Decarbonisation of Geographical Islands and the Feasibility of Green Hydrogen Production Using Excess Electricity †

Abstract

:1. Introduction

2. Methodology

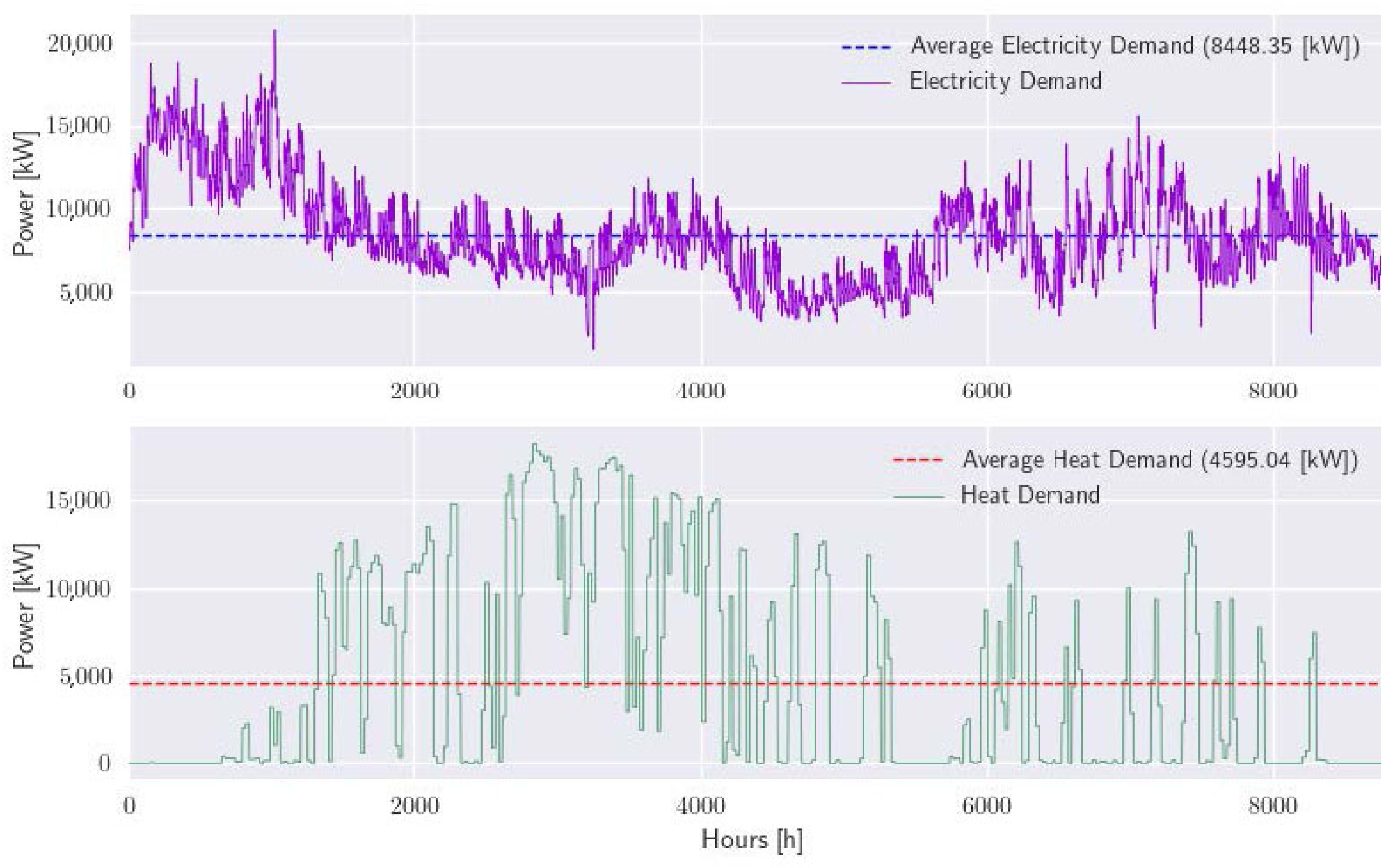

2.1. Eigerøy

2.2. Energy Price

2.3. Natural Resource Availability

2.3.1. Solar Irradiation

2.3.2. Wind Power

2.3.3. Biomass Availability

2.3.4. Energy System Modeling

2.3.5. Economic Variables

2.3.6. Green Hydrogen Production

3. Scenario Definition

- Scenario Zero represents the current situation of the island, where electricity is imported from the mainland, and a gas boiler, operated on LNG, provides the high-temperature heat demand of the factory. This scenario serves as the reference point.

- Scenario A evaluates the potential of installing PV in the energy system. Calculations are conducted initially based on reference values (based on literature reviews), followed by sensitivity analysis around these values.

- Scenario B investigates the role of onWF and offWF. Similar to Scenario A, the role of onshore and off-shore wind farms, individually, at the reference values for the mentioned parameters, are evaluated.

- Scenario C investigates a combination of PV and WFs. In this scenario, the model takes both PV and WFs (on- and off-shore) into account and provides the optimal economic solution.

- Scenario D investigates the role of biomass in the decarbonization of the CHP operation.

4. Results and Discussion

4.1. Scenario Zero—Current Situation

4.2. Scenario A—The Role of PV

4.3. Scenario B—The Role of onWF and offWF

4.4. Scenario C—Combination of PV and onWF

4.5. Scenario D—The Role of Biomass

4.6. Green Hydrogen Production

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Barney, A.; Polatidis, H.; Haralambopoulos, D. Decarbonisation of islands: A multi-criteria decision analysis platform and application. Sustain. Energy Technol. Assess. 2022, 52, 102115. [Google Scholar] [CrossRef]

- European Project ROBINSON. Available online: https://www.robinson-h2020.eu/ (accessed on 12 April 2023).

- SMILE H2020. Available online: https://h2020smile.eu/ (accessed on 12 April 2023).

- Gift H2020|Geographical Islands Flexibility. Available online: https://www.gift-h2020.eu/ (accessed on 12 April 2023).

- Homepage—MAESHA. Available online: https://www.maesha.eu/ (accessed on 12 April 2023).

- What Is REACT?—REACT. 2020. Available online: https://react2020.eu/ (accessed on 12 April 2023).

- Dorotić, H.; Doračić, B.; Dobravec, V.; Pukšec, T.; Krajačić, G.; Duić, N. Integration of transport and energy sectors in island communities with 100% intermittent renewable energy sources. Renew. Sustain. Energy Rev. 2019, 99, 109–124. [Google Scholar] [CrossRef]

- Flessa, A.; Fragkiadakis, D.; Zisarou, E. Decarbonizing the Energy System of Non-Interconnected Islands: The Case of Mayotte. Energies 2023, 16, 2931. [Google Scholar] [CrossRef]

- Gils, H.C.; Simon, S. Carbon neutral archipelago—100% renewable energy supply for the Canary Islands. Appl. Energy 2017, 188, 342–355. [Google Scholar] [CrossRef]

- Madi, H.; Lytvynenko, D.; Jansohn, P. Decarbonisation of Geographical Islands-The role of Solar, Wind and Biomass. In Proceedings of the 2022 2nd International Conference on Energy Transition in the Mediterranean Area (SyNERGY MED), Thessaloniki, Greece, 17–19 October 2022. [Google Scholar] [CrossRef]

- Stadler, P.M. Model-Based Sizing of Building Energy Systems with Renewable Sources. Ph.D. Thesis, École Polytechnique Fédérale de Lausanne, Lausanne, Switzerland, 2019. [Google Scholar] [CrossRef]

- Electricity Price Statistics—Statistics Explained. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Electricity_price_statistics#Electricity_prices_for_household_consumers (accessed on 23 August 2022).

- NASA POWER|Prediction of Worldwide Energy Resources. Available online: https://power.larc.nasa.gov/ (accessed on 24 August 2022).

- Smart integRation of Local Energy Sources and Innovative Storage for Flexible, Secure and Cost-Efficient Energy Supply on Industrialized Islands|ROBINSON Project|Results|H2020|CORDIS|European Commission. Available online: https://cordis.europa.eu/project/id/957752/results (accessed on 23 August 2022).

- Madi, H. Investigations into the Effects of Biofuel Contaminants on Solid Oxide Fuel Cells. Ph.D. Thesis, École Polytechnique Fédérale de Lausanne, Lausanne, Switzerland, 2016. [Google Scholar] [CrossRef]

- Gurobi Optimization. Available online: https://www.gurobi.com/ (accessed on 12 April 2023).

- Vartiainen, E.; Masson, G.; Breyer, C.; Moser, D.; Román Medina, E. Impact of weighted average cost of capital, capital expenditure, and other parameters on future utility-scale PV levelised cost of electricity. Prog. Photovolt. Res. Appl. 2020, 28, 439–453. [Google Scholar] [CrossRef]

- Sens, L.; Neuling, U.; Kaltschmitt, M. Capital expenditure and levelized cost of electricity of photovoltaic plants and wind turbines—Development by 2050. Renew. Energy 2022, 185, 525–537. [Google Scholar] [CrossRef]

- Steffen, B. Estimating the cost of capital for renewable energy projects. Energy Econ. 2020, 88, 104783. [Google Scholar] [CrossRef]

- Njiri, J.G.; Beganovic, N.; Do, M.H.; Söffker, D. Consideration of lifetime and fatigue load in wind turbine control. Renew. Energy 2019, 131, 818–828. [Google Scholar] [CrossRef]

- Duffy, A.; Hand, M.; Wiser, R.; Lantz, E.; Dalla Riva, A.; Berkhout, V.; Stenkvist, M.; Weir, D.; Lacal-Arántegui, R. Land-based wind energy cost trends in Germany, Denmark, Ireland, Norway, Sweden and the United States. Appl. Energy 2020, 277, 114777. [Google Scholar] [CrossRef]

| PV [17,18] | onWF [19,20,21] | offWF | WG [14] | CHP [14] | GBOI | H-EL | BAT | |

|---|---|---|---|---|---|---|---|---|

| CAPEX (EUR/kW) | 550 | 1300 | 3000 | 1400 | 1400 | 100 | 1300 | 275 |

| OPEX (%) | 1.7 | 2.5 | 2.5 | 3 | 3 | 5 | 2 | 2.5 |

| WACC (%) | 5 | 7 | 8 | 10 | 10 | 2.5 | 10 | 11 |

| 15 | - | - | - | 40 | - | 70 | ||

| - | - | - | - | 50 | 98 | - | ||

| - | - | - | 84 | - | - | - | ||

| Lifetime | 20 | 20 | 20 | 20 | 20 | 20 | 15 | 15 |

| onWF | offWF | |

|---|---|---|

| Wind speed | 5% increase (6.3 m/s) | 40% increase (9.9 m/s) |

| Electricity price | 10% increase (0.09 EUR/kWh) | 60% increase (0.13 EUR/kWh) |

| CAPEX | 10% reduction (1170 EUR/kW) | 30% reduction (2100 EUR/kW) |

| WACC | 25% reduction (5.25%) | 90% reduction (0.8%) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Madi, H.; Lytvynenko, D.; Schildhauer, T.; Jansohn, P. Decarbonisation of Geographical Islands and the Feasibility of Green Hydrogen Production Using Excess Electricity. Energies 2023, 16, 4094. https://doi.org/10.3390/en16104094

Madi H, Lytvynenko D, Schildhauer T, Jansohn P. Decarbonisation of Geographical Islands and the Feasibility of Green Hydrogen Production Using Excess Electricity. Energies. 2023; 16(10):4094. https://doi.org/10.3390/en16104094

Chicago/Turabian StyleMadi, Hossein, Dmytro Lytvynenko, Tilman Schildhauer, and Peter Jansohn. 2023. "Decarbonisation of Geographical Islands and the Feasibility of Green Hydrogen Production Using Excess Electricity" Energies 16, no. 10: 4094. https://doi.org/10.3390/en16104094

APA StyleMadi, H., Lytvynenko, D., Schildhauer, T., & Jansohn, P. (2023). Decarbonisation of Geographical Islands and the Feasibility of Green Hydrogen Production Using Excess Electricity. Energies, 16(10), 4094. https://doi.org/10.3390/en16104094