Embodied vs. Operational Energy and Carbon in Retail Building Shells: A Case Study in Portugal

Abstract

:1. Introduction

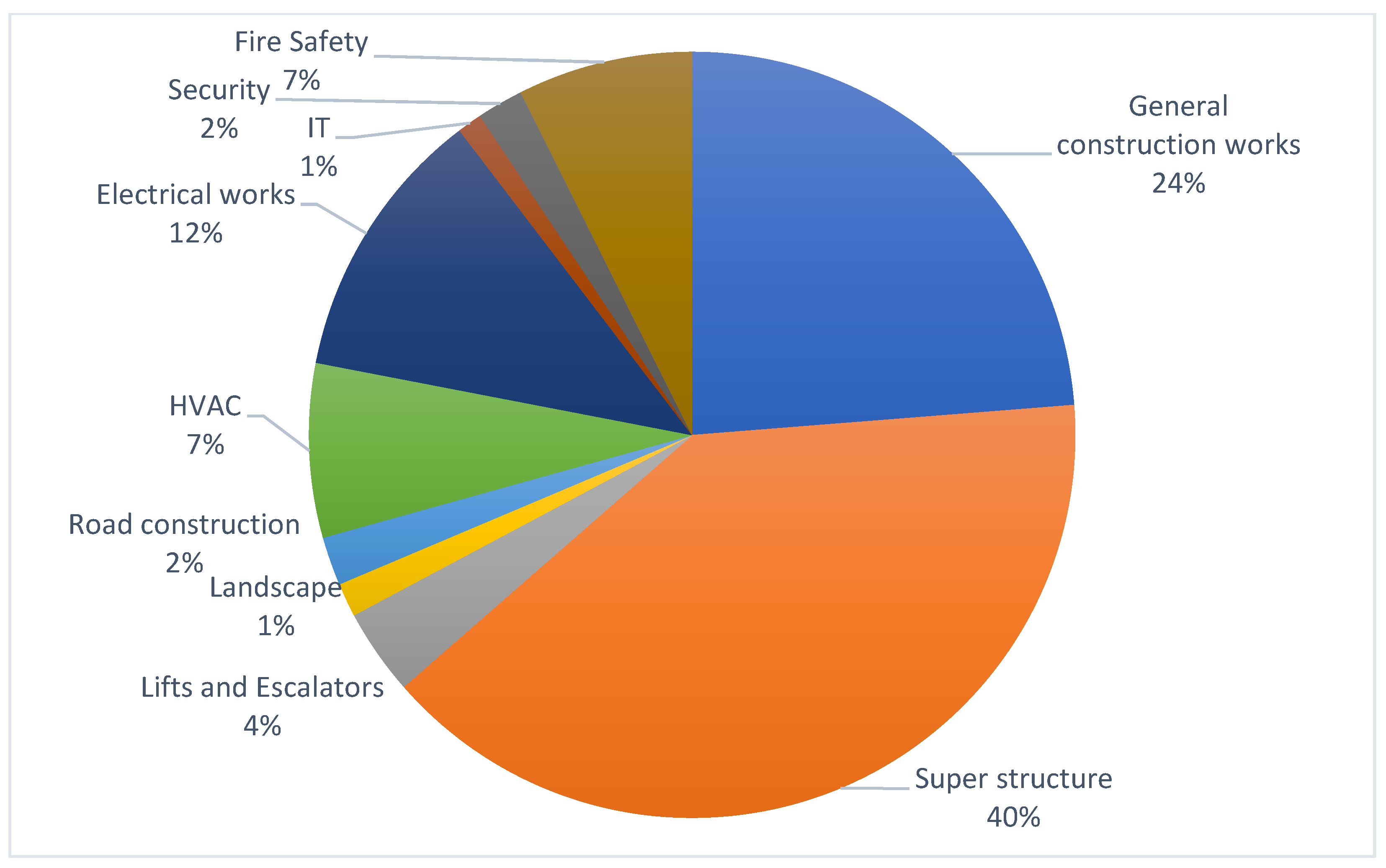

2. Materials and Methods

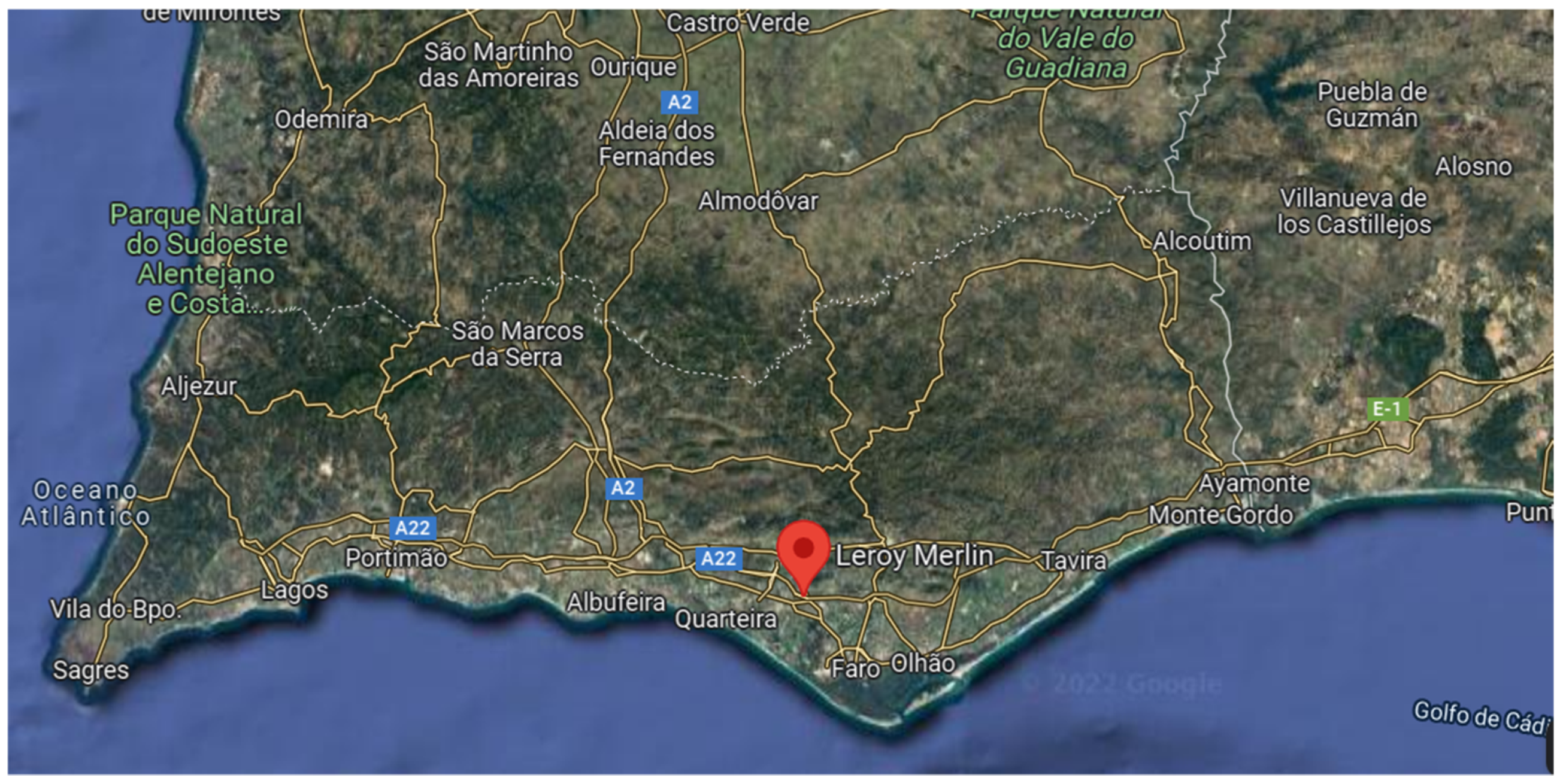

2.1. Case Study Description

2.2. Methodology

3. Results

4. Discussion

4.1. Embodied vs. Operational Energy and Carbon Emissions

4.2. Quantification of Material Flow and Materials Intensity

4.3. Strategies to Mitigate Materials’ Impacts in Retail

4.3.1. Use of Low Environmental Impact Materials

4.3.2. Optimized Design

4.3.3. Use of BSA Tools

4.3.4. Applicability of Mitigation Strategies in Retail Buildings

4.4. Implications

4.5. Limitations

5. Conclusions

Recommendations and Future Research

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Bill of Quantities Organised by the Main Building Parts and Elements | Floor Area (m2) | 9556.00 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Tier 1 Building Element | Tier 2 Building Element | Tier 3 Building Element | Description of the Product/Material Being Purchased | Bill of Quantities | Unit | Conversion Factor (kg/Unit) | Total (kg) | Cost €/Unit | Cost €/kg | Total Cost (EUR) |

| Shell | roof | Weatherproofing | roofing system: 0.75 mm metal sheet, 150 kg/m3 rock wool plates, waterproofing in 3 layers of 4 kg/m2 asphalt membrane | 9119 | m2 | 25 | 227,975.00 | 34.45 | 1.38 | 314,149.55 |

| Shell | Roof | Weatherproofing | waterproofing membrane in polymer bitumen 3 kg/m2 and fiberglass reinforcement, polymer bitumen 4 kg/m2, extruded polystyrene sheets 50 mm, synthetic fibre geotextile blanket 150 g/m2, pebble | 78 | m2 | 56.65 | 4418.70 | 35.25 | 0.62 | 2749.50 |

| Shell | Roof | Weatherproofing | waterproofing membrane in polymer bitumen 3 kg/m2 and fiberglass reinforcement, polymer bitumen 4 kg/m2, 50 mm extruded polystyrene plates, 150 g/m2 geotextile synthetic fibre mat; slabs, 35 mm screed and 30 mm insulation | 146 | m2 | 83.65 | 12,212.90 | 52.30 | 0.63 | 7635.80 |

| Shell | Roof | Weatherproofing | steel sheet 0.75 mm | 767 | m2 | 5 | 3835.00 | 16.25 | 3.25 | 12,463.75 |

| Shell | Facades | External wall systems, cladding and shading devices | 50 mm sandwich panels, with rock wool interior, and fastening structures | 3903 | m2 | 19 | 74,157.00 | 33.15 | 1.74 | 129,384.45 |

| Shell | Facades | External wall systems, cladding and shading devices | 0.5 mm steel sheet, including secondary metal frame | 1288 | m2 | 9 | 11,592.00 | 23.18 | 2.58 | 29,855.84 |

| Shell | Facades | External wall systems, cladding and shading devices | 3 mm perforated aluminium panels, including secondary aluminium frame | 416 | m2 | 17 | 7072.00 | 101.14 | 5.95 | 42,074.24 |

| Shell | Facades | External wall systems, cladding and shading devices | 2 mm steel plate including fastening frame | 200.15 | m2 | 17 | 3402.55 | 62.22 | 3.66 | 12,453.33 |

| Shell | Facades | External wall systems, cladding and shading devices | 2 mm metal grid including fastening frame | 40 | m2 | 17 | 680.00 | 266.91 | 15.70 | 10,676.40 |

| Shell | Facades | External wall systems, cladding and shading devices | reinforced masonry of concrete blocks, cement mortar and sand | 5284 | m2 | 270 | 1,426,680.00 | 20.51 | 0.08 | 108,374.84 |

| Shell | Facades | External wall systems, cladding and shading devices | masonry of concrete blocks 50 × 20 × 15 cm, cement and sand mortar | 306 | m2 | 270 | 82,620.00 | 11.06 | 0.04 | 3384.36 |

| Shell | Facades | External wall systems, cladding and shading devices | plastering with cement mortar, hydraulic lime and sand | 674 | m2 | 83.2 | 56,076.80 | 7.97 | 0.10 | 5371.78 |

| Shell | Facades | External paints, coatings and renders | Interior paintings on concrete block walls and plasterboard walls | 5241 | m2 | 0.26 | 1362.66 | 3.06 | 11.77 | 16,037.46 |

| Shell | Facades | External paints, coatings and renders | Interior paintings on concrete block walls and plasterboard walls | 742 | m2 | 0.26 | 192.92 | 3.42 | 13.15 | 2537.64 |

| Shell | Non_loadbearing_elements | Internal walls, partitions and doors | Steel door, metal frame, 80 cm | 14 | Unit | 10.64 | 148.96 | 1114.00 | 104.70 | 15,596.00 |

| Shell | Facades | Façade openings (including windows and external doors) | Fire door 60 min, 90 cm | 1 | Unit | 11.97 | 11.97 | 1960.00 | 163.74 | 1960.00 |

| Shell | Non_loadbearing_elements | Internal walls, partitions and doors | Fire door 60 min, 90 cm | 9 | Unit | 11.97 | 107.73 | 1960.00 | 163.74 | 17,640.00 |

| Shell | Non_loadbearing_elements | Internal walls, partitions and doors | Fire door 60 min, 90 cm | 16 | Unit | 11.97 | 191.52 | 5932.00 | 495.57 | 94,912.00 |

| Shell | Facades | Façade openings (including windows and external doors) | Automatic sliding doors, 2.00 m. Double glazing 8.8.6 (laminated colourless glass on the outside and tempered glass on the inside) | 3 | Unit | 25 | 75.00 | 6973.00 | 278.92 | 20,919.00 |

| Shell | Facades | Façade openings (including windows and external doors) | Thermo-lacquered aluminium frame with 6 mm tempered crystal glass | 12 | Unit | 33.6 | 403.20 | 336.00 | 10.00 | 4032.00 |

| Shell | Non_loadbearing_elements | Internal walls, partitions and doors | Fireproof sliding gate in iron frame, 60 min | 16 | Unit | 200 | 3200.00 | 13,166.00 | 65.83 | 210,656.00 |

| Shell | Facades | Façade openings (including windows and external doors) | Steel door, metal frame, 90 cm | 6 | Unit | 11.97 | 71.82 | 1968.00 | 164.41 | 11,808.00 |

| Shell | Facades | Façade openings (including windows and external doors) | Steel door, metal frame, 140 cm | 7 | Unit | 18.62 | 130.34 | 6134.00 | 329.43 | 42,938.00 |

| Shell | Facades | Façade openings (including windows and external doors) | Steel door, metal frame, 140 cm | 3 | Unit | 14 | 42.00 | 1167.00 | 83.36 | 3501.00 |

| Shell | Roof | Weatherproofing | Smoke exhaustion skylight 2000 × 2000 mm in transparent honeycomb polycarbonate | 49 | Unit | 7.08 | 346.92 | 1487.00 | 210.03 | 72,863.00 |

| Shell | Roof | Weatherproofing | Skylight 2000 × 2000 mm | 89 | Unit | 4.58 | 407.62 | 668.00 | 145.85 | 59,452.00 |

| Shell | Roof | Weatherproofing | Day light and smoke-exhaustion skylight 1400 × 1400 mm, 16 mm transparent honeycomb polycarbonate. | 2 | Unit | 5.92 | 11.84 | 1166.00 | 196.96 | 2332.00 |

| Shell | Roof | Weatherproofing | Natural tubular lighting system SOLATUBE®, 35 cm diameter | 17 | Unit | 1.75 | 29.75 | 703.00 | 401.71 | 11,951.00 |

| Shell | Facades | External wall systems, cladding and shading devices | Double-skinned sectional door filled with rigid polyurethane foam | 1 | unit | 200 | 200.00 | 4742.00 | 23.71 | 4742.00 |

| Shell | Facades | External wall systems, cladding and shading devices | Micro-perforated metal rolling grille | 4 | unit | 22 | 88.00 | 9725.00 | 442.05 | 38,900.00 |

| Shell | Facades | External wall systems, cladding and shading devices | Stapled glass facade composed of double-glazing: 12 mm tempered glass + 16 mm air chamber + 10+10.4 tempered, transparent laminated glass. Stainless steel fasteners. | 1 | unit | 10.5 | 10.50 | 117,390.00 | 11,180.00 | 117,390.00 |

| Shell | Parking_facilities | Above ground and underground (within the curtilage of the building and servicing the building occupiers) | Foam insulation 50 mm | 73596 | m2 | 1.65 | 121,433.40 | 5.17 | 3.13 | 380,491.32 |

| Shell | Parking_facilities | Above ground and underground (within the curtilage of the building and servicing the building occupiers) | soundproofing mineral wool 45 mm | 565 | m2 | 4.5 | 2542.50 | 3.79 | 0.84 | 2141.35 |

| Shell | Facades | External paints, coatings and renders | Bituminous emulsion; Waterproofing membrane in polymer bitumen 4 kg/m2 and polyester reinforcement protected with polyethylene on both sides; High density polyethylene granular sheet with embedded geotextile | 2613 | m2 | 4.4 | 11,497.20 | 15.00 | 3.41 | 39,195.00 |

| Shell | Foundations_substructure | Basements | C12/15 concrete | 2266 | m2 | 144.3 | 326,983.80 | 6.39 | 0.04 | 14,479.74 |

| Shell | Foundations_substructure | Basements | Rockfill in limestone quarry gravel, Ø40/70 mm | 8684 | m2 | 640 | 5,557,760.00 | 11.61 | 0.02 | 100,821.24 |

| Shell | Foundations_substructure | Retaining walls | formwork with modular metal panels for reinforced concrete walls | 5226 | m2 | 13 | 67,938.00 | 13.67 | 1.05 | 71,439.42 |

| Shell | Foundations_substructure | Basements | C30/37 reinforced concrete wall, A500 NR steel, 86.6 kg/m3 | 676.32 | m3 | 2586.6 | 1,749,369.31 | 135.29 | 0.05 | 91,499.33 |

| Shell | Foundations_substructure | Retaining walls | Gabion wall: 2.70 mm diameter galvanized steel wire mesh box, 80 × 100 mm2 hexagonal mesh, and limestone, on tires | 1050.695 | m3 | 1600 | 1,681,112.00 | 50.86 | 0.03 | 53,438.35 |

| Shell | Foundations_substructure | Piles | metal panel formwork for foundations | 2005.92 | m2 | 13 | 26,076.96 | 11.39 | 0.88 | 22,847.43 |

| Shell | Foundations_substructure | Piles | Foundation in reinforced concrete C30/37, steel A500 NR, 42.6 kg/m3 | 1430.316 | m3 | 2542.6 | 3,636,721.46 | 104.53 | 0.04 | 149,510.93 |

| Shell | Foundations_substructure | Retaining walls | Reinforced concrete foundation and concrete walls C30/37, A500 NR steel, 67.9 kg/m3 | 182.83 | m3 | 2567.9 | 469,489.16 | 122.22 | 0.05 | 22,345.48 |

| Shell | Non_loadbearing_elements | Ground floor slab | Slab in reinforced concrete C30/37 and steel A500 NR, 50 kg/m3 | 173.04 | m3 | 2550 | 441,252.00 | 109.70 | 0.04 | 18,982.49 |

| Shell | Loadbearing_structural_frame | Frame (beams, columns and slabs) | Steel S275JR (Fe430) in metallic structure, HEA | 450959 | kg | 1 | 450,959.00 | 2.18 | 2.18 | 983090.62 |

| Shell | Loadbearing_structural_frame | Frame (beams, columns and slabs) | C30/37 reinforced concrete column, A500 NR steel, 235.6 kg/m3; sheet metal formwork | 317 | m3 | 2736 | 867,312.00 | 345.00 | 0.13 | 109,365.00 |

| Shell | Loadbearing_structural_frame | Frame (beams, columns and slabs) | Reinforced concrete beam, C30/37, A500 NR steel, 122.8 kg/m3; wooden formwork | 1400 | m3 | 2623 | 3,672,200.00 | 176.00 | 0.07 | 246,400.00 |

| Shell | Non_loadbearing_elements | Ground floor slab | Slab foundation in reinforced concrete C30/37, steel A500 NR, 48 kg/m2; wooden formwork; quartz hardener powder 7 kg/m2 | 8284.31 | m2 | 1305 | 10,811,024.55 | 89.40 | 0.07 | 740,617.31 |

| Shell | Non_loadbearing_elements | Ground floor slab | Slab of reinforced concrete C30/37, steel A500 NR, 48 kg/m2; wooden formwork; quartz hardener powder 7 kg/m2 | 63.2 | m2 | 555 | 35,076.00 | 44.55 | 0.08 | 2815.56 |

| Shell | Non_loadbearing_elements | Ground floor slab | Slab of reinforced concrete C30/37, steel A500 NR, 48 kg/m2; quartz hardener powder 7 kg/m2 | 317 | m2 | 805 | 255,185.00 | 57.30 | 0.07 | 18,164.10 |

| Shell | Loadbearing_structural_frame | Upper floors | Fungiform slab of reinforced concrete C30/37, volume 0.269 m3/m2, steel A500 NR, 13.7 kg/m2; lightweight concrete block with expanded clay FB65/40; electrowelded mesh AR42 of A500 EL steel and quartz powder hardener 7 kg/m2 | 3295 | m2 | 1631 | 5,374,145.00 | 59.00 | 0.04 | 194,405.00 |

| Shell | Loadbearing_structural_frame | External walls | C30/37 reinforced concrete wall, A500 NR steel, 183.4 kg/m3 | 61 | m3 | 670.75 | 40,915.75 | 337.00 | 0.50 | 20,557.00 |

| Shell | Non_loadbearing_elements | Ground floor slab | C30/37 concrete flooring, steel fibres, polyethylene mesh, quartz hardener powder 7 kg/m2 | 8624 | m2 | 501.4 | 4,324,073.60 | 21.60 | 0.04 | 186,278.40 |

| Shell | Loadbearing_structural_frame | Upper floors | Slab with galvanized steel plate and reinforced concrete C30/37, total volume of concrete 0.082 m3/m2, steel A500 NR, 1 kg/m2 | 716 | m2 | 300.84 | 215,401.44 | 30.78 | 0.10 | 22,038.48 |

| Shell | Non_loadbearing_elements | Stairs and ramps | Concrete staircase C30/37, A500 NR steel, 22 kg/m2, olive leaf plate sill | 114 | m2 | 504.4 | 57,501.60 | 79.88 | 0.16 | 9106.32 |

| Shell | Non_loadbearing_elements | Stairs and ramps | Escalators, with a load capacity of 9000 kg/120 people | 4 | Unit | 15000 | 60,000.00 | 66823.00 | 4.45 | 267,292.00 |

| Shell | Non_loadbearing_elements | Stairs and ramps | Lift, with a load capacity of 2000 kg/27 people | 2 | unit | 5000 | 10,000.00 | 34778.00 | 6.96 | 69,556.00 |

| Shell | Non_loadbearing_elements | Internal walls, partitions and doors | Ceramic tile, mortar of cement, hydraulic lime and sand | 153 | m2 | 9 | 1377.00 | 29.51 | 3.28 | 4515.03 |

Appendix B

| Bill of Materials by Material Type (% Weight). | Normalised Weight of Materials Needed over Lifetime | Normalised Cost of Materials Needed over Lifetime | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Concrete, Brick, Tile, Ceramic, etc. | Glass | Plastic | Bituminous Mixtures | Metals | Insulation Materials | Electrical and Electronic Equipment | Total % (Should Be 100%) | Assumed Lifetime of Product/Material (Years) | Normalised Requirement Factor over Building Lifetime | ||

| 32.0% | 20.0% | 48.0% | 100.0% | 50 | 1.5 | 341,962.50 | 471,224.32 | ||||

| 84.7% | 12.4% | 2.9% | 100.0% | 50 | 1.5 | 6628.05 | 4124.25 | ||||

| 89.7% | 8.4% | 2.0% | 100.0% | 50 | 1.5 | 18,319.35 | 11,453.70 | ||||

| 100.0% | 100.0% | 50 | 2 | 7670.00 | 24,927.50 | ||||||

| 25.0% | 75.0% | 100.0% | 50 | 2 | 148,314.00 | 258,768.90 | |||||

| 100.0% | 100.0% | 50 | 2 | 23,184.00 | 59,711.68 | ||||||

| 100.0% | 100.0% | 50 | 1 | 7072.00 | 42,074.24 | ||||||

| 100.0% | 100.0% | 50 | 1.5 | 5103.82 | 18,679.99 | ||||||

| 100.0% | 100.0% | 50 | 2 | 1360.00 | 21,352.80 | ||||||

| 100.0% | 100.0% | 50 | 1 | 1,426,680.00 | 108,374.84 | ||||||

| 100.0% | 100.0% | 50 | 1 | 82,620.00 | 3384.36 | ||||||

| 100.0% | 100.0% | 50 | 1 | 56,076.80 | 5371.78 | ||||||

| 100.0% | 100.0% | 50 | 3 | 4087.98 | 48,112.38 | ||||||

| 100.0% | 100.0% | 50 | 3 | 578.76 | 7612.92 | ||||||

| 75.0% | 25.0% | 100.0% | 50 | 2 | 297.92 | 31,192.00 | |||||

| 75.0% | 25.0% | 100.0% | 50 | 2 | 23.94 | 3920.00 | |||||

| 75.0% | 25.0% | 100.0% | 50 | 2 | 215.46 | 35,280.00 | |||||

| 75.0% | 25.0% | 100.0% | 50 | 2 | 383.04 | 189,824.00 | |||||

| 75.0% | 25.0% | 100.0% | 50 | 2 | 150.00 | 41,838.00 | |||||

| 75.0% | 25.0% | 100.0% | 50 | 2 | 806.40 | 8064.00 | |||||

| 75.0% | 25.0% | 100.0% | 50 | 2 | 6400.00 | 421,312.00 | |||||

| 75.0% | 25.0% | 100.0% | 50 | 2 | 143.64 | 23,616.00 | |||||

| 75.0% | 25.0% | 100.0% | 50 | 2 | 260.68 | 85,876.00 | |||||

| 100.0% | 100.0% | 50 | 2 | 84.00 | 7002.00 | ||||||

| 75.0% | 25.0% | 100.0% | 50 | 2 | 693.84 | 145,726.00 | |||||

| 85.0% | 15.0% | 100.0% | 50 | 2 | 815.24 | 118,904.00 | |||||

| 75.0% | 25.0% | 100.0% | 50 | 2 | 23.68 | 4664.00 | |||||

| 75.0% | 25.0% | 100.0% | 50 | 1.5 | 44.62 | 17,926.50 | |||||

| 75.0% | 25.0% | 100.0% | 50 | 3 | 600.00 | 14,226.00 | |||||

| 100.0% | 100.0% | 50 | 2 | 176.00 | 77,800.00 | ||||||

| 75.0% | 25.0% | 100.0% | 50 | 1 | 10.50 | 117,390.00 | |||||

| 100.0% | 100.0% | 50 | 1 | 121,433.40 | 380,491.32 | ||||||

| 100.0% | 100.0% | 50 | 1 | 2542.50 | 2141.35 | ||||||

| 100.0% | 100.0% | 50 | 1 | 11,497.20 | 39,195.00 | ||||||

| 100.0% | 100.0% | 50 | 1 | 326,983.80 | 14,479.74 | ||||||

| 100.0% | 100.0% | 50 | 1 | 5,557,760.00 | 100,821.24 | ||||||

| 100.0% | 100.0% | 50 | 1 | 67,938.00 | 71,439.42 | ||||||

| 95.0% | 5.0% | 100.0% | 50 | 1 | 1,749,369.31 | 91,499.33 | |||||

| 95.0% | 5.0% | 100.0% | 50 | 1 | 1,681,112.00 | 53,438.34 | |||||

| 100.0% | 100.0% | 50 | 1 | 26,076.96 | 22,847.42 | ||||||

| 95.0% | 5.0% | 100.0% | 50 | 1 | 3,636,721.46 | 149,510.93 | |||||

| 95.0% | 5.0% | 100.0% | 50 | 1 | 469,489.15 | 22,345.48 | |||||

| 95.0% | 5.0% | 100.0% | 50 | 1 | 441,252.00 | 18,982.48 | |||||

| 100.0% | 100.0% | 50 | 1 | 450,959.00 | 983,090.62 | ||||||

| 95.0% | 5.0% | 100.0% | 50 | 1 | 867,312.00 | 109,365.00 | |||||

| 95.0% | 5.0% | 100.0% | 50 | 1 | 3,672,200.00 | 246,400.00 | |||||

| 95.0% | 5.0% | 100.0% | 50 | 1 | 10,811,024.55 | 740,617.31 | |||||

| 95.0% | 5.0% | 100.0% | 50 | 1 | 35,076.00 | 2815.56 | |||||

| 95.0% | 5.0% | 100.0% | 50 | 1 | 255,185.00 | 18,164.10 | |||||

| 95.0% | 5.0% | 100.0% | 50 | 1 | 5,374,145.00 | 194,405.00 | |||||

| 95.0% | 5.0% | 100.0% | 50 | 1 | 40,915.75 | 20,557.00 | |||||

| 95.0% | 5.0% | 100.0% | 50 | 1 | 4,324,073.60 | 186,278.40 | |||||

| 95.0% | 5.0% | 100.0% | 50 | 1 | 215,401.44 | 22,038.48 | |||||

| 95.0% | 5.0% | 100.0% | 50 | 1 | 57,501.60 | 9106.32 | |||||

| 100.0% | 100.0% | 50 | 1.5 | 90,000.00 | 400,938.00 | ||||||

| 100.0% | 100.0% | 50 | 1.5 | 15,000.00 | 104,334.00 | ||||||

| 100.0% | 100.0% | 50 | 1 | 1377.00 | 4515.03 | ||||||

References

- Gervasio, H.; Dimova, S. Model for Life Cycle Assessment (LCA) of Buildings, EUR 29123 EN, Publications Office of the European Union, 2018, JRC110082; Joint Research Center: Brussels, Belgium, 2018; ISBN 9789279799730. [Google Scholar] [CrossRef]

- Yin, S.; Dong, T.; Li, B.; Gao, S. Developing a Conceptual Partner Selection Framework: Digital Green Innovation Management of Prefabricated Construction Enterprises for Sustainable Urban Development. Buildings 2022, 12, 721. [Google Scholar] [CrossRef]

- Pomponi, F.; Moncaster, A. Embodied Carbon Mitigation and Reduction in the Built Environment—What Does the Evidence Say? J. Environ. Manag. 2016, 181, 687–700. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Omer, M.A.B.; Noguchi, T. A Conceptual Framework for Understanding the Contribution of Building Materials in the Achievement of Sustainable Development Goals (SDGs). Sustain. Cities Soc. 2020, 52, 101869. [Google Scholar] [CrossRef]

- Ramesh, T.; Prakash, R.; Shukla, K.K. Life Cycle Energy Analysis of Buildings: An Overview. ENERGY Build. 2010, 42, 1592–1600. [Google Scholar] [CrossRef]

- Leadership in Energy and Environmental Design Home|LEED Lookbook. Available online: https://leed.usgbc.org/ (accessed on 14 October 2021).

- BREEAM Sustainability Assessment Method. Available online: https://www.breeam.com/ (accessed on 14 October 2021).

- Gervasio, H. Resource Efficient Construction towards Sustainable Design|EFIResources Project|Fact Sheet|H2020|CORDIS|European Commission. Available online: https://cordis.europa.eu/project/id/707532 (accessed on 20 April 2022).

- Galvez-Martos, J.-L.; Styles, D.; Schoenberger, H. Identified Best Environmental Management Practices to Improve the Energy Performance of the Retail Trade Sector in Europe. Energy Policy 2013, 63, 982–994. [Google Scholar] [CrossRef]

- European Commission. A Roadmap for Moving to a Competitive Low Carbon Economy in 2050; European Commission: Brussels, Belgium, 2011. [Google Scholar]

- European Parliament. Directive 2018/844/EU Amending Directive 2010/31/EU on the Energy Performance of Buildings and Directive 2012/27/EU on Energy Efficiency; European Parliament: Luxembourg, 2018. [Google Scholar]

- Cole, R.J.; Kernan, P.C. Life-Cycle Energy Use in Office Buildings. Build. Environ. 1996, 31, 307–317. [Google Scholar] [CrossRef]

- Junnila, S.; Horvath, A.; Guggemos, A.A. Life-Cycle Assessment of Office Buildings in Europe and the United States. J. Infrastruct. Syst. 2006, 12, 10–17. [Google Scholar] [CrossRef]

- Chau, C.K.; Leung, T.M.; Ng, W.Y. A Review on Life Cycle Assessment, Life Cycle Energy Assessment and Life Cycle Carbon Emissions Assessment on Buildings. Appl. Energy 2015, 143, 395–413. [Google Scholar] [CrossRef]

- Wallhagen, M.; Glaumann, M.; Malmqvist, T. Basic Building Life Cycle Calculations to Decrease Contribution to Climate Change - Case Study on an Office Building in Sweden. Build. Environ. 2011, 46, 1863–1871. [Google Scholar] [CrossRef]

- Zabalza Bribian, I.; Aranda Uson, A.; Scarpellini, S. Life Cycle Assessment in Buildings: State-of-the-Art and Simplified LCA Methodology as a Complement for Building Certification. Build. Environ. 2009, 44, 2510–2520. [Google Scholar] [CrossRef]

- Verbeeck, G.; Hens, H. Life Cycle Inventory of Buildings: A Contribution Analysis. Build. Environ. 2010, 45, 964–967. [Google Scholar] [CrossRef]

- Ortiz, O.; Bonnet, C.; Bruno, J.C.; Castells, F. Sustainability Based on LCM of Residential Dwellings: A Case Study in Catalonia, Spain. Build. Environ. 2009, 44, 584–594. [Google Scholar] [CrossRef]

- Thormark, C. The Effect of Material Choice on the Total Energy Need and Recycling Potential of a Building. Build. Environ. 2006, 41, 1019–1026. [Google Scholar] [CrossRef]

- Karimpour, M.; Belusko, M.; Xing, K.; Bruno, F. Minimising the Life Cycle Energy of Buildings: Review and Analysis. Build. Environ. 2014, 73, 106–114. [Google Scholar] [CrossRef]

- Blengini, G.A.; Di Carlo, T. The Changing Role of Life Cycle Phases, Subsystems and Materials in the LCA of Low Energy Buildings. Energy Build. 2010, 42, 869–880. [Google Scholar] [CrossRef]

- Kofoworola, O.F.; Gheewala, S.H. Environmental Life Cycle Assessment of a Commercial Office Building in Thailand. Int. J. Life Cycle Assess. 2008, 13, 498. [Google Scholar] [CrossRef]

- Gustavsson, L.; Joelsson, A. Life Cycle Primary Energy Analysis of Residential Buildings. Energy Build. 2010, 42, 210–220. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Rincón, L.; Vilariño, V.; Pérez, G.; Castell, A. Life Cycle Assessment (LCA) and Life Cycle Energy Analysis (LCEA) of Buildings and the Building Sector: A Review. Renew. Sustain. Energy Rev. 2014, 29, 394–416. [Google Scholar] [CrossRef]

- Ding, G.K.C. Sustainable Construction—The Role of Environmental Assessment Tools. J. Environ. Manag. 2008, 86, 451–464. [Google Scholar] [CrossRef]

- Dutil, Y.; Rousse, D.; Quesada, G. Sustainable Buildings: An Ever Evolving Target. Sustainability 2011, 3, 443–464. [Google Scholar] [CrossRef] [Green Version]

- van Ooteghem, K.; Xu, L. The Life-Cycle Assessment of a Single-Storey Retail Building in Canada. Build. Environ. 2012, 49, 212–226. [Google Scholar] [CrossRef] [Green Version]

- Chau, C.K.; Yik, F.W.H.; Hui, W.K.; Liu, H.C.; Yu, H.K. Environmental Impacts of Building Materials and Building Services Components for Commercial Buildings in Hong Kong. J. Clean. Prod. 2007, 15, 1840–1851. [Google Scholar] [CrossRef]

- Cinelli, M.; Coles, S.R.; Kirwan, K. Analysis of the Potentials of Multi Criteria Decision Analysis Methods to Conduct Sustainability Assessment. Ecol. Indic. 2014, 46, 138–148. [Google Scholar] [CrossRef] [Green Version]

- Le, K.N.; Tran, C.N.N.; Tam, V.W.Y. Life-Cycle Greenhouse-Gas Emissions Assessment: An Australian Commercial Building Perspective. J. Clean. Prod. 2018, 199, 236–247. [Google Scholar] [CrossRef]

- Luo, Z.; Yujie, C.; Zhang, N.; Liu, Y.; Liu, J. A Quantitative Process-Based Inventory Study on Material Embodied Carbon Emissions of Residential, Office, and Commercial Buildings in China. J. Therm. Sci. 2019, 28, 1236–1251. [Google Scholar] [CrossRef]

- Anastaselos, D.; Giama, E.; Papadopoulos, A.M. An Assessment Tool for the Energy, Economic and Environmental Evaluation of Thermal Insulation Solutions. Energy Build. 2009, 41, 1165–1171. [Google Scholar] [CrossRef]

- Papadopoulos, A.M.; Giama, E. Environmental Performance Evaluation of Thermal Insulation Materials and Its Impact on the Building. Build. Environ. 2007, 42, 2178–2187. [Google Scholar] [CrossRef]

- Pargana, N.; Pinheiro, M.D.; Silvestre, J.D.; De Brito, J. Comparative Environmental Life Cycle Assessment of Thermal Insulation Materials of Buildings. Energy Build. 2014, 82, 466–481. [Google Scholar] [CrossRef]

- Deloitte Global Powers of Retailing. The Art and Science of Customers. 2017. Available online: https://www2.deloitte.com/content/dam/Deloitte/global/Documents/consumer-industrial-products/gx-cip-2017-global-powers-of-retailing.pdf (accessed on 11 September 2018).

- Master Draw Arquitectura e Planeamento Lda Leroy Merlin Loulé. Available online: https://www.masterdraw.pt/project/leroy-merlin-loule/ (accessed on 31 October 2022).

- European Commission Level(s) Common Framework|Product Groups Documents|Product Bureau. Available online: https://susproc.jrc.ec.europa.eu/product-bureau/product-groups/412/documents (accessed on 19 April 2022).

- Andrews, C.J.; Krogmann, U. Explaining the Adoption of Energy-Efficient Technologies in U.S. Commercial Buildings. Energy Build. 2009, 41, 287–294. [Google Scholar] [CrossRef]

- Irvine, S.J.C.; Rowlands-Jones, R.L. Potential for Further Reduction in the Embodied Carbon in PV Solar Energy Systems. IET Renew. POWER Gener. 2016, 10, 428–433. [Google Scholar] [CrossRef]

- Zabalza Bribián, I.; Valero Capilla, A.; Aranda Usón, A. Life Cycle Assessment of Building Materials: Comparative Analysis of Energy and Environmental Impacts and Evaluation of the Eco-Efficiency Improvement Potential. Build. Environ. 2011, 46, 1133–1140. [Google Scholar] [CrossRef]

- Santos Ferreira, A.S. Decarbonizing Strategies of the Retail Sector Following the Paris Agreement—27 Highest Revenue Retailers’ CSR Reports. Available online: https://data.mendeley.com/drafts/rjtrcrps5p (accessed on 10 September 2022).

- European Parliament Directive (EU) 2018/ 2002 on Energy Efficiency. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32018L2002&from=EN (accessed on 3 May 2019).

- Ferreira, A.; Pinheiro, M.D.; de Brito, J.; Mateus, R. Decarbonizing Strategies of the Retail Sector Following the Paris Agreement. Energy Policy 2019, 135. [Google Scholar] [CrossRef] [Green Version]

- Ferreira, A.; Pinheiro, M.D.; de Brito, J.; Mateus, R. Combined Carbon and Energy Intensity Benchmarks for Sustainable Retail Stores. Energy 2018, 165. [Google Scholar] [CrossRef] [Green Version]

- Huang, Y.; Niu, J.L.; Chung, T.M. Study on Performance of Energy-Efficient Retrofitting Measures on Commercial Building External Walls in Cooling-Dominant Cities. Appl. Energy 2013, 103, 97–108. [Google Scholar] [CrossRef]

- Kumanayake, R.; Luo, H.; Paulusz, N. Assessment of Material Related Embodied Carbon of an Office Building in Sri Lanka. Energy Build. 2018, 166, 250–257. [Google Scholar] [CrossRef]

- Rissman, J.; Bataille, C.; Masanet, E.; Aden, N.; Morrow, W.R.; Zhou, N.; Elliott, N.; Dell, R.; Heeren, N.; Huckestein, B.; et al. Technologies and Policies to Decarbonize Global Industry: Review and Assessment of Mitigation Drivers through 2070. Appl. Energy 2020, 266, 114848. [Google Scholar] [CrossRef]

- Cordero, A.S.; Melgar, S.G.; Márquez, J.M.A. Green Building Rating Systems and the New Framework Level(s): A Critical Review of Sustainability Certification within Europe. Energies 2019, 13, 66. [Google Scholar] [CrossRef] [Green Version]

- One Click LCA. What Is Level(s)? Read about the New Framework for Sustainable Buildings. Available online: https://www.oneclicklca.com/levels-framework-for-sustainable-buildings/ (accessed on 6 September 2021).

- European Commission Level(S). Available online: https://ec.europa.eu/environment/levels_en (accessed on 6 September 2021).

- Kneifel, J. Life-Cycle Carbon and Cost Analysis of Energy Efficiency Measures in New Commercial Buildings. Energy Build. 2010, 42, 333–340. [Google Scholar] [CrossRef]

- Hertwich, E.G.; Hammitt, J.K.; Pease, W.S. A Theoretical Foundation for Life-Cycle Assessment: Recognizing the Role of Values in Environmental Decision Making. J. Ind. Ecol. 2000, 4, 13–28. [Google Scholar] [CrossRef]

- European Parliament Directive 2012/27/EU of the European Parliament and of the Council of 25 October 2012 on Energy Efficiency, Amending Directives 2009/125/EC and 2010/30/EU and Repealing Directives 2004/8/EC and 2006/32/EC Text with EEA Relevance. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:02012L0027-20181224 (accessed on 28 April 2022).

| Energy Consumption per Building System | |

|---|---|

| HVAC | 17% |

| Lighting | 41% |

| Equipment (elevators and escalators) | 42% |

| Total annual energy consumption |

| Envelope Element | Building Element Detailed Composition | Building Element Abbreviation |

|---|---|---|

| Walls | Exterior wall in white colour composed by rigid polyurethane foam (PUR) sandwich panels (6 cm thickness and a density of 35–50 kg/m3) | 6 cm thick sandwich panels in rigid polyurethane foam (PUR) |

| Roofs | The roof is 34 cm thick, the external surface is white and has the following composition (from the interior to the exterior: (i) lightweight ceramic pot (2 rows of holes) and beam slab (total thickness of 23′cm and thermal resistance = 0.23 m2°C/ W); (ii) rock wool (density= 35–100 kg/m3, 10 cm thickness, and thermal resistance=2.50 m2°C/W); and (iii) flexible waterproofing membrane impregnated with bitumen (1 cm thickness) | flexible waterproofing bitumen membrane 1 cm + rock wool 10 cm + lightweight pot and beam slab 23 cm |

| Material Type Breakdown | Material Total (t) | Material Total (%) |

|---|---|---|

| Glass | 0.37 | 0.00% |

| Plastic | 2.19 | 0.01% |

| Bituminous mixtures | 86.02 | 0.20% |

| Metals | 2320.69 | 5.50% |

| Electrical and electronic equipment | 70 | 0.17% |

| Concrete, brick, tile, natural stone, ceramic | 39,415.43 | 93.44% |

| Round gravel | 3.74 | 0.01% |

| Concrete block | 1509.3 | 3.58% |

| Cement mortar | 56.08 | 0.13% |

| Screed | 326.98 | 0.78% |

| Crushed limestone | 7154.82 | 16.96% |

| Ceramic tile | 1.38 | 0.00% |

| Reinforced concrete | 30,363.13 | 71.98% |

| Insulation materials | 289.61 | 0.69% |

| Rock wool | 167.93 | 0.40% |

| Extruded polystyrene | 121.67 | 0.29% |

| Combined total * | 42,184.31 | 100.00% |

| Impact Category * | Energy (MJ) | Energy (kWh) | % | IPCC GWP 100a (kg CO2 eq) | % |

|---|---|---|---|---|---|

| Concrete, brick, tile, natural stone, ceramic | |||||

| Gravel, round {RoW}| market for gravel, round|Cut-off, S | 656 | 182 | 0% | 44 | 0% |

| Concrete block {GLO}| market for|Cut-off, S | 1,222,540 | 339,594 | 1% | 135,314 | 1% |

| Cement mortar {RoW}| market for cement mortar|Cut-off, S | 61,511,953 | 17,086,654 | 42% | 8,178,828 | 51% |

| Screed total amount | 485,943 | 134,984 | 0% | 62,547 | 0% |

| Limestone, crushed, washed {RoW}| market for limestone, crushed, washed|Cut-off, S | 582,959 | 161,933 | 0% | 39,466 | 0% |

| Ceramic tile {GLO}| market for|Cut-off, S | 16,250 | 4514 | 0% | 1130 | 0% |

| Concrete | 20,014,386 | 5,559,552 | 14% | 2,774,402 | 17% |

| Glass | 0% | 0% | |||

| Plastic | 0% | 0% | |||

| Acrylic varnish, without water, in 87.5% solution state {RoW}| market for acrylic varnish, without water, in 87.5% solution state|Cut-off, S | 66,874 | 18,576 | 0% | 4249 | 0% |

| Polycarbonate {GLO}| market for|Cut-off, S | 79,777 | 22,160 | 0% | 6558 | 0% |

| Bituminous mixtures | 0% | 0% | |||

| Bitumen adhesive compound, hot {GLO}| market for|Cut-off, S | 4,519,716 | 1,255,477 | 3% | 43,842 | 0% |

| Metals | 0% | 0% | |||

| Reinforcing steel {GLO}| market for|Cut-off, S | 57,631,652 | 16,008,792 | 39% | 4,893,783 | 30% |

| Insulation materials * | 0% | 0% | |||

| Stone wool, packed {GLO}| market for stone wool, packed|Cut-off, S | 3,021,457 | 839,294 | 2% | 226,984 | 1% |

| Polystyrene, extruded {GLO}| market for|Cut-off, S | 11,559,108 | 3,210,863 | 8% | 1,176,143 | 7% |

| Total | 146,132,705 | 40,592,419 | 16,140,162.98 |

| Energy Bill Month | Energy (kWh) | GHG Emissions (kg CO2 eq) |

|---|---|---|

| Jan/21 | 9736 | 66,619 |

| Feb/21 | 15,121 | 50,634 |

| Mar/21 | 10,955 | 36,684 |

| Apr/21 | 11,802 | 39,518 |

| May/21 | 9101 | 33,723 |

| Jun/21 | 11,727 | 43,456 |

| Jul/21 | 11,909 | 44,130 |

| Aug/21 | 14,755 | 54,674 |

| Sep/21 | 14,832 | 51,815 |

| Oct/21 | 15,415 | 53,850 |

| Nov/21 | 14,470 | 50,551 |

| Dec/21 | 17,106 | 59,758 |

| 43,183 * | ||

| Total | 156,930 | 628,595 ** |

| * GHG emissions from production stage of the installed PV panels (38 g CO2 eq/kWh according to the PV supplier) | ||

| ** HVAC systems did not have any leakages thus far. Their gas load is the following: | ||

| Heat pump packaged rooftop unit 1 | 79,340 | |

| Heat pump packaged rooftop unit 2 | 79,340 | |

| Heat pump packaged rooftop unit 3 | 22,970 | |

| VRF system | 41,550 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ferreira, A.; Pinheiro, M.D.; de Brito, J.; Mateus, R. Embodied vs. Operational Energy and Carbon in Retail Building Shells: A Case Study in Portugal. Energies 2023, 16, 378. https://doi.org/10.3390/en16010378

Ferreira A, Pinheiro MD, de Brito J, Mateus R. Embodied vs. Operational Energy and Carbon in Retail Building Shells: A Case Study in Portugal. Energies. 2023; 16(1):378. https://doi.org/10.3390/en16010378

Chicago/Turabian StyleFerreira, Ana, Manuel Duarte Pinheiro, Jorge de Brito, and Ricardo Mateus. 2023. "Embodied vs. Operational Energy and Carbon in Retail Building Shells: A Case Study in Portugal" Energies 16, no. 1: 378. https://doi.org/10.3390/en16010378

APA StyleFerreira, A., Pinheiro, M. D., de Brito, J., & Mateus, R. (2023). Embodied vs. Operational Energy and Carbon in Retail Building Shells: A Case Study in Portugal. Energies, 16(1), 378. https://doi.org/10.3390/en16010378