1. Introduction

The rapidly increasing population, pushed by the global economy, has dramatically increased the energy demand [

1,

2,

3]. However, economic energy needs are still based on fossil fuels (namely coal, natural gas, and oil). According to International Energy Agency (IEA), in 2018, the global total energy supply of fossil fuels reached over 80%. Electricity and heat accounted, respectively, for 19.31% and 3.03% of energy consumption; however, the primary energy sources for both are fossil fuels [

4]. Considering the climate change scenario and the economy’s decarbonization policies, in 2019, the European Commission published the European Green Pact (EGP) [

5]; the document presents policy efforts to achieve zero net greenhouse gas emissions by 2030–2050 timeframe objectives. State members are called to promote EGP, but the current state of the hydrogen economy, primarily green hydrogen, in global and individual countries, is only beginning. Due to current energy problems and volatile prices for hydrocarbon resources, transport, industry, and electricity are the focus. Considering the number of hydrogen syntheses and types, it is necessary to focus resources on the priority: green hydrogen. This work proposes an energy transition study for Portugal considering green hydrogen produced by electrolysis powered by renewable energy sources (RES).

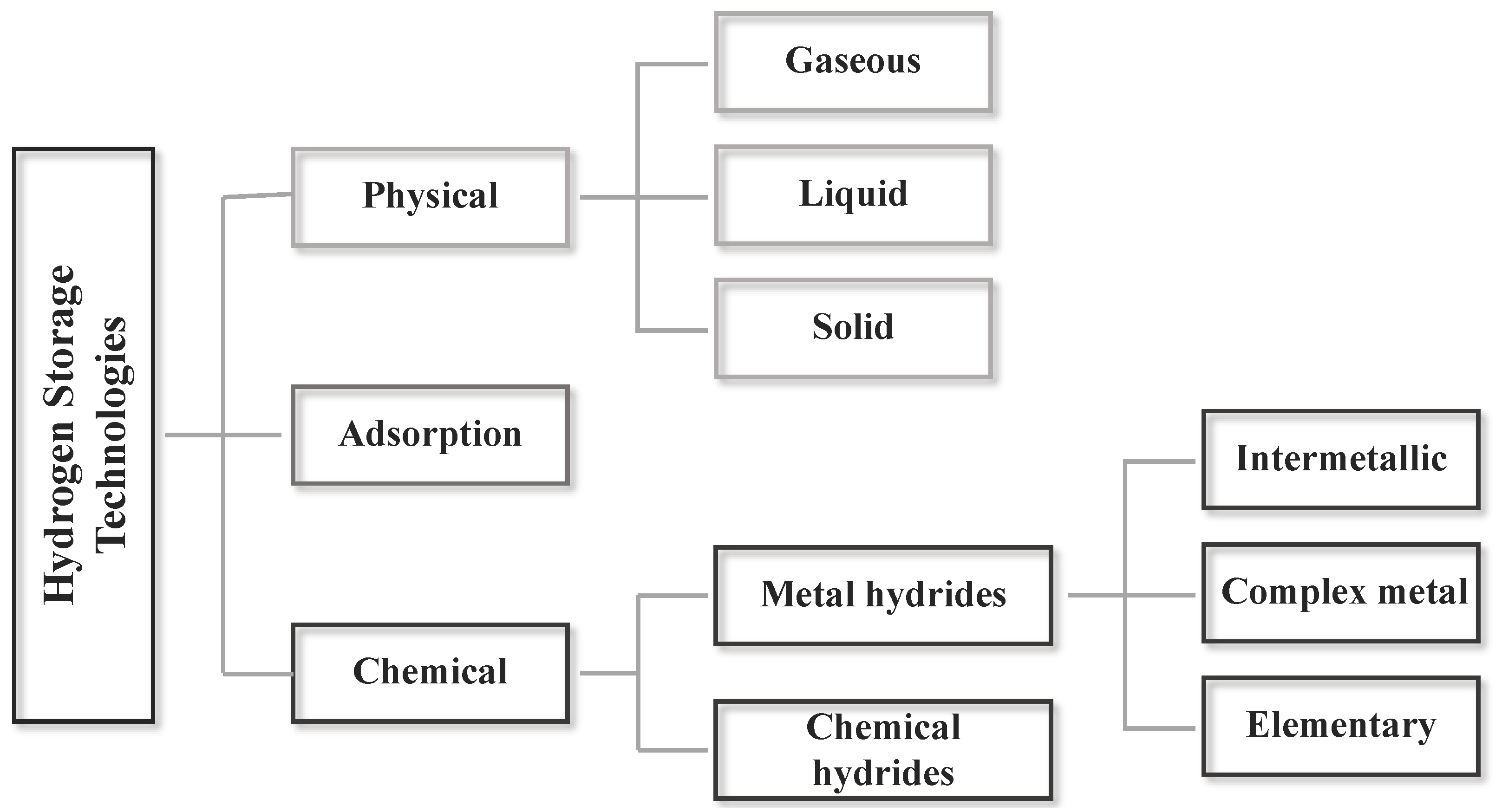

Nowadays, various technologies are related to hydrogen production, storage, and transport in terms of cost and life cycle environmental impact assessment. Depending on the techniques and resources employed, hydrogen can be created through various processes that produce carbon emissions in multiple ways. Globally, 120 million tons of hydrogen are produced each year, two-thirds pure hydrogen and one-third mixed with other gases. Natural gas and coal account for almost 95% of all the hydrogen produced. Products from electrolysis account for about 5% of the total. However, no significant amounts of hydrogen are produced from renewable sources [

6]. Currently, European Union consumes about 9.7 million tons of hydrogen per year [

7]. However, the origin is a hydrocarbon and must be decarbonized to attend EGP; Portugal’s average consumption is around 65 thousand tons. According to the ambitious scenario described in the roadmap and action plan for hydrogen [

7], the demand for hydrogen in the European Union + UK will be roughly 665 TWh or 16.9 million tons [

6]. Towards a greener future and aiming to meet EGP objectives, green hydrogen becomes an important alternative. Still, energy and raw materials must be supplied from renewable sources [

8] promoting CO

-free emissions. The potential of RES [

9] far exceeds the European energy demand [

10] but is capital observe geographic, social, and technical constraints [

11].

Hydrogen is a suitable component of the future of the power grid, serving as a flexible energy carrier for the industry and transportation sectors. The EGP predicts the need for renewable hydrogen will increase even while refinery consumption declines [

7]. The demand for petroleum products is expected to decrease as the EGP develops. However, the extensive decarbonization of the chemical and metallurgical industries will increase the demand for hydrogen production. Aiming to support the energy transition and grant a secure and reliable power grid operation is capital development alternatives to attend to energy demand growth; then, between 2020 and 2024, at least 6 GW of renewable electrolysis should be installed [

5]. This capability could create up to 0.8 million tons of pure hydrogen per year, depending on how it is used. By 2030, this number could rise to 40 GW. With a cost of 5 euros per kg in 2020 [

5], renewable hydrogen (green hydrogen) is a critical path to achieving zero net greenhouse gas emissions from electrolysis and utilizing renewable sources as fuel. By 2030 it is expected that hydrogen could be produced at around 2 euros per kilogram using wind energy [

5]. However, recent fast cost reductions in renewable energy production and global warming potential impact have opened some new possibilities [

12], especially for wind and solar generation.

The versatility of hydrogen allows transition requirements; however, supply chains comprise all parties involved, including producers, suppliers, logistic providers, and customers [

13]. Then, the study presented by [

14] proposes an option for infrastructure development considering the solution of a mixed-integer linear programming problem. Hydrogen, because of its high gravimetric energy content (about 143 MJ/kg), is attractive for grid storage and, used in combination with fuel cells, can be a power generation backup [

15]. The sub-products of the hydrogen process can also configure another option, demonstrated by [

16] with oxygen from electrolysis used in the wastewater treatment plant. The correlation of economies of scale, transport costs, and demand patterns in optimizing hydrogen fueling infrastructure are explored in [

17]. In addition, studies are related to specific countries like [

18] in Brazil, Ref. [

19] in India, and [

20] Poland and German. The work in [

21] presents a power scheduling optimization method, considering a distributed wind-hydrogen integrated energy system.

Green hydrogen has a vast potential for decarbonization in Europe and is the resource most compatible with the goals of the European Union’s carbon neutrality road map. This paper proposes a study to evaluate hydrogen production availing RES potential alongside Portugal. The conduct of these resources is considered through two different scenarios associated with renewable generation uncertainties. The novelty lies in incorporating the ratio between renewable generation and hydrogen production, energy transition on heavy-duty transport, and thermoelectric plants, allowing stakeholders to plan considering commitment degrees.

Considering the energy needs of Portugal and the European Green Deal, this work is based on answering “Can Portugal meet the 2030–2050 European green deal targets?”. The security of energy power grants stability for economic, technical, and social development; as soon as the situation is understood, the technologies evolve faster to develop other studies and promote policies that will boost energy transition. The contributions of this work are as follows:

A model considering the ratio between renewable generation and hydrogen production;

Water consumption and the importance of establishing a policy to avail sub-products of the process;

Investment costs, efficiencies, and logistics are major concerns and key variables;

Analysing the impact of commitment degrees measures over two scenarios using realistic data in power and energy systems;

Studying the reduction of emissions of CO by replacing internal combustion engine (ICE) vehicles with H vehicles.

The remaining of this paper is organized as follows:

Section 2 begins by outlining the current state of hydrogen technology, including a quick overview of what hydrogen is, its history, legislation, regulations, production, delivery, and storage. How the European Union can be decarbonized is discussed in

Section 3, while the methodology employed in the data analysis is presented in

Section 4. The two proposed hydrogen production scenarios and the obtained results are described in

Section 5. Finally, in

Section 6, the conclusion is drawn.

3. Decabornizing the European Union: A Green Hydrogen Economy

A green hydrogen economy that will be entirely established and operational is still a long way off. Despite the creation of a market for green hydrogen production, according to the International Energy Agency (IEA), the number of electrolyzer-related projects and their installed capacity has climbed from less than 1 MW in 2010 to more than 25 MW in 2019. This growth is mainly attributable to lower prices for renewable energy-related technologies and electrolyzers.

Players in the gas business urge a staged approach to the hydrogen economy’s development, beginning with the development of technologies capable of extracting carbon from the atmosphere to generate blue hydrogen. Given their gas reserves, evolving capture capabilities, carbon utilization and storage, and opportunities to re-purpose existing technology and facilities to accommodate blue hydrogen, resource exploration companies believe there are significant synergies with hydrogen that have yet to be exploited before a full transition to green hydrogen takes place. Because of the high costs of expanding hydrogen infrastructure, governments must play a key role in encouraging industry investments and establishing a regulatory framework that promotes the growth of hydrogen-related initiatives [

39].

Early indicators are encouraging. South Korea and Japan have made hydrogen a key component of their long-term energy plans. They have publicly called for establishing overseas hydrogen production bases to meet their import needs. Germany recently launched a €130 billion pandemic recovery budget, with green measures taking the lead, including a fully financed objective of 5 GW of electrolyzers by 2030 [

40]. Moreover, Australia is ideally positioned to become a long-term export powerhouse, thanks to its abundant natural resources and renewable energy [

41]. Synergies between the renewable energy and gas industries are needed to shift to a green hydrogen economy. Projects involving worldwide groupings of sponsors, lenders, and investors are also possible.

3.1. The Infrastructures Needed for a Green Hydrogen-Based Economy

The costs of green hydrogen production are essentially governed by the renewable resources available [

42,

43] and are dominated by energy expenses. However, production costs are only one of the things to consider; we must also consider transportation and storage expenses.

Green hydrogen produced locally from solar and wind power could be locally stored (e.g., in salt caves) or transported through limited pipelines. Hydrogen imported through ship and pipeline, or only long-distance pipelines, will face cost rivalry.

Large-scale manufacturing of green hydrogen will occur at the location of renewable power production rather than at the site of demand for this gas in both situations (production or import of hydrogen). The key reason is that transferring hydrogen via pipeline is ten times more cost-effective than transporting electricity via cable. Furthermore, pipeline capacities (15–20 GW) are more significant than power cable capacities (1–4 GW) [

44]. Therefore, delivering it via pipeline avoids power grid capacity constraints caused by growing renewable electricity output. As a result, instead of providing power, hydrogen transfer would be more cost-effective.

Furthermore, hydrogen, like natural gas, can be stored throughout the year and used as an always-available energy source, which is a significant benefit over electricity. A hydrogen pipeline system is required to move hydrogen from production sites (abundant renewable resources) to consumption sites. Large-scale hydrogen storage facilities (e.g., salt caverns or possibly empty gas containers) should be integrated into such a hydrogen transportation system to allow hydrogen delivery at the point of demand. This hydrogen pipeline system with storage facilities is nearly identical to modern natural gas pipeline systems.

3.2. Current Status of Hydrogen Market

Most hydrogen is used in the petrochemical industry to split heavy oils into lighter petroleum products or make ammonia for fertilizers. According to BNEF, the majority (90%) is manufactured close to its site of use, owing to enormous amounts necessary for consumption and high transportation costs. Most of the hydrogen produced is “gray”. According to the IEA, slightly over half is made at specialized facilities. The remaining 41% is made as a by-product of other chemical processes (usually in petrochemical plants and refineries).

The utilization of solar, wind, or other renewable energy sources to produce “green hydrogen”, which might serve as the foundation for a carbon-free hydrogen economy, is still in its early stages.

The global hydrogen demand at the end of 2021 grew nearly 5% compared to the previous year, as

Figure 2 shows. It also offers two different policies: the stated policies scenario (STEP) and the announced pledges scenario (APS). The first represents current policy settings. According to the STEPS projection, the demand for hydrogen might increase to 115 million tons by 2030. Most of this expansion would come from conventional usage, with little demand (less than 2 Mt) for novel applications or the further substitution of fossil-based hydrogen in traditional uses. The second scenario expects that all international climate agreements, including Nationally Determined Contributions and longer-term net zero objectives, will be fulfilled completely and on schedule [

45].

Despite the current supply shortage, the IEA estimated that government spending on hydrogen research and development increased by 4.7% per year on average in the four years leading up to 2018. The Chinese government has been at the forefront of this trend, with R&D spending rising from $19 million in 2015 to $129 million in 2018. The IEA surveyed government energy budgets and discovered that hydrogen and fuel cells received the most significant increases in 2019 (21% more than in 2018). With a budget of $303 million in 2019, Japan is the world’s largest donor to hydrogen and fuel cell research.

Players in the oil and gas industry advocate for a phased approach to the hydrogen economy, beginning with the development of carbon capture and storage (CCS) technology to produce “blue hydrogen” from natural gas, with the carbon dioxide byproduct captured and stored rather than emitted. Natural gas will likely overtake coal as the world’s leading energy source by the middle of this decade. Resource corporations believe blue hydrogen can serve as a “bridge” technology to green hydrogen. The integration of hydrogen into natural gas networks and investment in storage facilities to enhance grid stability capacity will be aided by investment in blue hydrogen.

3.3. Opportunities and Challenges for the Energy Sector Facing a Transition to a Green Hydrogen-Based Economy

A hydrogen-based economy would drastically alter the oil refining business. As refineries cut back on production in response to lower gasoline demand, the availability of diesel fuel, petrochemicals, and other by-products also decreases. Market opportunities for several things and technology are created by changes in supply and demand, including products made from biomass, coal, renewable, and other energy sources [

46].

Since the economy favors hydrogen technologies, as a result of higher prices for petroleum products, more hydrogen would be produced from coal and biomass. Nuclear and other renewables would also play a crucial and significant role, as a technology, in improving (nuclear) thermochemical production;

Biorefineries that produce biochemicals and hydrogen could be more expensive due to the domestic market’s rise in petroleum product prices. Consequently, more biomasses would be used;

Using coal for hydrogen production, with the use of carbon absorption technology, is more cost-effective when oil product prices are higher, and there is a need to reduce the intensity of greenhouse gases. It is observed that carbon emissions can be captured more advantageously when coal is gasified;

In a world where oil is increasingly scarce, hydrogen technology could significantly and rapidly reduce energy system costs, reduce greenhouse gas emissions, and help achieve sustainable economic development.

Initially, a market study should be conducted to identify niches where hydrogen technologies can penetrate, with economic constraints. As technology learning and economies of scale lower technology prices and fuel costs, hydrogen technologies will expand;

Government policies should play an essential role in transforming the energy system into a hydrogen economy. Hybrid vehicles, which share many technologies with fuel cell technologies, are becoming more energy efficient and cost-effective, as are fuel cell vehicles. However, as hydrogen technologies penetrate the markets, gasoline prices will fall, and hybrid vehicles may be more competitive than battery vehicles, dampening the entry of hydrogen-related technologies;

The transition to a hydrogen economy requires the design and implementation of an economic incentive system to encourage the construction of hydrogen infrastructures and the development of the fuel cell vehicle market;

Reducing the price of hydrogen at fuel pumps requires improvements throughout the hydrogen economy, from production, processing, transportation, distribution, and storage. Improving fuel cells will require revolutionary advances in traction technologies;

Transporting hydrogen exacerbates the cost of supplying the product. The challenges to achieving a better hydrogen delivery system should include the resources of a hydrogen input and output system, selecting the hydrogen production site, and establishing a viable transportation network;

Oil refineries have been producing hydrogen for decades. By reducing the cost of producing hydrogen, there would also be a reduction in the cost of producing gasoline. Low gasoline prices could impede the evolution of hydrogen technologies in a world abundant in oil.

4. Methodology

In this section, the steps used to achieve the data and the problem considerations are fully described along with the mathematical formulations used in green energy production; two scenarios for the adoption in Portugal are assessed: moderate and aggressive. The moderate case considers the output from existing renewable power plants; the aggressive case is a challenging proposal to change existing thermoelectric power plants by renewable generation forcing a high-level energy transition. The resources applied in both scenarios, namely wind turbine, solar panel, and electrolyzer, also are described. The chosen electrolysis is based on relatively low costs and low global warming potential [

12] compared to other processes. In addition, it is a good option to make full use of the surplus renewable energy [

49], and due to high purity, simple and green process [

50].

Figure 3 shows the diagram applied with an overview presenting the stakeholders and their contribution.

The process begins with data acquisition and database creation. Then a treatment is applied to the database converting raw data into meaningful information, namely clustering and comparison operations. Simulations occur in the third step, considering two scenarios (both are described in Experiments). In the fourth step, several analyses compare the simulation’s best results and heuristic aspects, and qualitative and quantitative results are presented.

Regarding the mathematical formulation, when considering the scenario where green hydrogen is produced using the existing renewable generation, as

Figure 3 presents. Equation (

1) was used to calculate how much power would be applied to produce green hydrogen.

where:

—power applied to green hydrogen production (MW);

—installed renewable power (MW);

p—percentage of power that will be applied to obtain the power for the production of green hydrogen (%).

It is also important to know how many electrolyzers will be used, as given by Equation (

2), and how much hydrogen they’ll create each day and year, as formulated in Equation (

3).

where:

N—number of electrolyzers;

—power of the electrolyzer (MW);

—quantity of hydrogen produced (ton/day)/(ton/year);

q—production capacity of the electrolyzer (8 tons/day).

The area required for the electrolyzers was calculated using Equation (

4):

where:

—total occupation area ()

—area of an electrolyzer ()

Finally, the costs of producing green hydrogen were computed hypothetically for the situation under investigation, with production costs of green hydrogen estimated to be roughly 5.55 €/kg or 5550 €/ton [

51].

where:

C—cost of producing green hydrogen (€/day)

c—hydrogen production cost (€/ton)

Considering the scenario where the thermoelectric power would be replaced by renewable generation to produce green hydrogen, the quantity of renewable equipment was calculated using Equations (

6)–(

9) were formulated to obtain the number of electrolyzers needed to produce hydrogen. Regarding the area occupied, Equation (

4) was used for the electrolyzer, and the wind and solar generators defined by Equations (

10) and (

11) were used.

where:

—Quantity of wind turbines for extra power;

—Quantity of solar panels for extra power;

—Power installed in the thermoelectric power plant;

—Power of one wind turbine (6 MW);

—Power of a solar panel (400 W);

—Quantity of electrolyzers for wind generation;

—Quantity of electrolyzers for solar generation;

—Energy produced per hour, considering Portugal’s yearly average wind;

—Energy produced per hour, considering Portugal’s irradiation level;

—Energy consumed by the electrolyzer;

—Total area occupied by all wind turbines ()

—Total area occupied by all solar panels ()

—Occupied area for 1 wind turbine ()

—Occupied area for 1 solar panel ()

As for wind power generator, (

Table 2), “EnVentus platform V162-6.2 MW”, from VESTAS was chosen [

52]. The wind power generator has a lower cut-in wind speed that fits with Portugal’s yearly average wind, 6 m/s.

The solar panel (

Table 3) “NeON

® R” from LG [

53], was selected for solar power generation. This panel has good efficiency and matches with Portugal’s solar sites.

In addition, the electrolyzer (

Table 4) picked for this work for hydrogen production was an “Atmospheric Alkaline Electrolyzer A3380” from NEL [

54].

Another contribution to this study was calculating the reduction of CO

emissions by replacing ICE vehicles with fuel-cell vehicles. We took the annual distance based on a Danish study [

55], and the emissions patterns based on [

56,

57]. As such, we calculate the carbon removal contributions by replacing vehicles using Equation (

12):

where:

—Carbon reduction (ton);

—Quantity of vehicles referred to the year and type of vehicle;

—Emission pattern of each vehicle type ();

—Annual distance traveled of each vehicle type (km).

Significant carbon emissions come from burning fossil resources, such as coal, natural gas, and oil. One way to reduce them is by injecting hydrogen into natural gas thermoelectric power plants.

We calculated the total carbon removals according to EGP goals, considering the energy production in 2020 of Natural Gas-fired power plants and their carbon emissions [

58,

59]. The contributions by replacing Natural gas with H

has an appropriate equation, calculated by Equation (

13):

where:

—Carbon reduction ();

—Energy generation using Natural gas (GWh);

—Emission pattern of Natural Gas ();

—Natural gas removal factor (30% for 2030 and 70% for 2050).

5. Experiments

This section shows the results obtained from the proposed methodologies for the different scenarios.

In 2018, the production and consumption of hydrogen were estimated at around 187 ktoe (about 65 thousand tons). This value represented a reduction of 7.7% compared to 2017 because of a decrease in refining activity, reflected in the production and consumption of hydrogen (

Figure 4) [

60].

In turn, the consumption of natural gas for hydrogen production (

Figure 5) was 222 ktoe, a reduction of 10.6% compared to 2017 [

60] but overall has been stable but not increasing.

Air Liquide is Portugal’s largest producer of hydrogen. Located in Estarreja, it has a production capacity of approximately 18,000 kg of hydrogen per day through the application of a process called Steam Methane Reforming (SMR). Such a method emits 9 kg of carbon dioxide for one kg of hydrogen [

28], i.e., it emits around 160,000 kg/day of carbon, as

Table 5 shows [

61].

It is imperative to reduce this amount of pollution that only one company makes. As such, two methods of green hydrogen production were developed for this purpose, evaluating the technical potential of RES at the regional and national level, considering environmental constraints, limitations related to their physical installation, and various technical-economic parameters.

5.1. Moderate Scenario

The first scenario developed started with collecting data about all the different renewables available in Portugal. With that done, there was a need to agglomerate the existent renewable production by type, as

Table 6 depicts, to simplify the analysis [

62].

Even if there was distribution by type, the country should be divided into districts. A table with the various renewable sources was constructed to agree with the actual figures; we acquired the data from the e2p project—Endogenous Energies of Portugal [

63] belonging to INEGI, where the location and kind of renewable output are found. This subdivision aids in determining where and how renewable technologies are used in Portugal. As shown in

Figure 6 and

Table 7, renewable technologies are more prevalent in the northern half of the country, with Vila Real (2361 MW) being the “greenest” district and Évora having the slightest expression (79 MW) [

62].

“Hydrogen is a gas that burns very cleanly, leaving just water vapor behind.” Because of this property, it can be a powerful weapon against fossil fuels.

Table 8 shows that the energy solely used to manufacture hydrogen comes exclusively from installed renewable power (not more than 50%). The NEL electrolyzer (see

Table 4) consumes 4.4 kWh/Nm

per stack and requires 0.9 L/Nm

of feed in water to create 8 tons of pure hydrogen daily while emitting zero greenhouse emissions into the atmosphere.

Table 7 shows that five districts concentrate almost 60% of Portugal’s renewable generation; it also implies green hydrogen production concentration.

Considering renewable power selected for the moderate scenario,

Table 8 and

Table 9 present hydrogen production results regarding each renewable resource level applied.

Considering all renewable generation (14 GW), 823 electrolyzers will be distributed on 633,356 m

using 68,973 kL/day of water. The cost in 2020 [

5] is the basis for establishing costs related in

Table 9.

5.2. Aggressive Scenario

There are six thermoelectric power plants on mainland Portugal, with a total installed power of 5585 MW and carbon emission of around 6.2 million tons per year, as

Table 10 demonstrates.

This scenario examines the possibility of replacing installed thermoelectric power plants with renewable generation and adding enough extra power to ensure that hydrogen synthesis produces no greenhouse gases. By retaining the same installed power (5585 MW) but generating electricity from renewable sources (see

Table 10), we achieved the removal of 6.2 million tons of CO

from the environment each year.

Considering data from

Table 10 and then calculating the amount of equipment that would replace fossil fuel power plants was possible,

Table 11 presents the results of the last scenario. The equivalent power can be produced using 3052 wind turbines or 14,794,595 solar panels.

In summary, the aggressive scenario increases green hydrogen production and becomes an attractive alternative but also implies high costs for the conversion of thermoelectric power plants. The uses should be defined as well because any option will create logistic issues (e.g., storage, transport, etc.); by choosing an aggressive scenario, the green hydrogen production will be distributed (

Figure 6) in five districts. Regions with ports facilitate transport and overseas business, including other European countries.

5.3. Hydrogen Production Based EGP Targets

This section presents the prospects considering EGP targets. According to Portugal’s objectives, the EN-H2 for the year 2030 proposed 5% of produced hydrogen should be dedicated exclusively to road vehicles and 25% for the year 2050. In addition, between 50 and 100 hydrogen gas stations would be installed [

60]. A range between 5–15% of the hydrogen produced in the year 2030 should be used in natural gas thermoelectric power plants concerning energy generation and for the year 2050, between 75–80% for the same purpose.

Considering EGP, related to 2030 and 2050, was considered the electrolysis demand power of 2 GW and 5 GW, respectively. The hydrogen production is obtained by applying Equation (

3). Results are shown in

Table 12, where we got an increase of 150% in 2050 from 2030.

As previously indicated, the total amount of H production must be applied to a specific area. As such, this study proposes two options: transport and energy production. In both of them, the main goal is to reduce carbon emissions. According to EN-H2, there are percentage values to consider in 2030 and 2050. This study proposes 100% of H production for each purpose.

5.4. Transport Carbon Emission Reduction

According to [

64], the transport sector was responsible for 28% of Portugal’s carbon emissions. Replacing fossil fuel vehicles with H

vehicles could be an alternative to achieve CO

emissions reduction. In 2020, Portugal’s fossil fuels fleet was 7,021,112, and the three significant types were selected to propose the conversion to H

: passenger cars, buses, and trucks. For each vehicle type, a specific model of Hyzon brand [

65,

66] was selected: Hyzon Class 8 (truck), Hyzon passenger coach (bus), and Hyzon Nexo (passenger). Based on their technical specifications and results from

Table 12, the total number of H

vehicles was calculated.

Table 13 shows the number of applicable ICE vehicles for conversion to fuel-cell vehicles and related data referring to 2030 and 2050 EGP goals. Considering the increase verified in the previous section from 2030 to 2050, the number of vehicles applicable for conversion increases in the same order.

The CO

reductions verified from this conversion are verified in

Table 14. Even though buses present less quantity of units when compared to passenger vehicles, they represent the most significant CO

reductions in 2030 and 2050 (54.80% of total CO

reduction). Even trucks that have the least units represent almost 20% of CO

reductions.

5.5. Energy Production and Carbon Emission Reduction

Fossil resources still dominate electricity production. Although significant investments in renewable production have been made lately, their intermittency makes these sources insecure.

Table 15 shows the total CO

emissions reduction in 2030 and 2050 from substituting thermoelectric plants for H

plants. In both years, the consumption is lower than H

production, and the surplus is available for other industrial processes. Compared to transport, applying the conversion of buses and trucks is better than energy generation. However, H

for energy production reduces Natural gas dependencies and improves energy security.

5.6. Discussion

The case study was evaluated from two hypothetical scenarios considering the possibility of producing green hydrogen in Portugal. The country’s small economy would not withstand drastic changes, at least in the aggressive scenario, where the thermoelectric plants would be removed entirely or converted, which would be ideal for the environment. Still, according to [

13], large projects (in the gigawatt range) require up to ten years from the initial feasibility analysis, which may cause green hydrogen demand reduction to be covered in the future. On the other hand, hydrogen production from existing plants would be the most appropriate, reducing costs as much as possible and making it possible to store energy from renewable sources (moderate scenario). According to [

67], using the current renewable power plants is the best way to push green hydrogen production and avoid wind or solar generation waste. The results show that the optimal power ratio between electrolysis and renewable energy is favorable for wind generation, similar to the results presented in [

68].

Both scenarios have positive aspects that can make hydrogen a potential alternative resource to fossil resources:

Potential to fully decarbonize the transportation and metallurgical industry;

If production is entirely green, there are no carbon emissions;

Future research and investments could help drastically reduce costs around hydrogen;

Avail energy surplus;

Optimize the ratio between electrolysis and renewable energy;

Export the green hydrogen surplus.

On the other hand, the negative aspects can heavily damage the image of hydrogen and its enormous potential:

Space needed;

Continued emissions from other sources;

The amount of equipment required for the necessary production of hydrogen;

The initial investment would be overwhelming;

The fuel cell maintenance and operation are complex;

Management the electrolysis sub-products.

The use of H

in transportation in the exchange of standard vehicles to H

fuel-cell vehicles [

69] presents an advantage with its excellent autonomy and quick recharging compared to electric vehicles. However, the high price of automobiles, a limited garage infrastructure, and the competition with other alternative and tax-reduced compounds (as seen in EAFO, device 94/2014 EU) [

70] create an environment of low demand. In addition, fuel cell maintenance and operation are complex and require proper training. It is also complicated for a group of customers to manage. As seen in

Figure 7, only three fuel-cell vehicles have been registered by 2022.

6. Conclusions

The main goal of this work was to propose an energy transition study analyzing the potential of green hydrogen for a sustainable future, considering Portugal as a case study. The adoption of H is an increasing reality, and investments in infrastructure projects foster sustainable growth and ensure Portugal’s energy security (especially considering the import balance). Portugal can meet 2030–2050 EGP targets. However, other studies—especially about infrastructure—are needed due to its small economy and lead time to start large projects. Blue hydrogen is an intermediary step to green hydrogen; blue hydrogen production can be considered an “energy transition” approach that will continue until green hydrogen production technologies and costs become mature and profitable.

According to the discussion, we can observe advantages regarding the use in transport—exchange for H

vehicles—and conversion of the thermoelectric plants fueled by fossil fuels into renewable generation plants. However, considerations and counterpoints must be presented. Due to other alternative fuel options, the low quantity of H

vehicles, as discussed in

Section 5.6, indicates an unfavorable scenario to promote, at least in the short term. The high costs to implement the aggressive scenario can be supported by private investments becoming this option feasible. The projected green hydrogen infrastructure is more promising for energy generation, market, and fueling the industrial processes.

The energy crisis caused by the Russia-Ukraine conflict enacted an energy security warning signal; the plurality of resources—mainly renewable—provide alternatives to moments of contingency. So, besides the reduction of carbon emissions, is the insertion and management capacity in a market that, according to projections, could reach more than 0.5 trillion dollars. A strategy that increasingly decentralizes and uses electrolyzers close to new renewable generations must be created; on the other hand, investments in logistics and infrastructure is necessary to sustain this emerging economy. In addition, the H market may become an adjustment option. As it can be developed without a spot market, the regulatory and trading models must also provide an attractive environment.

Finally, the costs were lower in the moderate scenario than in the aggressive scenario. The aggressive scenario implies at least 5% more costs than the moderate scenario. Electrolysis and wind generation presented the best power ratio. The substitution of buses and trucks for H-based fuel implies a higher CO reduction than thermoelectric plants fueled by H. Regarding buses, the reduction represents 269% and 288%—2030 and 2050, respectively—higher than fueling thermoelectric plants. The results are opposite and favorable to energy appliances representing 280% and 261% higher (for 2030 and 2050, respectively), comparing passenger cars and thermoelectric plants. On the other hand, regarding energy planning and security, thermoelectric plants fueled by H are the best option, especially because the H production capacity is more than the EGP goals so that the surplus can be applied in other sectors (e.g., storage, market, transport).

This study was applied to Portugal, but the methodology’s information, characteristics, and structure apply to other countries. This approach can verify the feasibility, identify gaps and opportunities, and establish goals according to the scenario and government policies.