [Google Scholar] [CrossRef]

- Chevallier, J. Hydrogen and doping issues in wide band gap semiconductors. Mater. Sci. Eng. B 2000, 71, 62–68. [Google Scholar] [CrossRef]

- Belmans, R.; dos Reis, P.C.; Vingerhoets, P. Electrification and Sustainable Fuels: Competing for Wind and Sun (Complement to the Policy Brief), Working Paper Containing Calculations and Assumptions in Support of the Accompanying Policy Brief with the Same Title, European University Institute, Robert Schuman Centre for Advanced Studies, Florence School of Regulation. Available online: https://cadmus.eui.eu/bitstream/handle/1814/71402/RSC%202021_55.pdf (accessed on 12 September 2021).

- Gidey, E.; Jilcha, K.; Beshah, B.; Kitaw, D. The plan-do-check-act cycle of value addition. Ind. Eng. Manag. 2014, 3, 2169-0316. [Google Scholar]

- Flame Temperatures Table for Different Fuels. Available online: https://www.thoughtco.com/flame-temperatures-table-607307 (accessed on 12 February 2022).

- Panasyuk, V.; Andreykiv, O.; Gembara, O. Hydrogen degradation of materials under long-term operation of technological equipment. Int. J. Hydrogen Energy 2000, 25, 67–74. [Google Scholar] [CrossRef]

- Material Considerations When Working with Hydrogen, HySafe—Safety of Hydrogen as an Energy Carrier. Available online: http://www.hysafe.org/download/1002/BRHS%20Chap3%20-%20material%20consideration-version%201_0_1.pdf (accessed on 12 February 2022).

- Gas Networks Ireland. Network Development Plan. 2021. Available online: https://www.gasnetworks.ie/docs/corporate/gas-regulation/GNI-2021-Network-Development-Plan.pdf (accessed on 22 December 2022).

- Slorach, P.C.; Stamford, L. Net zero in the heating sector: Technological options and environmental sustainability from now to 2050. Energy Convers. Manag. 2021, 230, 113838. [Google Scholar] [CrossRef]

- European Climate Foundation. Modelling the Socioeconomic Impacts of Zero Carbon Housing in Europe. 2022. Available online: https://europeanclimate.org/wp-content/uploads/2022/03/modelling-the-socioeconomic-impact-of-zero-carbon-housing-in-europe-final-technical-report-march2022.pdf (accessed on 22 December 2022).

- Quarton, C.J.; Samsatli, S. How to incentivise hydrogen energy technologies for net zero: Whole-system value chain optimisation of policy scenarios. Sustain. Prod. Consum. 2021, 27, 1215–1238. [Google Scholar] [CrossRef]

- Ekhtiari, A.; Flynn, D.; Syron, E. Investigation of the Multi-Point Injection of Green Hydrogen from Curtailed Re-newable Power into a Gas Network. Energies 2020, 13, 6047. [Google Scholar] [CrossRef]

- European Environmental Bureau. Face to Face with Hydrogen. The Reality behind the Hype. An EEB Position Paper for a Bet-ter-Informed Approach to Hydrogen. Available online: https://mk0eeborgicuypctuf7e.kinstacdn.com/wp-content/uploads/2021/05/EEB-Hydrogen-Position-Paper-FINAL.pdf (accessed on 12 September 2021).

- Mercury Renewables Plans €200m Wind and Hydrogen Plant, The Irish Times (2021). Available online: https://www.irishtimes.com/business/energy-and-resources/mercury-renewables-plans-200m-wind-and-hyrdogen-plant-1.4752258 (accessed on 22 December 2022).

- European Commission. Powering a Climate Neutral Economy: Commission Sets Out Plans for the Energy System of the Future and Clean Hydrogen. 2020. Available online: https://ec.europa.eu/commission/presscorner/detail/en/ip_20_1259 (accessed on 22 December 2022).

- Cunanan, C.; Tran, M.-K.; Lee, Y.; Kwok, S.; Leung, V.; Fowler, M. A Review of Heavy-Duty Vehicle Powertrain Technologies: Diesel Engine Vehicles, Battery Electric Vehicles, and Hydrogen Fuel Cell Electric Vehicles. Clean Technol. 2021, 3, 474–489. [Google Scholar] [CrossRef]

- Valente, A.; Tulus, V.; Galán-Martín, Á.; Huijbregts, M.A.; Guillén-Gosálbez, G. The role of hydrogen in heavy transport to operate within planetary boundaries. Sustain. Energy Fuels 2021, 5, 4637–4649. [Google Scholar] [CrossRef] [PubMed]

- Atilhan, S.; Park, S.; El-Halwagi, M.M.; Atilhan, M.; Moore, M.; Nielsen, R.B. Green hydrogen as an alternative fuel for the shipping industry. Curr. Opin. Chem. Eng. 2021, 31, 100668, Erratum in 2021, 34, 100775. [Google Scholar] [CrossRef]

- Dincer, I.; Acar, C. A review on potential use of hydrogen in aviation applications. Int. J. Sustain. Aviat. 2016, 2, 74. [Google Scholar] [CrossRef]

- Nicita, A.; Maggio, G.; Andaloro, A.; Squadrito, G. Green hydrogen as feedstock: Financial analysis of a photovoltaic-powered electrolysis plant. Int. J. Hydrogen Energy 2020, 45, 11395–11408. [Google Scholar] [CrossRef]

- Transport, Environmental Protection Agency. Available online: https://www.epa.ie/our-services/monitoring--assessment/climate-change/ghg/transport/ (accessed on 11 November 2022).

- Robinius, M.; Linßen, J.F.; Grube, T.; Reuß, M.; Stenzel, P.; Syranidis, K.; Kuckertz, P.; Stolten, D. Comparative Analysis of Infrastructures: Hydrogen Fueling and Electric Charging of Vehicles; Energie & Umwelt/Energy & Environment Band/Volume 408; 2018; ISBN 978-3-95806-295-5. Available online: http://www.smartenergyportal.ch/wp-content/uploads/2018/04/Energie_Umwelt_408_NEU.pdf (accessed on 22 December 2022).

- Isenstadt, A.; Lutsey, N. Developing Hydrogen Fueling Infrastructure for Fuel Cell Vehicles: A Status Update, Briefing of the International Council of Clean Transportation. 2017. Available online: https://theicct.org/wp-content/uploads/2021/06/Hydrogen-infrastructure-status-update_ICCT-briefing_04102017_vF.pdf (accessed on 16 February 2022).

- Haglind, F.; Hasselrot, A.; Singh, R. Potential of reducing the environmental impact of aviation by using hydrogen Part I: Background, prospects and challenges. Aeronaut. J. 2006, 110, 533–540. [Google Scholar] [CrossRef]

- FAQ: The What and How of E-Kerosene. A Briefing of Transport and Environment. 2021. Available online: https://www.transportenvironment.org/wp-content/uploads/2021/02/FAQ-e-kerosene-1.pdf (accessed on 22 December 2022).

- Decarbonisation Potential of Synthetic Kerosene. E4tech (UK) Ltd for Ministerie van Infrastructuur en Waterstaat. 2021. Available online: https://assets.website-files.com/6144857e3aac5ad07ebf212f/615c3cb88f7f25a651a66e2f_2021_E4tech_Decarbonisation%20potential%20synthetic%20kerosine.pdf (accessed on 22 December 2022).

- Zhang, F.; Zhao, P.; Niu, M.; Maddy, J. The survey of key technologies in hydrogen energy storage. Int. J. Hydrogen Energy 2016, 41, 14535–14552. [Google Scholar] [CrossRef]

- Li, P.; Wang, R.; Xia, S.; Zhang, F. Low-carbon economic dispatch of power system based on mobile hydrogen storage. J. Physics Conf. Ser. 2022, 2276, 012007. [Google Scholar] [CrossRef]

- Caglayan, D.G.; Heinrichs, H.U.; Robinius, M.; Stolten, D. Robust design of a future 100% renewable european energy supply system with hydrogen infrastructure. Int. J. Hydrogen Energy 2021, 46, 29376–29390. [Google Scholar] [CrossRef]

- Schnuelle, C.; Wassermann, T.; Stuehrmann, T. Mind the Gap—A Socio-Economic Analysis on Price Developments of Green Hydrogen, Synthetic Fuels, and Conventional Energy Carriers in Germany. Energies 2022, 15, 3541. [Google Scholar] [CrossRef]

- Government of Ireland. Renewable Fuels for Transport. Policy Statement November 2021. 2021. Available online: https://assets.gov.ie/205285/331035ce-e45c-493d-99be-7b8bad6a9ba8.pdf (accessed on 22 December 2022).

- HM Government. UK Hydrogen Strategy. 2021. Available online: https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/1011283/UK-Hydrogen-Strategy_web.pdf (accessed on 22 December 2022).

- Why Green Hydrogen—But Not Grey—Could Help Solve Climate Change. Available online: https://theconversation.com/why-green-hydrogen-but-not-grey-could-help-solve-climate-change-162987 (accessed on 30 March 2022).

- van Renssen, S. The hydrogen solution? Nat. Clim. Change 2020, 10, 799–801. [Google Scholar] [CrossRef]

- Gas Price Spike Puts Green Hydrogen at Cost Parity with Fossil Fuels. Available online: https://www.spglobal.com/commodity-insights/en/market-insights/latest-news/electric-power/102221-european-green-hydrogen-costs-already-competitive-with-fossil-fuels-say-producers (accessed on 30 March 2022).

- Vartiainen, E.; Breyer, C.; Moser, D.; Medina, E.R.; Busto, C.; Masson, G.; Bosch, E.; Jäger-Waldau, A. True Cost of Solar Hydrogen. Sol. RRL 2021, 6, 2100487. [Google Scholar] [CrossRef]

- Martens, P.; Vandezande, B. What Is Pink Hydrogen, and Does It Have a Future in Belgium? 2022. Available online: https://www.agoria.be/en/climate-environment-energy/energy-climate/renewable-energy/what-is-pink-hydrogen-and-does-it-have-a-future-in-belgium (accessed on 17 August 2022).

- The U.S. Department of Energy. Office of Energy Efficiency & Renewable Energy. Hydrogen Production: Biomass Gasification. Available online: https://www.energy.gov/eere/fuelcells/hydrogen-production-biomass-gasification (accessed on 17 August 2022).

- National Renewable Energy Laboratory. Hydrogen Production Cost Estimate Using Biomass Gasification. Report NREL/BK-6A10-51726. 2011. Available online: https://www.hydrogen.energy.gov/pdfs/51726.pdf (accessed on 17 August 2022).

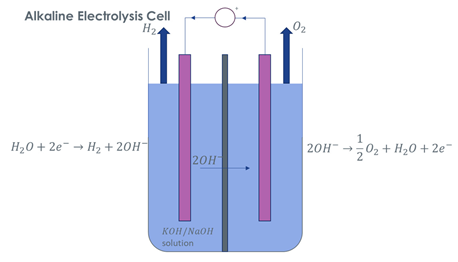

- Guo, Y.; Li, G.; Zhou, J.; Liu, Y. Comparison between hydrogen production by alkaline water electrolysis and hydrogen production by PEM electrolysis. IOP Conf. Series: Earth Environ. Sci. 2019, 371, 042022. [Google Scholar] [CrossRef]

- Götz, M.; Lefebvre, J.; Mörs, F.; McDaniel Koch, A.; Graf, F.; Bajohr, S.; Reimert, R.; Kolb, T. Renewable Power-to-Gas: A technological and economic review. Renew. Energy 2016, 85, 1371–1390. [Google Scholar] [CrossRef]

- Gondal, I.A. Hydrogen integration in power-to-gas networks. Int. J. Hydrogen Energy 2019, 44, 1803–1815. [Google Scholar] [CrossRef]

- Koelbl, B.S.; van den Broek, M.; Faaij, A.P.C.; van Vuuren, D.P. Uncertainty in Carbon Capture and Storage (CCS) deployment projections: A cross-model comparison exercise. Clim. Change 2014, 123, 461–476. [Google Scholar] [CrossRef]

- Khan, M.H.A.; Daiyan, R.; Neal, P.; Haque, N.; MacGill, I.; Amal, R. A framework for assessing economics of blue hydrogen production from steam methane reforming using carbon capture storage & utilisation. Int. J. Hydrogen Energy 2021, 46, 22685–22706. [Google Scholar] [CrossRef]

- George, J.F.; Müller, V.P.; Winkler, J.; Ragwitz, M. Is blue hydrogen a bridging technology?—The limits of a CO2 price and the role of state-induced price components for green hydrogen production in Germany. Energy Policy 2022, 167, 113072. [Google Scholar] [CrossRef]

- Howarth, R.W.; Jacobson, M.Z. How green is blue hydrogen? Energy Sci. Eng. 2021, 9, 1676–1687. [Google Scholar] [CrossRef]

- Papadopoulos, V.; Desmet, J.; Knockaert, J.; Develder, C. Improving the utilization factor of a PEM electrolyzer powered by a 15 MW PV park by combining wind power and battery storage—Feasibility study. Int. J. Hydrogen Energy 2018, 43, 16468–16478. [Google Scholar] [CrossRef]

- Sustainable Energy Authority of Ireland. Community Energy Resource Toolkit. Solar PV. 2021. Available online: https://www.seai.ie/publications/Community-Toolkit-Solar-PV.pdf (accessed on 22 December 2022).

- O’Hanlon, Z.; Cummins, V. A comparative insight of Irish and Scottish regulatory frameworks for offshore wind energy—An expert perspective. Mar. Policy 2020, 117, 103934. [Google Scholar] [CrossRef]

- Abdin, Z.; Zafaranloo, A.; Rafiee, A.; Mérida, W.; Lipiński, W.; Khalilpour, K.R. Hydrogen as an energy vector. Renew. Sustain. Energy Rev. 2020, 120, 109620. [Google Scholar] [CrossRef]

- Gunawan, T.A.; Singlitico, A.; Blount, P.; Burchill, J.; Carton, J.G.; Monaghan, R.F.D. At What Cost Can Renewable Hydrogen Offset Fossil Fuel Use in Ireland’s Gas Network? Energies 2020, 13, 1798. [Google Scholar] [CrossRef]

- European Commission. Electricity Market Design. 2022. Available online: https://energy.ec.europa.eu/topics/markets-and-consumers/market-legislation/electricity-market-design_en (accessed on 22 December 2022).

- Diab, J.; Fulcheri, L.; Hessel, V.; Rohani, V.; Frenklach, M. Why turquoise hydrogen will Be a game changer for the energy transition. Int. J. Hydrogen Energy 2022, 47, 25831–25848. [Google Scholar] [CrossRef]

- Noussan, M.; Raimondi, P.P.; Scita, R.; Hafner, M. The Role of Green and Blue Hydrogen in the Energy Transition—A Technological and Geopolitical Perspective. Sustainability 2020, 13, 298. [Google Scholar] [CrossRef]

- Garcia, D.A. Analysis of non-economic barriers for the deployment of hydrogen technologies and infrastructures in European countries. Int. J. Hydrogen Energy 2017, 42, 6435–6447. [Google Scholar] [CrossRef]

- Gas Networks Ireland. Safety Advice for Working in the Vicinity of Natural Gas Pipelines. Guideline No: HSQE/GU/016 Rev 2. 2020. Available online: https://www.gasnetworks.ie/docs/business/safety-in-the-business/Safety-Advice-for-working-in-the-vicinity-of-Gas-pipes-2021_.pdf (accessed on 22 December 2022).

- Andrews, J.; Shabani, B. The role of hydrogen in a global sustainable energy strategy. WIREs Energy Environ. 2014, 3, 474–489. [Google Scholar] [CrossRef]

- Cavana, M.; Leone, P. Biogas blending into the gas grid of a small municipality for the decarbonization of the heating sector. Biomass-Bioenergy 2019, 127, 105295. [Google Scholar] [CrossRef]

- Quintino, F.M.; Nascimento, N.; Fernandes, E.C. Aspects of Hydrogen and Bio-methane Introduction in Natural Gas Infrastructure and Equipment. Hydrogen 2021, 2, 301–318. [Google Scholar] [CrossRef]

- Smith, C.; Mouli-Castillo, J.; van der Horst, D.; Haszeldine, S.; Lane, M. Towards a 100% hydrogen domestic gas network: Regulatory and commercial barriers to the first demonstrator project in the United Kingdom. Int. J. Hydrogen Energy 2022, 47, 23071–23083. [Google Scholar] [CrossRef]

- Wind Energy Ireland. Hydrogen and Wind Energy. The Role of Green Hydrogen in Ireland’s Energy Transition. 2022. Available online: https://windenergyireland.com/images/files/final-hydrogen-and-wind-energy-report.pdf (accessed on 22 December 2022).

- Moriarty, P.; Honnery, D. Prospects for hydrogen as a transport fuel. Int. J. Hydrogen Energy 2019, 44, 16029–16037. [Google Scholar] [CrossRef]

- Andrews, J.; Shabani, B. Re-envisioning the role of hydrogen in a sustainable energy economy. Int. J. Hydrogen Energy 2012, 37, 1184–1203. [Google Scholar] [CrossRef]

- Madsen, A.N.; Andersen, P.D. Innovative regions and industrial clusters in hydrogen and fuel cell technolo-gy. Energy Policy 2010, 38, 5372–5381. [Google Scholar] [CrossRef]

- Hosseini, S.E.; Butler, B. An overview of development and challenges in hydrogen powered vehicles. Int. J. Green Energy 2020, 17, 13–37. [Google Scholar] [CrossRef]

- Kalghatgi, G. Running Heavy-Duty Transport on Batteries. 2020. Available online: https://www.realclearenergy.org/articles/2020/08/11/running_heavy-duty_transport_on_batteries_501650.html (accessed on 22 December 2022).

- Sanguesa, J.; Torres-Sanz, V.; Garrido, P.; Martinez, F.; Marquez-Barja, J. A Review on Electric Vehicles: Technologies and Challenges. Smart Cities 2021, 4, 372–404. [Google Scholar] [CrossRef]

- Umicore. Fuel Cells vs. Batteries: What’s the Difference? 2022. Available online: https://www.umicore.com/en/newsroom/news/fuel-cells-battery-difference/ (accessed on 22 December 2022).

- Hydrogen Europe. Lighthouse Initiative. 2022. Available online: https://hydrogeneurope.eu/lighthouse-initiative/ (accessed on 22 December 2022).

- Abad, A.V.; Dodds, P.E. Green hydrogen characterisation initiatives: Definitions, standards, guarantees of origin, and challenges. Energy Policy 2020, 138, 111300. [Google Scholar] [CrossRef]

- SSE Renewables. DETAILS OF GALWAY HYDROGEN HUB (GH2) ANNOUNCED. 2022. Available online: https://www.sserenewables.com/news-and-views/2022/06/details-of-galway-hydrogen-hub-gh2-announced/ (accessed on 22 December 2022).

- Wang, J.; Wang, H.; Fan, Y. Techno-Economic Challenges of Fuel Cell Commercialization. Engineering 2018, 4, 352–360. [Google Scholar] [CrossRef]

- McKinsey & Company. How Hydrogen Combustion Engines Can Contribute to Zero Emissions. 2021. Available online: https://www.mckinsey.com/industries/automotive-and-assembly/our-insights/how-hydrogen-combustion-engines-can-contribute-to-zero-emissions (accessed on 22 December 2022).

- Liu, X.; Reddi, K.; Elgowainy, A.; Lohse-Busch, H.; Wang, M.; Rustagi, N. Comparison of well-to-wheels energy use and emissions of a hydrogen fuel cell electric vehicle relative to a conventional gasoline-powered internal combustion engine vehicle. Int. J. Hydrogen Energy 2019, 45, 972–983. [Google Scholar] [CrossRef]

- Hydrogen Tank. Available online: https://www.doosanmobility.com/en/products/hydrogen-tank/ (accessed on 30 March 2022).

- Sandí, G. Hydrogen storage and its limitations. Electrochem. Soc. Interface 2004, 13, 40. [Google Scholar] [CrossRef]

- Bartlett, J.; Krupnick, A. Decarbonized Hydrogen in the US Power and Industrial Sectors: Identifying and Incentivizing Opportunities to Lower Emissions. 2020. Available online: https://media.rff.org/documents/RFF_Report_20-25_Decarbonized_Hydrogen.pdf (accessed on 22 December 2022).

- Dong, Z.Y.; Yang, J.; Yu, L.; Daiyan, R.; Amal, R. A green hydrogen credit framework for international green hy-drogen trading towards a carbon neutral future. Int. J. Hydrog. Energy 2022, 47, 728–734. [Google Scholar] [CrossRef]

- Turner, M.; Palmer, A.; Granville-Willet. End Game. A Zero-Carbon Electricity Plan for Ireland. 2021. Available online: https://windenergyireland.com/images/files/20210629-baringa-endgame-final-version.pdf (accessed on 22 December 2022).

- The Government of Ireland—New legislation to Implement a Circular Economy. Press Release from Department of the Envi-ronment, Climate and Communications, 15 June 2021. Available online: https://www.gov.ie/en/press-release/65f5e-new-legislation-to-implement-a-circular-economy/ (accessed on 22 December 2022).

- Natural Gas Grid, Dail Eireann Debate, Tuesday—14 December 2021. Available online: https://www.oireachtas.ie/en/debates/question/2021-12-14/28/ (accessed on 18 February 2022).

- Tomorrow’s Energy Scenarios, 2019 Ireland. Planning our Energy Future, EirGrid, October 2019, EirGrid-TES-2019-Report.pdf. Available online: Eirgridgroup.com (accessed on 18 August 2021).

- Mayyas, A.; Chadly, A.; Amer, S.T.; Azar, E. Economics of the Li-ion batteries and reversible fuel cells as energy storage systems when coupled with dynamic electricity pricing schemes. Energy 2022, 239, 121941. [Google Scholar] [CrossRef]

- Welder, L.; Stenzel, P.; Ebersbach, N.; Markewitz, P.; Robinius, M.; Emonts, B.; Stolten, D. Design and evaluation of hydrogen electricity reconversion pathways in national energy systems using spatially and temporally resolved energy system optimisation. Int. J. Hydrog. Energy 2019, 44, 9594–9607. [Google Scholar] [CrossRef]

- Schermeyer, H.; Vergara, C.; Fichtner, W. Renewable energy curtailment: A case study on today’s and tomorrow’s congestion management. Energy Policy 2018, 112, 427–436. [Google Scholar] [CrossRef]

- Ruggles, T.H.; Dowling, J.A.; Lewis, N.S.; Caldeira, K. Opportunities for flexible electricity loads such as hydrogen production from curtailed generation. Adv. Appl. Energy 2021, 3, 100051. [Google Scholar] [CrossRef]

- Frew, B.A.; Becker, S.; Dvorak, M.J.; Andresen, G.B.; Jacobson, M.Z. Flexibility mechanisms and pathways to a highly renewable US electricity future. Energy 2016, 101, 65–78. [Google Scholar] [CrossRef]

- González, A.; McKeogh, E.; Gallachóir, B. The role of hydrogen in high wind energy penetration electricity systems: The Irish case. Renew. Energy 2004, 29, 471–489. [Google Scholar] [CrossRef]

- Zhang, G.; Wan, X. A wind-hydrogen energy storage system model for massive wind energy curtailment. Int. J. Hydrogen Energy 2014, 39, 1243–1252. [Google Scholar] [CrossRef]

- Mason, J.; Zweibel, K. Centralized Production of Hydrogen using a Coupled Water Electrolyzer-Solar Photovoltaic System. In Solar Hydrogen Generation; Springer: New York, NY, USA, 2008; pp. 273–313. ISBN 9780387728094. [Google Scholar]

- Energy Ireland. Developing Ireland Hydrogen’s Potential. 2021. Available online: https://www.energyireland.ie/developing-irelands-hydrogen-potential/ (accessed on 22 December 2022).

- Mokhtara, C.; Negrou, B.; Settou, N.; Bouferrouk, A.; Yao, Y. Design optimization of grid-connected PV-Hydrogen for energy prosumers considering sector-coupling paradigm: Case study of a university building in Algeria. Int. J. Hydrogen Energy 2021, 46, 37564–37582. [Google Scholar] [CrossRef]

- Khan, I.; Kabir, Z. Waste-to-energy generation technologies and the developing economies: A multi-criteria analysis for sustainability assessment. Renew. Energy 2019, 150, 320–333. [Google Scholar] [CrossRef]

- Mona, S.; Kumar, S.S.; Kumar, V.; Parveen, K.; Saini, N.; Deepak, B.; Pugazhendhi, A. Green technology for sus-tainable biohydrogen production (waste to energy): A review. Sci. Total Environ. 2020, 728, 138481. [Google Scholar] [CrossRef]

- Ghaemi, S.; Li, X.; Mulder, M. Economic feasibility of green hydrogen in providing flexibility to medium-voltage distribution grids in the presence of local-heat systems. Appl. Energy 2023, 331, 120408. [Google Scholar] [CrossRef]

- Opportunities for Hydrogen Energy Technologies Considering the National Energy and Climate Plans. Fuel Cells and Hy-drogen 2 Joint Undertaking (FCH 2 JU) Study on Opportunities Arising from the Inclusion of Hydrogen Energy Technologies in the National Energy & Climate Plans. Available online: https://www.fch.europa.eu/publications/opportunities-hydrogen-energy-technologies-considering-national-energy-climate-plans (accessed on 4 September 2021).

- Gunawan, T.A.; Williamson, I.; Raine, D.; Monaghan, R.F. Decarbonising city bus networks in Ireland with re-newable hydrogen. Int. J. Hydrog. Energy 2021, 46, 28870–28886. [Google Scholar] [CrossRef]

- Butturi, M.A.; Gamberini, R. The potential of hydrogen technologies for low-carbon mobility in the urban-industrial symbiosis approach. Int. J. Energy Prod. Manag. 2022, 7, 151–163. [Google Scholar] [CrossRef]

- Olabi, A.G.; Wilberforce, T.; Abdelkareem, M.A. Fuel cell application in the automotive industry and future per-spective. Energy 2021, 214, 118955. [Google Scholar] [CrossRef]

- Hansen, O.R. Hydrogen infrastructure—Efficient risk assessment and design optimisation approach to ensure safe and practical solutions. Process Saf. Environ. Prot. 2020, 143, 164–176. [Google Scholar] [CrossRef]

- Government of Ireland. National Development Plan 2021–2030. 2021. Available online: https://www.gov.ie/en/publication/774e2-national-development-plan-2021-2030/ (accessed on 22 December 2022).

- Dail Eireann Debate. Thursday, 14 July 2022. Volume 1025 No. 5. Green Hydrogen Strategy Bill 2022: Second Stage [Private Members]. Available online: https://www.oireachtas.ie/en/debates/debate/dail/2022-07-14/52/ (accessed on 22 December 2022).

- Gas Networks Ireland. Testing of Blends of Hydrogen and Natural Gas. 2022. Available online: https://www.gasnetworks.ie/docs/hydrogen-blend.pdf (accessed on 22 December 2022).

- Muhammed, N.S.; Haq, B.; Al Shehri, D.; Al-Ahmed, A.; Rahman, M.M.; Zaman, E. A review on underground hydrogen storage: Insight into geological sites, influencing factors and future outlook. Energy Rep. 2022, 8, 461–499. [Google Scholar] [CrossRef]

- Hydrogen Projects in Teesside. Available online: https://www.bp.com/en/global/corporate/what-we-do/gas-and-low-carbon-energy/h2teesside.html (accessed on 27 February 2022).

- Salt Cavern Gas Storage Project at Islandmagee in County Antrim, Northern Ireland. Available online: https://www.islandmageeenergy.com/ (accessed on 27 February 2022).

- UK Hydrogen Policy Takes Shape: Defining “Low Carbon Hydrogen”. Available online: https://www.lexology.com/library/detail.aspx?g=9ac6c040-7336-4045-808a-0d7b835743ed (accessed on 29 September 2021).

- Westphal, K.; Dröge, S.; Geden, O. The International Dimensions of Germany’s Hydrogen Policy. 2020. Available online: https://www.swp-berlin.org/10.18449/2020C32/#:~:text=It%20contains%20plans%20to%20build,additional)%20renewables%2Dbased%20electricity (accessed on 22 December 2022).

- Gawlik, L.; Mokrzycki, E. Analysis of the Polish Hydrogen Strategy in the Context of the EU’s Strategic Documents on Hydrogen. Energies 2021, 14, 6382. [Google Scholar] [CrossRef]

- Government of France. National Strategy for the Development of Decarbonised and Renewable Hydrogen in France. 2020. Available online: https://www.bdi.fr/wp-content/uploads/2020/03/PressKitProvisionalDraft-National-strategy-for-the-development-of-decarbonised-and-renewable-hydrogen-in-France.pdf (accessed on 22 December 2022).

- Bernad, A.; Zarzuela, M.; Férriz, A.M.; Floristean, A.; HyLaw. National Policy Paper—Spain. 2019. Available online: https://www.hylaw.eu/files/2019-02/HyLAW_%20National%20policy%20Paper_ENG_Final.pdf (accessed on 22 December 2022).

- Government of Ireland. Consultation on Developing a Hydrogen Strategy for Ireland. 2022. Available online: https://www.gov.ie/en/consultation/5c087-consultation-on-developing-a-hydrogen-strategy-for-ireland/ (accessed on 22 December 2022).

| Stakeholder Number | Type of Organization |

|---|---|

| 1 | National association for hydrogen |

| 2 | Distribution System Operator |

| 3 | Manufacturer of electrolyzers |

| 4, 5 | Academic institution |

| Type of Hydrogen | Production Process | Advantages | Disadvantages | Cost |

|---|---|---|---|---|

| Grey | Steam Reforming Stage 1: high temperature (700–1100 °C) endothermic reaction: CH4 + H2O → CO + 3 H2 Stage 2: low temperature (360 °C) exothermic reaction: CO + H2O → CO2 + H2 | The production process is well-established and cheap compared to other types of hydrogen | 10 kg CO2/kg Ten tons of CO2 are generated as waste per ton of hydrogen produced [67] | 1.5 €/kg [68,69] |

| Blue | Steam Reforming with capture and storage of the produced CO2 or carbon capture and conversion | Low carbon emissions when compared to Grey, cheaper than Green 1 | Residual emissions of CO2 and fugitive methane are present. | 2–3 €/kg [68] |

| Turquoise | Methane Pyrolysis the natural gas is broken down into hydrogen and graphite or carbon granules | The production process is carbon-free (no CO2 production at all) | Turquoise technology is promising but at the development stage [87]. | Not |

| Green | Electrolysis of water 2H2O + electricity + heat → 2H2 + O2 Electricity and heat needed for the chemical reaction to happen are generated from renewable sources. | The production process is carbon-free (no CO2 production at all) | Production requires a renewable plant, solar or wind. Costs are currently higher than Blue. | 3.5–6 €/kg [68] Predicted in 2030: 0.7–1.8 €/kg [70] |

| Pink | Electrolysis is powered by nuclear energy or thermochemical process using very high temperatures from nuclear reactors. | CO2 free production process but producing radioactive toxic waste in the long term | Non-circular and unsustainable production pathway; nuclear wastes are dumped in the oceans, where they remain a potential biological hazard for an extremely long time. | 2.3–2.5 €/kg [71] |

| From biomass gasification (no color) | Biomass gasification Water shift reaction | Low net carbon emissions, offsetting the CO2 released from producing hydrogen with its consumption from plants’ growth process [72] | High capital cost of equipment. High biomass feedstock costs. | 4.7–6 €/kg [73] |

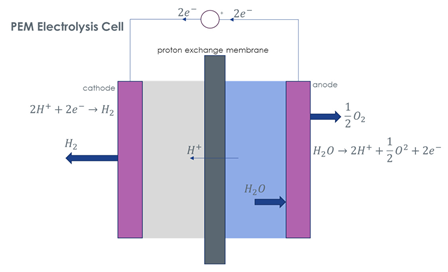

| Type of Electrolysis Cell | Notes |

|---|---|

|

|

| |

|

|

|

|

| Alkaline Electrolysis | PEM Electrolysis | Solid Oxide Electrolysis | |

|---|---|---|---|

| State of development | Commercial | Commercial | Laboratory |

| H2 production in m3/h (STP, per system) | <760, 2 MW | up to 450, 1.6 MW | - |

| Electrolyte | Alkaline solution | Solid polymer membrane | ZrO2 ceramic doped with Y2O3 |

| Charge carrier | OH− | H3O+/H+ | O2− |

| Cell temperature in °C | 40–90 | 20–100 | 800–1000 |

| Cell voltage in V | 1.8–2.4 | 1.8–2.2 | 0.91–1.3 |

| System power consumption (current) in kWh/m3 H2 | 5.4–8.2 | 4.9–5.2 | - |

| System power consumption (future) in kWh/m3 H2 (HS) | 4.3–5.7 | 4.1–4.8 | - |

| Cold start time | Minutes–hours | Seconds–minutes | - |

| Advantages | Available for large plant sizes, cost, lifetime | No corrosive substances, high power densities, high pressure > 100 bar, good dynamics | High electrical efficiency, integration of waste heat possible |

| Disadvantages | Low current density, maintenance costs (the system is highly corrosive) | Expensive, fast degradation | Limited long-term stability of the cells, not suited to fluctuating systems, expensive |

| Symbol | Meaning |

|---|---|

| wind energy used for electrolyzer system | |

| dispatched-down wind energy used for electrolyzer system using battery storage | |

| grid electricity used for electrolyzer system | |

| electrolyzer rated power | |

| average wind farm dispatched-down power in 10 min. used by the battery-electrolyzer system at time t | |

| battery energy in 10 min. used by the electrolyzer at time t | |

| total time when | |

| wind farm dispatched-down wind energy in 10 min at time t when | |

| average wind farm dispatched-down power in 10 min. at time t when | |

| total time when |

| Countries | Production | Consumption | Transport |

|---|---|---|---|

| Italy [15] | Electrolyzer capacity installation target of 5 GW by 2030 (12.5% of the European target). | Dedicated pipelines and adapted natural gas ones could likely accommodate half of the hydrogen trade, while the other half could be mainly transported on ships as synthetic fuels. | Prevalent consumption envisaged is blended with natural gas and injected into the natural gas network. |

| Germany [142] | Green hydrogen is produced by electrolysis from renewable electricity. Blue hydrogen is obtained from natural gas by means of steam reforming using the carbon capture and storage (CCS) process. | Transport network connecting ports and wind parks by using (to some extent) already existing infrastructure such as pipelines and waterways. Pipelines currently still used for transporting low-calorific gas could be transformed and integrated into a hydrogen network. | Industrial sectors, as well as heating and transport. |

| Poland [143] | Low-carbon hydrogen will be produced using steam reforming of hydrocarbons with CO2 capture and storage (CCS) or CO2 capture and use (CCU), coal gasification with CCS or CCU, biomass gasification with CCS or CCU, electrolysis using electricity from renewable energy sources, electrolysis using electricity from conventional sources with CCS or CCU, pyrolysis, and chemical processes that produce hydrogen as a by-product, including separation of hydrogen from coke oven gas. | Transmission of electricity to the place of hydrogen production, hydrogen transmission, SNG transmission with the existing gas network, or hydrogen transmission through dedicated pipelines. | Transport, industry, power generation, and heating |

| UK [66] | Steam methane reformation (SMR) or autothermal reformation (ATR) with carbon capture, grid electrolysis, renewable electrolysis, low-temperature nuclear electrolysis, high-temperature nuclear electrolysis, bioenergy with carbon capture and storage, thermochemical water splitting, methane Pyrolysis (turquoise hydrogen). | Blending of hydrogen into the gas grid; development of a dedicated hydrogen grid extending up to tens or hundreds of kilometers that may include hydrogen converted and distributed as ammonia for use as a shipping fuel. | Agriculture, industry, residential, services and transport sectors |

| France [144] | Electrolysis of water using decarbonized or renewable electricity. | Liquid H2, reuse in the gas network. | Industry (e.g., steel industry for the reduction of iron ore, or in the chemical industry for the manufacture of fertilizers), heavy-duty mobility (e.g., aircraft and ships). |

| Spain [145] | Electrolysis to produce renewable hydrogen (using renewable energy). | Hydrogen pipelines and public access hydrogen stations. | All industries use hydrogen. Transport (fuel cell buses, light and heavy-duty fuel cell vehicles for freight transport), power sector (consumption of previously produced and stored hydrogen). |

| Questions/Comments of Irish Government Consultation Document | Findings of this Paper | |

|---|---|---|

| Opportunities for green hydrogen production |

| Green hydrogen should be produced using mainly offshore wind, with a possible contribution of photo-voltaic production. A renewable electricity potential that does not have a route to market is curtailed energy. There is a concern regarding the usage of curtailed renewable energy to produce green hydrogen in relation to the possible very high costs. Electricity storage systems may add flexibility to the wind-electrolyzers systems, enabling a better harvesting of the curtailed energy, and must be studied in future research projects. |

| Role of blue hydrogen | “There will also be other competing technologies to meet medium and high-temperature heat use, including electric technologies, biomass and carbon capture, utilization and storage (CCUS) on sites with significant process emissions” | Possibly there will be no role for blue hydrogen due to a lack of trust in technology for carbon capture and storage (residual emissions might be too high) and concerns about Ireland’s dependence on imported natural gas. “Blue hydrogen in the short term” is considered a high-risk strategy and inconsistent with EU policy. |

| Hydrogen infrastructure | Determining factors in identifying economic solutions include the available volume of hydrogen and the extent to which it could meet demand, the length of time it would need to be stored, site location, whether any existing infrastructure can be used or adapted, and the potential end-use application, in addition to the need to satisfy any regulatory and statutory criteria which may be put in place. |

|

| Hydrogen in domestic heating |

|

|

| Other technologies for the decarbonization of society | How does hydrogen compare to competing technologies (direct electrification and other decarbonization options) for each of these end-uses? | Heat pumps are the most efficient option, which comes with rather high installation costs. Blending green hydrogen into the natural gas grid risks being a ‘waste’ of precious green hydrogen, which could be used for different applications because direct electrification using heat pumps is more efficient and cost-effective. |

| Green hydrogen certification | The options to produce renewable/green hydrogen will need to be examined in the context of the proposed changes to the Renewable Energy Directive (recast as RED III as part of the EU’s ‘Fit for 55′ package), particularly any requirements around co-location with new/existing generation and additionality. Certification will need to be examined to ensure the sustainability of hydrogen produced in Ireland. | Concerns arose from the additionality requirement of RED II in relation to green H2 production. Green H2 projects might be delayed if H2 production from the electrolyzer requires the commissioning of a new renewable asset to produce the electricity to power the electrolyzer. Moreover, green hydrogen might be very expensive if it could only be produced from curtailed renewable energy. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

De Tommasi, L.; Lyons, P. Towards the Integration of Flexible Green Hydrogen Demand and Production in Ireland: Opportunities, Barriers, and Recommendations. Energies 2023, 16, 352. https://doi.org/10.3390/en16010352

De Tommasi L, Lyons P. Towards the Integration of Flexible Green Hydrogen Demand and Production in Ireland: Opportunities, Barriers, and Recommendations. Energies. 2023; 16(1):352. https://doi.org/10.3390/en16010352

Chicago/Turabian StyleDe Tommasi, Luciano, and Pádraig Lyons. 2023. "Towards the Integration of Flexible Green Hydrogen Demand and Production in Ireland: Opportunities, Barriers, and Recommendations" Energies 16, no. 1: 352. https://doi.org/10.3390/en16010352

APA StyleDe Tommasi, L., & Lyons, P. (2023). Towards the Integration of Flexible Green Hydrogen Demand and Production in Ireland: Opportunities, Barriers, and Recommendations. Energies, 16(1), 352. https://doi.org/10.3390/en16010352