The Effect of Pore Structure on the Distribution of Wet Gases in Coal Seams of Enhong Syncline, SW China

Abstract

:1. Introduction

2. Samples and Methods

3. Results and Discussion

3.1. Pore Structure Parameters

3.2. Pore Structure

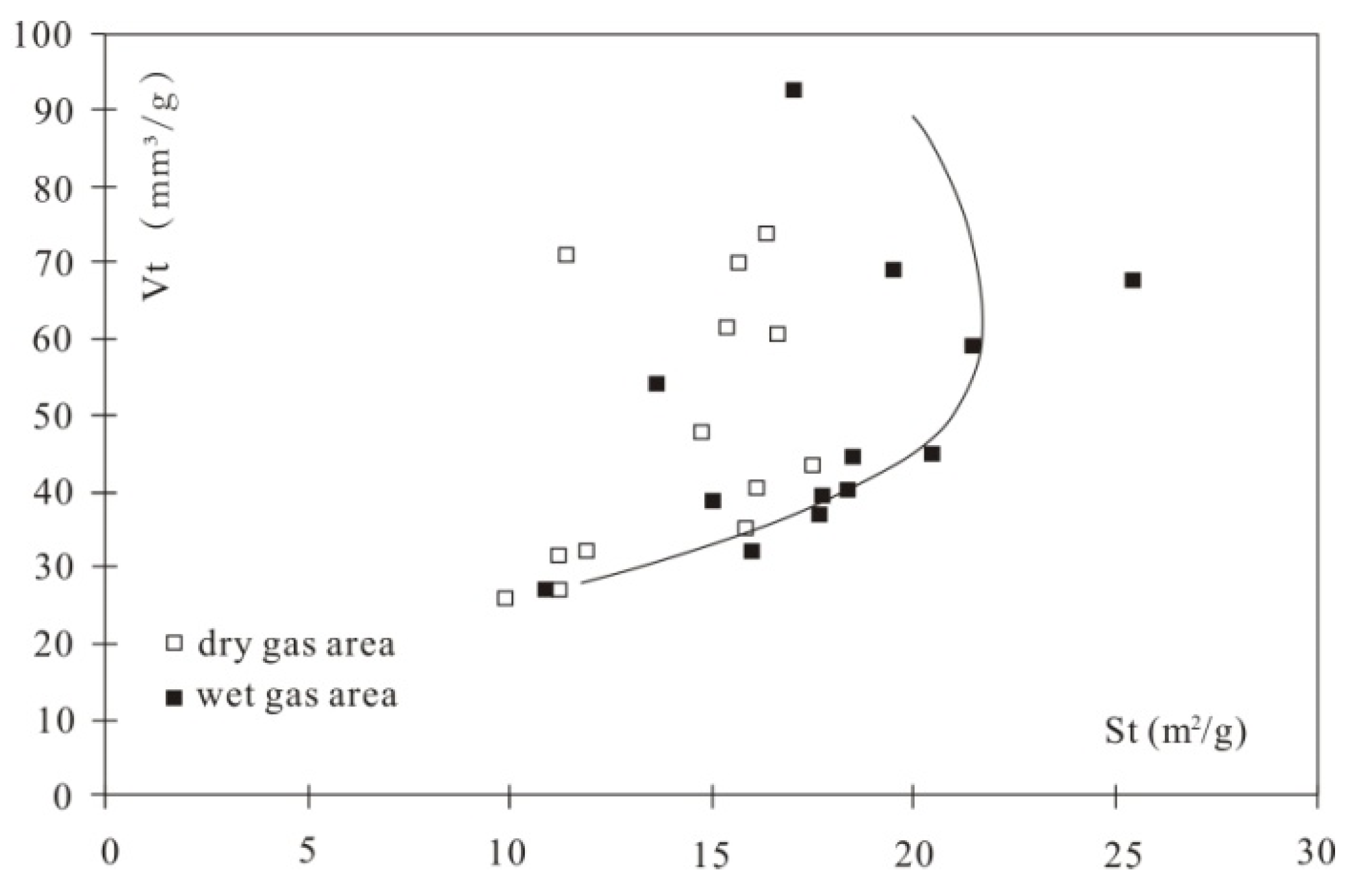

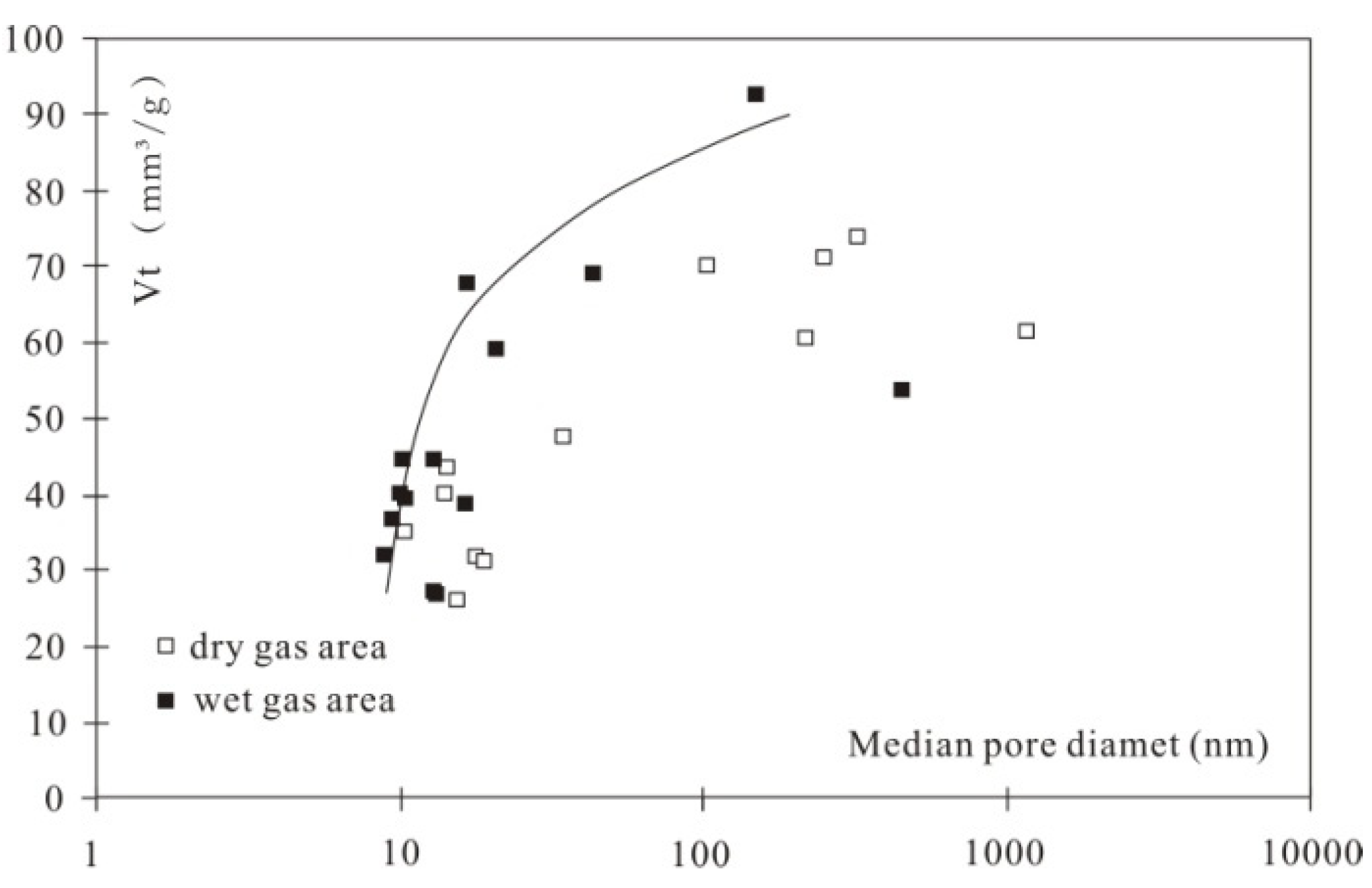

3.3. Effect of Pore Structure on the Concentration of Wet Gases

4. Conclusions

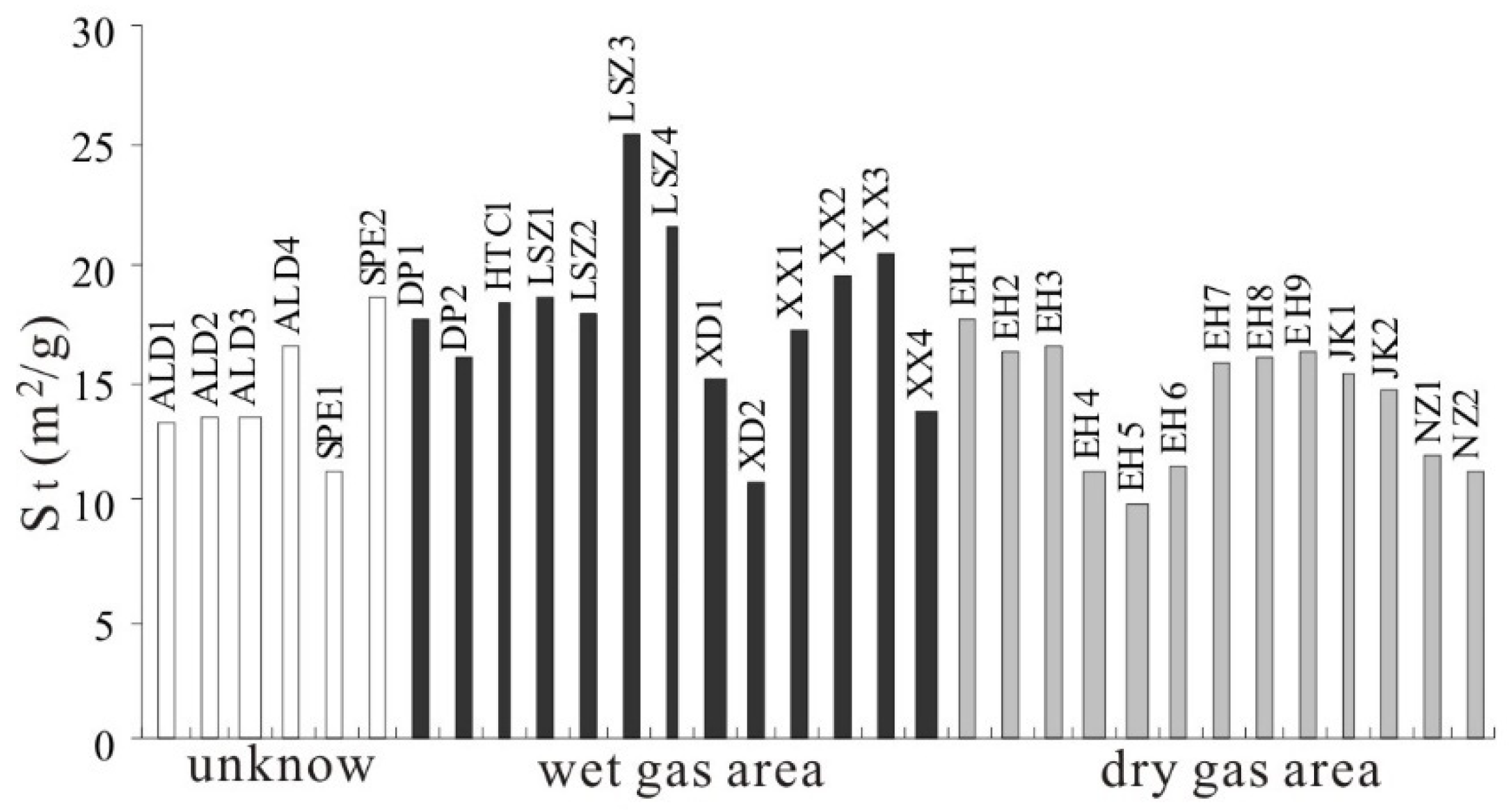

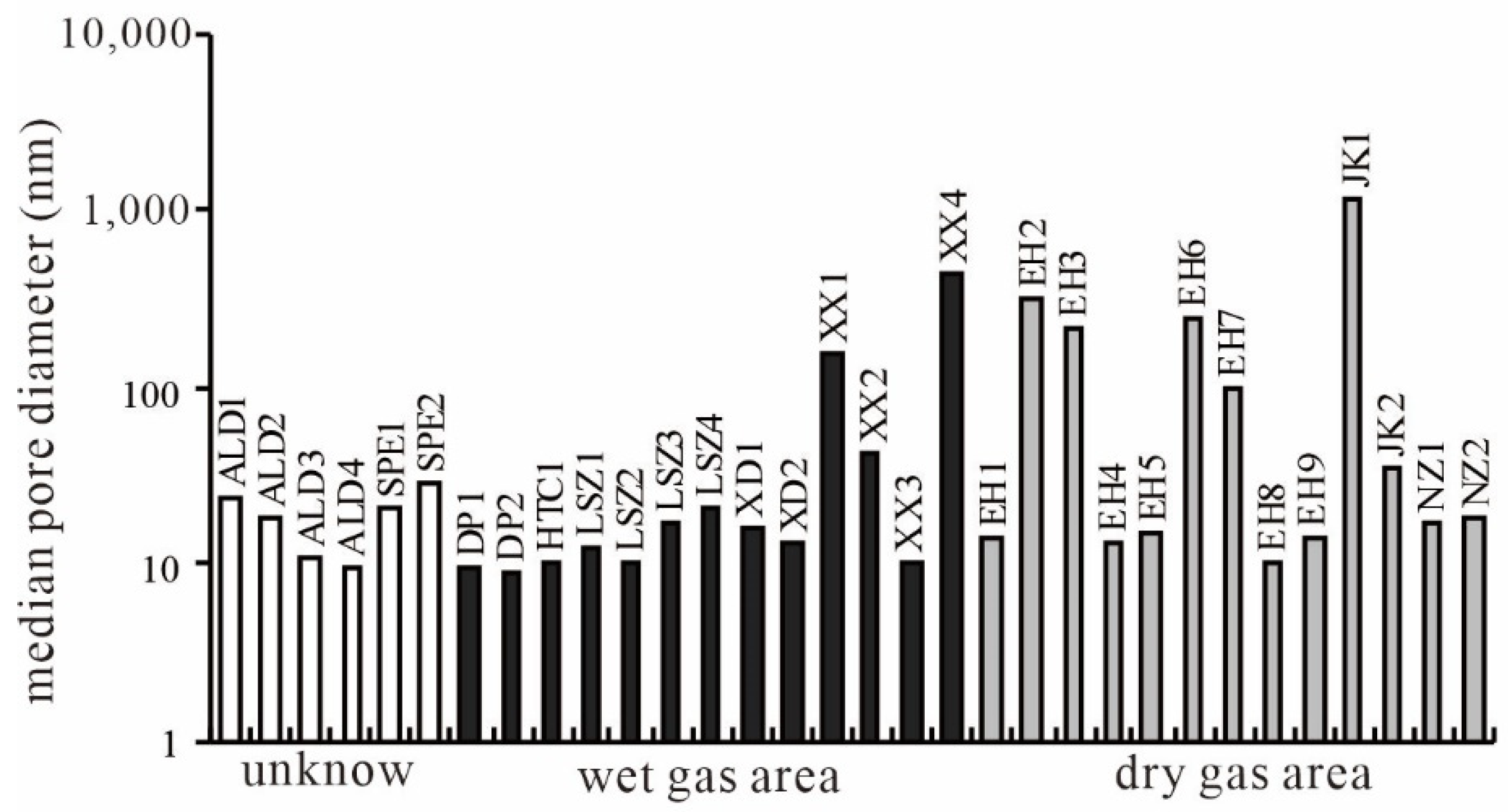

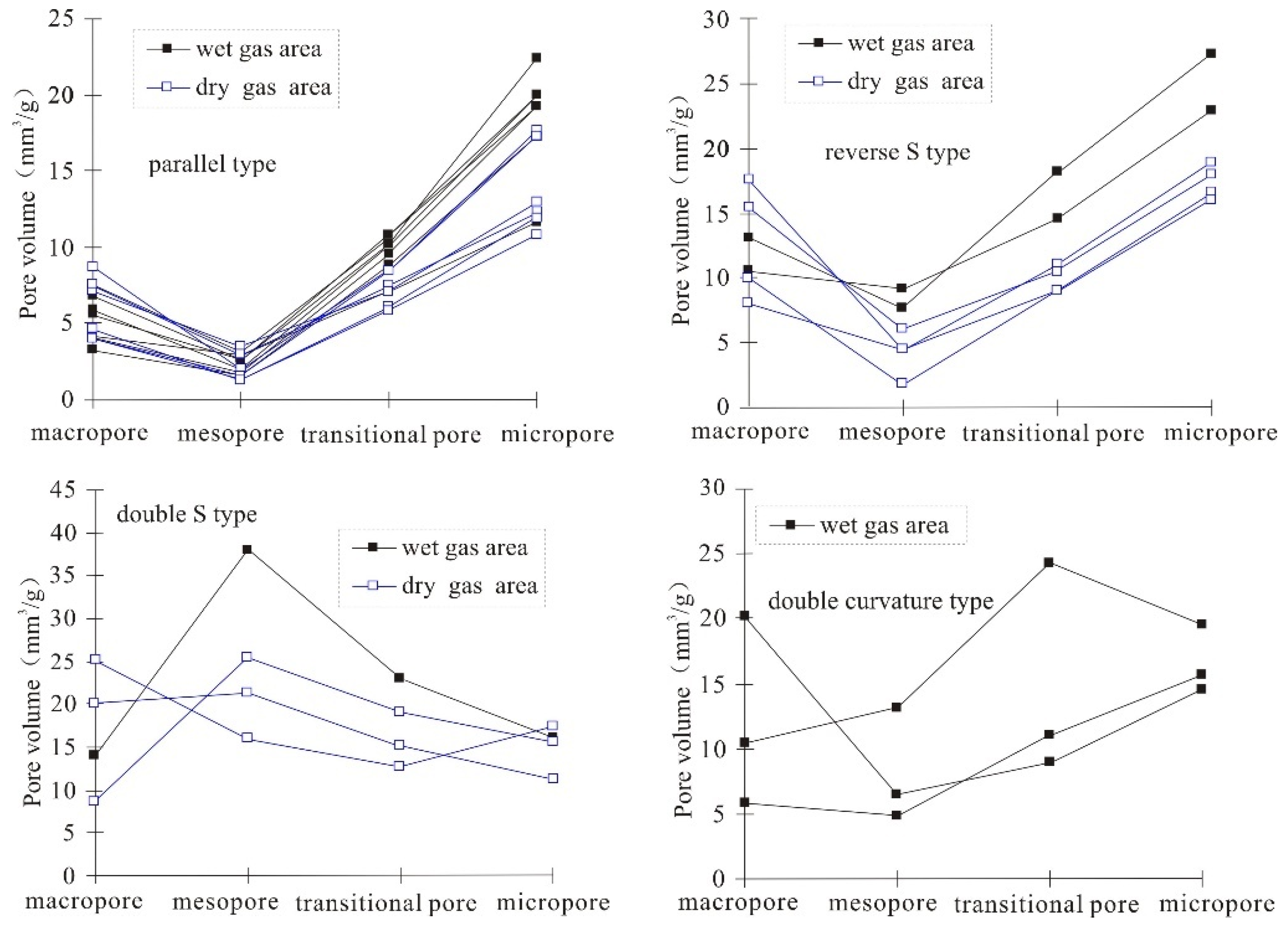

- Coals with different concentrations of wet gases in the Enhong syncline have different pore structures. In the pore structure parameters, the total pore volume and porosity are not very different between the wet gas area and the dry gas area, but the total pore-specific surface area is more and the median pore size is lower in the coals of the wet gas area. The pore size distributions of coal also show the difference. Coals in the wet gas area have more volume of the micropore and transition pore, while coals in the dry gas area have more volume of macropore relatively.

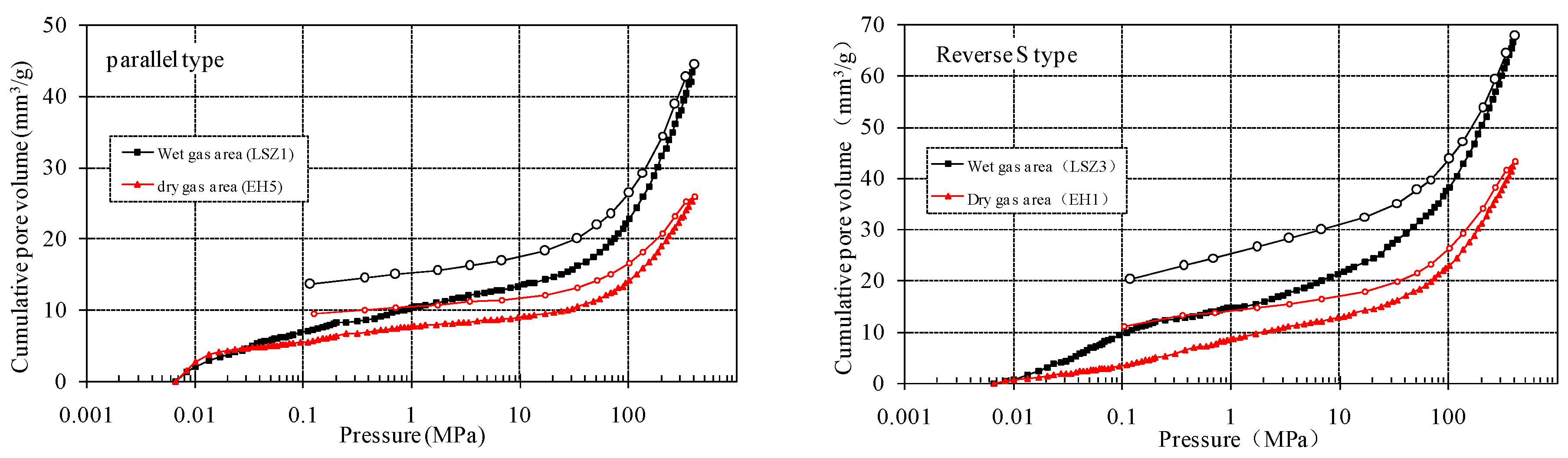

- Pore structures are divided into four types: parallel type, reverse S type, double S type, and double curvature type according to the mercury injection and ejection curve. Pore structures in the dry gas area are mainly parallel-type and reverse S type, which is favorable for the migration and dissipation of coalbed gases. Pore structures in the wet gas area are relatively closed. Coals in the wet gas area have the double S type and double curvature type pore structure, which are characterized by closed pores and bad connectivity.

- The quantity of the micropore and specific surface area and the connectivity of pore structure has important effects on the preservation of wet gases. The higher specific surface area of micropores and more pores make the coal have a stronger adsorption capacity of wet gases. The pore structure with better connectivity is conducive to the evacuation and migration of wet gases, which makes them difficult to preserve well. The pore structure with strong sealing is beneficial to the preservation of wet gases.

Author Contributions

Funding

Conflicts of Interest

References

- Chen, Y.; Qin, Y.; Li, Z.; Shi, Q.; Wei, C.; Wu, C.; Cao, C.; Qua, Z. Differences in desorption rate and composition of desorbed gases between unde-formed and mylonitic coals in the Zhina Coalfield, Southwest China. Fuel 2019, 239, 905–916. [Google Scholar] [CrossRef]

- Chen, Y.; Qin, Y.; Wei, C.; Huang, L.; Shi, Q.; Wu, C.; Zhang, X. Porosity changes in progressively pulverized anthracite subsamples: Implications for the study of closed pore distribution in coals. Fuel 2018, 225, 612–622. [Google Scholar] [CrossRef]

- Clarkson, C.R.; Bustin, R.M. Binary gas adsorption/desorption isotherms: Effect of moisture and coal composition upon carbon dioxide selectivity over methane. Int. J. Coal Geol. 2000, 42, 241–271. [Google Scholar] [CrossRef]

- Hotot. Coal and Gas Outburst; China Industry Press: Beijing, China, 1966; p. 318. [Google Scholar]

- Jiang, B.; Qin, Y.; Ju, Y.W.; Hong, J.; Li, M. The Coupling Mechanism of the Evolution of Chemical Structure with the Characteristics of Gas of Tectonic Coals. Earth Sci. Front. 2009, 16, 262–271, (In Chinese with English Abstract). [Google Scholar]

- Jiang, B.; Qu, Z.; Wang, G.G.; Li, M. Effects of structural deformation on formation of coalbed methane reservoirs in Huaibei coalfield, China. Int. J. Coal Geol. 2010, 82, 175–183. [Google Scholar] [CrossRef]

- Juang, S.; Kang, Y.; Yang, T.; Wang, J.; Zhang, B.; Gu, J.; Sun, H. Combined CBM drainage of multiple seams by single well in Enhong block, Yunnan Province. Coal Geol. Explor. 2018, 46, 80–89. [Google Scholar]

- Lan, F.; Qin, Y.; Li, M.; Tang, Y.; Guo, C.; Zhang, F. Microbial degradation and its influence on components of coalbed gases in Enhong syncline, China. Int. J. Min. Sci. Technol. 2013, 23, 293–299. [Google Scholar] [CrossRef]

- Lan, F.; Qin, Y.; Wang, A.; Li, M.; Wang, G. The origin of high and variable concentrations of heavy hydrocarbon gases in coal from the Enhong syncline of Yunnan, China. J. Nat. Gas Sci. Eng. 2020, 76, 103217. [Google Scholar] [CrossRef]

- Li, M.; Jiang, B.; Lan, F.J.; Qu, Z.H.; Dou, X.Z. Pore structures and structural control of coals with different degrees of deformation from western Guizhou and eastern Yunnan. Geol. J. China Univ. 2012, 18, 533–538. [Google Scholar]

- Li, M.; Jiang, B.; Lin, S.; Lan, F.; Wang, J. Structural controls on coalbed methane reservoirs in Faer coal mine, Southwest China. J. Earth Sci. 2013, 24, 437–448. [Google Scholar] [CrossRef]

- Li, S.; Tang, D.; Pan, Z.; Xu, H.; Guo, L. Evaluation of coalbed methane potential of different reservoirs in western Guizhou and eastern Yunnan, China. Fuel 2015, 139, 257–267. [Google Scholar] [CrossRef]

- McIntosh, J.; Martini, A.; Petsch, S.; Huang, R.; Nüsslein, K. Biogeochemistry of the Forest City Basin coalbed methane play. Int. J. Coal Geol. 2008, 76, 111–118. [Google Scholar] [CrossRef]

- Melnichenko, Y.B.; He, L.; Sakurovs, R.; Kholodenko, A.L.; Blach, T.; Mastalerz, M.; Radliński, A.P.; Cheng, G.; Mildner, D.F. Accessibility of pores in coal to methane and carbon dioxide. Fuel 2012, 91, 200–208. [Google Scholar] [CrossRef]

- Meng, X. Study on the Pore Structure of Coals and Characteristics of Gases Adsorption on Coals; Shandong University of Science and Technology: Qingdao, China, 2007. [Google Scholar]

- Pashin, J.C.; Groshong, R.H. Structural control of coalbed methane production in Alabama. Int. J. Coal Geol. 1998, 38, 89–113. [Google Scholar] [CrossRef]

- Qin, Y. Micropetrology and Structural Evolution of High-Bank Coals in P. R. China; China University of Mining and Technology Press: Xuzhou, China, 1994; p. 48. [Google Scholar]

- Qin, Y.; Moore, T.A.; Shen, J.; Yang, Z.; Shen, Y.; Wang, G. Resources and geology of coalbed methane in China: A review. Int. Geol. Rev. 2017, 60, 777–812. [Google Scholar] [CrossRef]

- Rice, D.D.; Claypool, G.E. Generation, accumulation, and resource potential of biogenic Gas. AAPG Bull. 1981, 65, 5–25. [Google Scholar]

- Tang, R.; Zeng, Y. The study on the retro-mercurometric efficiency of rocks. Exp. Pet. Geol. 1994, 16, 84–93. [Google Scholar]

- Tao, M.; Wang, W.; Xie, G.; Li, J.; Wang, Y.; Zhang, X.; Zhang, H.; Shi, B.; Gao, B. Secondary biogenic coalbed gas in some coal fields of China. Sci. Bull. 2005, 50, 24–29. [Google Scholar] [CrossRef]

- Wu, G.; Lin, Y.; Li, Y. Resources and occurrence characteristics of coalbed methane in Enhong and Laochang mining areas. Jiangsu Coal 2003, 26–27. [Google Scholar]

- Wu, J.; Jin, K.; Tong, Y.; Qian, R. Theory of coal pores and its application in evaluation of gas outburst proneness and gas drainage. J. China Coal Soc. 1991, 16, 86–95. [Google Scholar]

- Wu, J. Studies on characteristics of micropore and its relation with the migration and concentration of oil and gas. Sci. China (Ser. B) 1993, 23, 77–84. [Google Scholar]

- Wu, J. The Theory and Practice of Coal-Generated Hydrocarbon in China; China Coal Industry Publishing House: Beijing, China, 1994. [Google Scholar]

- Xu, H.; Zhang, S.; Leng, X.; Tang, D.; Wang, M. Analysis of pore system model and physical property of coal reservoir in the Qinshui Basin. Chin. Sci. Bull. 2005, 50, 52–58. [Google Scholar] [CrossRef]

- Yang, S.; Qin, Y.; Shen, J.; Lan, F.J.; Wang, B.W. Characteristics and Geological controls of coal reservoirs in Enhong syncline. China Coalbed Methane 2010, 7, 18–20. [Google Scholar]

- Yao, S.; Jiao, K.; Zhang, K.; Hu, W.; Ding, H.; Li, M.; Pei, W. An atomic force microscopy study of coal nanopore structure. Chin. Sci. Bull. 2011, 56, 2706–2712. [Google Scholar] [CrossRef] [Green Version]

- Yu, L.C.; Li, W.F. Study on composition of hydrocarbons in coal seams liable to outbursts. J. China Coal Soc. 1981, 4, 3–10. [Google Scholar]

- Zhong, N.; Qin, Y. Carbonate Organic Petrology: Maceral Characteristics, Origin, Evolution and Its Relationship with Oil and Gas; Science Press: Beijing, China, 1995. [Google Scholar]

- Zhong, L.W.; Zhang, H.; Yun, Z.R.; Lei, C.L. Influence of specific pore area and pore volume of coal on adsorption capacity. Coal Geol. Explor. 2002, 30, 26–28. [Google Scholar]

| Number of Samples | Coal Seam No. | Ro,max/% | Vt (mm3/g) | St (m2/g) | Medium Pore Diameter (nm) | Porosity (%) | Types of Pore Structures | Mercury Withdrawal Efficiency (%) | Area of Samples |

|---|---|---|---|---|---|---|---|---|---|

| DP1 | 10 | 1.45 | 36.5 | 17.748 | 9.4 | 4.40 | I | 81.92 | wet gas area |

| DP2 | 10 | 1.42 | 31.8 | 16.023 | 8.9 | 3.95 | I | 85.22 | wet gas area |

| HTC1 | 10 | 1.42 | 39.8 | 18.442 | 10.1 | 4.72 | I | 74.37 | wet gas area |

| LSZ1 | 8 | 1.40 | 44.3 | 18.532 | 12.9 | 5.18 | I | 69.53 | wet gas area |

| LSZ2 | 8 | 1.48 | 39.2 | 17.811 | 10.5 | 4.93 | I | 86.73 | wet gas area |

| LSZ3 | 9 | 1.59 | 67.6 | 25.461 | 16.9 | 7.50 | II | 70.12 | wet gas area |

| LSZ4 | 9 | 1.72 | 58.9 | 21.524 | 20.9 | 6.83 | II | 72.67 | wet gas area |

| XD1 | 4 | 1.06 | 38.4 | 15.097 | 16.3 | 5.05 | V | 61.98 | wet gas area |

| XD2 | 4 | 0.99 | 26.6 | 10.941 | 13.3 | 3.93 | I | 92.11 | wet gas area |

| XX1 | 7 | 1.36 | 92.5 | 17.127 | 150.9 | 10.71 | IV | 60.54 | wet gas area |

| XX2 | 7 | 1.14 | 68.8 | 19.564 | 43.2 | 8.14 | V | 59.74 | wet gas area |

| XX3 | 8 | 1.43 | 44.5 | 20.509 | 10.2 | 5.31 | I | 62.25 | wet gas area |

| XX4 | 8 | 1.38 | 53.7 | 13.692 | 450.7 | 6.41 | V | 42.46 | wet gas area |

| EH1 | 8 | 1.46 | 43.3 | 17.556 | 14.2 | 5.06 | II | 74.36 | dry gas area |

| EH2 | 9 | 1.65 | 73.7 | 16.439 | 325.9 | 8.50 | IV | 47.22 | dry gas area |

| EH3 | 9 | 1.78 | 60.4 | 16.664 | 218.4 | 7.07 | IV | 50.83 | dry gas area |

| EH4 | 14 | 1.73 | 26.8 | 11.263 | 13.1 | 3.60 | I | 65.30 | dry gas area |

| EH5 | 14 | 1.69 | 25.8 | 9.939 | 15.5 | 3.54 | I | 63.57 | dry gas area |

| EH6 | 15 | 1.62 | 71.0 | 11.463 | 249.8 | 9.25 | IV | 28.31 | dry gas area |

| EH7 | 15 | 1.69 | 69.9 | 15.708 | 102.5 | 8.27 | IV | 60.09 | dry gas area |

| EH8 | 16 | 1.76 | 34.7 | 15.936 | 10.4 | 4.23 | I | 73.49 | dry gas area |

| EH9 | 16 | 1.81 | 40.0 | 16.178 | 14.1 | 4.83 | I | 70.75 | dry gas area |

| JK1 | 11 | 1.28 | 61.3 | 15.402 | 1174.2 | 7.82 | II | 43.39 | dry gas area |

| JK2 | 11 | 1.41 | 47.6 | 14.790 | 34.9 | 6.39 | II | 47.06 | dry gas area |

| NZ1 | 4 | 1.24 | 31.9 | 11.978 | 17.8 | 4.23 | I | 68.03 | dry gas area |

| NZ2 | 4 | 1.28 | 31.1 | 11.245 | 18.8 | 4.16 | I | 70.10 | dry gas area |

| ALD1 | 9 | 1.07 | 37.9 | 13.312 | 23.5 | 4.80 | II | 56.73 | unknown |

| ALD2 | 9 | 1.31 | 36.0 | 13.437 | 18.9 | 4.84 | II | 64.44 | unknown |

| ALD3 | 11 | 1.28 | 30.1 | 13.441 | 11.1 | 3.75 | I | 72.09 | unknown |

| ALD4 | 11 | 1.28 | 33.9 | 16.500 | 9.4 | 4.23 | I | 82.60 | unknown |

| SPE1 | 8 | 1.21 | 32.1 | 11.263 | 20.7 | 4.45 | III | 61.37 | unknown |

| SPE2 | 8 | 1.44 | 58.1 | 18.588 | 29.0 | 6.74 | III | 62.31 | unknown |

| Area | Volume of Macropore (mm3/g) | Volume of Mesopore (mm3/g) | Volume of Transitional Pore (mm3/g) | Volume of Micropore (mm3/g) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Min | Max | Avg | Min | Max | Avg | Min | Max | Avg | Min | Max | Avg | |

| Wet gas area | 3.3 | 20.2 | 8.6 | 1.6 | 38.1 | 7.4 | 7.1 | 24.3 | 12.9 | 11.7 | 27.2 | 18.9 |

| Dry gas area | 4.0 | 25.2 | 10.8 | 1.3 | 25.5 | 7.1 | 5.9 | 19.2 | 10.0 | 10.8 | 18.9 | 15.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lan, F.; Qin, Y.; Li, M.; Wang, Y.; Liu, Y. The Effect of Pore Structure on the Distribution of Wet Gases in Coal Seams of Enhong Syncline, SW China. Energies 2023, 16, 432. https://doi.org/10.3390/en16010432

Lan F, Qin Y, Li M, Wang Y, Liu Y. The Effect of Pore Structure on the Distribution of Wet Gases in Coal Seams of Enhong Syncline, SW China. Energies. 2023; 16(1):432. https://doi.org/10.3390/en16010432

Chicago/Turabian StyleLan, Fengjuan, Yong Qin, Ming Li, Yugan Wang, and Yuhang Liu. 2023. "The Effect of Pore Structure on the Distribution of Wet Gases in Coal Seams of Enhong Syncline, SW China" Energies 16, no. 1: 432. https://doi.org/10.3390/en16010432